SITRANS F flowmeters

SITRANS F flowmeters

SITRANS F flowmeters

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

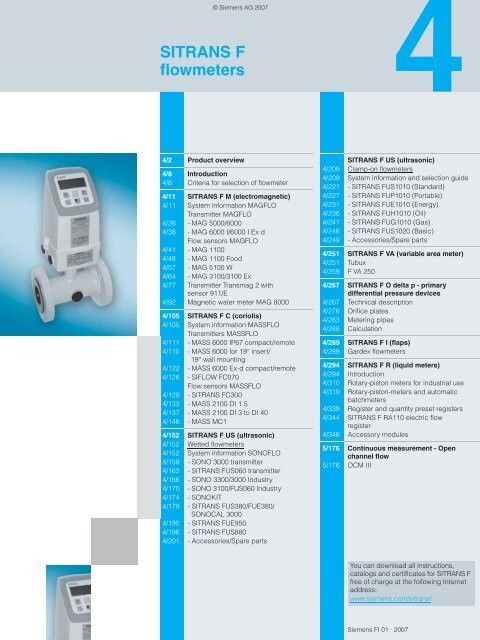

© Siemens AG 2007<strong>SITRANS</strong> F<strong>flowmeters</strong>4/2 Product overview4/8 Introduction4/8 Criteria for selection of flowmeter4/11 <strong>SITRANS</strong> F M (electromagnetic)4/11 System information MAGFLOTransmitter MAGFLO4/26 - MAG 5000/60004/38 - MAG 6000 I/6000 I Ex dFlow sensors MAGFLO4/41 - MAG 11004/48 - MAG 1100 Food4/57 - MAG 5100 W4/64 - MAG 3100/3100 Ex4/77 Transmitter Transmag 2 withsensor 911/E4/92 Magnetic water meter MAG 80004/105 <strong>SITRANS</strong> F C (coriolis)4/105 System information MASSFLOTransmitters MASSFLO4/111 - MASS 6000 IP67 compact/remote4/115 - MASS 6000 for 19“ insert/19“ wall mounting4/122 - MASS 6000 Ex-d compact/remote4/126 - SIFLOW FC070Flow sensors MASSFLO4/129 - <strong>SITRANS</strong> FC3004/133 - MASS 2100 DI 1.54/137 - MASS 2100 DI 3 to DI 404/146 - MASS MC14/152 <strong>SITRANS</strong> F US (ultrasonic)4/152 Wetted <strong>flowmeters</strong>4/152 System information SONOFLO4/159 - SONO 3000 transmitter4/163 - <strong>SITRANS</strong> FUS060 transmitter4/166 - SONO 3300/3000 Industry4/170 - SONO 3100/FUS060 Industry4/174 - SONOKIT4/179 - <strong>SITRANS</strong> FUS380/FUE380/SONOCAL 30004/190 - <strong>SITRANS</strong> FUE9504/196 - <strong>SITRANS</strong> FUS8804/201 - Accessories/Spare parts<strong>SITRANS</strong> F US (ultrasonic)4/209 Clamp-on <strong>flowmeters</strong>4/209 System information and selection guide4/221 - <strong>SITRANS</strong> FUS1010 (Standard)4/227 - <strong>SITRANS</strong> FUP1010 (Portable)4/231 - <strong>SITRANS</strong> FUE1010 (Energy)4/236 - <strong>SITRANS</strong> FUH1010 (Oil)4/241 - <strong>SITRANS</strong> FUG1010 (Gas)4/246 - <strong>SITRANS</strong> FUS1020 (Basic)4/249 - Accessories/Spare parts4/251 <strong>SITRANS</strong> F VA (variable area meter)4/251 Tubux4/259 F VA 2504/267 <strong>SITRANS</strong> F O delta p - primarydifferential pressure devices4/267 Technical description4/276 Orifice plates4/283 Metering pipes4/288 Calculation4/289 <strong>SITRANS</strong> F I (flaps)4/289 Gardex <strong>flowmeters</strong>4/294 <strong>SITRANS</strong> F R (liquid meters)4/294 Introduction4/310 Rotary-piston meters for industrial use4/319 Rotary-piston-meters and automaticbatchmeters4/339 Register and quantity preset registers4/344 <strong>SITRANS</strong> F RA110 electric flowregister4/346 Accessory modules5/176 Continuous measurement - Openchannel flow5/176 OCM IIIYou can download all instructions,catalogs and certificates for <strong>SITRANS</strong> Ffree of charge at the following Internetaddress:www.siemens.com/sitransfSiemens FI 01 · 2007

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© Siemens AG 2007Product overview■ Overview4Application Description Catalogpage<strong>SITRANS</strong> F M electromagnetic <strong>flowmeters</strong>Choose MAG 5000/6000 for moredemanding applications where youneed the benefits of highly functional,accurate performance.MAG 6000 I and MAG 6000 I Ex d inrobust die-cast aluminium enclosurefor demanding applications and whereexplosion proof protection is necessary.Transmitter MAGFLO MAG 5000/6000• Superior signal resolution for optimumturn down ratio• Comprehensive self-diagnostic, for errorindication and logging• Multi-lingual display and keypad interface• Custody transfer approval: PTB, OIMLR75, OIML R117 and OIML R49Transmitter MAGFLO MAG6000 I/6000 I Ex d• Remote and compact mounting on allsensors• Explosion proof design: ATEX and FM• Multi-lingual display and touchpad keypad• Comprehensive self-diagnosticsSoftware forparameterization4/26 SIMATIC PDM4/38 SIMATIC PDMDesigned for the general industryenvironment. The obstructionless performanceof the MAG 1100 is unaffectedby the suspended solids,viscosity and temperature challenges.Flow sensors MAGFLO MAG 1100• Metering tube DN 2 ... DN100(1/12“ ... 4“) flangeless design.• Corrosion resistant AISI 316 stainlesssteel housing.• Highly resistant liner and electrodes fittingmost extreme process media.• Temperature rating up to 200 °C(390 °F)• ATEX approval4/41Specially designed for the food & beverageindustry.Flow sensors MAGFLO MAG1100 Food• AISI 316 stainless steel enclosure• Hygienic seal, 3A and EHEDG-approvedconstruction• Easy to clean• Supplied with connections accordingto your specification• ATEX approval4/48The MAG 5100 W with its patentedcomposite elastomer lining is suitablefor all water applications.Flow sensors MAGFLO MAG 5100 W• Metering tube DN 25 ... DN 1200(1"¨ ... 48")• NBR Hard Rubber or EPDM lining• Integral grounding electrodes as standard• Increased low flow accuracy for waterleak detection• Drinking water approvals, OIML R49and PTB4/574/2 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FProduct overviewApplication Description CatalogpageThe MAG 3100 series with its flexibilityin the choice of linings, electrodes andflange material allows the measurementof even the most extreme processmedia.Designed for heavy-duty applicationslike pulp & paper stock over 3%;heavy mining slurries and mining slurrieswith magnetic particles.Flow sensors MAGFLO MAG3100/3100 Ex• For a wide range of pipe dimensions:DN 15 ... DN 2000 (½” ... 78”)• Wide range of liner and electrode materials• High temperature version for applicationwith temperatures up to 180 °C(355 °F)• High pressure solutions• Approved according to PTB,OIML R75, OIML R117 and ATEXTransmitter Transmag 2• Magnetic flowmeter with a very strongpulsed AC magnetic field• PROFIBUS PA or HART communication• Self-test function4/64Software forparameterization4/77 SIMATIC PDM4Application in conjunction with transmitterTransmag 2Battery operated electromagneticwater meter for water applicationswithin abstraction, distribution network,revenue metering and irrigation.Flow sensor 911/E• Metering tube: DN 15 ... DN 600(½" ... 24")• Metering tube liner: rubber, PTFE,Novolak• Integral smartPLUG for storing of calibrationvalues• Temperature of medium:-20 ... +150 °C (-4 ... +300 °F)Water meter MAG 8000• Battery operated water meter• Metering tube DN 25 ... DN 600(1" ... 24")• Remote and compact installation IP68/NEMA 6P enclosure• Custody transfer approval: OIML R49• Drinking water approvals4/824/92 SIMATIC PDMand Flow Tool<strong>SITRANS</strong> F C mass <strong>flowmeters</strong>Measurement of liquids and gases.Measurement of mass flow, density,temperature and fraction e.g. °Brix or°Plato.Measurement of liquids and gases.Measurement of mass flow, density,temperature and fraction e.g. °Brix or°Plato.Flow sensors MASSFLO MASS 2100(Single tube design)• DI 1.5, DI 3, DI 6, DI 15, DI 25 and DI 40• Flow from 0.1 ... 52,000 kg/h• Pipe material: 1.4435 (316L); 2.4602Hastelloy C-22• Accuracy typically ≤ 0.1% of flow rate0.0005 g/cm 3 and 0.5 °C• Liquid temp./pressure: -50 ... +180°C(-58 ... +356 °F) / Up to 410 bar(5946 psi)• Approved according to ATEX EEx ia IICT3 ... T6Flow sensor MASSFLO MC1(Dual tube design)• DN 50, DN 65, DN 80, DN 100 andDN 150• Flow from 0 ... 192,000 kg/h• Pipe material 1.4571 (316 Ti);Hastelloy C4• Accuracy typically ≤ 0.15% of rate.Density extended ≤ 0.001 g/cm 3• Liquid temp./pressure: -50 ... +180 °C(-58 ... +356 °F)/Up to 100 bar (1450 psi)• Approved according to ATEX EEx em[ib] IIC T2 ... T64/1334/146Modification 01/2007Siemens FI 01 · 20074/3

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© Siemens AG 2007Product overview4Application Description CatalogpageMeasurement of liquids and gasesMultiparameter transmitter for remoteor compact mounting measuring massflow, density, temperature and fractione.g. °Brix and °Plato<strong>SITRANS</strong> F US ultrasonic wetted <strong>flowmeters</strong>SONO 3000 is a transit time basedtransmitter designed for ultrasonicflowmetering on liquids of any pipe inthe SONO series up to DN 4000Transmitters MASS 6000 andMASS 6000 Ex d• Digital signal processing measuring30 times a second.• 3 current, 2 freq. and 2 relay outputs• Adaptive batch function• SENSORPROM memory unit making iteasy to start up the flowmeter.• Easy retrofitting of communicationmodules (AOM)• Approved according to ATEX [EEx ia]IIC / EEx de [ia/ib] IIC T6SONO 3000 transmitters• Selectable uni or bidirectional counting• Automatic reading of SENSORPROMdata for easy commissioning• Multiple functional output for processcontrol• Pulse/frequency and relay output (status,flow direction, limits)• Plug and play for all media4/122 SIMATIC PDM4/159Software forparameterization<strong>SITRANS</strong> FUS060 is a time basedtransmitter designed for ultrasonicflowmetering for any pipe in the SONOseries up to DN 4000The main application for SONO 3300ultrasonic <strong>flowmeters</strong> is to measurethe volume of:• Water and treated waste water• Oil and liquid gases• Hot water/cooling systemsThe main application for SONO 3100ultrasonic <strong>flowmeters</strong> is to measurethe volume of:• Water and treated waste water• Oil and liquid gases• Liquid cryogenic application• District heating systemsInstallation of one, two or four transducersets in existing concrete or steelpipes.<strong>SITRANS</strong> FUS060 transmitter• EEx approved according to ATEX• HART communication + 1 analog output,1 digital output for frequency orpulse and 1 relay output for alarms andflow direction• PROFIBUS PA communication with1 digital output for frequency or pulse• Multi-functional output for processcontrol• Easy menu based local operation withtwo-line displaySONO 3300/3000 Industry• DN 50 … DN 150 (2” … 6”) cast iron• DN 200, 250 and 300 (8”, 10”, 12”)welded steel• Flow 0.3 … 3200 m³/h• Transmitter can be compact or wallmounted• Signal cables from transmitter to transducerare highly protected from aggressiveenvironment by protection ofstainless steel pipesSONO 3100/FUS060 Industry• Replaceable transducers under pressure• ATEX approved• Measure of all liquids less than350 Cst, conductive or non-conductive• No pressure drop• 4-track on request• Special material on requestFlow sensor SONOFLO SONOKIT• DN 200 ... DN 4000 (8" ... 160")• Control and display unit• Temperature of medium:-20 ... +200 °C (-4 ... +395 °F)• Installation on empty pipes or pipes underpressure (hot-tap installation)4/1634/1664/1704/1744/4 Siemens FI 01 · 2007Modification 01/2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FProduct overviewApplication Description CatalogpageBattery or mains powered ultrasonicflowmeter for use within water baseddistrict heating, cooling systems andutility.<strong>SITRANS</strong> FUS380/SONOCAL 3000are designed to work with the<strong>SITRANS</strong> FUE950 energy calculatorUniversal thermal energy calculatorfordistrict heating and cooling applications.Battery operated ultrasonic retrofitflowmeter for water applications withinirrigation. Installation of one or twotransducer sets in existing PVC orconcrete pipes.<strong>SITRANS</strong> F US ultrasonic clamp-on <strong>flowmeters</strong>Dedicated <strong>flowmeters</strong> are suitable fora wide variety of liquid applications,including those in the:• Water Industry• Wastewater Industry•HVAC Industry• Power Industry• Processing Industry<strong>SITRANS</strong> FUS380/FUE380 Flow sensorand transmitter SONOCAL 3000• FUS380: DN 100 ... DN 800 (2" ... 32")• FUE380: Approved for custody transferaccording to EN 1434 Class 2 andOIML R 75 Class 2• SONOCAL 3000: DN 50, 65, 80, 900,1000, 1200 (2”, 2,5", 3", 36", 40", 42")• SONOCAL 3000: Approved for custodytransfer according to PTB Class C,OIML R75 Class 4• SONOCAL 3000: Only 115 ... 230 V ACpower supply• FUS380/SONOCAL 3000: Painted carbonsteel flanges and metering tube.AISI transducers• Water temperatures 3 … 200 °C(37 ... 392 °F)<strong>SITRANS</strong> FUE950• Choice of battery, 230 V AC +15%/-30% or 24 V AC• 24 months memory• Plug-in modules for data output, extrainput, M-Bus• Complete set with sensors and sensorpockets• Meets the requirements of OIML R 75and EN 1434<strong>SITRANS</strong> FUS880• Irrigation flowmeter FUS880• Battery operated or mains supply• DN 200 ... DN 1200 (8" ... 48")• Wetted transducer technology• Remote installation IP674/1794/1904/196<strong>SITRANS</strong> FUS1010 General purpose 4/221• Basic function dedicated meter• Full range of safety approvals, I/O'sand enclosure types available• Has wide applicability but not the specialfunctions found with FUH1010,FUG1010 and FUE1010 metersSoftware forparameterization4Portable <strong>flowmeters</strong> are suitable for awide variety of liquid applications,including those in the:• Water Industry• Wastewater Industry•HVAC Industry• Power Industry• Processing Industry<strong>SITRANS</strong> FUP1010 Portable• Basic function portable meter• Has all the capabilities of the FUS1010meter but in a battery powered, portableconfiguration• Ideal for high accuracy flow survey applications• Not available with hazardous area approvals4/227Portable and dedicated energymeters are ideal for thermal energy /power applications:• Chilled & hot water submetering• Condenser water, potable water• Glycol and brine solution• Thermal storage<strong>SITRANS</strong> FUE1010 Energy4/231• Accurate absolute and differential temperaturemeasurement with twomatched 1000 Ω RTD elements installedon supply and return side of theheating or cooling system• Efficiency calculation (kW/ton, EER orCOP) available in systems with optionalanalog inputModification 01/2007Siemens FI 01 · 20074/5

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© Siemens AG 2007Product overviewApplication Description CatalogpageDedicated hydrocarbon <strong>flowmeters</strong>are ideal for crude oil, refined petroleumor liquefied gas. There are threeapplication areas:• Viscosity compensated volumetric<strong>flowmeters</strong>• Standard volume (Net) mass <strong>flowmeters</strong>• Interface detectors/density meters<strong>SITRANS</strong> FUH1010 Oil• Volumetric <strong>flowmeters</strong> output viscositycompensated gross volume to externalRTU’s or flow computers• Mass <strong>flowmeters</strong> output standard volume(net) mass flow, API, liquid identification,density, interface & pigdetection• Interface Detectors are used for liquididentification and API density output,but do not output flow4/236Software forparameterization4Dedicated gas <strong>flowmeters</strong> are idealfor most natural and process gasindustry applications, including:• Checkmetering• Allocation• Flow survey verification• Lost and unaccounted for (LAUF)gas analysis• Production<strong>SITRANS</strong> FUG1010 Gas• Suitable for most gases (natural gas,oxygen, nitrogen, carbon monoxide,etc.) with typical minimum operatingpressure of 10 barg (145 psig).• Standard volume or mass flow outputfor fixed gas compositions• Analog input for pressure and temperaturecompensation4/241Dedicated flowmeter is a basic optionfor many clean liquid applications inthe:• Water Industry• Wastewater Industry• HVAC & Power Industries• Processing Industry<strong>SITRANS</strong> FUS1020 Basic• Has FUS1010 system function but withoutthe same I/O capability or safetyapproval ratings• This basic meter is intended for singleliquid applications that do not requirethese features4/246<strong>SITRANS</strong> F VA variable area metersMeasurement of flow of transparentliquids and gases.Tubux• Glass flow tube with various float materials• Connections: G ¼" ... G 3", alternativelywith adhesive bushing• Temperature of medium: max. 150 °C(302 °F)• Optionally available with contacts4/251Measurement of flow of liquids andgases, also highly suitable for corrosivemedia, high temperatures andhigh pressures.<strong>SITRANS</strong> F O delta p - primary differential pressure devicesMeasurement of flow with orificeplates and metering pipes for mountingbetween flanges, e.g. togetherwith <strong>SITRANS</strong> P transmitters, DS IIIand DS III PA series.250• All-metal variable area meter with variousfloat materials• Connections: DN 15 ... DN 100(½" ... 4")• Temperature of medium:-20 °C ... +300 °C(-4 ... +572 °F)• Optionally available with analog outputor contacts• Nominal diameters DN 10 ... DN 1000(0.4" ... 40")• Temperature of medium:-200 ... +500 °C (-328 ... +932 °F) forvapors, gases and liquids.<strong>SITRANS</strong> P transmitters• DS III series• DS III PA series• DS III FF series4/2584/2674/6 Siemens FI 01 · 2007Modification 01/2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FProduct overviewApplication Description CatalogpageSoftware forparameterization<strong>SITRANS</strong> F I flap <strong>flowmeters</strong>Measurement of flow of liquids andgases, e.g. for use with domesticinstallations and heating systems.Gardex• Baffle plate flowmeter• Nominal diameters: DN 25 ... DN 300(1" ... 12")• Temperature of medium: max. 300 °C(572 °F)• Optionally available with analog outputor contacts4/289<strong>SITRANS</strong> F R liquid metersRotary-piston metersIndustrial design for measurement offlowing liquids• DN 15 ... DN 80 (½" ... 3") for industrialrequirements• DN 25 (1") as acid-resistant version• With the required registers and quantitypreset registers• Temperature of medium: from-30 ... +300 °C (-22 ... +572 °F)4/3104Automatic batchmeterAny quantity of liquid can be preselectedand filled automatically.• DN 25 ... DN 50 (1" ... 2")• Temperature of medium: from-30 ... +300 °C (-22 ... +572 °F)4/319Continuous level - Open channel flowHigh accuracy ultrasonic flow monitorfor open channels to complete systemstudiesOCM III• High accuracy on unique or non-standardweirs and flumes• AC and DC operation.• Automatically switches to battery operationfor uninterrupted power.• Low power remote monitoring5/170Siemens FI 01 · 20074/7

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© Siemens AG 2007Introduction■ Overview4Criteria for selection of flowmeterEach method for measuring flow has specific properties, andeach flow measuring point is characterized by specific requirements.The table shown below compares the properties of thevarious measuring instruments and thus provides assistance inselection of the optimum device.This section of the field device catalog includes the following instrumentsfor measuring flow:• Electromagnetic• Coriolis mass flow• Ultrasonic• Variable area meter• Orifice plate• Flap• Rotary-piston meters and drum metersTo measure concentration in binary mixtures, it is possible toevaluate the sound velocity measurements of the ultrasonic flowmethod. The <strong>SITRANS</strong> F has been specially developed for usewith alcohol/water mixtures.Measuring principle Electromagnetic Coriolis Ultrasonic Orifice plate Rotary-pistonmeterMedium Liquid (conductive) Liquid or gas Liquid Liquid, vapor, LiquidgasNominal diameter DN 2 … 2000(0.08” … 78”)Temperaturerange°C (°F) -40 … +200(-40 … +392)Max. pressure bar (psi) 160 (2320), optionalhigher1.5 … 150 mm(0.06” … 6”)-50 … +180(-58 … +356)Up to 410(Up to 5950)DN 50 ... DN 4000(2" ... 160")-250 ... +200(-328 ... +490)40 (580)430 (6235)DN 10 … 1000(0.4” … 40”)-200 … +500(-328 … +932)DN 15 … 80(½” … 3”)-30 … +300(-22 … +572)Variable areameterLiquid or gasDN 10 … 100(0.4” … 4”)G½” … G3”-20 … +300(-4 … +572)315 (4569) 63 (914) 40 (580)Accuracy % ±0.25 or ±0.5 ±0.1 or ±0.15 ±0.5 … ±2 ±0.5 … ±2 ±0.2 … ±0.5 ±2Repeatability % 0.1 … 0.2 0.05 0.2 0.5 0.005 0.5Dynamic1:100 1:100 1:100 1:6 1:10 1:10responseStart-of-scale m/s (ft/s) 0 (0) 0 (0) 0.1 (0.33) R a > 500 0.3 (0.98) 0.2valueFull-scale value R e < 10 8• For liquids m/s (ft/s) 0 … 1010 (32.8) 10 (32.8) 3 3 3.5 (11.4)(0 … 33)• For vapors/gasesm/s (ft/s) Approx. 30050/2560 (197)(1000)(164/82)Measured values• Volume flow • • • • • •• Sound velocity•• Sound amplitude•• Density•• Mass flow•• Bidirectional• • • •measurementUse• For custody• • •transfer• As batchingsystem• • •• In viscosityrangemPa⋅s(cp)0.1 … 100,000(0.1 … 100,000)0 ... 100,000(0 ... 100,000)0 ... 350(0 ... 350)0 … 10(0 … 10)0.3 … 350,000(0.3 … 350,000)Power supply Mains or battery Mains Mains or battery 2-wire non non0.5 … 100(0.5 … 100)4/8 Siemens FI 01 · 2007Modification 01/2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> FCommunication solutionsTransmitter HART PROFIBUS PA PROFIBUS DP Modbus RTURS485<strong>SITRANS</strong> F M MAG 5000 • 1) 2) 4)<strong>SITRANS</strong> F M MAG 6000 • 1) 2) 4) 5) • 1) 5) 6) 7) • 1) 5) 6) 7) 1) 5)•<strong>SITRANS</strong> F M MAG 6000 I • 1) 2) 4) 5) • 1) 5) 6) 7) • 1) 5) 6) 7) • 1) 5)<strong>SITRANS</strong> F M MAG 6000 I Ex-d • 1) 2) 4) 5) 1) 6) 7)•<strong>SITRANS</strong> F M Transmag 2 • 1) 4) 1) 7)•Modbus RTURS232IntroductionModbus RTUIrDA<strong>SITRANS</strong> FM MAG 8000 • 1) • 1) • 1) 3)<strong>SITRANS</strong> F C MASS 6000 • 1) 2) • 1) 6) 7) • 1) 6) 7) • 1)<strong>SITRANS</strong> F C MASS 6000 Ex-d • 1) 2) 1) 6) 7)•<strong>SITRANS</strong> FUS060 • 1) 1) 7)•<strong>SITRANS</strong> FUS080 (FUS380) • 1)<strong>SITRANS</strong> FUE080 (FUS380) • 1)1) Supports SIMATIC PDM2)Supports AMS3)Supports Siemens Flow Tool4)Supports HH275/3755) Pluggable add-on modules6)Profile 27)Profile 34Siemens FI 01 · 20074/9

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F© Siemens AG 2007Introduction4■ Technical specifications PROFIBUS PA/DPGeneral specificationsPROFIBUS device profile 3.00 Class BCertifiedYes, according to Profile for processcontrol devices v3.00.MS0 connections 1MS1 connections 1MS2 connections 2Electrical specification DPPhysical layer specificationsApplicable standard EN 50170 vol. 2Physical Layer (Transmission RS 485technology)Transmission speed≤ 1.5 Mbits/sNumber of stationsUp to 32 per line segment, (maximumtotal of 126)Cable specification (Type A)Cable designTwo wire twisted pairShieldingCU shielding braid or shielding braidand shielding foilImpedance35 up to 165 Ω at frequencies from3 ... 20 MHzCable capacity< 30 pF per meterCore diameter > 0.34 mm², corresponds to AWG 22Resistance< 110 Ω per kmSignal attenuationMax. 9 dB over total length of line sectionMax. bus length200 m at 1500 kbit/s, up to 1.2 km at93.75 kbit/s. Extendable by repeatersElectrical specification PAPhysical layer specificationsApplicable standard EN 50170Physical Layer (Transmission IEC-61158-2technology)Transmission speed31,25 Kbits/secondNumber of stationsUp to 32 per line segment, (maximumtotal of 126)Max. basic current [I B ] 14 mAFault current [I FDE ]0 mABus voltage9 ... 32 V (non Ex)Preferred cable specification (Type A)Cable designTwo wire twisted pairConductor area (nominal) 0.8 mm 2 (AWG 18)Loop resistance44 Ω/kmImpedance 100 Ω ± 20%Wave attenuation at 39 kHz 3 dB/kmCapacitive asymmetry2 nF/kmBus terminationPassive line termination at bothMax. bus lengthUp to 1.9 km. Extendable by repeatersIS (Intrinsic Safety) dataRequired sensor electronicsCompact mounted<strong>SITRANS</strong> F CMASSFLOMASS 6000 Ex-dFISCO Yes YesMax. U I 17.5 V 17.5 VMax. I I 380 mA 380 mAMax. P I 5.32 V 5.32 VMax. L I 10 µH 0 µHMax. C I 5 nF 0 nFMax. U o 1.3 V -Max. I o 50 µA -FISCO cable requirementsLoop resistance R C15 ... 150 Ω/kmLoop inductance L C0.4...1mH/kmCapacitance C C80 ... 200 nF/kmMax. Spur length in IIC and IIB 30 mMax. Trunk length in IIC 1 kmMax. Trunk length in IIB 5 kmPROFIBUS parameter supportThe following parameters are accessible using a MS0 relationshipfrom a Class 1 Master.MS0 specifies cyclic Data Exchange between a Master and aSlave.1) Requires a SENSORPROM containing valid fraction data.2) Value returned is dependent on the BATCH function.When ON, Batch progress is returned.When OFF, TOTALIZER 2 is returned.Compact orremote mounted<strong>SITRANS</strong> F MMAGFLOMAG 6000 IndustryEx-dCyclic services:Input (Master view) Parameter MAG 6000 MASS 6000Mass flow✓Volume flow ✓ ✓Temperature✓Density✓Fraction A 1)✓Fraction B 1)✓Pct Fraction A 1)✓Totalizer 1 ✓ ✓Totalizer 2 2) ✓ ✓Batch progress 2) ✓ ✓Batch setpoint ✓ ✓Batch compensation ✓ ✓Batch status✓✓(running...)Output (Master view) Set Totalizer 1+2 ✓ ✓Set Mode Totalizer ✓✓1+2Batch control✓✓(start, stop ...)Batch setpoint ✓ ✓Batch compensation ✓ ✓4/10 Siemens FI 01 · 2007

■ Overview<strong>SITRANS</strong> F M family<strong>SITRANS</strong> F M electromagnetic <strong>flowmeters</strong> are designed for measuringthe flow of electrically conductive mediums.■ Benefits© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>Easier to commissionAll MAGFLO electromagnetic <strong>flowmeters</strong> feature a uniqueSENSORPROM memory unit which stores sensor calibrationdata and transmitter settings for the lifetime of the product.At commissioning the flowmeter commences measurementwithout any initial programming.The factory settings matching the sensor size are stored in theSENSORPROM unit. Also customer specified settings are downloadedto the unit. Should the transmitter be replaced, the newtransmitter will upload all previous settings and resume measurementwithout any need for reprogramming.Further, the "fingerprint" used in connection with the MAGFLOVerificator is stored during the initial sensor calibration.Easier to serviceTransmitter replacement requires no programming.SENSORPROM automatically updates all settings after initialization.Room for growthUSM II the Universal Signal Module with "plug & play" simplicity,makes it easy to access and integrate the flow measurementwith almost any system and bus-protocol and it ensures the flowmeterwill be easy to upgrade to future communication/bus platforms.4■ ApplicationElectromagnetic <strong>flowmeters</strong> are suitable for measuring the flowof almost all electrically conducting liquids, pastes and slurries.A prerequisite is that the medium must have a minimum conductivityof 5 µS/cm. The temperature, pressure, density and viscosityhave no influence on the result.The main applications of the electromagnetic <strong>flowmeters</strong> can befound in the following sectors:• Water and waste water• Chemical and pharmaceutical industries• Food and beverage industry• Mining, aggregates and cements industries• Pulp and paper industry• Steel industry• Power; utility and chilled water industryThe wide variety of combinations and versions from the modularsystem means that ideal adaptation is possible to each measuringtask.Greater flexibility• Wide product program• Compact or remote installation using the same transmitter andsensor• USM II communication platform for easy integration with allsystemsSiemens FI 01 · 20074/11

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>© Siemens AG 2007Please see Product selector onthe Internet, since some constrainsmight be related tosome of the featuresMAG3100MAG3100 ExMAG3100 HTMAG5100 WMAG1100MAG1100 ExMAG1100 HTMAG1100 FMAG1100 FEx911/E MAG80004IndustryWater / waste water X X X XXX X X XXChemical XXX XXX XXX X XX XXX XXX XX XXPharma XX XXX XX X X XX XX XXX XXX XXFood & beverage X X XX XXX X XXMining, aggregates & cement XXX X XX XXX XXHPI XX XX X X XX XX X XXOther XX XX XX XX XX XX XX XX XXX XXDesignCompact ● ● ● ● ● ● ● ● ●Remote ● ● ● ● ● ● ● ● ● ● ●Constant field (DC) ● ● ● ● ● ● ● ● ● ● ●Alternating field (AC)●Nominal diameterDN 2 (1/12“) ● ●DN 3 (1/8“) ● ●DN 6 (1/4“) ● ●DN 10 (3/8“) ● ● ● ●DN 15 (½“) ● ● ● ● ● ● ● ● ●DN 20 (3/4“)●DN 25 (1“) ● ● ● ● ● ● ● ● ● ● ●DN 32 (1¼“) ● ● ●DN 40 (1½“) ● ● ● ● ● ● ● ● ● ● ●DN 50 (2“) ● ● ● ● ● ● ● ● ● ● ●DN 65 (2½“) ● ● ● ● ● ● ● ● ● ● ●DN 80 (3“) ● ● ● ● ● ● ● ● ● ● ●DN 100 (4“) ● ● ● ● ● ● ● ● ● ● ●DN 125 (5“) ● ● ● ● ● ●DN 150 (6“) ● ● ● ● ● ●DN 200 (8“) ● ● ● ● ● ●DN 250 (10“) ● ● ● ● ● ●DN 300 (12“) ● ● ● ● ● ●DN 400 (16“) ● ● ● ● ●DN 450 (18“) ● ● ● ● ●DN 500 (20“) ● ● ● ● ●DN 600 (24“) ● ● ● ● ●DN 700 (28“) ● ● ●DN 750 (30“) ● ● ●DN 800 (32“) ● ● ●DN 900 (36“) ● ● ●DN 1000 (40“) ● ● ●DN 1050 (42“) ● ● ●DN 1100 (44“) ● ● ●DN 1200 (48“) ● ● ●DN 1400 (54“) ● ●DN 1500 (60“) ● ●DN 1600 (66“) ● ●DN 1800 (72“) ● ●DN 2000 (78“) ● ●● = available, X = can be used, XX = often used, XXX = most often used4/12 Siemens FI 01 · 2007Modification 01/2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>Please see Product selector onthe Internet, since some constrainsmight be related tosome of the featuresMAG3100MAG3100 ExMAG3100 HTMAG5100 WMAG1100MAG1100 ExMAG1100 HTMAG1100 FMAG1100 FEx911/E MAG8000Process connectionWafer design ● ● ●Sanitary process connections ● ●Flanges ● ● ● ● ● ●Flange normsEN 1092-1 ● ● ● ● ● ●ANSI B 16.5 class 150 ● ● ● ● ● ●ANSI B 16.5 class 300 ● ● ● ●AWWA class D ● ● ●AS 2129 ● ● ●AS 4087, PN 16 ● ● ● ● ●AS 4087, PN 21 ● ● ●AS 4087, PN 35 ● ● ●JIS 10K 3)●Pressure rating 1)PN 6 ● ●PN 10 ● ● ● ● ● ●PN 16 ● ● ● ● ● ● ● ● ●PN 25 ● ● ● ●PN 40 ● ● ● ● ● ● ● ● ● ● ●PN 63 ● ●PN 100 ● ●Accuracy0.2% ●0.25% ● ● ● ● ● ● ● ● ●0.4% ●0.5% ● ● ●Grounding electrodes, incl. 2) ● ● ● ( ● ) ●Cable glandsPG 13.5●M20 ● ● ● ● ● ● ● ● ● ● ●½" NPT ● ● ● ● ● ● ● ● ● ●Materials:Liner material / max . temperaturesNBR Hard Rubber: 70 °C (158 °F)●Neoprene: 70 °C (158 °F) ● ● ●EPDM: 70 °C (158 °F) ● ● ● ● 7) ●PTFE: 100 °C (212 °F) ● ● ●PTFE: 180 °C (356 °F) ● 6) ( ● ) 4)Ebonite: 95 °C (203 °F) ● ●Linatex: 70 °C (158 °F) ● ●Ceramic: 150 °C (302 °F) ● ● 5) ● ● 5)Ceramic: 200 °C (392 °F)●PFA: 130 (150) °C (266 (302) °F) ● ●Novolak: 130 °C (266 °F)●● = available1) Pressure may be limited by the liner material chosen2) Not for PTFE liner and tantalum/platinum electrodes3) On request4) 150 °C (300 °F)5) Ex versions limited to 100 °C (212 °F)6) Also available in 130 °C (266 °F)7) 95 °C (203 °F)4Modification 01/2007Siemens FI 01 · 20074/13

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>© Siemens AG 2007Please see Product selector onthe Internet, since some constrainsmight be related tosome of the featuresMAG3100MAG3100 ExMAG3100 HTMAG5100 WMAG1100MAG1100 ExMAG1100 HTMAG1100 FMAG1100 FEx911/E MAG80004Materials (continued):ElectrodesS/S AISI 316 Ti ● ● ● ●Hastelloy C ● ● ● ● ● ● ● ●Platinum ● ● ● ● ● ● ● ● ●Titanium ● ● ● ●Tantalum ● ● ● ●Monel●Flange/housing materialCarbon steel ● ● ● ● ● ●Stainless steel / carbon steel ● ● ● ●Polished stainless steel ● ● ● ● ● ● ● ●Approvals:Custody transferCold water -DANAK TS 22.36.001● ● ●● ●Cold water - OIML R 49 ● ●Cold water - PTB ● ● ● ● ● ● ●Hot water - OIML R 75 ● ● ● ● ●Hot water - PTB ● ● ● ● ●Other media than water -● ● ● ● ●OIML R 117Other media than water - PTB ● ● ● ● ●Hazardous areasATEX - zone 1 ● ● ●ATEX - zone 2 1) ● ● ● ●FM - class 1, div 2 ● ● ● ● ● ●CSA - class 1, div 22) 2)Hygienic3A ● ●EHEDG ● ●Drinking waterWRAS (WRc) - (UK ) ● ● ●NSF - (US ) ● ● ●ACS (FR) ● ●Belgaque (B) ● ●KTW (D) ● ●DVGW-W270 (D) ● ●OtherGOSS / GOST (Russia ) ● ● ● ● ● ● ● ● ●CRN (Canada) ● ● ● ● ● ● ● ● ● ●Other national approvals, see● ● ● ● ● ● ● ● ● ● ●internetMAGFLO Verificator compatible ● ● ● ● ● ●● = available1) Compact MAG 6000 I2) On request4/14 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>Please see Product selectoron the Internet, since someconstrains might be relatedto some of the featuresMAG 5000 MAG 6000 MAG 6000 I MAG 6000 IEx dMAG 6000 +Ex barriereMAG 6000 +Cleaning unitTransmag 2 MAG 8000IndustryWater / waste water XXX XXX XX X XX XXXChemical X XX XX XXX X XXXPharma X XXX XX XXX X XXXFood & beverage XX XXX XX XXXMining, aggregates & cement XX X XX X XXX XXXHPI X X X XX XXXOther XX XX XX XX X XDesignCompact ● ● ● ● ● ●Remote ● ● ● ● ● ● ● ●Constant field (DC) ● ● ● ● ● ● ●Alternating field (AC)●Enclosure transmitterPolyamide, IP67 ● ●Die-cast aluminium ● ● ●Stainless steel ● ● 1)19“ rack ● ● ● ●Back of panel ● ● ● ●Panel mounting ● ● ● ●IP67 wall mounting ● ● ● ●Accuracy0.2% ●0.25% ● ● ● ● ●0.4% ●0.5% ● ●CommunicationHART ● ● ● ● ● ● ●PROFIBUS PA ● ● ● ● ● ●PROFIBUS DP ● ● ● ●MODBUS RTU/RS 485 ● ● ● ● ● 2)Batching ● ● ● ● ●Electrode cleaning●PG 13,5 ● ● ●M20 ● ● ● 4) ● 4) ● ●½" NPT ● ● ● ● ●Supply voltage24 V ● 3) ● 3) ● ● ● 3) ● 3)5)115 V - 230 V ● ● ● ● ● ● ● ● 5)Battery●● = available, X = can be used, XX = often used, XXX = most often used1) IP68 for MAG 8000 enclosure2) Modbus RTU also as serial RS2323) 12/24 V AC/DC4) M255) Main power with battery backup4Siemens FI 01 · 20074/15

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>© Siemens AG 2007Please see Product selectoron the Internet, since someconstrains might be relatedto some of the featuresMAG 5000 MAG 6000 MAG 6000 I MAG 6000 IEx dMAG 6000 +Ex barriereMAG 6000 +Cleaning unitTransmag 2 MAG 80004Approvals:Custody transferCold water -●●DANAK TS 22.36.001Cold water - OIML R 49 ● ● ●Cold water PTB ● ● ●Hot water - OIML R 75 ● ●Hot water - PTB ● ●Other media than water -●●OIML R 117Other media than water - PTB ● ●Hazardous areasATEX - zone 1 ● ( ● )ATEX - zone 2 ● 1)FM - class 1, div 2 ● ● ●UL / cUL - general safety ● ● ● ●OtherC - tick (Australia ) ● ● ● ●GOSS / GOST (Russia ) ● ● ● ● ● ● ●Other national approvals, seeinternetMAGFLO Verificator compatible● ● pending● = available1)Compact version only■ Practical examples of ordering<strong>SITRANS</strong> F M compact installation<strong>SITRANS</strong> F M remote installation+ =+ =MAG 6000 transmitter MAG 3100 sensor MAG 6000 compactmounted on aMAG 3100 sensorExampleSensor7ME6310-3TC11-1AA1Pipe size DN 100LinerNeopreneElectrodes SS 316Flanges EN 1092-1, PN 16Transmitter 7ME6920-1AA10-0AA0Accuracy 0.25%Supply230 V ACNote:Transmitter and sensor are shipped in separate boxes.In orderto get a compact unit, it is necessary to order transmitter andsensor separately. These will be delivered individually packedand the final assembly takes place during installation at thecustomer's place.Please also see www.siemens.com/<strong>SITRANS</strong>Forderingfor practical examples of orderingWall bracket MAG 6000+ =MAG 3100 2 x cable MAG 3100 remoteinstallationExampleSensor7ME6310-3TC11-1AA1Pipe size DN 100LinerNeopreneElectrodes SS 316Flanges EN 1092-1, PN 16Transmitter7ME6920-1AA10-0AA0Accuracy 0.25%Supply230 V ACWall mounting kit FDK-085U1018Cable coils, 10 m FDK-083F0121Cable electrodes, 10 m FDK-083F01214/16 Siemens FI 01 · 2007

■ FunctionAll electromagnetic <strong>flowmeters</strong> are based on Faraday’s law of induction:U M = B ⋅ v ⋅ d ⋅ kU M = Measured voltage induced in the medium perpendicular tothe magnetic field and the flow direction. The voltage is tappedat two point electrodes.B = Magnetic flux density which permeates the flowing mediumperpendicular to the flow direction.v = flow velocity of mediumd = internal diameter of metering tubek = proportionality factor or sensor constant© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>MAGFLO diagnosticsThe diagnostic functions are all internal tools in the meter:• Identification in clear text and error log• Error categories: function; warning; permanent and fatalerrors• Transmitter self-check including all outputs and the accuracy• Sensor check: coil and electrode circuit test• Overflow• Empty pipe: partial filling; low conductivity; electrode foulingMAGFLO VerificatorThe MAGFLO Verificator is an external tool designed for allMAGFLO products to verify the entire product, the installationand the application.The goal is to improve the operation, reduce downtime andmaintain measurement accuracy as long as possible.Thus we have developed the SIEMENS MAGFLO Verificator ahighly advanced instrument to carry out the complex verificationand performance check of the entire flowmeter system, accordingto unique SIEMENS patented principles. The whole verificationtest is automated and easy to operate so there is no opportunityfor human error or influence. The system is traceable tointernational standards and tested by WRc (Water ResearchCouncil).4Function and measuring principle of electromagnetic measurementAn electromagnetic flowmeter generally consists of a magneticallynon-conducting metering tube with an internal electricallynon-conducting surface, magnet coils connected in series andmounted diametrically on the tube, and at least two electrodeswhich are inserted through the pipe wall and are in contact withthe measured medium. The magnet field coils through which thecurrent passes generate a pulsed electromagnetic field with themagnetic flux density B perpendicular to the pipe axis.This magnetic field penetrates the magnetically non-conductingmetering tube and the medium flowing through it, which musthave a minimum electrical conductivity.According to Faraday’s law of induction, a voltage U M is generatedin an electrically conducting medium, and is proportional tothe flow velocity v of the medium, the magnetic flux density B,and the distance between the electrodes d (internal diameter ofpipe).The signal voltage U M is tapped by the electrodes which are incontact with the medium, and passed through the insulatingpipe wall. The signal voltage U M which is proportional to the flowvelocity is converted by an associated transmitter into appropriatestandard signals such as 4 to 20 mA.MAGFLO VerificatorThe MAGFLO Verificator consists of:• a stand alone Verificator to measure a number of selected parametersin the flow sensor and a transmitter which affects theintegrity of the flow measurement• a Windows based PC programme enabling printing and managementof verification reports.Verification - StepsVerification of a <strong>SITRANS</strong> F M MAGFLO flowmeter consists of thefollowing test routines1. Transmitter test2. Flowmeter and cable insulation test3. Sensor magnetism testSiemens FI 01 · 20074/17

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>1. Transmitter testThe transmitter test is the traditional way of on-site testing on themarket and checks the complete electronic system from signalinput to output.© Siemens AG 20074Transmitter testUsing the excitation power output, which is generated to drivethe magnetic field of the sensor, the verificator simulates flowsignal to the transmitter input. By measuring the transmitter outputsthe verificator calculates its accuracy against defined values.Test includes:• excitation power to drive the magnetic field• signal function from signal input to output• signal processing – gain, offset and linearity• test of analogue and frequency output2. Insulation testSignal disturbance coilFlowmeter insulation testThe verification test of the flowmeter insulation is a "cross-talk"test of the entire flowmeter which ensures that the flow signalgenerated in the sensor is not affected by any external influences.Signal disturbance outsideIn the "cross-talk" test the verificator generates a high voltagedisturbance within the coil circuit and then looks for any"crosstalk" induced in the flow signal circuit. By generating dynamicdisturbances close-coupled to the flow signal, the flowmeteris tested for noise immunity to a maximum level:• EMC influence on the flow signal• Moisture in sensor, connection and terminal box• Non-conductive deposit coating the electrodes within the sensor• Missing or poor grounding, shielding and cable connection.4/18 Siemens FI 01 · 2007

3. Sensor magnetism test© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>CertificateThe test certificate generated by a PC contains:• Test result with passed or failed• Installation specification• Flowmeter specification and configuration• Verificator specification with date of calibration ensuringtraceability to international standards.4Sensor magnetism testThe verification of the sensor magnetism is a "boost" test of themagnetic field coil. The test ensures that the magnetism behaviouris like the first time, by comparing the current sensor magnetismwith the "fingerprint" which was determined during initialcalibration and stored in the SENSORPROM memory unit.In the "Boost" test the verificator changes the magnetic field incertain pattern and with high voltage to get quick stable magneticcondition. This unique test is fulfilled without any interferenceor compensation of surrounding temperature or interconnectingcabling.• Changes in dynamic magnetic behaviour• Magnetic influence inside and outside the sensor• Missing or poor coil wire and cable connectionDescription Order No. SymbolMAGFLO Verificator• 24 V, 115 ... 230 V, 50 Hz FDK-083F5060• 24 V, 115 ... 230 V, 60 Hz FDK-083F5061Siemens FI 01 · 20074/19

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>© Siemens AG 20074■ Technical specificationsFlowmeter uncertaintyTo ensure continuous accurate measurement, <strong>flowmeters</strong> mustbe calibrated. The calibration is conducted at SIEMENS flow facilitiesaccredited according to ISO/IEC 17025 by DANAK orUKAS.The accreditation bodies DANAK and UKAS have signed theILAC MRA agreement (International Laboratory AccreditationCorporation - Mutual Recognition Arrangement). Therefore theaccreditation ensures international traceability and recognitionof the test results in 39 countries world wide, including the US(NIST traceability).A calibration certificate is shipped with every sensor and calibrationdata are stored in the SENSORPROM memory unit.Reference conditionsReference conditions (ISO 9104 and DIN EN 29104)Temperature medium20 °C ± 5K (68°F ± 9°F)Temperature ambient20 °C ± 5K (68°F ± 9°F)Supply voltage U n ± 1%Warming-up time30 minutesIncorporation in conductive pipesection• Inlet section 10 x DN (DN ≤ 1200/48”)5 x DN (DN > 1200/48“)• Outlet section 5 x DN (DN ≤ 1200/48”)3 x DN (DN > 1200/48“)Flow conditionsFully developed flow profileAdditions in the event of deviations from reference conditionsCurrent outputEffect of ambient temperature• Display / frequency / pulse output• Current outputEffect of supply voltageRepeatabilityAs pulse output (± 0.1 % of actualflow + 0.05 % FSO)< ±0.003% / K act.< ±0.005% / K act.< 0.005% of measuring value on1% change± 0.1% of actual flow forv ≥ 0.5 m/s (1.5 ft/s) and conductivity> 10 µS/cmFlowmeter uncertainty:• MAG 5000,• MAG 6000 or MAG 6000 I used with MAG 1100 PFA± %E1. 5v ³ 0.5 m/s (1.5 ft/sec.) Þ E: ±0.25 % of measured value *)v < 0.5 m/s Þ E: ±(0.125 / v) % of measured value *)v < 1.5 ft/sec. Þ E: ±(0.41 / v) % of measured value *)10.50.2500.1 0.5 5 10 12 m/s0.3 1.5 15 30 36 ft/sec.v : Flow velocityE : Meter uncertainty as a percentage of measured value*) ±1.25 mm/s zero-point for MAG 5100 W with DN 350 ... DN 1200Flowmeter uncertainty:• MAG 6000 or MAG 6000 I used with MAG 3100, MAG 1100(Ceramic) or MAG 5100 W4/20 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>Selection of sensorMetric4Sizing table (DN 2 … DN 2000)The table shows the relationship between flow velocity v, flowquantity Q and sensor dimension DN.Guidelines for selection of sensorMin. measuring range: 0 … 0.25 m/sMax. measuring range: 0 … 10 m/sNormally the sensor is selected so that the nominal flow velocityv lies within the measuring range 1 … 3 m/s.Flow velocity calculation formula Unitsv = 1273.24 ⋅ Q / DN 2 orv : [m/s], Q : [l/s], DN : [mm]v = 353.68 ⋅ Q / DN 2v : [m/s], Q : [m 3 /h], DN : [mm]Link to „Sizing program“: www.siemens.com/flow-productsizingModification 01/2007Siemens FI 01 · 20074/21

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>Imperial© Siemens AG 20074Flow velocitySizing table ( 1 / 12 ” … 78”)The table shows the relationship between flow velocity v, flowquantity Q and sensor dimension size.Guidelines for selection of sensorMin. measuring range: 0 … 0.8 ft/sMax. measuring range: 0 … 33 ft/sNormally the sensor is selected so that the nominal flow velocityv lies within the measuring range 3 … 10 ft/s.Flow velocity calculation formula Unitsv = 0.408 ⋅ Q / (Pipe I.D.) 2 or v : [ft/s], Q : [GPM], Pipe I.D. :[inch]v = 283.67 ⋅ Q / (Pipe I.D.) 2 v : [ft/s], Q : [MGD], Pipe I.D. :[inch]Link to „Sizing program“: www.siemens.com/flow-productsizing4/22 Siemens FI 01 · 2007Modification 01/2007

Installation conditionsThe sensor must always be completely filled with liquid.© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>Installation in vertical pipesRecommended flow direction: upwards. This minimizes the effecton the measurement of any gas/air bubbles in the liquid.Install in pipelines which are always fullThe sensor must always be completely filled with liquid. Thereforeavoid:• Installation at the highest point in the pipe system• Installation in vertical pipes with free outletInstall in vertical pipes with upward flow directionInstallation in horizontal pipesThe sensor must be mounted as shown in the below figure. Donot mount the sensor as shown in the lower figure. This will positionthe electrodes at the top where there is possibility for airbubbles and at the bottom where there is possibility for mud,sludge, sand etc.445454545Do not install in pipelines which can run emptyFor partially filled pipes or pipes with downward flow and freeoutlet the flowmeter should be located in a U-Tube.If using empty pipe detection, the sensor can be tilted 45°.Install in U-tubes when pipe is partially filledSiemens FI 01 · 20074/23

-++<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>Measuring abrasive liquids and liquids containing particlesRecommended installation is in a vertical/inclined pipe to minimizethe wear and deposits in the sensor.© Siemens AG 2007Potential equalization4-Potential equalizationmin. 5 x D i min. 3 x D iInstall in vertical pipelines with upward flow direction if measuring abrasiveliquidsInlet and outlet conditionsThe electrical potential of the liquid must always be equal to theelectrical potential of the sensor. This can be achieved in differentways depending on the application:• Wire jumper between sensor and adjacent flange (MAG 1100,MAG 3100)• Direct metallic contact between sensor and fittings(MAG 1100 Food)• Build-in grounding electrodes (MAG 3100, MAG 3100 W,MAG 5100 W)• Optional grounding/protection flanges/rings (MAG 1100,MAG 3100)• Optional graphite gaskets on MAG 1100 (standard forMAG 1100 High Temperature)Vacuum+Installation between elbows, pumps and valves: standard inlet and outletpipe sectionsTo achieve maximum accurate flow measurement it is essentialto have straight length of inlet and outlet pipes and a certain distancebetween the flowmeter and pumps or valves.It is also important to center the flowmeter in relation to pipeflange and gaskets.Avoid a vaccum in the measuring pipe, since this can damage certain liners.Installation in large pipesaa £ 8°d1d2Reduction in nominal pipe diameterThe flowmeter can be installed between two reducers (e.g.DIN 28545). Assuming that at 8° the following pressure dropcurve applies. The curves are applicable to water.4/24 Siemens FI 01 · 2007

+ [psi] [mbar]© Siemens AG 2007Remote installation:<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MSystem information MAGFLOelectromagnetic <strong>flowmeters</strong>1.501000.5 0.6 0.7 0.8 0.9 10.750.600,450.30504030200.150.0750.0600.0450.030105432V=8m/s[25ft/sec.]V=7m/s[23ft/sec.]V=6m/s[20ft/sec.]V=5m/s[16ft/sec.]Remote installation-Standard cable40.0151V=4m/s[13ft/sec.][mS/cm]0.00750.00600.00450.50.40.3V=3m/s[10ft/sec.]V=2m/s[6ft/sec.]Conductivityof medium3002000.00300.2V=1.5m/s[5ft/sec.]1000.00150.10.50.6Pressure drop as function of diameter reduction between reducersExample:Flow velocity (v) of 3 m/s (10 ft/s) in a sensor with a diameter reductionDN 100 (4”) to DN 80 (3”) (d 1 /d 2 = 0.8) gives a pressuredrop of 2.9 mbar (0.04 psi).Ambient temperature0.70.8 0.9d 1 /d 2V=1m/s[3ft/sec.]1Conductivity of medium (using standard electrode cable)[mS/cm]5505 100 200 300 [m]150300 600 900 [ft]Cable lengthSpecial cableConductivity ofmedium403020 Max. ambient temperature as a function of temperature of mediumThe transmitter can be installed either compact or remote.With compact installation the temperature of medium must beaccording to the graph.Sensor cables and conductivity of mediumCompact installation:Liquids with an electrical conductivity ≥ 5 µS/cm.10550 100 200 300 400 500 [m]150 300 600 900 1200 1500 [ft]Cable lengthConductivity of medium (using special electrode cable)NoteFor detection of empty sensor the minimum sensor conductivitymust always be ≥ 20 µS/cm and the maximum length of electrodecable when remotely mounted is 50 m (150 ft). Specialshield cable must be used.For DN 2, DN 3 and for remote mounting in Ex applications specialcable cannot be used, empty sensor cannot be detectedand the conductivity must be ≥ 30 µS/cm. For remotely mountedCT installations the maximum cable length is 200 m (600 ft).For Ex installations with safety barriers, 25 m (75 ft) of cablecan be used in order to obtain ±0,25%, and 50 m (150 ft) to obtain±0.5%.Siemens FI 01 · 20074/25

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© Siemens AG 2007Transmitter MAGFLO MAG 5000/60004■ OverviewTransmitter MAG 5000/6000 compact version (left) and 19“ insert version(right)The MAG 5000 and 6000 are microprocessor-based transmittersengineered for high performance, easy installation, commissioningand maintenance. The transmitters evaluate the signals fromthe <strong>SITRANS</strong> F M MAGFLO sensors type MAG 1100,MAG 1100 F, MAG 3100 and MAG 5100 W.Transmitter types:• MAG 5000: Max. measuring error 0.5% of rate (incl. sensor)• MAG 6000: Max. measuring error 0.25% of rate (incl. sensor,see also sensor specifications) and with additional featuressuch as: Plug & Play insert bus modules; integrated batchfunctions.■ Benefits• Superior signal resolution for optimum turn down ratio• Digital signal processing with many possibilities• Automatic reading of SENSORPROM data for easy commissioning• User configurable operation menu with password protection.• 3 lines, 20 characters display in 11 languages.• Flow rate in various units• Totalizer for forward, reverse and net flow as well as additionalinformation available• Multiple functional outputs for process control, minimum configurationwith analogue, pulse/frequency and relay output(status, flow direction, limits)• Comprehensive self-diagnostic for error indication and errorlogging (see under <strong>SITRANS</strong> F M MAGFLO diagnostics)• Batch control• Custody transfer approval: PTB, OIML R75, R117, R49• MAG 6000 with add-on bus modules for HART, MODBUSRTU/RS485, PROFIBUS PA and DP■ ApplicationThe MAG <strong>flowmeters</strong> are suitable for measuring the flow of almostall electrically conductive liquids, pastes and slurries. Themain applications can be found in:• Water and waste water• Chemical and pharmaceutical industries• Food & beverage industries• Power generation and utility■ DesignThe transmitter is designed as either IP67 NEMA 4X/6 enclosurefor compact or wall mounting or 19" version as a 19” insert as abase to be used in:• 19" rack systems• Panel mounting IP65/NEMA 4• Back of panel mounting IP20/NEMA 2• Wall mounting IP66/NEMA 4Several options on 19” versions are available such as:• Transmitters for EEx ATEX approved flow sensors (incl. barriers)• Transmitters with electrode cleaning unit■ FunctionThe MAG 5000/6000 are microprocessor-based transmitterswith a build-in alphanumeric display in several languages. Thetransmitters evaluate the signals from the associated electromagneticsensors and also fulfil the task of a power supply unitwhich provides the magnet coils with a constant current.Operating anddisplay panelHART communicationMasterTransmitterFurther information on connection, mode of operation and installationcan be found in the data sheets for the sensors.Displays and controlsOperation of the transmitter can be carried out using:• Control and display unit• HART communicator• PC/laptop and SIMATIC PDM software via HART communication• PC/laptop and SIMATIC PDM software using PROFIBUS communicationHART-CommunicatorPROFIBUS DPPROFIBUS PA communication+Coupler withpower supplyCouplingmodulePC/LaptopRS-232PROFIBUS PA.......Min. 230 WTransmitter withPROFIBUS PA interfaceTBusterminator4/26 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitter MAGFLO MAG 5000/6000■ Technical specificationsDegree of protectionMode of operation and designMeasuring principleEmpty pipeElectromagnetic with pulsed constantfieldDetection of empty pipe (specialcable required in remote mountedinstallation)• Compact version• 19“ insertEMC performance• Emitted interferenceIP67/NEMA 4X/6 to IEC 529 andDIN 40050 (1 mH 2 O 30 min.)IP20/NEMA 2 to IEC 529 andDIN 40050To EN 50081-1 (Light industry)Excitation frequencyElectrode input impedanceInputSensor size dependingpulsating DC current> 1 x 10 14 Ω• Noise immunityDisplay and keypadTotalizerTo EN 50082-1 (Industry)Two eight-digit counters for forward,net or reverse flowDigital input• Activation time• CurrentOutputCurrent output• Signal range11 ... 30 V DC, R i = 4. 4 KΩ50 msI DC 11 V = 2.5 mA, I DC 30 V = 7 mA0 ... 20 mA or 4 ... 20 mADisplay• Time constantBackground illumination withalphanumeric text, 3 x 20 charactersto indicate flow rate, totalizedvalues, settings and faults;Reverse flow indicated by negativesignTime constant as current outputtime constant4• Load< 800 ΩDesign• Time constant0.1 … 30 s, adjustableEnclosure materialDigital output• Frequency• Pulse (active)• Pulse (passive)• Time constantRelay output• Time constant• LoadLow flow cut offGalvanic isolationMax. measuring error (incl. sensor)0 ... 10 kHz, 50% duty cycle(uni/bidirectional)DC 24 V, 30 mA, 1 KΩ ≤ R i ≤10 KΩ, short-circuit-protected(power supplied from flowmeter)DC 3…30 V, max. 110 mA, 200 Ω≤ R i ≤ 10 KΩ (powered from connectedequipment)0.1 … 30 s, adjustableChangeover relay, same as currentoutput42 V AC/2 A, 24 V DC/1 A0 ... 9.9% of maximum flowAll inputs and outputs are galvanicallyisolated• Compact version• 19“-insert• Back of panel• Panel mounting• Wall mountingDimensional drawings• Compact version• 19“ insertWeight• Compact version• 19“ insertFiber glass reinforced polyamide;optional (IP67 only):AISI 316 stainless steelStandard 19“ insert of aluminium/steel(DIN 41494), width:21 TE, height: 3 HEIP20/NEMA 2; AluminiumIP65/NEMA 4; ABS plasticIP66/NEMA 4; ABS plasticSee dimensional drawingsSee dimensional drawings0.75 kg (2 lb)See dimensional drawingsPower supply • 115 ... 230 V AC +10% -15%,50 ... 60 Hz, 17 VA• 11 ... 30 V DC or 11 ... 24 V AC• MAG 5000• MAG 6000Rated operation conditionsAmbient temperature0.5% of rate0.25% of ratePower consumption• 230 V AC: 17 VA•24VAC: 9W, I N = 380 mA,I ST =8A (30ms)• 12 V DC : 11 W, I N = 920 mA,I ST = 4 A (250 ms)• Operation• StorageMechanical load• Compact version• Display version:-20...+50°C(-4...+122°F)• Blind version:-20...+60°C(-4...+140°F)-40 ... +70 °C (-40 ... +158 °F)18 ... 1000 Hz, 3,17 G rms, sinusoidalin all directions toIEC 68-2-36Certificates and approvalsCustody transfer approval(MAG 5000/6000 CT)CommunicationStandardCE, ULc general purpose, C-tick;FM Class 1, div 2• PTB OIML R49 (cold water)• PTB and DANAK OIML R75 (hotwater)• PTB and DANAK OIML R117(cold water/milk, beer etc.)• 19“ insert1 ... 800 Hz, 1 G, sinusoidal in alldirections to IEC 68-2-36• MAG 5000Without serial communication orHART as option• MAG 6000Prepared for client mounted addonmodulesOptional (MAG 6000 only)HART, MODBUS RTU/RS485,PROFIBUS PA, PROFIBUS DP asadd-on modulesModification 01/2007Siemens FI 01 · 20074/27

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© Siemens AG 2007Transmitter MAGFLO MAG 5000/60004Safety barrier (ia/ib) DN ≤ 300 / 12”ApplicationEx approvalSafety barrier (e/ia) DN ≥ 350 / 14”ApplicationAs combined unit with MAG 6000 only and MAG 1100 Ex / MAG 3100 Ex in the sizerange DN 2 to 300 / 1/12” to 12”[EEx ia/ib] IIB, ATEX for MAG 3100 Ex and 1100 ExCable parameter Group Capacity in µF Inductance in mH• Electrode IIB ≤ 31 ≤ 80•Coil IIB ≤ 0.5 ≤ 8Ambient temperature• During operation -20 to +50 °C (-4 to +122 °F)• During storage-20 to +70 °C (-4 to +158 °F)Enclosure• Material Standard 19” insert in aluminium/steel (DIN 41494)• Width 21 TE (4.75”)• Height 3 HE (5.25”)• Rating IP 20 / NEMA 2 to EN 60529 and DIN 40050• Mechanical load 1 g, 1 … 800 Hz sinusoidal in all directions to EN 60068-2-36EMC performance• EmissionEN 50081-1 (Light industry)• ImmunityEN 50082-2 (Industry)Ex approvalCable parameter• ElectrodeFor use with MAG 5000/6000 19” and MAG 3100 Ex in the size range DN 350 to2000 / 14” to 78”[EEx e ia] IIC ATEXGroup Capacity in µF Inductance in mHIIC ≤ 4.1 ≤ 80IIB ≤ 45 ≤ 87IIA ≤ 45 ≤ 87Ambient temperature• During operation -20 to +50 °C (-4 to +122 °F)• During storage-20 to +70 °C (-4 to +158 °F)Enclosure• Material Standard 19” insert in aluminium/steel (DIN 41494)• Width 21 TE (4.75”)• Height 3 HE (5.25”)• Rating IP20 / NEMA 2 to EN 60529 and DIN 40050• Mechanical load 1 g, 1 … 800 Hz sinusoidal in all directions to EN 60068-2-36EMC performance• EmissionEN 50081-1 (Light industry)• ImmunityEN 50082-2 (Industry)4/28 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MElectrode cleaning unitApplicationTransmitter MAGFLO MAG 5000/6000For use with transmitters MAG 5000 and 6000 19” to clean the electrodes on sensorsMAG 1100, MAG 3100 or MAG 5100 WNB: Must not be used with intrinsically safe ATEX sensorsCleaning voltageAC cleaning60 V ACDC cleaning30 V DCCleaning period60 s + 60 s pause periodRelay• Load42 V / 2 AOperationSwitch relay activated when cleaning is in progress• AutomaticYes• ManualNoIndicator lampsLEDs: “ON” and “CLEANING”Supply voltage and powerconsumption115 … 230 V AC, +10% … -15%, 50 … 60 Hz, 7 VA cleaning, 5 VA stand by11 … 30 V DC / 11 … 24 V AC, 50 … 60 Hz, 7 VA cleaning, 5 VA stand byAmbient temperature• During operation -20 to +50 °C (-4 to +122 °F)• During storage-20 to +70 °C (-4 to +158 °F)Enclosure• Material Standard 19” insert in aluminium/steel (DIN 41494)• Width 21 TE (4.75”)• Height 3 HE (5.25”)• Rating IP20 / NEMA 2 to EN 60529 and DIN 40050• Mechanical load 1 g, 1 … 800 Hz sinusoidal in all directions to EN 60068-2-364Cleaning unitThe Siemens cleaning unit can be used with MAG 5000 or 6000in 19” insert version.The cleaning unit can be used in applications where the linerand subsequently the electrodes may be coated with deposits.If the coating is electrically insulating, the electrode signal will bereduced. If the coating is electrically inductive, the electrode signalwill be partly short-circuited and in both cases the accuracyof the meter will decrease (dependent on coating type and thickness).Note:The cleaning unit cannot be used for inflammable or explosivemedia!Empty pipe detection and cleaning facility cannot be used atthe same time.Mode of operationThe cleaning unit cleans the electrodes electro-chemically byapplying a voltage to the electrodes for approx. 60 seconds.While cleaning, the transmitter stores and holds the latest measuredflow reading on the display and also the signal outputs. Afteran additional pausing period of 60 seconds the flowmeter resumesnormal measurement and the cleaning is now completed.The relay in the transmitter activates the cleaning cycle. In the relayoutput menu (under cleaning) the cleaning interval can beset between 1 hour and 24 hours.Cleaning should only take place with liquid in the pipe.This canbe detected via the empty pipe function. It is therefore recommendedto select “empty pipe detection” ON when using thecleaning.The cleaning sequence can also be controlled manually throughthe electrical input of the transmitter. Before this is done, ensurethat the measuring pipe is full.Siemens FI 01 · 20074/29

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© Siemens AG 2007Transmitter MAGFLO MAG 5000/6000AC cleaningi £ 80 mA4AC-cleaning is used to remove fatty deposits on the electrodes.These fatty deposits are seen in waste water applications, in abattoirsand water applications with oil residuals. During thecleaning process, the surface of the electrodes get warmer,which tends to soften grease particles and the gas bubbles generatedmechanically lift deposits away from the surface of theelectrodes.DC cleaningi £ 20 mADC-cleaning is used to eliminate electrically conductive depositsin the measuring pipe influencing the measuring accuracy.Particularly in district heating applications an electrically conductivedeposit (magnetite) may occur and short-circuit theelectrode signal. In this case the accuracy of the meter decreasesand the signal/noise conditions of the meter become inferior.The problem only arises if the conductivity of the water isless than approx. 250 µS/cm.During DC-cleaning electrolysis takes place where the flow ofelectrons removes the particle deposits from the electrode area.Note:Do not use DC-cleaning on sensors with tantalum electrodes.4/30 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M■ Selection and Ordering DataTransmitter MAG 5000Description Order No. SymbolTransmitter MAG 5000 Blindfor compact and wall mounting;IP67/NEMA 4X, fibreglassreinforced polyamide• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 5000 Displayfor compact and wallmounting;IP67/NEMA 4X, fibre-glassreinforced polyamide• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz• 115/230 V AC, 50/60 Hz,with HARTTransmitter MAG 5000 CTfor compact and wall mounting,approved for custodytransfer;IP67/NEMA 4X, fibre-glassreinforced polyamide• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 60007ME6910-1AA30-0AA07ME6910-1AA10-0AA0} 7ME6910-1AA30-1AA0} 7ME6910-1AA10-1AA07ME6910-1AA10-1BA07ME6910-1AA30-1AB07ME6910-1AA10-1AB0Transmitter MAG 5000for 19” rack and wall mounting• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz7ME6910-2CA30-1AA07ME6910-2CA10-1AA0Description Order No. SymbolTransmitter MAG 6000 Blindfor compact and wall mounting;IP67/NEMA 4X, fibre-glassreinforced polyamide• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 6000for compact and wall mounting;IP67/NEMA 4X, fibre-glassreinforced polyamide• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzIP67/NEMA 4X, AISI 316stainless steel(without S/S terminal box)• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz7ME6920-1AA30-0AA07ME6920-1AA10-0AA0} 7ME6920-1AA30-1AA0} 7ME6920-1AA10-1AA07ME6920-1QA30-1AA07ME6920-1QA10-1AA0Transmitter MAG 6000 CTfor compact and wall mounting,approved for custodytransfer;IP67/NEMA 4X, fibre-glassreinforced polyamide• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 6000 SVfor compact and wall mounting;special excitation 44 Hzsettings for Batch applicationDN ≤ 25/1“IP67/NEMA 4X, fibre-glassreinforced polyamide11 ... 30 V DC /11 ... 24 V ACTransmitter MAGFLO MAG 5000/6000Description Order No. Symbol7ME6920-1AA30-1AB07ME6920-1AA10-1AB07ME6920-1AB30-1AA0• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 6000 19“(DN ≤ 300/12“)Insert with safety barrier[EEx ia/ib] IIB ATEX• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzTransmitter MAG 6000 SVfor 19“ rack and wall mounting;special excitation 44 Hzsettings, Batch applicationDN ≤ 25/1“• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 HzMAG 6000 withIP66/NEMA 4X enclosure;115/230 V AC, 50/60 HzMAG 6000 with electrodecleaning unit, completemounted withIP66/NEMA 4X mountingenclosure• 11 ... 30 V DC /11 ... 24 V AC• 115/230 V AC, 50/60 Hz} Available ex stock115/230 V AC, 50/60 Hz 7ME6920-1AB10-1AA0Transmitter MAG 6000for 19“ rack and wall mounting7ME6920-2CA30-1AA07ME6920-2CA10-1AA07ME6920-2NA31-1AA07ME6920-2NA11-1AA07ME6920-2CB30-1AA07ME6920-2CB10-1AA07ME6920-2EA10-1AA07ME6920-2PA30-1AA07ME6920-2PA10-1AA04Siemens FI 01 · 20074/31

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© Siemens AG 20074Transmitter MAGFLO MAG 5000/6000Description Order No. SymbolMAG 6000 with electrodesafety barrier, completemounted withIP66/NEMA 4X wall mountingenclosure, ATEX,115/230 V AC, 50/60 Hz• DN ≤ 300/12“, [EEx ia/ib]IIB• DN ≥ 350/14“, [EEx e ia]IICMAG 6000 SV, 19” insert, inIP66/NEMA 4X , ABS plasticenclosure, excitation frequency44 Hz, Batchapplication DN ≤ 25/1“,11 … 30 V DC,11 … 24 V AC, 50/60 Hz7ME6920-2LA11-1AA07ME6920-2MA11-1AA07ME6920-2EB30-1AA0Accessories for MAG 5000 and MAG 6000Description Order No. SymbolWall mounting unit forIP67/NEMA 4X version,wall bracket, terminal box inpolyamide• 4 x M20 cable glands } FDK-085U1018• 4 x ½“ NPT cable glands } FDK-085U1053Cable for standard electrodeor coil, 3 x 1.5 mm² /18 gage with shield PVC•10m(33ft) } FDK-083F0121•20m(65ft) } FDK-083F0210• 40 m (130 ft) } FDK-083F0211• 60 m (200 ft) } FDK-083F0212• 100 m (330 ft)FDK-083F0213• 150 m (500 ft)FDK-083F3052• 200 m (650 ft)FDK-083F3053• 500 m (1650 ft)FDK-083F3054Electrode cable for emptypipe or low conductivity,double shielded,3 x 0.25 mm²•10m(33ft)FDK-083F3020•20m(65ft) } FDK-083F3095• 40 m (130 ft)FDK-083F3094• 60 m (200 ft)FDK-083F3093• 100 m (330 ft)FDK-083F3092• 150 m (500 ft)FDK-083F3056• 200 m (650 ft)FDK-083F3057• 500 m (1650 ft)FDK-083F3058Cable glands, for abovecable, 2 pcs.• M20A5E00822490•½“ NPTA5E00822501Description Order No. SymbolSealing screws for sensor/ FDK-085U0221transmitter, 2 pcsTerminal box, in polyamide,inclusive lid•M20 } FDK-085U1050•½" NPTFDK-085U1052Terminal box for MAG 6000,in stainless steel, inclusivelid•M20A5E00836867•½" NPTA5E00836868Terminal box (3A) in polyamide,inclusive lid•M20A5E00822478•½" NPTA5E00822479Potting kit for terminal box of } FDK-085U0220MAG sensors forIP68/NEMA 6P19“ cleaning unit for electrodecleaning (21TE) incl.back plate• 11 ... 30 V DC /11 ... 24 V AC• 115 ... 230 V AC, 50/60 Hz19“ safety barrier [EEx e ia]IIC for MAG 3100 Ex,DN 350 ... 2000 (14“ ... 78“)(21TE), incl. back platePanel mounting enclosurefor 19“ insert (21TE);IP65/NEMA 4 enclosure inABS plastic for front panelmountingPanel mounting enclosurefor 19“ insert (42TE);IP65/NEMA 4 enclosure inABS plastic for front panelmountingBack of panel mountingenclosure for 19“ insert(21TE); IP20/NEMA 2 enclosurein aluminiumBack of panel mountingenclosure for 19“ insert(42TE); IP20/NEMA 2 enclosurein aluminiumFDK-083F5039FDK-083F5036FDK-083F5034FDK-083F5030FDK-083F5031FDK-083F5032FDK-083F5033} Available ex stock4/32 Siemens FI 01 · 2007Modification 01/2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitter MAGFLO MAG 5000/6000Description Order No. SymbolIP66/NEMA 4, wall mountingenclosure for 19“ inserts(without backplates)• 21TE FDK-083F5037Spare partsDescription Order No. SymbolConnection plate• 12 ... 24 VFDK-083F4149• 115 ... 230 VFDK-083F4148• 42TE } FDK-083F503819“ enclosure, 12 ... 24 V,115 ... 230 V•Transmitter FDK-083F4117Front cover (7TE)FDK-083F45254Back plates (if wall enclosure IP66 is used as part)Description Order No. SymbolWall unit enclosure IP66,12 ... 24 V, 115 ... 230 V• Transmitter FDK-083F4121• Transmitter ia and safetybarrier• Transmitter ia/ib and safetybarrier• Transmitter and cleaningunitFDK-083F4122FDK-083F4120FDK-083F4124Communication modules for MAG 6000Description Order No. SymbolHART} FDK-085U0226(not for MAG 6000 I)MODBUS RTU/RS485 } FDK-085U0234PROFIBUS PA Profile 3 } FDK-085U0236PROFIBUS DP Profile 3 } FDK-085U0237• Transmitter ia and safetybarrier• Transmitter ia/ib and safetybarrier• Transmitter and cleaningunitSENSORPROM memory unit(Sensor code and serialnumbers must be specifiedon order)• 2 kB(for MAG 5000/6000/MAG 6000 I)• 250 B(for MAG 2500/3000)Display unitfor MAG 5000/6000• black neutral front• Siemens front} Available ex stockFDK-083F4118FDK-083F4119FDK-083F4123FDK-085U1005FDK-085U1008FDK-085U1038FDK-085U1039Modification 01/2007Siemens FI 01 · 20074/33

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© Siemens AG 2007Transmitter MAGFLO MAG 5000/6000■ Dimensional drawingsTransmitter IP67/NEMA 4X/6 compact polyamide155 (6.10)6 (0.24)131 (5.16)128 (7.16)4Transmitter integral mountedTransmitter, 19” IP20/ NEMA 2 standard unitTransmitter wall mountedTransmitter, wall mounting IP66/NEMA 4, 21 TE210 (8.27)235 (9.25)22 (0.86)90 (3.54)13(0.51)90 (3.54)120 (4.72)146 (5.75)13 (0.51)192 (7.56)Weight excl. transmitter: 2.3 kg (5.0 lbs)4/34 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitter MAGFLO MAG 5000/6000Transmitter, wall mounting IP66/NEMA 4, 42 TE13 (0.51) 90 (3.54) 120 (4.72)13 (0.51)357 (14.05)339 (13.35)Weight excl. transmitter: 2.9 kg (7.0 lbs)22 (0.87)90 (3.54) 146 (5.75)235 (9.25)4Transmitter, panel front IP65/NEMA 4, 21 TE197 (7.75)144 (5.67)184 (7.24) 198 (7.80) 50 (1.97)140 (5.51)Weight excl. transmitter: 1.2 kg (2.7 lbs)185 (7.28)Siemens FI 01 · 20074/35

<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F M© Siemens AG 2007Transmitter MAGFLO MAG 5000/6000Transmitter, panel front IP65/NEMA 4, 42 TE294 (1.57)144 (5.67)4281 (1.06)198 (7.80) 50 (1.97)140 (5.51)Weight excl. transmitter: 1.6 kg (3.5 lbs)282 (1.10)Transmitter, back of panel IP20/NEMA 2, 21 TE163 (6.42)144 (5.67)218 (8.58)132 (5.20)57 (2.24)Weight: 0.7 kg (1.6 lbs)Transmitter, back of panel IP20/NEMA 2, 42 TE269 (10.59)253 (9.96)218 (8.58)132 (5.20)57 (2.24)Weight: 0.9 kg (2.0 lbs)4/36 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitter MAGFLO MAG 5000/6000■ SchematicsElectrical connectionGroundingPE must be connected due to safety class 1 power supply.Mechanical countersWhen mounting a mechanical counter to terminals 57 and 58(active output), a 1000 µF capacitor must be connected to theterminals 56 and 58. Capacitor + is connected to terminal 56and capacitor - to terminal 58.Output cablesIf the output cable length is long in noisy environment, werecommend to use screened cable.41)Shield1) NoteSpecial cable with individual wire shields (shown as dotted lines)are only required when using empty pipe function or long cablesSiemens FI 01 · 20074/37

4<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitterMAGFLO MAG 6000 I/6000 I Ex d■ Overview© Siemens AG 2007The MAG 6000 I/6000 I Ex d is a microprocessor-based transmitterwith a build-in alphanumeric display in several languages.The transmitters evaluate the signals from the associated electromagneticsensors and also fulfil the task of a power supplyunit which provides the magnet coils with a constant current.Further information on connection, mode of operation and installationcan be found in the data sheets for the sensors.Displays and keypadsOperation of the transmitter can be carried out using:• Keypad and display unit• HART communicator• PC/laptop and SIMATIC PDM software via HART communication• PC/laptop and SIMATIC PDM software using PROFIBUS communicationThe <strong>SITRANS</strong> F M MAGFLO MAG 6000 I / I Ex d transmitter isdesigned for the demands in the process industry. The robustdie cast aluminium housing provides superb protection, even inthe most harsh industrial environments. Full input and outputfunctionality is given even in the Ex version.■ Benefits• Full range of ATEX rated <strong>flowmeters</strong> with intrinsically safe ratedinput and outputs• For compact or remote installation• HART, PROFIBUS PA/DP, MODBUS RTU/RS485 add-on communicationmodules available• Superior signal resolution for optimum turn down ratio• Digital signal processing with many possibilities• Automatic reading of SENSORPROM data for easy commissioning• User configurable operation menu with password protection- 3 lines, 20 characters display in 11 languages- Flow rate in various units- Totalizer for forward, reverse and net flow as well as muchmore information available.• Multiple functional outputs for process control, minimum configurationwith analogue, pulse/frequency and relay output(status, flow direction, limits)• Comprehensive self-diagnostic for error indication and errorlogging• Batch control■ DesignThe transmitter is designed for either compact or remote installationin non-hazardous or hazardous areas.■ FunctionThe following functions are available:• Flow rate• 2 measuring ranges• 2 totalizers• Low flow cut-off• Flow direction• Error system• Operating time• Uni-/bidirectional flow• Limit switches and pulse output• Batch control■ Technical specificationsMode of operation and designMeasuring principleEmpty pipeExcitation frequencyElectrode input impedanceInputDigital input• Activation time• CurrentOutputCurrent output• Signal range• Load• Time constantDigital output• Frequency• Time constant• Pulse (passive)• Time constantRelay output• Time constant• LoadLow flow cut offGalvanic isolationMax. measuring error• MAG 6000 IElectromagnetic with pulsed constantfieldDetection of empty pipe (specialcable required in separatemounted installation)Sensor size dependent pulsatingDC current> 1 x 10 14 ΩDC 11 ... 30 V, Ri = 4.4 kΩ50 msI DC 11 V = 2.5 mA, I DC 30 V = 7 mA0 ... 20 mA or 4 ... 20 mA (Active/passive)< 560 Ω0.1 … 30 s, adjustable0 … 10 kHz, 50% duty cycle (uni-/bidirectional)0.1 … 30 s, adjustable3 … 30 V DC, max 110 mA(30 mA Ex version), 200 Ω ≤ Ri ≤10 kΩ (powered from connectedequipment)0.1 … 30 s, adjustableChangeover relay, same as currentoutput42 V AC/2 A, 24 V DC/1 A0 … 9.9% of maximum flowAll inputs and outputs aregalvanic isolated0.25% of rate4/38 Siemens FI 01 · 2007

© Siemens AG 2007<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitterMAGFLO MAG 6000 I/6000 I Ex d■ Technical specifications (continued)Rated operation conditionsAmbient temperature• Operation-20 … +60 °C (-4 … +140 °F)• Storage-40 … +70 °C (-40 … +158 °F)Mechanical load18 … 1000 Hz, 1.14 G rms, sinusoidalin all directions toIEC 68-2-36Degree of protectionIP67/NEMA 4X to IEC 529 andDIN 40050 (1 mH 2 O 30 min.)EMC performance EN 61326Display and keypadTotalizerTwo eight-digit counters for forward,net or reverse flowDisplayBackground illumination withalphanumeric text, 3 x 20 charactersto indicate flow rate, totalizedvalues, settings and faults;Reverse flow indicated by negativesignKeypadCapacitive touch keypad withLED light for feedback indicationTime constantTime constant as current outputtime constantDesignEnclosure materialDie cast aluminium, painted• Wall mountingWall mounting bracket enclosedfor remote versionDimensional drawingsSee dimensional drawingsWeightSee dimensional drawingsPower supply• Non Ex d: 18 ... 90 V DC;115 ... 230 V AC; 50 ... 60 Hz• Ex d: 18 ... 30 V DC• Ex d: 115 ... 230 V AC;50 ... 60 HzPower consumption• 230 V AC: 21.5 VA• 24 V DC: 12 W, I N = 380 mA,I ST = 1 A (3 ms)Certificates and approvalsMAG 6000 I• CE•C-tick• FM Class 1, div 2• FM Class 1, Zone 2• CSA Class 1, div 2• CSA Class 1, Zone 2MAG 6000 I Ex-d ATEX category 2versions for compact and remotemounting DN 2 ... 300For use with MAG 3100 Ex sizesDN 350 ... 2000Cable entries• SIRA 03 ATEX 1503X• EX II 2 (1) G D• EEx d [ia] ia [ib] ib IIB, T6• SIRA 03 ATEX 2072X• EX II 2 (1) (2) G D• EEx d e [ia] ia [ib] ib IIC, T6Metric: M25/M16; (M20/M16,ATEX cat. 2 versions) ½ NPTCommunication• Non ATEX versions HART, MODBUS RTU/RS 485,PROFIBUS PA, PROFIBUS DPadd-on modules• ATEX category 2 versions HART, PROFIBUS PA available asintegrated versionSelection and Ordering data<strong>SITRANS</strong> F M TransmitterMAGFLO MAG 6000 I / Ex dRemote, local display, die cast aluminiumCommunication modules for MAG 6000 IAccessories MAG 6000 IOrder-No.7 M E 6 9 3 0 -2 B A 7 7 - 1 7 A 7Supply voltage115 ... 230 V AC, 50 ... 60 Hz; 18 ... 90 V DC 2ATEX, 18 ... 30 V DC 4ATEX, 115 ... 230 V AC, 50...60 Hz 5Ex approvalFM Class 1 div 2/No ATEX 0ATEX, ≤ 300 mm/12" sensor 1ATEX, > 300 mm/12" sensor 2CommunicationNone (add-on modules can be ordered separately,Asee below)HARTBPROFIBUS PA Profile 3FPROFIBUS DP Profile 3 (not Ex version)GMODBUS RTU/RS 485 (not Ex version)ECable gland entriesMetric 0½" NPT 2Description Order No. SymbolHARTFDK-085U0321(only for MAG 6000 I/Ex)MODBUS RTU/RS485 FDK-085U0234PROFIBUS PA Profile 3 FDK-085U0236PROFIBUS DP Profile 3 FDK-085U0237Description Order No. SymbolCable for standard electrodeor coil, 3 x 1.5 mm² /18 gage with shield PVC•10m(33ft) } FDK-083F0121•20m(65ft) } FDK-083F0210• 40 m (130 ft) } FDK-083F0211• 60 m (200 ft) } FDK-083F0212• 100 m (330 ft)FDK-083F0213• 150 m (500 ft)FDK-083F3052• 200 m (650 ft)FDK-083F3053• 500 m (1650 ft)FDK-083F3054Electrode cable for emptypipe or low conductivity,double shielded,3 x 0.25 mm²•10m(33ft)FDK-083F3020•20m(65ft) } FDK-083F3095• 40 m (130 ft)FDK-083F3094• 60 m (200 ft)FDK-083F3093• 100 m (330 ft)FDK-083F3092• 150 m (500 ft)FDK-083F3056• 200 m (650 ft)FDK-083F3057• 500 m (1650 ft)FDK-083F3058} Available ex stock4Modification 01/2007Siemens FI 01 · 20074/39

4<strong>SITRANS</strong> F <strong>flowmeters</strong><strong>SITRANS</strong> F MTransmitterMAGFLO MAG 6000 I/6000 I Ex dSpare partsDescription Order No. SymbolDisplayFDK-085U3122Accessory bag includingcable gland inserts coil & electrodeconnectorsFDK-085U3144Complete spare part PCB unitDescription Order No. SymbolNot ExFDK-085U3123Ex d version 18 ... 30 V DC FDK-085U3124for sensors ≤ DN 300 (12")Ex d version 115 ... 230 V AC FDK-085U3125for sensors ≤ DN 300 (12")MAG 6000 I Ex dA5E0101334018 ... 30 V DC Spare PCB unitfor sizes > DN 300MAG 6000 I Ex d115 ... 230 V AC Spare PCBunit for sizes > DN 300A5E01013127Please use online Product selector to get latest updates.Product selector link:www.pia-selector.com/its_main_en.aspPlease also see www.siemens.com/<strong>SITRANS</strong>Forderingfor practical examples of ordering■ Dimensional drawings© Siemens AG 2007■ Schematics Ω Ω Dimensions in mm (inch), weight: 6 kg (13.5 lbs)4/40 Siemens FI 01 · 2007Modification 01/2007