131 LA UR 03 5862 - National Nuclear Security Administration ...

131 LA UR 03 5862 - National Nuclear Security Administration ...

131 LA UR 03 5862 - National Nuclear Security Administration ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

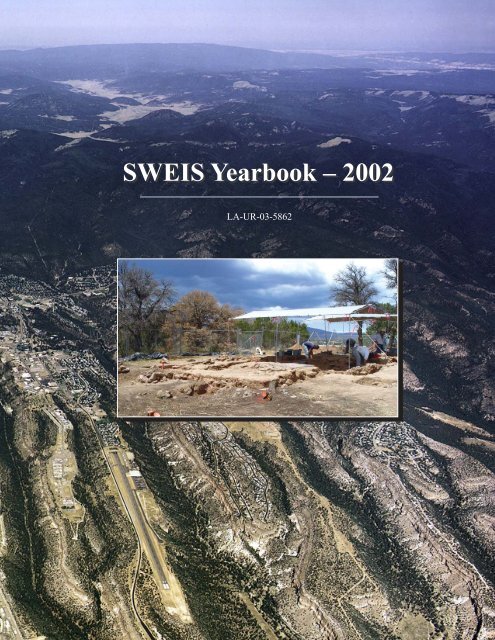

SWEIS Yearbook – 2002<strong>LA</strong>-<strong>UR</strong>-<strong>03</strong>-<strong>5862</strong>

<strong>LA</strong>-<strong>UR</strong>-<strong>03</strong>-<strong>5862</strong>Issued: September 20<strong>03</strong>Approved for public release;distribution is unlimitedSWEIS Yearbook—2002Comparison of 1998 to 2002 Data to Projections of theSite-Wide Environmental Impact Statement forContinued Operation of the Los Alamos <strong>National</strong> LaboratoryEcology GroupRisk Reduction and Environmental Stewardship Division

CONTENTSList of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viiList of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiAcronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiiiPreface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvReferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviExecutive Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviiReferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiAcknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii1.0 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11.1 The SWEIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11.2 Annual Yearbook. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11.3 This Yearbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31.4 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32.0 Facilities and Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12.1 Plutonium Complex (TA-55). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-342.1.1 Construction and Modifications at the Plutonium Complex . . . . . . . . . . . . . . . . . . . . 2-342.1.2 Operations at the Plutonium Complex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-372.1.3 Operations Data for the Plutonium Complex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-372.1.4 Cerro Grande Fire Effects at the Plutonium Complex. . . . . . . . . . . . . . . . . . . . . . . . . 2-442.2 Tritium Facilities (TA-16 and TA-21) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-452.2.1 Construction and Modifications at the Tritium Facilities . . . . . . . . . . . . . . . . . . . . . . 2-452.2.2 Operations at the Tritium Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-462.2.3 Operations Data for the Tritium Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-502.2.4 Cerro Grande Fire Effects at the Tritium Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-502.3 Chemistry and Metallurgy Research Building (TA-<strong>03</strong>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-522.3.1 Construction and Modifications at the CMR Building . . . . . . . . . . . . . . . . . . . . . . . . 2-532.3.2 Operations at the CMR Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-542.3.3 Operations Data for the CMR Building. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-542.3.4 Cerro Grande Fire Effects at the CMR Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-542.4 Pajarito Site (TA-18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-652.4.1 Construction and Modifications at the Pajarito Site . . . . . . . . . . . . . . . . . . . . . . . . . . 2-662.4.2 Operations at the Pajarito Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-672.4.3 Operations Data for the Pajarito Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-712.4.4 Cerro Grande Fire Effects at the Pajarito Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-722.5 Sigma Complex (TA-<strong>03</strong>). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-732.5.1 Construction and Modifications at the Sigma Complex . . . . . . . . . . . . . . . . . . . . . . . 2-742.5.2 Operations at the Sigma Complex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-752.5.3 Operations Data for the Sigma Complex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-752.5.4 Cerro Grande Fire Effects at the Sigma Complex . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-752.6 Materials Science Laboratory (TA-<strong>03</strong>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-792.6.1 Construction and Modifications at the Materials Science Laboratory. . . . . . . . . . . . . 2-792.6.2 Operations at the Materials Science Laboratory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-792.6.3 Operations Data for the Materials Science Laboratory . . . . . . . . . . . . . . . . . . . . . . . . 2-832.6.4 Cerro Grande Fire Effects at the Materials Science Laboratory . . . . . . . . . . . . . . . . . 2-84SWEIS Yearbook—2002iii

5.4.4 Production Readiness/Plant Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-215.4.5 Environment, Safety, and Health/Regulatory Issues . . . . . . . . . . . . . . . . . . . . . . . . . . 5-215.4.6 <strong>Security</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-225.4.7 Workforce Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-225.4.8 Transportation and Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-235.4.9 Current Planning Initiatives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-235.4.10 Facility Strategic Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-235.5 Facilities and Infrastructure Projects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-235.5.1 Overview of Site Project Prioritization and Cost Profile. . . . . . . . . . . . . . . . . . . . . . . 5-235.5.2 Line Item Highlighted Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-235.5.3 FIRP Highlighted Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-245.5.4 RTBF/Operations of Facilities Highlighted Projects. . . . . . . . . . . . . . . . . . . . . . . . . . 5-245.5.5 Non-RTBF/FIRP Highlighted Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-255.5.6 Institutional General Plant Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-265.5.7 Facilities and Infrastructure Cost Projection Spreadsheets . . . . . . . . . . . . . . . . . . . . . 5-275.6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-286.0 Summary and Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16.1 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16.2 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-66.3 To the Future . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6Appendix A. Chemical Usage and Emissions Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1Appendix B. <strong>Nuclear</strong> Facilities Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1Appendix C. Radiological Facility List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1Appendix D. NPDES Outfall Status Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1Appendix E. Preliminary Assessment of Potential Impact of <strong>LA</strong>NL Site Boundary Changes andLand Transfer on Accident Analyses in the SWEIS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1Appendix F. Future Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1LIST OF TABLES2.0-1. Maximum Offsite Dose Estimates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12.0-2. Radiological Exposure to <strong>LA</strong>NL Workers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22.0-3. Radioactive Liquid Waste Treated at <strong>LA</strong>NL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32.0-4. Low-Level Waste Generation at <strong>LA</strong>NL by Facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42.0-5. Mixed Low-Level Waste Generation at <strong>LA</strong>NL by Facility . . . . . . . . . . . . . . . . . . . . . . . . 2-52.0-6. TRU Waste Generation at <strong>LA</strong>NL by Facility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62.0-7. Mixed TRU Waste Generation at <strong>LA</strong>NL by Facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72.0-8. Overall Solid Radioactive Waste Generation at <strong>LA</strong>NL . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-82.0-9. Chemical Waste Generated at <strong>LA</strong>NL by Facility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-92.0-10. <strong>LA</strong>NL <strong>Nuclear</strong> Facilities–SWEIS and 2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-112.0-11. Projected Construction and Modifications in the SWEIS ROD. . . . . . . . . . . . . . . . . . . . 2-142.0-12. Projected Construction and Modifications Completed 1998–2002 . . . . . . . . . . . . . . . . . 2-182.0-13. Capabilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-192.0-14. Summary of Inactive Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-242.0-15. Summary of Wastes Generated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-252.0-16. Flow from Permitted Outfalls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-262.0-17. Acreage for Key and Non-Key Facilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30SWEIS Yearbook—2002vii

2.13-1. Radiochemistry Buildings with <strong>Nuclear</strong> Hazard Classification. . . . . . . . . . . . . . . . . . . 2-1362.13.1-1. Construction and Modifications at the Radiochemistry Facility . . . . . . . . . . . . . . . . . . 2-1372.13.2-1. Radiochemistry Facility (TA-48)/Comparison of Operations . . . . . . . . . . . . . . . . . . . . 2-1382.13.3-1. Radiochemistry Facility (TA-48)/Operations Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1412.13.4-1. Fire-Damaged Structures at TA-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1432.14-1. Radioactive Liquid Waste Treatment Facility Buildings with <strong>Nuclear</strong> HazardClassification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1442.14.1-1. Radioactive Liquid Waste Treatment Facility Construction and Modifications . . . . . . 2-1452.14.2-1. Radioactive Liquid Waste Treatment Facility (TA-50)/Comparisonof Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1472.14.3-1. Radioactive Liquid Waste Treatment Facility (TA-50)/Operations Data. . . . . . . . . . . . 2-1502.15-1. Solid Radoactive and Chemical Waste Buildings with <strong>Nuclear</strong> HazardClassification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1522.15.1-1. Solid Radioactive and Chemical Waste Facilities Constructionand Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1552.15.2-1. Solid Radioactive and Chemical Waste Facilities (TA-54 and TA-50)/Comparison of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1562.15.3-1. Solid Radioactive and Chemical Waste Facilities (TA-54 and TA-50)/Operations Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1612.16-1. Non-Key Facilities with <strong>Nuclear</strong> Hazard Classification . . . . . . . . . . . . . . . . . . . . . . . . 2-1622.16-2. Non-Key Facilities with Radiological Hazard Classification . . . . . . . . . . . . . . . . . . . . 2-1622.16.1-1. Non-Key Facilities Construction and Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1642.16.2-1. Operations at the Non-Key Facilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1762.16.3-1. Non-Key Facilities/Operations Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1782.17.2-1. Environmental Restoration Project/Operations Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1832.17.3-1. Evaluated and Stabilized PRSs following the Cerro Grande Fire . . . . . . . . . . . . . . . . . 2-1843.1.1-1. Radioactive Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23.1.1-2. Maximum Offsite Dose Estimates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23.1.2.1-1. Emissions of Criteria Pollutants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33.1.2.2-1. Emissions of Volatile Organic Compounds and Hazardous Air Pollutants fromChemical Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43.2-1. NPDES Permitted Outfalls by Watershed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53.2-2. Discharges to Watersheds from NPDES Permitted Outfalls . . . . . . . . . . . . . . . . . . . . . . . 3-63.2-3. NPDES Permitted Outfalls by Facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73.2-4. Discharges from NPDES Permitted Outfalls by Facility. . . . . . . . . . . . . . . . . . . . . . . . . . 3-83.3-1. <strong>LA</strong>NL Waste Types and Generation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1<strong>03</strong>.3.2-1. Chemical Waste Generators and Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-113.3.3-1. LLW Generators and Quantities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-123.3.4-1. MLLW Generators and Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-123.3.5-1. Transuranic Waste Generators and Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-143.3.6-1. Mixed Transuranic Waste Generators and Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-143.4.1-1. Gas Consumption (decatherms) at <strong>LA</strong>NL/Fiscal Years 1991-2002. . . . . . . . . . . . . . . . . 3-153.4.1-2. Steam Production at <strong>LA</strong>NL/Fiscal Years 1996-2002. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-153.4.2-1. Electric Peak Coincident Demand/Fiscal Years 1991-2002. . . . . . . . . . . . . . . . . . . . . . . 3-163.4.2-2. Electric Consumption/Fiscal Years 1991-2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-173.4.3-1. Water Consumption for Calendar Years 1992-2002. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-183.5.1-1. Total Recordable and Lost Workday Case Rates at <strong>LA</strong>NL . . . . . . . . . . . . . . . . . . . . . . . 3-193.5.2-1. Radiological Exposure to <strong>LA</strong>NL Workers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20SWEIS Yearbook—2002ix

3.5.2-2. Highest Individual Doses from External Radiation to <strong>LA</strong>NL Workers . . . . . . . . . . . . . . 3-2<strong>03</strong>.6-1. <strong>LA</strong>NL-Affiliated Workforce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-213.6-2. County of Residence for UC Employees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-223.6-3. UC Employee Index for Key Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-233.7.5-1. Site-wide Land Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-263.7.5-2. Land Transfers during CY 2002. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-263.8-1. Groundwater Characterization Wells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-283.9-1. Acreage Surveyed, Prehistoric Cultural Resource Sites Recorded, and CulturalResource Sites Eligible for the <strong>National</strong> Register of Historic Places at<strong>LA</strong>NL FY 2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-333.9-2. Historic Period Cultural Resource Properties at <strong>LA</strong>NL. . . . . . . . . . . . . . . . . . . . . . . . . . 3-343.9.3-1. Historic Building Documentation and Demolition Numbers. . . . . . . . . . . . . . . . . . . . . . 3-373.10.2-1. Biological Resources Reviews. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-394.3-1. <strong>LA</strong>NL Sanitary Waste Generation in FY 2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85.2.3.1-1. Site-Wide Land Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-65.2.3.2-1. Land Subparcels Transferred during CY 2002. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-85.2.4-1. Primary Construction Projects Funded through FY 2002 . . . . . . . . . . . . . . . . . . . . . . . . . 5-95.2.4-2. Selected Proposed Construction Projects through FY 2012 . . . . . . . . . . . . . . . . . . . . . . 5-105.3.6-1. Specialized Facilities and Supported Mission Needs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-135.3.7-1. Specialized Non-NNSA Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-155.4.2-1. Summary of Proposed Future Condition by Gross Square Feet—FY 2002and FY 20<strong>03</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-175.4.3-1. Electrical Power Concerns and Related Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-185.4.3-2. Sanitary Waste Disposal System Concerns and Related Projects . . . . . . . . . . . . . . . . . . 5-185.4.3-3. Radioactive Liquid Waste Concerns and Related Projects . . . . . . . . . . . . . . . . . . . . . . . 5-195.4.3-4. Central Steam System Concerns and Related Projects . . . . . . . . . . . . . . . . . . . . . . . . . . 5-195.4.3-5. Water Supply System Concerns and Related Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-205.4.3-6. Natural Gas Concerns and Related Projects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-205.4.7-1. Current and Projected Workforce Levels by Directorate . . . . . . . . . . . . . . . . . . . . . . . . . 5-225.5.1-1. Funding Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24A-1. Chemistry and Metallurgy Research Building Air Emissions . . . . . . . . . . . . . . . . . . . . . . A-1A-2. Bioscience Air Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3A-3. High Explosives Processing Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5A-4. High Explosives Testing Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7A-5 <strong>LA</strong>NSCE Air Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8A-6. Machine Shops Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10A-7. Materials Science Laboratory Air Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11A-8. Pajarito Site Air Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13A-9. Plutonium Facility Complex Air Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14A-10. Radiochemistry Site Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16A-11. Sigma Complex Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21A-12. Target Fabrication Facility Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-23A-13. Tritium Operations Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-26A-14. Waste Management Operations Air Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27B-1. Comparison of <strong>Nuclear</strong> Facilities Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1C-1. Radiological Facility List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1E-1. Land Parcels Transferred and to be Transferred . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6E-2 Sixteen Radiological Accidents Evaluated in <strong>LA</strong>NL SWEIS and Affected Areas . . . . . . E-7xSWEIS Yearbook—2002

F-1. RTBF Line Item Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2F-2. RTBF Operations of Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4F-3. Facilities and Infrastructure Recapitalization Program (FIRP) . . . . . . . . . . . . . . . . . . . . . F-7F-4. Non-RTBF and Non-FIRP Facilities and Infrastructure—Line Item and ProposedCapital Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-13F-5. Non-RTBF and Non-FIRP Facilities and Infrastructure—Expense, General Plant,Institutional General Plant, and Institutional Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . F-16F-6. Non-RTBF and Non-FIRP Facilities and Infrastructure—Maintenance, Standby Facility,Decommissioning and Demolition, and Facilities Management andSite Planning Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-21F-7. Other General Plant Projects in 2001 TYCSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-23F-8. Summary of Decommissioning and Demolition Projects . . . . . . . . . . . . . . . . . . . . . . . . F-24LIST OF FIG<strong>UR</strong>ES2-1. Location of <strong>LA</strong>NL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-312-2. Location of technical areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-322-3. Location of Key Facilities.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-333-1. Location of the groundwater characterization wells. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-274-1. Total radioactive emissions from point sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24-2. Total tritium emissions from Tritium Key Facilities’ stacks. . . . . . . . . . . . . . . . . . . . . . . . 4-34-3. Maximum offsite dose.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34-4. Carbon monoxide emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44-5. Emissions of nitrogen oxides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44-6. Particulate matter emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44-7. Emissions of sulfur oxides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54-8. Emissions of volatile organic compounds and hazardous air pollutants.. . . . . . . . . . . . . . 4-54-9. NPDES discharges by facility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64-10. <strong>LA</strong>NL chemical waste generation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74-11. <strong>LA</strong>NL low-level waste generation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-104-12. <strong>LA</strong>NL mixed low-level waste generation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-104-13. <strong>LA</strong>NL transuranic waste generation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-114-14. <strong>LA</strong>NL mixed transuranic waste generation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-114-15. <strong>LA</strong>NL natural gas consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-124-16. <strong>LA</strong>NL electric consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-124-17. <strong>LA</strong>NL electric peak coincident demand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-134-18. <strong>LA</strong>NL water consumption.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-134-19. Total recordable injuries at <strong>LA</strong>NL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-144-20. Lost workday case rates at <strong>LA</strong>NL.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-144-21. Radiological exposure to <strong>LA</strong>NL workers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-145-1. Existing land use at <strong>LA</strong>NL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45-2. Future land use at <strong>LA</strong>NL.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55-3. <strong>LA</strong>NL parcels for conveyance and transfer.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7E-1. Site boundaries for conducting accident analyses at <strong>LA</strong>NL . . . . . . . . . . . . . . . . . . . . . . . E-3E-2a. TA-55 old evaluation boundary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4E-2b. TA-55 new evaluation boundary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4E-3. Location of transfer parcels and key accident facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8SWEIS Yearbook—2002xi

xiiSWEIS Yearbook—2002

AcronymsAFCIA<strong>LA</strong>RAAOCBABSLCASACDCCDISCINTCiCMRCRMTSWEIS Yearbook—2002Advanced Fuel Cycle Initiativeas low as reasonably achievablearea of concernbiological assessmentBiosafety LevelCritical Assembly and Storage AreaCenters for Disease ControlChange During Interim StatusCenter for IntegratedNanotechnologiescurieChemical and Metallurgy ResearchCultural Resources ManagementTeamCSP2000 Comprehensive Site Plan for 2000CXCX-TBDCYDARHTD&DDOEDVRSDXEAEA-CXcategorical exclusionthe planned activity is anticipated tobe within categorical exclusioncalendar yearDual-Axis RadiographicHydrodynamic Test (facility)Decommissioning and demolitionUS Department of EnergyDecontamination and VolumeReduction SystemDynamic Experimentation (Division)environmental assessmentan environmental assessment foundthe proposed activity to be withincategorical exclusionEA-FONSI an environmental assessment wasconducted with a finding of nosignificant impactEA-TBDEISEIS DraftEIS-Prepan environmental assessment has notbeen conducted but is anticipatedenvironmental impact statementan EIS was drafted and issued forpublic commentan EIS has been determined tobe needed and is currently beingpreparedEIS-RODEIS-TBDEPAERESAFIRPFITSFTEFYGPPHCHEPAHEWTFHRLHSWAHVACIAEAICEJCNNMkV<strong>LA</strong><strong>LA</strong>NL<strong>LA</strong>NSCELEDAlinacLIRLLWLPSSan EIS was written and record ofdecision issueda determination of need for EIS is notyet complete, but an EIS isanticipatedUS Environmental ProtectionAgencyEnvironmental Restoration (Project)Engineering Sciences andApplications (Division)Facilities and InfrastructureRecapitalization ProgramFacility Improvement TechnicalSupport (building)full-time equivalent (employee)fiscal yearGeneral Plant ProjectHazard Categoryhigh-efficiency particulate air (filter)High Explosives Waste TreatmentFacilityHealth Research LaboratoryHazardous and Solid WasteAmendmentheating, ventilation, and airconditioningInternational Atomic Energy AgencyIrradiation of Chips and ElectronicsJohnson Controls Northern NewMexicokilovoltLaboratory of AnthropologyLos Alamos <strong>National</strong> LaboratoryLos Alamos Neutron Science CenterLow-Energy DemonstrationAcceleratorlinear acceleratorLaboratory ImplementingRequirementlow-level wasteLong-Pulse Spallation Sourcexiii

LWCmMDAMeVMGYMLLWMSLNEPANFANISCNMEDNMSFNMSHPDNNSANO xNPDESNRCNRHPOPCOSRPCBPE & Dxivlost workday cases (rate)meterMaterial Disposal Areamillion electron voltsmillion gallons per yearmixed low-level wasteMaterials Science Laboratory<strong>National</strong> Environmental Policy Actno further actionNonproliferation and International<strong>Security</strong> CenterNew Mexico EnvironmentDepartment<strong>Nuclear</strong> Materials Storage FacilityNew Mexico State HistoricPreservation Department<strong>National</strong> <strong>Nuclear</strong> <strong>Security</strong><strong>Administration</strong>nitrogen oxides<strong>National</strong> Pollutant DischargeElimination SystemUS <strong>Nuclear</strong> Regulatory Commission<strong>National</strong> Register of Historic PlacesOther Project CostsOffsite Source Recovery (Program)polychlorinated biphenylPreliminary Engineering and DesignPHERMEX Pulsed High-Energy RadiographicMachine Emitting X-rays (facility)PNMPRSpsiPT<strong>LA</strong>Public Service Company of NewMexicopotential release sitepounds per square inchProtection Technology Los AlamosRAMROD Radioactive Materials ResearchOperations and Demonstration(facility)RANTRCRAremRadioactive Assay andNondestructive Test (facility)Resource Conservation and RecoveryActroentgen equivalent manRLWTFRODRTBFRadioactive Liquid Waste TreatmentFacilityrecord of decisionReadiness in Technical Base andFacilitiesS-3 <strong>Security</strong> Systems GroupSCCSHEBASNMSO xSWEISSWMUTATBDTECTEDETFFTRITRUTSCATSFFTSTATWISPTYCSPU 3O 8UCUF/ROUNHVCAWCRRWETFWIPPWNRWTAStrategic Computing ComplexSolution High-Energy BurstAssemblyspecial nuclear materialsulfur oxidesSite-Wide Environmental ImpactStatementsolid waste management unitTechnical Areato be determinedTotal Estimated Costtotal effective dose equivalentTarget Fabrication Facilitytotal recordable incident (rate)transuranicToxic Substances Control ActTritium Science and FabricationFacilityTritium System Test Assembly(facility)Transuranic Waste InspectableStorage ProjectTen-Year Comprehensive Site Planuranium oxideUniversity of Californiaultrafiltration/reverse osmosisuranium nitrate hexahydratevoluntary corrective actionWaste Characterization, Reduction,and Repackaging (facility)Weapons Engineering TritiumFacilityWaste Isolation Pilot PlantWeapons Neutron Research (facility)Western Technical AreaSWEIS Yearbook—2002

PrefaceIn the Record of Decision for StockpileStewardship and Management, the US Departmentof Energy (DOE) 1 charged <strong>LA</strong>NL with several newtasks, including war reserve pit production. DOEevaluated potential environmental impacts of theseassignments in the Site-Wide Environmental ImpactStatement for Continued Operation of the LosAlamos <strong>National</strong> Laboratory (DOE 1999a). ThisSite-Wide Environmental Impact Statement (SWEIS)provided the basis for DOE decisions to implementthese new assignments at <strong>LA</strong>NL through the SWEISRecord of Decision (ROD) issued in September 1999(DOE 1999b).Every five years, DOE performs a formal analysisof the adequacy of the SWEIS to characterizethe environmental envelope for continuingoperations at <strong>LA</strong>NL. The Annual SWEIS Yearbookwas designed to assist DOE in this analysis bycomparing operational data with projections of theSWEIS for the level of operations selected by theROD. As originally planned, the Yearbook wasto be published one year following the activities;however, publication was moved approximately sixmonths earlier to achieve timely presentation of theinformation. Yearbook publications to date includethe following:• “SWEIS 1998 Yearbook,” <strong>LA</strong>-<strong>UR</strong>-99-6391,December 1999 (<strong>LA</strong>NL 1999, http://libwww.lanl.gov/cgi-bin/getfile?00460172.pdf).• “SWEIS Yearbook – 1999,” <strong>LA</strong>-<strong>UR</strong>-00-5520, December 2000 (<strong>LA</strong>NL 2000a, http://lib-www.lanl.gov/cgi-bin/getfile?<strong>LA</strong>-<strong>UR</strong>-00-5520.htm).• “SWEIS Yearbook – 2000,” <strong>LA</strong>-<strong>UR</strong>-01-2965,July 2001. (<strong>LA</strong>NL 2001, http://lib-www.lanl.gov/la-pubs/00818189.pdf).• “SWEIS Yearbook – 2001,” <strong>LA</strong>-<strong>UR</strong>-02-3143,September 2002 (<strong>LA</strong>NL 2002, http://libwww.lanl.gov/cgi-bin/getfile?00818857.pdf).• “SWEIS Yearbook – 2002” <strong>LA</strong>-<strong>UR</strong>-<strong>03</strong>-<strong>5862</strong>, September 20<strong>03</strong> (<strong>LA</strong>NL 20<strong>03</strong>, http://lib-www.lanl.gov/cgi-bin/getfile?<strong>LA</strong>-<strong>UR</strong>-<strong>03</strong>-<strong>5862</strong>.htm).The collective set of Yearbooks contains dataneeded for trend analyses, identifies potentialproblem areas, and enables decision-makers todetermine when and if an updated SWEIS orother <strong>National</strong> Environmental Policy Act (NEPA)analysis is necessary. This edition of the Yearbooksummarizes the data from 1998 to 2002, and providestrend analysis of these data to assist DOE in itsdecision-making process. A similar summarizationwill be prepared every five years, as appropriate.As with previous editions, the covers includeinset photographs depicting important events thathappened during the calendar year under review. Thephotograph on the front cover this year representspast human occupation of the Pajarito Plateau withan archaeological excavation on property destinedfor transfer from the Department of Energy to LosAlamos County. The photograph on the back coverdepicts a current capability at the Laboratory—‘theWall’ in the Strategic Computing Complex whichhouses the world’s fastest computers.• “A Special Edition of the SWEIS Yearbook,Wildfire 2000,” <strong>LA</strong>-<strong>UR</strong>-00-3471, August 2000(<strong>LA</strong>NL 2000b, http://lib-www.lanl.gov/cgi-bin/getfile?0<strong>03</strong>93627.pdf).1 Congress established the <strong>National</strong> <strong>Nuclear</strong> <strong>Security</strong> <strong>Administration</strong> (NNSA) within the DOE to manage the nuclear weapons program for theUnited States. Los Alamos <strong>National</strong> Laboratory (<strong>LA</strong>NL or Laboratory) is one of the facilities now managed by the NNSA. The NNSA officiallybegan operations on March 1, 2000. Its mission is to carry out the national security responsibilities of the DOE, including maintenance of a safe,secure, and reliable stockpile of nuclear weapons and associated materials capabilities and technologies; promotion of international nuclear safety andnonproliferation; and administration and management of the naval nuclear propulsion program.SWEIS Yearbook—2002xv

ReferencesDepartment of Energy, 1999a. “Site-WideEnvironmental Impact Statement for ContinuedOperation of the Los Alamos <strong>National</strong>Laboratory,” US Department of Energy documentDOE/EIS-0238, Albuquerque, NM.Department of Energy, 1999b. “Record of Decision:SWEIS in the State of New Mexico,” 64 FR50797, Washington, D.C.Los Alamos <strong>National</strong> Laboratory, 1999. “SWEIS1998 Yearbook,” Los Alamos <strong>National</strong> Laboratoryreport <strong>LA</strong>-<strong>UR</strong>-99-6391, Los Alamos, NM. (http://lib-www.lanl.gov/cgi-bin/getfile?00460172.pdf).Los Alamos <strong>National</strong> Laboratory, 2002. “SWEISYearbook – 2001,” Los Alamos <strong>National</strong>Laboratory report <strong>LA</strong>-<strong>UR</strong>-02-3143, LosAlamos, NM. (http://lib-www.lanl.gov/cgi-bin/getfile?00818857.pdf).Los Alamos <strong>National</strong> Laboratory, 20<strong>03</strong>. “SWEISYearbook – 2002” Los Alamos <strong>National</strong>Laboratory report <strong>LA</strong>-<strong>UR</strong>-<strong>03</strong>-<strong>5862</strong>, Los Alamos,NM. (http://lib-www.lanl.gov/cgi-bin/getfile?<strong>LA</strong>-<strong>UR</strong>-<strong>03</strong>-<strong>5862</strong>.htm).Los Alamos <strong>National</strong> Laboratory, 2000a. “SWEISYearbook – 1999,” Los Alamos <strong>National</strong>Laboratory report <strong>LA</strong>-<strong>UR</strong>-00-5520, Los Alamos,NM. (http://lib-www.lanl.gov/cgi-bin/getfile?<strong>LA</strong>-<strong>UR</strong>-00-5520.htm).Los Alamos <strong>National</strong> Laboratory, 2000b. “A SpecialEdition of the SWEIS Yearbook, Wildfire2000,” Los Alamos <strong>National</strong> Laboratory report<strong>LA</strong>-<strong>UR</strong>-00-3471, Los Alamos, NM. (http://libwww.lanl.gov/cgi-bin/getfile?0<strong>03</strong>93627.pdf).Los Alamos <strong>National</strong> Laboratory, 2001. “SWEISYearbook – 2000,” Los Alamos <strong>National</strong>Laboratory report <strong>LA</strong>-<strong>UR</strong>-01-2965, LosAlamos, NM. (http://lib-www.lanl.gov/la-pubs/00818189.pdf).xviSWEIS Yearbook—2002

Executive SummaryIn 1999, the US Department of Energy (DOE)published a Site-Wide Environmental ImpactStatement (SWEIS) for Continued Operationof Los Alamos <strong>National</strong> Laboratory (<strong>LA</strong>NL orLaboratory)(DOE 1999a). DOE issued a Record ofDecision (ROD) for this document in September1999 (DOE 1999b).DOE and <strong>LA</strong>NL implemented a program, theAnnual Yearbook, making comparisons betweenSWEIS ROD projections and actual operations datafor two reasons: first, to preserve and enhance theusefulness of the SWEIS as a “living” document,and second, to provide DOE with a tool to assist indetermining the continued adequacy of the SWEISin characterizing existing operations. The Yearbooksfrom calendar year (CY) 1998 through CY 2001focus on operations during one calendar year andspecifically address the following:• facility and/or process modifications or additions,• types and levels of operations during the calendaryear,• operations data for the Key Facilities, and• site-wide effects of operations for the calendaryear.The 2002 Yearbook is a special edition to assistDOE/<strong>National</strong> <strong>Nuclear</strong> <strong>Security</strong> <strong>Administration</strong> inevaluating the need for preparing a new SWEIS for<strong>LA</strong>NL. This edition of the Yearbook summarizesthe data routinely collected from CY 1998 throughCY 2002 as described above. It also containsadditional text and tabular summaries as well as atrend analysis. The 2002 Yearbook also indicatesthe Laboratory’s programmatic progress in movingtowards the SWEIS projections.The SWEIS analyzed the potential environmentalimpacts of scenarios for future operations at<strong>LA</strong>NL. DOE announced in its ROD that it wouldoperate <strong>LA</strong>NL at an expanded level and thatthe environmental consequences of that level ofoperations were acceptable. The ROD is not apredictor of specific operations, but establishesboundary conditions for operations. The RODSWEIS Yearbook—2002provides an environmental operating envelope forspecific facilities and for the Laboratory as a whole.If operations at <strong>LA</strong>NL were to routinely exceed theoperating envelope, DOE would evaluate the needfor a new SWEIS. As long as <strong>LA</strong>NL operationsremain below the level analyzed in the ROD, theenvironmental operating envelope is valid. Thus, thelevels of operation projected by the SWEIS RODshould not be viewed as goals to be achieved, butrather as acceptable operational levels.The Yearbooks address capabilities and operationsusing the concept of “Key Facility” as presentedin the SWEIS. The definition of each Key Facilityhinges upon operations (research, production, orservices) and capabilities and is not necessarilyconfined to a single structure, building, or technicalarea. Chapter 2 discusses each of the 15 KeyFacilities from three aspects—significant facilityconstruction and modifications that have occurredfrom 1998 through 2002, the types and levels ofoperations that occurred from 1998 through 2002,and the 1998 through 2002 operations data. Chapter2 also discusses the “Non-Key Facilities,” whichinclude all buildings and structures not part of a KeyFacility, or the balance of <strong>LA</strong>NL.During 2002, planned construction and/ormodifications continued at six of the 15 KeyFacilities. These activities were both modificationswithin existing structures and new or replacementfacilities. New structures completed and occupiedduring 2002 included the Technical Area (TA) 18Relocation Project Office Building between TA-48 and TA-55, the Vessel Preparation Facility atTA-15, a Camera Room at TA-36-12, a CarpenterShop at TA-15, the X-Ray Calibration Facility atTA-15, a Warehouse at TA-15, and the transportableoffice building TA-48-210. Additionally, 13 majorconstruction projects were either completed orcontinued for the Non-Key Facilities. These projectswere as follows:• Construction continued on the Nonproliferationand International <strong>Security</strong> Center that was begunin March 2001.• Atlas was disassembled and relocated to theNevada Test Site in December 2002.xvii

• Construction of the Emergency OperationsCenter started in January 2002.• Construction of the S-3 <strong>Security</strong> SystemsSupport Facility started in July 2002.• Construction of the Decision ApplicationsDivision Office Building started in September2002.• Construction of the new Medical Facility startedin October 2002.• The Chemistry Division Office Building wasconstructed, completed, and occupied.• Construction of the Materials Science andTechnology Office Building started in November2002.• Construction of the TA-72 Live Fire Shoot Housestarted in November 2002.• The <strong>Security</strong> Truck Inspection Station wasconstructed and became operational.• The High Pressure Tritium Facility (TA-33-86) underwent decontamination anddecommissioning and is now demolished.• Demolition activities began in July 2002 on theOmega West Reactor Facility.• TA-41-30 and the front of TA-41-4 weredemolished August to October 2002.The ROD projected a total of 38 facilityconstruction and modification projects for <strong>LA</strong>NL.Twenty projects have now been completed: six in1998, eight in 1999, two in 2000, and four in 2002.The number of projects started or continued eachyear were 13 in 1998, 10 in 1999, seven in 2000, andsix in both 2001 and 2002.A major modification project, elimination and/orrerouting of <strong>National</strong> Pollutant Discharge EliminationSystem (NPDES) outfalls, was completed in 1999,bringing the total number of permitted outfalls downfrom the 55 identified by the SWEIS ROD to 20.During 2000, Outfall <strong>03</strong>A-199, which will serve theTA-<strong>03</strong>-1837 cooling towers, was included in thenew NPDES permit issued by the US EnvironmentalProtection Agency (EPA) on December 29, 2000.This brings the total number of permitted outfalls upto 21. During 2002, only 17 of the 21 outfalls flowed.As in the Yearbooks since 1999, this issue reportschemical usage and calculated emissions (expressedas kilograms per year) for the Key Facilities, basedon an improved chemical reporting system. The2002 chemical usage amounts were extracted fromthe Laboratory’s EX3 chemical inventory systemrather than the Automated Chemical InventorySystem used in the past. The quantities used forthis report represent chemicals procured or broughton site by calendar year from 1999 through 2002.Information is presented in Appendix A for actualchemical use and estimated emissions for each KeyFacility. Additional information for chemical useand emissions reporting can be found in the annualEmissions Inventory Report as required by NewMexico Administrative Code, Title 20, Chapter 2,Part 73 (20 NMAC 2.73). The most recent report is“Emissions Inventory Report Summary, ReportingRequirements for the New Mexico AdministrativeCode, Title 20, Chapter 2, Part 73 (20 NMAC 2.73)for Calendar Year 2000” (<strong>LA</strong>NL 2001).With a few exceptions, the capabilities identifiedin the SWEIS ROD for <strong>LA</strong>NL have remainedconstant since 1998. The exceptions are the• movement of the Nonproliferation Training/<strong>Nuclear</strong> Measurement School between PajaritoSite and the Chemistry and Metallurgy Research(CMR) Building during 2000 and 2002,• relocation of the Decontamination OperationsCapability from the Radioactive Liquid WasteTreatment Facility (RLWTF) to the SolidRadioactive and Chemical Waste Facilities in2001,• transfer of part of the Characterization ofMaterials Capability from Sigma to the TargetFabrication Facility (TFF) in 2001, and• loss of Cryogenic Separation Capability at theTritium Key Facilities in 2001.xviiiSWEIS Yearbook—2002

Also, following the events of September 11, 2001,the Laboratory was requested to provide support forhomeland security.Since CY 1998, fewer than the 96 capabilitiesidentified for <strong>LA</strong>NL have been active. During 1998,only 87 capabilities were active. The nine capabilitieswith no activity were Manufacturing PlutoniumComponents at the Plutonium Complex; bothUranium Processing and Nonproliferation Trainingat the CMR Building; Accelerator Transmutation ofWastes at the Los Alamos Neutron Science Center(<strong>LA</strong>NSCE); Biologically Inspired Materials andChemistry, Computational Biology, and Molecularand Cell Biology at the Bioscience Facilities; andboth Size Reduction and Other Waste Processing atthe Solid Radioactive and Chemical Waste Facilities.During CY 1999, 91 capabilities were active.The five inactive capabilities were Fabricationand Metallography at CMR; both AcceleratorTransmutation of Wastes and Medical IsotopeProduction at <strong>LA</strong>NSCE; and both Size Reduction andOther Waste Processing at the Solid Radioactive andChemical Waste Facilities.During CY 2000, 89 capabilities were active.The seven inactive capabilities were Fabricationof Ceramic-Based Reactor Fuels at the PlutoniumComplex; Diffusion and Membrane Purificationat the Tritium Facilities; both Destructive andNondestructive Assay and Fabrication andMetallography at CMR; Accelerator Transmutationof Wastes and Medical Isotope Production at<strong>LA</strong>NSCE; and both Size Reduction and Other WasteProcessing at the Solid Radioactive and ChemicalWaste Facilities.During CY 2001, 87 capabilities were active. Thenine inactive capabilities were both ManufacturingPlutonium Components and Fabrication of Ceramic-Based Reactor Fuels at the Plutonium Complex; bothCryogenic Separation and Diffusion and MembranePurification at the Tritium Facilities; both Destructiveand Nondestructive Assay and Fabrication andMetallography at CMR; Accelerator Transmutation ofWastes and Medical Isotope Production at <strong>LA</strong>NSCE;and Other Waste Processing at the Solid Radioactiveand Chemical Waste Facilities.During CY 2002, 88 capabilities were active.The eight inactive capabilities were ManufacturingPlutonium Components at the Plutonium Complex;both the Cryogenic Separation and the Diffusion andMembrane Purification capabilities at the TritiumFacilities; both the Destructive and NondestructiveAssay and the Fabrication and Metallographycapabilities at CMR; both the AcceleratorTransmutation of Wastes and the Medical IsotopeProduction capabilities at <strong>LA</strong>NSCE; and Other WasteProcessing at the Solid Radioactive and ChemicalWaste Facilities.As in the preceding calendar years from 1998through 2001, only three of <strong>LA</strong>NL’s facilitiesoperated during 2002 at levels approximating thoseprojected by the ROD—the Materials ScienceLaboratory (MSL), the Bioscience Facilities(formerly Health Research Laboratory), and the Non-Key Facilities. The two Key Facilities (MSL andBioscience) are more akin to the Non-Key Facilitiesand represent the dynamic nature of researchand development at <strong>LA</strong>NL. More importantly,none of these facilities are major contributors tothe parameters that lead to significant potentialenvironmental impacts. The remaining 13 KeyFacilities all conducted operations at or belowprojected activity levels.From 1998 through 2002, radioactive airborneemissions from point sources (i.e., stacks) havevaried from a low of 1,900 curies during 1999 to ahigh of approximately 15,400 curies during 2001,70 percent of the ten-year average of 21,700 curiesprojected by the SWEIS ROD. The final dose overthis same five-year period has varied from a lowof 0.32 millirem in 1999 to a high of 1.84 milliremduring 2001 (compared to 5.44 projected), with thefinal dose for 2002 being reported to the EPA byJune 30, 2002. Calculated NPDES discharges haveranged from a low of 124 million gallons per yearin 2001 to a high of 317 million gallons per year in1999 compared to a projected volume of 278 milliongallons per year. However, the apparent decreasein flows is primarily due to the methodology bywhich flow was measured and reported in the past.Historically, instantaneous flow was measured duringfield visits as required in the NPDES permit. Thesemeasurements were then extrapolated over a 24-hourday/seven-day week. With implementation of theSWEIS Yearbook—2002xix

new NPDES permit on February 1, 2001, data arecollected and reported using actual flows recordedby flow meters at most outfalls. At those outfallsthat do not have meters, the flow is calculated asbefore, based on instantaneous flow. Quantities ofsolid radioactive and chemical wastes generated haveranged from approximately 3.2 percent of the mixedlow-level radioactive waste projections during both1999 and 2002 to 1,291 percent and 1,309 percentof the chemical waste projections during 2001 and2000, respectively. The extremely large quantities ofchemical waste (23.0 million kilograms during 2001and 27.2 million kilograms during 2000) are a resultof Environmental Restoration (ER) Project activities.(For example, the remediation of Material DisposalArea [MDA] P resulted in 21.5 million kilograms, or88 percent, of the 24.4 million kilograms of chemicalwaste generated during 2001.) Most chemicalwastes are shipped offsite for disposal at commercialfacilities; therefore, these large quantities of chemicalwaste will not impact <strong>LA</strong>NL environs. The chemicalwaste quantities are the only solid waste type tohave met or exceeded the SWEIS ROD projectionsbetween 1998 and 2002.The workforce has been above ROD projectionssince 1997. The 13,524 employees at the end of CY2002 represent 2,173 more employees than projectedand the highest number of employees over theperiod. Since 1998, the peak electricity consumptionwas 394 gigawatt-hours during 2002 and the peakdemand was 72 megawatts during 2001 comparedto projections of 782 gigawatt-hours with a peakdemand of 113 megawatts. The peak water usagewas 461 million gallons during 1998 (compared to759 million gallons projected), and the peak naturalgas consumption was 1.49 million decathermsduring 2001 (compared to 1.84 million decathermsprojected). Between 1998 and 2002, the highestcollective Total Effective Dose Equivalent (TEDE)for the <strong>LA</strong>NL workforce was 196 person-rem during2000, which is considerably lower than the workforcedose of 704 person-rem projected by the ROD.Measured parameters for ecological resourcesand groundwater were similar to ROD projections,and measured parameters for cultural resources andland resources were below ROD projections. Forland use, the ROD projected the disturbance of 48acres of new land at TA-54 because of the need foradditional disposal cells for low-level radioactivewaste. As of 2002, this expansion had not becomenecessary. However, construction continued on 44acres of land that are being developed along WestJemez Road for the Los Alamos Research Park. Thisproject has its own <strong>National</strong> Environmental PolicyAct documentation (an environmental assessment),and the land is being leased to Los Alamos Countyfor this privately owned development.Cultural resources remained protected, and noexcavation of sites at TA-54 of <strong>LA</strong>NL has occurred.(The ROD projected that 15 prehistoric sites wouldbe affected by the expansion of Area G into Zones 4and 6 at TA-54.) However, excavations did occur atthe Airport East and White Rock tracts beginning inJune 2002 and ending in March 20<strong>03</strong>. These two landtracts are now available to the County of Los Alamosfor development.As projected by the ROD, water levels in wellspenetrating into the regional aquifer continue todecline in response to pumping, typically by severalfeet each year. In areas where pumping has beenreduced, water levels show some recovery. Nounexplained changes in patterns have occurred in the1995–2002 period, and water levels in the regionalaquifer have continued a gradual decline that startedin about 1977. In addition, ecological resources arebeing sustained as a result of protection afforded byDOE ownership of <strong>LA</strong>NL. These resources includebiological resources such as protected sensitivespecies, ecological processes, and biodiversity. Therecovery and response to the Cerro Grande Fireof May 2000 included a wildfire fuels reductionprogram, burned area rehabilitation and monitoringefforts, and enhanced vegetation and wildlifemonitoring.In conclusion, <strong>LA</strong>NL operations data mostly fellwithin projections. Operations data that exceededprojections, such as number of employees orchemical waste from cleanup, either produced apositive impact on the economy of northern NewMexico or resulted in no local impact because thesewastes were shipped offsite for disposal. Overall,the 1998 through 2002 operations data indicate thatthe Laboratory was operating within the SWEISenvelope and still ramping up operations towards thepreferred Expanded Alternative in the ROD.xxSWEIS Yearbook—2002

ReferencesDepartment of Energy, 1999a. “Site-WideEnvironmental Impact Statement for ContinuedOperation of the Los Alamos <strong>National</strong>Laboratory,” US Department of Energy documentDOE/EIS-0238, Albuquerque, NM.Department of Energy, 1999b. “Record of Decision:SWEIS in the State of New Mexico,” 64 FR50797, Washington, D.C.Los Alamos <strong>National</strong> Laboratory, 2001. “EmissionsInventory Report Summary, ReportingRequirements for the New Mexico AdministrativeCode, Title 20, Chapter 2, Part 73 (20 NMAC2.73) for Calendar Year 2000,” Los Alamos<strong>National</strong> Laboratory report, Los Alamos, NM.SWEIS Yearbook—2002xxi

xxiiSWEIS Yearbook—2002

AREA OF CONTRIBUTION (continued)Los Alamos Neutron Science CenterLos Alamos Neutron Science CenterLos Alamos Neutron Science CenterMachine ShopsMaterials Science Laboratory<strong>National</strong> Pollutant Discharge Elimination System DataNon-Key Facilities–AtlasNon-Key Facilities–Industrial Research ParkNon-Key Facilities–Nonproliferation and International <strong>Security</strong> CenterNon-Key Facilities–Nonproliferation and International <strong>Security</strong> CenterNon-Key Facilities–Strategic Computing ComplexNon-Key Facilities–<strong>LA</strong>NL Medical FacilityNon-Key Facilities–Multichannel CommunicationsNon-Key Facilities–D Division Office BuildingNon-Key Facilities–Emergency Operations CenterNon-Key Facilities–Biosafety Level 3 FacilityNon-Key Facilities–Truck Inspection StationNon-Key Facilities–Live-Fire Shoot HouseNon-Key Facilities–Live-Fire Shoot HouseNon-Key Facilities–Safeguards and <strong>Security</strong>Non-Key Facilities–Omega WestNon-Key Facilities–C Division Office BuildingPajarito SitePlutonium ComplexRadioactive Liquid Waste Treatment FacilityRadioactive Liquid Waste Treatment FacilityRadiochemistry FacilitySigmaSigmaSocioeconomicsSolid Radioactive and Chemical Waste FacilitiesSolid Radioactive and Chemical Waste FacilitiesSolid Radioactive and Chemical WasteSolid Radioactive and Chemical WasteSolid Radioactive and Chemical WasteTarget Fabrication FacilityTarget Fabrication FacilityTrend AnalysisTrend AnalysisTrend AnalysisTrend AnalysisTritium FacilitiesUtilitiesUtilitiesUtilitiesWorker Safety/DosesWorker Safety/DosesCONTRIBUTOR (continued)Frank MerrillAlexander (Andy) SaundersGabriela Lopez EscobedoJerry LeechesJennifer RezmerMarc BaileyDave ScudderTony BeugelsdijkWilliam (Bill) HamiltonMark GambleNick NagyAleene JenkinsLyle KerstiensKathleen FillmoreKeith OrrLinda BakerRuth LarkinSkip AndersonSteve RiveraBill SoleKeith RendellGeorge MartinezDebbie BacaHarvey DeckerRick AlexanderRobert McClenahanSara HelmickGreg LowerStephen CosseyJohn PantanoSean FrenchGarry AllenDeborah DaymonTim SloanJulie Minton-HughesJerry GrindstaffStephen CosseyTrisha SanchezRichard RomeroKen BostickJohn KellyRichard CarlsonJerome GonzalesMark HinrichsGilbert MontoyaRobin DeVoreTom BuhlxxivSWEIS Yearbook—2002

1.0 Introduction1.1 The SWEISIn 1999, the US Department of Energy (DOE) 1 published a Site-Wide Environmental Impact Statementfor Continued Operation of the Los Alamos <strong>National</strong> Laboratory (DOE 1999a). DOE issued its Record ofDecision (ROD) on this Site-Wide Environmental Impact Statement (SWEIS) in September 1999 (DOE1999b). The ROD identified the decisions DOE made on levels of operation for <strong>LA</strong>NL for the foreseeablefuture.1.2 Annual YearbookTo enhance the usefulness of this SWEIS, a <strong>National</strong> Environmental Policy Act (NEPA) document, DOEand <strong>LA</strong>NL implemented a program making annual comparisons between SWEIS ROD projections and actualoperations via an Annual Yearbook. The Yearbook’s purpose is not to present environmental impacts orenvironmental consequences, but rather to provide data that could be used to develop an impact analysis. TheYearbook focuses on the following:• Facility and process modifications or additions (Chapter 2). These include projected activities, forwhich NEPA coverage was provided by the SWEIS, and some post-SWEIS activities for whichenvironmental coverage was not provided. In the latter case, the Yearbook identifies the additionalNEPA analyses (i.e., categorical exclusions and environmental assessments) that were performed.• The types and levels of operations during the calendar year (Chapter 2). Types of operations aredescribed using capabilities defined in the SWEIS. Levels of operations are expressed in unitsof production, numbers of researchers, numbers of experiments, hours of operation, and otherdescriptive units.• Operations data for the Key Facilities, comparable to data projected by the SWEIS ROD (Chapter2). Data for each facility include waste generated, air emissions, liquid effluents, and number ofworkers.• Site-wide effects of operations for the calendar year (Chapter 3). These include measures such asnumber of workers, radiation doses, workplace incidents, utility requirements, air emissions, liquideffluents, and solid wastes. These effects also include changes in the regional aquifer, ecologicalresources, and other resources for which the DOE has long-term stewardship responsibilities as anowner of federal lands.• Trend analysis (Chapter 4). This includes analysis on land use, quantities of waste generated, utilityconsumption, long-term effects from Laboratory operations, and the Cerro Grande RehabilitationProject.• Ten-Year Comprehensive Site Plan (TYSCP; Chapter 5). This is a summary of what the Laboratoryis proposing for potential future projects relative to land usage; structure maintenance, construction,and decontamination and demolition; and infrastructure maintenance and improvements.1Congress established the <strong>National</strong> <strong>Nuclear</strong> <strong>Security</strong> <strong>Administration</strong> (NNSA) within the DOE to manage the nuclear weapons program for theUnited States. Los Alamos <strong>National</strong> Laboratory (<strong>LA</strong>NL or Laboratory) is one of the facilities now managed by the NNSA. The NNSA officiallybegan operations on March 1, 2000. Its mission is to carry out the national security responsibilities of the DOE, including maintenance of a safe,secure, and reliable stockpile of nuclear weapons and associated materials capabilities and technologies; promotion of international nuclear safety andnonproliferation; and administration and management of the naval nuclear propulsion program.SWEIS Yearbook—2002 1-1

• Summary and conclusion (Chapter 6). This chapter summarizes CY 1998 through CY 2002 forthe Laboratory in terms of overall facility construction and modifications, facility operations, andoperations data and environmental parameters. These data form the basis of the conclusion forwhether or not the Laboratory is operating within the envelope of the SWEIS ROD.• Chemical usage and emissions data (Appendix A). These data summarize the chemical usage andair emissions by Key Facility.• <strong>Nuclear</strong> facilities list (Appendix B). This appendix provides a summary of the facilities identifiedas nuclear at the time the SWEIS was developed through CY 2002.• Radiological facilities list (Appendix C). These data identify the facilities considered asradiological in CY 2001 and CY 2002 and indicate their categorization at the time the SWEIS wasdeveloped.• Outfall status table (Appendix D). This table delineates outfalls at <strong>LA</strong>NL and chronicles usagehistory.• Preliminary Assessment of Potential Impact of <strong>LA</strong>NL Site Boundary Changes and Land Transferon Accident Analyses in the SWEIS (Appendix E). This appendix provides an assessment of thepotential impact of land transfers on the accident analyses in the SWEIS.• Future projects (Appendix F). This appendix summarizes the projects identified in the TYCSP.Data for comparison come from a variety of sources, including facility records, operations reports,facility personnel, and the annual Environmental Surveillance Report. The focus on operations rather than onprograms, missions, or funding sources is consistent with the approach of the SWEIS.The Annual Yearbooks provide DOE with information needed to evaluate adequacy of the SWEIS andenables DOE to make decisions on when and if a new SWEIS is needed. Once every five years, DOE willmake a formal evaluation of the SWEIS as to its adequacy, and therefore, every fifth year, the Yearbook willnot only report the previous years, data on operations, but will also include summaries and trends of the datapresented in the previous four editions.The Yearbooks also provide facilities and managers at the Laboratory a guide in determining whetheractivities are within the SWEIS operating envelope. The report does not reiterate the detailed informationfound in other <strong>LA</strong>NL documents, but rather points the interested reader to those documents for the additionaldetail. The Yearbook serves as a guide to environmental information collected and reported by the variousgroups at <strong>LA</strong>NL.The SWEIS analyzed the potential environmental impacts of scenarios for future operations at <strong>LA</strong>NL.DOE announced in its ROD that it would operate <strong>LA</strong>NL at an expanded level and that the environmentalconsequences of that level of operations were acceptable. The ROD is not a predictor of specific operations,but establishes boundary conditions for operations. The ROD provides an environmental operating envelopefor specific facilities and for the Laboratory as a whole. If operations at <strong>LA</strong>NL were to routinely exceedthe operating envelope, DOE would evaluate the need for a new SWEIS. As long as <strong>LA</strong>NL operationsremain below the level analyzed in the ROD, the environmental operating envelope is valid. Thus, the levelsof operation projected by the SWEIS ROD should not be viewed as goals to be achieved, but rather asacceptable operational limits.1-2SWEIS Yearbook—2002

1.3 This YearbookThe ROD selected levels of operations, and the SWEIS provided projections for these operations.This Yearbook compares data from 1998 through 2002 to the appropriate SWEIS projections. Hence, thisreport uses the phrases “SWEIS ROD projections,” “SWEIS ROD,” or “ROD” to convey this concept, asappropriate.The collection of data on facility operations is a unique effort. The type of information developed for theSWEIS is not routinely collected at <strong>LA</strong>NL. Nevertheless, this information is the heart of the SWEIS and theYearbook. Although this requires a special effort, the description of current operations and indications offuture changes in operations are believed to be sufficiently important to warrant an incremental effort.This Yearbook represents the fifth year of data collection and comparison. Therefore, this Yearbookincludes summaries of the previous four years, trends in the data across these years, and additionalinformation as deemed necessary to enable DOE to use this document as the primary source of informationfor determination of the adequacy of the existing SWEIS.1.4 ReferencesDepartment of Energy, 1999a. “Site-Wide Environmental Impact Statement for Continued Operation of theLos Alamos <strong>National</strong> Laboratory,” US Department of Energy document DOE/EIS-0238, Albuquerque,NM.Department of Energy, 1999b. “Record of Decision: SWEIS in the State of New Mexico,” 64 FR 50797,Washington, D.C.Entrance to <strong>LA</strong>NLSWEIS Yearbook—2002 1-3

Aerial view–North from Pajarito Road1-4SWEIS Yearbook—2002

2.0 Facilities and Operations<strong>LA</strong>NL has more than 2,000 structures with approximately eight million square feet under roof, spreadover an area of approximately 40 square miles. In order to present a logical and comprehensive evaluation of<strong>LA</strong>NL’s potential environmental impacts, the SWEIS developed the Key Facility concept. Fifteen facilitieswere identified that were both critical to meeting mission assignments and• housed operations that have potential to cause significant environmental impacts, or• were of most interest or concern to the public (based on comments in the SWEIS public hearings), or• would be more subject to change because of DOE programmatic decisions.The remainder of <strong>LA</strong>NL was called “Non-Key,” not to imply that these facilities were any less importantto accomplishment of critical research and development, but because they did not fit the above criteria (DOE1999a).Taken together, the 15 Key Facilities represent the great majority of environmental risks associated with<strong>LA</strong>NL operations. Specifically, the SWEIS projected that the Key Facilities would contribute• more than 99 percent of all radiation doses to the public,• more than 90 percent of all radioactive liquid waste generated at <strong>LA</strong>NL,• more than 90 percent of all radioactive solid waste generated at <strong>LA</strong>NL,• more than 99 percent of all radiation doses to the <strong>LA</strong>NL workforce, and• approximately 30 percent of all chemical waste generated by <strong>LA</strong>NL.Offsite and Onsite DosesTable 2.0-1 compares the actual maximum offsite doses to the SWEIS projections. As expected, the dosesvary from the projection because the pit production mission has not reached maturity. Table 2.0-1 presentsthe readily available calendar year radiation doses, estimated and actual, to the public from <strong>LA</strong>NL operations.These data have not been captured by facility for the SWEIS Yearbooks.Table 2.0-1. Maximum Offsite Dose Estimates (mrem)MAXIMUMOFFSITEDOSE SWEIS ROD 1998 1999 2000 2001 2002Estimate 5.44 1.72 0.32 0.65 1.9 1.6Actual --- 1.72 0.32 0.65 1.84 1.69Occupational radiation exposures for workers at <strong>LA</strong>NL from CY 1998 through CY 2002 are summarizedin Table 2.0-2. The collective Total Effective Dose Equivalent, or collective TEDE, for the <strong>LA</strong>NL workforceduring 2002 was 164 person-rem, considerably lower than the workforce dose of 704 person-rem projectedfor the ROD.SWEIS Yearbook—2002 2-1

Table 2.0-2. Radiological Exposure to <strong>LA</strong>NL WorkersPARAMETERCollective TEDE (external +internal)Number of workers with nonzerodoseAverage non-zero dose:• external + internalradiation exposure• external radiation exposure onlySWEIS VALUE VALUE VALUE VALUE VALUEUNITS ROD FOR 1998 FOR 1999 FOR 2000 FOR 2001 FOR 2002person-rem 704 161 <strong>131</strong> 196 113 164number 3,548 1,839 1,427 1,316 1,332 1696milliremmilliremNotprojectedNotprojected87.4Notprojected92901496585839695Comparison with the Projected TEDE in the ROD. In addition to being less than the collectiveTEDE levels in 1993–1995, the collective TEDE for 2002 is less than the TEDE projected in the ROD. Theimplementation of war reserve pit manufacture, which was approved in the ROD, has not become fullyoperational at <strong>LA</strong>NL. This contributed to lower doses than projected. The collective dose may increase oncethe pit manufacture program is fully implemented.Collective TEDEs for Key Facilities. In general, collective TEDEs by Key Facility or technical area aredifficult to determine because these data are collected at the group level, and members of many groups and/ororganizations receive doses at several locations. The fraction of a group’s collective TEDE coming from aspecific Key Facility or technical area can only be estimated. For example, personnel from the Health PhysicsOperations group and Johnson Controls Northern New Mexico (JCNNM) are distributed over the entireLaboratory, and these two organizations account for a significant fraction of the total <strong>LA</strong>NL collective TEDE.Radioactive Waste GenerationTables 2.0-3 through 2.0-8 compare the actual waste generation volumes to the SWEIS projections. Asexpected, the volumes vary from the projections because the pit production mission has not reached maturity.Please note that the Facility and Waste Operations (FWO) database has been improved and adjusted for wastegenerator variances.Table 2.0-3 shows the total amount of radioactive liquid waste treated at <strong>LA</strong>NL. The facilities contributingliquid waste to the Radioactive Liquid Waste Treatment Facility (RLWTF), located at TA-50, can be found inthe Annual Reports generated by the RLWTF operating group. Inspection of these reports substantiates theprojection of greater than 90 percent of all radioactive liquid waste being generated by the 15 Key Facilities.(The most recent report is <strong>LA</strong>NL 20<strong>03</strong>.)Tables 2.0-4 through 2.0-8 show the solid radioactive waste data by Key Facility. The solid radioactivewaste data are presented by individual types (LLW, mixed LLW [MLLW], TRU, and Mixed TRU) andsummarized overall. Percentage comparisons have been given with and without environmental restorationbecause the environmental restoration contribution was an unknown at the time of the SWEIS publication.Chemical Waste GenerationThe chemical waste generated by Key Facility is summarized in Table 2.0-9. As with the solid radioactivewaste, percentage comparisons have been given with and without environmental restoration because theenvironmental restoration contribution was an unknown at the time of the SWEIS publication.2-2SWEIS Yearbook—2002

SWEIS Yearbook—2002 2-3Table 2.0-3. Radioactive Liquid Waste Treated at <strong>LA</strong>NLWASTE TREATMENT ACTIVITY SWEIS ROD 1998 1999 2000 2001 2002TOTAL(1998–2002)Pretreatment of radioactive liquid 900,000 liters/yr 370,000 liters 45,000 liters 45,000 liters 457,000 liters 30,300 liters 947,300 literswaste at TA-21Percentage of SWEIS projection of- 41% 5% 5% 51% 3% 21%pretreatment at TA-21Pretreatment of radioactive liquidwaste from TA-5580,000 liters/yr 39,000 liters Less than80,000 liters9,000 liters 22,000 liters 35,400 liters Less than185,400 litersPercentage of SWEIS projection of- 49% Less than 100% 11% 28% 44% 46%pretreatment from TA-55Solidification of transuranic (TRU) 3 m 3 /yr None 5 m 3 5 m 3 None None 10 m 3sludge at TA-50Percentage of SWEIS projection of- 0% 167% 167% 0% 0% 67%solidification of TRU sludgeRadioactive liquid waste treated atTA-5<strong>03</strong>5,000,000 liters/yr 23,000,000liters20,000,000liters19,000,000liters14,000,000liters11,500,000liters87,500,000litersPercentage of SWEIS projection of- 66% 57% 54% 40% 33% 50%radioactive liquid waste treated atTA-50De-water low-level radioactive waste 10 m 3 /yr 28 m 3 37 m 3 48 m 3 60 m 3 10 m 3 183 m 3(LLW) sludge at TA-50Percentage of SWEIS projection of- 280% 370% 480% 600% 100% 366%LLW sludge de-watered at TA-50Radioactive liquid waste treated at Not Projecteda a b b243,000 liters NATA-53Percentage of SWEIS projection ofradioactive liquid waste treated atTA-53NA NA NA NA NA NA NAabRecords of flows into the TA-53 lagoons started in CY 2000.The first records of flows into the TA-53 RLWTF were reported in the 2002 annual report (<strong>LA</strong>NL 20<strong>03</strong>).

2-4Table 2.0-4. Low-Level Waste Generation at <strong>LA</strong>NL by Facility (in m 3 /yr)FACILITY SWEIS ROD 1998 1999 2000 2001 2002TOTAL(1998–2002)2.1 Plutonium Complex 754 238 345 199 300 296.3 1,378.302.2 Tritium Facility 480 46 47 49 0 90 232.002.3 Chemistry and Metallurgy Research (CMR)1,820 124 184 264 448 389 1,409.00Building2.4 Pajarito Site 145 4 31.3 14 13 0 62.302.5 Sigma Complex 960 3 61 52 0.5 202 318.502.6 Materials Science Laboratory (MSL) 0 0 0 0 0 0 0.002.7 Target Fabrication Facility (TFF) 10 0 0 0 0.2 0.4 0.602.8 Machine Shops 606 27 40.4 409 22 44 542.402.9 High Explosives Processing 16 6 8.3 3 1 8.69 26.992.10 High Explosives Testing 940 0 0.01 0.6 0 0 0.612.11 Los Alamos Neutron Science Center (<strong>LA</strong>NSCE) 1,085 16 70 28 0.1 0 114.102.12 Bioscience Facilities 34 7 14 0 0 0 21.002.13 Radiochemistry Facility 270 89 44 57 55 34 279.002.14 RLWTF 160 132 175 132 517 193 1,149.002.15 Solid Radioactive and Chemical Waste Facilities 174 15 21 13 14 35 98.00Total of LLW for Key Facilities 7,454 707 1,042.01 1,221.60 1,406.80 1,292.39 5,669.802.16 Non-Key Facilities 520 386 350 2,781 569 534 4,620Total of LLW for Key and Non-Key Facilities 7,974 1,092 1,392.01 4,002.60 1,975.80 1,826.39 10,288.80Percentage of Total from Key Facilities 93.5% 65.7% 74.8% 43.9% 71.2% 70.8% 55.1%2.17 Environmental Restoration (ER) Project 4,260 744 286 226 621 5,484 7,361Total of LLW for Non-Key Facilities and ER Project 4,780 1,130 636 3,007 1,190 6,018 11,981Total LLW = Key + Non-Key and ER Project 12,234 1,837 1,678.01 4,228.60 2,596.80 7,310 17,650.41Percentage of Total from Key Facilities 60.9% 38.5% 62.1% 28.9% 54.2% 17.7% 32.1%SWEIS Yearbook—2002