Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

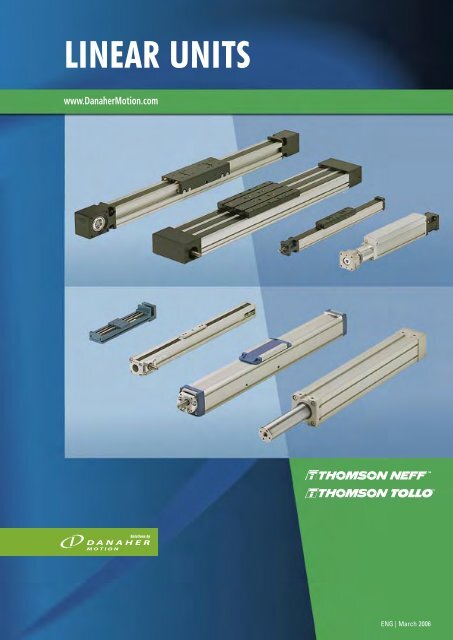

Linear Units<br />

<strong>LINEAR</strong> <strong>UNITS</strong><br />

www.DanaherMotion.com<br />

1<br />

ENG | March 2006

New Name, Established Brands<br />

Mechanical and Electro-Mechanical<br />

Product Solutions by Danaher Motion<br />

Danaher Motion’s wide range of motion control systems and components<br />

offer customers an unprecedented choice in selecting the right solution for<br />

their particular application requirements.<br />

Our product innovations have been improving the effi ciency and productivity<br />

of complex manufacturing operations for over 60 years through trusted brand<br />

names such as Dover, Kollmorgen, Pacifi c Scientifi c, Portescap and Thomson<br />

in industries as diverse as semiconductor, aerospace and defence, mobileoff-highway,<br />

packaging, medical and robotics.<br />

Our growing family of leading motion control products tells only half the story.<br />

With a worldwide service and support infrastructure, our fi eld service engineers<br />

and support teams are available when you need them.<br />

It is part of the Danaher Corporation’s unrelenting focus on you, our customer.<br />

That’s why more and more design engineers are turning to Danaher Motion<br />

to meet their motion control requirements.<br />

Danaher Motion Values<br />

• Application Expertise<br />

• Broad & Innovative Motion Control Products and Systems<br />

• Customer Focus<br />

• Customisable Products and Services<br />

• Motion Control Pioneers with Global Staying Power<br />

• Operational Excellence<br />

2<br />

Linear Units

Linear Units<br />

Table of Contents<br />

Introduction ..................................................................................................... 5<br />

Introduction ............................................................................................ 5<br />

How to choose unit ............................................................................6 - 7<br />

Technical introduction .....................................................................8 - 11<br />

Linear Units with Ball Screw Drive and Ball Guide .............................. 13<br />

Introduction ............................................................................................ 13<br />

Overview ..........................................................................................14 - 15<br />

WM40S .............................................................................................16 - 17<br />

WM40D .............................................................................................18 - 19<br />

WM60D .............................................................................................20 - 21<br />

WM60S .............................................................................................22 - 23<br />

WM60X .............................................................................................24 - 25<br />

WM80D .............................................................................................26 - 27<br />

WM80S .............................................................................................28 - 29<br />

WM120D ...........................................................................................30 - 31<br />

WV60 .................................................................................................32 - 33<br />

WV80 .................................................................................................34 - 35<br />

WV120 ...............................................................................................36 - 37<br />

MLSM60D .........................................................................................38 - 39<br />

MLSM80D .........................................................................................40 - 41<br />

2HBE10 ..............................................................................................42 - 43<br />

2HBE20 ..............................................................................................44 - 45<br />

Linear Units with Ball Screw Drive and Slide Guide ............................ 47<br />

Introduction ............................................................................................ 47<br />

Overview ..........................................................................................48 - 49<br />

WB40 .................................................................................................50 - 51<br />

M55 ....................................................................................................52 - 53<br />

M75 ....................................................................................................54 - 55<br />

M100 ..................................................................................................56 - 57<br />

M75D .................................................................................................58 - 59<br />

M100D ...............................................................................................60 - 61<br />

Linear Units with Belt Drive and Ball Guide ........................................... 63<br />

Introducti ..........................................................................................64 - 65<br />

WH40 .................................................................................................66 - 67<br />

M55 ....................................................................................................68 - 69<br />

M75 ....................................................................................................70 - 71<br />

M100 ..................................................................................................72 - 73<br />

MLSM80Z .........................................................................................74 - 75<br />

Linear Units with Belt Drive and Slide Guide ......................................... 77<br />

Introduction ............................................................................................ 77<br />

Overview ..........................................................................................78 - 79<br />

M50 ....................................................................................................80 - 81<br />

M55 ....................................................................................................82 - 83<br />

M75 ...................................................................................................84 - 85<br />

M100 ..................................................................................................86 - 87<br />

Table of Contents<br />

Linear Units with Belt Drive and Wheel Guide ...................................... 89<br />

Introduction ............................................................................................ 89<br />

Overview ..........................................................................................90 - 91<br />

WH50 .................................................................................................92 - 93<br />

WH80 .................................................................................................94 - 95<br />

WH120 ...............................................................................................96 - 97<br />

MLSH60Z ..........................................................................................98 - 99<br />

MLSH80Z ......................................................................................100 - 101<br />

Linear Lifting Units ..................................................................................... 103<br />

Introduction .......................................................................................... 103<br />

Overview ..................................................................................... 104 - 105<br />

WHZ50 ..........................................................................................106 - 107<br />

WHZ80 ..........................................................................................108 - 109<br />

Z2 ...................................................................................................110 - 111<br />

Z3 ...................................................................................................112 - 113<br />

ZB ..................................................................................................114 - 115<br />

Linear Rod Units ......................................................................................... 117<br />

Introduction .......................................................................................... 117<br />

Overview ......................................................................................118 - 119<br />

WZ60 .............................................................................................120 - 121<br />

T90 .................................................................................................122 - 123<br />

T130 ...............................................................................................124 - 125<br />

Accessories ................................................................................................. 127<br />

Accessory index .................................................................................. 127<br />

Mounting Kits ..............................................................................128 - 134<br />

Cover, Protection and Service Kits ..........................................135 - 137<br />

Motors, Gears and Transmission Kits .....................................138 - 163<br />

Electrical Feedback Devices ....................................................164 - 173<br />

Undriven Units .............................................................................174 - 179<br />

Dynamic Servo Actuators .................................................................. 180<br />

Multi Axis System Kits ........................................................................ 181<br />

Additional Technical Data ........................................................................ 183<br />

Additional Technical Data Tables ............................................183 - 187<br />

Drive Calculations .......................................................................188 - 189<br />

Deflection Calculations ..............................................................190 - 191<br />

Ordering ....................................................................................................... 193<br />

How to order ......................................................................................... 193<br />

Keys for Units with Ball Screw and Ball Guides ....................194 - 197<br />

Keys for Units with Ball Screw and Slide Guides ..................198 - 200<br />

Keys for Units with Belt Drive and Ball Guides ......................201 - 202<br />

Keys for Units with Belt Drive and Slide Guides ............................. 203<br />

Keys for Units with Belt Drive and Wheel Guides .................204 - 205<br />

Keys for Linear Lifting Units ......................................................206 - 207<br />

Keys for Linear Rod Units ................................................................... 208<br />

Keys for Undriven Units .............................................................209 - 210<br />

3

4<br />

Linear Units

Linear Units<br />

Introduction<br />

Danaher Motions linear units range consists of products from world known<br />

brands such as Thomson, Neff and Tollo. These three companies have been a part<br />

of the linear unit development elite for decades and are now forming one group of<br />

products offered to the market under the brand name Thomson.<br />

Regardless of your application you can be sure that Danaher Motion can offer you<br />

a product to match your linear motion needs.<br />

Neff<br />

Thomson<br />

Tollo<br />

Neff was founded in 1905 offering products for the linear motion<br />

market and over the decades Neff has become a market<br />

leader the ball screw technology. The fi rst linear unit from Neff<br />

was presented in 1981 at the FAMETA show in Stuttgart.<br />

Thomson dates back to the 1940s when the fi rst ball bushing<br />

bearing in the world was presented to the market. The product<br />

porfolio expanded and in the 1980s Thomson built their fi rst<br />

complete linear unit.<br />

Tollo was founded in 1981 and started as a lifting equipment<br />

manufacturer. The product potfolio grew rapidly and in 1982<br />

Tollo presented their fi rst linear unit at the Technical Fair in<br />

Stockholm.<br />

Introduction<br />

Thomson<br />

Danaher Motion has now selected the most competitive<br />

products from each brand resulting in a state of the art product<br />

range. The range covers the smallest and most compact<br />

linear units to the biggest and most robust. Danaher Motion<br />

can match your linear motion needs with a wide range of ball<br />

screw and belt driven units using a variety of guide technologies<br />

, designed to work in harsh environments, at high speeds<br />

or in high precision systems.<br />

5

How to Choose Unit<br />

How to Choose a Unit<br />

Thomson offer a wide range of linear units, each designed for a<br />

specific purpose and with its own unique features. You’ll find sizing<br />

and selection tools on our website to help you specify the unit<br />

you need, and our application engineers will be happy to help<br />

you with further technical advice.<br />

The diagrams shown here give you a brief overview of the key<br />

strengths of each group.<br />

Ball Screw Driven, Slide Guided Units<br />

Maintenance<br />

6<br />

Cost<br />

Noise<br />

Velocity<br />

Acceleration<br />

Designed for low cost, high thrust operations in demanding<br />

environments.<br />

• Cost efficient unit • Washdown protected versions<br />

• Durable guide system<br />

Linear Units<br />

Ball Screw Driven, Ball Guided Units<br />

Maintenance<br />

Cost<br />

Repeatability Maintenance<br />

Force<br />

Guide Robustness Load Torque<br />

Stiffness<br />

Noise<br />

Velocity<br />

Stiffness<br />

Units designed for high thrust, payload, high precision and<br />

stiffness.<br />

• Force up to 12000 N<br />

• Repeatability down to 0,005mm<br />

Belt Driven, Ball Guided Units<br />

Acceleration<br />

Guide Robustness Load Torque<br />

Cost<br />

Noise<br />

Velocity<br />

Acceleration<br />

Guide Robustness Load Torque<br />

Stiffness<br />

Repeatability<br />

Force<br />

Repeatability<br />

Force<br />

Smooth running units for dynamic applications with high speed,<br />

high acceleration and high loads requiring a long lifetime.<br />

• Speed up to 5 m/s<br />

• Accelartion up to 40 m/s 2

Linear Units<br />

Belt Driven, Slide Guided Units<br />

Maintenance<br />

Cost<br />

Units for dynamic applications requiring high speed, high acceleration,<br />

low maintenance and smooth travel.<br />

• Cost efficient guide system<br />

• Chemically protected versions<br />

Linear Lifting Units<br />

Load up to<br />

750 kg<br />

Speed up to<br />

10 m/s<br />

Noise<br />

Telescopic models<br />

available<br />

Ball, slide or<br />

wheel guided models<br />

Units for lifting applications. Often used in X-Y configurations in<br />

combination with other linear units.<br />

Belt Driven, Wheel Guided Units<br />

Velocity Velocity<br />

Developed for lifting applications<br />

Load torque<br />

up to 2000 Nm<br />

Acceleration<br />

Repeatability Maintenance<br />

Force<br />

Guide Robustness Load Torque<br />

Stiffness<br />

Models with ball<br />

screw or belt drive<br />

High<br />

repeatability<br />

Stroke up to<br />

3000 mm<br />

Large range<br />

of accessories<br />

Cost<br />

Units for dynamic applications with high speed, high acceleration,<br />

smooth motion and medium to high loads.<br />

• Speed up to 10 m/s<br />

• Acceleration up to 40 m/s 2<br />

Linear Rod Units<br />

Perfect for hydraulics<br />

replacement<br />

Load up to<br />

40 000 N<br />

Speed up<br />

to 2 m/s<br />

Noise<br />

Ball or slide<br />

guided models<br />

Stiffness<br />

Linear units with rod<br />

Models with<br />

IP65 sealing<br />

How to Choose Unit<br />

Acceleration<br />

Repeatability<br />

Force<br />

Guide Robustness Load Torque<br />

High accuracy<br />

ball screw drive<br />

High<br />

repeatability<br />

Stroke up to<br />

2000 mm<br />

Large range<br />

of accessories<br />

Units designed for lifting applications or for the replacement of<br />

hydraulic and pneumatic cylinders.<br />

7

Technical Introduction<br />

Technical Introduction<br />

Basic Linear Unit Terminology<br />

Screw Driven Unit Belt Driven Unit<br />

Ball Screw Drive<br />

A ball screw is made up of a rotating screw and a moving ball nut. The<br />

ball nut is attached to the carriage of the unit. It does not have a normal<br />

thread, instead balls circulate inside the nut making it work as an<br />

effi cient ball bearing that travels along the screw. Ball screws come<br />

in a large variety of leads, diameters and tolerance classes. The tolerance<br />

class (T3, T5, T7 or T9) indicates the lead tolerance of the screw.<br />

The lower the number, the higher the tolerance. High load capability and<br />

high accuracy are typical of ball screw driven units.<br />

8<br />

Drive shaft<br />

Double Carriages<br />

Front Bearing Housing<br />

Profi le<br />

Drive Station<br />

Rear Bearing Housing<br />

Cover Band<br />

Drive shaft<br />

Single Carriage<br />

T-slot/mounting groove<br />

Linear Units<br />

Tension Station<br />

Belt Drive<br />

A belt drive consists of a toothed belt which is attached to the carriage<br />

of the unit. The belt runs between two pulleys positioned at either end of<br />

the profi le. One pulley is attached to the motor while the other is mounted<br />

in a tensioning station. The belts are made of plastic reinforced with<br />

steel cords. High speeds, long stroke, low noise and low overall weight<br />

are typical features of belt driven units.

Linear Units<br />

Technical Introduction<br />

Ball Guides<br />

A ball guide consists of a ball rail and a ball bushing. The ball rail is<br />

made of hardened steel and runs along the inside of the profi le. The ball<br />

bushing is attached to the carriage of the unit and contains balls that<br />

roll against the rail. The balls in the bushing can be recirculating or have<br />

fi xed ball positions depending on the type of ball guide. The recirculating<br />

type has a longer life and better load capability while the fi xed type<br />

typically is much smaller. Thomson uses three major types of ball guides<br />

in its linear units. Either the compact single rail type with recirculating<br />

ball bushing (A), the stronger double rail type also with recirculating ball<br />

bushings (B) or the fi xed ball position ball bushings type (not shown)<br />

which require very little space and are used in the smallest units. Ball<br />

guides offer high accuracy, high loads and medium speed.<br />

A<br />

B<br />

Slide Guides<br />

A slide guide consist of a guide attached to the inside of the profi le and a<br />

slide bushing attached to the carriage. The guide can be made of different<br />

materials (e.g. polished hardened steel, anodized aluminium) while<br />

the bushing is made of a polymer material. There are two types of bushings,<br />

fi xed and prism. Prism bushings can move in relation to the guide<br />

which results in longer life and higher load capabilities. Slide bushings<br />

are silent, simple, reliable and robust and can be used in dirty and dusty<br />

environments. They are also resistant to shock loads, have a long life<br />

expectancy and require little or no maintenance.<br />

Technical Introduction<br />

Wheel Guides<br />

A wheel guide consists of ball bearing wheels that run on a hardened<br />

steel rail. Wheel guides are a simple and robust guiding method offering<br />

high speeds, high loads and medium accuarcy.<br />

Screw Supports<br />

Screw supports allow screw driven units to travel at high speed even<br />

when stroke becomes longer. The supports reduce the unsupported<br />

length of the screw, that otherwise would be subjected to vibrations.<br />

Screw supports come in single (one screw support on each side of the<br />

carriage) or double (two supports on each side) versions. Screw support<br />

units will have a slightly shorter stroke for a given overall length.<br />

Ball Screw Units with Double Ball Nuts<br />

Using double ball nuts will increase the repeatability of the unit. The<br />

ball nuts are installed so that they are pre-tensioned against each other<br />

eleminating the play between the nuts and the screw. A double nut unit<br />

will have a slightly shorter stroke for a given overall length.<br />

9

Technical Introduction<br />

Technical Introduction<br />

Single Carriage<br />

Single carriage units have one carriage. Some linear unit models also<br />

have the option of long or short single carriage. The long carriage handle<br />

higher loads but will have a longer overall length for a given stroke.<br />

Cover Band<br />

Cover bands are used on some units to protect then from the ingress of<br />

foreign objects through the opening in the profi le where the carriage<br />

runs. They are made of plastic (A) or stainless steel (B). In the case of<br />

plastic the cover band seals the profi le by snapping into small grooves<br />

running along the carriage opening. In the case of stainless steel the<br />

cover band seal the profi le magnetically using magnet strips mounted<br />

on each side of the carriage opening. Some units equipped with cover<br />

bands also have a self-adjusting cover band tensioning mechanism.<br />

This eleminates any slack in the cover band that can occur from temperaure<br />

changes, thus improving the sealing degree and the expected<br />

life of the cover band.<br />

10<br />

A<br />

B<br />

Linear Units<br />

Double Carriages<br />

Double carriage units have two carriages which gives them higher load<br />

capabilites than single carriage units. When ordering a double carriage<br />

unit the distance between the two carriages needs to be defi ned. This<br />

distance is called LA or Lc depending on the model.<br />

Theoretical Stroke and Practical Stroke<br />

The theoretical maximum stroke (S max) is the length that the carriage<br />

can travel from one end of the unit to the other. However, using the maximum<br />

stroke means that the carriage will collide with the ends of the<br />

profi le. The practical stroke is therefore shorter. We recommend that<br />

you specify a unit that have 100 mm longer stroke than the theoretical<br />

maximum stroke.<br />

Units with Left/right Moving Carriages<br />

Units with left/right moving carriages have two carriages moving in opposite<br />

directions when the drive shaft is rotated. This type of unit has a<br />

ball screw where half of the screw has a left hand thread and the other<br />

half a right hand thread.

Linear Units<br />

Technical Introduction<br />

Maintenance<br />

Most units require lubrication. General lubrication requirements can be<br />

found in the general specifications table on the product data pages. The<br />

lubrication intervals, grease qualities and specific lubrication instructions<br />

can be found in the installation and service manual of each unit. No other<br />

regular maintenance is needed except for normal cleaning and inspection.<br />

Units with a cover band may also require irregular cover band replacement<br />

due to wear. The belt in belt driven units should not require<br />

re-tensioning under normal operating conditions.<br />

Mounting Position<br />

Most units can be mounted in any direction. Any restrictions on mounting<br />

positions are shown on the product presentation pages at the beginning<br />

of each product category chapter. Even where units may be mounted in<br />

any direction there are some considerations. None of the units are selflocking<br />

which means that a vertical unit will drop the carriage/load if no<br />

external brake (such as a brake in the motor, etc.) is applied to the drive<br />

shaft of the unit. In the case of belt driven units care must be taken as the<br />

carriage/load will drop immediately in the case of a belt breakage. This is<br />

particularly important in vertical applications. All ball screw driven units<br />

are equipped with a safety nut to prevent the carriage/load being released<br />

in case of ball breakage.<br />

Working Environment<br />

All units are designed for use in normal industrial environments. Units<br />

which have an open profile (i.e. have no cover band) are more sensitive<br />

to dust, dirt and fluids. These units require some kind of cover if they are<br />

used in environments where dust, dirt or fluids are present. Optional bellows/shrouds<br />

are available for some of our open profile units. Enhanced<br />

wash-down or chemical protection can be ordered for our closed profile<br />

units. Please refer to the accessory pages. In all cases where a unit will<br />

be exposed to aggressive chemicals, heavy vibrations or other potentially<br />

harmful processes we recommend that you contact us for further advice.<br />

Duty Cycle<br />

All units are designed for a 100% duty cycle. However, where the unit runs<br />

at extreme load, speed, acceleration and temperature or for long operating<br />

periods the expected life time may be reduced.<br />

Operation and Storage Temperature<br />

Operational temperature limits can be found in the performance tables<br />

on the product data pages. Units can be stored or transported within the<br />

same temperature range. Please contact us if the unit will be exposed to<br />

higher/lower temperatures than recommended during storage or transportation<br />

Technical Introduction<br />

Load and Load Torque Values<br />

For some units the load and load torque values are given for both the complete<br />

unit and the guiding system. The values for the complete unit are<br />

the values under which the unit can operate. The values for the guiding<br />

system should only be used when comparing different units and do not<br />

describe the actual performance of the complete unit.<br />

Deflection of the Profile<br />

Some units require support along the whole profile whilst some are self<br />

supporting over a specified span. Further details can be found on the<br />

product data pages. The recommended support intervals should be followed<br />

to minimise deflection of the unit. The maximum distance between<br />

the support points is shown on the product data pages. The deflection of<br />

the unit can also be calculated using the information in the Additional data<br />

and calculations chapter.<br />

Lifetime Expectancy<br />

When determining the lifetime for a linear unit it is necessary to evaluate<br />

all forces and moments that are acting on the unit. The data and formulas<br />

given in this catalogue serve as a basis for this. For a more detailed<br />

lifetime calculation please use our sizing and selection software. Please<br />

contact us for further guidance.<br />

End of Stroke Limit Switches<br />

If a unit runs at speed to the ends of its stroke there is a risk of damage.<br />

Damage can be prevented by using end of stroke limit switches to detect<br />

and engage a break and/or cut power to the motor when the unit nears the<br />

end of the unit. You must ensure that there is sufficient distance between<br />

the end of stroke limit switch and the end of the unit, to allow the carriage<br />

to come to a complete stop before colliding with the end. The required<br />

stopping distance depends on the speed and the load and will have to be<br />

calculated for each application. The stopping distance must be taken into<br />

account when defining the necessary stroke.<br />

Position Feedback<br />

The position of the carriage/rod/lifting profile can be obtained in many<br />

ways. The most common way is to equip the unit with an encoder or to<br />

use a motor which has a built in feed back device (encoder, resolver, etc.).<br />

To many units there are encoders or/and encoder mounting kits available.<br />

See the accessory chapter.<br />

Packages and Multi Axis Kits<br />

Thomson can offer complete pre-defined packages (linear unit, gear and<br />

servo motor assembled and shipped with servo drive and cables) as well<br />

as mounting kits for the creation of two and three axis systems Please<br />

contact us for further information.<br />

11

12<br />

Linear Units

Linear Units<br />

Linear Units with Ball Screw Drive and Ball Guide<br />

PowerLine, ForceLine, Microstage, AccuSlide<br />

Maintenance<br />

Cost<br />

Noise<br />

Guide Robustness<br />

Typical Applications<br />

Velocity<br />

Stiffness<br />

Acceleration<br />

Repeatability<br />

Force<br />

Typical applications are where high accuracy and load capability is required but<br />

where speed is less important. Typical examples are machining operations and in<br />

the handling of heavy goods that need accurate positioning.<br />

Ball Screw Drive and Ball Guide<br />

Load Torque<br />

13

Ball Screw Drive and Ball Guide<br />

PowerLine WM<br />

14<br />

Linear Units<br />

Parameter WM40S WM40D WM60D WM60S WM60X WM80D WM80S WM120D<br />

Profi le size (width × height) [mm] 40 × 40 40 × 40 60 × 60 60 × 60 60 × 60 80 × 80 80 × 80 120 × 120<br />

Stroke length (S max), maximum [mm] 2000 2000 11000 5000 10340 11000 5000 11000<br />

Linear speed, maximum [m/s] 0,25 0,25 2,5 2,5 0,25 2,5 2,5 2,0<br />

Dynamic carriage load (Fz), maximum [N] 600 600 2000 1400 2000 3000 2100 6000<br />

Remarks single ball<br />

nut<br />

double ball<br />

nuts<br />

double ball<br />

nuts<br />

single ball<br />

nut<br />

left/right<br />

screw<br />

double ball<br />

nuts<br />

single ball<br />

nut<br />

Page 16 18 20 22 24 26 28 30<br />

PowerLine WV<br />

WV80<br />

WM40<br />

Parameter WV60 WV80 WV120<br />

Profi le size (width × height) [mm] 60 × 60 80 × 80 120 × 120<br />

Stroke length (S max), maximum [mm] 11000 11000 11000<br />

Linear speed, maximum [m/s] 2,5 2,5 2,0<br />

Dynamic carriage load (Fz), maximum [N] - - -<br />

Remarks double ball nuts<br />

the units has no guides<br />

double ball nuts<br />

the units has no guides<br />

double ball<br />

nuts<br />

double ball nuts<br />

the units has no guides<br />

Page 32 34 36<br />

ForceLine MLSM<br />

MLSM80D<br />

Features<br />

• Can be installed in all directions<br />

• Patented guide system<br />

• Patented self-adjusting plastic cover band<br />

• Patented screw support system<br />

Features<br />

• Can be installed in all directions<br />

• Patented self-adjusting plastic cover band<br />

• Patented screw support system<br />

• The units require external guides<br />

Features<br />

• Can be installed in all directions<br />

• Patented guide system<br />

• Patented plastic cover band<br />

• Patented screw support system<br />

Parameter MLSM60D<br />

MLSM80D<br />

Profi le size (width × height) [mm] 160 × 65 240 × 85<br />

Stroke length (S max), maximum [mm] 5500 5200<br />

Linear speed, maximum [m/s] 2,5 2,0<br />

Dynamic carriage load (Fz), maximum [N] 6000 8000<br />

Remarks double ball nuts double ball nuts<br />

Page 38 40

Linear Units<br />

AccuSlide 2HBE<br />

2HBE20<br />

Features<br />

Parameter 2HBE10 2HBE20<br />

Profile size (width × height) [mm] 100�× 33,5 200 × 44<br />

Stroke length (S max), maximum [mm] 850 2800<br />

Linear speed, maximum [m/s] 0,5 1,3<br />

Dynamic carriage load (Fz), maximum [N] 8250 38000<br />

Remarks no cover band, bellows or shrouds option<br />

available<br />

• Can be installed in all directions<br />

• High load capablities<br />

• Low profile height<br />

• Play free ball screw offer high repeatability<br />

no cover band, bellows or shrouds option<br />

available<br />

Page 42 44<br />

Ball Screw Drive and Ball Guide<br />

15

Ball Screw Drive and Ball Guide<br />

WM40S<br />

Ball Screw Drive, Ball Guide, Single Ball Nut<br />

General Specifications<br />

Parameter WM40S<br />

Profile size (w × h) [mm] 40 × 40<br />

Type of screw ball screw with single nut<br />

Carriage sealing system self-adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM40S<br />

Stroke length (S max), maximum [mm] 2000<br />

Linear speed, maximum [m/s] 0,25<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,02<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 1000<br />

Dynamic load (Fy), maximum [N] 450 1 / 5300 2<br />

Dynamic load (Fz), maximum [N] 600 1 / 6790 2<br />

Dynamic load torque (Mx), maximum [Nm] 10 1 / 30 2<br />

Dynamic load torque (My), maximum [Nm] 30 1 / 230 2<br />

Dynamic load torque (Mz), maximum [Nm] 30 1 / 230 2<br />

Drive shaft force (Frd), maximum [N] 100<br />

Drive shaft torque (Mta), maximum [Nm] 3<br />

Ball screw diameter (d0) [mm] 12<br />

Ball screw lead (p) [mm] 5<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

16<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

1,50<br />

0,30<br />

0,36<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5<br />

150 0,3<br />

1500 0,5<br />

3000 0,8<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information.<br />

Critical Speed<br />

Definition of Forces

Linear Units<br />

WM40S<br />

Ball Screw Drive, Ball Guide, Single Ball Nut<br />

A1: depth 7<br />

A2: lubricating nipple on both sides DIN3405 D 1/A<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 – 500 (0 – 450) 65 35 270 (320)<br />

501 – 1100 (451 – 1050) 65 45 280 (330)<br />

1101 – 2000 (1051 – 1950) 70 60 300 (350)<br />

Values between brackets = for units with long carriage<br />

Long Carriage<br />

Parameter WM40S<br />

Carriage length [mm] 210<br />

Dynamic load torque (My), maximum [Nm] 50<br />

Dynamic load torque (Mz), maximum [Nm] 50<br />

Weight [kg] 0,55<br />

Double Carriages<br />

Parameter WM40S<br />

Minimum distance between carriages (L A) [mm] 175<br />

Dynamic load (Fy), maximum [N] 900<br />

Dynamic load (Fz), maximum [N] 1200<br />

Dynamic load torque (My), maximum [Nm] L A 1 × 0,45<br />

Dynamic load torque (Mz), maximum [Nm] L A 1 × 0,6<br />

Force required to move second carriage [N] 40<br />

Total length (L tot) [mm] S max + C + L A<br />

1 Value in mm<br />

A3: socket cap screw ISO4762-M5×12 8.8<br />

A4: ENF inductive sensor rail option kit (optional)<br />

A1: depth 6<br />

Ball Screw Drive and Ball Guide<br />

17

Ball Screw Drive and Ball Guide<br />

WM40D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts, Long Carriage<br />

General Specifications<br />

Parameter WM40D<br />

Profile size (w × h) [mm] 40 × 40<br />

Type of screw ball screw with double nuts<br />

Carriage sealing system self-adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM40D<br />

Stroke length (S max), maximum [mm] 1950<br />

Linear speed, maximum [m/s] 0,25<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 1000<br />

Dynamic load (Fy), maximum [N] 450 1 / 5300 2<br />

Dynamic load (Fz), maximum [N] 600 1 / 6790 2<br />

Dynamic load torque (Mx), maximum [Nm] 10 1 / 30 2<br />

Dynamic load torque (My), maximum [Nm] 30 1 / 230 2<br />

Dynamic load torque (Mz), maximum [Nm] 30 1 / 230 2<br />

Drive shaft force (Frd), maximum [N] 100<br />

Drive shaft torque (Mta), maximum [Nm] 3<br />

Ball screw diameter (d0) [mm] 12<br />

Ball screw lead (p) [mm] 5<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

18<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

1,90<br />

0,30<br />

0,60<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5<br />

150 0,4<br />

1500 0,6<br />

3000 0,9<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information.<br />

Critical Speed<br />

Definition of Forces<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WM40D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts, Long Carriage<br />

A1: depth 6<br />

A2: lubricating nipple on both sides DIN3405 D 1/A<br />

Double Long Carriages<br />

Parameter WM40D<br />

Minimum distance between carriages (L A) [mm] 225<br />

Dynamic load (Fy), maximum [N] 900<br />

Dynamic load (Fz), maximum [N] 1200<br />

Dynamic load torque (My), maximum [Nm] L A 1 × 0,45<br />

Dynamic load torque (Mz), maximum [Nm] L A 1 × 0,6<br />

Force required to move second carriage [N] 40<br />

Total length (L tot) [mm] S max + C + L A<br />

A3: socket cap screw ISO4762-M5×12 8.8<br />

A4: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 – 500 65 35 320<br />

501 – 1100 65 45 330<br />

1101 – 2000 70 60 350<br />

1 Value in mm<br />

Ball Screw Drive and Ball Guide<br />

19

Ball Screw Drive and Ball Guide<br />

WM60D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts<br />

General Specifications<br />

Parameter WM60D<br />

Profile size (w × h) [mm] 60 × 60<br />

Type of screw ball screw with double nut<br />

Carriage sealing system self-adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM60D<br />

Stroke length (S max), maximum<br />

screw lead 5, 20 mm<br />

screw lead 50 mm<br />

20<br />

[mm]<br />

11000<br />

5000<br />

Linear speed, maximum [m/s] 2,5<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 4000<br />

Dynamic load (Fy), maximum [N] 2000 1 / 45980 2<br />

Dynamic load (Fz), maximum [N] 2000 1 / 42320 2<br />

Dynamic load torque (Mx), maximum [Nm] 100 1 / 740 2<br />

Dynamic load torque (My), maximum [Nm] 200 1 / 2990 2<br />

Dynamic load torque (Mz), maximum [Nm] 200 1 / 3250 2<br />

Drive shaft force (Frd), maximum [N] 500<br />

Drive shaft torque (Mta), maximum [Nm] 35<br />

Ball screw diameter (d0) [mm] 20<br />

Ball screw lead (p) [mm] 5, 20, 50<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

6,16<br />

0,65<br />

1,99<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 20 p = 50<br />

150 0,8 1,3 1,6<br />

1500 1,4 2,0 2,4<br />

3000 1,8 2,3 2,6<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information. Units with a profile length over 6300 mm consists of two<br />

profiles where the joint between the two profiles must be addequately supported on both<br />

sides.<br />

Definition of Forces<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WM60D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts<br />

A1: depth 11<br />

A2: socket cap screw ISO4762-M6×20 8.8<br />

A3: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 - 695 (0 - 505) 115 65 460 (650)<br />

696 - 1335 (506 - 1145) 165 115 560 (750)<br />

1336 - 2075 (1146 - 1885) 185 135 600 (790)<br />

2076 - 2780 (1886 - 2590) 210 160 650 (840)<br />

Values between brackets = for units with long carriage<br />

Long Carriage<br />

Parameter WM60D<br />

Carriage length [mm] 450<br />

Dynamic load torque (My), maximum [Nm] 500<br />

Dynamic load torque (Mz), maximum [Nm] 500<br />

Weight [kg] 3,1<br />

Double Carriages<br />

Parameter WM60D<br />

Minimum distance between carriages (L A) [mm] 335<br />

Dynamic load (Fy), maximum [N] 4000<br />

Dynamic load (Fz), maximum [N] 4000<br />

Dynamic load torque (My), maximum [Nm] L A 1 × 2<br />

Dynamic load torque (Mz), maximum [Nm] L A 1 × 2<br />

Force required to move second carriage [N] 200<br />

Total length (L tot) [mm] S max + C + L A<br />

1 Value in mm<br />

A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard feature<br />

A5: can be changed over to one of the three alternative lubricating points by the customer<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

2781 - 3545 (2591 - 3355) 230 180 690 (880)<br />

3546 - 4285 (3366 - 4095) 250 200 730 (920)<br />

4286 - 5015 (4096 - 4825) 275 225 780 (970)<br />

5016 - 11000 (4826 - 10810) contact customer service<br />

A1: depth 11<br />

Ball Screw Drive and Ball Guide<br />

21

Ball Screw Drive and Ball Guide<br />

WM60S<br />

Ball Screw Drive, Ball Guide, Single Ball Nut, Short Carriage<br />

General Specifications<br />

Parameter WM60S<br />

Profile size (w × h) [mm] 60 × 60<br />

Type of screw ball screw with single nut<br />

Carriage sealing system self adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM60S<br />

Stroke length (S max), maximum [mm] 5000<br />

Linear speed, maximum [m/s] 2,5<br />

Acceleration, maximum [m/s 2 ] 10<br />

Repeatability [± mm] 0,02<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 2800<br />

Dynamic load (Fy), maximum [N] 1400 1 / 25920 2<br />

Dynamic load (Fz), maximum [N] 1400 1 / 23860 2<br />

Dynamic load torque (Mx), maximum [Nm] 50 1 / 410 2<br />

Dynamic load torque (My), maximum [Nm] 100 1 / 320 2<br />

Dynamic load torque (Mz), maximum [Nm] 100 1 / 320 2<br />

Drive shaft force (Frd), maximum [N] 500<br />

Drive shaft torque (Mta), maximum [Nm] 35<br />

Ball screw diameter (d0) [mm] 20<br />

Ball screw lead (p) [mm] 5, 20, 50<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

22<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

3,80<br />

0,65<br />

1,00<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 20 p = 50<br />

150 0,7 1,0 1,4<br />

1500 1,1 1,6 2,0<br />

3000 1,5 1,8 2,2<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information.<br />

Definition of Forces<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WM60S<br />

Ball Screw Drive, Ball Guide, Single Ball Nut, Short Carriage<br />

A1: depth 11<br />

A2: socket cap screw ISO4762-M6×20 8.8<br />

A3: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 - 580 95 20 335<br />

581 - 1140 110 60 390<br />

1141 - 1805 130 80 430<br />

1806 - 2460 155 105 480<br />

Double Short Carriages<br />

Parameter WM60S<br />

Minimum distance between carriages (L A) [mm] 255<br />

Dynamic load (Fy), maximum [N] 2800<br />

Dynamic load (Fz), maximum [N] 2800<br />

Dynamic load torque (My), maximum [Nm] L A 1 × 1,4<br />

Dynamic load torque (Mz), maximum [Nm] L A 1 × 1,4<br />

Force required to move second carriage [N] 180<br />

Total length (L tot) [mm] S max + C + L A<br />

1 Value in mm<br />

Ball Screw Drive and Ball Guide<br />

A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard feature<br />

A5: can be changed over to one of the three alternative lubricating points by the customer<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

2461 - 3125 175 125 520<br />

3126 - 3780 200 150 570<br />

3781 - 4445 220 170 610<br />

4446 - 5000 240 190 650<br />

23

Ball Screw Drive and Ball Guide<br />

WM60X<br />

Ball Screw Drive, Ball Guide, Left/right Moving Carriages<br />

General Specifications<br />

Parameter WM60X<br />

Profile size (w × h) [mm] 60 × 60<br />

Type of screw ball screw with double nut<br />

Carriage sealing system self adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM60X<br />

Stroke length (S max), maximum [mm] 10340<br />

Linear speed, maximum [m/s] 0,25<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 4000<br />

Dynamic load (Fy), maximum [N] 2000 1 / 45980 2<br />

Dynamic load (Fz), maximum [N] 2000 1 / 42320 2<br />

Dynamic load torque (Mx), maximum [Nm] 100 1 / 740 2<br />

Dynamic load torque (My), maximum [Nm] 200 1 / 2990 2<br />

Dynamic load torque (Mz), maximum [Nm] 200 1 / 3250 2<br />

Drive shaft force (Frd), maximum [N] 500<br />

Drive shaft torque (Mta), maximum [Nm] 35<br />

Ball screw diameter (d0) [mm] 20<br />

Ball screw lead (p) [mm] 5<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

24<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

10,33<br />

0,65<br />

1,99<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5<br />

150 1,6<br />

1500 2,8<br />

3000 3,6<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information. Units with a profile length over 5400 mm consists of two<br />

profiles where the joint between the two profiles must be addequately supported on both<br />

sides.<br />

Definition of Forces<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WM60X<br />

Ball Screw Drive, Ball Guide, Left/right Moving Carriages<br />

A1: depth 11<br />

A2: socket cap screw ISO4762-M6×20 8.8<br />

A3: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm] X [mm] Y [mm] Z [mm]<br />

0 - 1390 (0 - 1200) 115 65 60 80 620 800<br />

1391 - 2670 (1201 - 2480) 165 115 210 230 770 1050<br />

2671 - 4150 (2481 - 3960) 185 135 250 270 810 1130<br />

4151 - 5560 (3961 - 5370) 210 160 300 320 860 1230<br />

5561 - 10340 (5371 - 10150) contact customer sevice<br />

Values between brackets = for units with long carriage<br />

Long Carriage<br />

Parameter WM60X<br />

Carriage length [mm] 450<br />

Dynamic load torque (My), maximum [Nm] 500<br />

Dynamic load torque (Mz), maximum [Nm] 500<br />

Weight [kg] 3,1<br />

A1: depth 11<br />

Ball Screw Drive and Ball Guide<br />

A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard feature<br />

A5: can be changed over to one of the three alternative lubricating points by the customer<br />

25

Ball Screw Drive and Ball Guide<br />

WM80D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts<br />

General Specifications<br />

Parameter WM80D<br />

Profile size (w × h) [mm] 80 × 80<br />

Type of screw ball screw with double nuts<br />

Carriage sealing system self adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM80D<br />

Stroke length (S max), maximum<br />

screw lead 5, 10, 20 mm<br />

screw lead 50 mm<br />

26<br />

[mm]<br />

11000<br />

5000<br />

Linear speed, maximum [m/s] 2,5<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 5000<br />

Dynamic load (Fy), maximum [N] 3000 1 / 57420 2<br />

Dynamic load (Fz), maximum [N] 3000 1 / 54950 2<br />

Dynamic load torque (Mx), maximum [Nm] 350 1 / 1360 2<br />

Dynamic load torque (My), maximum [Nm] 300 1 / 4230 2<br />

Dynamic load torque (Mz), maximum [Nm] 300 1 / 4220 2<br />

Drive shaft force (Frd), maximum [N] 700<br />

Drive shaft torque (Mta), maximum [Nm] 55<br />

Ball screw diameter (d0) [mm] 25<br />

Ball screw lead (p) [mm] 5, 10, 20, 50<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

11,57<br />

1,08<br />

4,26<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 10 p = 20 p = 50<br />

150 1,1 1,5 1,8 2,3<br />

1500 1,7 2.1 2,3 3,0<br />

3000 2,1 2,5 2,6 3,6<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information. Units with a profile length over 6300 mm consists of two<br />

profiles where the joint between the two profiles must be addequately supported on both<br />

sides.<br />

Definition of Forces<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WM80D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts<br />

A1: depth 12 mm<br />

A2: socket cap screw ISO4762-M6×20 8.8<br />

A3: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 - 780 (0 - 610) 120 80 500 (670)<br />

781 - 1535 (611 - 1365) 170 125 595 (765)<br />

1536 - 2375 (1366 - 2205) 190 145 635 (805)<br />

2376 - 3205 (2206 - 3035) 215 170 685 (855)<br />

Values between brackets = for units with long carriage<br />

Long Carriage<br />

Parameter WM80D<br />

Carriage length [mm] 450<br />

Dynamic load torque (My), maximum [Nm] 750<br />

Dynamic load torque (Mz), maximum [Nm] 750<br />

Weight [kg] 6,4<br />

Double Carriages<br />

Parameter WM80D<br />

Minimum distance between carriages (L A) [mm] 360<br />

Dynamic load (Fy), maximum [N] 6000<br />

Dynamic load (Fz), maximum [N] 6000<br />

Dynamic load torque (My), maximum [Nm] L A 1 × 3<br />

Dynamic load torque (Mz), maximum [Nm] L A 1 × 3<br />

Force required to move second carriage [N] 250<br />

Total length (L tot) [mm] S max + C + L A<br />

1 Value in mm<br />

A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard feature<br />

A5: can be changed over to one of three alternative lubrication points by customer<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

3206 - 4045 (3036 - 3875) 235 190 725 (895)<br />

4046 - 4885 (3876 - 4715) 255 210 765 (935)<br />

4886 - 5000 (4716 - 4830) 280 235 815 (985)<br />

5001 - 11000 (4717 - 10830) contact customer service<br />

A1: depth 12 mm<br />

Ball Screw Drive and Ball Guide<br />

27

Ball Screw Drive and Ball Guide<br />

WM80S<br />

Ball Screw Drive, Ball Guide, Singel Ball Nut, Short Carriage<br />

General Specifications<br />

Parameter WM80S<br />

Profile size (w × h) [mm] 80 × 80<br />

Type of screw ball screw with single nut<br />

Carriage sealing system self adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM80S<br />

Stroke length (S max), maximum [mm] 5000<br />

Linear speed, maximum [m/s] 2,5<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,02<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 3500<br />

Dynamic load (Fy), maximum [N] 2100 1 / 37440 2<br />

Dynamic load (Fz), maximum [N] 2100 1 / 35830 2<br />

Dynamic load torque (Mx), maximum [Nm] 150 1 / 890 2<br />

Dynamic load torque (My), maximum [Nm] 180 1 / 580 2<br />

Dynamic load torque (Mz), maximum [Nm] 180 1 / 600 2<br />

Drive shaft force (Frd), maximum [N] 700<br />

Drive shaft torque (Mta), maximum [Nm] 55<br />

Ball screw diameter (d0) [mm] 25<br />

Ball screw lead (p) [mm] 5, 10, 20, 50<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

28<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

7,0<br />

1,1<br />

1,6<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 10 p = 20 p = 50<br />

150 0,9 1,1 1,3 2,0<br />

1500 1,3 1,5 1,8 2,4<br />

3000 1,7 1,8 2,0 2,9<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information.<br />

Definition of Forces<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WM80S<br />

Ball Screw Drive, Ball Guide, Singel Ball Nut, Short Carriage<br />

A1: depth 12 mm<br />

A2: socket cap screw ISO4762-M6×20 8.8<br />

A3: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 - 680 95 35 350<br />

681 - 1310 125 80 425<br />

1311 - 2065 150 105 475<br />

2066 - 2830 170 125 515<br />

Double Carriages<br />

Parameter WM80S<br />

Minimum distance between carriages (L A) [mm] 280<br />

Dynamic load (Fy), maximum [N] 4200<br />

Dynamic load (Fz), maximum [N] 4200<br />

Dynamic load torque (My), maximum [Nm] L A 1 × 2,1<br />

Dynamic load torque (Mz), maximum [Nm] L A 1 × 2,1<br />

Force required to move second carriage [N] 225<br />

Total length (L tot) [mm] S max + C + L A<br />

1 Value in mm<br />

Ball Screw Drive and Ball Guide<br />

A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard feature<br />

A5: can be changed over to one of three alternative lubrication points by customer<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

2831 - 3590 195 150 565<br />

3591 - 4355 215 170 605<br />

4356 - 5000 235 190 645<br />

29

Ball Screw Drive and Ball Guide<br />

WM120D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts<br />

General Specifications<br />

Parameter WM120D<br />

Profile size (w × h) [mm] 120 × 120<br />

Type of screw ball screw with double nuts<br />

Carriage sealing system self adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WM120D<br />

Stroke length (S max), maximum<br />

screw lead 5, 10, 20 mm<br />

screw lead 40 mm<br />

30<br />

[mm]<br />

11000<br />

5000<br />

Linear speed, maximum [m/s] 2,0<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum<br />

screw lead 5, 10, 20 mm<br />

screw lead 40 mm<br />

[N]<br />

12000<br />

8000<br />

Dynamic load (Fy), maximum [N] 6000 1 / 74890 2<br />

Dynamic load (Fz), maximum [N] 6000 1 / 71670 2<br />

Dynamic load torque (Mx), maximum [Nm] 500 1 / 2890 2<br />

Dynamic load torque (My), maximum [Nm] 600 1 / 6660 2<br />

Dynamic load torque (Mz), maximum [Nm] 600 1 / 6960 2<br />

Drive shaft force (Frd), maximum [N] 1000<br />

Drive shaft torque (Mta), maximum [Nm] 80<br />

Ball screw diameter (d0) [mm] 32<br />

Ball screw lead (p) [mm] 5, 10, 20, 40<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

1 Value for the complete unit<br />

2 Value for the ball guide only<br />

[kg]<br />

25,91<br />

1,93<br />

9,25<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 10 p = 20 p = 40<br />

150 1,4 2,0 2,3 2,4<br />

1500 2,5 3,0 3,3 3,8<br />

3000 3,0 3,7 4,0 4,3<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information. Units with a profile length over 5400 mm consists of two<br />

profiles where the joint between the two profiles must be addequately supported on both<br />

sides.<br />

Definition of Forces<br />

» Ordering key - see page 194<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WM120D<br />

Ball Screw Drive, Ball Guide, Double Ball Nuts<br />

A1: depth 22<br />

A2: socket cap screw ISO4762-M8×20 8.8<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 - 890 (0 - 710) 155 100 595 (775)<br />

891 - 1695 (711 - 1515) 225 170 735 (815)<br />

1696 - 2625 (1516 - 2445) 260 205 805 (985)<br />

2626 - 3555 (2446 - 3375) 295 240 875 (1055)<br />

Values between brackets = for units with long carriage<br />

Long Carriage<br />

Parameter WM120D<br />

Carriage length [mm] 500<br />

Dynamic load torque (My), maximum [Nm] 1500<br />

Dynamic load torque (Mz), maximum [Nm] 1500<br />

Weight [kg] 14,2<br />

Double Carriages<br />

Parameter WM120D<br />

Minimum distance between carriages (L A) [mm] 450<br />

Dynamic load (Fy), maximum [N] 12000<br />

Dynamic load (Fz), maximum [N] 12000<br />

Dynamic load torque (My), maximum [Nm] L A 1 × 6<br />

Dynamic load torque (Mz), maximum [Nm] L A 1 × 6<br />

Force required to move second carriage [N] 300<br />

Total length (L tot) [mm] S max + C + L A<br />

1 Value in mm<br />

A3: tapered lubricating nipple to DIN71412 M8×1 on fixed-bearing side as standard feature<br />

A4: can be changed over to one of the three alternative lubricating points by the customer<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

3556 - 4485 (3376 - 4305) 330 275 945 (1125)<br />

4486 - 5000 (4306 - 4820) 365 310 1015 (1195)<br />

5001 - 11000 (4307 - 10820) contact customer service<br />

A1: depth 22<br />

Ball Screw Drive and Ball Guide<br />

31

Ball Screw Drive and Ball Guide<br />

WV60<br />

Ball Screw Drive, No Guides<br />

General Specifications<br />

Parameter WV60<br />

Profile size (w × h) [mm] 60 × 60<br />

Type of screw ball screw with double nut<br />

Carriage sealing system self-adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WV60<br />

Stroke length (S max), maximum<br />

screw lead 5, 20 mm<br />

screw lead 50 mm<br />

32<br />

[mm]<br />

11000<br />

5000<br />

Linear speed, maximum [m/s] 2,5<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 4000<br />

Dynamic load (Fy), maximum [N] 0<br />

Dynamic load (Fz), maximum [N] 0<br />

Dynamic load torque (Mx), maximum [Nm] 0<br />

Dynamic load torque (My), maximum [Nm] 0<br />

Dynamic load torque (Mz), maximum [Nm] 0<br />

Drive shaft force (Frd), maximum [N] 500<br />

Drive shaft torque (Mta), maximum [Nm] 35<br />

Ball screw diameter (d0) [mm] 20<br />

Ball screw lead (p) [mm] 5, 20, 50<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

[kg]<br />

4,72<br />

0,55<br />

1,42<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 20 p = 50<br />

150 0,7 0,9 1,1<br />

1500 1,3 1,5 1,5<br />

3000 1,7 1,9 2,1<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information. Units with a profile length over 6300 mm consists of two<br />

profiles where the joint between the two profiles must be addequately supported on both<br />

sides.<br />

Definition of Forces<br />

» Ordering key - see page 195<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WV60<br />

Ball Screw Drive, No Guides<br />

A1: depth 11<br />

A2: socket cap screw ISO4762-M6×20 8.8<br />

A3: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 - 690 130 80 430<br />

691 - 1415 155 105 480<br />

1416 - 2155 175 125 520<br />

2156 - 2885 200 150 570<br />

Ball Screw Drive and Ball Guide<br />

A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard feature<br />

A5: can be changed over to one of the three alternative lubricating points by the customer<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

2886 - 3625 220 170 610<br />

3626 - 4355 245 195 660<br />

4256 - 5095 265 215 700<br />

5096 - 11000 contact customer service<br />

33

Ball Screw Drive and Ball Guide<br />

WV80<br />

Ball Screw Drive, No Guides<br />

General Specifications<br />

Parameter WV80<br />

Profile size (w × h) [mm] 80 × 80<br />

Type of screw ball screw with double nuts<br />

Carriage sealing system self adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WV80<br />

Stroke length (S max), maximum<br />

screw lead 5, 10, 20 mm<br />

screw lead 50 mm<br />

34<br />

[mm]<br />

11000<br />

5000<br />

Linear speed, maximum [m/s] 2,5<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum [N] 5000<br />

Dynamic load (Fy), maximum [N] 0<br />

Dynamic load (Fz), maximum [N] 0<br />

Dynamic load torque (Mx), maximum [Nm] 0<br />

Dynamic load torque (My), maximum [Nm] 0<br />

Dynamic load torque (Mz), maximum [Nm] 0<br />

Drive shaft force (Frd), maximum [N] 700<br />

Drive shaft torque (Mta), maximum [Nm] 55<br />

Ball screw diameter (d0) [mm] 25<br />

Ball screw lead (p) [mm] 5, 10, 20, 50<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

[kg]<br />

7,95<br />

0,99<br />

2,25<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 10 p = 20 p = 50<br />

150 0,9 1,1 1,3 1,4<br />

1500 1,6 1,9 2,1 2,3<br />

3000 2,0 2,4 2,6 3,0<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information. Units with a profile length over 6300 mm consists of two<br />

profiles where the joint between the two profiles must be addequately supported on both<br />

sides.<br />

Definition of Forces<br />

» Ordering key - see page 195<br />

» Accessories - see page 127<br />

» Additional data - see page 183

Linear Units<br />

WV80<br />

Ball Screw Drive, No Guides<br />

A1: depth 12 mm<br />

A2: socket cap screw ISO4762-M6×20 8.8<br />

A3: ENF inductive sensor rail option kit (optional)<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

0 - 775 125 50 395<br />

776 - 1670 145 95 460<br />

1671 - 2505 170 115 505<br />

2506 - 3340 190 140 550<br />

Ball Screw Drive and Ball Guide<br />

A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard feature<br />

A5: can be changed over to one of three alternative lubrication points by customer<br />

Stroke length (S max) [mm] A [mm] B [mm] C [mm]<br />

3341 - 4175 210 160 590<br />

4176 - 5015 235 180 635<br />

5016 - 11000 contact customer service<br />

35

Ball Screw Drive and Ball Guide<br />

WV120<br />

Ball Screw Drive, No Guides<br />

General Specifications<br />

Parameter WV120<br />

Profile size (w × h) [mm] 120 × 120<br />

Type of screw ball screw with double nuts<br />

Carriage sealing system self adjusting plastic cover band<br />

Screw supports<br />

Lubrication<br />

Performance Specifications<br />

Parameter WV120<br />

Stroke length (S max), maximum<br />

screw lead 5, 10, 20 mm<br />

screw lead 40 mm<br />

36<br />

[mm]<br />

11000<br />

5000<br />

Linear speed, maximum [m/s] 2,0<br />

Acceleration, maximum [m/s 2 ] 20<br />

Repeatability [± mm] 0,01<br />

Input speed, maximum [rpm] 3000<br />

Operation temperature limits [°C] 0 – 80<br />

Dynamic load (Fx), maximum<br />

screw lead 5, 10, 20 mm<br />

screw lead 40 mm<br />

[N]<br />

12000<br />

8000<br />

Dynamic load (Fy), maximum [N] 0<br />

Dynamic load (Fz), maximum [N] 0<br />

Dynamic load torque (Mx), maximum [Nm] 0<br />

Dynamic load torque (My), maximum [Nm] 0<br />

Dynamic load torque (Mz), maximum [Nm] 0<br />

Drive shaft force (Frd), maximum [N] 1000<br />

Drive shaft torque (Mta), maximum [Nm] 80<br />

Ball screw diameter (d0) [mm] 32<br />

Ball screw lead (p) [mm] 5, 10, 20, 40<br />

Weight<br />

of unit with zero stroke<br />

of every 100 mm of stroke<br />

of each carriage<br />

included in all units that require<br />

screw supports<br />

central lubrication of all parts that<br />

require lubrication<br />

Included accessories 4 × mounting clamps<br />

[kg]<br />

18,10<br />

1,94<br />

4,75<br />

Linear Units<br />

Carriage Idle Torque (M idle) [Nm]<br />

Input speed [rpm]<br />

Screw lead [mm]<br />

p = 5 p = 10 p = 20 p = 40<br />

150 1,0 1,1 1,4 1,5<br />

1500 2,1 2,2 2,5 2,8<br />

3000 2,4 2,6 3,0 3,5<br />

M idle = the input torque needed to move the carriage with no load on it.<br />

Deflection of the Profile<br />

A mounting clamp must be installed at least at every 750 mm to be able to operate the<br />

maximum load. Less clamps may be required if less load is being operated, see the additional<br />

technical data for more information. Units with a profile length over 5400 mm consists of two<br />