m return - mbm-Service GmbH

m return - mbm-Service GmbH

m return - mbm-Service GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

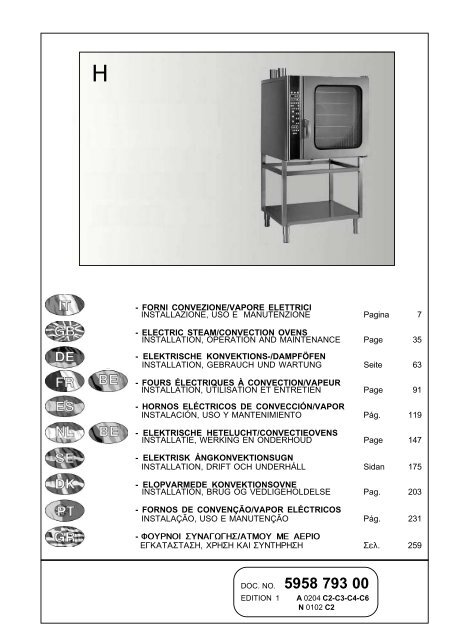

H<br />

- FORNI CONVEZIONE/VAPORE ELETTRICI<br />

INSTALLAZIONE, USO E MANUTENZIONE Pagina 7<br />

- ELECTRIC STEAM/CONVECTION OVENS<br />

INSTALLATION, OPERATION AND MAINTENANCE Page 35<br />

- ELEKTRISCHE KONVEKTIONS-/DAMPFÖFEN<br />

INSTALLATION, GEBRAUCH UND WARTUNG Seite 63<br />

- FOURS ÉLECTRIQUES À CONVECTION/VAPEUR<br />

INSTALLATION, UTILISATION ET ENTRETIEN Page 91<br />

- HORNOS ELÉCTRICOS DE CONVECCIÓN/VAPOR<br />

INSTALACIÓN, USO Y MANTENIMIENTO Pág. 119<br />

- ELEKTRISCHE HETELUCHT/CONVECTIEOVENS<br />

INSTALLATIE, WERKING EN ONDERHOUD Page 147<br />

- ELEKTRISK ÅNGKONVEKTIONSUGN<br />

INSTALLATION, DRIFT OCH UNDERHÅLL Sidan 175<br />

- ELOPVARMEDE KONVEKTIONSOVNE<br />

INSTALLATION, BRUG OG VEDLIGEHOLDELSE Pag. 203<br />

- FORNOS DE CONVENÇÃO/VAPOR ELÉCTRICOS<br />

INSTALAÇÃO, USO E MANUTENÇÃO Pág. 231<br />

- ÖÏÕÑÍÏÉ ÓÕÍÁÃÙÃÇÓ/ÁÔÌÏÕ ÌÅ ÁÅÑÉÏ<br />

ÅÃÊÁÔÁÓÔÁÓÇ, ×ÑÇÓÇ ÊÁÉ ÓÕÍÔÇÑÇÓÇ Óåë. 259<br />

DOC. NO. 5958 793 00<br />

EDITION 1 A 0204 C2-C3-C4-C6<br />

N 0102 C2

DICHIARAZIONE DI CONFORMITA'<br />

ELECTROLUX PROFESSIONAL SPA<br />

Viale Treviso 15<br />

33170PORDENONE<br />

Dichiara sotto la propria autorità che le macchine appartenenti a questa documentazione,<br />

descritte nella targhetta di identificazione, sono conformi alle seguenti disposizioni legislative:<br />

- Direttiva Europea 73/23/CEE (L.V.D. apparecchiature elettriche bassa tensione)<br />

- Direttiva Europea 89/336/CEE (E.M.C. compatibilità elettromagnetica)<br />

- Direttiva Europea 93/68/CEE (Aggiornamento alle direttive)<br />

- Direttiva Europea 90/396/CEE (Apparecchiature gas)<br />

Data: Pordenone 1.01.2000<br />

Nome: Beniamino Zambon<br />

(Responsabile Stabilimento)<br />

DECLARATION OF CONFORMITY<br />

ELECTROLUX PROFESSIONAL SPA<br />

Viale Treviso 15<br />

33170PORDENONE<br />

Hereby declares under its own authority that the machine described in this document<br />

and specified on the identification plate, conforms to the following provisions laid down<br />

by law:<br />

- European Directive 73/23/CEE (L.V.D. Low Voltage Directive)<br />

- European Directive 89/336/CEE (E.M.C. Electro Magnetic Compatibility)<br />

- European Directive 93/68/CEE (Amendment to the Directive)<br />

- European Directive 90/396/CEE (Gas appliances)<br />

Date: Pordenone 1.01.2000<br />

Name: Beniamino Zambon<br />

(Plant Manager)<br />

2

IT<br />

GB<br />

DE<br />

FR BE<br />

ES<br />

NL<br />

SE<br />

DK<br />

PT<br />

GR<br />

BE<br />

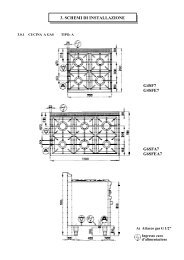

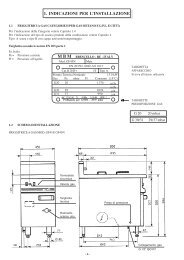

SCHEMI DI INSTALLAZIONE<br />

INSTALLATION DIAGRAM<br />

INSTALLATIONSPLAN<br />

SCHEMAS D'INSTALLATION<br />

ESQUEMA PARA LA INSTALACIÓN<br />

INSTALLATIESCHEMA<br />

INSTALLATIONSRITNING<br />

INSTALLATIONSDIAGRAM<br />

ESQUEMAS DE INSTALAÇAO<br />

���������������������������<br />

3

Mod.: 6 GN 1/1 Mod.: 10 GN 1/1 isg<br />

Mod.: 10 GN 1/1<br />

4<br />

Mod.: 10 GN 2/1

Mod.: 20 GN 1/1<br />

IT<br />

I - Entrata cavo elettrico<br />

B - Attacco alim. acqua (0,5 - 5 °F) ø3/4"M ISO 7/1<br />

C - Collettore scarico acqua ø1"1/4M ISO 7/1<br />

N - Attacco acqua Conden. fumane ø3/4" M ISO 7/1<br />

GB - IE<br />

I - Power supply cable inlet<br />

B - Water supply connection (0.5- 5 °F) ø3/4"M ISO 7/1<br />

C - Water drain connection ø1"1/4M ISO 7/1<br />

N - Steam condens. water connection ø3/4"M ISO 7/1<br />

DE - AT - CH<br />

I - Netzkabeleingang<br />

B - Wasseranschluß(0,5 - 5 °fH) ø3/4"M ISO 7/1<br />

C - Wasserablauf-Sammelrohr ø1"1/4M ISO 7/1<br />

N - Wasseranschluß<br />

Schwadenkondensator ø3/4"M ISO 7/1<br />

FR - BE<br />

I - Entrée câble électrique<br />

B - Entrée eau (0,5 - 5 °F) ø3/4"M ISO 7/1<br />

C - Collecteur évacuation eau ø1"1/4M ISO 7/1<br />

N - Entrée eau Conden.vapeurs ø3/4"M ISO 7/1<br />

ES<br />

I - Ingreso cable eléctrico<br />

B - Conexión de agua (0,5 - 5 °F) ø3/4"M ISO 7/1<br />

C - Colector del desagüe ø1"1/4M ISO 7/1<br />

N - Entrada del agua de condensación ø3/4" M ISO 7/1<br />

5<br />

Mod.: 20 GN 2/1<br />

NL - BE<br />

I - Voedingskabel<br />

B - Aansluiting watertoevoer (0,5 - 5°F) ø3/4"M ISO 7/1<br />

C - Aansluiting waterafvoer ø1"1/4M ISO 7/1<br />

N - Wateraansluiting stoomcondensatie ø3/4"M ISO 7/1<br />

SE<br />

I - Nätkabelintag<br />

B - Vattenanslutning (0,5 – 5° F) ø3/4"M ISO 7/1<br />

C - Vattendräneringsrör ø1"1/4M ISO 7/1<br />

N - Vattenanslutning ångkondensering ø3/4"M ISO 7/1<br />

DK<br />

I - Strømforsyningstilslutning<br />

B - Tilslutning til vandforsyning (0,5 - 5 °F) ø3/4"M ISO 7/1<br />

C - Opsamler til udtømningsvand ø1"1/4M ISO 7/1<br />

N - Tilslutning til kondensvand, dampe ø3/4"M ISO 7/1<br />

PT<br />

I - Entrada do cabo de alimentação eléctrica<br />

B - Ligação de abastecimento<br />

da água (0,5 – 5º F) ø3/4"M ISO 7/1<br />

C - Colector de descarga da água ø1"1/4M ISO 7/1<br />

N - Ligação da água<br />

“condensação de vapor” ø3/4" M ISO 7/1<br />

GR<br />

� �����������������������������<br />

� ������������������������������������� ������ �������<br />

� ��������������������������� ������� �������<br />

� ��������������������������������� ������ �������

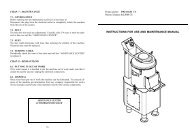

ELECTRIC STEAM/CONVECTION OVENS<br />

INSTRUCTIONS FOR INSTALLATION AND USE (for the United Kingdom)<br />

CONTENTS Page<br />

- Declaration of conformity .................................................................................................... 2<br />

- Installation diagrams.......................................................................................................... 3<br />

- Appliance identification .................................................................................................... 35<br />

I. MAIN FEATURES .............................................................................................. 36<br />

1. Description of appliance ................................................................................................... 36<br />

2. Main components (exploded diagrams) .......................................................................... 36<br />

- Table 1: Technical data .................................................................................................... 38<br />

3 Precautions ....................................................................................................................... 39<br />

4 Safeguarding the environment ......................................................................................... 39<br />

II. INSTRUCTIONS FOR INSTALLATION .............................................................. 40<br />

1. Installation place ............................................................................................................... 40<br />

2. Positioning ........................................................................................................................ 40<br />

3. Electrical connection ........................................................................................................ 41<br />

4. Water mains connection ................................................................................................... 41<br />

5. Safety device .................................................................................................................... 43<br />

6. Operation check ................................................................................................................ 43<br />

7. Servicing ........................................................................................................................... 43<br />

8. Troubleshooting ................................................................................................................ 43<br />

9. Layout of main components ............................................................................................. 44<br />

III. INSTRUCTIONS FOR USE ................................................................................ 45<br />

1. Opening the oven door ..................................................................................................... 45<br />

2. Closing the oven door ...................................................................................................... 45<br />

3. Description of control panel .............................................................................................. 46<br />

- Using the oven .................................................................................................................. 49<br />

4. Functional levels 2-3 ........................................................................................................ 49<br />

5. Functional level 4.............................................................................................................. 52<br />

6. Functional level 6.............................................................................................................. 55<br />

7. All models ......................................................................................................................... 60<br />

- CONTROL PANEL FIGURES (C2-C3-C4-C6) .................................................... 287<br />

Appliance identification<br />

35<br />

GB

GB<br />

I. MAIN FEATURES<br />

1. DESCRIPTION OF APPLIANCE<br />

This booklet describes a number of appliance models.<br />

For more detailed information about the model in your possession,<br />

refer to "Technical Data" table 1.<br />

The appliance has the following features:<br />

• Digital temperature indicator.<br />

• Thermostatic probe for measuring the core temperature of<br />

products (core temperature probe) (only available on certain<br />

models).<br />

• Continuous monitoring of cooking parameters throughout the<br />

entire cooking cycle.<br />

• Periodic draining and automatic washing of the boiler to prevent<br />

the build-up of lime-scale (only available on certain models).<br />

• Boiler lime-scale level indicator (see corresponding paragraph).<br />

• Dehumidification device (with automatic or manual operation<br />

depending on the model) to reduce excess humidity in the oven<br />

for gratinating.<br />

• Oven chamber lighting.<br />

• Double-action door opening mechanism designed to protect<br />

the user from scalding steam.<br />

• Double-glazed oven door for reduced heat dispersion into the<br />

kitchen and low external oven temperatures.<br />

• Daily oven chamber cleaning cycle (clean).<br />

• Self-diagnostics system indicating oven malfunctions by way<br />

of error codes (see "Alarm and diagnostics messages").<br />

6 GN 1/1<br />

10<br />

1<br />

8<br />

2<br />

3<br />

9<br />

36<br />

2. MAIN COMPONENTS<br />

The components marked by a hatched line are not installed on<br />

the following models:<br />

6 GN 1/1 C2-C3, 10 GN 1/1 C2.<br />

KEY:<br />

1.............................................................resistances (steam generator)<br />

2...........................................................electronic card support<br />

3......................................................................electronic card<br />

4...............................................................................control panel<br />

5..........................................................resistances(convector)<br />

6................................door with double-glazing opening system<br />

7������������������������������������������������������������������oven chamber fan<br />

8.........................................................................steam boiler<br />

9............................................................................water injector<br />

10...............................................................water pressure gauge<br />

5<br />

4<br />

7<br />

6<br />

com_e6gn1<br />

1

10 GN 2/1<br />

1<br />

10<br />

20 GN 2/1<br />

1<br />

2<br />

8<br />

8<br />

2<br />

3<br />

5 9<br />

37<br />

5<br />

7<br />

7<br />

com_e10gn1<br />

com_e20gn1<br />

10 GN 1/1<br />

6<br />

6<br />

4<br />

3<br />

20 GN 1/1<br />

4<br />

2<br />

3<br />

GB

GB<br />

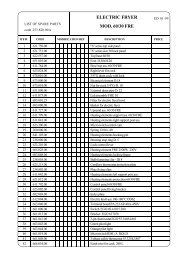

TABLE 1: TECHNICAL DATA<br />

FIGURES<br />

SHELVES<br />

PNC 9731 *<br />

FUNCTIONAL LEVEL<br />

CONVECTOR °<br />

STEAM GENERAT.**<br />

POWER SUPPLY<br />

VOLTAGE (VOLT)<br />

FREQUENCY (Hz)<br />

Max. electrical power<br />

absorption<br />

Mains fuses<br />

(3x500V)<br />

Power supply cable<br />

cross-section (m m 2 )<br />

Electrical output<br />

fan motor (Kw)<br />

Electrical output<br />

steam unit (Kw)<br />

Electrical output<br />

convection unit(Kw)<br />

1 2 3<br />

6 GN 1/1 10 GN 1/1 10 GN 2/1 20 GN 1/1 20 GN 2/1<br />

724251 697821<br />

697807<br />

724253<br />

697843 697883 697845 697885 697847 697887 697849 697889<br />

C2 (ISG) C3 C2 (ISG) C4 C6 C4 C6 C4 C6 C4 C6<br />

°<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

Noise emission data: Noise emissions generated by the appliances<br />

described in this booklet do not exceed 70 dB (A).<br />

* Your appliance model is indicated in the box marked PNC on<br />

the "Technical Data" label affixed to the bottom left hand side of<br />

your oven.<br />

°<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

38<br />

°<br />

**<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

°<br />

**<br />

380...400<br />

3N~<br />

50 50 50 50 50 50 50 50 50 50 50<br />

9,3 9,5 17,3 17,3 17,3 24,5 24,5 34,5 34,5 48,9 48,9<br />

16 25 32 32 32 40 40 50 50 80 80<br />

5x1,5 5x2,5 5x4 5x5 4 5x6 5x6 5x10 5x10<br />

0,19 0,19 0,19 0,19 0,19 0,35 0,35 0,19x2 0,19x2 0,35x2 0,35x2<br />

- 9 - 17 17 24 24 24 24 48 48<br />

9 9 17 17 17 24 24 17x2 17x2 24x2 24x2<br />

5x6<br />

5x6<br />

5x6<br />

5x6

3. PRECAUTIONS<br />

• Before installing or using the appliance, carefully read this<br />

instructions booklet, in as much as it contains important information<br />

concerning the safety, operation and maintenance of the<br />

appliance.<br />

• Keep this instructions booklet in a safe place for future consultation<br />

by other users or purchasers in the event that the appliance<br />

is resold.<br />

Important: Installation and maintenance of the appliance<br />

and its conversion to a different gas supply, must only be<br />

performed by a qualified installer authorised by the<br />

manufacturer.<br />

• This appliance is intended for industrial use only and is<br />

specifically designed to cook food. Any other use of the appliance<br />

is deemed improper.<br />

The appliance must only be used by trained staff and must be<br />

supervised at all times when in use.<br />

• Switch off the appliance if it breaks down or malfunctions.<br />

• Only contact the technical service centre authorised by the<br />

manufacturer for repairs and only use original spare parts.<br />

Failure to comply with the above requirement may jeopardise<br />

the safety of the appliance and render the guarantee null and<br />

void.<br />

• Do not wash the appliance with water jets.<br />

• Do not use products containing chlorine (bleach, hydrochloric<br />

acid etc.) even diluted, to clean steel surfaces.<br />

• Do not use corrosive substances (i.e. muriatic acid) to clean the<br />

floor under the appliance.<br />

• For more information, refer to the chapter on "Care and maintenance".<br />

39<br />

4. SAFEGUARDING THE ENVIRONMENT<br />

4.1. Packaging<br />

• All the packaging materials used are environmentally friendly.<br />

They may be stored at no risk or burnt at an authorised incineration<br />

plant. Plastic materials suitable for recycling are marked with<br />

the following symbols:<br />

polyethylene : external wrapping film, instructions<br />

PE booklet bag and gas injectors bag<br />

pp<br />

PS<br />

polypropylene: top packaging panels and straps<br />

expanded polystyrene: protective surround elements<br />

4.2. Use<br />

• The appliance has been designed and perfected under laboratory<br />

testing conditions to offer exceptional levels of performance.<br />

However, to minimise energy consumption (electricity, gas and<br />

water) , we recommend turning the appliance off when not in use<br />

for long periods and not using it, for example, with the door open<br />

as this may impair the oven's performance. We also recommend<br />

preheating the appliance immediately prior to use.<br />

4.3. Cleaning<br />

• To minimise the emission of pollutants into the environment,<br />

we recommend cleaning the appliance (externally and, where<br />

necessary, internally) with products which are at least 90%<br />

biodegradable.<br />

4.4 Disposal<br />

• The appliance must be disposed of properly at the end of its<br />

service life.<br />

• The appliance is made from 90% recyclable materials (stainless<br />

steel, iron, aluminium, galvanised sheet steel, etc.). These<br />

materials may therefore be scrapped in accordance with local<br />

waste disposal regulations at a conventional recycling plant.<br />

• Make the appliance unusable by cutting off the power cord. Also<br />

remove any compartment or interior closure device fitted on the<br />

appliance to prevent persons from becoming trapped inside.<br />

GB

GB<br />

II. INSTRUCTIONS FOR INSTALLATION<br />

Important: The external oven panels must be removed to perform the operations described in this chapter. Since the appliance<br />

must be switched on to make certain adjustments, exercise the utmost care when working in the vicinity of the appliance’s “live”<br />

parts.<br />

1. INSTALLATION PLACE<br />

• The appliance must only be installed in adequately ventilated premises.<br />

2. POSITIONING<br />

• Unpack the appliance and carefully remove the protective film from the external panels to avoid leaving any trace of glue.<br />

Use a suitable diluent to remove any glue residue.<br />

• Dispose of the packaging as instructed in the chapter on "Safeguarding the environment"<br />

• Refer to the installation diagrams at the beginning of this booklet for the space requirements and connection dimensions of the<br />

appliance.<br />

• The LH side of the appliance must be installed at least 50 cm from adjacent units to provide easy access for maintenance, while<br />

the RH side must be installed 10 cm from adjacent units made from flammable materials.<br />

• Place the appliance in the required position and adjust the height of the work surface using the adjustable feet.<br />

• The appliance is not suitable for built-in installation.<br />

Important:<br />

Make sure vapours from the oven’s drain or adjacent appliances do not enter the aeration vents under the appliance,<br />

which cool the oven’s internal components.<br />

40

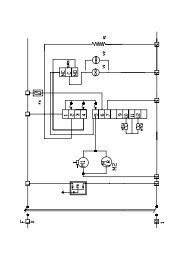

3. ELECTRICAL CONNECTION<br />

• The appliance must be connected to the mains power supply<br />

in compliance with current regulations.<br />

• Before connecting the appliance to the mains supply, make<br />

sure that the voltage and frequency shown on the appliance<br />

rating plate correspond with that of the power supply.<br />

• The appliance must be permanently connected to the mains<br />

power supply with an H05 RN-F type cable. The power supply<br />

cable must be protected by a metal or rigid plastic tube. If the<br />

appliance is connected by way of an existing lead, do not insert<br />

the installation tube in the appliance and make sure the tube<br />

has no sharp edges.<br />

• A safety cutout switch of suitable capacity with a contact<br />

breaking distance of at least 3 mm must be fitted upstream of<br />

the appliance.<br />

This cutout switch must be installed near the appliance in the<br />

permanent electrical system of the premises.<br />

• The appliance must be suitably earthed. The earthing conductor<br />

must therefore be connected to the terminal marked G on<br />

the connection terminal board. The appliance must also be<br />

connected to an equipotential system.<br />

This connection is made using the stop screw marked E<br />

located on the outside of the appliance near the power cable<br />

inlet.<br />

The equipotential wire must have a minimum cross-section of<br />

10 mm 2 .<br />

4.1 INSTALLING THE POWER SUPPLY CABLE<br />

(Fig. "10")<br />

To access the power supply cable connection terminal board,<br />

proceed as follows:<br />

Mod. 6 GN1/1 - 10 GN1/1 - 10 GN2/1<br />

• Undo screws "V" fixing the terminal board support panel located<br />

underneath the appliance on the front LH side.<br />

• Feed the power supply cable through cable clamp inlet "B".<br />

• Connect the cable to terminal board “A” as shown in the<br />

enclosed wiring diagram and fasten with the corresponding<br />

cable clamp.<br />

• Remount the panel and secure with the fixing screws.<br />

10<br />

Mod. 20 GN1/1 - 20 GN2/1<br />

• Open the control panel.<br />

• Connect the cable to terminal board as shown in the enclosed<br />

wiring diagram and fasten with the corresponding cable clamp.<br />

The manufacturer declines any responsibility for failure to<br />

comply with existing accident prevention standards.<br />

41<br />

4. WATER MAINS CONNECTION<br />

(Refer to the installation diagrams at the beginning of this booklet).<br />

The appliance is fitted with two separate water inlets ("B" and "N").<br />

The water lines supplying both inlets must be fitted with a<br />

mechanical filter and shut-off cock.<br />

Before fitting the filters, pump water through the system to expel<br />

any solid particles from the piping.<br />

4.1. WATER SUPPLY CHARACTERISTICS<br />

4.1.1 Water inlet "N".<br />

The steam condensation system must be connected to a cold<br />

drinking water supply with the following characteristics:<br />

- total hardness: up to 40°F;<br />

- pressure: 150 to 250 kPa (1.5-2.5 bar); higher pressure<br />

values result in increased water consumption.<br />

4.1.2 Water inlet "B".<br />

The steam production system must be connected to a drinking<br />

water supply with the following characteristics:<br />

- total hardness: 0.5 to 5 °F to prevent the build-up of limescale<br />

inside the boiler (or oven chamber on models with automatic<br />

generation).<br />

On request the oven is supplied with an optional water softener<br />

device with automatic regeneration which must be installed on<br />

inlet line "B". This device is also supplied with a resin sterilisation<br />

kit (available on request).<br />

- pressure: 150 to 250 kPa (1.5-2.5 bar); higher pressure<br />

values result in increased water consumption.<br />

- chlorine ion concentration (Cl -): not more than ~10 ppm<br />

(acceptable value) to avoid damaging the oven's internal steel<br />

elements.<br />

- pH: over 7.<br />

On request the oven is supplied with an optional special filtration<br />

unit which is installed on inlet line "B". This unit also acts as a water<br />

softener by reducing water hardness to less than 5°F.<br />

- electrical conductivity: 50 to 2000 µS/cm (20°C).<br />

Important: Only install the water treatment systems supplied by<br />

the manufacturer. Failure to do so automatically invalidates the<br />

guarantee.<br />

The use of dosing systems designed to prevent the buildup<br />

of lime-scale in pipes (i.e. polyphosphate dosing<br />

systems) is also prohibited since it may impair the<br />

performance of the appliance.<br />

GB

GB<br />

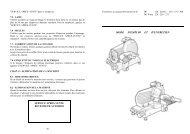

4.2 WATER PRESSURE ADJUSTMENT (ONLY FOR<br />

MODELS 6 GN 1/1 C2-C3 AND 10 GN 1/1 C2)<br />

For correct operation of these appliances, in addition to the<br />

requirements stipulated in point 4.1 above, the water pressure<br />

must also be adjusted using the relative internal pressure<br />

regulator. To adjust the water pressure, proceed as follows (Fig.<br />

"11"):<br />

1) Remove the LH side panel from the oven;<br />

2) Start a steam cooking cycle (see "Instructions for use");<br />

3) Undo knurled cap "A";<br />

4) Using a flat-blade screwdriver, turn the screw underneath until<br />

the read-out on pressure gauge "B" is 120 kPa (1.2 bar);<br />

5) Refit cap "A" and remount the side panel.<br />

11<br />

4.3 WATER DRAIN SYSTEM (Fig. 12a-12b)<br />

Connect drain fitting “C” to a drain pipe of the same<br />

diameter which is between 0.5 and 3 metres in length and<br />

is resistant to temperatures of at least 100°C. The drain pipe<br />

must be siphoned (height 80 mm) to an open drain “O” (“Air-<br />

Break”) or floor grating (see Fig. 12b) in order to prevent any<br />

back-flow from the sewage system from reaching the piping<br />

inside the oven or oven chamber.<br />

Check the hoses and elbows on metal pipes for kinks or pinching<br />

along the entire drain line and make sure the drain line has a<br />

minimum gradient of 5° to prevent water from collecting inside<br />

the system.<br />

Important: The drain system must be installed so that any<br />

vapours from the open drain do not enter the aeration vents<br />

under the appliance.<br />

Note for model 6 GN 1/1 C4:<br />

This model is fitted with two separate drain fittings (see installation<br />

diagram). These fittings must be connected to each other externally<br />

on the appliance before flowing into a single drain.<br />

42<br />

12a<br />

12b

5. SAFETY DEVICES<br />

The appliance is fitted with the following safety devices:<br />

6.1 Safety fuses (see electrical circuit diagram) positioned<br />

behind the control panel.<br />

To replace, loosen the retainer cap, and replace the damaged<br />

component with one of the same capacity; this value is specified<br />

on the relative data plate.<br />

6.5 Chamber safety thermostat, with manual reset located<br />

behind control panel; when this device trips, convection heating<br />

power is shut off.<br />

Reset operations must be performed by specialised technical<br />

personnel after eliminating the cause of the fault.<br />

6.6 Thermal cutout inside fan motor, which trips in the event of<br />

overheating on fuse F1 (see electrical circuit diagram) and shuts<br />

down appliance operation.<br />

Reset operations must be performed by specialised technical<br />

personnel after eliminating the cause of the fault and fuse F1 must<br />

be replaced with a version of the same capacity.<br />

To replace, open the control panel, loosen the retainer cap, and<br />

replace the damaged component with one of the same capacity;<br />

this value is specified on the relative data plate.<br />

6. OPERATION CHECK<br />

- Switch on the appliance in accordance with the instructions for<br />

use.<br />

- Using the instructions manual, explain the operation and<br />

maintenance instructions to the user.<br />

Important:<br />

- Exercise due care since certain areas of the oven exterior get<br />

hot during use.<br />

- Do not cover the exhausts on top of the appliance.<br />

43<br />

7. SERVICING<br />

All components requiring routine maintenance may be easily<br />

reached by opening the control panel or removing the LH side<br />

panel and rear panel.<br />

8. TROUBLESHOOTING<br />

Even during the regular running of the appliance anomalies<br />

or failures can occur.<br />

The oven chamber heating does not activate or is<br />

inefficient.<br />

Possible cause:<br />

- The oven chamber temperature limit switch has intervened<br />

- The heating elements are damaged<br />

- Check the contactor coil relative to the damaged component<br />

- Damaged thermostat probe showing error “EPt1”.<br />

- The controller is damaged<br />

- Fuse “F2” has intervened, see wiring diagram.<br />

Steam production does not start up or is inefficient.<br />

Possible cause:<br />

- The heating elements are damaged<br />

- Check the contactor coil relative to the damaged component<br />

- The controller is damaged<br />

- Fuse “F2” has intervened.<br />

- No water supply from the mains.<br />

- Boiler drainage outlet closing device damaged<br />

- Water inlet solenoid valves are damaged (do not open)<br />

The oven chamber temperature reading is erratic<br />

Possible cause:<br />

- The electronic controller is damaged<br />

- The thermostat probe is damaged, dirty or interrupted see<br />

error “EPt1”.<br />

The oven switches off<br />

Possible cause:<br />

- The fuse “F1” has intervened due to motor overheating and<br />

the oven chamber lighting switches off<br />

- The fuse “F2” has intervened due to damage to the auxiliary<br />

components.<br />

GB

GB<br />

9. LAYOUT OF MAIN COMPONENTS<br />

(All work inside the appliance must only be carried out by a<br />

trained installer authorised by the manufacturer)<br />

(These interventions must be carried out by an authorised<br />

installer)<br />

Removing the left-hand side and rear panels from the<br />

appliance will allow access to the following components:<br />

- Vapour damping system solenoid valve with flow regulator<br />

- Access to the steam generator heating elements<br />

- Probe PT1000 (oven chamber temperature)<br />

- Control circuit ventilator fan<br />

- Oven chamber ventilator fan<br />

- Probe PT1000 (by-pass) activating the vapour damping<br />

system and water injection for the production of steam.<br />

- Motorised boiler drainage valve<br />

- Water loading solenoid valve.<br />

Removing the control panel will allow access to the following<br />

components:<br />

- Electronic PCB card<br />

- Main terminal board (can also be accessed externally from<br />

the bottom of the appliance)<br />

- Oven chamber temperature limit thermostat<br />

- Fuses<br />

- RIF filters<br />

- Heating element contactors<br />

- Door microswitches<br />

- Oven chamber lamp holder<br />

- Oven chamber ventilator fan condenser<br />

- Oven chamber lamp transformer<br />

- Geared motor for the oven chamber butterfly relief valve.<br />

- Control shutter relay controlling the speed of the oven chamber<br />

ventilator fan.<br />

44

III. INSTRUCTIONS FOR USE<br />

Before switching on the appliance, carefully read this instructions<br />

booklet, in as much as it contains important information concerning<br />

correct and optimum use of the appliance. If you require<br />

further information about the oven's features and cooking performance,<br />

consult your local dealer.<br />

• Do not place pans or utensils on top of the oven to avoid<br />

obstructing the fume and steam exhaust ducts.<br />

• Once every six months the burners, the uniformity of their flame<br />

and related components must be inspected by a qualified technician.<br />

• Periodically (at least once a year) the appliance should undergo<br />

a general inspection. For this purpose we recommend<br />

taking out a service contract.<br />

• Some models are equipped with a temperature probe which<br />

measures the core temperature of products. This is a precision<br />

instrument and must therefore be handled with the utmost care<br />

to avoid knocks or damage caused by abrupt insertion or removal<br />

of the lead (particularly when using trolley-mounted units). The<br />

guarantee does not cover damage to the temperature probe<br />

caused by improper usage.<br />

• When using the mixed cooking cycle, do not exceed cooking<br />

temperatures of 200-210°C which might otherwise impair the<br />

performance of the oven chamber seals.<br />

• When using the oven, leave a gap of at least 40 mm between<br />

each container to facilitate the correct circulation of hot air inside<br />

the oven.<br />

• Do not salt foods inside the oven chamber, particularly<br />

during cooking cycles with humidification.<br />

• Do not cook with flammable liquids such as high-alcohol<br />

spirits.<br />

1. OPENING THE OVEN DOOR<br />

1.1. 6 AND 10 SHELF MODELS<br />

a) Pull and lift the bottom of the handle. The door will open<br />

just enough to allow the steam inside the oven to escape.<br />

Any cooking program already in progress stops.<br />

b) Release the handle.<br />

c) Pull and lift the bottom of the handle again to fully open the<br />

oven door.<br />

45<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

1.2. 20 SHELF MODELS<br />

a) Turn the door handle anticlockwise until it is horizontal.<br />

The door will open just enough to allow the steam inside the oven<br />

to escape.<br />

Any cooking program already in progress stops.<br />

b) Pull the handle; the door offers a little resistance before<br />

opening completely.<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

2. CLOSING THE OVEN DOOR<br />

2.1. 6 AND 10 SHELF MODELS<br />

Simply push the oven door to so that it locks.<br />

2.2. 20 SHELF MODELS<br />

a) Holding the door handle in the horizontal position, push<br />

the door to.<br />

b) Then, holding the door against the oven, turn the handle<br />

clockwise until it is vertical again.<br />

GB

GB<br />

3. DESCRIPTION OF CONTROL PANEL<br />

3.1. INTRODUCTION<br />

To facilitate familiarisation with the oven's functions, refer to the<br />

fold-out page at the end of this booklet illustrating the control<br />

panel of your oven model.<br />

The different functions available on the various models are<br />

described below.<br />

Some functions are common to all models while others are<br />

only available on certain models.<br />

3.2. STANDARD CONTROLS<br />

S1 Main switch.<br />

L1 "Oven on" indicator led.<br />

TS Digital Thermometer/Thermostat: controls the oven<br />

temperature.<br />

TM Timer: sets the cooking time.<br />

PRB Digital Thermometer/Thermostat: controls the core temperature<br />

of products (not available on Functional level C2).<br />

startno2_alp.eps<br />

Cooking cycle/program Start/Stop button.<br />

(Functional levels C4 and C6 only)<br />

3.3. MAIN COOKING CYCLES<br />

c1alp.eps<br />

C1 Convection cycle: ideal for roasting and gratinating at<br />

temperatures of up to 300°C.<br />

c2_2alp.eps<br />

C2 Mixed cycle: combined convection and steam cycle<br />

which simultaneously uses both the convectors and boiler to<br />

keep dishes perfectly tender (maximum temperature 250°C).<br />

c3alp.eps<br />

C3 Steam cycle: ideal for boiling (steam operating temperature:<br />

100°C).<br />

30÷99<br />

c4alp.eps<br />

C4 Low-temperature steam cycle: ideal for delicate and<br />

vacuum-packed cooking and for defrosting at temperatures<br />

between 30°C and 99°C.<br />

Note: On functional level 6 ovens, this option is selected in the<br />

normal steam cycle (C3) by setting a cooking temperature of less<br />

than 100°C.<br />

c5alp.eps<br />

C5 Convection cycle with automatic dehumidification: reduces<br />

excess humidity in the oven when required, thereby<br />

making it ideal for dry cooking (maximum temperature 300°C).<br />

Note: On functional level ovens C2, C3 and C4, this option is<br />

selected in the normal convection cycle (C1) by manually<br />

opening the oven chamber vent using the RH lever above the<br />

door.<br />

46<br />

3.4. SPECIAL COOKING CYCLES<br />

R<br />

cr_alp.eps<br />

CR Regeneration cycle: produces the ideal temperature<br />

and humidity required to quickly reheat previously cooked dishes<br />

(maximum temperature 250°C).<br />

Note: On functional level 6 ovens, this cycle is preprogrammed<br />

and selected in AUTO mode. Refer to the chapter on<br />

INSTRUCTIONS FOR USE - Functional Level 6<br />

COOK<br />

&<br />

HOLD<br />

cokhold2_alp.eps<br />

Cook and hold cycle: this slow, low-heat cooking cycle is ideal<br />

for cooking large joints.<br />

Used in conjunction with convection (C1) and steam (C3)<br />

cooking cycles.<br />

spillone_alp.eps<br />

Cooking with temperature probe: this cooking method precision<br />

controls the core temperature of products between 0 and<br />

99°C.<br />

Used in conjunction with all cooking cycles.<br />

The cooking cycle automatically stops when the set core temperature<br />

is reached.<br />

1<br />

2 potrid2_alp.eps<br />

Low speed and power cycle: ideal for delicate cooking as<br />

required by light pastries.<br />

Used in conjunction with all cooking cycles.<br />

PAUSE<br />

pausa_alp.eps<br />

Pause: by setting a pause using this function you can delay the<br />

start of cooking programs or set a pause between two cooking<br />

cycles (i.e. for proving).

3.5. ADDITIONAL FUNCTIONS<br />

ventola_alp.eps<br />

Rapid oven cooling: this function is used to switch from one<br />

cooking cycle to another operating at a lower temperature. It<br />

controls fan activation and automatic water injection (Levels 4<br />

and 6 only), even when the oven door is open.<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

iniezion_alp.eps<br />

Manual water injection: this function immediately increases the<br />

humidity level inside the oven during a cooking cycle.<br />

CLEAN<br />

clean_alp.eps<br />

Clean cycle: this function activates a semi-automatic oven<br />

cleaning cycle (see paragraph 7.3 on "Cleaning").<br />

?SET<br />

occhio_n_alp.eps<br />

Programmed cooking settings display: this display allows you<br />

to check cooking cycle settings at a glance.<br />

1 2<br />

CYCLE<br />

fase12_2alp.eps<br />

1 2 3 4 5 6<br />

PHASE<br />

fase_alp.eps<br />

C4 C6<br />

- Sequential phase controls and leds: used to set automatic<br />

multi-phase cooking programs comprising two sequential<br />

phases on functional level 4 ovens and 6 sequential phases on<br />

functional level 6 ovens.<br />

umidità_alp.eps<br />

- Electronic humidity control (only on functional level 6<br />

ovens): this control allows you to obtain the required degree of<br />

humidity in the oven during convection, mixed and regeneration<br />

cooking cycles.<br />

A<br />

U<br />

T<br />

O<br />

automan_alp.eps<br />

Manual or automatic program (only on functional level 6 ovens):<br />

this function allows you to work in either manual or AUTO mode.<br />

In auto mode you can select one of the programs stored in the<br />

program archive.<br />

PROGRAM<br />

prog_88_alp.eps<br />

- Program display (only on functional level 6 ovens): this<br />

display panel allows you to find and select the required program<br />

using the relative display buttons.<br />

47<br />

M<br />

RETURN CANCEL<br />

biblio_alp.eps<br />

- Program archive control buttons (only on functional<br />

level 6 ovens): these buttons allow you to save, edit and delete<br />

cooking programs.<br />

portaper_alp.eps<br />

Door "open" indicator led.<br />

HACCP haccp.eps<br />

HACCP button (only available on request): this button enables<br />

you to record cooking programs in conformity with Standard<br />

H.A.C.C.P. (Hazard Analysis and Critical Control Points).<br />

Depending on the system installed, you can print cooking parameters<br />

on a dedicated printer or save them directly onto a Personal<br />

Computer.<br />

GB

GB<br />

3.6. STEAM BOILER CONTROLS<br />

Note: the steam boiler is not installed on models 10 GN<br />

1/1 C2 and 6 GN 1/1 C2-C3<br />

scarico_alp.eps<br />

Manual boiler water drain: pressing button "A" this function<br />

allows you to empty the boiler<br />

In the case of all other models, the boiler is emptied using the lever<br />

located under the control panel.<br />

Important! Risk of scalding.<br />

Exercise due care when manually emptying the boiler.<br />

Important! To prevent the build-up of lime-scale inside the<br />

boiler:<br />

� Make sure the water supply corresponds with the required<br />

characteristics - see Installation.<br />

� Always empty the boiler at the end of each day.<br />

genvapor_alp.eps<br />

A<br />

Functional level C6<br />

Boiler status indicator led:<br />

- off: boiler ready;<br />

- on: boiler preheating. Wait until the led switches off.<br />

- flashing: boiler filling or empty. Check the water supply to the<br />

oven!<br />

calcare_alp.eps<br />

Lime-scale indicator led: this indicator led starts flashing when<br />

the boiler needs descaling. To do this, follow the instructions<br />

given in paragraph 7.<br />

Before using the oven make sure:<br />

- the external electrical safety switch is connected;<br />

- the gas shut-off valve is open;<br />

- the water shut-off valves are open;<br />

- the boiler drain lever is in the closed position (only on<br />

those models fitted with a drain lever).<br />

48

USING THE OVEN<br />

4. FUNCTIONAL LEVELS C2 AND<br />

C3<br />

4.1 TURNING ON THE OVEN<br />

To turn on the oven, simply rotate main switch/selector knob S1<br />

from "0" to the required cooking cycle. The following sequence<br />

then occurs:<br />

L1<br />

S1<br />

0<br />

accforno alp eps<br />

4.1.1. ON ALL MODELS<br />

- Green indicator led L1 illuminates;<br />

- Thermometer/Thermostat display TS indicates the oven temperature;<br />

- The oven light switches on.<br />

4.1.2. MODELS WITH STEAM BOILER<br />

- The boiler starts filling.<br />

genva_l_alp2.eps<br />

(flashing led);<br />

- The boiler starts heating up.<br />

genvapor_alp.eps<br />

(fixed illuminated led);<br />

- The boiler is ready (led off)<br />

4.1.3 TURNING OFF THE OVEN<br />

To turn off the oven, simply <strong>return</strong> selector knob S1 back to "0".<br />

C1<br />

C2<br />

C3<br />

49<br />

4.2. SELECTING THE COOKING CYCLE<br />

Set selector S1 to the required cooking cycle, for example, the<br />

"mixed cooking cycle" (the cooking cycle may also be selected<br />

even after cooking has started).<br />

L1 S1<br />

0<br />

CR<br />

C4<br />

modocott alp eps<br />

4.3. SETTING THE COOKING TEMPERATURE<br />

- Turn thermostat knob TS clockwise.<br />

- The temperature setting immediately starts flashing on the<br />

display.<br />

TS<br />

200<br />

t tt l<br />

60<br />

100<br />

150<br />

C1<br />

C2<br />

C3<br />

- Stop the knob at the temperature setting required, for example,<br />

200°C.<br />

200<br />

t 200 l<br />

After about 5 seconds, the display stops flashing and restores the<br />

current oven temperature.<br />

Note: Each cooking cycle (C1, C2, etc. - see paragraph above)<br />

has its own maximum temperature limit beyond which temperature<br />

control knob TS cannot be turned.<br />

In the case of steam cycle C3, no temperature setting is<br />

required since the cycle is automatically set at 100°C.<br />

60<br />

100<br />

150<br />

TS<br />

GB

GB<br />

4.4. START OF COOKING CYCLE<br />

- Make sure the oven door is closed.<br />

- Set timer knob TM to the required cooking time, for example, 20<br />

minutes.<br />

10<br />

90<br />

80 70<br />

20<br />

30<br />

40<br />

50<br />

60<br />

timer20_alp.eps<br />

The cooking cycle now starts. The yellow indicator leds above<br />

knobs TS and TM illuminate to indicate activation of heating and<br />

cooking.<br />

- The pointer on timer knob TM indicates at a glance the time<br />

remaining until the end of the cooking cycle. The time setting may<br />

also be changed even in the middle of a cooking cycle, simply by<br />

turning the knob.<br />

4.4.1. MODELS WITH STEAM BOILER<br />

- The steam, mixed and regeneration cycles cannot start until the<br />

boiler is ready as indicated by extinction of the corresponding led.<br />

During this phase, timer TM remains stationary and green indicator<br />

led L1 flashes.<br />

The same also occurs if the oven door is opened once the cooking<br />

cycle has started.<br />

- The oven does not stop however if the oven door is opened<br />

during a regeneration cooking cycle (CR).<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

4.5. END OF COOKING CYCLE<br />

When the set cooking time has elapsed (pointer on timer TM at<br />

zero), the cooking cycle stops automatically and the yellow<br />

indicator leds above knobs TS and TM switch off. The oven then<br />

beeps for about one minute to let you know that the cooking cycle<br />

has finished.<br />

Note:<br />

- To silence the acoustic signal before the full minute has elapsed,<br />

simply press any button on the control panel or open the oven<br />

door.<br />

- The cooking cycle may also be interrupted manually by <strong>return</strong>ing<br />

timer knob TM back to zero.<br />

Open the oven door and remove the cooked food.<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

4.6. MANUAL CYCLE �<br />

You can also set manual cooking cycles simply by deactivating<br />

the timer.<br />

To do this, just turn timer knob TM clockwise to "Continuous<br />

cooking" ��<br />

In this case, the cooking cycle can only be stopped by <strong>return</strong>ing<br />

timer knob TM back to zero or by switching off the oven.<br />

50<br />

10<br />

120<br />

110<br />

100<br />

20<br />

30<br />

40<br />

TM<br />

90<br />

80 70<br />

50<br />

60<br />

4.7. PREHEATING<br />

timer_co_alp.eps<br />

To preheat the oven prior to cooking, proceed as follows:<br />

- First switch on the empty oven by setting selector S1 to the<br />

required cooking cycle and then set thermostat TS to the preheating<br />

temperature and timer TM to "Continuous cooking" �.<br />

- Wait until the preheating temperature is indicated on the oven<br />

temperature display.<br />

- Open the oven door and place the food inside.<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

Close the oven door, set the required cooking time on timer TM<br />

and, if necessary, readjust the cooking temperature using thermostat<br />

knob TS.<br />

4.8. COOKING WITH TEMPERATURE PROBE (Core<br />

temperature probe)<br />

ONLY AVAILABLE ON FUNCTIONAL LEVEL 3 OVENS<br />

This cooking method offers precise control over the core<br />

temperature of products. Simply set the required core temperature<br />

and the cycle will stop as soon as this temperature is<br />

reached.<br />

Important: The temperature probe is a precision instrument. It<br />

must therefore be handled with the utmost care to avoid knocks<br />

or damage caused by abrupt insertion or removal of the lead<br />

(particularly when using trolley-mounted units). The guarantee<br />

does not cover damage to the core temperature probe caused<br />

by improper usage.<br />

Switch on the oven and, if necessary, preheat as described in the<br />

paragraph above.<br />

Remove the temperature probe from its holder and insert in the<br />

product, taking care not to force it. Make sure the sensor head is<br />

positioned at the heart of the product and close the oven door.<br />

2) Make sure timer knob TM is set to zero.<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

10<br />

20<br />

30<br />

50<br />

60<br />

40<br />

timer_00_alp.eps<br />

TM

3) Set the required cooking cycle and temperature setting using<br />

knobs S1 and TS.<br />

4) Start of cooking cycle with temperature probe. Turn temperature<br />

probe control knob PRB clockwise.<br />

prb_50_alp.eps<br />

PRB<br />

- The cooking cycle now starts.<br />

- The temperature setting immediately starts flashing on display<br />

PRB. The preset start setting is 50°C.<br />

- Turn the knob clockwise or counter-clockwise to increase or<br />

reduce the setting accordingly until the required temperature is<br />

obtained (i.e. 57°C).<br />

prb_57_alp.eps<br />

PRB<br />

- Release the knob. After 5 seconds the display restores the<br />

current core temperature of the product.<br />

Note: The target core temperature may be changed whenever<br />

required, simply by adjusting probe knob PRB.<br />

The target core temperature may also be checked without actually<br />

changing the setting, simply by turning knob PRB either<br />

clockwise or counter-clockwise by just one notch.<br />

5) End of cooking cycle with temperature probe. When the<br />

target core temperature is reached, the oven switches off automatically<br />

as described in paragraph 4.5 above.<br />

Note: The oven overrides the setting on probe knob PRB during<br />

cooking cycles set by timer TM. Likewise, the oven overrides the<br />

setting on timer TM during temperature probe cooking cycles.<br />

6) Deactivation of temperature probe. Turn knob PRB counterclockwise<br />

until the display switches off (below 0°C).<br />

PRB<br />

prb_57_2_alp.eps<br />

56-55-54.........2-1-0<br />

51<br />

GB

GB<br />

5. FUNCTIONAL LEVEL C4<br />

5.1. TURNING ON THE OVEN<br />

To turn on the oven, simply press the button on main switch S1.<br />

L1<br />

S1<br />

s1_alp.eps<br />

- Green indicator led L1 illuminates;<br />

- The control panel illuminates;<br />

-Thermometer/Thermostat display TS indicates the oven temperature;<br />

- The oven light switches on;<br />

- The boiler starts filling;<br />

genva_l_alp2.eps<br />

(flashing led);<br />

- The boiler starts heating up;<br />

genvapor_alp.eps<br />

(fixed illuminated led);<br />

- The boiler is ready (led off).<br />

5.1.1 TURNING OFF THE OVEN<br />

To turn off the oven, simply press the button on main switch S1<br />

for two seconds.<br />

The oven will not switch off if the button is pressed for less than<br />

two seconds.<br />

5.2. SELECTING THE COOKING CYCLE<br />

When the oven is switched on, the relative cooking cycle leds start<br />

flashing. Select the required cooking cycle simply by pressing the<br />

corresponding button (for example, Mixed cycle C2).<br />

c2alp.eps<br />

The corresponding button led illuminates while the others switch<br />

off.<br />

Note: During this phase you can:<br />

- change the cooking cycle by pressing another cycle button;<br />

-select the low fan speed and power option;<br />

1<br />

2<br />

potrid_alp.eps<br />

- select the cook and hold option.<br />

COOK<br />

&<br />

HOLD<br />

cookhold_alp.eps<br />

(Cook & Hold: only available during Convection and<br />

Steam cooking cycles, and only at low speed and power).<br />

After selecting the required cooking cycle, the displays of Thermostat<br />

TS, Timer TM and temperature probe PRB start flashing<br />

ready to be programmed (a dashed line indicates that the<br />

displays are blank).<br />

5.3. SETTING THE COOKING TEMPERATURE<br />

- Turn thermostat knob TS clockwise.<br />

- The temperature setting immediately starts flashing on the<br />

display.<br />

52<br />

timer_190_alp.eps<br />

- Stop the knob at the temperature setting required (for example,<br />

200°C).<br />

timer200_alp.eps<br />

After about 5 seconds, the display stops flashing and restores the<br />

current oven temperature.<br />

Note: Each cooking cycle (C1, C2, etc. - see paragraph above)<br />

has its own maximum temperature limit beyond which temperature<br />

control knob TS cannot be turned.<br />

In the case of steam cycle C3, no temperature setting is<br />

required since the cycle is automatically set at 100°C.<br />

5.4. SETTING THE COOKING TIME<br />

- Turn timer knob TM clockwise.<br />

timer_alp.eps<br />

- The time setting immediately starts flashing in hours and<br />

minutes on the display.<br />

- Stop the knob at the time setting required (for example, 20<br />

minutes).<br />

timer_20_alp.eps<br />

After about 5 seconds, the display stops flashing.

5.5. START OF COOKING CYCLE<br />

- Make sure the oven door is closed.<br />

start_alp.eps<br />

- Press the cooking start button<br />

The yellow indicator led above the start button illuminates and the<br />

cooking cycle starts. The yellow indicator leds above knobs TS<br />

and TM also illuminate to indicate activation of heating and<br />

cooking.<br />

The displays for Thermostat/Thermometer TS and Timer TM<br />

indicate the following:<br />

- TS - oven temperature;<br />

- TM - time remaining until the end of the cycle.<br />

Note:<br />

- The steam, mixed and regeneration cycles cannot start until the<br />

boiler is ready as indicated by extinction of the corresponding led<br />

(see paragraph 5.1).<br />

During this phase, the timer remains stationary and the yellow<br />

indicator led above the Cooking start button flashes. The same<br />

also occurs if the oven door is opened once the cooking cycle has<br />

started.<br />

The oven does not stop however if the oven door is opened during<br />

a regeneration cooking cycle (CR).<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

5.6. END OF COOKING CYCLE<br />

When the set cooking time has elapsed the cooking cycle stops<br />

automatically and the yellow indicator leds above the cooking<br />

start button and knobs TS and TM switch off. The oven then beeps<br />

for about one minute to let you know that the cooking cycle has<br />

finished.<br />

Open the oven door and remove the cooked food.<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

Note:<br />

- To silence the acoustic signal before the full minute has elapsed,<br />

simply press any button on the control panel or open the oven<br />

door.<br />

- The cooking cycle may also be interrupted manually by holding<br />

the cycle Start/Stop button pressed in for two seconds.<br />

startnol_alp.eps<br />

To repeat the same cycle, simply press the Start/Stop button<br />

again.<br />

53<br />

5.7. MANUAL CYCLE<br />

You can also set manual cooking cycles simply by deactivating<br />

the timer.<br />

To do this, turn timer knob TM clockwise until the word "Cont" is<br />

displayed. This indicates a continuous cooking cycle which<br />

effectively overrides the timer's maximum setting of 8 hours.<br />

timercon_alp.eps<br />

Press the Start/Stop button to start the cooking cycle.<br />

In this case, the cooking cycle can only be stopped manually by<br />

pressing the Start/Stop button for two seconds or by switching off<br />

the oven.<br />

5.8. PREHEATING<br />

To preheat the oven prior to cooking, proceed as follows:<br />

- Switch on the empty oven:<br />

- set the required cooking cycle;<br />

- set the preheating temperature on thermostat TS;<br />

- set timer TM to "Cont";<br />

- wait until the preheating temperature is indicated on the oven<br />

temperature display, open the oven door and place the food<br />

inside.<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

Close the oven door, set the required cooking time on timer TM<br />

and, if necessary, readjust the cooking temperature using thermostat<br />

knob TS.<br />

5.9. COOKING WITH TEMPERATURE PROBE<br />

(Core temperature probe)<br />

This cooking method offers precise control over the core temperature<br />

of products. Simply set the required core temperature<br />

and the cycle will stop as soon as this temperature is reached.<br />

Important: The temperature probe is a precision instrument. It<br />

must therefore be handled with the utmost care to avoid knocks<br />

or damage caused by abrupt insertion or removal of the lead<br />

(particularly when using trolley-mounted units). The guarantee<br />

does not cover damage to the core temperature probe caused<br />

by improper usage.<br />

Switch on the oven and, if necessary, preheat.<br />

2) Stop the cooking cycle.<br />

Remove the temperature probe from its holder and insert in the<br />

product, taking care not to force it. Make sure the sensor head is<br />

positioned at the heart of the product and close the oven door.<br />

3) Select the required cooking cycle and set the cooking temperature<br />

using thermostat knob TS.<br />

Important: do not set timer TM.<br />

GB

GB<br />

4) Turn temperature probe control knob PRB clockwise.<br />

prb_50_alp.eps<br />

PRB<br />

- The temperature setting immediately starts flashing on display<br />

PRB. The preset start setting is 50°C.<br />

- Turn the knob clockwise or counter-clockwise to increase or<br />

reduce the setting accordingly until the required temperature is<br />

obtained (i.e. 57°C).<br />

prb_57_alp.eps<br />

PRB<br />

- Release the knob. After 5 seconds the display restores the<br />

current core temperature of the product.<br />

5) Start of cooking cycle with temperature probe. Press the<br />

Cooking start button.<br />

startnol_alp.eps<br />

6) End of cooking cycle with temperature probe. When the<br />

target core temperature is reached, the oven switches off automatically<br />

as described above (see paragraph 5.6).<br />

7) Deactivation of temperature probe. (Only possible when the<br />

cooking cycle has stopped). Set any cooking time on timer TM to<br />

automatically zero any previous temperature probe setting. Likewise,<br />

set any temperature setting on probe control knob PRB to<br />

automatically zero any previous timer setting. The temperature<br />

probe cooking cycle may also be deactivated by switching off the<br />

oven.<br />

5.10. AUTOMATIC TWO-PHASE COOKING CYCLE<br />

Functional level 4 ovens enable you to program cooking cycles<br />

comprising two sequential phases. For example:<br />

- Phase 1: - Convection, 200°C<br />

- Temperature probe, 70°C<br />

- Phase 2: - Mixed, 220°C<br />

- Length, 40 minutes<br />

The cycle automatically passes from phase 1 to phase 2.<br />

The two-phase cooking cycle is controlled by the button illustrated<br />

below.<br />

1 2<br />

CYCLE<br />

fase12_alp.eps<br />

This button is equipped with two indicator leds (one for each<br />

phase) which illuminate red or green depending on whether the<br />

relative phase is activated or deactivated.<br />

To program a two-phase cooking cycle, proceed as follows:<br />

1) switch on and preheat the oven;<br />

2) stop the cycle when the oven is preheated;<br />

3) set the required cooking cycle, oven temperature and time<br />

setting (or probe temperature setting) as described above.<br />

4) Press the "PHASE" button:<br />

54<br />

1 2<br />

CYCLE<br />

fase1_2_alp.eps<br />

The led for phase 2 turns red while the led for phase 1 turns green.<br />

At the same time, the cooking cycle button leds start flashing<br />

again ready to program phase 2.<br />

5) Select:<br />

- the required cooking cycle for phase 2;<br />

- the required oven temperature for phase 2;<br />

- the required time setting (or probe temperature setting) for<br />

phase 2.<br />

6) The two-phase cooking cycle is now set. Place the product in<br />

the oven and press the Cooking start button.<br />

start_alp.eps<br />

The cooking cycle starts at phase 1 (phase led 1 red) and then<br />

automatically proceeds to phase 2 (phase led 2 red).<br />

The start of phase 2 is also signalled by a brief acoustic signal.<br />

On completion of phase 2, the cooking cycle stops automatically<br />

as previously described.<br />

5.11. EDITING/DISPLAYING COOKING SETTINGS<br />

- Before starting the cooking cycle, you can modify the following<br />

cooking parameters:<br />

1) cooking cycle;<br />

2) cooking temperature TS;<br />

3) cooking time TM;<br />

4) probe temperature PRB (instead of cooking time).<br />

- Once the cooking cycle has started, you can only modify the<br />

cooking parameters by pressing the Parameters view button.<br />

?SET<br />

occhio_alp.eps<br />

In this mode, you can view and change the settings for the active<br />

phase (as indicated by the corresponding red phase led). To view<br />

or edit the parameters of the next phase (if set), you must instead<br />

first press the view button and then the phase button.<br />

?SET<br />

occhio_alp.eps<br />

1 2<br />

CYCLE<br />

fase1_2_alp.eps<br />

To exit viewing mode, simply press the view button again so that<br />

the led switches off. After 5 seconds the display in any case<br />

automatically <strong>return</strong>s to the current parameter settings.

6. FUNCTIONAL LEVEL C6<br />

6.1. TURNING ON THE OVEN<br />

To turn on the oven, simply press the button on main switch S1.<br />

The following sequence then occurs:<br />

- Green indicator led L1 illuminates;<br />

L1<br />

S1<br />

s1_alp.eps<br />

- The control panel illuminates;<br />

- Thermometer/Thermostat display TS indicates the oven<br />

temperature;<br />

- The oven light switches on;<br />

- The boiler starts filling;<br />

genva_l_alp2.eps<br />

(flashing led);<br />

- The boiler starts heating up;<br />

genvapor_alp.eps<br />

(fixed illuminated led);<br />

- The boiler is ready (led off).<br />

6.1.1 TURNING OFF THE OVEN<br />

To turn off the oven, simply press the button on main switch S1<br />

for two seconds.<br />

The oven will not switch off if the button is pressed for less than<br />

two seconds.<br />

6.2. SELECTING MANUAL/AUTO MODE<br />

When the oven is switched on the two leds above the "manual/<br />

AUTO" mode selector button start flashing.<br />

A<br />

U<br />

T<br />

O<br />

automanl_alp.eps<br />

Press the button until the led for the required operating mode<br />

illuminates.<br />

- Manual: In this mode, you must set the required cooking program<br />

each time you turn the oven on. When the oven is turned off the<br />

selected program is thus deleted.<br />

- AUTO: in this mode, you can select one of the cooking programs<br />

stored in the program archive. These programs can be set and<br />

saved as required and are not deleted when the oven is turned<br />

off. This type of oven can memorise up to 50 different cooking<br />

programs.<br />

Each time you press the manual/AUTO button the corresponding<br />

operating mode is selected.<br />

A description follows first of the Manual operating mode and then<br />

of the AUTO operating mode.<br />

6.3. MANUAL MODE<br />

When the oven is switched on press the corresponding button<br />

until the manual operating mode led illuminates.<br />

A<br />

U<br />

T<br />

O<br />

manuale_alp.eps<br />

55<br />

6.4. SELECTING THE COOKING CYCLE<br />

The relative cooking cycle leds start flashing. Select the required<br />

cooking cycle by pressing the corresponding button (for<br />

example, Mixed cycle C2).<br />

C2<br />

PAUSE<br />

c2liv6_alp.eps<br />

The corresponding button led illuminates while the others switch<br />

off.<br />

Note: During this phase you can:<br />

- change the cooking cycle by pressing another cycle button;<br />

- select the low fan speed and power option;<br />

- select the Cook and Hold option (this option is only available<br />

during Convection and Steam cycles and only at low speed and<br />

power).<br />

After selecting the required cooking cycle, the displays for Thermostat<br />

TS, Timer TM and temperature probe PRB start flashing<br />

ready to be programmed (a dashed line indicates that the<br />

displays are blank).<br />

6.5. SETTING THE COOKING TEMPERATURE<br />

Press the up and down buttons on thermostat TS to increase<br />

or reduce the flashing temperature setting shown on the<br />

display.<br />

Release the button when the required temperature setting is<br />

obtained (e.g. 200°C).<br />

ts_200_alp.eps<br />

After about 5 seconds, the display stops flashing and restores the<br />

current oven temperature.<br />

Note: Each cooking cycle (C1, C2, etc. - see paragraph above)<br />

has its own maximum temperature limit beyond which thermostat<br />

buttons TS cannot be set.<br />

In the case of steam cycle C3, no temperature setting is required<br />

since the cycle is automatically set at 100°C. Lower temperatures<br />

may instead be set to select the low-temperature steam<br />

cycle (C4).<br />

6.6. SETTING THE COOKING TIME<br />

Press the up and down buttons on timer TM to increase or<br />

reduce the flashing time setting shown in hours and minutes<br />

on the display.<br />

Release the button when the required time setting is obtained<br />

(i.e. 20 minutes).<br />

After about 5 seconds, the display stops flashing.<br />

tm_20_alp.eps<br />

GB

GB<br />

6.7. START OF COOKING CYCLE<br />

- Make sure the oven door is closed.<br />

- Press the cooking start button.<br />

start_alp.eps<br />

The yellow indicator led above the start button illuminates.<br />

The displays for Thermostat/Thermometer TS and Timer TM<br />

indicate the following:<br />

- TS - oven temperature;<br />

- TM - time remaining until the end of the cycle.<br />

Note:<br />

- The steam, mixed and regeneration cycles cannot start until the<br />

boiler is ready as indicated by extinction of the corresponding led<br />

(see paragraph 5.1).<br />

During this phase, the timer remains stationary and the yellow<br />

indicator led above the Cooking start button flashes. The same<br />

also occurs if the oven door is opened once the cooking cycle has<br />

started.<br />

The oven does not stop however if the oven door is opened during<br />

a regeneration cooking cycle (CR).<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

6.8 END OF COOKING CYCLE<br />

When the set cooking time has elapsed the cooking cycle stops<br />

automatically and the oven beeps for about one minute to let you<br />

know that the cooking cycle has finished.<br />

Open the oven door and remove the cooked food.<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

Note:<br />

- To silence the acoustic signal before the full minute has elapsed,<br />

simply press any button on the control panel or open the oven door.<br />

- The cooking cycle may also be interrupted manually by holding<br />

the cycle Start/Stop button pressed in for two seconds.<br />

startnol_alp.eps<br />

The oven will not switch off if the button is pressed for less than<br />

two seconds.<br />

To repeat the same cycle, simply press the Start/Stop button<br />

again.<br />

6.9. MANUAL CYCLE<br />

You can also set manual cooking cycles, simply by deactivating<br />

the timer.<br />

To do this, press the down button on timer TM until the word<br />

"Cont" is shown on the display indicating the Continuous<br />

cooking cycle.<br />

cont_liv_alp.eps<br />

In this case, the cooking cycle can only be stopped manually by<br />

pressing the Start/Stop button for two seconds or by switching off<br />

the oven.<br />

6.10. PREHEATING<br />

To preheat the oven prior to cooking, proceed as follows:<br />

Switch on the empty oven:<br />

- set the required cooking cycle;<br />

- set the preheating temperature on thermostat TS;<br />

- set timer TM to "Cont";<br />

- wait until the preheating temperature is indicated on the oven<br />

temperature display, open the oven door and place the food<br />

inside.<br />

56<br />

Important! Risk of burning.<br />

Open the door with due care when the appliance is hot.<br />

Close the oven door, set the required cooking time on timer TM<br />

and, if necessary, readjust the cooking temperature on thermostat<br />

TS.<br />

6.11. COOKING WITH TEMPERATURE PROBE (Core<br />

temperature probe)<br />

This cooking method offers precise control over the core<br />

temperature of products. Simply set the required core temperature<br />

and the cycle will stop as soon as this temperature is<br />

reached.<br />

Important: The temperature probe is a precision instrument. It<br />

must therefore be handled with the utmost care to avoid knocks<br />

or damage caused by abrupt insertion or removal of the lead<br />

(particularly when using trolley-mounted units). The guarantee<br />

does not cover damage to the core temperature probe caused<br />

by improper usage.<br />

1) Switch on the oven and, if necessary, preheat.<br />

2) Stop the cooking cycle.<br />

Remove the temperature probe from its holder and insert in the<br />

product, taking care not to force it. Make sure the sensor head is<br />

positioned at the heart of the product and close the oven door.<br />

3) Select the required cooking cycle and set the cooking temperature<br />

on thermostat TS.<br />

Important: do not set timer TM.<br />

- The temperature setting immediately starts flashing on display<br />

PRB. The preset start setting is 50°C.<br />

4) Press the up and down buttons on probe control PRB to<br />

increase or reduce the temperature setting shown on the<br />

display.<br />

prb2_alp.eps<br />

- Release the button at the required temperature setting.<br />

After 5 seconds the display restores the current core temperature<br />

of the product.<br />

5) Start of cooking cycle with temperature probe. Press the<br />

Cooking Start/Stop button.<br />

start_alp.eps

6) End of cooking cycle with temperature probe. When the<br />

target core temperature is reached, the oven switches off automatically<br />

as described in paragraph 6.8 above.<br />

7) Deactivation of temperature probe. (Only possible when the<br />

cooking cycle has stopped). Set any cooking time on timer TM to<br />

automatically zero any previous temperature probe setting. Likewise,<br />

set any temperature setting on probe control knob PRB to<br />

automatically zero any previous timer setting. The temperature<br />

probe cooking cycle may also be deactivated by switching off the<br />

oven.<br />

6.12. AUTOMATIC MULTI-PHASE COOKING CYCLE<br />

Functional level 6 ovens enable you to program cooking cycles<br />

comprising up to 6 sequential phases. For example:<br />

- Phase 1: - Convection, 200°C<br />

- Temperature probe, 70°C<br />

- Phase 2: - Mixed, 220°C<br />

- Length, 40 minutes<br />

- Phase 3: - Convection, 250°C<br />

- Length, 15 minutes<br />

and so forth up to a maximum of 6 phases.<br />

The cycle automatically passes from one phase to the next until<br />

the program stops on completion of the last phase.<br />

The multi-phase cooking program is controlled by the button<br />

illustrated below.<br />

1 2 3 4 5 6<br />

PHASE<br />

fase_alp.eps<br />

This button is equipped with six indicator leds (one for each<br />

phase) which illuminate red or green depending on whether the<br />