Blade CX2 Manual - hapo - trade Modellbau

Blade CX2 Manual - hapo - trade Modellbau

Blade CX2 Manual - hapo - trade Modellbau

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

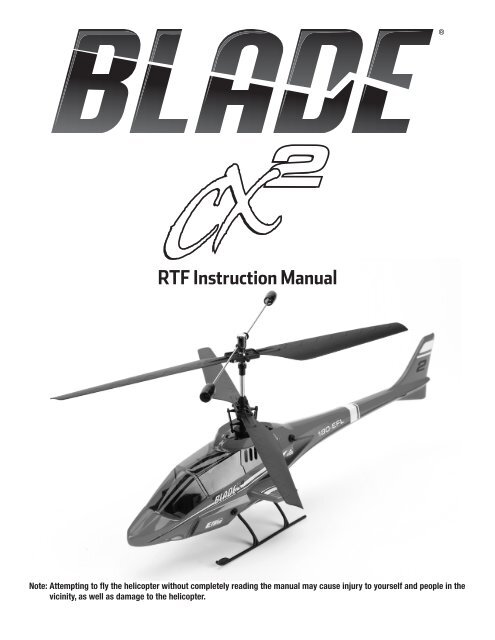

RTF Instruction <strong>Manual</strong><br />

Note: Attempting to fly the helicopter without completely reading the manual may cause injury to yourself and people in the<br />

vicinity, as well as damage to the helicopter.

NOTICE<br />

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon Hobby, Inc.<br />

For up-to-date product literature, visit www.horizonhobby.com and click on the support tab for this product.<br />

Meaning of Special Language<br />

The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:<br />

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND a little or no possibility of injury.<br />

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a possibility of serious injury.<br />

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage, and serious injury OR create<br />

a high probability of superficial injury.<br />

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating.<br />

Failure to operate the product correctly can result in damage to the product, personal property and cause<br />

serious injury.<br />

This is a sophisticated hobby product and NOT a toy. It must be operated with caution and common sense and requires some basic<br />

mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury or damage to the product or<br />

other property. This product is not intended for use by children without direct adult supervision. Do not attempt disassembly, use with<br />

incompatible components or augment product in any way without the approval of Horizon Hobby, Inc. This manual contains instructions<br />

for safety, operation and maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to<br />

assembly, setup or use, in order to operate correctly and avoid damage or serious injury.<br />

2

Table of Contents<br />

Introduction ..........................................................................................4<br />

Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Additional Safety Precautions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

<strong>Blade</strong> <strong>CX2</strong> RTF Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

Preparing for the First Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Flying Checklist .......................................................................................6<br />

Battery Warnings and Guidelines ..........................................................................7<br />

Battery Charging ......................................................................................8<br />

Charge Errors and Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Installing the Transmitter Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Installing the Flight Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Center of Gravity .....................................................................................11<br />

Control Test .........................................................................................12<br />

3-in-1 Control Unit Description, Arming and Motor Control Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Understanding the Controls .............................................................................16<br />

Choosing a Flying Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

Flying the <strong>Blade</strong> <strong>CX2</strong> ..................................................................................19<br />

Main Motor Proportional Mix Trimmer Pot Description and Adjustment .............................................20<br />

Gyro Gain Trimmer Pot Description and Adjustment ...........................................................21<br />

Upper Main Rotor <strong>Blade</strong> Tracking Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

Channel 5 Knob Description and Function ..................................................................23<br />

Transmitter and 3-in-1 Control Unit Receiver Binding and Fail-Safe ...............................................23<br />

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

Optional Parts List ....................................................................................25<br />

Exploded View .......................................................................................26<br />

Exploded View Parts Listing .............................................................................27<br />

2010 Official Academy of Model Aeronautics Safety Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

Warranty and Repair Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Contact Information ...................................................................................30<br />

Customer Service Information ...........................................................................30<br />

Compliance Information for the European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

3

Introduction<br />

The <strong>Blade</strong> ® <strong>CX2</strong> takes the beginner-friendly flight stability of the original <strong>Blade</strong> CX and adds Spektrum 2.4GHz DSM ® radio control<br />

that lets you fly anywhere, anytime without ever having to worry about interference.<br />

Best of all, the <strong>Blade</strong> <strong>CX2</strong> is a truly Ready-for-Anyone-to-Fly micro class electric helicopter. Its coaxial counter-rotating blades cancel<br />

out the rotational torque that makes hovering a conventional helicopter so difficult while providing unsurpassed stability in all other<br />

phases of flight too. And whether you are a first-time helicopter pilot or an experienced pilot looking for the best in coaxial<br />

micro helicopter performance, you’ll enjoy many of the outstanding features that have the <strong>Blade</strong> <strong>CX2</strong> flying in no time such as<br />

factory installed main motors, 3-in-1 control unit with mixer, ESCs and gyro, and S60 Super Sub-Micro Servos. With the<br />

included 5-channel transmitter, 2-cell 800mAh Li-Po battery pack, DC charger and AC adapter, you’ll have precise control for<br />

hovering, forward flight and more with durations of up to 10–15 minutes per charge.<br />

While the <strong>Blade</strong> <strong>CX2</strong> is nearly ready-to-fly right from the box, please take the time to read through this manual completely for tips<br />

on battery safety and charging, control checks, flying and more. Please also take a few minutes to watch the included Instructional<br />

Video CD for additional tips and to see the <strong>Blade</strong> <strong>CX2</strong> in action.<br />

Product Support<br />

For assistance in charging, setting up, binding or operating your <strong>Blade</strong> <strong>CX2</strong>, contact the appropriate Horizon Product Support office.<br />

Warning<br />

An RC helicopter is not a toy! If misused, it can cause serious bodily harm and damage to property. Fly only in open areas, preferably<br />

at AMA (Academy of Model Aeronautics) approved flying sites, following all instructions.<br />

Keep loose items that can get entangled in the rotor blades away from the main and tail blades, including loose clothing, or other<br />

objects such as pencils and screwdrivers. Always keep your hands away from the rotor blades.<br />

Additional Safety Precautions and Warnings<br />

As the user of this product, you are solely responsible for operating it in a manner that does not endanger yourself and others or<br />

result in damage to the product or the property of others.<br />

This model is controlled by a radio signal that is subject to interference from many sources outside your control. This interference<br />

can cause momentary loss of control so it is advisable to always keep a safe distance in all directions around your model, as this<br />

margin will help to avoid collisions or injury.<br />

• Never operate your model with low transmitter batteries.<br />

• Always operate your model in an open area away from cars, traffic, or people.<br />

• Avoid operating your model in the street where injury or damage can occur.<br />

• Never operate the model out into the street or populated areas for any reason.<br />

• Carefully follow the directions and warnings for this and any optional support equipment (chargers, rechargeable battery packs,<br />

etc.) that you use.<br />

• Keep all chemicals, small parts and anything electrical out of the reach of children.<br />

• Moisture causes damage to electronics. Avoid water exposure to all equipment not specifically designed and protected for<br />

this purpose.<br />

•<br />

Never lick or place any portion of your model in your mouth as it could cause serious injury or even death.<br />

4

Specifications<br />

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.42 in (417mm)<br />

Height .............................7.17 in (182mm)<br />

Main Rotor Diameter ..................13.60 in (345mm)<br />

Weight RTF w/Battery .................8.0 oz (227 g)<br />

Main Motor .........................180 (2 installed)<br />

Battery ............................7.4V 800mAh Li-Po (included)<br />

Transmitter .........................2.4GHz DSM 5-Channel (included)<br />

On-Board Electronics . . . . . . . . . . . . . . . . . 3-in-1Mixer/ESC/Gyro (installed)<br />

Servos . . . . . . . . . . . . . . . . . . . . . . . . . . . . S60 Super Sub-Micro (2 installed)<br />

Receiver ...........................Spektrum 6100eb (installed)<br />

<strong>Blade</strong> <strong>CX2</strong> RTF Contents<br />

Item Description<br />

Not Available Separately ...............<strong>Blade</strong> <strong>CX2</strong> RTF Airframe<br />

EFLH1055 ..........................LP5DSM 5-Channel Transmitter, 2.4GHz<br />

EFLB0990 ..........................7.4V 800mAh 2-Cell Li-Po, JST/Balance<br />

EFLC3110 ..........................2- to 3-Cell Li-Po Balancing Charger, 0.65A<br />

EFLC4000 ..........................AC to 12V DC, 1.5-Amp Power Supply<br />

EFLH1209 ..........................Mounting Accessories & Screwdriver<br />

EFLH1022 ..........................Bind Plug<br />

No additional equipment is required to complete your <strong>Blade</strong> <strong>CX2</strong>.<br />

5

Preparing for the First Flight<br />

Please note this checklist is not intended to be a replacement for the content of this instruction manual. Although it can be used as a<br />

quick start guide, we strongly suggest reading through this manual completely before proceeding.<br />

• Remove and inspect contents<br />

• Charge the flight battery<br />

• Install the 4 included AA batteries in the transmitter<br />

• Install the flight battery in the helicopter (once it has been fully charged)<br />

• Check the center of gravity of the helicopter<br />

• Test the controls<br />

• Install the optional Training Gear Set (EFLH1205; strongly recommended if this is your first helicopter model)<br />

• Familiarize yourself with the controls<br />

• Find a suitable area for flying<br />

Flying Checklist<br />

Please note this checklist is not intended to be a replacement for the content included in this instruction manual. Although it can be<br />

used as a quick start guide, we strongly suggest reading through this manual completely before proceeding.<br />

❏ Always turn the transmitter on first<br />

❏ Plug the flight battery into the 3-in-1 control unit<br />

❏ Allow the 3-in-1 control unit to arm properly<br />

❏ Fly the model<br />

❏ Land the model<br />

❏ Unplug the flight battery from the 3-in-1 control unit<br />

❏<br />

Always turn the transmitter off last<br />

6

Battery Warnings and Guidelines<br />

The 7.4V 800mAh 2-cell Lithium Polymer Battery Pack (EFLB0990) included with your <strong>Blade</strong> <strong>CX2</strong> features Balance Charging<br />

via the included 2- to 3-Cell Lithium Polymer Balancing Charger (EFLC3110) to help ensure a safe charge every time. You<br />

MUST read the following safety instructions and warnings before handling, charging or using the Li-Po battery pack.<br />

WARNING: All instructions and warnings must be followed exactly. Mishandling of Li-Po batteries can result in fire.<br />

By handling, charging or using the included Li-Po battery you assume all risks associated with lithium batteries. If you do not agree<br />

with these conditions, return your complete <strong>Blade</strong> <strong>CX2</strong> model in new, unused condition to the place of purchase immediately.<br />

• You must charge the included 7.4V 800mAh 2-cell Li-Po battery pack in a safe area away from flammable materials.<br />

• Do not charge the battery when installed in the helicopter.<br />

• Never charge the battery unattended. When charging the battery you should always remain in constant observation to monitor<br />

the charging process and react to potential problems that may occur.<br />

• After flight, the battery must be cooled to ambient temperature before charging.<br />

• You MUST use the included 2- to 3-Cell 7.4-11.1V Li-Po Balancing Charger ONLY. Failure to do so may result in a<br />

fire causing personal injury and/or property damage. DO NOT use a Ni-Cd or Ni-MH charger.<br />

• If at any time during the charge or discharge process the battery begins to balloon or swell, discontinue charging or<br />

discharging immediately. Quickly and safely disconnect the battery, then place it in a safe, open area away from flammable<br />

materials to observe it for at least 15 minutes. Continuing to charge or discharge a battery that has begun to balloon or swell<br />

can result in a fire. A battery that has ballooned or swollen even a small amount must be removed from service completely.<br />

• In the event of a crash, you must quickly and safely disconnect and remove the battery from the model, then place it in a safe,<br />

open area away from flammable materials to observe it for at least 15 minutes.<br />

• Store the battery at room temperature and approximately ½ charge (3.8V per cell; 7.6V for a 2-cell battery pack) for best results.<br />

• When transporting or temporarily storing the battery, the temperature range should be from 40–120 degrees Fahrenheit. Do not<br />

store the battery or model in a car or direct sunlight whenever possible. If stored in a hot car, the battery can be damaged or<br />

even cause a fire.<br />

• Do not over-discharge the battery. Discharging the battery too low can cause damage to the pack resulting in reduced<br />

performance and duration. Li-Po cells should not be discharged to below 3V each under load. In the case of the 2-cell<br />

Li-Po packs used for the <strong>Blade</strong> <strong>CX2</strong>, do not allow the battery voltage to fall below 6V during flight.<br />

7

The <strong>Blade</strong> <strong>CX2</strong> 3-in-1 control unit does not feature a voltage cutoff of any type, so we suggest that you be extremely<br />

aware of the power level of the Li-Po battery pack during flight. If at any time the helicopter begins to require more<br />

throttle than typical to maintain hover or flight, or has lost significant power, you must land the helicopter and power<br />

the motors down IMMEDIATELY to prevent over-discharge of the Li-Po battery pack. If you continue to run the motors<br />

after noticing a loss in power, it is possible to discharge the Li-Po battery pack too far, causing permanent damage to<br />

the pack.<br />

Over-discharge of the Li-Po battery pack can result in shortened flight times, loss of power output or failure of the pack<br />

entirely.<br />

Battery Charging<br />

It is important that you only charge the included 7.4V 800mAh 2-cell Li-Po Battery Pack (EFLB0990) with the included 2- to 3-Cell<br />

7.4-11.1V Li-Po Balancing Charger (EFLC3110). Your battery pack is equipped with a Balance Charge Lead with connector that is<br />

only compatible with this charger. Attempting to charge the pack using another Li-Po charger or non-Li-Po compatible charger could<br />

result in serious damage. Please familiarize yourself thoroughly with the warnings and guidelines before continuing.<br />

The included 2- to 3-Cell 7.4-11.1V Li-Po Balancing Charger will charge a near fully discharged (not over-discharged) 7.4V 800mAh<br />

2-cell Li-Po Battery Pack in approximately 1.2–1.5 hours. In some cases the charge time may be shorter depending on the actual<br />

amount of capacity left in the pack after a flight. NEVER charge the battery unattended.<br />

Note: The Li-Po battery pack included with your <strong>Blade</strong> <strong>CX2</strong> will arrive partially charged. For this reason the initial charge may only<br />

take approximately 30–50 minutes.<br />

The charger requires up to 1.5 amps of 11.5- to 15-Volt DC input power that can be supplied by the included AC to 12V DC, 1.5-Amp<br />

Power Supply (EFLC4000) for convenient charging anywhere an AC outlet is available.<br />

CAUTION: NEV ,ER attempt to power the charger from an AC outlet without the use of a proper AC to DC adapter/power supply.<br />

Note: When using the AC to DC adapter/power supply, the charger is protected to prevent damage if the alligator clips touch.<br />

However, please take care to ensure that the alligator clips do not cause shorting of the battery, adapter/power supply, etc.<br />

by keeping them clear.<br />

8

The charger is equipped with two LED indicators marked RED and GREEN on the label. These LEDs indicate the following (also found<br />

on the label of the charger):<br />

• Red Flashing LED Only:<br />

Input power with no battery connected<br />

• Red and Green Solid LED:<br />

Battery connected and charging<br />

• Red Solid LED Only:<br />

Charge complete<br />

• Red and Green Flashing LED:<br />

Charge error<br />

Once you have connected the charger to a power source (Use care to ensure proper polarity when connecting the charger to the<br />

power source), its red LED will flash to indicate the charger has power and is ready to begin charging. Connect the Li-Po battery<br />

pack to the charger using the specially marked Balance Charge Lead exiting the battery pack and the connector labeled with 7.4V on<br />

the charger. The connector is keyed to prevent reverse polarity connection.<br />

Note: Do not force the connector on the Balance Charge Lead into the connector labeled 11.1V on the charger. Doing so could<br />

result in damage to the battery pack and charger, and could result in a fire.<br />

When the battery is properly connected and charging normally, the red and green LED indicators will glow solid. Once the battery<br />

has been fully charged, the green LED will go out, leaving just the red LED glowing solid. The battery can now be removed from the<br />

charger and installed into the <strong>Blade</strong> <strong>CX2</strong> for flight.<br />

Charge Errors and Indications<br />

In the event that both the red and green LEDs flash, a charge error has occurred. Some examples of charge errors and their indications<br />

include:<br />

• Alternating flashing of the red and green LEDs will indicate that the charge process has been interrupted. If input power to the<br />

charger has been interrupted due to disconnection from the power source or a drop in voltage/current output from the power<br />

source, unplug the battery from the charger. Next, check to make sure that the input power plug from the AC to 12V DC adapter/<br />

power supply is connected or that the alligator clips are firmly and properly attached to the power source. Also be sure that the<br />

power source is providing the proper amount of voltage and current required to the charger.<br />

After confirming the connections and that the power source is delivering the necessary voltage and current, re-start the charge<br />

process by connecting the battery pack. Continue to monitor the charge process to ensure that no further charge errors occur.<br />

• Simultaneous flashing of the red and green LEDs will indicate that the voltage of the Li-Po battery pack is too low to allow the<br />

charge process to begin. In this case the battery may have been over-discharged due to flying the model too long (For more<br />

information on preventing over-discharge of the Li-Po battery pack, see the guidelines section found on page 6), or that a single<br />

cell or even all cells in the battery pack may be damaged.<br />

If after several charging attempts you continue to see this charge error indication, you should remove the battery pack<br />

from service and replace it with a new one.<br />

9

Installing the Transmitter Batteries<br />

Install the 4 included AA batteries in the transmitter. Check the power level of the batteries and operation of the transmitter by<br />

switching the power switch on (upward). The LCD screen at the top of the transmitter will indicate the power level of the batteries. If<br />

at any time the voltage indicated on the LCD screen falls to 4.5V or less, an alarm will sound, and it will be necessary to replace the<br />

batteries with new ones.<br />

Note: Because the LP5DSM transmitter included with the <strong>Blade</strong> <strong>CX2</strong> is equipped with Spektrum 2.4GHz DSM technology, it<br />

does not require the same input voltage or current consumption as a typical 72MHz transmitter for proper operation and<br />

optimum performance.<br />

Installing the Flight Battery<br />

Use the included hook and loop material for mounting the Li-Po battery pack. The “hook” material is already installed on the battery<br />

frame stop. The included “loop” material can be installed on the end of the battery with or without the wire leads, depending on how<br />

you choose to install the battery and route the wire leads.<br />

If you choose to install the loop material on the end of the battery with the wire leads, it will be a little more difficult to install the<br />

battery in the model but the wire leads can be tucked neatly inside of the body.<br />

If you choose to install the loop material on the end of the battery without the wire leads, it will be easier to install the battery in the<br />

model but the power leads (red and black leads with red JST connector) will need to be placed outside of the body.<br />

The battery can be installed through the opening in the rear of the body. Be sure to install the end of the battery with the loop<br />

material first. If you have installed the loop material on the end of the battery with the wire leads, be sure that the wire leads are<br />

oriented to the left side of the model so that they can pass by the stop. Slide the battery into the support frame until the hook and<br />

loop material makes contact.<br />

10

Quick Tip: You can install a tape “pull tab” on the end of the battery to make it easier to remove. You can also carefully remove some<br />

additional material from the opening in the rear of the body.<br />

Center of Gravity<br />

Once the battery has been properly installed and secured you will need to check the helicopter’s center of gravity. If the helicopter is<br />

not properly balanced it can be difficult to control and constantly try to move forward or backward in hover.<br />

To check the center of gravity, lift the helicopter by the stabilizer flybar with the flybar positioned perpendicular to the tail section of<br />

the body. Make sure that the helicopter balances level. If it does not, confirm that the battery has been properly installed and reposition<br />

it forward or aft if necessary.<br />

Must Balance Level<br />

11<br />

Support by Flybar

Control Test<br />

Although each <strong>Blade</strong> <strong>CX2</strong> model is test flown at the factory, it is a good idea to test the controls prior to the first flight to ensure none<br />

of the servos, linkages or other parts were damaged during shipping and handling. Before proceeding, disconnect both of the<br />

main motor plugs from the 3-in-1 control unit, making note of their direction and polarities for proper re-installation after<br />

the control test is complete. It is not safe to perform the control test with the main motor plugs connected to the 3-in-1<br />

control unit after power up.<br />

Turn the transmitter on first then plug the battery into the battery lead of the 3-in-1 unit.<br />

Position the helicopter to view it from the left-hand side. Move the elevator control stick on the transmitter forward and back to<br />

check elevator pitch control. When the stick is pushed forward, the rear servo should push the swashplate upward.<br />

12

When the stick is pulled back, the rear servo should pull the swashplate downward.<br />

Position the helicopter to view it from the right-hand side. Move the aileron control stick on the transmitter left and right to check<br />

aileron roll control. When the stick is pushed to the left, the forward servo should push the swashplate upward.<br />

When the stick is pushed to the right, the forward servo should pull the swashplate downward.<br />

13

If at any time during the test the controls do not respond properly, double-check the servo reversing switches located under the door<br />

on the bottom left front of the transmitter. Dip switches 1 (THR channel reversing), 6 (AIL channel reversing), and 7 (ELE channel<br />

reversing) should be positioned as shown to ensure proper control response.<br />

CAUTION:All other dip switches should also be positioned as shown to ensure proper operation. DO NOT attempt to fly your<br />

<strong>Blade</strong> <strong>CX2</strong> with any of the dip switches set in positions that are not shown.<br />

If the controls still do not respond properly after ensuring that the servo reversing dip switch positions are correct, you may also<br />

check the servo connections on the receiver side of the 3-in-1 unit. These should be positioned as follows (when viewing the helicopter<br />

from behind):<br />

AIL Channel – Forward aileron servo<br />

ELE Channel – Rear elevator servo<br />

Once you have confirmed that the servo connection locations are correct, all controls should be functioning properly. If you do encounter<br />

any problems with your <strong>Blade</strong> <strong>CX2</strong> responding properly to the transmitter, do not fly.<br />

If you have confirmed proper control operation of your <strong>Blade</strong> <strong>CX2</strong>, unplug the flight battery from the 3-in-1 unit and reconnect the<br />

main motor plugs to the 3-in-1 unit, taking care to keep the proper polarity and location of each as they were before the test. Use the<br />

label on the 3-in-1 unit for reference of the proper polarity and locations. Note that the red wire leads are positive (+) and the black<br />

wire leads are negative (−).<br />

3-in-1 Control Unit Description, Arming and Motor Control Test<br />

The unique 3-in-1 Control Unit installed on your <strong>Blade</strong> <strong>CX2</strong> is a lightweight combination of 6-channel 2.4GHz DSM receiver, main<br />

motor mixer, main motor electronic speed controls, and piezo gyro. The 3-in-1 unit also contains a gyro gain trimmer pot, main<br />

motor proportional mix trimmer pot and status LED.<br />

Gain Trimmer Pot<br />

Main Motor Proportional<br />

Mix Trimmer Pot<br />

Status LED<br />

14<br />

Motor Plugs<br />

Remove the helicopter front body to access the 3-in-1 unit. The gain and proportional pots can be adjusted when the front body<br />

is removed. Note: It will not be necessary to access the 3-in-1 unit for proper arming and usual operation.

The following checklist contains the steps you must follow to ensure proper arming and operation of the 3-in-1 unit as well as<br />

proper motor control response:<br />

❏ Each time before you fly you must ALWAYS turn on the transmitter power first before connecting the flight battery to the 3-in-1<br />

unit. Never connect the flight battery to the 3-in-1 unit before first powering on the transmitter.<br />

❏Also,<br />

never turn off the transmitter before disconnecting the flight battery from the 3-in-1 unit first.<br />

❏ Both the throttle stick and throttle trim MUST be in their lowest possible position in order for the 3-in-1 unit to arm the electronic<br />

speed controls for the main motors.<br />

If this is the first test flight, or a test flight following repairs, you will also want to center the rudder, aileron and elevator trims.<br />

Set Throttle<br />

Trim and<br />

Throttle Stick<br />

at Lowest<br />

Position<br />

Rudder<br />

Trim<br />

Throttle Trim<br />

15<br />

Elevator Trim<br />

❏ After confirming that the transmitter has been turned on and has an adequate level of battery power as displayed by the LCD<br />

screen at the top of the transmitter, it is now safe to connect the flight battery to the 3-in-1 unit.<br />

Note: Each time you power the transmitter on, it will enter “Bind Mode” for a few seconds, as indicated by the red blinking LED<br />

located under the door on the left bottom front of the transmitter. Once this LED becomes solid, the transmitter is no longer<br />

in bind mode. We recommend waiting to connect the flight battery to the 3-in-1 unit until after the transmitter has exited<br />

bind mode, otherwise the 3-in-1 unit may not arm properly or as quickly.<br />

❏ With battery power applied, the 3-in-1 unit status LED will blink red, and then blink green. Do not move or sway the<br />

helicopter once the status LED begins to blink green confirming that the initialization process and calibration of the<br />

gyro has begun. It is OK to move the model when the status LED is blinking red (as in the time it takes to connect the flight<br />

battery to the 3-in-1 unit and place the model at rest), as long as the model remains motionless when the status LED begins to<br />

blink green. The gyro will not calibrate correctly if the model is moved and the green LED is blinking.<br />

❏ When the status LED becomes solid green, the unit is armed and ready for flight. Use caution as both main motors will<br />

now run with throttle stick or throttle trim input. Do not advance the throttle stick or trim until you are clear of the rotor blades<br />

and ready to fly.<br />

Note: If the status LED does not become solid green, please review the following:<br />

• If after blinking red the status LED becomes solid red, you have a positive Radio Frequency (RF) link between the transmitter<br />

and receiver of the 3-in-1 unit, but the throttle stick and throttle trim may not be in their lowest possible positions. Check<br />

to be sure that both the throttle stick and throttle trim are in their lowest possible position and the status LED should blink<br />

green then become solid green indicating the unit is armed and ready for flight. Proceed to the next step of the checklist<br />

once the unit is armed.<br />

• If after blinking red the status LED continues to flash from green to red, you do not have a positive RF link between the transmitter<br />

and receiver of the 3-in-1 unit. First, check to be sure that the transmitter has been powered on and has an adequate<br />

level of battery power. If the transmitter was indeed powered on, power both the transmitter and 3-in-1 unit down, then<br />

follow the steps to bind the 3-in-1 unit’s receiver to the transmitter (see pages 33–34 for more information). Once you have<br />

confirmed that the transmitter and receiver are properly bound, the 3-in-1 unit should now arm normally.<br />

Aileron<br />

Trim<br />

Mode 2 transmitter<br />

shown for reference

❏ Once you have placed the helicopter in a safe area to test motor control, free from obstructions, and are clear of the rotor<br />

blades, you can safely begin to power up the model.<br />

❏ Advance the throttle stick slowly, just until the main rotor blades begin to spin. Be sure not to advance the throttle stick too far<br />

to keep the helicopter from lifting off the ground. Note the direction that each of the main rotor blades spins. When viewed from<br />

the top, the lower main rotor blade should spin clockwise and the upper main rotor blade should spin counterclockwise.<br />

If either rotor blade is operating in the wrong direction, unplug the battery, then simply reverse its motor plug polarity on<br />

the 3-in-1 unit. Note that the proper polarity is marked on the label of the 3-in-1 unit.<br />

❏ After confirming that the direction of rotation for both rotor blades is correct, it is best to confirm that both rotor blades respond<br />

properly to rudder control inputs. With both main rotor blades spinning at a low level of power, move the rudder (left-hand) stick<br />

all the way to the right. This should cause the speed of the upper main rotor blade to increase, and the speed of the lower main<br />

rotor blade to decrease. Next, move the rudder stick all the way to the left. This should cause the speed of the lower main rotor<br />

blade to increase and the speed of the upper main rotor blade to decrease. If both rotor blades are not responding properly to<br />

rudder input, simply reverse the locations of their motor plugs on the 3-in-1 unit. Note that the proper motor plug locations are<br />

marked on the label of the 3-in-1 unit.<br />

Understanding the Controls<br />

If you are not familiar with the controls of your <strong>Blade</strong> <strong>CX2</strong>, please take a few minutes to familiarize yourself with them before attempting<br />

your first flight.<br />

The left stick on the Mode 2 transmitter controls both throttle (climb/descend) and rudder (yaw left/right). When the left-hand stick<br />

and throttle trim lever are in their lowest positions, the main rotor blades will not spin. Advancing the stick upward will increase the<br />

speed of the main rotor blades. Increasing the speed of the main rotor blades will cause the model to climb.<br />

Throttle Trim<br />

16<br />

Climb<br />

Decreasing the speed of the main rotor blades by lowering the left-hand stick will cause the model to descend.<br />

Throttle Trim<br />

Descend<br />

After lifting the model off the ground, you can balance the throttle by carefully moving the left-hand stick up and down so that the<br />

model will hold a stationary hover without climbing or descending.

You can also use the throttle trim to adjust the throttle value for a given stick position. For example, raising the throttle trim will allow<br />

the model to hover at a lower throttle stick position. However, if you do raise the throttle trim, you MUST remember to lower it (and<br />

the throttle stick) to the lowest possible position IMMEDIATELY in the event of a crash or rotor blade strike.<br />

Failure to lower the throttle trim (and throttle stick) to its lowest possible position immediately in the event of a crash could result in<br />

damage to the main motor ESCs in the 3-in-1 unit, which may require replacement of the<br />

3-in-1 unit.<br />

Moving the left-hand stick to the left will turn (yaw) the nose of the helicopter to the left about the axis of the main shaft. This is<br />

accomplished by increasing the speed of the lower main rotor blade while decreasing the speed of the upper main rotor blade.<br />

Rudder Trim Nose Yaws Left<br />

Moving the stick to the right will turn (yaw) the nose of the helicopter to the to the right about the axis of the main shaft. This is<br />

accomplished by increasing the speed of the upper main rotor blade while decreasing the speed of the lower main rotor blade.<br />

Rudder Trim<br />

17<br />

Nose Yaws Right<br />

The rudder trim can be used to help keep the nose of the helicopter from rotating to the left or right when in hover with no rudder<br />

stick input. For example, if the nose of the helicopter drifts to the right when in hover, add left rudder trim until the nose stays as<br />

close to straight as possible. Also note that further adjustments to the rudder trim can be made using the Main Motor Proportional<br />

Mix Trimmer Pot.<br />

The right-hand stick controls both elevator (pitch fore/aft) and aileron (roll). Pushing the stick forward will pitch the nose of the<br />

helicopter downward, allowing the helicopter to be flown forward.<br />

Elevator Trim<br />

Helicopter Moves Forward

Pulling the stick backward will pitch the nose of the helicopter upward, allowing the helicopter to be flown backward.<br />

Elevator Trim<br />

18<br />

Helicopter Moves Backward<br />

The elevator trim can be used to help keep the helicopter from drifting forward or backward when in hover with no elevator stick<br />

input. For example, if the helicopter drifts forward when in hover, pull the elevator trim downward until the helicopter hovers as level<br />

as possible with no forward drifting.<br />

Moving the stick to the left will roll the helicopter to the left, allowing the helicopter to be flown to the left.<br />

Aileron Trim<br />

Helicopter Slides Left<br />

Moving the stick to the right will roll the helicopter to the right, allowing the helicopter to be flown to the right.<br />

Aileron Trim<br />

Helicopter Slides Right<br />

The aileron trim can be used to help keep the helicopter from drifting left or right when in hover with no aileron stick input. For<br />

example, if the helicopter drifts to the right when in hover, add left aileron trim until the helicopter hovers as level as possible with no<br />

drifting to the right.<br />

Once you have become familiar with the controls of the helicopter, you are almost ready to fly.

Choosing a Flying Area<br />

When you are ready for your first flight, you will want to select a large, open area that is free of people and obstructions. We<br />

strongly recommend an indoor area with at least 20-feet by 20-feet of floor space and no less than 8-foot ceilings.<br />

If you have to make your first flight (and subsequent flights) outdoors, you MUST pick a time when wind conditions are<br />

COMPLETELY CALM. Due to the relatively small size and low weight of the <strong>Blade</strong> <strong>CX2</strong>, even the slightest amount of wind can cause<br />

you to lose control, or the rotor blades to strike each other, resulting in a crash.<br />

Flying the <strong>Blade</strong> <strong>CX2</strong><br />

Having followed the proper 3-in-1 control unit arming procedure, confirmed proper control of the servos and motors, and found a<br />

suitable flying area, your <strong>Blade</strong> <strong>CX2</strong> is ready for flight.<br />

In addition to reviewing the flight maneuvers outlined below, we recommend that you watch the included Instructional Video CD to<br />

see many of these maneuvers and adjustments performed by the <strong>Blade</strong> <strong>CX2</strong> and pilot.<br />

• Slowly raise the throttle stick, increasing the speed of the main rotor blades until the model begins to lift off. Do not raise the<br />

throttle stick too quickly as the model could climb too fast causing you to lose control or make contact with objects<br />

above.<br />

• Lift the model off the ground just a few inches and concentrate on balancing the left-hand (throttle) stick position so that the<br />

model holds a steady hover altitude. In some cases it may be best to make a few short “hops” to an altitude of just a few inches<br />

until you become familiar with the control inputs and trim settings required to maintain a steady hover and altitude.<br />

As you will find, the <strong>Blade</strong> <strong>CX2</strong> requires minor throttle adjustments to maintain its altitude in hover. Remember to keep these<br />

throttle adjustments as minimal as possible as large adjustments could result in a loss of control and/or a possible crash.<br />

• While attempting to establish a low-level hover, you can also check to see if any trim adjustments are required to help keep the<br />

<strong>Blade</strong> <strong>CX2</strong> from constantly drifting in various directions. If you find the helicopter constantly drifts without any directional control<br />

input, it will be best to land the model before making any adjustments to the trim levers.<br />

If the nose of the helicopter is drifting to the left or right, you will need to adjust the rudder trim. You can also adjust the<br />

Main Motor Proportional Mix if you experience any difficulties in trimming nose drift with the rudder trim lever only.<br />

If the helicopter is drifting forward or backward, you will need to adjust the elevator trim.<br />

If the helicopter is drifting to the left or right, you will need to adjust the aileron trim.<br />

Continue to make trim adjustments until the helicopter can hover at a low altitude with very little drifting and directional control<br />

input. If the <strong>Blade</strong> <strong>CX2</strong> is your first helicopter model, it may be best to have the help of an experienced helicopter pilot to trim the<br />

model for you before making your first flight.<br />

• Once you have the <strong>Blade</strong> <strong>CX2</strong> properly trimmed and maintaining a stable low-level hover, practice using the rudder, elevator and<br />

aileron controls to get a feel for how the helicopter responds to control inputs. Remember to keep the control inputs as minimal<br />

as possible to prevent over-controlling the helicopter, especially when in hover.<br />

• After becoming comfortable with hovering the <strong>Blade</strong> <strong>CX2</strong> at low-levels of altitude just a few inches off the ground, you can<br />

transition to hovering and flying the helicopter at higher altitudes of approximately three to four feet. At these higher altitudes<br />

you will be able to get a feel for the flight characteristics of the <strong>Blade</strong> <strong>CX2</strong> when it is flying out of “ground effect.”<br />

• If at any time during flight you feel like the helicopter is drifting out of control, simply release all of the controls except for<br />

throttle. You will need to use the throttle to maintain altitude, but due to the inherent stability of the coaxial counter-rotating<br />

blades, the <strong>Blade</strong> <strong>CX2</strong> will simply return to a stable hover on its own if space allows.<br />

• Don’t be afraid to set the helicopter down on the ground quickly by lowering the throttle when approaching walls or other<br />

obstacles to help prevent main rotor blade strikes. Also, the optional Training Gear Set (EFLH1205) will help to further prevent<br />

damage to the helicopter in the event that you must make an abrupt landing to avoid walls or other obstacles.<br />

• In the unfortunate event of a crash or rotor blade strike, no matter how minor or major, you MUST lower both the throttle<br />

(left-hand) stick and throttle trim to their lowest possible position as quickly as possible to prevent damage to the ESCs of the<br />

3-in-1 unit.<br />

19

Failure to lower both the throttle stick and throttle trim to their lowest possible positions in the event of a crash could result in<br />

damage to the main motor ESCs in the 3-in-1 unit, which may require replacement of the 3-in-1 unit.<br />

Note: Crash damage is not covered under warranty.<br />

• It is extremely important when hovering and flying the <strong>Blade</strong> <strong>CX2</strong> to be aware of the power level of the Li-Po battery pack. If at<br />

any time the helicopter begins to require more throttle than typical to maintain hover or flight, or has lost the ability to maintain<br />

hover or flight due to significant loss of power, you must land the helicopter and power the motors down IMMEDIATELY to prevent<br />

over-discharge of the Li-Po battery pack.<br />

If you continue to run the motors after noticing a loss in power it is possible to discharge the Li-Po battery pack too far, causing<br />

permanent damage to the pack. Over-discharge of the Li-Po battery pack can result in shortened flight times, loss of power<br />

output or failure of the pack entirely.<br />

Once you have gained experience and confidence in hovering the <strong>Blade</strong> <strong>CX2</strong>, you can attempt more advanced maneuvers including:<br />

Forward Flight Backward Flight Pirouettes<br />

Skidding Takeoffs Skidding Landings Spot Landings<br />

Main Motor Proportional Mix Trimmer Pot Description and Adjustment<br />

The Main Motor Proportional Mix Trimmer Pot can be found on the left side of the 3-in-1 control unit. This “proportional” trimmer pot<br />

adjusts the amount of mixing between the main motors allowing you to “fine-tune” the rudder trim (sub-trim) to help prevent the<br />

nose from drifting to the left or right when in hover.<br />

Main Motor<br />

Proportional Mix<br />

Trimmer Pot<br />

• In a stable hover, with the rudder trim centered and no rudder control input, note toward which direction the nose of the<br />

helicopter is trying to drift. If the nose of the helicopter is drifting to the left, you will want to increase power to the right-hand<br />

motor (spinning the upper main rotor blade). This is accomplished by turning the “proportional” trimmer pot clockwise. (+)<br />

• If the nose of the helicopter is drifting to the right in hover, you will want to increase the power to the left-hand motor (spinning<br />

the lower main rotor blade). This is accomplished by turning the “proportional” trimmer pot counterclockwise. (–)<br />

20

Note: You must always power down the 3-in-1 unit before making adjustments to the proportional mix trimmer pot. Any changes<br />

made to the trimmer pot will not take effect until the 3-in-1 unit is re-initialized and re-armed.<br />

Also, you should always center the rudder trim lever on the transmitter after making adjustments to the proportional mix trimmer pot<br />

on the 3-in-1 unit.<br />

Note: Be sure to use the proper size and type of screwdriver to carefully make adjustments to the trimmer pot. Use of the<br />

improper size and type of screwdriver or too much force can damage the trimmer pot. Also be sure to take your time when<br />

making adjustments to the proportional trimmer pot as it may only require very slight adjustment to achieve the desired<br />

level of performance.<br />

As the battery output voltage decreases throughout the flight, it may be necessary to make small adjustments to the rudder trim or<br />

rudder control input in order to keep the nose of the helicopter straight. These small adjustments can be made using the rudder trim<br />

lever or rudder control stick and do not require additional adjustments of the proportional trimmer pot.<br />

Gyro Gain Trimmer Pot Description and Adjustment<br />

The “gain” trimmer pot adjusts the gain setting value of the piezo gyro used to aid in keeping the tail of the helicopter straight/on<br />

heading during flight.<br />

Gain Trimmer Pot<br />

• The gain value is set too high if the tail of the helicopter twitches/bounces quickly from side to side when in hover. If this is case<br />

for your model, reduce the gyro gain in small increments until the tail of the helicopter no longer twitches/bounces from side to<br />

side in hover.<br />

• Turn the gyro gain trimmer pot counterclockwise (-) to decrease gyro gain.<br />

• The gain value is set too low when the tail of the helicopter feels “loose” during flight, requiring constant left and right rudder<br />

inputs to maintain heading when in hover. If this is the case for your model, increase the gyro gain in small increments until few,<br />

if any, left and right rudder inputs are required to maintain heading.<br />

• Turn the gyro gain trimmer pot clockwise (+) to increase gyro gain.<br />

Note: When adjusting the gyro gain trimmer pot, the changes will take effect without the need to power down and re-arm the<br />

3-in-1 unit. However, please exercise extreme caution when adjusting the gyro gain trimmer pot with the model armed to<br />

prevent personal injury or damage to the model.<br />

21

Upper Main Rotor <strong>Blade</strong> Tracking Adjustment<br />

NOTICE: Be sure to maintain a safe distance from the helicopter (approximately 10–15 feet) when tracking the Upper Main Rotor<br />

<strong>Blade</strong>.<br />

Your <strong>Blade</strong> <strong>CX2</strong> is equipped with an adjustable linkage between the Stabilizer Flybar and Upper Main Rotor <strong>Blade</strong>. This linkage allows<br />

you to adjust the tracking of the upper main rotor blade for smoother and more stable flight performance.<br />

• You can check the upper main rotor blade tracking either on the ground or in the air at eye level. It might be a good idea to have<br />

an assistant on hand to help sight the blade tracking.<br />

• Once the main rotor blades have been brought up to speed, note whether the tips of the upper main rotor blade are tracking in<br />

the same plane or not.<br />

Tips Out Of Track —<br />

Adjustment Necessary<br />

22<br />

Tips In Track —<br />

No Adjustment Necessary<br />

• If the tips are not tracking in the same plane, power the helicopter down to make adjustments to the adjustable linkage. You can<br />

start by turning the ends of the linkage in one-half to one-full turn at a time. Power the helicopter up again and re-check the<br />

blade tracking.<br />

If the tracking has gotten better, continue to turn the ends of the linkage in one-half to one-full turn at a time until the tips are<br />

tracking in the same plane.<br />

If the tracking has gotten worse after first turning the ends of the adjustable linkage in, turn the ends of the linkage back out onehalf<br />

to one-full turn at a time. If the tracking then gets better, continue to turn the ends of the linkage out one-half to one-full turn at<br />

a time until the tips are tracking in the same plane.<br />

Typically, not much adjustment should be necessary to properly track the tips of the upper main rotor blade. However, due to the<br />

small size of the linkage ends and threaded rods it may not always be possible to achieve absolutely perfect blade tracking. Don’t<br />

worry as the helicopter will still perform well as long as the blade tracking is adjusted as closely as possible.<br />

Note: It will not be necessary to adjust the Lower Main Rotor <strong>Blade</strong> tracking as fixed links are used between the rotor blade and<br />

swashplate.

Channel 5 Knob Description and Function<br />

The transmitter included with your <strong>Blade</strong> <strong>CX2</strong> is equipped with an optional-use “Channel 5” knob (labeled as “CH 5”) on the top right<br />

panel.<br />

This knob allows you to control function of the transmitter’s 5th channel. This channel remains unused for flying the <strong>Blade</strong> <strong>CX2</strong>,<br />

however, it is available for use in controlling a variety of potential optional features including actuation of an additional servo or<br />

certain electronic components. It allows full proportional control of the 5th channel from approximately 0–100% travel.<br />

The knob can be operated in either direction for control. You can use either the most clockwise (+) or most counterclockwise (-)<br />

position for 0 or 100% travel, and you will achieve approximately 50% travel with the knob in the middle position, pointing directly to<br />

the rear of the transmitter.<br />

0% Travel<br />

50% Travel<br />

Transmitter and 3-in-1 Control Unit Receiver Binding and Fail-Safe<br />

23<br />

100% Travel<br />

Binding is the process of programming the receiver to recognize the GUID (Globally Unique Identifier) code of a single specific<br />

transmitter. If you ever find that it is necessary to replace your transmitter or the 3-in-1 control unit in your model, it will be<br />

necessary for you to “Bind” the new transmitter or 3-in-1 control unit receiver to your existing transmitter or receiver for proper<br />

operation.<br />

During the binding process, the smart fail-safe (SmartSafe ) positions of your system are also set. With SmartSafe, in case of loss of<br />

signal, the throttle will go to the preset position that was stored during the binding process and all other channels will hold their last<br />

position. And if the receiver (3-in-1 Control Unit) is powered on before the transmitter, all channels but throttle will go to the fail-safe<br />

positions that were stored during the binding process, while the throttle channel will not generate a pulse in order to prevent the<br />

ESC(s) from arming.<br />

Note: Because the SmartSafe positions are set during the binding process, it is important to set all channels to the preferred<br />

fail-safe positions before proceeding. In the case of the <strong>Blade</strong> <strong>CX2</strong>, we strongly recommend setting the throttle stick and<br />

throttle trim to their lowest positions, and the rudder, aileron and elevator channels to their neutral positions. Channel 5<br />

should be set to your preferred position if you have chosen to utilize it.<br />

The following steps outline the binding process:<br />

• Each time the transmitter is turned on, it enters “Bind Mode” for a few seconds. You can tell that the transmitter is in bind mode<br />

when you see the red LED located under the door on the bottom left front of the transmitter blink rapidly. Once the LED becomes<br />

solid, the transmitter is no longer in bind mode and will transmit normally.<br />

LED Location

Note: For safety, disconnect both main motor plugs from the 3-in-1 control unit (as shown on page 12) before proceeding. Once<br />

the binding process is complete and the flight battery is unplugged from the 3-in-1 unit, reconnect the main motor plugs<br />

to 3-in-1 unit (as noted on page 15).<br />

• In order to bind the 3-in-1 control unit’s receiver to the transmitter, you must first insert the Bind Plug (included with your <strong>Blade</strong><br />

<strong>CX2</strong> and replacement 3-in-1 control units) into the “BAT” opening on the receiver. Then you will need to power on the 3-in-1<br />

control unit by connecting the flight battery BEFORE powering the transmitter on.<br />

• When you connect the flight battery to the 3-in-1 unit with the bind plug inserted into the “BAT” opening on the receiver, you will<br />

see an orange LED blink rapidly on the receiver itself.<br />

• Once the orange LED on the receiver begins to blink, turn on the transmitter. The transmitter will immediately enter bind<br />

mode. Then, once the orange LED on the receiver and the red LED on the transmitter turn solid, the 3-in-1 unit’s receiver is<br />

bound to the transmitter. Now you will need to power down the 3-in-1 control unit and transmitter, and remove the bind plug<br />

from the receiver.<br />

Note: It is extremely important that you remove the bind plug from the receiver once it has been bound to the transmitter. If you<br />

do not remove the bind plug, the receiver will enter bind mode every time the 3-in-1 unit is powered on.<br />

24

Replacement Parts List<br />

EFLH1250 <strong>Blade</strong> <strong>CX2</strong> RTF Electric Coaxial Heli<br />

EFLB0990 7.4V 800mAh 2-Cell Li-Po, JST/Balance<br />

EFLC3110 2-3 Cell Li-Po Balancing Charger, 0.65A<br />

EFLC4000 AC to 12VDC, 1.5 Amp Power Supply<br />

EFLH1022 Bind Plug<br />

EFLH1024 3-in-1 Control Unit, Rx/ESC/Mixer/Gyro 2.4GHz<br />

EFLH1055 LP5DSM 5-Channel Transmitter, 2.4GHz<br />

EFLH1058 Transmitter Antenna, 2.4GHz<br />

EFLRS60 6.0-Gram Super Sub-Micro S60 Servo<br />

EFLRS601 Gear Set: S60<br />

EFLRS602 Case Set: S60<br />

EFLRSA100 Standard Arm Set, Fine Spline: S60<br />

EFLH1121 Bearing 2x6x3mm (2): BCP, BCX/2<br />

EFLH1209 Mounting Accessories & Screwdriver<br />

EFLH1210 180 Motor w/8T 0.5M Pinion Left<br />

EFLH1211 180 Motor w/8T 0.5M Pinion Right<br />

EFLH1213 Outer Shaft & Main Gear Set<br />

EFLH1214 Shaft Retaining Collar Set<br />

EFLH1215 Bearing 4x6x3mm (2)<br />

EFLH1216 Swashplate Set<br />

EFLH1217 Lower Rotor Head & Linkage Set<br />

EFLH1218 Servo Pushrod Set<br />

EFLH1219 Stabilizer Flybar Set<br />

EFLH1220 Lower Main <strong>Blade</strong> Set (2 pair)<br />

EFLH1221 Upper Main <strong>Blade</strong> Set (2 pair)<br />

EFLH1222 Landing Skid Set<br />

EFLH1223 Battery Support Set<br />

EFLH1225 Hardware Set<br />

EFLH1226 Body Mount Rod & Grommet Set<br />

EFLH1242 Inner Shaft w/Head/Hub<br />

EFLH1243 Inner Shaft Main Gear<br />

EFLH1254 Main Frame Set<br />

EFLH1255 Front Body/Canopy<br />

EFLH1256 Rear Body<br />

EFLH1257 Complete Body Set<br />

25<br />

Optional Parts List<br />

EFLH1205 Training Gear Set<br />

EFLH1208 Main Motor Heat Sink<br />

EFLM1913 Heat Sink Compound, 5g<br />

EFLH1227 Front Body, Yellow<br />

EFLH1228 Rear Body, Yellow:<br />

EFLH1229 Complete Body Set, Yellow<br />

EFLH1230 Front Body, Police, Blue<br />

EFLH1231 Rear Body, Police, Blue<br />

EFLH1232 Complete Body Set, Police, Blue<br />

EFLH1240 Inner Shaft w/Aluminum Head/Hub<br />

EFLH1241 Inner Shaft for Aluminum Head/Hub<br />

EFLH1244 Aluminum Bearing Holder w/Bearing<br />

EFLH1245 Aluminum Lower Rotor Head Set<br />

EFLH1246 Aluminum Swashplate Set<br />

EFLH1258 Front Body, Marines w/o Decals<br />

EFLH1259 Rear Body, Marines w/o Decals<br />

EFLH1260 Complete Body Set, Marines w/Decals/Gun/Missiles<br />

EFLH1261 Decal Set, Marines<br />

EFLH1262 Gun and Missile Set<br />

Please see your favorite retailer or visit our web site<br />

(www.E-fliteRC.com) to find the latest in new replacement and<br />

option parts releases for your <strong>Blade</strong> <strong>CX2</strong>.

Exploded View<br />

029<br />

032<br />

038<br />

006<br />

007<br />

008<br />

013<br />

015<br />

017<br />

018<br />

020<br />

021<br />

022<br />

044<br />

040<br />

028<br />

26<br />

027<br />

001<br />

002<br />

003<br />

039<br />

030<br />

031<br />

033<br />

034<br />

035<br />

036<br />

025<br />

026<br />

004<br />

005<br />

009<br />

010<br />

011<br />

012<br />

014<br />

037<br />

016<br />

019<br />

023<br />

041<br />

042<br />

043<br />

024

Exploded View Parts Listing<br />

# Item Description<br />

1 EFLH1219 ........ Stabilizer Flybar Rubber Tip (2)<br />

2 EFLH1219 . . . . . . . . Stabilizer Flybar Weight (2)<br />

3 EFLH1219 . . . . . . . . Stabilizer Flybar (1)<br />

4 EFLH1221 . . . . . . . . Upper Main <strong>Blade</strong> (2)<br />

5 EFLF1225 . . . . . . . . 1.2 x 6mm Screw (5)<br />

6 EFLH1242 . . . . . . . . Stabilizer Flybar Hub/Holder (1)<br />

7 EFLH1242 . . . . . . . . Upper Rotor Head & Inner Shaft (1)<br />

8 EFLH1219 . . . . . . . . Stabilizer Flybar Linkage (1)<br />

9 EFLH1121 . . . . . . . . Bearing 2mm x 6mm x 3mm (2)<br />

10 EFLH1217 . . . . . . . . Bearing Holder (1)<br />

11 EFLH1213 . . . . . . . . Outer Shaft (1)<br />

12 EFLH1217 . . . . . . . . Lower Rotor Head (1)<br />

13 EFLH1225 . . . . . . . . M2 x 2.5mm Screw (5)<br />

14 EFLH1220 . . . . . . . . Lower Main <strong>Blade</strong> (2)<br />

15 EFLH1217 . . . . . . . . Lower Rotor Head/Swash Linkage (2)<br />

16 EFLH 1216 ........ Upper Swashplate (1)<br />

17 EFLH1216 . . . . . . . . Bearing 7mm x 13mm x 4mm (1)<br />

18 EFLH1216 ........ Lower Swashplate (1)<br />

19 EFLH1218 . . . . . . . . Servo Pushrod Control Link (2)<br />

20 EFLH1214 . . . . . . . . Outer Shaft Retaining Collar (1)<br />

21 EFLH1210 . . . . . . . . Main Motor Left (1)<br />

EFLH1211 . . . . . . . . Main Motor Right (1)<br />

22 EFLH1210 . . . . . . . . Pinion Gear Left (1)<br />

EFLH1211 . . . . . . . . Pinion Gear Right (1)<br />

23 EFLH1254 . . . . . . . . Servo Mount (1)<br />

24 EFLH1226 ........ Body Mount Rod (2)<br />

25 EFLRS60 . . . . . . . . . Super Sub-Micro Servo (2)<br />

26 EFLH1225 . . . . . . . . 1.7 x 4mm Screw (8)<br />

27 EFLH1215 . . . . . . . . Bearing 4mm x 8mm x 3mm (2)<br />

28 EFLH1218 . . . . . . . . Servo Pushrod (2)<br />

29 EFLH1024 . . . . . . . . 3-in-1 Control Unit (1)<br />

30 EFLH1254 . . . . . . . . Main Frame (1)<br />

31 EFLH1225 . . . . . . . . M2 x 4mm Screw (6)<br />

32 EFLH1255 . . . . . . . . Front Body (1)<br />

33 EFLH1256 . . . . . . . . Rear Body (1)<br />

34 EFLH1213 . . . . . . . . Outer Shaft Main Gear (1)<br />

35 EFLH1243 . . . . . . . . Inner Shaft Main Gear (1)<br />

36 EFLH1214 . . . . . . . . Inner Shaft Retaining Collar (1)<br />

37 EFLH1223 . . . . . . . . Battery Support Rear (1)<br />

38 EFLH1223 . . . . . . . . Battery Support Front (1)<br />

39 EFLH1223 . . . . . . . . Battery Support Joiner (2)<br />

40 EFLH1226 . . . . . . . . Body Mount Grommet (4)<br />

41 EFLB0990 . . . . . . . . Battery Pack (1)<br />

42 EFLH1222 . . . . . . . . Landing Skid Right (1)<br />

43 EFLH1222 . . . . . . . . Landing Skid Left (1)<br />

44 EFLH1225 . . . . . . . . Step Washer (1)<br />

27

2010 Official Academy of Model Aeronautics Safety Code<br />

GENERAL<br />

1. A model aircraft shall be defined as a non-human carrying device capable of sustained flight in the atmosphere. It shall not<br />

exceed limitations established in this code and is intended to be used exclusively for recreational or competition activity.<br />

2. The maximum takeoff weight of a model aircraft, including fuel, is 55 pounds, except for those flown under the AMA<br />

Experimental Aircraft Rules.<br />

3. I will abide by this Safety Code and all rules established for the flying site I use. I will not willfully fly my model aircraft in a<br />

reckless and/or dangerous manner.<br />

4. I will not fly my model aircraft in sanctioned events, air shows, or model demonstrations until it has been proven airworthy.<br />

5. I will not fly my model aircraft higher than approximately 400 feet above ground level, when within three (3) miles of an airport<br />

without notifying the airport operator. I will yield the right-of-way and avoid flying in the proximity of full-scale aircraft, utilizing a<br />

spotter when appropriate.<br />

6. I will not fly my model aircraft unless it is identified with my name and address, or AMA number, inside or affixed to the outside<br />

of the model aircraft. This does not apply to model aircraft flown indoors.<br />

7. I will not operate model aircraft with metal-blade propellers or with gaseous boosts (other than air), nor will I operate model<br />

aircraft with fuels containing tetranitromethane or hydrazine.<br />

8. I will not operate model aircraft carrying pyrotechnic devices which explode, burn, or propel a projectile of any kind. Exceptions<br />

include Free Flight fuses or devices that burn producing smoke and are securely attached to the model aircraft during flight.<br />

Rocket motors up to a G-series size may be used, provided they remain firmly attached to the model aircraft during flight. Model<br />

rockets may be flown in accordance with the National Model Rocketry Safety Code; however, they may not be launched from<br />

model aircraft. Officially designated AMAAir Show Teams (AST) are authorized to use devices and practices as defined within the<br />

Air Show Advisory Committee Document.<br />

9. I will not operate my model aircraft while under the influence of alcohol or within eight (8) hours of having consumed alcohol.<br />

10. I will not operate my model aircraft while using any drug which could adversely affect my ability to safely control my model<br />

aircraft.<br />

11. Children under six (6) years old are only allowed on a flightline or in a flight area as a pilot or while under flight instruction.<br />

12. When and where required by rule, helmets must be properly worn and fastened. They must be OSHA, DOT, ANSI, SNELL or<br />

NOCSAE approved or comply with comparable standards.<br />

RADIO CONTROL<br />

1. All model flying shall be conducted in a manner to avoid over flight of unprotected people.<br />

2. I will have completed a successful radio equipment ground-range check before the first flight of a new or repaired model<br />

aircraft.<br />

3. I will not fly my model aircraft in the presence of spectators until I become a proficient flier, unless I am assisted by an<br />

experienced pilot.<br />

4. At all flying sites a line must be established, in front of which all flying takes place. Only personnel associated with flying the<br />

model aircraft are allowed at or in front of the line. In the case of airshows demonstrations straight line must be established. An<br />

area away from the line must be maintained for spectators. Intentional flying behind the line is prohibited.<br />

5. I will operate my model aircraft using only radio control frequencies currently allowed by the Federal Communications<br />

Commission (FCC). Only individuals properly licensed by the FCC are authorized to operate equipment on Amateur Band<br />

frequencies.<br />

28

Warranty and Repair Policy<br />

Warranty Period<br />

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties that the Products purchased (the “Product”) will be free from defects in materials<br />

and workmanship at the date of purchase by the Purchaser.<br />

Limited Warranty<br />

Horizon reserves the right to change or modify this warranty without notice and disclaims all other warranties, express or<br />

implied.<br />

(a) This warranty is limited to the original Purchaser (“Purchaser”) and is not transferable. REPAIR OR REPLACEMENT AS PROVIDED UNDER<br />

THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This warranty covers only those Products purchased from an authorized<br />

Horizon dealer. Third party transactions are not covered by this warranty. Proof of purchase is required for all warranty claims.<br />

(b) Limitations- HORIZON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANT-<br />

ABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE<br />

DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.<br />

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall be that Horizon will, at its option, (i) repair or (ii) replace, any Product<br />

determined by Horizon to be defective. In the event of a defect, these are the Purchaser’s exclusive remedies. Horizon reserves the right to<br />

inspect any and all equipment involved in a warranty claim. Repair or replacement decisions are at the sole discretion of Horizon. This warranty<br />

does not cover cosmetic damage or damage due to acts of God, accident, misuse, abuse, negligence, commercial use, or modification<br />

of or to any part of the Product. This warranty does not cover damage due to improper installation, operation, maintenance, or attempted<br />

repair by anyone other than Horizon. Return of any Product by Purchaser must be approved in writing by Horizon before shipment.<br />

Damage Limits<br />

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COM-<br />

MERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCT, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLI-<br />

GENCE, OR STRICT LIABILITY. Further, in no event shall the liability of Horizon exceed the individual price of the Product on which liability is<br />

asserted. As Horizon has no control over use, setup, final assembly, modification or misuse, no liability shall be assumed nor accepted for<br />

any resulting damage or injury. By the act of use, setup or assembly, the user accepts all resulting liability.<br />

If you as the Purchaser or user are not prepared to accept the liability associated with the use of this Product, you are advised to return<br />

this Product immediately in new and unused condition to the place of purchase.<br />

Law: These Terms are governed by Illinois law (without regard to conflict of law principals).<br />

Warranty Services<br />

Questions, Assistance, and Repairs<br />

Your local hobby store and/or place of purchase cannot provide warranty support or repair. Once assembly, setup or use of the Product<br />

has been started, you must contact Horizon directly. This will enable Horizon to better answer your questions and service you in the event<br />

that you may need any assistance. For questions or assistance, please direct your email to productsupport@horizonhobby.com, or call<br />

877.504.0233 toll free to speak to a Product Support representative. You may also find information on our website at www.horizonhobby.<br />

com.<br />

Inspection or Repairs<br />

If this Product needs to be inspected or repaired, please use the Horizon Online Repair Request submission process found on our website<br />

or call Horizon to obtain a Return Merchandise Authorization (RMA) number. Pack the Product securely using a shipping carton. Please<br />

Note that original boxes may be included, but are not designed to withstand the rigors of shipping without additional protection. Ship via a<br />

carrier that provides tracking and insurance for lost or damaged parcels, as Horizon is not responsible for merchandise until it arrives and<br />

is accepted at our facility. An Online Repair Request is available at www.horizonhobby.com http://www.horizonhobby.com under the Repairs<br />

tab. If you do not have internet access, please contact Horizon Product Support to obtain a RMA number along with instructions for submitting<br />

your product for repair. When calling Horizon, you will be asked to provide your complete name, street address, email address and<br />

phone number where you can be reached during business hours. When sending product into Horizon, please include your RMA number, a<br />

list of the included items, and a brief summary of the problem. A copy of your original sales receipt must be included for warranty consideration.<br />

Be sure your name, address, and RMA number are clearly written on the outside of the shipping carton.<br />

Notice: Do not ship batteries to Horizon. If you have any issue with a battery, please contact the appropriate Horizon Product<br />

Support office.<br />

Warranty Inspection and Repairs<br />

To receive warranty service, you must include your original sales receipt verifying the proof-of-purchase date. Provided warranty<br />

conditions have been met, your Product will be repaired or replaced free of charge. Repair or replacement decisions are at the sole discretion<br />

of Horizon.<br />

Non-Warranty Repairs<br />

Should your repair not be covered by warranty the repair will be completed and payment will be required without notification<br />

or estimate of the expense unless the expense exceeds 50% of the retail purchase cost. By submitting the item for repair<br />

you are agreeing to payment of the repair without notification. Repair estimates are available upon request. You must include this request<br />

with your repair. Non-warranty repair estimates will be billed a minimum of ½ hour of labor. In addition you will be billed for return freight.<br />

Horizon accepts money orders and cashiers checks, as well as Visa, MasterCard, American Express, and Discover cards. By submitting any<br />

item to Horizon for inspection or repair, you are agreeing to Horizon’s Terms and Conditions found on our website under the Repairs tab.<br />

29

Contact Information<br />

Country of Purchase Horizon Hobby Address Phone Number / Email Address<br />

United States of<br />

America<br />

Parts Information<br />

Horizon Service Center<br />

(Electronics and engines)<br />

Horizon Product Support<br />

(All other products)<br />

United Kingdom Horizon Hobby Limited<br />

Germany Horizon Technischer Service<br />

France Horizon Hobby SAS<br />

Compliance Information for the European Union<br />

4105 Fieldstone Rd<br />

Champaign, Illinois, 61822 USA<br />

4105 Fieldstone Rd<br />

Champaign, Illinois, 61822 USA<br />

Units 1-4 Ployters Rd<br />

Staple Tye<br />

Harlow, Essex<br />

CM18 7NS, United Kingdom<br />

Hamburger Str. 10<br />

25335 Elmshorn, Germany<br />

14 Rue Gustave Eiffel<br />

Zone d’Activité du Réveil Matin<br />

91230 Montgeron<br />

30<br />

877-504-0233<br />

Online Repair Request:<br />

visit www.horizonhobby.com/repairs<br />

877-504-0233<br />

productsupport@horizonhobby.com<br />

+44 (0) 1279 641 097<br />

sales@horizonhobby.co.uk<br />

+49 4121 46199 66<br />

service@horizonhobby.de<br />