PowerFlex 400 Adjustable Frequency AC Drive ! ! !

PowerFlex 400 Adjustable Frequency AC Drive ! ! !

PowerFlex 400 Adjustable Frequency AC Drive ! ! !

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

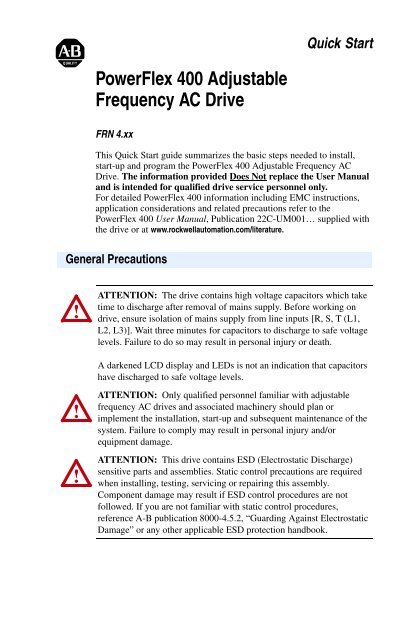

Quick Start<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong><strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong>FRN 4.xxThis Quick Start guide summarizes the basic steps needed to install,start-up and program the <strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong><strong>Drive</strong>. The information provided Does Not replace the User Manualand is intended for qualified drive service personnel only.For detailed <strong>PowerFlex</strong> <strong>400</strong> information including EMC instructions,application considerations and related precautions refer to the<strong>PowerFlex</strong> <strong>400</strong> User Manual, Publication 22C-UM001… supplied withthe drive or at www.rockwellautomation.com/literature.General Precautions!ATTENTION: The drive contains high voltage capacitors which taketime to discharge after removal of mains supply. Before working ondrive, ensure isolation of mains supply from line inputs [R, S, T (L1,L2, L3)]. Wait three minutes for capacitors to discharge to safe voltagelevels. Failure to do so may result in personal injury or death.A darkened LCD display and LEDs is not an indication that capacitorshave discharged to safe voltage levels.!!ATTENTION: Only qualified personnel familiar with adjustablefrequency <strong>AC</strong> drives and associated machinery should plan orimplement the installation, start-up and subsequent maintenance of thesystem. Failure to comply may result in personal injury and/orequipment damage.ATTENTION: This drive contains ESD (Electrostatic Discharge)sensitive parts and assemblies. Static control precautions are requiredwhen installing, testing, servicing or repairing this assembly.Component damage may result if ESD control procedures are notfollowed. If you are not familiar with static control procedures,reference A-B publication 8000-4.5.2, “Guarding Against ElectrostaticDamage” or any other applicable ESD protection handbook.

English-2<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick Start!!ATTENTION: An incorrectly applied or installed drive can result incomponent damage or a reduction in product life. Wiring or applicationerrors, such as, undersizing the motor, incorrect or inadequate <strong>AC</strong>supply, or excessive ambient temperatures may result in malfunction ofthe system.ATTENTION: The bus regulator function is extremely useful forpreventing nuisance overvoltage faults resulting from aggressivedecelerations, overhauling loads, and eccentric loads. However, it canalso cause either of the following two conditions to occur.1. Fast positive changes in input voltage or imbalanced input voltagescan cause uncommanded positive speed changes;2. Actual deceleration times can be longer than commandeddeceleration timesHowever, a “Stall Fault” is generated if the drive remains in this statefor 1 minute. If this condition is unacceptable, the bus regulator must bedisabled (see parameter A187).Mounting Considerations• Mount the drive upright on a flat, vertical and level surface.Frame Screw Size Screw TorqueC M5 (#10-24) 2.45-2.94 N-m (22-26 lb.-in.)D M8 (5/16 in.) 6.0-7.4 N-m (53.2-65.0 lb.-in.)E M8 (5/16 in.) 8.8-10.8 N-m (78.0-95.3 lb.-in.)F M10 (3/8 in.) 19.6-23.5 N-m (173.6-208.3 lb.-in.)• Protect the cooling fan by avoiding dust or metallic particles.• Do not expose to a corrosive atmosphere.• Protect from moisture and direct sunlight.Maximum Surrounding Air TemperatureFrame Enclosure Rating Temperature Range Minimum MountingClearancesC IP 20/UL Open-Type -10° to 45°C (14° to 113°F) Figure 1: Option AIP 30/NEMA 1/UL Type 1 (1) -10° to 45°C (14° to 113°F) Figure 1: Option BIP 20/UL Open-Type -10° to 50°C (14° to 122°F) Figure 1: Option BD, E, F IP 30/NEMA 1/UL Type 1 -10° to 45°C (14° to 113°F) Figure 2:(1)Frame C drives require installation of the <strong>PowerFlex</strong> <strong>400</strong> IP 30/NEMA 1/UL Type 1option kit to achieve this rating.

English-4<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartUngrounded Distribution Systems!ATTENTION: <strong>PowerFlex</strong> <strong>400</strong> drives contain protective MOVs thatare referenced to ground. These devices must be disconnected if thedrive is installed on an ungrounded or resistive grounded distributionsystem.Phase to Ground MOV RemovalFrame CFrame E & FR/L1S/L2T/L31 2 3 4Important:Tighten screw afterjumper removal.Note: Frame D drives do not contain a MOV to ground connection andare suitable for operation in both grounded and ungrounded distributionsystems without modification.CE ConformityRefer to the <strong>PowerFlex</strong> <strong>400</strong> User Manual supplied with the drive fordetails on how to comply with the Low Voltage (LV) andElectromagnetic Compatibility (EMC) Directives.EMC Line Filters240V 50/60 Hz 3-PhasekWHP480V 50/60 Hz 3-PhaseCatalogNumber kW HPCatalogNumber2.2 3.0 22-RF034-CS 2.2 3.0 22-RF018-CS4.0 5.0 22-RF034-CS 4.0 5.0 22-RF018-CS5.5 7.5 22-RF034-CS 5.5 7.5 22-RF018-CS7.5 10 22-RF034-CS 7.5 10 22-RF018-CS11 15 22-RFD070 11 15 22-RF026-CS15 20 22-RFD100 15 20 22-RFD03618.5 25 22-RFD100 18.5 25 22-RFD05022 30 22-RFD150 22 30 22-RFD05030 40 22-RFD150 30 40 22-RFD07037 50 22-RFD180 37 50 22-RFD10045 60 22-RFD10055 75 22-RFD15075 100 22-RFD18090 125 Consult Factory110 150 Consult Factory

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-5Specifications, Fuses and Circuit Breakers<strong>Drive</strong> RatingsCatalogOutput Ratings Input Ratings Branch Circuit ProtectionNumberAmps VoltagekW (HP) Range kVA Amps Fuses 140M Motor50°C(1) Protectors (2) Contactors200 - 240V <strong>AC</strong> – 3-Phase Input, 0 - 230V 3-Phase Output22C-B012N103 2.2 (3.0) 12 180-265 6.5 15.5 20 140M-F8E-C16 100-C23 14622C-B017N103 3.7 (5.0) 17.5 180-265 8.8 21 30 140M-F8E-C25 100-C37 20722C-B024N103 5.5 (7.5) 24 180-265 10.9 26.1 35 140M-F8E-C32 100-C37 26622C-B033N103 7.5 (10) 33 180-265 14.4 34.6 45 140M-F8E-C45 100-C45 35922C-B049A103 11 (15) 49 180-265 21.3 51 70 140-CMN-6300 100-C60 48822C-B065A103 15 (20) 65 180-265 28.3 68 90 140-CMN-9000 100-C85 65022C-B075A103 18.5 (25) 75 180-265 32.5 78 100 140-CMN-9000 100-D95 73422C-B090A103 22 (30) 81 180-265 38.3 92 125 – 100-D110 77822C-B120A103 30 (40) 120 180-265 51.6 124 175 – 100-D180 105522C-B145A103 37 (50) 130 180-265 62.4 150 200 – 100-D180 1200380 - 480V <strong>AC</strong> – 3-Phase Input, 0 - 460V 3-Phase Output22C-D6P0N103 2.2 (3.0) 6 340-528 6.3 7.5 10 140M-D8E-C10 100-C09 10522C-D010N103 4.0 (5.0) 10.5 340-528 10.9 13 20 140M-D8E-C16 100-C16 17122C-D012N103 5.5 (7.5) 12 340-528 11.9 14.2 20 140M-D8E-C16 100-C23 20022C-D017N103 7.5 (10) 17 340-528 15.3 18.4 25 140M-D8E-C20 100-C23 26722C-D022N103 11 (15) 22 340-528 19.2 23 30 140M-F8E-C32 100-C30 32922C-D030N103 15 (20) 27 340-528 25.8 31 40 140M-F8E-C32 100-C37 43522C-D038A103 18.5 (25) 38 340-528 33.3 40 50 140M-F8E-C45 100-C60 60622C-D045A103 22 (30) 45.5 340-528 39.1 47 60 140-CMN-6300 100-C60 73822C-D060A103 30 (40) 54 340-528 53.3 64 80 140-CMN-9000 100-C85 66422C-D072A103 37 (50) 72 340-528 60.7 73 100 140-CMN-9000 100-C85 101922C-D088A103 45 (60) 88 340-528 74.9 90 125 – 100-D110 124522C-D105A103 55 (75) 105 340-528 89 107 150 – 100-D140 148722C-D142A103 75 (100) 128 340-528 124.8 150 200 – 100-D180 204322C-D170A103 90 (125) 170 340-528 142 170 250 – 100-D250 261722C-D208A103 110 (150) 208 340-528 167 200 250 – 100-D250 3601PowerDissipationIP20 OpenWatts(1) Recommended Fuse Type: UL Class J, CC, T or Type BS88; 600V (550V) or equivalent.(2) Refer to the Bulletin 140M Motor Protectors Selection Guide, publication 140M-SG001… todetermine the frame and breaking capacity required for your application.

English-8<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartPower Terminal Block SpecificationsFrame Maximum Wire Size (1) Minimum Wire Size (1)(1) Maximum/minimum sizes that the terminal block will accept - these are notrecommendations. If national or local codes require sizes outside this range, lugs maybe used.Important: Frame C, D, and F drives utilize a finger guard over thepower wiring terminals. Replace the finger guard whenwiring is complete.Refer to the <strong>PowerFlex</strong> <strong>400</strong> User Manual for maximum power cablelength recommendations.Input Power ConditionsRecommendedTorqueC 8.4 mm 2 (8 AWG) 1.3 mm 2 (16 AWG) 2.9 N-m (26 lb.-in.)D 33.6 mm 2 (2 AWG) 8.4 mm 2 (8 AWG) 5.1 N-m (45 lb.-in.)E 480V37-45 kW(50-60 HP)33.6 mm 2 (2 AWG) 3.5 mm 2 (12 AWG) 5.6 N-m (49.5 lb.-in.)E240V30-37 kW(40-50 HP)480V55-75 kW(75-100 HP)107.2 mm 2 (4/0 AWG) 53.5 mm 2 (1/0 AWG) 19.5 N-m (173 lb.-in.)F 152.5 mm 2 (300 MCM) 85.0 mm 2 (3/0 AWG) 19.5 N-m (173 lb.-in.)Input Power ConditionLow Line Impedance (less than 1% linereactance)Corrective Action• Install Line Reactor (1)• or Isolation TransformerLine has power factor correction capacitors • Install Line Reactor (1)Line has frequent power interruptionsLine has intermittent noise spikes in excess of6000V (lightning)• or Isolation TransformerPhase to ground voltage exceeds 125% ofnormal line to line voltageUngrounded distribution system• Remove MOV jumper to ground(Frame C, E & F drives only)• or Install Isolation Transformer withgrounded secondary if necessary(1)Refer to the <strong>PowerFlex</strong> <strong>400</strong> User Manual for accessory ordering information.

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-9I/O Wiring RecommendationsWire Type(s) Description MinimumInsulation RatingBelden 8760/9460(or equiv.)Belden 8770(or equiv.)0.8 mm 2 (18AWG), twisted pair, 100%shield with drain. (1)0.8 mm 2 (18AWG), 3 conductor, shielded forremote pot only.300V60 degrees C(140 degrees F)(1) If the wires are short and contained within a cabinet which has no sensitive circuits,the use of shielded wire may not be necessary, but is always recommended.I/O Terminal Block SpecificationsFrame Maximum Wire Size (2) Minimum Wire Size (2) TorqueC, D, E, F 1.3 mm 2 (16 AWG) 0.13 mm 2 (26 AWG) 0.5-0.8 N-m (4.4-7 lb.-in.)(2) Maximum/minimum sizes that the terminal block will accept - these are notrecommendations.Refer to the <strong>PowerFlex</strong> <strong>400</strong> User Manual for maximum control cablelength recommendations.

English-10<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartControl Terminal BlockENBLEnable (4)Jumper#1 Relay N.O.R1#1 Relay CommonR2#1 Relay N.C.R3#2 Relay N.O.R4#2 Relay CommonR5#2 Relay N.C.R6SNKSRCSNK+24VEarth Referenced +10VFrames D & E (5) 0-10V0-20mAIsolated1 of 7 Digital Input Circuits30V DC50mANon-inductiveSRC0-10V0-20mA0-10V0-20mA0102030405060708091011121314151617181920Stop/Function Loss (1)(4)Start/Run FWD (2)Direction/Run REVDigital CommonDigital Input 1Digital Input 2Digital Input 3Digital Input 4Digital CommonOpto Common+24V DC Source+10V DC SourceAnalog Input 1 (AI1)Analog Common 1Analog Output 1 (AO1)Analog Output 2 (AO2)Analog Input 2 (AI2)Analog Common 2 (6)Opto OutputRS485 ShieldTypicalSRC WiringPot must be1-10k ohm2 Watt Min.TypicalSNK WiringCommon(3)24VAO110V 20MAAO210V 20MAAI110V 20MAAI210V 20MARS485(DSI)(1)(2)(3)(4)(5)(6)Important: I/O Terminal 01 is always a coast to stop inputexcept when P036 [Start Source] is set to option 1 “3-Wire” or6 “2-W Lvl/Enbl”. In three wire control, I/O Terminal 01 iscontrolled by P037 [Stop Mode]. All other stop sources arecontrolled by P037 [Stop Mode].Important: The drive is shipped with a jumper installedbetween I/O Terminals 01 and 11. Remove this jumper whenusing I/O Terminal 01 as a stop or enable input.Two wire control shown. For three wire control use a momentary inputstart. If reverse is enabled by A166, use a maintained inputP036 [Start Source] Stop I/O Terminal 01 StopKeypad Per P037 Coast3-Wire Per P037 Per P037 (4)2-Wire Per P037 CoastRS485 Port Per P037 Coaston I/O Terminal 02 to command afor I/O Terminal 03 to change direction.When using an opto output with an inductive load such as a relay, install a recovery diode parallel to the relay asshown, to prevent damage to the output.When the ENBL enable jumper is removed, I/O Terminal 01 will always act as a hardware enable, causing acoast to stop without software interpretation.Most I/O terminals labeled “Common” are not referenced to the safety ground (PE) terminal and are designed togreatly reduce common mode interference. On Frame D and E drives, Analog Common 1 is referenced toground.Common for Analog Input 2 (AI2). Electronically isolated from digital I/O and opto output. Not to be used withAnalog Input 1 (AI1), Analog Output 1 (AO1) or Analog Output 2 (AO2). With Analog Input 2, provides one fullyisolated analog input channel.

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-11Control I/O Terminal DesignationsNo. Signal Default Description Param.01 Stop (1) /Coast Factory installed jumper or a normally closed input must P036 (1)Function Lossbe present for the drive to start.Program with P036 [Start Source].02 Start/Run FWD – HAND Mode: Command comes from Integral Keypad.AUTO Mode: I/O Terminal 02 is active.Program with P036 [Start Source].P036, P03703 Direction/Run REV Rev Disabled To enable reverse operation, program with A166[Reverse Disable].Program with P036 [Start Source].P036, P037,A16604 Digital Common – For digital inputs. Tied to I/O Terminal 09.Electronically isolated with digital inputs from analog I/Oand opto output.05 Digital Input 1 Purge (2) Program with T051 [Digital In1 Sel]. T05106 Digital Input 2 Local Program with T052 [Digital In2 Sel]. T05207 Digital Input 3 Clear Fault Program with T053 [Digital In3 Sel]. T05308 Digital Input 4 Comm Port Program with T054 [Digital In4 Sel]. T05409 Digital Common – For digital inputs. Tied to I/O Terminal 04.Electronically isolated with digital inputs from analog I/Oand opto output.10 Opto Common – For opto-coupled outputs. Electronically isolated withopto output from analog I/O and digital inputs.11 +24V DC – <strong>Drive</strong> supplied power for digital inputs.Referenced to Digital Common. Max. Output: 100mA.12 +10V DC – <strong>Drive</strong> supplied power for 0-10V external potentiometer.Referenced to Analog Common. Max. Output: 15mA.P03813 Analog Input 1 0-10V External 0-10V (unipolar), 0-20mA or 4-20mA inputsupply or potentiometer wiper. Default input is 0-10V.For current (mA) input, set AI1 DIP Switch to 20mA.Program with T069 [Analog In 1 Sel].Input Impedance: 100k ohm (Voltage Mode)250 ohm (Current Mode)14 Analog Common 1 – Common for Analog Input 1 and Analog Output 1 and 2.Electrically isolated from digital I/O and opto output.15 Analog Output 1 OutFreq 0-10 Default analog output is 0-10V.For current (mA) value, set AO1 DIP Switch to 20mA.Program with T082 [Analog Out1 Sel].Maximum Load: 4-20mA = 525 ohm (10.5V)0-10V = 1k ohm (10mA)16 Analog Output 2 OutCurr 0-10 Default analog output is 0-10V.For a current (mA) value, set AO2 DIP Switch to 20mA.Program with T085 [Analog Out2 Sel].Maximum Load: 4-20mA = 525 ohm (10.5V)0-10V = 1k ohm (10mA)17 Analog Input 2 0-10V Optically isolated external 0-10V (unipolar), ±10V(bipolar), 0-20mA or 4-20mA input supply orpotentiometer wiper. Default input is 0-10V.For current (mA) input, set AI2 DIP Switch to 20mA.Program with T073 [Analog In 2 Sel].Input Impedance: 100k ohm (Voltage Mode)250 ohm (Current Mode)T069, T070,T071, T072P038,T051-T054,A152T082, T084,T085, T086,T087T073, T074,T075, T07618 Analog Common 2 – For Analog Input 2. Electronically isolated from digital I/Oand opto output. With Analog Input 2, provides one fullyisolated analog input channel.19 Opto Output At <strong>Frequency</strong> Program with T065 [Opto Out Sel]. T065, T066,T06820 RS485 (DSI) Shield – Terminal connected to Safety Ground - PE when usingthe RS485 (DSI) Communication Port.(1)(2)See Footnotes (1) and (4) on previous page.See the User Manual for Important information regarding Stop commands and the [Digital Inx Sel] Purge option.

English-12<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartRelay Terminal Designations and DIP SwitchesNo. Signal Default Description Param.R1 #1 Relay N.O. Ready/Fault Normally open contact for No. 1 output relay. T055R2 #1 Relay Common – Common for output relay.R3 #1 Relay N.C. Ready/Fault Normally closed contact for No. 1 output relay. T055R4 #2 Relay N.O. Motor Running Normally open contact for No. 2 output relay. T060R5 #2 Relay Common – Common for output relay.R6 #2 Relay N.C. Motor Running Normally closed contact for No. 2 output relay. T060Selection DIP Switches:Analog Input (AI1 & AI2)Analog Output (AO1 & AO2)0-10V Sets analog output to either voltage or current.Settings must match: AI1 & T069 [Analog In 1 Sel]AI2 & T073 [Analog In 2 Sel]AO1 & T082 [Analog Out1 Sel]AO2 & T085 [Analog Out2 Sel]Sink/Source DIP Switch Source (SRC) Inputs can be wired as Sink (SNK) or Source (SRC) via DIPSwitch setting.Figure 4: User Installed Auxiliary Relay Card (Frames D, E, & F Only)3A 3B 4A 4B 5A 5B6A 6B 7A 7B 8A 8BImportant: If using auxiliary motor control, ensure that wiring and parameterconfiguration are correct before wiring contactor outputs. All relayson the Auxiliary Relay Card will energize on power-up by default.Failure to verify proper wiring and parameter configuration can resultin improper motor operation or drive damage. Refer to Appendix Dfor more details.User Installed Relay Board Terminal DesignationsNo. Signal Default Description Param.3A #3 Relay N.O. Ready/Fault Normally open contact for Number 3 Output Relay R2213B #3 Relay Common – Common for Number 3 Output Relay4A #4 Relay N.O. Ready/Fault Normally open contact for Number 4 Output Relay R2244B #4 Relay Common – Common for Number 4 Output Relay5A #5 Relay N.O. Ready/Fault Normally open contact for Number 5 Output Relay R2275B #5 Relay Common – Common for Number 5 Output Relay6A #6 Relay N.O. Ready/Fault Normally open contact for Number 6 Output Relay R2306B #6 Relay Common – Common for Number 6 Output Relay7A #7 Relay N.O. Ready/Fault Normally open contact for Number 7 Output Relay R2337B #7 Relay Common – Common for Number 7 Output Relay8A #8 Relay N.O. Ready/Fault Normally open contact for Number 8 Output Relay R2368B #8 Relay Common – Common for Number 8 Output Relay

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-13Prepare For <strong>Drive</strong> Start-Up!❏❏❏❏ATTENTION: Power must be applied to the drive to perform thefollowing start-up procedures. Some of the voltages present are atincoming line potential. To avoid electric shock hazard or damage toequipment, only qualified service personnel should perform thefollowing procedure. Thoroughly read and understand the procedurebefore beginning. If an event does not occur while performing thisprocedure, Do Not Proceed. Remove All Power including usersupplied control voltages. User supplied voltages may exist even whenmain <strong>AC</strong> power is not applied to the drive. Correct the malfunctionbefore continuing.Before Applying Power to the <strong>Drive</strong>1. Confirm that all inputs are connected to the correct terminals and aresecure.2. Verify that <strong>AC</strong> line power at the disconnect device is within the ratedvalue of the drive.3. Verify that any digital control power is 24 volts.4. Verify that the Sink (SNK)/Source (SRC) Setup DIP Switch is set tomatch your control wiring scheme.Important: The default control scheme is Source (SRC). The Stopterminal is jumpered (I/O Terminals 01 and 11) to allowstarting from the keypad. If the control scheme is changedto Sink (SNK), the jumper must be removed from I/OTerminals 01 and 11 and installed between I/O Terminals01 and 04.❏5. Verify that the Stop input is present or the drive will not start.Important: If I/O Terminal 01 is used as a stop input, the jumperbetween I/O Terminals 01 and 11 must be removed.❏❏❏6. Verify that the Analog I/O DIP Switches are set to 10 volts.Applying Power to the <strong>Drive</strong>7. Apply <strong>AC</strong> power and control voltages to the drive.8. Familiarize yourself with the integral keypad features before settingany Program Group parameters.Start, Stop, Direction and Speed ControlFactory default parameter values allow the drive to be controlled fromthe integral keypad. No programming is required to start, stop, andcontrol speed directly from the integral keypad.If a fault appears on power up, refer to page 25 for an explanation of thefault code. For complete troubleshooting information, refer to the<strong>PowerFlex</strong> <strong>400</strong> User Manual supplied with the drive.

English-14<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartIntergral KeypadOperator KeysKey Name DescriptionEscapeBack one step in programming menu.Cancel a change to a parameter value and exit ProgramMode.SelectAdvance one step in programming menu.Select a digit when viewing parameter value.Up ArrowDown ArrowEnterDigital SpeedIncrement andDecrement ArrowsScroll through groups and parameters.Increase/decrease the value of a flashing digit.Advance one step in programming menu.Save a change to a parameter value.Used to control speed of drive. Default is active.Control is activated by parameter P038 [Speed Reference] orP042 [Auto Mode].Run/Start & Hand (1) Used to start the drive. Default is Hand mode as controlled byparameter P042 [Auto Mode].Control is activated by parameter P036 [Start Source] orP042 [Auto Mode].Auto (1)Used to select Auto control mode.Controlled by parameter P042 [Auto Mode].Stop/OffUsed to stop the drive or clear a fault.This key is always active.Controlled by parameter P037 [Stop Mode].(1)Important: Certain digital input settings can override drive operation. Refer to the <strong>PowerFlex</strong> <strong>400</strong>User Manual for details.

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-15LED Status IndicatorsLED LED State DescriptionProgram Status Steady Red Indicates parameter value can be changed.Selected digit will flash.Fault Status Flashing Red Indicates that the drive is faulted.Speed Status Steady Green Indicates that the digital speed control keys areenabled.Hand Status Steady Green Indicates that the Run/Start key is enabled.Auto Status Steady Yellow Indicates that the drive is in Auto mode.LCD Display➊➋➌No.➊➋➌DescriptionParameter NameRun/Stop Status: = Stopped / = Runningflashes to indicate that the drive is stopping, but is still decelerating.flashes when DC Injection is commanded.Direction Indication: The Direction Arrow indicates the commanded direction ofrotation. If the Arrow is flashing, the drive has been commanded to change direction, but is stilldecelerating.Sleep Mode Indication: flashes to indicate that the drive is in sleep mode.Parameter Group and Number:= Basic Display = Basic Program = Terminal Block= Communications = Advanced Program = Aux Relay Card= Advanced Display➍➎➍➎Fault Indication and Fault NumberFault Name

English-16<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartKeypad Hand-Off-Auto FunctionsParameter P042 [Auto Mode] defines the operation mode of the controlkeys on the integral keypad. Hand-Off-Auto is the default operationmode for <strong>PowerFlex</strong> <strong>400</strong> drives. For detailed information on otheroperation modes, refer to the <strong>PowerFlex</strong> <strong>400</strong> User Manual supplied withthe drive.Hand-Off-Auto ModeIn HAND mode:• Control keys operate as Hand-Off-Auto.• Start command and speed reference come from the integral keypadStart/Hand and Digital Speed Increment and Decrement keys.• Auto key switches control from HAND mode to AUTO mode in abumpless transfer as long as there is an active Run command.In AUTO mode:• Auto key LED is illuminated.• Start command is defined by P036 [Start Source].• Speed Reference command is defined by P038 [Speed Reference].• Start/Hand key switches control to the integral keypad in a bumplesstransfer and switches the speed reference to the integral keypad.• Stop key stops the drive and the drive switches to HAND mode.Table 4.A P042 [Auto Mode] = 1 “Hnd-Off-Auto” (Default)T051-T054 [Digital Inx Sel] ≠ 2 “Auto Mode” or 3 “Local”HAND ModeAUTO ModeKey LED Key Function LED Key FunctionOn Starts drive.On Changes to HAND Mode and StartsRuns according to Speed Increment/ drive.Decrement keys.Runs according to Speed Increment/Decrement keys.On Changes speed. Off Not active.Keys are only active if P038 [SpeedSource] = 0 “<strong>Drive</strong> Pot”.Off Changes to AUTO Mode. On Not active.N/A Stops drive.N/A Changes to HAND Mode and Stopsdrive.

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-17Viewing and Editing ParametersThe following is an example of basic integral keypad and display functions. This example provides basicnavigation instructions and illustrates how to program the first Basic Program Group parameter.Step Key(s) Example Displays1. When power is applied, the last user-selectedBasic Display Group parameter number isdisplayed with flashing characters. The displaythen defaults to that parameter’s current value.(Example shows the value of b001 [OutputFreq] with the drive stopped.)2. Press the Up Arrow or Down Arrow to scrollthrough the Basic Display Group parameters. or(Only in Display Groups)3. Press Esc once to display the Basic DisplayGroup parameter number shown on power-up.The parameter number will flash.4. Press Esc again to enter the group menu. Thegroup menu letter will flash.5. Press the Up Arrow or Down Arrow to scrollthrough the group menu (b, P, T, C, A and d).6. Press Enter or Sel to enter a group. The rightdigit of the last viewed parameter in that groupororwill flash.7. Press the Up Arrow or Down Arrow to scrollthrough the parameters that are in the group.8. Press Enter or Sel to view the value of aparameter. If you do not want to edit the value,ororpress Esc to return to the parameter number.9. Press Enter or Sel to enter program mode toedit the parameter value. The right digit will orflash and the Program LED will illuminate if theparameter can be edited.10. If desired, press Sel to move from digit to digitor bit to bit. The digit or bit that you can changewill flash.11. Press the Up Arrow or Down Arrow to changethe parameter value.or12. Press Esc to cancel a change. The digit willstop flashing, the previous value is restored andthe Program LED will turn off.OrPress Enter to save a change. The digit will stopflashing and the Program LED will turn off.13. Press Esc to return to the parameter list.Continue to press Esc to back out of theprogramming menu.If pressing Esc does not change the display,then b001 [Output Freq] is displayed. PressEnter or Sel to enter the last group menuviewed.

English-18<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartBasic Display Group ParametersThe Basic Program Group contains the most commonly changed parameters.No. Parameter Min/Max Display/Optionsb001 [Output Freq] 0.00/[Maximum Freq] 0.01 Hzb002 [Commanded Freq] 0.00/[Maximum Freq] 0.01 Hzb003 [Output Current] 0.0/(<strong>Drive</strong> Amps × 2) 0.1 Ampsb004 [Output Voltage] 0/510 1 V<strong>AC</strong>b005 [DC Bus Voltage] 0/820 1 VDCb006 [<strong>Drive</strong> Status] 0/1 (1 = Condition True) Bit 4 Bit 3 Bit 2 Bit 1Decelerating Accelerating Forward Runningb007 [Fault 1 Code] 0/122 1b008 [Process Display] 0.00/9999.99 0.01b010 [Output Power] 0.0/999.9 kW 0.1 kWb011 [Elapsed MWh] 0/3276.7 MWh 0.1 MWhb012 [Elapsed Run Time] 0/9999 Hrs 1 = 10 Hrsb013 [Torque Current] 0.0/(<strong>Drive</strong> Amps × 2) 0.1 Ampsb014 [<strong>Drive</strong> Temp] 0/120 degC 1 degCb015 [Elapsed kWh] 0.0/100.0 kWh 0.1 kWhSmart Start-Up with Basic Program GroupThe <strong>PowerFlex</strong> <strong>400</strong> is designed so that start up is simple and efficient. The Program Groupcontains the most commonly used parameters.= Stop drive before changing this parameter.No. Parameter Min/Max Display/Options DefaultP031 [Motor NP Volts] 20/<strong>Drive</strong> Rated Volts 1 V<strong>AC</strong> Based on <strong>Drive</strong> RatingSet to the motor nameplate rated volts.P032 [Motor NP Hertz] 15/320 Hz 1 Hz 60 HzSet to the motor nameplate rated frequency.P033 [Motor OL Current] 0.0/(<strong>Drive</strong> Amps × 2) 0.1 Amps Based on <strong>Drive</strong> RatingSet to the maximum allowable motor current.P034 [Minimum Freq] 0.0/320.0 Hz 0.1 Hz 0.0 HzSets the lowest frequency the drive will outputcontinuously.P035 [Maximum Freq] 0.0/320.0 Hz 0.1 Hz 60.0 HzSets the highest frequency the drive will output.P036 [Start Source] 0/6 0 = “Keypad”31 = “3-Wire”Sets the control scheme used to start the drive2 = “2-Wire”when in Auto/Remote mode.3 = “2-W Lvl Sens”4 = “2-W Hi Speed”5 = “Comm Port”6 = “2-W Lvl/Enbl”P037 [Stop Mode] 0/7 0 = “Ramp, CF” (1)0Active stop mode for all stop sources [e.g. keypad,run forward (I/O Terminal 02), run reverse (I/OTerminal 03), RS485 port] except as noted below.Important: I/O Terminal 01 is always a coast tostop input except when P036 [Start Source] is setfor “3-Wire” control. When in three wire control, I/OTerminal 01 is controlled by P037 [Stop Mode].1 = “Coast, CF” (1)2 = “DC Brake, CF” (1)3 = “DCBrkAuto,CF” (1)4 = “Ramp”5 = “Coast”6 = “DC Brake”7 = “DC BrakeAuto”(1) Stop input also clears active fault.

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-19= Stop drive before changing this parameter.No. Parameter Min/Max Display/Options DefaultP038 [Speed Reference] 0/5 0 = “<strong>Drive</strong> Keypad”21 = “InternalFreq”Sets the source of the speed reference to the drive.2 = “Analog In 1”Important: When T051 – T054 [Digital Inx Sel] is3 = “Analog In 2”set to option 1, 2, 3, 4, 5, 8, 14, 15, 16 or 17 and4 = “Preset Freq”the digital input is active, or if A152 [PID Ref Sel] is5 = “Comm Port”not set to option 0, the speed referencecommanded by this parameter will be overridden.Refer to Chapter 1 of the <strong>PowerFlex</strong> <strong>400</strong> UserManual for details.P039 [Accel Time 1] 0.00/600.00 Secs 0.01 Secs 20.00 SecsSets the rate of accel for all speed increases.P040 [Decel Time 1] 0.00/600.00 Secs 0.01 Secs 20.00 SecsSets the rate of decel for all speed decreases.P041 [Reset To Defalts] 0/1 0 = “Ready/Idle”0Resets all parameter values to factory defaults.1 = “Factory Rset”P042 [Auto Mode] 0/3 0 = “No Function”1Determines the operation of the “Auto” key on the 1 = “Hnd-Off-Auto”integral keypad.2 = “Local/Remote”3 = “Auto/Manual”P043 [Motor OL Ret] 0/1 0 = “Disabled”0 = “Disabled”Enables/disables the Motor Overload Retention1 = “Enabled”function.Terminal Block Group ParametersNo. Parameter Min/Max Display/Options DefaultT051T052T053T054[Digital In1 Sel]I/O Terminal 05[Digital In2 Sel]I/O Terminal 06[Digital In3 Sel]I/O Terminal 07[Digital In4 Sel]I/O Terminal 080/36 0 = “Not Used”1 = “Purge”2 = “Auto Mode”3 = “Local”4 = “Comm Port”5 = “PID Disable”6 = “PID Hold”7 = “PID Reset”8 = “Preset Freq”9 = “Aux Fault”10 = “Clear Fault”11 = “RampStop,CF”12 = “CoastStop,CF”13 = “DCInjStop,CF”14 = “Anlg1 InCtrl”15 = “Anlg2 InCtrl”16 = “MOP Up”17 = “MOP Down”18 = “Acc & Dec 2”19 = “Current Lmt2”20 = “Force DC”21 = “Mtr I-Lock 1”22 = “Mtr I-Lock 2”23 = “Mtr I-Lock 3”24 = “Mtr I-Lock 4”25 = “Cmd Reverse”31 = “Logic In 1”32 = “Logic In 2”36 = “Damper Input”13104T055T060[Relay Out1 Sel][Relay Out2 Sel]0/23 0 = “Ready/Fault”1 = “At <strong>Frequency</strong>”2 = “MotorRunning”3 = “Hand Active”4 = “Motor Overld”5 = “Ramp Reg”6 = “Above Freq”7 = “Above Cur”8 = “Above DCVolt”9 = “Above Anlg 2”10 = “Above PF Ang”11 = “Anlg In Loss”12 = “ParamControl”13 = “Retries Exst”14 = “NonRec Fault”15 = “Reverse”16 = “Logic In 1”17 = “Logic In 2”23 = “Aux Motor”T056 [Relay Out1 Level] 0.0/9999 0.1 0.0T058 [Relay 1 On Time] 0.0/600.0 Secs 0.1 Secs 0.0 SecsT059 [Relay 1 Off Time] 0.0/600.0 Secs 0.1 Secs 0.0 SecsT061 [Relay Out2 Level] 0.0/9999 0.1 0.0T060 SettingT061 Min/Max6 0/320 Hz7 0/180%8 0/815 Volts9 0/100%10 1/180 degs12 0/1T063 [Relay 2 On Time] 0.0/600.0 Secs 0.1 Secs 0.0 Secs02

English-20<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartNo. Parameter Min/Max Display/Options DefaultT064 [Relay 2 Off Time] 0.0/600.0 Secs 0.1 Secs 0.0 SecsT065 [Opto Out Sel] 0/17 0 = “Ready/Fault” 9 = “Above Anlg 2” 11 = “At <strong>Frequency</strong>”2 = “MotorRunning”3 = “Hand Active”4 = “Motor Overld”5 = “Ramp Reg”6 = “Above Freq”7 = “Above Cur”8 = “Above DCVolt”10 = “Above PF Anlg”11 = “Anlg In Loss”12 = “ParamControl”13 = “Retries Exst”14 = “NonRec Fault”15 = “Reverse”16 = “Logic In 1”17 = “Logic In 2”T066 [Opto Out Level] 0.0/9999 0.1 0.0T065 SettingT066 Min/Max6 0/<strong>400</strong> Hz7 0/180%8 0/815 Volts9 0/100%10 1/180 degs12 0/1T068 [Opto Out Logic] 0/1 1 0T068 OptionOpto Out Logic0 NO (Normally Open)1 NC (Normally Closed)T069 [Analog In 1 Sel] 0/6 1 2T069 Option Setting Input Range DIP Switch AI1 Setting0 Current Mode 0-20 mA 0-10V1 Current Mode 4-20 mA 0-10V2 Voltage Mode - Unipolar 0-10V 0-10V4 Current Mode (Square Root) 0-20 mA 0-10V5 Current Mode (Square Root) 4-20 mA 0-10V6 Voltage Mode - Unipolar (Square Root) 0-10V 0-20 mAT070T074[Analog In 1 Lo][Analog In 2 Lo]0.0/100.0% 0.1% 0.0%T071T075T072T076[Analog In 1 Hi][Analog in 2 Hi][Analog In 1 Loss][Analog In 2 Loss]0.0/100.0% 0.1% 100.0%0/6 0 = “Disabled”1 = “Fault (F29)”2 = “Stop”3 = “Zero Ref”4 = “Min Freq Ref”5 = “Max Freq Ref”6 = “Int Freq Ref”T073 [Analog In 2 Sel] 0/7 1 2T073 Option Setting Input Range DIP Switch AI1 Setting0 Current Mode 0-20 mA 20 mA1 Current Mode 4-20 mA 20 mA2 Voltage Mode - Unipolar 0-10V 10V3 Voltage Mode - Bipolar -10 to +10V 10V4 Current Mode (Square Root) 0-20 mA 20 mA5 Current Mode (Square Root) 4-20 mA 20 mA6 Voltage Mode - Unipolar (Square Root) 0-10V 10V7 Voltage Mode - Bipolar (Square Root) -10 to +10V 10VT077 [Sleep-Wake Sel] 0/3 0 = “Disabled”1 = “Analog In 1”2 = “Analog In 2”3 = “Command Freq”T078 [Sleep Level] 0.0/100.0% 0.1% 10.0%T079 [Sleep Time] 0.0/600.0 Secs 0.1 Secs 0.0 SecsT080 [Wake Level] 0.0/100.0% 0.1% 15.0%T081 [Wake Time] 0.0/600.0 Secs 0.1 Secs 0.0 Secs00

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-21No. Parameter Min/Max Display/Options DefaultT082T085[Analog Out1 Sel][Analog Out2 Sel]SettingOutputRange0/20 1 01Min. OutputValue Max. Output Value FilterDIP SwitchAO1RelatedParameter0 OutFreq 0-10 0-10V 0V = 0 Hz [Maximum <strong>Frequency</strong>] None 10V b0011 OutCurr 0-10 0-10V 0V = 0 Amps 200% <strong>Drive</strong> Rated FLA Filter A 10V b0032 OutTorq 0-10 0-10V 0V = 0 Amps 200% <strong>Drive</strong> Rated FLA Filter A 10V b0133 OutVolt 0-10 0-10V 0V = 0 Volts 120% <strong>Drive</strong> Rated Output V None 10V b0044 OutPowr 0-10 0-10V 0V = 0 kW 200% <strong>Drive</strong> Rated Power Filter A 10V b0105 Setpnt 0-10 0-10V 0V = 0.0% 100.0% Setting None 10V T0846 TstData 0-10 0-10V 0V = 0000 65535 (Hex FFFF) None 10V A1967 OutFreq 0-20 0-20 mA 0 mA = 0 Hz [Maximum <strong>Frequency</strong>] None 20 mA b0018 OutCurr 0-20 0-20 mA 0 mA = 0 Amps 200% <strong>Drive</strong> Rated FLA Filter A 20 mA b0039 OutTorq 0-20 0-20 mA 0 mA = 0 Amps 200% <strong>Drive</strong> Rated FLA Filter A 20 mA b01310 OutVolt 0-20 0-20 mA 0 mA = 0 Volts 120% <strong>Drive</strong> Rated Output V None 20 mA b00411 OutPowr 0-20 0-20 mA 0 mA = 0 kW 200% <strong>Drive</strong> Rated Power Filter A 20 mA b01012 Setpnt 0-20 0-20 mA 0 mA = 0.0% 100.0% Setting None 20 mA T08413 TstData 0-20 0-20 mA 0 mA = 0000 65535 (Hex FFFF) None 20 mA A19614 OutFreq 4-20 4-20 mA 4 mA = 0 Hz [Maximum <strong>Frequency</strong>] None 20 mA b00115 OutCurr 4-20 4-20 mA 4 mA = 0 Amps 200% <strong>Drive</strong> Rated FLA Filter A 20 mA b00316 OutTorq 4-20 4-20 mA 4 mA = 0 Amps 200% <strong>Drive</strong> Rated FLA Filter A 20 mA b01317 OutVolt 4-20 4-20 mA 4 mA = 0 Volts 120% <strong>Drive</strong> Rated Output V None 20 mA b00418 OutPowr 4-20 4-20 mA 4 mA = 0 kW 200% <strong>Drive</strong> Rated Power Filter A 20 mA b01019 Setpnt 4-20 4-20 mA 4 mA = 0.0% 100.0% Setting None 20 mA T08420 TstData 4-20 4-20 mA 4 mA = 0000 65535 (Hex FFFF) None 20 mA A196T083T086[Analog Out1 High][Analog Out2 High]0/800% 1% 100%T084T087T083 Setting T082 Setting T082 Max. Output Value50% 1 “OutCurr 0-10” 5V for 200% <strong>Drive</strong> Rated Output Current90% 11 “OutPowr 0-20” 18 mA for 200% <strong>Drive</strong> Rated Power[Anlg Out1 Setpt][Anlg Out2 Setpt]0.0/100.0% 0.1% 0.0%T088 [Anlg Loss Delay] 0.0/20.0 Secs 0.1 Secs 0.0 SecsCommunications Group ParametersNo. Parameter Min/Max Display/Options DefaultC101 [Language] 1/10 1 = “English”2 = “Français”3 = “Español”4 = “Italiano”5 = “Deutsch”6 = “Reserved”7 = “Português”8 = “Reserved”9 = “Reserved”10 = “Nederlands”1C102 [Comm Format] 0/9 0 = “RTU 8-N-1”Power to drive must be cycled before any1 = “RTU 8-E-1”changes will affect drive operation.2 = “RTU 8-O-1”3 = “RTU 8-N-2”4 = “RTU 8-E-2”C103 [Comm Data Rate] 0/5 0 = “1200”1 = “2<strong>400</strong>”2 = “4800”5 = “RTU 8-O-2”6 = “MetaSys N2”7 = “P1 8-N-1”8 = “P1 8-E-1”9 = “P1 8-O-1”3 = “9600”4 = “19.2K”5 = “38.4K”C104 [Comm Node Addr] 1/247 1 100C105 [Comm Loss Action] 0/5 0 = “Fault”3 = “Continu Last” 01 = “Coast Stop”2 = “Stop”4 = “Run Preset 0”5 = “Kypd Inc/Dec”C106 [Comm Loss Time] 0.1/60.0 Secs 0.1 Secs 5.0 SecsC107 [Comm Write Mode] 0/1 0 = “Save” 1 = “RAM Only” 0C108 [Start Source 2] 0/6 0 = “Keypad”Sets the control scheme used to start the drive1 = “3-Wire”when in Auto/Remote mode.2 = “2-Wire”C109 [Speed Ref 2] 0/5 0 = “<strong>Drive</strong> Keypad”1 = “InternalFreq”2 = “Analog In 1”3 = “2-W Lvl Sens”4 = “2-W Hi Speed”5 = “Comm Port”6 = “2-W Lvl/Enbl”3 = “Analog In 2”4 = “Preset Freq”5 = “Comm Port”0032

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-23No. Parameter Min/Max Display/Options Default3A182 [<strong>Drive</strong> OL Mode] 0/3 0 = “Disabled”1 = “Reduce CLim”2 = “Reduce PWM”3 = “Both-PWM 1st”A183 [SW Current Trip] 0.0/(<strong>Drive</strong> Amps × 1.8) 0.1 Amps 0.0 (Disabled)A184 [Load Loss Level] 0.0/<strong>Drive</strong> Amps 0.1 Amps 0.0 (Disabled)A185 [Load Loss Time] 0/9999 Secs 1 Secs 0 (Disabled)A186 [Stall Fault Time] 0/5 0 = “60 Seconds”1 = “120 Seconds”2 = “240 Seconds”3 = “360 Seconds”4 = “480 Seconds”5 = “Flt Disabled”A187 [Bus Reg Mode] 0/1 0 = “Disabled” 1 = “Enabled” 1A188 [Skip <strong>Frequency</strong> 1] 0/320 Hz 1 Hz 0 HzA189 [Skip Freq Band 1] 0.0/30.0 Hz 0.1 Hz 0.0 HzA190 [Skip <strong>Frequency</strong> 2] 0/320 Hz 1 Hz 0 HzA191 [Skip Freq Band 2] 0.0/30.0 Hz 0.1 Hz 0.0 HzA192 [Skip <strong>Frequency</strong> 3] 0/320 Hz 1 Hz 0 HzA193 [Skip Freq Band 3] 0.0/30.0 Hz 0.1 Hz 0.0 HzA194 [Compensation] 0/3 0 = “Disabled”1 = “Electrical”2 = “Mechanical”3 = “Both”A195 [Reset Meters] 0/2 0 = “Ready/Idle” 1 = “Reset MWh” 02 = “Reset Time”A196 [Testpoint Sel] 1024/65535 1 1024A197 [Fault Clear] 0/2 0 = “Ready/Idle” 1 = “Reset Fault”2 = “Clear Buffer”0A198 [Program Lock] 0/3 0 = “Unlocked”1 = “Locked” (All)2 = “Locked” (Not Network) 03 = “Locked” (P035, A170)A199 [Motor NP Poles] 2/40 1 4A200 [Motor NP FLA] 0.1/(<strong>Drive</strong> Amps × 2) 0.1 Amps Rated Amps03Aux Relay Card Group ParametersNo. Parameter Min/Max Display/Options DefaultR221R224R227R230R233R236[Relay Out3 Sel][Relay Out4 Sel][Relay Out5 Sel][Relay Out6 Sel][Relay Out7 Sel][Relay Out8 Sel]0R222R225R228R231R234R237[Relay Out3 Level][Relay Out4 Level][Relay Out5 Level][Relay Out6 Level][Relay Out7 Level][Relay Out8 Level]0/23 0 = “Ready/Fault”1 = “At <strong>Frequency</strong>”2 = “MotorRunning”3 = “Hand Active”4 = “Motor Overld”5 = “Ramp Reg”6 = “Above Freq”7 = “Above Cur”8 = “Above DCVolt”9 = “Above Anlg 2”10 = “Above PF Ang”11 = “Anlg In Loss”12 = “ParamControl”13 = “Retries Exst”14 = “NonRec Fault”15 = “Reverse”16 = “Logic In 1”17 = “Logic In 2”23 = “Aux Motor”0.0/9999 Hz 0.1 0.0[Relay OutX Select] Setting [Relay OutX Level] Min/Max6 0/320 Hz7 0/180%8 0/815 Volts9 0/100%10 1/180 degs12 0/1R239 [Aux Motor Mode] 0/1 0 = “Disabled” 1 = “Enabled” 0R240 [Aux Motor Qty] 1/6 1 = “1 Aux Mtr”2 = “2 Aux Mtr”3 = “3 Aux Mtr”4 = “1 Mtr + Swap”5 = “2 Mtr + Swap”6 = “3 Mtr + Swap”1R241R244R247[Aux 1 Start Freq][Aux 2 Start Freq][Aux 3 Start Freq]0.0/320.0 Hz 0.1 Hz 50.0 Hz

English-24<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartNo. Parameter Min/Max Display/Options Default0.0/320.0 Hz 0.1 Hz 25.0 HzR242R245R248R243R246R249[Aux 1 Stop Freq][Aux 2 Stop Freq][Aux 3 Stop Freq][Aux 1 Ref Add][Aux 2 Ref Add][Aux 3 Ref Add]0.0/100.0% 0.1% 0.0%R250 [Aux Start Delay] 0.0/999.9 Secs 0.1 Secs 5.0 SecsR251 [Aux Stop Delay] 0.0/999.9 Secs 0.1 Secs 3.0 SecsR252 [Aux Prog Delay] 0.00/60.00 Secs 0.01 Secs 0.50 SecsR253 [Aux AutoSwap Tme] 0.0/999.9 Hrs 0.1 Hrs 0.0 HrR254 [Aux AutoSwap Lvl] 0.0/100.0% 0.1% 50.0%Advanced Display Group ParametersNo. Parameter Min/Max Display/Options Defaultd301 [Control Source] 0/99 Digit 0: Start Command Digit 1: Speed Command Read Only0 = Keypad1 = Terminal Block2 = Communications0 = Local Keypad Pot1 = A1422 = Analog Input 13 = Analog Input 24 = A143-1465 = Communicationsd302 [Control In Status] 0/1(1 = Condition True)Read Onlyd303 [Comm Status] 0/1(1 = Condition True)Digit 0: Received Good Message PacketDigit 1: Transmitting MessageDigit 2: DSI Peripheral ConnectedDigit 3: Received Bad Message PacketRead Onlyd304 [PID Setpnt Displ] 0.0/100.0% 0.1% 0.0%d305 [Analog In 1] 0.0/120.0% 0.1% 0.0%d306 [Analog In 2]d307d308d309d310d312d314d311d313d315Display Digit (Right to Left) I/O Terminal Control Input0 02 Start/FWD In1 03 Dir/Rev In2 01 Stop Input3 05 Digital In 14 06 Digital In 25 07 Digital In 36 08 Digital In 4[Fault 1 Code][Fault 2 Code][Fault 3 Code][Fault 1 Time-hr][Fault 2 Time-hr][Fault 3 Time-hr][Fault 1 Time-min][Fault 2 Time-min][Fault 3 Time-min]0/122 1 Read Only0/9999 Hrs 1 Hrs Read Only0.0/60.0 Min 0.1 Min Read Onlyd316 [Elapsed Time-hr] 0/32767 1 Hr Read Onlyd317 [Elapsed Time-min] 0.0/60.0 Min 0.1 Min Read Onlyd318 [Output Powr Fctr] 0.0/180.0 deg 0.1 deg Read Onlyd319 [Testpoint Data] 0/FFFF 1 Hex Read Onlyd320 [Control SW Ver] 1.00/99.99 0.01 Read Onlyd321 [<strong>Drive</strong> Type] Used by Rockwell Automation field service personnel.d322 [Output Speed] 0.0/100.0% 0.1% Read Onlyd323 [Output RPM] 0/2<strong>400</strong>0 RPM 1 RPM Read Onlyd324 [Fault <strong>Frequency</strong>] 0.00/320.00 Hz 0.01 Hz Read Onlyd325 [Fault Current] 0.0/(<strong>Drive</strong> Amps × 2) 0.1 Amps Read Onlyd326 [Fault Bus Volts] 0/820 VDC 1 VDC Read Onlyd327 [Status @ Fault] 0/1 1 Read Only

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-25Fault CodesTo clear a fault, press the Stop key, cycle power or set A100 [Fault Clear] to 1 or2.No. Fault DescriptionF2 Auxiliary Input (1) Check remote wiring.F3 Power Loss Monitor the incoming <strong>AC</strong> line for low voltage or line power interruption.F4 UnderVoltage (1) Monitor the incoming <strong>AC</strong> line for low voltage or line power interruption.F5 OverVoltage (1) Monitor the <strong>AC</strong> line for high line voltage or transient conditions. Bus overvoltage can also becaused by motor regeneration. Extend the decel time or install a dynamic brake chopper.F6 Motor Stalled (1) Increase [Accel Time x] or reduce load so drive output current does not exceed the current setby parameter A089 [Current Limit].F7 Motor Overload (1) An excessive motor load exists. Reduce load so drive output current does not exceed thecurrent set by parameter P033 [Motor OL Current].F8 Heatsink OvrTmp (1) Check for blocked or dirty heat sink fins. Verify that ambient temperature has not exceeded 40°C(104°F) for IP 30/NEMA 1/UL Type 1 installations or 50°C (122°F) for Open type installations.Check fan.F12 HW OverCurrent Check programming. Check for excess load, improper DC boost setting, DC brake volts set toohigh or other causes of excess current.F13 Ground Fault Check the motor and external wiring to the drive output terminals for a grounded condition.F15 Load Loss Check for load loss (i.e., a broken belt).F29 Analog Input Loss (1) An analog input is configured to fault on signal loss. A signal loss has occurred.F33 Auto Rstrt Tries Correct the cause of the fault and manually clear.F38 Phase U to Gnd Check the wiring between the drive and motor. Check motor for grounded phase.F39 Phase V to Gnd Replace drive if fault cannot be cleared.F40 Phase W to GndF41 Phase UV Short Check the motor and drive output terminal wiring for a shorted condition.F42 Phase UW Short Replace drive if fault cannot be cleared.F43 Phase VW ShortF48 Params Defaulted The drive was commanded to write default values to EEPROM. Clear the fault or cycle power tothe drive. Program the drive parameters as needed.F63 SW OverCurrent (1) Check load requirements and A098 [SW Current Trip] setting.F64 <strong>Drive</strong> Overload Reduce load or extend Accel Time.F70 Power Unit Cycle power. Replace drive if fault cannot be cleared.F71 Net Loss The communication network has faulted.F81 Comm Loss If adapter was not intentionally disconnected, check wiring to the port. Replace wiring, portexpander, adapters or complete drive as required. Check connection. An adapter wasintentionally disconnected. Turn off using C105 [Comm Loss Action].F94 Function Loss Close input to terminal 01 and re-start the drive.F100 Parameter Checksum Restore factory defaults.F122 I/O Board Fail Cycle power. Replace drive if fault cannot be cleared.(1) Auto-Reset/Run type fault. Configure with parameters A092 and A093.For a complete listing of Faults and Alarms, refer to the <strong>PowerFlex</strong> <strong>400</strong>User Manual.

English-26<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartDimensions<strong>PowerFlex</strong> <strong>400</strong> FramesOutput PowerFrame SizekW HP 208-240V <strong>AC</strong> Input <strong>400</strong>-480V <strong>AC</strong> Input2.2-7.5 3-10 C C11-15 15-20 D C18.5-22 25-30 D D30-37 40-50 E E45-75 60-100 – E90-110 125-150 – FFigure 5: <strong>PowerFlex</strong> <strong>400</strong> Frames C-FIP20/66 (NEMA Type 1/4X/12)ADC300(11.81)Flange Mount244(9.61)EB325(12.8)FDimensions are in millimeters and (inches).24.5(0.96)105.8(4.17)EMC Line FiltersFigure 6: Catalog Numbers: 22-RF018-CS, 22-RF018-CL, 22-RF026-CS,22-RF026-CL, 22-RF026-CL, 22-RF034-CS138.2(5.44)Frame A B C D E FWeight (1)kg (lbs.)C 130.0 (5.1) 260.0 (10.2) 180.0 (7.1) 116.0 (4.57) 246.0 (9.7) 5.8 (0.23) 4.33 (9.5)D 250.0 (9.84) 436.2 (17.17) 206.1 (8.11) 226.0 (8.90) 383.4 (15.09) 9.0 (0.35) 14.0 (30.9)E 370.0 (14.57) 605.5 (23.84) 259.2 (10.21) 335.0 (13.19) 567.4 (22.34) 8.5 (0.33) 51.2 (112.9)F 425.0 (16.73) 850.0 (33.46) 264.0 (10.39) 381.0 (15.00) 647.5 (25.49) 13.0 (0.51) 88.0 (194.0)(1) Weights include HIM and Standard I/O.32(1.26)60(2.36)13090 (5.12)(3.54)309297(12.17)(11.69) 297(11.69)17(0.67) 30(1.18)5.5 (0.22)

<strong>PowerFlex</strong> <strong>400</strong> <strong>Adjustable</strong> <strong>Frequency</strong> <strong>AC</strong> <strong>Drive</strong> Quick StartEnglish-27Figure 7: Catalog Numbers: 22-RFD036, 22-RFD050, 22-RFD070, 22-RFD100,22-RFD150, 22-RFD180ADCFBEGCatalogNumber A B C D E F G22-RFD036 74 (2.91) 272 (10.71) 161 (6.34) 60 (2.36) 258 (10.16) 7.5 (0.30) 7 (0.28)22-RFD050 93 (3.66) 312 (12.28) 190 (7.48) 79 (3.11) 298 (11.73) 13.5 (0.53) 7 (0.28)22-RFD070 93 (3.66) 312 (12.28) 190 (7.48) 79 (3.11) 298 (11.73) 13.5 (0.53) 7 (0.28)22-RFD100 93 (3.66) 312 (12.28) 190 (7.48) 79 (3.11) 298 (11.73) 13.5 (0.53) 7 (0.28)22-RFD150 126 (4.96) 312 (12.28) 224 (8.82) 112 (4.41) 298 (11.73) 19.5 (0.77) 7 (0.28)22-RFD180 126 (4.96) 312 (12.28) 224 (8.82) 112 (4.41) 298 (11.73) 27 (1.06) 7 (0.28)Dimensions are in millimeters and (inches).Figure 8: Catalog Numbers: 22-RFD33065(2.56)235(9.25)65(2.56)40(1.57)15(0.59)68(2.68)386(15.20)306(12.05)120(4.72)120(4.72)55(2.17)∅ 12(2.56)∅ 10.5(2.56)25(0.98)

www.rockwellautomation.comPower, Control and Information Solutions HeadquartersAmericas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846Publication 22C-QS001A-EN-P – February 2006Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Printed in Taiwan.