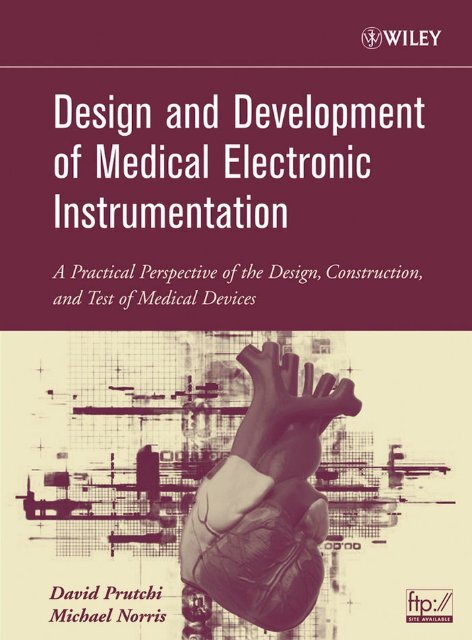

DESIGN AND DEVELOPMENT OF MEDICAL ELECTRONIC ...

DESIGN AND DEVELOPMENT OF MEDICAL ELECTRONIC ...

DESIGN AND DEVELOPMENT OF MEDICAL ELECTRONIC ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>DESIGN</strong> <strong>AND</strong> <strong>DEVELOPMENT</strong><strong>OF</strong> <strong>MEDICAL</strong> <strong>ELECTRONIC</strong>INSTRUMENTATION

<strong>DESIGN</strong> <strong>AND</strong> <strong>DEVELOPMENT</strong><strong>OF</strong> <strong>MEDICAL</strong> <strong>ELECTRONIC</strong>INSTRUMENTATIONA Practical Perspective of the Design, Construction,and Test of Medical DevicesDAVID PRUTCHIMICHAEL NORRIS

Copyright © 2005 by John Wiley & Sons, Inc. All rights reserved.Published by John Wiley & Sons, Inc., Hoboken, New Jersey.Published simultaneously in Canada.No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or byany means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permittedunder Section 107 or 108 of the 1976 United States Copyright Act, without either the prior writtenpermission of the Publisher, or authorization through payment of the appropriate per-copy fee to theCopyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, 978-750-8400, fax 978-646-8600, or on the web at www.copyright.com. Requests to the Publisher for permission should be addressedto the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008.Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts inpreparing this book, they make no representations or warranties with respect to the accuracy orcompleteness of the contents of this book and specifically disclaim any implied warranties ofmerchantability or fitness for a particular purpose. No warranty may be created or extended by salesrepresentatives or written sales materials. The advice and strategies contained herein may not be suitablefor your situation. You should consult with a professional where appropriate. Neither the publisher norauthor shall be liable for any loss of profit or any other commercial damages, including but not limited tospecial, incidental, consequential, or other damages.For general information on our other products and services please contact our Customer Care Departmentwithin the U.S. at 877-762-2974, outside the U.S. at 317-572-3993 or fax 317-572-4002.Wiley also publishes its books in a variety of electronic formats. Some content that appears in print, however,may not be available in electronic format.Library of Congress Cataloging-in-Publication Data:Prutchi, David.Design and development of medical electronic instrumentation: a practical perspective ofthe design, construction, and test of material devices / David Prutchi, Michael Norris.p. cm.Includes bibliographical references and index.ISBN 0-471-67623-3 (cloth)1. Medical instruments and apparatus–Design and construction. I. Norris, Michael. II.Title.R856.P78 2004681’.761–dc222004040853Printed in the United States of America10 9 8 7 6 5 4 3 2 1

In memory of Prof. Mircea Arcan,who was a caring teacher, a true friend,and a most compassionate human being.—David

CONTENTSPREFACEDISCLAIMERABOUT THE AUTHORSixxiiixv1 BIOPOTENTIAL AMPLIFIERS 12 B<strong>AND</strong>PASS SELECTION FOR BIOPOTENTIAL AMPLIFIERS 413 <strong>DESIGN</strong> <strong>OF</strong> SAFE <strong>MEDICAL</strong> DEVICE PROTOTYPES 974 ELECTROMAGNETIC COMPATIBILITY <strong>AND</strong><strong>MEDICAL</strong> DEVICES 1475 SIGNAL CONDITIONING, DATA ACQUISITION,<strong>AND</strong> SPECTRAL ANALYSIS 2056 SIGNAL SOURCES FOR SIMULATION, TESTING,<strong>AND</strong> CALIBRATION 2497 STIMULATION <strong>OF</strong> EXCITABLE TISSUES 3058 CARDIAC PACING <strong>AND</strong> DEFIBRILLATION 369EPILOGUE 441APPENDIX A: SOURCES FOR MATERIALS <strong>AND</strong> COMPONENTS 447APPENDIX B: ACCOMPANYING CD-ROM CONTENT 451INDEX 457vii

PREFACEThe medical devices industry is booming. Growth in the industry has not stopped despiteglobally fluctuating economies. The main reason for this success is probably the self-sustainingnature of health care. In essence, the same technology that makes it possible forpeople to live longer engenders the need for more health-care technologies to enhance thequality of an extended lifetime. It comes as no surprise, then, that the demand for trainedmedical-device designers has increased tremendously over the past few years. Unfortunately,college courses and textbooks most often provide only a cursory view of the technologybehind medical instrumentation. This book supplements the existing literature byproviding background and examples of how medical instrumentation is actually designedand tested. Rather than delve into deep theoretical considerations, the book will walk youthrough the various practical aspects of implementing medical devices.The projects presented in the book are truly unique. College-level books in the field ofbiomedical instrumentation present block-diagram views of equipment, and high-levelhobby books restrict their scope to science-fair projects. In contrast, this book will helpyou discover the challenge and secrets of building practical electronic medical devices,giving you basic, tested blocks for the design and development of new instrumentation.The projects range from simple biopotential amplifiers all the way to a computer-controlleddefibrillator. The circuits actually work, and the schematics are completely readable.The project descriptions are targeted to an audience that has an understanding ofcircuit design as well as experience in electronic prototype construction. You will understandall of the math if you are an electrical engineer who still remembers Laplace transforms,electromagnetic fields, and programming. However, the tested modular circuits andsoftware are easy to combine into practical instrumentation even if you look at them as“black boxes” without digging into their theoretical basis. We will also assume that youhave basic knowledge of physiology, especially how electrically excitable cells work, aswell as how the aggregate activities of many excitable cells result in the various biopotentialsignals that can be detected from the body. For a primer (or a refresher), we recommendreading Chapters 6 and 7 of Intermediate Physics for Medicine and Biology, 3rd ed.,by Russell K. Hobbie (1997).Whether you are a student, hobbyist, or practicing engineer, this book will show youhow easy it is to get involved in the booming biomedical industry by building sophisticatedinstruments at a small fraction of the comparable commercial cost.ix

xPREFACEThe book addresses the practical aspects of amplifying, processing, simulating, andevoking these biopotentials. In addition, in two chapters we address the issue of safety inthe development of electronic medical devices, bypassing the difficult math and providinglots of insider advice.In Chapter 1 we present the development of amplifiers designed specifically for thedetection of biopotential signals. A refresher on op-amp-based amplifiers is presented in thecontext of the amplification of biopotentials. Projects for this chapter include chloriding silverelectrodes, high-impedance electrode buffer array, pasteless bioelectrode, single-endedelectrocardiographic (ECG) amplifier array, body potential driver, differential biopotentialamplifier, instrumentation-amplifier biopotential amplifier, and switched-capacitor surfacearray electromyographic amplifier.In Chapter 2 we look at the frequency content of various biopotential signals and discussthe need for filtering and the basics of selecting and designing RC filters, active filters, notchfilters, and specialized filters for biopotential signals. Projects include a dc-coupled biopotentialamplifier with automatic offset cancellation, biopotential amplifier with dc rejection,ac-coupled biopotential amplifier front end, bootstrapped ac-coupled biopotential amplifier,biopotential amplifier with selectable RC bandpass filters, state-variable filter with tunablecutoff frequency, twin-T notch filter, gyrator notch filter, universal harmonic eliminatornotch comb filter, basic switched-capacitor filters, slew-rate limiter, ECG amplifier withpacemaker spike detection, “scratch and rumble” filter for ECG, and an intracardiac electrogramevoked-potential amplifier.In Chapter 3 we introduce safety considerations in the design of medical device prototypes.We include a survey of applicable standards and a discussion on mitigating the dangersof electrical shock. We also look at the way in which equipment should be tested forcompliance with safety standards. Projects include the design of an isolated biopotentialamplifier, transformer-coupled analog isolator module, carrier-based optically coupled analogisolator, linear optically coupled analog isolator with compensation, isolated eight-channel12-bit analog-to-digital converter, isolated analog-signal multiplexer, ground bondintegrity tester, microammeter for safety testing, and basic high-potential tester.In Chapter 4 we discuss international regulations regarding electromagnetic compatibilityand medical devices. This includes mechanisms of emission of and immunity againstradiated and conducted electromagnetic disturbances as well as design practices for electromagneticcompatibility. Projects include a radio-frequency spectrum analyzer, near-fieldH-field and E-field probes, comb generator, conducted emissions probe, line impedance stabilizationnetwork, electrostatic discharge simulators, conducted-disturbance generator,magnetic field generator, and wideband transmitter for susceptibility testing.In Chapter 5 we present the new breed of “smart” sensors that can be used to detectphysiological signals with minimal design effort. We discuss analog-to-digital conversionof physiological signals as well as methods for high-resolution spectral analysis. Projectsinclude a universal sensor interface, sensor signal conditioners, using the PC sound card asa data acquisition card, voltage-controlled oscillator for dc-correct signal acquisitionthrough a sound card, as well as fast Fourier transform and high-resolution spectral estimationsoftware.In Chapter 6 we discuss the need for artificial signal sources in medical equipmentdesign and testing. The chapter covers the basics of digital signal synthesis, arbitrary signalgeneration, and volume conductor experiments. Projects include a general-purpose signalgenerator, direct-digital-synthesis sine generator, two-channel digital arbitrary waveformgenerator, multichannel analog arbitrary signal source, cardiac simulator for pacemakertesting, and how to perform volume-conductor experiments with a voltage-to-current converterand physical models of the body.In Chapter 7 we look at the principles and clinical applications of electrical stimulationof excitable tissues. Projects include the design of stimulation circuits for implantable

PREFACExipulse generators, fabrication of implantable stimulation electrodes, external neuromuscularstimulator, TENS device for pain relief, and transcutaneous/transcranial pulsed-magneticneural stimulator.In Chapter 8 we discuss the principles of cardiac pacing and defibrillation, providing abasic review of the electrophysiology of the heart, especially its conduction deficienciesand arrhythmias. Projects include a demonstration implantable pacemaker, external cardiacpacemaker, impedance plethysmograph, intracardiac impedance sensor, externaldefibrillator, intracardiac defibrillation shock box, and cardiac fibrillator.The Epilogue is an engineer’s perspective on bringing a medical device to market. Theregulatory path, Food and Drug Administration (FDA) classification of medical devices,and process of submitting applications to the FDA are discussed and we look at the valueof patents and how to recruit venture capital.Finally, in Appendix A we provide addresses, Web sites, telephone numbers, and faxnumbers for suppliers of components used in the projects described in the book. The contentsof the book’s ftp site, which contains software and information used for many ofthese projects, is given in Appendix B.DAVID PRUTCHIMICHAEL NORRIS

DISCLAIMERThe projects in this book are presented solely as examples of engineering building blocksused in the design of experimental electromedical devices. The construction of any and allexperimental systems must be supervised by an engineer experienced and skilled withrespect to such subject matter and materials, who will assume full responsibility for thesafe and ethical use of such systems.The authors do not suggest that the circuits and software presented herein can orshould be used by the reader or anyone else to acquire or process signals from, or stimulatethe living tissues of, human subjects or experimental animals. Neither do theauthors suggest that they can or should be used in place of or as an adjunct to professionalmedical treatment or advice. Sole responsibility for the use of these circuitsand/or software or of systems incorporating these circuits and/or software lies with thereader, who must apply for any and all approvals and certifications that the law mayrequire for their use. Furthermore, safe operation of these circuits requires the use of isolatedpower supplies, and connection to external signal acquisition/processing/monitoringequipment should be done only through signal isolators with the proper isolationratings.The authors and publisher do not make any representations as to the completeness oraccuracy of the information contained herein, and disclaim any liability for damage orinjuries, whether caused by or arising from a lack of completeness, inaccuracy of information,misinterpretation of directions, misapplication of circuits and information, or otherwise.The authors and publisher expressly disclaim any implied warranties ofmerchantability and of fitness of use for any particular purpose, even if a particularpurpose is indicated in the book.References to manufacturers’ products made in this book do not constitute anendorsement of these products but are included for the purpose of illustration and clarification.It is not the authors’ intent that any technical information and interface datapresented in this book supersede information provided by individual manufacturers. Inthe same way, various government and industry standards cited in the book are includedsolely for the purpose of reference and should not be used as a basis for design ortesting.Since some of the equipment and circuitry described in this book may relate to or becovered by U.S. or other patents, the authors disclaim any liability for the infringement ofxiii

xivDISCLAIMERsuch patents by the making, using, or selling of such equipment or circuitry, and suggestthat anyone interested in such projects seek proper legal counsel.Finally, the authors and publisher are not responsible to the reader or third parties for anyclaim of special or consequential damages, in accordance with the foregoing disclaimer.

ABOUT THE AUTHORSDavid Prutchi is Vice President of Engineering at Impulse Dynamics, where he is responsiblefor the development of implantable devices intended to treat congestive heart failure,obesity, and diabetes. His prior experience includes the development of Sulzer-Intermedics’ next-generation cardiac pacemaker, as well as a number of other industrialand academic positions conducting biomedical R&D and developing medical electronicinstrumentation. David Prutchi holds a Ph.D. in biomedical engineering from Tel-AvivUniversity and conducted postdoctoral research at Washington University, where he taughta graduate course in neuroelectric systems. Dr. Prutchi has over 40 technical publicationsand in excess of 60 patents in the field of active implantable medical devices.Michael Norris is a Senior Electronics Engineer at Impulse Dynamics, where he has developedmany cardiac stimulation devices, cardiac contractility sensors, and physiological signalacquisition systems. His 25 years of experience in electronics include the developmentof cardiac stimulation prototype devices at Sulzer-Intermedics as well as the design, construction,and deployment of telemetric power monitoring systems at Nabla Inc. in Houston,and instrumentation and controls at General Electric. Michael Norris has authored varioustechnical publications and holds patents related to medical instrumentation.xv

1BIOPOTENTIAL AMPLIFIERSIn general, signals resulting from physiological activity have very small amplitudes andmust therefore be amplified before their processing and display can be accomplished. Thespecifications and lists of characteristics of biopotential amplifiers can be as long and confusingas those for any other amplifier. However, for most typical medical applications, themost relevant amplifier characterizing parameters are the seven described below.1. Gain. The signals resulting from electrophysiological activity usually have amplitudes onthe order of a few microvolts to a few millivolts. The voltage of such signals must be amplifiedto levels suitable for driving display and recording equipment. Thus, most biopotentialamplifiers must have gains of 1000 or greater. Most often the gain of an amplifier is measuredin decibels (dB). Linear gain can be translated into its decibel form through the use ofGain(dB) 20 log 10 (linear gain)2. Frequency response. The frequency bandwidth of a biopotential amplifier should besuch as to amplify, without attenuation, all frequencies present in the electrophysiologicalsignal of interest. The bandwidth of any amplifier, as shown in Figure 1.1, is the differencebetween the upper cutoff frequency f 2 and the lower cutoff frequency f 1 . The gain at thesecutoff frequencies is 0.707 of the gain in the midfrequency plateau. If the percentile gainis normalized to that of the midfrequency gain, the gain at the cutoff frequencies hasdecreased to 70.7%. The cutoff points are also referred to as the half-power points, due tothe fact that at 70.7% of the signal the power will be (0.707) 2 0.5. These are also knownas the 3-dB points, since the gain at the cutoff points is lower by 3 dB than the gain inthe midfrequency plateau: 3dB 20 log 10 (0.707).3. Common-mode rejection. The human body is a good conductor and thus will act asan antenna to pick up electromagnetic radiation present in the environment. As shown inFigure 1.2, one common type of electromagnetic radiation is the 50/60-Hz wave and itsharmonics coming from the power line and radiated by power cords. In addition, otherspectral components are added by fluorescent lighting, electrical machinery, computers,Design and Development of Medical Electronic Instrumentation By David Prutchi and Michael NorrisISBN 0-471-67623-3 Copyright © 2005 John Wiley & Sons, Inc.1

2 BIOPOTENTIAL AMPLIFIERSGainG70.7%G0f1 f 2Figure 1.1 Frequency response of a biopotential amplifier.Frequency(Hz)Power LinesBiopot entialAmplifierFigure 1.2EarthCoupling of power line interference to a biopotential recording setup.and so on. The resulting interference on a single-ended bioelectrode is so large that it oftenobscures the underlying electrophysiological signals.The common-mode rejection ratio (CMRR) of a biopotential amplifier is measurementof its capability to reject common-mode signals (e.g., power line interference), and it isdefined as the ratio between the amplitude of the common-mode signal to the amplitude ofan equivalent differential signal (the biopotential signal under investigation) that wouldproduce the same output from the amplifier. Common-mode rejection is often expressed indecibels according to the relationshipCommon-mode rejection (CMR) (dB) 20 log 10 CMRR

BIOPOTENTIAL AMPLIFIERS 34. Noise and drift. Noise and drift are additional unwanted signals that contaminate abiopotential signal under measurement. Both noise and drift are generated within theamplifier circuitry. The former generally refers to undesirable signals with spectralcomponents above 0.1 Hz, while the latter generally refers to slow changes in the baselineat frequencies below 0.1 Hz.The noise produced within amplifier circuitry is usually measured either in microvoltspeak to peak (µV p-p ) or microvolts root mean square (RMS) (µV RMS ), and applies as if itwere a differential input voltage. Drift is usually measured, as noise is measured, in microvoltsand again, applies as if it were a differential input voltage. Because of its intrinsic lowfrequencycharacter, drift is most often described as peak-to-peak variation of the baseline.5. Recovery. Certain conditions, such as high offset voltages at the electrodes caused bymovement, stimulation currents, defibrillation pulses, and so on, cause transient interruptionsof operation in a biopotential amplifier. This is due to saturation of the amplifiercaused by high-amplitude input transient signals. The amplifier remains in saturation for afinite period of time and then drifts back to the original baseline. The time required for thereturn of normal operational conditions of the biopotential amplifier after the end of thesaturating stimulus is known as recovery time.6. Input impedance. The input impedance of a biopotential amplifier must besufficiently high so as not to attenuate considerably the electrophysiological signal undermeasurement. Figure 1.3a presents the general case for the recording of biopotentials.Each electrode–tissue interface has a finite impedance that depends on many factors, suchas the type of interface layer (e.g., fat, prepared or unprepared skin), area of electrode surface,or temperature of the electrolyte interface.In Figure 1.3b, the electrode–tissue has been replaced by an equivalent resistance network.This is an oversimplification, especially because the electrode–tissue interface is notmerely a resistive impedance but has very important reactive components. A more correctrepresentation of the situation is presented in Figure 1.3c, where the final signal recorded asthe output of a biopotential amplifier is the result of a series of transformations among theparameters of voltage, impedance, and current at each stage of the signal transfer. As shownin the figure, the electrophysiological activity is a current source that causes current flow i ein the extracellular fluid and other conductive paths through the tissue. As these extracellularcurrents act against the small but nonzero resistance of the extracellular fluids R e , theyproduce a potential V e , which in turn induces a small current flow i in in the circuit made upof the reactive impedance of the electrode surface X Ce and the mostly resistive impedanceof the amplifier Z in . After amplification in the first stage, the currents from each of the bipolarcontacts produce voltage drops across input resistors R in in the summing amplifier,where their difference is computed and amplified to finally produce an output voltage V out .The skin between the potential source and the electrode can be modeled as a seriesimpedance, split between the outer (epidermis) and the inner (dermis) layers. The outerlayer of the epidermis—the stratum corneum—consists primarily of dead, dried-up cellswhich have a high resistance and capacitance. For a 1-cm 2 area, the impedance of the stratumcorneum varies from 200 kΩ at 1 Hz down to 200 Ω at 1 MHz. Mechanical abrasionwill reduce skin resistance to between 1 and 10 kΩ at 1 Hz.7. Electrode polarization. Electrodes are usually made of metal and are in contact withan electrolyte, which may be electrode paste or simply perspiration under the electrode.Ion–electron exchange occurs between the electrode and the electrolyte, which results involtage known as the half-cell potential. The front end of a biopotential amplifier must beable to deal with extremely weak signals in the presence of such dc polarization components.These dc potentials must be considered in the selection of a biopotential amplifier gain, sincethey can saturate the amplifier, preventing the detection of low-level ac components.International standards regulating the specific performance of biopotential recording systems

4 BIOPOTENTIAL AMPLIFIERSVolumeConductor(Tissue)CurrentfromSourcesVinRinOutputBiopotentialSourceCurrenttoSourcesElectrodeElectrode-TissueInterfaceBiopotentialAmplifier(a)RinterfaceiinBiopotentialSourceVinRinOutputRinterfaceTissue(b)TissueXceiinXinBiopotentialSourceRinReVeElectrodeTissueInterfaceVinXinRinOutputVoutFigure 1.3Xce(c)BiopotentialAmplifier(a) Simplified view of the recording of biopotentials; (b) equivalent circuit; (c) generalized equivalent circuit.

LOW-POLARIZATION SURFACE ELECTRODES 5usually specify the electrode offsets that are commonly present for the application coveredby the standard. For example, the standards issued by the Association for the Advancementof Medical Instrumentation (AAMI) specify that electrocardiography (ECG) amplifiers musttolerate a dc component of up to 300 mV resulting from electrode–skin contact.Commercial ECG electrodes have electrode offsets that are usually low enough, ensuringlittle danger of exceeding the maximum allowable dc input offset specifications of thestandards. However, the design of a biopotential amplifier must consider that there aretimes when the dc offset may be much larger. For example, neonatal ECG monitoringapplications often use sets of stainless-steel needle electrodes, whose offsets are muchhigher than those of commercial self-adhesive surface ECG electrodes. In addition, manyphysicians still prefer to use nondisposable suction cup electrodes (which have a rubbersqueeze bulb attached to a silver-plated brass hemispherical cup). After the silver platingwears off, these brass cup electrodes can introduce very large offsets.LOW-POLARIZATION SURFACE ELECTRODESSilver (Ag) is a good choice for metallic skin-surface electrodes because silver forms aslightly soluble salt, silver chloride (AgCl), which quickly saturates and comes to equilibrium.A cup-shaped electrode provides enough volume to contain an electrolyte, includingchlorine ions. In these electrodes, the skin never touches the electrode material directly.Rather, the interface is through an ionic solution.One simple method to fabricate Ag/AgCl electrodes is to use electrolysis to chloride asilver base electrode (e.g., a small silver disk or silver wire). The silver substrate isimmersed in a chlorine-ion-rich solution, and electrolysis is performed using a common 9-V battery connected via a series 10-kΩ potentiometer and a milliammeter. The positive terminalof the battery should be connected to the silver metal, and a plate of platinum or silvershould be connected to the negative terminal and used as the opposite electrode in the solution.Our favorite electrolyte is prepared by mixing 1 part distilled water (the supermarketkind is okay), 1/2 part HCl 25%, and FeCl 3 at a rate of 0.5 g per milliliter of water.If you want to make your own electrodes, use refined silver metal (99.9 to 99.99% Ag)to make the base electrode. Before chloriding, degrease and clean the silver using a concentratedaqueous ammonia solution (10 to 25%). Leave the electrodes immersed in thecleaning solution for several hours until all traces of tarnish are gone. Rinse thoroughlywith deionized water (supermarket distilled water is okay) and blot-dry with clean filterpaper. Don’t touch the electrode surface with bare hands after cleaning. Suspend the electrodesin a suitably sized glass container so that they don’t touch the sides or bottom. Pourthe electrolyte into the container until the electrodes are covered, but be careful not toimmerse the solder connections or leads that you will use to hook up to the electrode.When the silver metal is immersed, the silver oxidation reaction with concomitant silverchloride precipitation occurs and the current jumps to its maximal value. As the thicknessof the AgCl layer deposited increases, the reaction rate decreases and the currentdrops. This process continues, and the current approaches zero. Adjust the potentiometerto get an initial current density of about 2.5 mA/cm 2 , making sure that no hydrogen bubblesevolve at the return electrode (large platinum or silver plate). You should remove theelectrode from the solution once the current density drops to about 10 µA/cm 2 . Coatingshould take no more than 15 to 20 minutes. Once done, remove the electrodes and rinsethem thoroughly but carefully under running (tap) water.An alternative to the electrolysis method is to immerse the silver electrode in a strong bleachsolution. Yet another way of making a Ag/AgCl electrode is to coat by dipping the silver metalin molten silver chloride. To do so, heat AgCl in a small ceramic crucible with a gas flame untilit melts to a dark brown liquid, then simply dip the electrode in the molten silver chloride.

6 BIOPOTENTIAL AMPLIFIERSWarning! The materials used to form Ag/AgCl electrodes are relatively dangerous.Do not breathe dust or mist and do not get in eyes, on skin, or on clothing. When workingwith these materials, safety goggles must be worn. Contact lenses are not protectivedevices. Appropriate eye and face protection must be worn instead of, or in conjunctionwith, contact lenses. Wear disposable protective clothing to prevent exposure. Protectiveclothing includes lab coat and apron, flame- and chemical-resistant coveralls, gloves, andboots to prevent skin contact. Follow good hygiene and housekeeping practices whenworking with these materials. Do not eat, drink, or smoke while working with them.Wash hands before eating, drinking, smoking, or applying cosmetics.If you don’t want to fabricate your own electrodes, you can buy all sorts of very stableAg/AgCl electrodes from In Vivo Metric. They make them using a very fine grained homogeneousmixture of silver and silver chloride powder, which is then compressed and sinteredinto various configurations. Alternatively, Ag/AgCl electrodes are cheap enough thatyou may get a few pregelled disposable electrodes free just by asking at the nurse’s stationin the emergency department or cardiology service of your local hospital.Recording gel is available at medical supply stores (also from In Vivo Metric). However,if you really want a home brew, heat some sodium alginate (pure seaweed, commonly usedto thicken food) and water with low-sodium salt (e.g., Morton Lite Salt) into a thick soupthat when cooled can be applied between the electrodes and skin. Note that there is no guaranteethat this concoction will be hypoallergenic! A milder paste can be made by dissolving0.9 g of pure NaCl in 100 mL of deionized water. Add 2 g of pharmaceutical-gradeKaraya gum and agitate in a magnetic stirrer for 2 hours. Add 0.09 g of methyl paraben and0.045 g of propyl paraben as preservatives and keep in a clean capped container.SINGLE-ENDED BIOPOTENTIAL AMPLIFIERSMost biopotential amplifiers are operational-amplifier-based circuits. As a refresher, thevoltage present at the output of the operational amplifier is proportional to the differentialvoltage across its inputs. Thus, the noninverting input produces an in-phase output signal,while the inverting input produces an output signal that is 180 out of phase with the input.In the circuit of Figure 1.4, an input signal V in is presented through resistor R in to theinverting input of an ideal operational amplifier. Resistor R f provides feedback from theamplifier’s output to its inverting input. The noninverting input is grounded, and due to thefact that in an ideal op-amp the setting conditions at one input will effectively set the sameconditions at the other input, point A can be treated as it were also grounded. The powerconnections have been deleted for the sake of simplicity.Ideal op-amps have an infinite input impedance, which implies that the input currenti in is zero. The inverting input will neither sink nor source any current. According toKirchhoff’s current law, the total current at junction A must sum to zero. Hence, i in i fBut by Ohm’s law, the currents are defined byandini in V Rinouti f V Rf

SINGLE-ENDED BIOPOTENTIAL AMPLIFIERS 7IfRfIinRinA-+-VCCVin+VCCVoutFigure 1.4Inverting voltage amplifier.Therefore, by substitution and by solving for V out ,This equation can be rewritten asf VinV out R RinV out GV inwhere G represents the voltage gain constant R f /R in .The circuit presented in Figure 1.5 is a noninverting voltage amplifier, also known as anoninverting follower, which can be analyzed in a similar manner. The setting of the noninvertinginput at input voltage V in will force the same potential at point A. Thus,i in V Randi f V out V inRfBut in the noninverting amplifier i in i out , so by replacing and solving for V out , we obtainV out 1 RfR V inThe voltage gain in this case isinininRfG 1 RA special case of this configuration is shown in Figure 1.6. Here R f 0, and R in is unnecessary,which leads to a resistance ratio R f /R in 0, which in turn results in unity gain.This configuration, termed a unity-gain buffer or voltage follower, is often used in biomedicalinstrumentation to couple a high-impedance signal source, through the (almost)infinite input impedance of the op-amp, to a low-impedance processing circuit connectedto the very low impedance output of the op-amp.in

8 BIOPOTENTIAL AMPLIFIERSIfRf-VccRinIinA-++VccVoutVinFigure 1.5Noninverting op-amp voltage amplifier; also known as a noninverting follower.-VCC-+Vin+VCCVoutFigure 1.6 A unity-gain buffer is a special case of the noninverting voltage amplifier in which theresistance ratio is R f /R in 0, which translates into unity gain. This configuration is often used in biomedicalinstrumentation to buffer a high-impedance signal source.ULTRAHIGH-IMPEDANCE ELECTRODE BUFFER ARRAYSA group of ultrahigh-impedance, low-power, low-noise op-amp voltage followers is commonlyused as a buffer for signals collected from biopotential electrode arrays. Thesecircuits are usually placed in close proximity to the subject or preparation to avoid contaminationand degradation of biopotential signals. The circuit of Figure 1.7 comprises 32 unity-gain

ULTRAHIGH-IMPEDANCE ELECTRODE BUFFER ARRAYS 9+VIN-1IN-2GuardRingGuardRing45+6-11-V43+2-11ICxB7TLC27L4ICxA1TLC27L4OUT-1OUT-2J1-1J1-2J1-3J1-4J1-5J1-6J1-7J1-8J1-9J1-10J1-11J1-12J1-13J1-14J1-15J1-16In1In2In3In4In1In2In3In4In1In2In3In4In1In2In3In4IC1IC2IC3IC4Out1Out2Out3Out4Out1Out2Out3Out4Out1Out2Out3Out4Out1Out2Out3Out4J2-34J2-1J2-33J2-2J2-32J2-3J2-31J2-4J2-30J2-5J2-29J2-6J2-29J2-7J2-27J2-8IN-3GuardRing412+13-11ICxD14TLC27L4OUT-3J1-17J1-18J1-19J1-20J1-21J1-22J1-23J1-24In1In2In3In4In1In2In3In4IC5IC6Out1Out2Out3Out4Out1Out2Out3Out4J2-26J2-9J2-25J2-10J2-24J2-11J2-23J2-12IN-4GuardRing410+9-11ICxC8TLC27L4OUT-4J1-25J1-26J1-27J1-28J1-29J1-30J1-31J1-32In1In2In3In4In1In2In3In4IC7IC8Out1Out2Out3Out4Out1Out2Out3Out4J2-22J2-13J2-21J2-14J2-20J2-15J2-19J2-16Figure 1.7 CMOS-input unity-gain buffers are often placed in close proximity to high-impedance electrodes to provide impedance conversion,making it possible to transmit the signal over relatively long distances without picking up noise, despite the fact that the contactimpedance of the electrodes may range into the thousands of megohms.buffers, which present an ultrahigh input impedance to an array of up to 32 electrodes. Eachbuffer in the array is implemented using a LinCMOS 1 precision op-amp operated as a unitygainvoltage follower. An output signal has the same amplitude as that of its correspondinginput. The output impedance is very low, however (in the few kilohm range) and can source orsink a maximum of 25 mA. As a result of this impedance transformation, the signal at thebuffer’s output can be transmitted over long distances without picking up noise, despite the factthat the contact impedance of the electrodes may range into the thousands of megohms. Powerfor the circuit must be symmetrical 3 to 9 V dc with real or virtual ground.In the circuit, input signals at J1 are buffered by eight TLC27L4 precision quad op-amp.The buffered output is available at J2. Despite its apparent simplicity, the circuit must be1 LinCMOS is a trademark of Texas Instruments Incorporated.

10 BIOPOTENTIAL AMPLIFIERSFigure 1.8 Printed circuit board for a high-input-impedance buffer array. The output of each channelis used to drive guard rings which form low-impedance isopotential barriers that shield all inputpaths from leakage currents.laid out and constructed with care to take advantage of the op-amp’s high input impedance.As shown in the PCB layout of Figure 1.8, the output of each channel is used to drive guardrings that form low-impedance isopotential barriers that shield all input paths from leakagecurrents.The selection of op-amps from the TLC27 family has the additional advantage thatelectrostatic display (ESD) protection circuits that may degrade high input impedance areunnecessary because LinCMOS chips have internal safeguards against high-voltage staticcharges. Applications requiring ultrahigh input impedances (on the order of 10 10 Ω) necessitateadditional precautions to minimize stray leakage. These precautions include maintainingall surfaces of the printed circuit board (PCB), connectors, and components free ofcontaminants, such as smoke particles, dust, and humidity. Residue-free electronic-gradeaerosols can be used effectively to dust off particles from surfaces. Humidity must beleached out from the relatively hygroscopic PCB material by drying the circuit board in alow-pressure oven at 40C for 24 hours and storing in sealed containers with dry silica gel.If even higher input impedances are required, approaching the maximal input impedanceof the TLC24L4, you may consider using Teflon 2 PCB material instead of the more commonglass–epoxy type.Typical applications for this circuit include active medallions, which are electrode connectorblocks mounted in close proximity to the subject or preparation. The low inputnoise (68 nV/ Hz) and high bandwidth (dc—10 kHz) make it suitable for a broad range ofapplications. For example, 32 standard Ag/AgCl electroencephalography (EEG) electrodesfor a brain activity mapper could be connected to such a medallion placed on a headcap.Figure 1.9 shows another application for the circuit as an active electrode array in electromyography(EMG). Here eight arrays were used to pick up muscle signals from 256points. Connectors J1 in each of the circuits were made of L-shaped gold-plated pins that areused as electrodes to form an array with a spatial sampling period of 2.54 mm (given by thepitch of a standard connector with 0.1-in. pin center to center). The outputs of the op-ampbuffers can then carry signals to the main biopotential signal amplifiers and signal processors2 Teflon is a trademark of the DuPont Corporation.

PASTELESS BIOPOTENTIAL ELECTRODES 11Figure 1.9 Eight high-input-impedance buffer arrays are used to detect muscle signals from 256points for a high-resolution large-array surface electromyography system. Arrays of gold-plated pinssoldered directly to array inputs are used as the electrodes.using a long flat cable. Power could be supplied either locally, using a single 9-V battery andtwo 10-kΩ resistors, to create a virtual ground, or directly from a remotely placed symmetricalisolated power supply.Low-impedance op-amp outputs are compatible with the inputs of most biopotentialamplifiers. Wires from J2 can be connected to the inputs of instrumentation just as normalelectrodes would. The isolated common post of the biopotential amplifiers should be connectedto the ground electrode on the subject or preparation as well as to the ground pointof the buffer array.PASTELESS BIOPOTENTIAL ELECTRODESOp-amp voltage followers are often used to buffer signals detected from biopotentialsources with intrinsically high input impedance. One such application is detecting biopotentialsignals through capacitive bioelectrodes. One area in which these electrodes are particularlyuseful is in the measurement and analysis of biopotentials in humans subjected toconditions similar to those existing during flight. Knowledge regarding physiological reactionsto flight maneuvers has resulted in the development of devices capable of predicting,detecting, and preventing certain conditions that might endanger the lives of crew members.For example, the detection of gravitationally induced loss of consciousness (loss of consciousnesscaused by extreme g-forces during sharp high-speed flight maneuvers in warplanes) may save many pilots and their aircraft by allowing an onboard computer to takeover the controls while the aviator regains consciousness [Whinnery et al., 1987]. G z -induced loss of consciousness (GLOC) detection is achieved through the analysis of variousbiosignals, the most important of which is the electroencephalogram (EEG).Another new application is the use of the electrocardiography (ECG) signal to synchronizethe inflation and deflation of pressure suits adaptively to gain an increase in thelevel of gravitational accelerations that an airman is capable of tolerating. Additional applications,such as the use of the processed electromyography (EMG) signal as a measure ofmuscle fatigue and pain as well as an analysis of eye blinks and eyeball movement throughthe detection of biopotentials around the eye as a measure of pilot alertness, constitute thepromise of added safety in air operations.One problem in making these techniques practical is that most electrodes used for thedetection of bioelectric signals require skin preparation to decrease the electrical impedance

12 BIOPOTENTIAL AMPLIFIERSof the skin–electrode interface. This preparation often involves shaving, scrubbing the skin,and applying an electrolyte paste: actions unacceptable as part of routine preflight procedures.In addition, the electrical interface characteristics deteriorate during long-term use ofthese electrodes as a result of skin reactions and electrolyte drying. Dry or pasteless electrodescan be used to get around the constraints of electrolyte–interface electrodes. Pastelesselectrodes incorporate a bare or dielectric-coated metal plate, in direct contact with the skin,to form a very high impedance interface. By using an integral high-input-impedanceamplifier, it is possible to record a signal through the capacitive or resistive interface.Figure 1.10 presents the constitutive elements of a capacitive pasteless bioelectrode. Init, a highly dielectric material is used to form a capacitive interface between the skin anda conductive plate electrode. Ideally, this dielectric layer has infinite leakage resistance, butin reality this resistance is finite and decreases as the dielectric deteriorates. Signalspresented to the buffer stage result from capacitive coupling of biopotentials to the networkformed by series resistor R1 and the input impedance Z in of the buffer amplifier. In addition,circuitry that is often used to protect the buffer stage from ESD further attenuatesavailable signals. Shielding is usually provided in the enclosure of a bioelectrode assemblyto protect it from interfering noise. The signal at the output of the buffer amplifier haslow impedance and can be relayed to remotely placed processing apparatus without attenuation.External power must be supplied for operation of the active buffer circuitry.A dielectric substance is used in capacitive biopotential electrodes to form a capacitorbetween the skin and the recording surface. Thin layers of aluminum anodization, pyrevarnish, silicon dioxide, and other dielectrics have been used in these electrodes. Forexample, 17.5-µm (0.7-mil) film is easily prepared by anodic treatment, resulting in electrodeplates that have a dc resistance greater than 1 GΩ and a capacitance of 5000 pF atFigure 1.10 Block diagram of a typical capacitive active bioelectrode. A highly dielectric materialis used to form a capacitive interface between the skin and a conductive plate electrode. Signals presentedto the buffer stage result from capacitive coupling of biopotentials to the network formed byseries resistor R1 and the input impedance Z in of the buffer amplifier. (Reprinted from Prutchi andSagi-Dolev [1993], with permission from the Aerospace Medical Association.)

PASTELESS BIOPOTENTIAL ELECTRODES 1330 Hz. Unfortunately, standard anodization breaks down in the presence of saline (e.g.,from sweat), making the electrodes unreliable for long-term use.A relatively new anodization process was used by Lisa Sagi-Dolev, the former head ofR&D at the Israeli Airforce Aeromedical Center, and one of us [Prutchi and Sagi-Dolev,1993] to manufacture pasteless EEG electrodes that could be embedded in flight helmets.The hard anodization Super coating process developed by the Sanford Process Corporation 3is formed on the surface of an aluminum part and penetrates in a uniform manner, makingit very stable and resistant. The main characteristics of this type of coating are hardness(strength types Rockwell 50c–70c), high resistance to erosion (exceeding military standardMIL-A-8625), high resistance to corrosion (complete stability after 1200 hours in a saltwaterchamber), stable dielectric properties at high voltages (up to 1500 V with a coating thicknessof 50 µm, and up to 4500 V with a coating thickness of 170 µm), and high uniformity.Hard anodization Super has been authorized as a coating for aluminum kitchen utensils,and it proves to be very stable even under high temperatures and the presence of corrosivesubstances used while cooking. The coating does not wear off with the use ofabrasive scrubbing pads and detergents. These properties indicate that no toxic substancesare released in the presence of heat, alkaline or acid solutions, and organic solvents. Thismakes its use safe as a material in direct contact with skin, and resistant to sweat, bodyoils, and erosion due to skin friction.Figure 1.11 is a circuit diagram of a prototype active pasteless bioelectrode. The biopotentialsource is coupled to buffer IC1A through resistor R1 and the capacitor formed bythe biological tissues, aluminum oxide dielectric, and aluminum electrode plate.Operational amplifier IC1A is configured as a unity-gain buffer and is used to transformthe extremely high impedance of the electrode interface into a low-impedance source thatcan carry the biopotential signal to processing equipment with low loss and free ofFlatCableAnodizedPlateDrivenShieldR110KC2J20.01uF 1-V1J1+VR2100R310K784+-IC1B56TL082C15pFIC1ATL08283+2-41C30.01uF1J3OutputShieldFigure 1.11 Schematic diagram of a capacitive active bioelectrode. Biopotentials are coupled to buffer IC1A through resistor R1 and thecapacitor formed by the biological tissues, aluminum oxide dielectric, and aluminum electrode plate. Operational amplifier IC1A is configuredas a unity-gain buffer. IC1B drives a shield that protects the input from current leakage and noise. Resistors R3 and R2 reduce the gain of theshield driver to just under unity to improve the stability of the guarding circuit. C1 limits the bandwidth of input signals buffered by IC1.3 Hard anodization Super is a process licensed by the Sanfor Process Corporation (United States) to ElgatAerospace Finishing Services (Israel) and is described in Elgat Technical Publication 100, Hard Anodizing:“Super’’ Design and Applications.

14 BIOPOTENTIAL AMPLIFIERScontamination. IC1B, also a unity-gain buffer, is fed by the input signal, and its outputdrives a shield that protects the input from leaks and noise. Resistors R3 and R2 reduce thegain of the shield driver to just under unity in order to improve the stability of the guardingcircuit. Capacitor C1 limits the bandwidth of input signals buffered by IC1A. The circuitis powered by a single supply of 4 V dc. Miniature power supply decouplingcapacitors are mounted in close proximity to the op-amp.IC1A and IC1B are each one-half of a TLC277 precision dual op-amp’s IC. Here again,the selection of op-amps from the TLC27 family has the additional advantage that ESDprotection circuits which may degrade high input impedance are unnecessary becauseLinCMOS chips have internal safeguards against high-voltage static charges. Note that thiscircuit shows no obvious path for op-amp dc bias current. This is true if we assume that allelements are ideal or close to ideal. However, the imperfections in the electrode anodization,as well as in the dielectric separations and circuit board, provide sufficient paths forthe very weak dc bias required by the TL082 op-amp.The circuit is constructed on a miniature PCB in which ground planes, driven shieldplanes, and rings have been etched. The circuit is placed on top of a 1-cm 2 plate of thinaluminum coated with hard anodization Super used as the bioelectrode. A grounded conductivefilm layer shields the encapsulated bioelectrode and flexible printed circuit ribboncable, which carries power for both the circuit and the signal output.Figure 1.12 presents a prototype bioelectrode array designed to record frontal EEG signalsmeasured differentially (between positions Fp1 and Fp2 of the International 10-20System), as required for an experimental GLOC detection system. One of the bioelectrodescontains the same circuitry as that described above. The second, in addition to thebuffer and shield drive circuits, also contains a high-accuracy monolithic instrumentationamplifier and filters. Such a configuration provides high-level filtered signals which maybe carried to remotely placed processing stages with minimal signal contamination fromnoisy electronics in the helmet and elsewhere in the cockpit.A miniaturized version of the circuit may be assembled on a single flexible printed circuit.Driven and ground shields, as well as the flat cables used to interconnect the electrodesand carry power and output lines, may be etched on the same printed circuit. Asshown in Figure 1.13, the thin assembly may then be encapsulated and embedded at theappropriate position within the inner padding of a flight helmet. Nonactive reference forthe instrumentation amplifier may be established by using conductive foam lining theheadphone cavities (approximating positions A1 and A2 of the International 10-20System) or as cushioning for the chin strap.Figure 1.12 Block diagram of a capacitive bioelectrode array with integrated amplification and filter circuits designed to record frontal EEGsignals. One of the bioelectrodes contains the same circuitry as Figure 1.11. The second also contains a high-accuracy monolithic instrumentationamplifier and filters. (Reprinted from Prutchi and Sagi-Dolev [1993], with permission from the Aerospace Medical Association.)

SINGLE-ENDED BIOPOTENTIAL AMPLIFIER ARRAYS 15Figure 1.13 A miniaturized version of the capacitive bioelectrode array may be assembled on asingle flexible printed circuit. This assembly can be encapsulated and embedded at the appropriateposition within the inner padding of a flight helmet for differential measurement of the EEG betweenpositions Fp1 and Fp2 of the International 10-20 System. Conductive foam is used to establish nonactivereference either at positions A1 and A2 or at the chin of the subject. (Reprinted from Prutchiand Sagi-Dolev [1993], with permission from the Aerospace Medical Association.)EEG and ECG signals recorded using the new pasteless bioelectrodes compare very wellto recordings obtained through standard Ag/AgCl electrodes. Figure 1.14 presents adigitized tracing of a single-lead ECG signal detected with a capacitive pasteless bioelectrodeas well as with a standard Ag/AgCl electrode. Figure 1.15 shows digitized EEG signalsrecorded from a frontal differential pair with a reference at A2 using a pastelessbiopotential electrode array and with standard Ag/AgCl electrodes.SINGLE-ENDED BIOPOTENTIAL AMPLIFIER ARRAYSSingle-ended op-amp amplifiers were in the past used as front-end stages for biopotentialamplifiers. As we will see later, the advent of low-cost integrated instrumentationamplifiers has virtually eliminated the need to design single-ended biopotential amplifiers,and as such, the use of single-ended biopotential amplifiers is not recommended. Despitethis, this section has strong educational value because it demonstrates the design principlesof using single-ended amplifiers, which are common in the stages that follow thebioamplifier’s front end. Figure 1.16 shows an array of 16 single-ended biopotentialamplifiers. A number of these circuits may be stacked up to form very large arrays, whichmade them common for applications such as body potential mapping electrocardiographyin the days when single op-amps were expensive.Each biopotential amplification channel features high-impedance ESD-protectedinputs, current limiting, and defibrillation protection. Individual shield drives are used toprotect each input lead from external noise. Each channel provides a fixed gain of 1000within a fixed (3-dB) bandpass of 0.2 to 100 Hz. The chief advantage of the singleendedconfiguration is its simplicity, but this comes at the cost of lacking high immunityto common-mode signals. Because of this, single-ended biopotential amplifiers areusually found in equipment that incorporates other ways of suppressing common-modesignals. In this circuit, an onboard adjustable 50/60-Hz notch filter is connected at theoutput of each channel. The schematic diagram of Figure 1.17 shows how each channel

16 BIOPOTENTIAL AMPLIFIERSFigure 1.14 Single-lead ECG recordings: (a) using an Ag/AgCl standard bioelectrode; (b) usingthe capacitive active bioelectrode. (Reprinted from Prutchi and Sagi-Dolev [1993], with permissionfrom the Aerospace Medical Association.)is built around one-half of two TL064 quad op-amps. Eight copies of this circuitconstitute the 16 identical biopotential amplification channels. Operation of a singlechannel is described in the following discussion.A biopotential signal detected by a bioelectrode is coupled to the noninverting inputs ofthe first-stage amplifier and the shield driver amplifier. The input impedance is givenmostly by the input impedance of the front-stage op-amps, yielding 100 MΩ paralleledwith 100 pF. R1 limits the current that can flow through the input lead, while diodes D1and D2 shunt to ground any signal that exceeds their zener voltage. This arrangement protectsthe inputs of the amplifiers from ESD and from the high voltages present during cardiacdefibrillation. Furthermore, it protects the subject from currents that may leak backfrom the amplifiers or associated circuitry.The shield driver is configured as a unity-gain buffer. The actual drive, however, determinedby R2 and R3, is set to 99% of the signal magnitude at the inner wire to stabilize

SINGLE-ENDED BIOPOTENTIAL AMPLIFIER ARRAYS 17Figure 1.15 EEG measured differentially between positions Fp1 and Fp2 showing eyeblink EMG artifacts:(a) using an Ag/AgCl standard bioelectrode; (b) using the capacitive active bioelectrode. (Reprintedfrom Prutchi and Sagi-Dolev [1993], with permission from the Aerospace Medical Association.)the driver circuit while reducing the effective input cable capacitance by two orders ofmagnitude. The first amplification stage has a gain determined byG 1 1 R 5 11R4C2 and R5 form a low-pass filter with a (3-dB) cutoff frequency of 160 Hz, which stabilizesthe amplifier’s operation. In addition, R1 and C1 (plus the capacitances of D1 andD2) also form a low-pass filter, which further prevents oscillatory behavior and rejectshigh-frequency noise.The amplified signal is high-pass filtered by C3 and R13, with a (3-dB) cutoff frequencyof 0.16 Hz, before being amplified by the second stage. The gain of this stage is set byG 2 1 R 8 101R7

18 BIOPOTENTIAL AMPLIFIERSFigure 1.16 Array of 16 single-ended biopotential amplifiers. A number of these circuits may bestacked up to form very large arrays, making them ideally suited for applications such as body potentialmapping electrocardiography.The last processing stage of each channel is an active notch filter, which can be tuned tothe power line frequency by adjusting R12. Supply voltage to this circuit must be symmetricaland within the range of 5 V (minimum) to 18 V (absolute maximum). Two9-V alkaline batteries can be used efficiently due to the circuit’s very low power consumption.Capacitors C9–C12 are used to decouple the power supply and filter noise fromthe op-amp power lines.To minimize electrical interference, the circuit should be built with a compact layout onan appropriate printed circuit board or small piece of stripboard. The construction of thecircuit is straightforward, but care must be taken to keep wiring as short and clean as possible.Leads to the bioelectrodes should be low-loss coaxial cables, whose shields are connectedto their respective shield drives at J1 (J1x-2 for left-side channels and J1y-1 forright-side channels). The circuit’s ground should be connected to the subject’s reference(patient ground) electrode. When connected to a test subject, the circuit must always bepowered from batteries or through a properly rated isolation power supply. The same isolationrequirements apply to the outputs of the amplifier channels.It is important to note that the performance of a complete system is determined primarilyby its input circuitry. Equivalent input noise is practically that of the first stage(approximately 10 µV p-p within the amplifier’s 3-dB bandwidth of 0.2 to 100 Hz).BODY POTENTIAL DRIVERSRejection of common-mode signals in the prior circuit example is limited to the singleendedperformance of the input-stage op-amp and the 50/60-Hz rejection of the notch filter.Often, however, environmental noise (e.g., power line interference) is so large that common-modepotentials eclipse the weak biopotentials that can be picked up through singleendedamplifiers. Notch filters do not necessarily remove interfering signals in a substantialmanner either. The first few harmonics of the power line constitute strong interfering signalsin the recording of biopotentials. The range of these signals, however, is by no meansconfined to 100 or 200 Hz. High-frequency interference originating from fluorescent andother high-efficiency lamps commonly occurs with a maximal spectral density of approximately1 kHz and with amplitudes of up to 50% of the 50/60-Hz harmonic.

1J2x-1Output X1J2x-21J2y-2Output Y1J2y-1+V-VShieldRx310KRx2100IC1BTL06474+-11Rx120KDx11N914Dx21N914Cx1220pF-VRx5100KCx30.1uFRx610KRx1310M4+-5656Rx410K32411+-Cx20.01uFIC1ATL0641Rx71K11Rx8100KCx40.01uFIC2BTL0647Cx50.1uFCx6.047uFRx9120KCx7.047uFRx10120KCx8.047uF23114-++VIC2ATL0641Rx118.2K213Rx1210KShieldRy310KRy2100Ry120KDy2 Cy1Dy110M1N914 1N914 220pFIC1CRy5TL0644+8-11109Ry410K12134+14-11100KCy20.01uFIC1DTL064Cy3 Ry6IC2C0.1uF 10KRy13Ry71K1094+8-11Ry8100KCy40.01uFTL064Cy50.1uFRy9 Ry10120K 120KCy6 Cy7 Cy8.047uF .047uF.047uF131211-+4IC2DTL064Ry118.2K14123Ry1210KFigure 1.17 Each channel of the single-ended biopotential amplifier array is built around one-half of two TL064 quad op-amps. Eightcopies of this circuit constitute the 16 identical biopotential amplification channels.Electrode XShield XElectrode YShield Y19

20 BIOPOTENTIAL AMPLIFIERSA way of improving the common-mode rejection problem is to use single-endedamplifiers concurrently with body potential driver (BPD) circuits to cancel out commonmodesignals. Power line and other contaminating common-mode signals are capacitivelycoupled to the body, causing current to flow through it and into ground. The body, actingas a resistor through which a current flows, causes a voltage difference between any twopoints on it. The goal of a BPD is to detect and eliminate this voltage, effectively reducingcommon-mode signals between biopotential detection electrodes in the vicinity of its senseelectrode.A BPD is implemented by detecting the common-mode potential in the area of interestand then feeding into the body a 180 version of the same signal. A feedback loop is thusestablished which cancels out the common-mode potential. Circuits that have feedback areinherently unstable, and oscillatory behavior must be prevented to make a BPD useful.This, however, limits the BPD to a range well under its first resonance. The performanceof the circuit within this range is dependent on the internal delay of the loop and variesaccording to the frequency of common-mode signal components.The common-mode potential used for a BPD is often acquired from the outputs of thefront stages of differential biopotential amplifiers. In electrocardiography, for example, acomposite signal is often generated by summing the various differential leads. This signalis inverted and fed back to the subject’s body through the right-leg electrode. This practice,commonly referred to as right-leg driving, is not optimal, especially at higher frequencieswhere the additional delay caused by the front stages and summing circuitsdegrades BPD performance.Superior performance can be obtained by implementing a separate BPD circuit whichuses an additional electrode (sense). Any modern operational amplifier operated in openloopmode (with a feedback capacitor in the order of a few picofarads) can be used as theheart of the BPD [Levkov, 1982, 1988]. In the circuit of Figure 1.18, the common-modesignal is measured between the sense and common electrodes. This signal is appliedthrough current-limiting resistor R2 to the inverting input of one-half of op-amp IC1.Operated in open-loop mode, a 180 out-of-phase signal is injected into the body throughthe drive electrode in order to cancel the common-mode voltage. D3 and D4 clip the BPDoutput so as not to exceed a safe current determined by resistor R3. In addition, this measureprotects the circuit from defibrillation pulses. D1 and D2 are used to protect the inputof the BPD from ESD and other transients. The low-pass filter formed by R2 and C5, aswell as the presence of feedback capacitor C2, stabilize the circuit and prevent it fromentering into oscillation.The output of the BPD op-amp is rectified by the full-wave bridge formed by D5–D8and then amplified by the differential amplifier built using the other half of IC1. The outputof this op-amp is measured and displayed by the bar graph voltmeter formed by IC3 inconjunction with a 10-element LED display DISP1. The LM3914 bar graph driver IC hasconstant-current outputs, and thus series resistors are not required with the LEDs. The currentis controlled by the value of resistors R8 and R9. Resistor values also set the rangeover which the input voltage produces a moving dot on the display. Power for the circuitis supplied by a single 9-V alkaline battery. The 9-V supply required by IC1 is generatedusing IC2, an integrated-circuit voltage converter. C3, D9, and C4 are required by IC2to produce an inverted output of the power fed through pin 8.An additional advantage of using the BPD is the possibility of monitoring the skin–electrodeimpedance of every electrode connected to the input of a single-ended biopotentialamplifier system. To do so, a test voltage V test fed into the inverting input of the BPDthrough J1-4 induces an additional component on each of the amplified output signals.Phased demodulation of one of these signals removes components corresponding todetected biopotentials, leaving only an amplified version of the detected test signal V i .Assuming that an ideal BPD is used, the amplitude of this signal depends on the

+9VDriveComSenseJ1-4R247KD31N473871 18 17161514131211105 6 4 9 8 3 212IC310LM3914SIGIN REFOUTLED1LED2LED3MODE LED4REF ADJ LED5LED6V+LED7V-J1-5J1-6J1-1J1-2C310uF, 25V tant.+9VR1470K+ C7+1uF, 25V tant.-9VD11N4148D21N4148678D41N4738IC2ICL7660CPA24 CAP+CAP-LVOSCV+3VOUT565-+48-9VIC1BTL082+7C410uF, 25V tant.D51N4148D61N4148D81N4148D71N4148R447K32+-84-9VIC1ATL0821C50.1uFC60.1uFR81.2K2 3 4 5 6 7 81918DISP11615R9101413C90.1uF911+9VGNDGNDTestSignalJ1-3R34.7K+9VC15pFD91N4148C25pFR547KR647K+9VR742M+9V12017RHIRLOLED8LED9LED10+C84.7uF, 25V t ant .Figure 1.18 A body potential driver is implemented by detecting the common mode potential in the area of interest and then feeding thebody a 180 version of the same signal. A feedback loop is thus established, which cancels out common-mode potentials.SubjectElectrodes21

22 BIOPOTENTIAL AMPLIFIERSskin– electrode impedance and is given byV i G i V test( Z i R2)R1 where G i is the gain of each amplifier in the array.For simplicity and convenience, the test signal can be generated by a computerand phased demodulation can be implemented in software. Impedance tests can beperformed just prior to data collection as well as at selected times throughout anexperiment, making it easy to locate faulty electrode–skin connections even in largeamplifier arrays. Further theoretical and practical considerations regarding the constructionof large single-ended biopotential amplifier arrays may be found in a paper by VanRijn et al. [1990].To use the BPD circuit in conjunction with biopotential amplifiers, connect the BPDreference terminal (J1-1) to the reference electrode (subject ground) of the biopotentialamplifier system. Place the sense electrode (e.g., a standard Ag/AgCl ECG electrode) incontact with the body in the proximity of the biopotential amplifier’s active electrode(s)and connect it to J1-2 of the BPD circuit using shielded cable (with the shield connectedto J1-1). A similar electrode placed at a distant point on the body should be connected tothe “drive’’ output (J1-3) of the BPD. Upon hooking up a 9-V alkaline battery to the appropriatepower inputs ( terminal to J1-5 and terminal to J1-6), common-mode signalsshould be neutralized. The moving dot on the display shows the relative maximum amplitudeof the BPD voltage. This can be used to assess the conditions of the recording environment.In general, use of a separate sense electrode is not be recommended for any newlydesigned equipment. Whenever active common-mode suppression is required, the instrumentshould be designed such that the common-mode potential used for BPD is obtainedfrom the outputs of the biopotential amplifier’s front end. However, a stand-alone BPDsuch as the one shown in Figure 1.19 can be used to boost the performance of olderFigure 1.19 A body potential driver can be constructed as a stand-alone unit powered by a 9-V battery.This circuit can be used in conjunction with existing biopotential amplifiers to boost the common-moderejection of older equipment. The LED display shows the relative maximum amplitudeof the BPD voltage to assess the conditions of the recording environment.

DIFFERENTIAL AMPLIFIERS 23equipment. For example, when the BPD is used in conjunction with an existing singleendedECG channel, J1-1 should be connected to the right-leg cable, and the other twoelectrodes can be placed at convenient sites on the body.DIFFERENTIAL AMPLIFIERSWhen a differential voltage is applied to the input terminals of an op-amp as depicted inFigure 1.20, the transfer function of the inverting follower must be rewritten asRfV out (V R 1 V 2 )Similarly, the transfer function of the noninverting follower must be modified toV out 1 RfR (V 1 V 2 )ininV1VdiffV2VoutVcmFigure 1.20Differential and common-mode voltages applied to the input of an op-amp.R110KR3100K++V-VinR210K-VVoutR4100KR1=R2R3=R4Vout=(R3/R1)VinFigure 1.21 Differential amplifier implemented with an op-amp.

24 BIOPOTENTIAL AMPLIFIERSFigure 1.21 presents a differential amplifier based on a single op-amp. If R1 R2 andR3 R4, the gain of the stage is given byIn this case, the transfer function isG R 3 R 4R2R1V out V in R 4R1orV out V in R 3R2where V 1 V 2 is the differential voltage V in .The balance of a differential amplifier is critical to preserve the property of an ideal opampby which its common-mode rejection ratio is infinite. If V 1 V 2 , an output voltage ofzero should be obtained, disregarding any common-mode voltage V CM . If the resistor equalitiesR1 R2 and R3 R4 are not preserved, the common-mode rejection deteriorates.The main problem regarding use of a simple differential amplifier as a biopotentialamplifier is its low input impedance. Especially in older equipment, where thisconfiguration was used to amplify differential biopotentials, high-input-impedance JFETtransistors or MOSFET-input op-amp unity-gain voltage followers were used to buffereach input of the differential amplifier. Despite the enhanced CMR of the differentialamplifier configuration over that of a single-ended system, use of a BPD circuit canincrease considerably the CMR of differential biopotential amplifiers. This is especiallytrue regarding the rejection of interfering signals with high-frequency components.C10.1uFR410M-9V+9VInputR110KR210KR310M234 5-+7 1+9VIC1TL0816R51MC21uFC30.47uFR61M327 1+-4 5-9VIC2TL081612J1BNCFigure 1.22 In this simple differential biopotential amplifier, signals originating from electrophysiological activity in the body are detectedby measuring the potential differences between electrodes connected to the inputs. If the sensing bioelectrodes are placed in the proximityof the biopotential source, common-mode electrical interference affects both probes more or less equally and are rejected by the differentialamplifier stage.

DIFFERENTIAL AMPLIFIERS 25Simple Differential Biopotential AmplifierFigure 1.22 presents the circuit diagram of a simple differential biopotential amplifier.Potential differences originating from electrophysiological activity in the body may bedetected with this circuit by attaching bioelectrodes and measuring the potential differencesbetween them. If the sensing bioelectrodes are placed in the proximity of a biopotentialsource, electrical interference induced from the power line or originating from other sourcesof biopotentials in more remote parts of the body will affect both probes more or less equally.The changes of signal detected simultaneously by both electrodes are rejected by the first stageof the preamplifier. This stage is made up by op-amp IC1 wired as a differential amplifier.For low-frequency signals, the gain of the differential stage is given byG R 3 R 4 1 0 MΩ 1000R2R110kΩAt high frequencies, however, C1 has low impedance, forcing the first stage to act as a lowpassfilter. In addition to limiting the bandwidth of the amplifier, C1 and C3 damp oscillationsand instabilities of the circuit. Note that a gain of 1000 requires that large dc offsetvoltages not be present on the biopotential signal. At this gain, the circuit will stop operatingif the offset voltage exceeds a mere 10 mV. If higher offset voltages are expected, thegain of the amplifier formed around IC1 must be decreased. For example, to use this circuitas part of a surface ECG amplifier, the gain must be recalculated to cope with offsetpotentials of up to 300 mV.The output of IC1 is ac-coupled via C2 to IC2. The 3-dB cutoff for the high-pass filterformed by C2 and R6 is approximately 0.16 Hz. The filtered signal is then buffered byunity-gain voltage follower IC2. To minimize electrical interference, the circuit should bebuilt with a compact layout on an appropriate printed circuit board or small piece of stripboard.The construction of the circuit is straightforward, but care must be taken to keepwiring as short and clean as possible. Leads to the electrodes are coaxial cables with theirshields connected to ground at the circuit board.This circuit is very useful to demonstrate how to measure the CMR and input impedanceof a biopotential amplifier. First, test and calibrate the circuit. You will need a twochanneloscilloscope and a signal generator. Take the following steps:1. Connect the oscilloscope and the signal generator to the biopotential amplifier asshown in Figure 1.23a.2. Apply a 10-Hz signal of 1-mV amplitude as measured by channel 2 of the oscilloscope.3. Verify that the output signal is an amplified version of the input signal.4. Determine the theoretical gain of the equivalent circuit and confirm that the outputsignal has an amplitude of G noninverting 1mV.5. Without changing the settings of the instruments, connect the oscilloscope and thesignal generator to the biopotential amplifier as shown in Figure 1.23b.6. Verify that the output signal is an amplified and inverted (opposite phase) versionof the input signal. Determine the theoretical gain of the equivalent circuit andconfirm that the output signal has an amplitude of G inverting 1mV.To measure the CMR, do the following:1. Connect the equipment as shown in Figure 1.24.2. Adjust the signal generator to produce a 60-Hz 5-V p-p common-mode input signalV in CM .3. Measure the corresponding common-mode output voltage V out CM .

26 BIOPOTENTIAL AMPLIFIERSOscilloscopeBiopotential Amplifier10mV p-p10Hz+IN-INREFOUTInput 1 Input 2(a)Oscilloscope10mV p-p10Hz-INREFBiopotential AmplifierOUTInput1 Input 2+INFigure 1.23 The gain of a differential biopotential amplifier can be measured by injecting a signal (e.g., 10-Hz sinusoidal) at an amplitudesimilar to that expected from the biopotential (e.g., 1 mV) to the inputs. (a) When the amplifer is configured as single-ended, the output signalshould be an amplified version of the input signal. (b) When the circuit is reconfigured to use the inverting input, the output signal shouldbe an amplified and inverted (opposite phase) version of the input signal.(b)4. Calculate the common-mode gain G CM V out CM /V in CM .5. Considering that the differential gain of this biopotential amplifier is given by theratio between the resistor pairs (i.e., G differential 10 MΩ/10 kΩ 1000), calculatethe common-mode rejection ratio, CMRR G differential /G CM , and common-moderejection, CMR(dB) 20 log 10 (G differential /G CM ).Next, measure the input impedance of the biopotential amplifier. You will need an ohmmeter(e.g., a digital multimeter or VOM) and a 10-MΩ multiturn potentiometer in additionto the oscilloscope and signal generator. Follow this procedure:1. Connect the equipment as depicted in Figure 1.25.2. Adjust the signal generator to produce a 100-Hz sinusoidal wave with an amplitudeof 1 mV p-p . This signal is measured by channel 2 of the oscilloscope.3. Set the potentiometer to 0 Ω and measure the amplifier’s peak-to-peak output voltageon channel 1. Record this value.4. Carefully adjust the 10-MΩ potentiometer until the voltage measured on channel 1reaches half the value recorded in the preceding step.

OP-AMP INSTRUMENTATION AMPLIFIERS 27OscilloscopeBiopotential Amplifier+INOUTV out cmInput1Input 2Vin cm5V p-p60Hz-INREFFigure 1.24 To measure the CMR of a biopotential amplifier, the differential inputs should be shorted and a relatively large common-modesignal (e.g., 60-Hz 5-V p-p sinusoidal) injected between the shorted differential inputs and the biopotential amplifier’s common referenceinput. The common-mode rejection is then calculated as CMR (dB) 20 log 10 (G differential /G CM ).OscilloscopeR110M+INBiopotential Amplifier1mV p-pOUTInput 1 Input 2-INREFFigure 1.25 To measure the input impedance of the biopotential amplifier, inject an in-band test signal of known amplitude (e.g., 1 mV) tothe biopotential amplifier’s inputs through a 10-MΩ potentiometer. Adjust the potentiometer until the output voltage is half of the amplitudeobtained with the potentiometer set to 0 Ω. The resistance of the potentiometer at the half-output point is equal to the input impedance of thebiopotential amplifier at the test frequency. This measurement should be repeated for a number of in-band frequencies to compute the capacitiveand resistive components of the input.5. Without changing the setting of the potentiometer, measure its resistance with theohmeter. This value is equal to the input impedance of the biopotential amplifier atthe specified frequency.6. Repeat the experiment for various frequencies from 0.1 Hz to 20 kHz. Use appropriatesettings for the oscilloscope’s time base. Compute the capacitive and resistivecomponents of the input impedance based on the data obtained.OP-AMP INSTRUMENTATION AMPLIFIERSAn alternative to the simple differential amplifier is the multiple op-amp configuration presentedin Figure 1.26. This differential configuration, known as an instrumentation

28 BIOPOTENTIAL AMPLIFIERS+15VV 1327 1+A1-4 8-15VIC1OP-076R250k, 1.0%VaR510k, 0.1%R610k, 0.1%J112-IN+INR11.0k, 1.0%-15VIC34 8 OP-07J22 -6V1A3out3 +2OUTPUTV 223-15V4 8-A2+IC2OP-076R350k, 1.0%R410k, 0.1%7 1+15VR710k, 0.1%7 1+15VFigure 1.26VbOp-amp instrumentation amplifier.amplifier, has the advantage of preserving the high input impedance of the noninvertingfollower, yet offering gain. Input amplifiers A1 and A2 can be analyzed as noninvertingamplifiers which produce output voltages ofV A 1 R 2 R1V 1 (R 2)V 2R1andV B 1 R 3 R1V 2 (R 3)V 1R1Initially, if it is assumed that the gain of amplifier A3 is unity and that R2 R3, thenV out V B V ASubstituting into the two preceding equations gives the output voltage:V out (V 2 V 1 ) 1 2 RR 2 1Whenever the gain of amplifier A3 is greater than unity, this equation must be multipliedby the gain of the differential stage. If R4 R5 and R6 R7, the overall voltage gain ofthe instrumentation amplifier is given byV out (V 2 V 1 ) 1 2 RR 2 1R 6R 5