SITRANS F flowmeters - Industria de Siemens

SITRANS F flowmeters - Industria de Siemens

SITRANS F flowmeters - Industria de Siemens

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

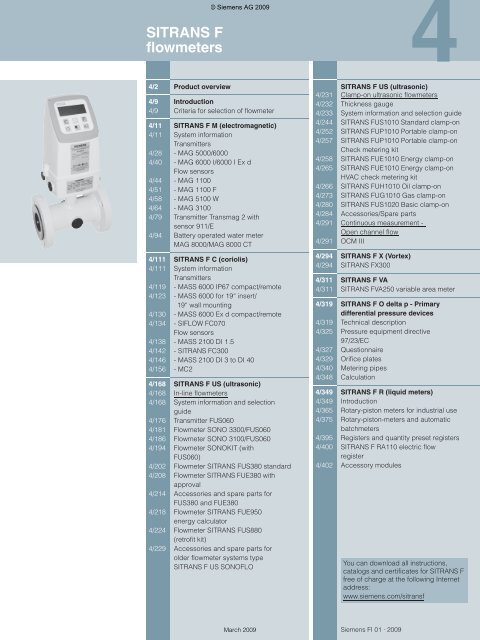

<strong>SITRANS</strong> F<strong>flowmeters</strong>© <strong>Siemens</strong> AG 20094/2 Product overview4/9 Introduction4/9 Criteria for selection of flowmeter4/11 <strong>SITRANS</strong> F M (electromagnetic)4/11 System informationTransmitters4/28 - MAG 5000/60004/40 - MAG 6000 I/6000 I Ex dFlow sensors4/44 - MAG 11004/51 - MAG 1100 F4/58 - MAG 5100 W4/64 - MAG 31004/79 Transmitter Transmag 2 withsensor 911/E4/94 Battery operated water meterMAG 8000/MAG 8000 CT4/111 <strong>SITRANS</strong> F C (coriolis)4/111 System informationTransmitters4/119 - MASS 6000 IP67 compact/remote4/123 - MASS 6000 for 19“ insert/19“ wall mounting4/130 - MASS 6000 Ex d compact/remote4/134 - SIFLOW FC070Flow sensors4/138 - MASS 2100 DI 1.54/142 - <strong>SITRANS</strong> FC3004/146 - MASS 2100 DI 3 to DI 404/156 - MC24/168 <strong>SITRANS</strong> F US (ultrasonic)4/168 In-line <strong>flowmeters</strong>4/168 System information and selectiongui<strong>de</strong>4/176 Transmitter FUS0604/181 Flowmeter SONO 3300/FUS0604/186 Flowmeter SONO 3100/FUS0604/194 Flowmeter SONOKIT (withFUS060)4/202 Flowmeter <strong>SITRANS</strong> FUS380 standard4/208 Flowmeter <strong>SITRANS</strong> FUE380 withapproval4/214 Accessories and spare parts forFUS380 and FUE3804/218 Flowmeter <strong>SITRANS</strong> FUE950energy calculator4/224 Flowmeter <strong>SITRANS</strong> FUS880(retrofit kit)4/229 Accessories and spare parts forol<strong>de</strong>r flowmeter systems type<strong>SITRANS</strong> F US SONOFLO<strong>SITRANS</strong> F US (ultrasonic)4/231 Clamp-on ultrasonic <strong>flowmeters</strong>4/232 Thickness gauge4/233 System information and selection gui<strong>de</strong>4/244 <strong>SITRANS</strong> FUS1010 Standard clamp-on4/252 <strong>SITRANS</strong> FUP1010 Portable clamp-on4/257 <strong>SITRANS</strong> FUP1010 Portable clamp-onCheck metering kit4/258 <strong>SITRANS</strong> FUE1010 Energy clamp-on4/265 <strong>SITRANS</strong> FUE1010 Energy clamp-onHVAC check metering kit4/266 <strong>SITRANS</strong> FUH1010 Oil clamp-on4/273 <strong>SITRANS</strong> FUG1010 Gas clamp-on4/280 <strong>SITRANS</strong> FUS1020 Basic clamp-on4/284 Accessories/Spare parts4/291 Continuous measurement -Open channel flow4/291 OCM III4/294 <strong>SITRANS</strong> F X (Vortex)4/294 <strong>SITRANS</strong> FX3004/311 <strong>SITRANS</strong> F VA4/311 <strong>SITRANS</strong> FVA250 variable area meter4/319 <strong>SITRANS</strong> F O <strong>de</strong>lta p - Primarydifferential pressure <strong>de</strong>vices4/319 Technical <strong>de</strong>scription4/325 Pressure equipment directive97/23/EC4/327 Questionnaire4/329 Orifice plates4/340 Metering pipes4/348 Calculation4/349 <strong>SITRANS</strong> F R (liquid meters)4/349 Introduction4/365 Rotary-piston meters for industrial use4/375 Rotary-piston-meters and automaticbatchmeters4/395 Registers and quantity preset registers4/400 <strong>SITRANS</strong> F RA110 electric flowregister4/402 Accessory modulesYou can download all instructions,catalogs and certificates for <strong>SITRANS</strong> Ffree of charge at the following Internetaddress:www.siemens.com/sitransfMarch 2009<strong>Siemens</strong> FI 01 · 2009

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© <strong>Siemens</strong> AG 2009Product overview■ OverviewApplication Description Catalogpage<strong>SITRANS</strong> F M electromagnetic <strong>flowmeters</strong> - Pulsed DC magnetic flowmeterMAG 5000/6000 transmitter range inrobust IP67 polyamid enclosures forcompact or remote mounting.19", back of panel and front of panelenclosure program.Transmitter MAG 5000/6000• Superior signal resolution for optimumturn down ratio• Comprehensively self-diagnostic, forerror indication and logging• Multi-lingual display and keypad interface• Custody transfer approval: PTB,OIML R 75, OIML R 117, OIML R 49and MI-001Software forparameterization4/28 SIMATIC PDM4MAG 6000 I and MAG 6000 I Ex d inrobust die-cast aluminium enclosurefor <strong>de</strong>manding applications and whereexplosion proof protection is necessary.Transmitter MAG 6000 I/6000 I Ex d• Remote and compact mounting with allsensors• Explosion proof <strong>de</strong>sign:ATEX II 2(1)(2) GD andFM Class 1, Div. 2• Multi-lingual display andtouchpad keypad• Comprehensively self-diagnostic4/40 SIMATIC PDMDesigned for the general industryenvironment. The obstructionless performanceof the MAG 1100 is unaffectedby the suspen<strong>de</strong>d solids,viscosity and temperature challenges.Flow sensor MAG 1100• Metering tube DN 2 ... DN100(1/12“ ... 4“) flangeless <strong>de</strong>sign.• Corrosion-resistant AISI 316 stainlesssteel housing.• Highly resistant liner ceramic or PFAand electro<strong>de</strong>s fitting most extremeprocess media.• Temperature rating up to 200 °C(390 °F)• ATEX II 2(1) GD approval version• CSA/FM Class, 1 Div 24/44Specially <strong>de</strong>signed for the food & beverageand pharmaceutical industry.Flow sensor MAG 1100 F• AISI 316 stainless steel enclosure• Hygienic seal, 3A and EHEDG-approvedconstruction• Easy to clean• Supplied with connections accordingto your specification• ATEX II 2(1) GD approval version• CSA/FM class 1 Div 24/51The MAG 5100 W <strong>de</strong>signed for allwater and waste applications in waterplants and industrial applications.Flow sensor MAG 5100 W• Metering tube DN 25 ... DN 1200(1"¨ ... 48")• NBR Hard Rubber or EPDM lining• Integral grounding electro<strong>de</strong>s asstandard• Increased low flow accuracy for waterleak <strong>de</strong>tection• Drinking water approvals and custodytransfer approvals , OIML R 49, MI-001and PTB4/584/2 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FProduct overviewApplication Description CatalogpageThe MAG 3100 series with its flexibilityin the choice of liner, electro<strong>de</strong> andflange material allows the measurementof even the most extreme processmedia.<strong>SITRANS</strong> F M electromagnetic <strong>flowmeters</strong> - High-power AC magnetic flowmeterDesigned for heavy-duty applicationslike pulp & paper stock over 3%;heavy mining slurries and mining slurrieswith magnetic particles.Flow sensor MAG 3100• For a wi<strong>de</strong> range of pipe dimensions:DN 15 ... DN 2000 (½” ... 78”)• Wi<strong>de</strong> range of liner and electro<strong>de</strong> materials• High-temperature version for applicationwith temperatures up to 180 °C(355 °F)• High-pressure solutions• Approved according to PTB,OIML R 75, OIML R 117, CSA/FM andATEXTransmitter Transmag 2• Magnetic flowmeter with a very strongpulsed AC magnetic field• PROFIBUS PA or HART communication• Self-test function4/64Software forparameterization4/79 SIMATIC PDM4Application in conjunction with transmitterTransmag 2<strong>SITRANS</strong> F M electromagnetic <strong>flowmeters</strong> - Battery-operated magnetic watermeter<strong>SITRANS</strong> F C mass <strong>flowmeters</strong>Battery-operated electromagneticwater meter for water applicationswithin abstraction, distribution network,revenue metering and irrigation.Measurement of liquids and gases.Measurement of mass flow, <strong>de</strong>nsity,temperature and fraction e.g. °Brix or°Plato.Flow sensor 911/E• Metering tube: DN 15 ... DN 600(½" ... 24")• Metering tube liner: rubber, PTFE,Novolak• Integral smartPLUG for storing of calibrationvalues• Temperature of medium:-20 ... +150 °C (-4 ... +300 °F)Water meter MAG 8000• Battery-operated water meter• Metering tube DN 25 ... DN 600(1" ... 24")• Remote and compact installation IP68/NEMA 6P enclosure• Custody transfer approval: OIML R 49and MI-001• Drinking water approvalsFlow sensors MASS 2100(Single tube <strong>de</strong>sign) and FC300• DI 1.5, DI 3, DI 6, DI 15, DI 25, DI 40and DN 4• Flow from 0.1 ... 52 000 kg/h• Pipe material: W 1.4435 (316L);W 2.4602 Hastelloy C22• Accuracy, typically:-Flow: ≤ 0.1% of flow rate-Density: ≤ 0.0005 g/cm 3• Liquid temp./pressure: -50 ... +180°C(-58 ... +356 °F) / Up to 410 bar(5946 psi)• Approved according to ATEX EEx ia IICT3 ... T64/844/94 SIMATIC PDMand Flow Tool4/138,4/142March 2009<strong>Siemens</strong> FI 01 · 20094/3

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© <strong>Siemens</strong> AG 2009Product overview4Application Description CatalogpageMeasurement of liquids and gases.Measurement of mass flow, <strong>de</strong>nsity,temperature and fraction e.g. °Brix or°Plato.Measurement of liquids and gasesMultiparameter transmitter for remoteor compact mounting measuring massflow, <strong>de</strong>nsity, temperature and fractione.g. °Brix and °Plato<strong>SITRANS</strong> F US ultrasonic in-line <strong>flowmeters</strong><strong>SITRANS</strong> FUS060 is a time basedtransmitter <strong>de</strong>signed for ultrasonicflowmetering for any pipe in the F USin-line series up to DN 4000The main application for SONO 3300ultrasonic <strong>flowmeters</strong> is to measurethe volume flow of:• Water and treated waste water• Oil and liquefied gases• Hot water/cooling systemsFlow sensor MC2(Dual tube <strong>de</strong>sign)• Standard MC2- DN 50, DN 65, DN 80, DN 100 andDN 150- Flow from 0 ... 510 000 kg/h / 112 400lb/h- Tube material: W 1.4571 (316Ti) andHastelloy C4• Hygienic MC2- Approvals: EHEDG- DN 20, DN 25, DN 40, DN 50, DN 65and DN 80- Flow from 0 ... 113 600 kg/h /250 000 lb/h- Tube material: W 1.4435 (316L)- Connectors: DIN 11851, DIN 32676and DIN 11864-2A• Accuracy: ≤ 0.15% of rate• Density: ≤ 0.001 g/cm 3• Liquid temp.: -50 ... +180 °C(-58 ... +356 °F)• Pressure: < 100 bar (1450 psi)• Approvals: ATEX EEx em [ib] IICT2 ... T6Transmitters MASS 6000 andMASS 6000 Ex d• Digital signal processing measuring30 times a second.• 3 current, 2 freq. and 2 relay outputs• Adaptive batch function• SENSORPROM memory unit making iteasy to start up the flowmeter.• Easy retrofitting of communicationmodules (AOM)• Approved according to ATEX [EEx ia]IIC / EEx <strong>de</strong> [ia/ib] IIC T6<strong>SITRANS</strong> FUS060 transmitter• EEx approved according to ATEX• HART communication + 1 analog output,1 digital output for frequency orpulse and 1 relay output for alarms andflow direction• PROFIBUS PA communication with1 digital output for frequency or pulse• Multi-functional output for processcontrol• Easy menu based local operation withtwo-line displaySONO 3300/FUS060• Ex approved according to ATEX• DN 50 … DN 300 (2” … 12”) steelpipes• PN 10 ... PN 40 or class 150 ... class300 pressure rates• Flow 0.3 … 3200 m³/h(1.3 ... 14 089 GPM)• No pressure drop• FUS060 transmitter for separatemounting• Signal cables from sensor to transducerare highly protected from aggressiveenvironment by stainless steel pipes4/1564/119,4/130Software forparameterizationSIMATIC PDM4/176 SIMATIC PDM4/181 SIMATIC PDM4/4 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FProduct overviewApplication Description CatalogpageThe main application for SONO 3100ultrasonic <strong>flowmeters</strong> is to measurethe volume flow of:• Water and treated waste water• Oil and liquefied gases• Liquid cryogenic application• District heating systemsInstallation of one, two or four transducersets in existing concrete or steelpipes.Battery or mains-powered ultrasonicflowmeter for use within water-baseddistrict heating, cooling systems andutility.The FUS380 can also be used forwater irrigation systems.<strong>SITRANS</strong> FUS380/FUE380 are<strong>de</strong>signed to work with the<strong>SITRANS</strong> FUE950 energy calculatorUniversal thermal energy calculatorfor district heating and cooling applications.Battery-operated ultrasonic retrofitflowmeter for water applications withinirrigation. Installation of one or twotransducer sets in existing PVC orconcrete pipes.Accessories and spare parts for ol<strong>de</strong>rflowmeter systems type<strong>SITRANS</strong> F US SONOFLOSONO 3100/FUS060• DN 100 ... DN 1200 (4" ... 48")• Pipe in carbon or stainless steel• Transducers can be replaced un<strong>de</strong>rpressure• ATEX-approved• Measure of all liquids less than350 Cst, conductive or non-conductive• No pressure drop• 4-track on request• Special material on requestSONOKIT• DN 100 ... DN 4000 (4" ... 160")• Control and display unit• Temperature of medium:-20 ... +200 °C (-4 ... +395 °F)• Installation on empty pipes or pipes un<strong>de</strong>rpressure (hot-tap installation)FUS380/FUE380• FUS380/FUE380: DN 50 ... DN 1200(2" ... 48")• FUE380: Approved for custody transferaccording to EN 1434 Class 2,OIML R 75 and MID• FUS380/FUE380: Red brass or paintedcarbon steel flanges and meteringtube. AISI transducers• Water temperatures 2 … 200 °C(35.6 ... 392 °F)• Battery or mains-powered<strong>SITRANS</strong> FUE950• Choice of battery, 230 V AC +15%/-30% or 24 V AC• 24 months memory• Plug-in modules for data output, extrainput, M-Bus• Complete set with sensors and sensorpockets• Meets the requirements of OIML R 75and EN 1434<strong>SITRANS</strong> FUS880• Irrigation flowmeter FUS880• Battery or mains-powered• DN 200 ... DN 1200 (8" ... 48")• Wetted transducer technology4/186 SIMATIC PDM4/194 SIMATIC PDM4/202,4/2084/218• Remote installation IP67Spare parts for sensors and transmitters 4/229of ol<strong>de</strong>r flowmeter type SONOFLO:E.g. transducer type SONO 3200, coaxialcables, SONO 3000 transmitter spareparts, SENSORPROMSoftware forparameterizationSIMATIC PDM4/224 SIMATIC PDM4March 2009<strong>Siemens</strong> FI 01 · 20094/5

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© <strong>Siemens</strong> AG 20094Product overview<strong>SITRANS</strong> F US ultrasonic clamp-on <strong>flowmeters</strong>Application Description CatalogpageThe thickness gauge can be used inany field application where there is aneed for flow measurement. Includingbut not limited to:• Water and waste water• Energy measurement• Oil and gas industriesDedicated <strong>flowmeters</strong> are suitable fora wi<strong>de</strong> variety of liquid applications,including those in the:• Water Industry• Wastewater Industry•HVAC Industry• Power Industry• Processing IndustryThickness gaugeThe hand-held micro-processor controlledgauge is <strong>de</strong>signed to measurethe thickness of various metallic or nonmetallicpipes.• Materials inclu<strong>de</strong> steel, aluminium, titanium,plastics and ceramics• Measurements shown in millimeter orinches• Simple-to-read 4-digit LCD display• Weighs 150 g (5.3 oz)• Battery operation for 250 h4/232<strong>SITRANS</strong> FUS1010 General purpose 4/244• Basic function <strong>de</strong>dicated meter• Full range of safety approvals, I/O'sand enclosure types available• Has wi<strong>de</strong> applicability but not the specialfunctions found in FUH1010,FUG1010 and FUE1010 meters• Hazardous area approvals: FM, CSA,ATEXSoftware forparameterizationPortable <strong>flowmeters</strong> are suitable for awi<strong>de</strong> variety of liquid applications,including those in the:• Water Industry• Wastewater Industry•HVAC Industry• Power Industry• Processing IndustryThe <strong>SITRANS</strong> FUP1010 check metermeasures practically all conductive ornon-conductive clean or mo<strong>de</strong>ratelyaerated liquids or liquids with suspen<strong>de</strong>dsolids. This basic featureenables the perfomance check andverification of existing meters used invarious water and wastewater applicationssuch as:• Water Industry- Raw water- Potable water- Chemicals• Wastewater industry-Raw sewage- Effluent- Sludges- Mixed liquor- ChemicalsPortable and <strong>de</strong>dicated energymeters are i<strong>de</strong>al for thermal energy /power applications:• Chilled & hot water submetering• Con<strong>de</strong>nser water, potable water• Glycol and brine solution• Thermal storage<strong>SITRANS</strong> FUP1010 Portable4/252• Basic function portable meter• Has all the capabilities of the FUS1010meter but in a battery-powered,portable configuration• I<strong>de</strong>al for high-accuracy flow survey applications• Not available with hazardous area approvals• Unclassified, ordinary location approvals:UL, C-UL, CE<strong>SITRANS</strong> FUP1010 Portable Check 4/257metering kit• Pipe sizes 25.4 mm to 9.14 m(1“ to 360“)• Current, voltage, frequency andRS 232 outputs• Optional current, voltage and temperatureinputs• Zeromatic Path automatically sets zero• Bi-directional flow operation• 1 MByte data logger with both site anddata logger storage<strong>SITRANS</strong> FUE1010 Energy4/258• Accurate absolute and differential temperaturemeasurement with twomatched 1000 Ω RTD elements installedon supply and return si<strong>de</strong> of theheating or cooling system• Efficiency calculation (kW/ton, EER orCOP) available in systems with optionalanalog input• Dedicated available with hazardousarea approvals: FM, CSA• Portable available with unclassified/ordinarylocations approval: UL, C-UL,FM4/6 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FProduct overviewContinuous measurement - Open channel flowApplication Description CatalogpageThe <strong>SITRANS</strong> FUE1010 check meteringkit is a highly accurate clamp-onnon-intrusive ultrasonic flow displaycomputer for revenue gra<strong>de</strong> thermalenergy sub-metering and energy efficiencydistribution monitoring, with areal-time coefficient of performance(COP) for HVAC systems. This kit isi<strong>de</strong>al for applications which inclu<strong>de</strong>:• Chilled water sub-metering• Con<strong>de</strong>nser water• Potable water• Ammonia and glycol• River and lake water• Lake source coolingDedicated hydrocarbon <strong>flowmeters</strong>are i<strong>de</strong>al for cru<strong>de</strong> oil, refined petroleumor liquefied gas. There are threeapplication areas:• Viscosity compensated volumetric<strong>flowmeters</strong>• Standard volume (Net) mass <strong>flowmeters</strong>• Interface <strong>de</strong>tectors/<strong>de</strong>nsity metersDedicated gas <strong>flowmeters</strong> are i<strong>de</strong>alfor most natural and process gasindustry applications, including:• Checkmetering• Allocation• Flow survey verification• Lost and unaccounted for (LAUF)gas analysis• ProductionDedicated flowmeter is a basic optionfor many clean liquid applications inthe:• Water Industry• Wastewater Industry• HVAC & Power Industries• Processing IndustryHigh accuracy ultrasonic flow monitorfor open channels to complete systemstudies<strong>SITRANS</strong> FUE1010 HVAC Checkmetering kit• Pipe sizes 25.4 mm to 9.14 m(1“ to 360“)• Built-in energy/BTU mo<strong>de</strong>• 4-wire 1000 Ω platinum RTDs for supplyand return temperature measurementsare precision matched to within0.01 °C (0.02 °F)• Chiller efficiency analysis: accepts anin<strong>de</strong>pen<strong>de</strong>nt analog input representingkW usage for calculation of the followingfunctions which can be selected fordata logging or output purposes:- Cooling load (kW/ton)- Coefficient of performance (COP)- Energy efficiency ratio (EER)• Current, voltage, frequency andRS 232 outputs• 1 MByte data logger with both site anddata logger storage<strong>SITRANS</strong> FUH1010 Oil• Volumetric <strong>flowmeters</strong> output viscositycompensated gross volume to externalRTU’s or flow computers• Mass <strong>flowmeters</strong> output standard volume(net) mass flow, API, liquid i<strong>de</strong>ntification,<strong>de</strong>nsity, interface & pig<strong>de</strong>tection• Interface Detectors are used for liquidi<strong>de</strong>ntification and API <strong>de</strong>nsity output,but do not output flow• Hazardous area approvals: FM, CSA,ATEX<strong>SITRANS</strong> FUG1010 Gas• Suitable for most gases (natural gas,oxygen, nitrogen, carbon monoxi<strong>de</strong>,etc.) with typical minimum operatingpressure of 10 barg (145 psig).• Standard volume or mass flow outputfor fixed gas compositions• Analog input for pressure and temperaturecompensation• Hazardous area approvals: FM, CSA,ATEX<strong>SITRANS</strong> FUS1020 Basic• Has FUS1010 system function but withoutthe same I/O capability or safetyapproval ratings• This basic meter is inten<strong>de</strong>d for singleliquid applications that do not requirethese features• Not available with hazardous area approvals• Unclassified, ordinary locatons approvals:UL, C-UL, CEOCM III• High accuracy on unique or non-standardweirs and flumes• AC and DC operation.• Automatically switches to battery operationfor uninterrupted power.• Low-power remote monitoring4/2654/2664/2734/2804/291Software forparameterization4March 2009<strong>Siemens</strong> FI 01 · 20094/7

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© <strong>Siemens</strong> AG 20094Product overview<strong>SITRANS</strong> F X Vortex FlowmeterMeasurement of steam, gases and liquidsin:• Chemical• HVAC / Power plants•Oil& Gas• Food & Beverage• Pharma<strong>SITRANS</strong> F VA variable area metersMeasurement of flow of liquids andgases, also highly suitable for corrosivemedia, high temperatures andhigh pressures.<strong>SITRANS</strong> F O <strong>de</strong>lta p - primary differential pressure <strong>de</strong>vicesMeasurement of flow with orificeplates and metering pipes for mountingbetween flanges, e.g. togetherwith <strong>SITRANS</strong> P transmitters, DS III,DS III PA and DS III FF series.<strong>SITRANS</strong> F R liquid metersApplication Description CatalogpageRotary-piston meters<strong>Industria</strong>l <strong>de</strong>sign for measurement offlowing liquids<strong>SITRANS</strong> FX3004/294• Flange DN 15 … DN 300 (½" … 12")Sandwich DN 15 … DN 100 (½" … 4")• 2-wire <strong>de</strong>vice 4 ... 20 mA, with integratedtemperature and pressure sensorsfor compensation• HART communication• Medium temp.: -40 … 240 °C(-40 … 464 °F)• Medium pressure: up to 100 bar(1450 psi)• Hazardous area approvals: FM, CSA,ATEXFVA250• All-metal variable area meter with variousfloat materials• Connections: DN 15 ... DN 100(½" ... 4")• Temperature of medium:-20 °C ... +300 °C (-4 ... +572 °F)• Optionally available with analog outputor contacts• Nominal diameters DN 10 ... DN 1000(0.4" ... 40")• Temperature of medium:-200 ... +500 °C (-328 ... +932 °F) forvapors, gases and liquids.<strong>SITRANS</strong> P transmitters• DS III series• DS III PA series• DS III FF series• DN 15 ... DN 80 (½" ... 3") for industrialrequirements• DN 25 (1") as acid-resistant version• With the required registers andquantity-preset registers• Temperature of medium:-30 ... +300 °C (-22 ... +572 °F)4/3114/3194/366Software forparameterizationAutomatic batchmeterAny quantity of liquid can be preselectedand filled automatically.• DN 25 ... DN 50 (1" ... 2")• Temperature of medium:-30 ... +300 °C (-22 ... +572 °F)4/3754/8 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FIntroduction■ OverviewCriteria for selection of flowmeterEach method for measuring flow has specific properties, an<strong>de</strong>ach flow measuring point is characterized by specific requirements.The table shown below compares the properties of thevarious measuring instruments and thus provi<strong>de</strong>s assistance inselection of the optimum <strong>de</strong>vice.This section of the field <strong>de</strong>vice catalog inclu<strong>de</strong>s the following instrumentsfor measuring flow:• Electromagnetic• Coriolis mass flow• Ultrasonic• Vortex volumetric- and mass flow• Variable area meter• Orifice plate• Rotary-piston meters and drum metersMeasuring principle ElectromagneticMediumLiquid(conductive)Nominal diameter DN 2 … 2000(0.08” … 78”)Temperaturerange°C (°F) -40 … +200(-40 … +392)Max. pressure bar (psi) 160 (2 320),optional higherCoriolisUltrasonic(In-line)Liquid or gas Liquid Steam/vapor,gases, liquid1.5 … 150 mm(0.06” … 6”)-50 … +180(-58 … +356)Up to 410(Up to 5 950)DN 50 … 4000(2" … 160")optional downto DN 15 (½“)-200 ... +250(-328 ... +482)40 (580)optionally430 (6 235)Vortex Orifice plate Rotary-pistonmeterDN 15 … 300(½" … 12")-40 ... +240(-40 ... +464)Liquid, vapor,gasDN 10 … 1000(0.4” … 40”)-200 … +500(-328 … +932)LiquidDN 15 … 80(½” … 3”)-30 … +300(-22 … +572)Variable areameterLiquid or gasDN 10 … 100(0.4” … 4”)G½” … G3”-20 … +300(-4 … +572)100 (1 450) 315 (4 569) 63 (914) 40 (580)Accuracy % ± 0.25 or ± 0.5 ± 0.1 or ± 0.15 ± 0.5 … ± 2 ± 0.75 … ± 1 ± 0.5 … ± 2 ± 0.2 … ± 0.5 ± 2Repeatability % 0.1 … 0.2 0.05 0.25 0.1 0.5 0.005 0.5Dynamic1:100 1:100 1:100 1:25 1:6 1:10 1:10response rangeStart-of-scale m/s (ft/s) 0 (0) 0 (0) 0.1 (0.33) 0.4 (1.31) Re > 500 0.3 (0.98) 0.2value2.0 (6.56)Full-scale value Re < 10 8• For liquids m/s (ft/s) 0.25 … 10(0.825 … 33)10 (32.8) 10 (32.8) 10 (32.8) 3 3 3.5 (11.4)• For steam/vapor,gasesMeasured valuesm/s (ft/s) Approx. 300(1000)80 (262.5) 50/25(164/82)60 (197)• Volume flow • • • • • • •• Sound velocity•• Sound amplitu<strong>de</strong>•• Density•• Mass flow • • •• Bidirectional• • • •measurementUse• For custody• • • •transfer• As batchingsystem• • •• In viscosityrangePower supplymPa⋅s(cp)0.1 … 100 000(0.1…100 000)Mains orbattery0 ... 100 000(0 ... 100 000)Mains0 ... 350(0 ... 350)Mains orbattery0 … 10(0 … 10)0 … 10(0 … 10)0.3 … 350 000(0.3…350 000)2-wire 2-wire non non0.5 … 100(0.5 … 100)4March 2009<strong>Siemens</strong> FI 01 · 20094/9

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© <strong>Siemens</strong> AG 2009IntroductionCommunication solutionsTransmitter HART PROFIBUS PA PROFIBUS DP FOUNDATIONFieldbus<strong>SITRANS</strong> F M MAG 5000 • 1) 2) 4)FOUNDATIONFieldbus H1DeviceNetModbus RTU<strong>SITRANS</strong> F M MAG 6000 • 1) 2) 4) 5) • 1) 5) 6) 7) • 1) 5) 6) 7) • 2) 4) 5) • 5) • 1) 5) 10)<strong>SITRANS</strong> F M MAG 5000/6000 CT 8) 2) 5)•<strong>SITRANS</strong> F M MAG 6000 I • 1) 2) 4) 5) • 1) 5) 6) 7) • 1) 5) 6) 7) • 2) 5) • 2) 4) 5) • 5) 1) 5) 10)•<strong>SITRANS</strong> F M MAG 6000 I Ex-d • 1) 2) 4) 5) • 1) 5) 6) 7) • 2) 5) • 2) 4) 5) • 5)<strong>SITRANS</strong> F M Transmag 2 • 1) 4) 1) 6)•<strong>SITRANS</strong> FM MAG 80001) 3) 10) 11) 12)•4<strong>SITRANS</strong> F C MASS 6000 • 1) 2) 4) 5) • 1) 5) 6) 7) • 1) 5) 6) 7) • 2) 5) • 2) 4) 5) • 5) 1) 10)•<strong>SITRANS</strong> F C MASS 6000 Ex d • 1) 2) 4) 5) • 1) 5) 6) 7) • 2) 5) • 2) 4) 5) • 5)<strong>SITRANS</strong> FUS060 • 1) 1) 6)•<strong>SITRANS</strong> FUS080 (FUS380)1) 5) 10) 11) 12)•<strong>SITRANS</strong> FUE080 (FUS380) • 1) 5) 8) 10) 11) 12)<strong>SITRANS</strong> FUS1010 9) 9) 10) 11)•<strong>SITRANS</strong> FX300 • 1)<strong>SITRANS</strong> P DS IIIDifferential pressure and flow1) Supports SIMATIC PDM2) Supports AMS3) Supports <strong>Siemens</strong> Flow Tool4) Supports HH275/3755) Pluggable add-on modules6) Profile 2• 1) 2) • 1) 2) 7) • 2)7) Profile 38) CT versions are not approved with communication modules.9) All wall mount mo<strong>de</strong>ls10) RS48511) RS23212) IrDA (Infrared)4/10 <strong>Siemens</strong> FI 01 · 2009March 2009

■ Overview<strong>SITRANS</strong> F M products<strong>SITRANS</strong> F M electromagnetic <strong>flowmeters</strong> are <strong>de</strong>signed for measuringthe flow of electrically conductive mediums.■ Benefits© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>Easier commissioning of MAG 5000, 6000, 6000 IAll <strong>SITRANS</strong> F M pulsed DC electromagnetic <strong>flowmeters</strong> featurea unique SENSORPROM memory unit which stores sensor calibrationdata and transmitter settings for the lifetime of the product.At commissioning the flowmeter commences measurementwithout any initial programming.The factory settings matching the sensor size are stored in theSENSORPROM unit. Also customer specified settings are downloa<strong>de</strong>dto the unit. Should the transmitter be replaced, the newtransmitter will upload all previous settings and resume measurementwithout any need for reprogramming.Further, the „fingerprint“ used in connection with the<strong>SITRANS</strong> F M Verificator is stored during the initial sensor calibration.Easier serviceTransmitter replacement requires no programming.SENSORPROM automatically updates all settings after initialization.Room for growthUSM II the Universal Signal Module with "plug & play" simplicity,makes it easy to access and integrate the flow measurementwith almost any system and bus-protocol and it ensures the flowmeterwill be easy to upgra<strong>de</strong> to future communication/bus platforms.4■ ApplicationElectromagnetic <strong>flowmeters</strong> are suitable for measuring the flowof almost all electrically conductive liquids, pastes and slurries.A prerequisite is that the medium must have a minimum conductivityof 5 μS/cm. The temperature, pressure, <strong>de</strong>nsity and viscosityhave no influence on the result.The main applications of the electromagnetic <strong>flowmeters</strong> can befound in the following sectors:• Water and waste water• Chemical and pharmaceutical industries• Food and beverage industry• Mining, aggregates and cements industries• Pulp and paper industry• Steel industry• Power; utility and chilled water industryThe wi<strong>de</strong> variety of combinations and versions from the modularsystem means that i<strong>de</strong>al adaptation is possible to each measuringtask.Greater flexibility• Wi<strong>de</strong> product program• Compact or remote installation using the same transmitter andsensor• USM II communication platform for easy integration with allsystemsMarch 2009<strong>Siemens</strong> FI 01 · 20094/11

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>© <strong>Siemens</strong> AG 2009Please see Product selector on the Internet,since some constrains might be related tosome of the features:www.pia-selector.automation.siemens.com4MAG3100MAG3100 HTMAG3100 PMAG5100 WMAG1100MAG1100 HTMAG1100 F7ME6310 7ME6320 7ME6340 7ME6520 7ME6110 7ME6120 7ME6140 7ME517ME527ME53911/E MAG8000/MAG8000 CT7ME68107ME6820IndustryWater / waste water XX X XXX XX XXXChemical XXX XXX XXX X XXX XXX XX XPharma XX XX XX X XX XX XXX XFood & beverage X X X X XX XXX XMining, aggregates & cement XXX X XX XXX XHPI XX X XX X XX X XOther XX XX XX XX XX XX XX XXX XDesignCompact ● ● ● ● ● ● ● ●Remote ● ● ● ● ● ● ● ● ●Constant field (DC) ● ● ● ● ● ● ● ● ●Alternating field (AC)●Battery-operated constant field (DC)●SizeDN 2 (1/12“)●DN 3 (1/8“)●DN 6 (1/4“)●DN 10 (3/8“) ● ●DN 15 (½“) ● ● ● ● ● ● ●DN 20 (3/4“)●DN 25 (1“) ● ● ● ● ● ● ● ● ●DN 32 (1¼“) ● ●DN 40 (1½“) ● ● ● ● ● ● ● ● ●DN 50 (2“) ● ● ● ● ● ● ● ● ●DN 65 (2½“) ● ● ● ● ● ● ● ● ●DN 80 (3“) ● ● ● ● ● ● ● ● ●DN 100 (4“) ● ● ● ● ● ● ● ● ●DN 125 (5“) ● ● ● ● ● ●DN 150 (6“) ● ● ● ● ● ●DN 200 (8“) ● ● ● ● ● ●DN 250 (10“) ● ● ● ● ● ●DN 300 (12“) ● ● ● ● ● ●DN 400 (16“) ● ● ● ●DN 450 (18“) ● ● ● ●DN 500 (20“) ● ● ● ●DN 600 (24“) ● ● ● ●DN 700 (28“) ● ● ●DN 750 (30“) ● ● ●DN 800 (32“) ● ● ●DN 900 (36“) ● ● ●DN 1000 (40“) ● ● ●DN 1050 (42“) ● ● ●DN 1100 (44“) ● ● ●DN 1200 (48“) ● ● ●DN 1400 (54“)●DN 1500 (60“)●DN 1600 (66“)●DN 1800 (72“)●DN 2000 (78“)●● = available, X = can be used, XX = often used, XXX = most often used4/12 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>Please see Product selector on the Internet,since some constrains might be related tosome of the features:www.pia-selector.automation.siemens.comMAG3100MAG3100 HTMAG3100 PMAG5100 WProcess connectionWafer <strong>de</strong>sign ● ●Sanitary process connections●Flanges ● ● ● ● ● ●Flange normsEN 1092-1 ● ● ● ● ● ●ANSI B 16.5 class 150 ● ● ● ● ● ●ANSI B 16.5 class 300 ● ● ●AWWA class D ● ●AS 2129 ● ●AS 4087, PN 16 ● ● ● ●AS 4087, PN 21 ● ●AS 4087, PN 35 ● ●JIS 10K 3) 3) ●Pressure rating 1)PN 6●PN 10 ● ● ● ● ● ●PN 16 ● ● ● ● ● ● ● ●PN 25 ● ● ●PN 40 ● ● ● ● ● ● ● ● ●PN 63●PN 100●Accuracy0.2% ●MAG1100MAG1100 HTMAG1100 F7ME6310 7ME6320 7ME6340 7ME6520 7ME6110 7ME6120 7ME6140 7ME517ME527ME53911/E MAG8000/MAG8000 CT7ME68107ME682040.25% ● ● ● ● ● ● ●0.4% ●0.5% ● ● ● ● ● ● ● ●Grounding electro<strong>de</strong>s, incl. 2) ● ● ( ● ) ●Cable glandsPG 13.5●M20 ● ● ● ● ● ● ● ● ●½" NPT ● ● ● ● ● ● ● ●Materials / temperature:Liner material / max . temperaturesNBR Hard Rubber: 70 °C (158 °F)●EPDM: 70 °C (158 °F) ● ● ● 5) ●Neoprene: 70 °C (158 °F) ● ● ●PTFE: 100 °C (212 °F)●PTFE: 130 °C (266 °F) ● ● ●PTFE: 180 °C (356 °F) ● ( ● ) 4)Ebonite: 95 °C (203 °F)●Linatex: 70 °C (158 °F)●Ceramic: 150 °C (302 °F) 6) ● ●Ceramic: 200 °C (392 °F)●PFA: 100 °C (212 °F)●PFA: 150 °C (302 °F) ● ● ● ●Novolak: 130 °C (266 °F)● = available1) Pressure may be limited by the liner material chosen2) Not for PTFE and PFA liner and tantalum/platinum electro<strong>de</strong>s.For 911/E grounding electro<strong>de</strong>s are optional3) On request4) 150 °C (302 °F)5) 95 °C (203 °F)6) ATEX: 180 °C (356 °F)●March 2009<strong>Siemens</strong> FI 01 · 20094/13

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>© <strong>Siemens</strong> AG 2009Please see Product selector on the Internet,since some constrains might be related tosome of the features:www.pia-selector.automation.siemens.com4Materials (continued):Electro<strong>de</strong>sS/S AISI 316 Ti ● ● ●Hastelloy C ● ● ● ● ● ● ● ●Platinum ● ● ● ● ● ●Titanium ● ● ●Tantalum ● ●Monel●Flange/housing materialCarbon steel ● ● ● ● ● ●Stainless steel / carbon steel●Polished stainless steel ● ● ● ● ●Approvals (Or<strong>de</strong>r as specials except for MAG 8000 CT version):Custody transferCold water - MI 001 (EU) ● ●Cold water - DANAK TS 22.36.001●Cold water pattern approval - OIML R 49●●(Denmark)Cold water pattern approval PTB (Germany) ● ● ● ● ● ●Heat meter pattern approval - OIML R 75● ● ●(Denmark)Hot water pattern approval - PTB (Germany)●Other media than water pattern approval -● ● ●OIML R 117Hazardous areasATEX - 2 GD zone 1 ● ● ● ● ● ●FM - class 1, div 2 ● ● ● ● ● ● ●CSA - class 1, div 2 ● ● ●Hygienic3A●Drinking waterWRAS (WRc) - (UK ) EPDM liner ● ● ●NSF/ANSI - (US ) NBR & EPDM liner ● ●ACS (FR) EPDM liner ● ● ●Belgaque (B) EPDM liner ● ● ●DVGW-W270 (D) EPDM liner ● ● ●OtherGOSS / GOST (Russia ) ● ● ● ● ● ● ● ●CRN (Canada) ● ● ● 3) ● 1) ● 1)Other national approvals, see internet ● ● ● ● ● ● ● ● ●Verificator compatible 2) ● ● ● ● ● ● ●● = available1) Only PFA liner.2) Only for MAG 5000 and MAG 6000 transmitters.3) Only DN 50 ... 300/2" ... 12".MAG3100MAG3100 HTMAG3100 PMAG5100 WMAG1100MAG1100 HTMAG1100 F7ME6310 7ME6320 7ME6340 7ME6520 7ME6110 7ME6120 7ME6140 7ME517ME527ME53911/E MAG8000/MAG8000 CT7ME68107ME68204/14 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>Please see Product selectoron the Internet, since someconstrains might be relatedto some of the features:www.pia-selector.automation.siemens.comMAG 5000 MAG 6000 MAG 6000 I MAG 6000 IEx dMAG 6000 +Ex barriereMAG 6000 +CleaningunitTransmag 2 MAG 8000/MAG8000 CT7ME6910 7ME6920 7ME6930 7ME6930 7ME6920 7ME6920 7ME5034 7ME68107ME6820IndustryWater / waste water XXX XXX XX X XX XXXChemical X XX XX XXX X XPharma X XXX XX XXX X XFood & beverage XX XXX XX XMining, aggregates & cement XX X XX X XXX XHPI X X X XX XOther XX XX XX XX X XDesign4Compact ● ● ● ● ● ●Remote ● ● ● ● ● ● ● ●Constant field (DC) ● ● ● ● ● ● ●Alternating field (AC)Battery operated constantfield (DC)Enclosure transmitterPolyami<strong>de</strong>, IP67 ● ●●●Die-cast aluminium ● ● ●Stainless steel ● ● 1)19“ rack ● ● ● ●Back of panel ● ● ● ●Panel mounting ● ● ● ●IP67 wall mounting ● ● ● ● ● ●Accuracy0.2% ●0.25% ● ● ● ● ●0.4% ●0.5% ● ●CommunicationHART ● ● ● ● ● ● ●PROFIBUS PA ● ● ● ● ● ●PROFIBUS DP ● ● ● ●FOUNDATION Fieldbus H1 ● ● ● ● ●DeviceNet ● ● ● ●MODBUS RTU/RS 485 ● ● ● ● ● 2)Batching ● ● ● ● ●Electro<strong>de</strong> cleaning●Cable glandsPG 13,5 ● ● ●M20 ● ● ● 3) ● ● ●½" NPT ● ● ● ● ●● = available, X = can be used, XX = often used, XXX = most often used1) IP68 enclosure2) Modbus RTU also as serial RS2323) M25March 2009<strong>Siemens</strong> FI 01 · 20094/15

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>© <strong>Siemens</strong> AG 20094Please see Product selectoron the Internet, since someconstrains might be relatedto some of the features:www.pia-selector.automation.siemens.comMAG 5000 MAG 6000 MAG 6000 I MAG 6000 IEx dMAG 6000 +Ex barriereMAG 6000 +CleaningunitTransmag 2 MAG 8000/MAG8000 CT7ME6910 7ME6920 7ME6930 7ME6930 7ME6920 7ME6920 7ME5034 7ME68107ME6820Power supply24 V ● 1) ● 1) ● ● ● 1) 1) 2)●115 V - 230 V ● ● ● ● ● ● ● ● 2)Battery●Approvals:Custody transferCold water - MI-001 (EU) ● ● ●Cold water -●●DANAK TS 22.36.001Cold water pattern approval - ● ● ●OIML R 49 (Denmark)Cold water pattern approval ● ● ●PTB (Germany)Heat meter pattern approval -●OIML R 75 (Denmark)Hot water pattern approval●PTB (Germany)Other media than water pattern●approval - OIML R 117Hazardous areasATEX - 2 GD zone 1 ● ( ● )FM - class 1 div 2 ● ● ●CSA - class 1 div 2 ● ●UL / C-UL- general safety ● ● ● ●OtherC - tick (Australia ) ● ● ● ● ● ●GOSS / GOST (Russia ) ● ●Other national approvals, see ● ● ● ● ● ● ● ●internetVerificator compatible ● ●● = available1) 12/24 V AC/DC2) Main power with battery backupFor more national approvals please check our internet pagehttp://support.automation.siemens.com/WW/view/en/10806954/1342004/16 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>■ Practical examples of or<strong>de</strong>ring<strong>SITRANS</strong> F M compact installation<strong>SITRANS</strong> F M remote installation+ =+ =MAG 6000transmitterMAG 3100sensorMAG 6000 compactmounted on aMAG 3100 sensorExampleSensor7ME6310-3TC11-1JA1Pipe size DN 100LinerNeopreneElectro<strong>de</strong>s SS 316Flanges EN 1092-1, PN 16Transmitter MAG 6000, Polyami<strong>de</strong>, 115/230 V ACAccuracy 0.25%Supply230 V ACNote:MAG 5000/6000 transmitters and sensors are packed in separateboxes, the final assembly takes place during installation atthe customer's place.Please also see www.siemens.com/<strong>SITRANS</strong>For<strong>de</strong>ringfor practical examples of or<strong>de</strong>ringWall bracket MAG 6000+ =MAG 3100 2 x cable MAG 3100 remoteinstallationExampleSensor7ME6310-3TC11-1AA1Pipe size DN 100LinerNeopreneElectro<strong>de</strong>s SS 316Flanges EN 1092-1, PN 16Transmitter7ME6920-1AA10-0AA0Accuracy 0.25%Supply230 V ACWall mounting kit FDK-085U1018Cable kit with sensorcabel and electro<strong>de</strong>cableA5E011816474March 2009<strong>Siemens</strong> FI 01 · 20094/17

4<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>■ FunctionAll electromagnetic <strong>flowmeters</strong> are based on Faraday’s law of induction:U M = B ⋅ v ⋅ d ⋅ kU M = Measured voltage induced in the medium perpendicular tothe magnetic field and the flow direction. The voltage is tappedat two point electro<strong>de</strong>s.B = Magnetic flux <strong>de</strong>nsity which permeates the flowing mediumperpendicular to the flow direction.v = flow velocity of mediumd = internal diameter of metering tubek = proportionality factor or sensor constant© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F M diagnosticsThe diagnostic functions are all internal tools in the meter:• I<strong>de</strong>ntification in clear text and error log• Error categories: function; warning; permanent and fatalerrors• Transmitter self-check including all outputs and the accuracy• Sensor check: coil and electro<strong>de</strong> circuit test• Overflow• Empty pipe: partial filling; low conductivity; electro<strong>de</strong> fouling<strong>SITRANS</strong> F M Verificator (MAG 5000 and 6000 )The <strong>SITRANS</strong> F M Verificator is an external tool <strong>de</strong>signed forMAG 5000 and MAG 6000 with MAG 1100, MAG 1100 F,MAG 3100 or MAG 5100 W sensors to verify the entire product,the installation and the application.The goal is to improve operation, reduce downtime and maintainmeasurement accuracy as long as possible.The <strong>SITRANS</strong> F M Verificator is highly advanced and carries outthe complex verification and performance check of the entireflowmeter system, according to unique SIEMENS patented principles.The whole verification test is automated and easy to operateso there is no opportunity for human error or influence. Thesystem is traceable to international standards and tested byWRc (Water Research Council).Function and measuring principle of electromagnetic measurementAn electromagnetic flowmeter generally consists of a magneticallynon-conducting metering tube with an internal electricallynon-conducting surface, magnet coils connected in series andmounted diametrically on the tube, and at least two electro<strong>de</strong>swhich are inserted through the pipe wall and are in contact withthe measured medium. The magnet field coils through which thecurrent passes generate a pulsed electromagnetic field with themagnetic flux <strong>de</strong>nsity B perpendicular to the pipe axis.This magnetic field penetrates the magnetically non-conductingmetering tube and the medium flowing through it, which musthave a minimum electrical conductivity.According to Faraday’s law of induction, a voltage U M is generatedin an electrically conducting medium, and is proportional tothe flow velocity v of the medium, the magnetic flux <strong>de</strong>nsity B,and the distance between the electro<strong>de</strong>s d (internal diameter ofpipe).The signal voltage U M is tapped by the electro<strong>de</strong>s which are incontact with the medium, and passed through the insulatingpipe wall. The signal voltage U M which is proportional to the flowvelocity is converted by an associated transmitter into appropriatestandard signals such as 4 to 20 mA.<strong>SITRANS</strong> F M Verificator• Stand alone Verificator to measure a number of selected parametersin the flow sensor and a transmitter which affects theintegrity of the flow measurement• Up to 20 measurements can be stored in the Verificator• The Verificator can be connected via a serial cable to a PC enablingdownload of the data. A Windows OC program enablesprinting and management of verificator reports.Verification - StepsVerification of a <strong>SITRANS</strong> F M flowmeter consists of the followingtest routines1. Transmitter test2. Flowmeter and cable insulation test3. Sensor magnetism test4/18 <strong>Siemens</strong> FI 01 · 2009March 2009

1. Transmitter testThe transmitter test is the traditional way of on-site testing on themarket and checks the complete electronic system from signalinput to output.Transmitter testUsing the excitation power output, which is generated to drivethe magnetic field of the sensor, the verificator simulates flowsignal to the transmitter input. By measuring the transmitter outputsthe verificator calculates its accuracy against <strong>de</strong>fined values.Test inclu<strong>de</strong>s:• Excitation power to drive the magnetic field• Signal function from signal input to output• Signal processing – gain, offset and linearity• Test of analogue and frequency output2. Insulation test© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>The verification of the sensor magnetism is a "boost" test of themagnetic field coil. The test ensures that the magnetism behaviouris like the first time, by comparing the current sensor magnetismwith the "fingerprint" which was <strong>de</strong>termined during initialcalibration and stored in the SENSORPROM memory unit.In the "boost" test the verificator changes the magnetic field incertain pattern and with high voltage to get quick stable magneticcondition. This unique test is fulfilled without any interferenceor compensation of surrounding temperature or interconnectingcabling.• Changes in dynamic magnetic behaviour• Magnetic influence insi<strong>de</strong> and outsi<strong>de</strong> the sensor• Missing or poor coil wire and cable connectionCertificateThe test certificate generated by a PC contains:• Test result with passed or failed• Installation specification• Flowmeter specification and configuration• Verificator specification with date of calibration ensuringtraceability to international standards.4Flowmeter insulation testThe verification test of the flowmeter insulation is a „cross talk“test of the entire flowmeter which ensures that the flow signalgenerated in the sensor is not affected by any external influences.In the "cross-talk" test the verificator generates a high voltagedisturbance within the coil circuit and then looks for any"crosstalk" induced in the flow signal circuit. By generating dynamicdisturbances close-coupled to the flow signal, the flowmeteris tested for noise immunity to a maximum level:• EMC influence on the flow signal• Moisture in sensor, connection and terminal box• Non-conductive <strong>de</strong>posit coating the electro<strong>de</strong>s within the sensor• Missing or poor grounding, shielding and cable connection.3. Sensor magnetism testSensor magnetism testDescription<strong>SITRANS</strong> F M Verificator• 11 ... 30 V DC, 11 ... 24 V AC, 115 ... 230 V, 50 Hz• 11 ... 30 V DC, 11 ... 24 V AC, 115 ... 230 V, 60 HzOr<strong>de</strong>r No.FDK-083F5060FDK-083F5061Note:It is mandatory to have the Verificator return to the factory oncea year for check and re-verification.March 2009<strong>Siemens</strong> FI 01 · 20094/19

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>© <strong>Siemens</strong> AG 20094■ Technical specificationsFlowmeter Calibration and traceabilityTo ensure continuous accurate measurement, <strong>flowmeters</strong> mustbe calibrated. All measuring instrumentation, used in the calibrationof the <strong>flowmeters</strong>, has either been calibrated by a UKAS orDANAK accedited laboratory or has been calibrated againstcertified master sensors. This provi<strong>de</strong>s an unbroken chain ofmeasurement-traceability to national standards.<strong>Siemens</strong> Flow Instruments can provi<strong>de</strong> accredited calibration inthe flow range from 0.0001 m 3 /h to 4350 m 3 /h.The accreditation bodies DANAK and UKAS have signed theILAC MRA agreement (International Laboratory AccreditationCorporation - Mutual Recognition Arrangement). Therefore theaccreditation ensures international traceability and recognitionof the test results in 39 countries world wi<strong>de</strong>, including the US(NIST traceability).A calibration certificate is shipped with every sensor and calibrationdata are stored in the SENSORPROM memory unit.Flowmeter uncertaintyReference conditionsReference conditions (ISO 9104 and DIN EN 29104)Temperature medium20 °C ± 5K (68°F ± 9°F)Temperature ambient20 °C ± 5K (68°F ± 9°F)Supply voltage U n ± 1%Warming-up time30 minutesIncorporation in conductive pipesection• Inlet section 10 x DN (DN ≤ 1200/48”)5 x DN (DN > 1200/48“)• Outlet section 5 x DN (DN ≤ 1200/48”)3 x DN (DN > 1200/48“)Flow conditionsFully <strong>de</strong>veloped flow profileAdditions in the event of <strong>de</strong>viations from reference conditionsCurrent outputAs pulse otput (± 0.1% of actualflow + 0.05% FSO)Effect of ambient temperature• Display / frequency / pulse output < ± 0.003%/K act.• Current output< ± 0.005%/K act.Effect of supply voltage< 0.005% of measuring value on1% changeRepeatability± 0.1% of actual flow forv ≥ 0.5 m/s (1.5 ft/s) and conductivity> 10 μS/cmCertificates• EN 10204 2.1Certificate of conformity, statingthat the <strong>de</strong>livered parts are ma<strong>de</strong>of the material quality that wasor<strong>de</strong>red• EN 10204 2.2Test report certificate, a nonbatch specific material analysis ofthe or<strong>de</strong>red material• EN 10204 3.1Material analysis certificate, abatch specific analysis of thematerial issued by an in<strong>de</strong>pen<strong>de</strong>ntinspectorMAG 5000 and MAG 6000/6000I with MAG 1100 (PFA)/MAG 1100 F (PFA)MAG 6000 or MAG 6000 I used with MAG 3100, MAG 1100 (Ceramic) orMAG 5100 W4/20 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>■ Technical specifications PROFIBUS PA/DPGeneral specificationsPROFIBUS <strong>de</strong>vice profile 3.00 Class BCertifiedYes, according to Profile for processcontrol <strong>de</strong>vices v3.00.MS0 connections 1MS1 connections 1MS2 connections 2Electrical specification DPPhysical layer specificationsApplicable standard EN 50170 vol. 2Physical Layer (Transmission RS 485technology)Transmission speed≤ 1.5 Mbits/sNumber of stationsUp to 32 per line segment, (maximumtotal of 126)Cable specification (Type A)Cable <strong>de</strong>signTwo wire twisted pairShieldingCU shielding braid or shielding braidand shielding foilImpedance35 up to 165 Ω at frequencies from3 ... 20 MHzCable capacity< 30 pF per meterCore diameter > 0.34 mm², corresponds to AWG 22Resistance< 110 Ω per kmSignal attenuationMax. 9 dB over total length of line sectionMax. bus length200 m at 1500 kbit/s, up to 1.2 km at93.75 kbit/s. Extendable by repeatersElectrical specification PAPhysical layer specificationsApplicable standard EN 50170Physical Layer (Transmission IEC-61158-2technology)Transmission speed31.25 Kbits/secondNumber of stationsUp to 32 per line segment, (maximumtotal of 126)Max. basic current [I B ] 14 mAFault current [I FDE ]0 mABus voltage9 ... 32 V (non Ex)Preferred cable specification (Type A)Cable <strong>de</strong>signTwo wire twisted pairConductor area (nominal) 0.8 mm 2 (AWG 18)Loop resistance44 Ω/kmImpedance 100 Ω ± 20%Wave attenuation at 39 kHz 3 dB/kmCapacitive asymmetry2 nF/kmBus terminationPassive line termination at bothMax. bus lengthUp to 1.9 km. Extendable by repeatersIS (Intrinsic Safety) dataRequired sensor electronicsFISCOMax. U IMax. I IMax. P IMax. L IMax. C IFISCO cable requirementsLoop resistance R CLoop inductance L CCapacitance C CMax. Spur length in IIC and IIBMax. Trunk length in IICMax. Trunk length in IIBCompact mounted <strong>SITRANS</strong> F CMASS 6000 Ex dYes17.5 V380 mA5.32 V0 μH0 nF15 ... 150 Ω/km0.4 ... 1 mH/km80 ... 200 nF/km30 m1 km5 kmPROFIBUS parameter supportThe following parameters are accessible using a MS0 relationshipfrom a Class 1 Master.MS0 specifies cyclic Data Exchange between a Master and aSlave.Cyclic services:Input (Master view) Parameter MAG 6000Mass flowVolume flow✓TemperatureDensityFraction A 1)Fraction B 1)Pct Fraction A 1)Totalizer 1✓Totalizer 2 2)✓Batch progress 2)✓Batch setpoint✓Batch compensation✓Batch status✓(running ...)Output (Master view) Set Totalizer 1+2✓Set Mo<strong>de</strong> Totalizer 1+2✓Batch control✓(start, stop ...)Batch setpoint✓Batch compensation✓1) Requires a SENSORPROM containing valid fraction data.2) Value returned is <strong>de</strong>pen<strong>de</strong>nt on the BATCH function.When ON, Batch progress is returned.When OFF, TOTALIZER 2 is returned.4March 2009<strong>Siemens</strong> FI 01 · 20094/21

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>© <strong>Siemens</strong> AG 2009Selection of sensorMetric4Sizing table (DN 2 … DN 2000)The table shows the relationship between flow velocity v, flowquantity Q and sensor dimension DN.Gui<strong>de</strong>lines for selection of sensorMin. measuring range: 0 to 0.25 m/sMax. measuring range: 0 to 10 m/sNormally the sensor size is selected so that the nominal flow velocityv lies within the measuring range 1 to 3 m/s.Example:Flow quantity of 50 m 3 /h and a sensor dimension of DN 80 givesa flow velocity of 2.7 m/s, which is within the recommen<strong>de</strong>dmeasuring range of 1 to 3 m/s.Flow velocity calculation formulav = 1273.24 ⋅ Q / DN 2 orv = 353.68 ⋅ Q / DN 2Unitsv : [m/s], Q : [l/s], DN : [mm]v : [m/s], Q : [m 3 /h], DN : [mm]Link to "Sizing program":https://pia.khe.siemens.com/in<strong>de</strong>x.aspx?nr=115014/22 <strong>Siemens</strong> FI 01 · 2009March 2009

Imperial© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>4Flow velocitySizing table ( 1 / 12 ” … 78”)The table shows the relationship between flow velocity v, flowquantity Q and sensor dimension size.Gui<strong>de</strong>lines for selection of sensorMin. measuring range: 0 to 0.8 ft/sMax. measuring range: 0 to 33 ft/sNormally the sensor size is selected so that the nominal flow velocityv lies within the measuring range 3 to 10 ft/s.Example:Flow quantity of 500 GPM and a sensor dimension of 6" gives aflow velocity of 5.6 ft/s, which is within the recommen<strong>de</strong>d measuringrange of 3 to 10 ft/s.Flow velocity calculation formula Unitsv = 0.408 ⋅ Q / (Pipe I.D.) 2 or v : [ft/s], Q : [GPM], Pipe I.D. :[inch]v = 283.67 ⋅ Q / (Pipe I.D.) 2 v : [ft/s], Q : [MGD], Pipe I.D. :[inch]Link to "Sizing program":https://pia.khe.siemens.com/in<strong>de</strong>x.aspx?nr=11501March 2009<strong>Siemens</strong> FI 01 · 20094/23

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>Installation conditionsVibrationsStrong vibrations should be avoi<strong>de</strong>d.In applications with strong vibrations, we recommend remotemounting of the transmitter.© <strong>Siemens</strong> AG 2009For partially filled pipes or pipes with downward flow and freeoutlet the flowmeter should be located in a U-Tube.4Install in U-tubes when pipe is partially filledInstallation in vertical pipesRecommen<strong>de</strong>d flow direction: upwards. This minimizes theeffect on the measurement of any gas/air bubbles in the liquid.The sensor must always be completely filled with liquid.Install in pipelines which are always fullThe sensor must always be completely filled with liquid. Thereforeavoid:• Installation at the highest point in the pipe system• Installation in vertical pipes with free outletInstall in vertical pipes with upward flow directionInstallation in horizontal pipesThe sensor must be mounted as shown in the below figure. Donot mount the sensor as shown in the lower figure. This will positionthe electro<strong>de</strong>s at the top where there is possibility for airbubbles and at the bottom where there is possibility for mud,sludge, sand etc.45454545Do not install in pipelines which can run empty4/24 <strong>Siemens</strong> FI 01 · 2009March 2009

-© <strong>Siemens</strong> AG 2009Measuring abrasive liquids and liquids containing particles Potential equalizationRecommen<strong>de</strong>d installation is in a vertical/inclined pipe to minimizethe wear and <strong>de</strong>posits in the sensor.Potential equalizationInstall in vertical pipelines with upward flow direction if measuring abrasiveliquidsInlet and outlet conditionsmin. 5 x D i min. 3 x D i+<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>The electrical potential of the liquid must always be equal to theelectrical potential of the sensor. This can be achieved in differentways <strong>de</strong>pending on the application:• Wire jumper between sensor and adjacent flange (MAG 1100,MAG 3100)• Direct metallic contact between sensor and fittings(MAG 1100 F)• Build-in grounding electro<strong>de</strong>s (MAG 3100, MAG 5100 W)• Optional grounding/protection flanges/rings (MAG 1100,MAG 3100, MAG 8000)• Optional graphite gaskets on MAG 1100 (standard forMAG 1100 High Temperature)• MAG 8000 installed in plastic or coated pipes: two groundingrings to be used.Bonding and grounding4Installation between elbows, pumps and valves: standard inlet and outletpipe sectionsTo achieve maximum accurate flow measurement it is essentialto have straight length of inlet and outlet pipes and a certain distancebetween the flowmeter and pumps or valves.It is also important to center the flowmeter in relation to pipeflange and gaskets.Ambient temperature-InstallationTemperature changes can cause expansion or contraction in thepipe system. To avoid damage on the sensor use of proper gasketand torque should be ensured. For more information see sensorinstruction.MAG 3100 (not PTFE and PFA), MAG 5100 W: with earthing electro<strong>de</strong>s inconductive and non-conductive pipes (no further action necessary)MAG 1100, MAG 3100 (PTFE and PFA): without earthing electro<strong>de</strong>s inconductive pipes (MAG 1100 use graphite gasket)March 2009<strong>Siemens</strong> FI 01 · 20094/25

+<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>© <strong>Siemens</strong> AG 2009 [psi]1.50 [mbar]0.5 0.6 0.7 0.8 0.9 11000.750.600,450.30504030200.15104With earthing electro<strong>de</strong>s in non-conductive pipes (MAG 1100 use graphitegasket)MAG 1100 F grounding via process connections. MAG 8000grounding see MAG 8000 pages.Vacuum0.0750.0600.0450.0305432V=8m/s[25ft/sec.]V=7m/s[23ft/sec.]V=6m/s[20ft/sec.]V=5m/s[16ft/sec.]0.0151V=4m/s[13ft/sec.]0.00750.00600.00450.50.40.3V=3m/s[10ft/sec.]V=2m/s[6ft/sec.]0.00300.2V=1.5m/s[5ft/sec.]Avoid a vaccum in the measuring pipe, since this can damage certain liners.Installation in large pipesaa £ 8°0.00150.10.50.6Pressure drop as function of diameter reduction between reducersExample:Flow velocity (v) of 3 m/s (10 ft/s) in a sensor with a diameter reductionDN 100 (4”) to DN 80 (3”) (d 1 /d 2 = 0.8) gives a pressuredrop of 2.9 mbar (0.04 psi).Ambient temperature0.70.8 0.9d 1 /d 2V=1m/s[3ft/sec.]1d1d2Reduction in nominal pipe diameterThe flowmeter can be installed between two reducers (e.g.DIN 28545). Assuming that at 8° the following pressure dropcurve applies. The curves are applicable to water. Max. ambient temperature as a function of temperature of mediumThe transmitter can be installed either compact or remote.With compact installation the temperature of medium must beaccording to the graph.4/26 <strong>Siemens</strong> FI 01 · 2009March 2009

Sensor cables and conductivity of mediumCompact installation:Liquids with an electrical conductivity ≥ 5 μS/cm.© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information <strong>SITRANS</strong> F Melectromagnetic <strong>flowmeters</strong>Remote installation4Standard cable[mS/cm]300Conductivityof medium20010055 100 200 300 [m]150 300 600 900 [ft]Cable lengthMinimum conductivity of medium (using standard electro<strong>de</strong> cable)[mS/cm]50Special cableConductivity ofmedium40302010550100 200 300 400 500 [m]150 300 600 900 1200 1500 [ft]Cable lengthMinimum conductivity of medium (using special electro<strong>de</strong> cable)NoteFor <strong>de</strong>tection of empty sensor the minimum sensor conductivitymust always be ≥ 20 μS/cm and the maximum length of electro<strong>de</strong>cable when remotely mounted is 50 m (150 ft). Specialshield cable must be used.For DN 2, DN 3 or for remote mounting in Ex applications specialcable cannot be used, empty sensor cannot be <strong>de</strong>tected andthe conductivity must be ≥ 30 μS/cm. For remote mounted CT installationsthe maximum cable length is 200 m (600 ft).March 2009<strong>Siemens</strong> FI 01 · 20094/27

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© <strong>Siemens</strong> AG 2009Transmitter MAG 5000/6000■ Overview■ DesignThe transmitter is <strong>de</strong>signed as either IP67 NEMA 4X enclosurefor compact or wall mounting or 19" version as a 19” insert as abase to be used in:• 19" rack systems• Panel mounting IP65/NEMA 4• Back of panel mounting IP20/NEMA 2• Wall mounting IP66/NEMA 4Several options on 19” versions are available such as:• Transmitters mounted in safe area for Ex ATEX approved flowsensors (incl. barriers)• Transmitters with electro<strong>de</strong> cleaning unit4Transmitter MAG 5000/6000 compact version (left) and 19“ insert version(right)The MAG 5000 and 6000 are microprocessor-based transmittersengineered for high performance, easy installation, commissioningand maintenance. The transmitters evaluate the signals fromthe <strong>SITRANS</strong> F M sensors type MAG 1100, MAG 1100 F,MAG 3100 and MAG 5100 W.Transmitter types:• MAG 5000: Max. measuring error 0.5% of rate (incl. sensor)• MAG 6000: Max. measuring error 0.25% of rate (incl. sensor,see also sensor specifications) and with additional featuressuch as: "plug & play" insert bus modules; integrated batchfunctions.■ Benefits• Superior signal resolution for optimum turn down ratio• Digital signal processing with many possibilities• Automatic reading of SENSORPROM data for easy commissioning• User configurable operation menu with password protection.• 3 lines, 20 characters display in 11 languages.• Flow rate in various units• Totalizer for forward, reverse and net flow as well as additionalinformation available• Multiple functional outputs for process control, minimum configurationwith analogue, pulse/frequency and relay output(status, flow direction, limits)• Comprehensive self-diagnostic for error indication and errorlogging (see un<strong>de</strong>r <strong>SITRANS</strong> F M diagnostics)• Batch control• Custody transfer approval: PTB, OIML R 75, OIML R 117,OIML R 49 and MI-001,• MAG 6000 with add-on bus modules for HART, FOUNDATIONFieldbus H1, DeviceNet, MODBUS RTU/RS485,PROFIBUS PA and DP■ FunctionThe MAG 5000/6000 are microprocessor-based transmitterswith a build-in alphanumeric display in several languages. Thetransmitters evaluate the signals from the associated electromagneticsensors and also fulfil the task of a power supply unitwhich provi<strong>de</strong>s the magnet coils with a constant current.Further information on connection, mo<strong>de</strong> of operation and installationcan be found in the data sheets for the sensors.Displays and controlsOperation of the transmitter can be carried out using:• Control and display unit• HART communicator• PC/laptop and SIMATIC PDM software via HART communication• PC/laptop and SIMATIC PDM software using PROFIBUS orMODBUS communicationOperating anddisplay panelHART communicationMasterTransmitterHART-CommunicatorPROFIBUS DP+CouplingmodulePC/LaptopRS-232PROFIBUS PAMin. 230 WTBusterminator■ ApplicationThe <strong>SITRANS</strong> F M <strong>flowmeters</strong> are suitable for measuring the flowof almost all electrically conductive liquids, pastes and slurries.The main applications can be found in:• Water and waste water• Chemical and pharmaceutical industries• Food & beverage industries• Power generation and utilityCoupler withpower supplyPROFIBUS PA communication.......Transmitter withPROFIBUS PA interface4/28 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M■ Technical specificationsMo<strong>de</strong> of operation and <strong>de</strong>signMeasuring principleEmpty pipeExcitation frequencyElectro<strong>de</strong> input impedanceInputDigital input• Activation time• CurrentOutputCurrent output• Signal range• Load• Time constantDigital outputFrequencyPulse (active)Pulse (passive)Time constantRelay outputTime constantLoadLow flow cut offGalvanic isolationMax. measuring error (incl. sensorand zero point)MAG 5000MAG 6000Rated operation conditionsAmbient temperature• Operation• StorageMechanical loadCompact versionElectromagnetic with pulsed constantfieldDetection of empty pipe (specialcable required in remote mountedinstallation)Depend on sensor size> 1 x 10 14 Ω11 ... 30 V DC, R i = 4.4 KΩ50 msI DC 11 V = 2.5 mA, I DC 30 V = 7 mA0 ... 20 mA or 4 ... 20 mA< 800 Ω0.1 … 30 s, adjustable0 ... 10 kHz, 50% duty cycle(uni/bidirectional)DC 24 V, 30 mA,1KΩ ≤ R i ≤ 10 KΩ, short-circuitprotected(power supplied fromflowmeter)DC 3 … 30 V, max. 110 mA,200 Ω ≤ R i ≤ 10 KΩ (poweredfrom connected equipment)0.1 … 30 s, adjustableChangeover relay, same as currentoutput42 V AC/2 A, 24 V DC/1 A0 ... 9.9% of maximum flowAll inputs and outputs are galvanicallyisolated0.5% of rate0.25% of rate• Display version:-20...+50°C(-4...+122°F)• Blind version:-20...+60°C(-4...+140°F)-40 ... +70 °C (-40 ... +158 °F)18 ... 1000 Hz, 3,17 g rms, sinusoidalin all directions toIEC 68-2-3619“ insert 1 ... 800 Hz, 1 g, sinusoidal in alldirections to IEC 68-2-36Degree of protectionCompact versionIP67/NEMA 4X to IEC 529 andDIN 40050 (1 mH 2 O 30 min.)19“ insert IP20/NEMA 2 to IEC 529 andDIN 40050EMC performanceDisplay and keypadTotalizerDisplayTime constantDesignEnclosure material• Compact version• 19" insertTransmitter MAG 5000/6000EN 61326-1 (all environments)EN 61326-2-5Two eight-digit counters for forward,net or reverse flowBackground illumination withalphanumeric text, 3 x 20 charactersto indicate flow rate, totalizedvalues, settings and faults;Reverse flow indicated by negativesignTime constant as current outputtime constantFiber glass reinforced polyami<strong>de</strong>;optional (IP67 only):AISI 316 stainless steelStandard 19“ insert of aluminium/steel(DIN 41494), width:21 TE, height: 3 HEIP20/NEMA 2; AluminiumIP65/NEMA 4; ABS plasticIP66/NEMA 4; ABS plastic• Back of panel• Panel mounting• Wall mountingDimensional drawingsCompact versionSee dimensional drawings19“ insert See dimensional drawingsWeightCompact version0.75 kg (2 lb)19“ insert See dimensional drawingsPower supply • 115 ... 230 V AC +10% -15%,50 ... 60 Hz• 11 ... 30 V DC or 11 ... 24 V ACPower consumption• 230 V AC: 17 VA• 24 V AC : 9 VA, I N = 380 mA,I ST =8A (30ms)• 12 V DC : 11 W, I N = 920 mA,I ST = 4 A (250 ms)Certificates and approvals CE, C-UL general purpose,C-tick; CSA/FM Class 1, div 2Custody transfer approval(MAG 5000/6000 CT)CommunicationStandard• MAG 5000• MAG 6000Optional (MAG 6000 only)• MAG 5000/6000 CT• PTB OIML R 49 (cold water patternapproval); MI-001• PTB and DANAK OIML R 75 (hotwater pattern approval)(MAG 6000 CT)• PTB and DANAK OIML R 117Other media than water (milk,beer etc.) pattern approval(MAG 6000 CT)Without serial communication orHART as optionPrepared for client mounted addonmodulesHART, MODBUS RTU/RS485,FOUNDATION Fieldbus H1,DeviceNet, PROFIBUS PA,PROFIBUS DP as add-on modulesNo communication modulsapproved4March 2009<strong>Siemens</strong> FI 01 · 20094/29

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© <strong>Siemens</strong> AG 2009Transmitter MAG 5000/6000Safety barrier (e/ia)4ApplicationFor use with MAG 5000/6000 19” and MAG 1100 Ex ATEX/MAG 3100 Ex ATEXEx approvalMAG 1100 Ex [EEx e ia] IIB ATEXMAG 3100 Ex [EEx e ia] IIC ATEXCable parameterGroup Capacity in μF Inductance in mH• Electro<strong>de</strong>IIC ≤ 4.1 ≤ 80IIB ≤ 45 ≤ 87IIA ≤ 45 ≤ 87Ambient temperature• During operation -20 ... +50 °C (-4 ... +122 °F)• During storage-20 ... +70 °C (-4 ... +158 °F)Enclosure• Material Standard 19” insert in aluminium/steel (DIN 41494)• Width 21 TE (4.75”)• Height 3 HE (5.25”)• Rating IP20 / NEMA 2 to EN 60529 and DIN 40050• Mechanical load 1 g, 1 … 800 Hz sinusoidal in all directions to EN 60068-2-36EMC performance• EmissionEN 50081-1 (Light industry)• ImmunityEN 50082-2 (Industry)Electro<strong>de</strong> cleaning unitApplicationFor use with transmitters MAG 5000 and 6000 19” to clean the electro<strong>de</strong>s onsensors MAG 1100 or MAG 3100NB: Must not be used with intrinsically safe ATEX sensorsNB: Not to be used with sensors with Hastelloy and Tantalum electro<strong>de</strong>sCleaning voltageAC cleaning60 V ACDC cleaning30 V DCCleaning period60 s + 60 s pause periodRelay• Load42 V/2 AOperationSwitch relay activated when cleaning is in progress• AutomaticYes• ManualNoIndicator lampsLEDs: “ON” and “CLEANING”Supply voltage and powerconsumption115 … 230 V AC, +10% … -15%, 50 … 60 Hz, 7 VA cleaning, 5 VA stand by11 … 30 V DC / 11 … 24 V AC, 50 … 60 Hz, 7 VA cleaning, 5 VA stand byAmbient temperature• During operation -20 ... +50 °C (-4 ... +122 °F)• During storage-20 ... +70 °C (-4 ... +158 °F)Enclosure• Material Standard 19” insert in aluminium/steel (DIN 41494)• Width 21 TE (4.75”)• Height 3 HE (5.25”)• Rating IP20 / NEMA 2 to EN 60529 and DIN 40050• Mechanical load 1 g, 1 … 800 Hz sinusoidal in all directions to EN 60068-2-36Cleaning unitThe <strong>Siemens</strong> cleaning unit can be used with MAG 5000 or 6000in 19” insert version.The cleaning unit can be used in applications where the linerand subsequently the electro<strong>de</strong>s may be coated with <strong>de</strong>posits.If the coating is electrically insulating, the electro<strong>de</strong> signal will bereduced. If the coating is electrically inductive, the electro<strong>de</strong> signalwill be partly short-circuited and in both cases the accuracyof the meter will <strong>de</strong>crease (<strong>de</strong>pen<strong>de</strong>nt on coating type and thickness).Note:The cleaning unit cannot be used for inflammable or explosivemedia!4/30 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitter MAG 5000/6000Mo<strong>de</strong> of operationThe cleaning unit cleans the electro<strong>de</strong>s electro-chemically byapplying a voltage to the electro<strong>de</strong>s for approx. 60 seconds.While cleaning, the transmitter stores and holds the latest measuredflow reading on the display and also the signal outputs. Afteran additional pausing period of 60 seconds the flowmeter resumesnormal measurement and the cleaning is now completed.The relay in the transmitter activates the cleaning cycle. In the relayoutput menu (un<strong>de</strong>r cleaning) the cleaning interval can beset between 1 hour and 24 hours.Cleaning should only take place with liquid in the pipe.This canbe <strong>de</strong>tected via the empty pipe function. It is therefore recommen<strong>de</strong>dto select “empty pipe <strong>de</strong>tection” ON when using thecleaning.The cleaning sequence can also be controlled manually throughthe electrical input of the transmitter. Before this is done, ensurethat the measuring pipe is full.AC cleaning4i £ 80 mAAC-cleaning is used to remove fatty <strong>de</strong>posits on the electro<strong>de</strong>s.These fatty <strong>de</strong>posits are seen in waste water applications, in abattoirsand water applications with oil residuals. During thecleaning process, the surface of the electro<strong>de</strong>s get warmer,which tends to soften grease particles and the gas bubbles generatedmechanically lift <strong>de</strong>posits away from the surface of theelectro<strong>de</strong>s.Note:Do not use AC-cleaning on sensors with Tantalum or Hastelloyelectro<strong>de</strong>s.DC cleaningi £ 20 mADC-cleaning is used to eliminate electrically conductive <strong>de</strong>positsin the measuring pipe influencing the measuring accuracy.Particularly in district heating applications an electrically conductive<strong>de</strong>posit (magnetite) may occur and short-circuit theelectro<strong>de</strong> signal. In this case the accuracy of the meter <strong>de</strong>creasesand the signal/noise conditions of the meter become inferior.The problem only arises if the conductivity of the water isless than approx. 250 μS/cm.During DC-cleaning electrolysis takes place where the flow ofelectrons removes the particle <strong>de</strong>posits from the electro<strong>de</strong> area.Note:Do not use DC-cleaning on sensors with Tantalum or Hastelloyelectro<strong>de</strong>s.March 2009<strong>Siemens</strong> FI 01 · 20094/31

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© <strong>Siemens</strong> AG 20094Transmitter MAG 5000/6000■ Selection and Or<strong>de</strong>ring DataTransmitter MAG 5000DescriptionOr<strong>de</strong>r No.Transmitter MAG 5000 Blindfor compact and wall mounting;IP67/NEMA 4X, fibreglass reinforced polyami<strong>de</strong>• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 5000 Displayfor compact and wallmounting;IP67/NEMA 4X, fibre glassreinforced polyami<strong>de</strong>• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz• 115/230 V AC, 50/60 Hz,with HARTTransmitter MAG 5000 CTfor compact and wall mounting,approved for custodytransfer;IP67/NEMA 4X, fibre glassreinforced polyami<strong>de</strong>• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 6000DescriptionTransmitter MAG 6000 Blindfor compact and wall mounting;IP67/NEMA 4X, fibre glassreinforced polyami<strong>de</strong>• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzIP67/NEMA 4X, AISI 316stainless steel (only for sensorwith SS terminal box )• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz7ME6910-1AA30-0AA07ME6910-1AA10-0AA0} 7ME6910-1AA30-1AA0} 7ME6910-1AA10-1AA07ME6910-1AA10-1BA07ME6910-1AA30-1AB07ME6910-1AA10-1AB0Transmitter MAG 5000for 19” rack and wall mounting• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz7ME6910-2CA30-1AA07ME6910-2CA10-1AA0Or<strong>de</strong>r No.7ME6920-1AA30-0AA07ME6920-1AA10-0AA0Transmitter MAG 6000for compact and wall mounting;• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz7ME6920-1AA30-1AA07ME6920-1AA10-1AA07ME6920-1QA30-1AA07ME6920-1QA10-1AA0DescriptionTransmitter MAG 6000 CTfor compact and wall mounting,approved for custodytransfer (no communicationmoduls possible);IP67/NEMA 4X, fibre glassreinforced polyami<strong>de</strong>• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 6000 SVfor compact and wall mounting;special excitation 44 Hzsettings for Batch applicationDN ≤ 25/1“IP67/NEMA 4X, fibre glassreinforced polyami<strong>de</strong>11 ... 30 V DC /11 ... 24 V AC7ME6920-1AA30-1AB07ME6920-1AA10-1AB07ME6920-1AB30-1AA0115/230 V AC, 50/60 Hz 7ME6920-1AB10-1AA0Transmitter MAG 6000 for19“ rack and wall mounting• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 6000 SVfor 19“ rack and wall mounting;special excitation 44 Hzsettings for Batch applicationDN ≤ 25/1“• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzMAG 6000 withIP66/NEMA 4X enclosure;115/230 V AC, 50/60 HzMAG 6000 with electro<strong>de</strong>cleaning unit, completemounted withIP66/NEMA 4X mountingenclosure• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzMAG 6000 with safety barrierfor ATEX 2G D approvedsensors, complete mountedwith IP66/NEMA 4X wallmounting enclosure, ATEX,115/230 V AC, 50/60 Hz• For ATEX 2G D sensorsMAG 6000 SV, 19” insert, inIP66/NEMA 4X , ABS plasticenclosure, excitation frequency44 Hz for Batchapplication DN ≤ 25/1“,11 … 30 V DC,11 … 24 V AC, 50/60 HzOr<strong>de</strong>r No.7ME6920-2CA30-1AA07ME6920-2CA10-1AA07ME6920-2CB30-1AA07ME6920-2CB10-1AA07ME6920-2EA10-1AA07ME6920-2PA30-1AA07ME6920-2PA10-1AA07ME6920-2MA11-1AA07ME6920-2EB30-1AA0} Available ex stock4/32 <strong>Siemens</strong> FI 01 · 2009March 2009

© <strong>Siemens</strong> AG 2009<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitter MAG 5000/6000Communication modules for MAG 6000DescriptionHART(not for MAG 6000 I)MODBUS RTU/RS485PROFIBUS PA Profile 3PROFIBUS DP Profile 3Or<strong>de</strong>r No.} FDK-085U0226} FDK-085U0234} FDK-085U0236} FDK-085U0237DeviceNet} FDK-085U0229FOUNDATION Fieldbus H1 } A5E02054250 1)1)Pending for MAG 6000 I ATEXDescriptionCable kit with standard coilcable, 3 x 1.5 mm²/18 gagewith shield PVC and electro<strong>de</strong>cable doubleshiel<strong>de</strong>d, 3 x 0.25 mm²• 5 m (16 ft)•10m(33ft)•15m(49ft)•20m(65ft)•25m(82ft)Or<strong>de</strong>r No.A5E02296329A5E01181647A5E02296464A5E01181656A5E02296490•30m (98ft)A5E02296494Accessories for MAG 5000 and MAG 6000DescriptionOr<strong>de</strong>r No.Wall mounting unit forIP67/NEMA 4X version,wall bracket, terminal box inpolyami<strong>de</strong>• 4 x M20 cable glands } FDK-085U1018• 4 x ½“ NPT cable glands } FDK-085U1053Cable for standard electro<strong>de</strong>or coil, 3 x 1.5 mm² /18 gage with shield PVC•10m(33ft)} FDK-083F0121•20m(65ft)} FDK-083F0210• 40 m (130 ft)} FDK-083F0211• 40 m (130 ft)• 60 m (200 ft)• 100 m (330 ft)• 150 m (500 ft)• 200 m (650 ft)• 500 m (1640 ft)Cable glands, for abovecable, 2 pcs.•M20•½“ NPTSealing screws for sensor/transmitter, 2 pcsA5E01181686A5E01181689A5E01181691A5E01181699A5E01181703A5E01181705A5E00822490A5E00822501FDK-085U0221½“ NPTM204• 60 m (200 ft)} FDK-083F0212• 100 m (330 ft)• 150 m (500 ft)FDK-083F0213FDK-083F3052Terminal box, in polyami<strong>de</strong>,inclusive lid• 200 m (650 ft)FDK-083F3053•M20} FDK-085U1050• 500 m (1650 ft)FDK-083F3054•½" NPTFDK-085U1052Electro<strong>de</strong> cable for emptypipe or low conductivity,double shiel<strong>de</strong>d,3 x 0.25 mm²Terminal box lid, in polyamidFDK-085U1003•10m (33ft)FDK-083F3020•20m(65ft)• 40 m (131 ft)• 60 m (200 ft)• 100 m (330 ft)} FDK-083F3095FDK-083F3094FDK-083F3093FDK-083F3092Terminal box for MAG 6000, instainless steel, inclusive lid•M20•½" NPTA5E00836867A5E00836868• 150 m (500 ft)• 200 m (650 ft)• 500 m (1650 ft)FDK-083F3056FDK-083F3057FDK-083F3058Terminal box (3A) forMAG 1100 F in polyami<strong>de</strong>,inclusive lid•M20A5E00822478•½" NPTA5E00822479Potting kit for terminal box ofMAG sensors forIP68/NEMA 6P (not ATEX)} FDK-085U022019“ cleaning unit for electro<strong>de</strong>cleaning (21TE) incl.back plate• 11 ... 30 V DC /11 ... 24 V AC• 115 ... 230 V AC, 50/60 HzFDK-083F5039FDK-083F5036March 2009<strong>Siemens</strong> FI 01 · 20094/33