You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

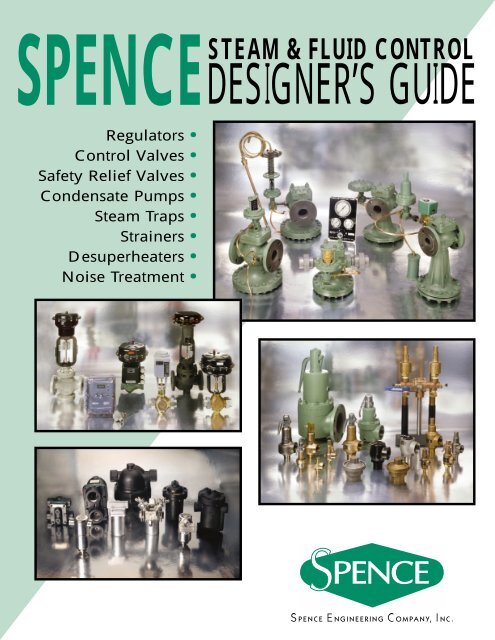

SPENCERegulators •<strong>Control</strong> Valves •Safety Relief Valves •Condensate Pumps •Steam Traps •Strainers •Desuperheaters •Noise Treatment •STEAM & FLUID CONTROLDESIGNER’S GUIDE

It is the philosophy of theSpence Engineering Company that,to win and be deserving of the trust ofour customers, we must be ever mindfulof and totally dedicated to quality; inall that we do; at every levelof our operation.SPENCE ENGINEERING COMPANY is a member of the Fluid <strong>Control</strong>s Institute.SPENCE ENGINEERING COMPANY has a policy of continuous product research and improvement and reserves the right to changedesign and specifications without notice. Responsibility for typographical errors is specifically disclaimed.

SPENCESTEAM & FLUID CONTROLDESIGNER’S GUIDECONDENSATE PUMPSREFERENCEREGULATORSCONTROL VALVESSAFETY RELIEF VALVESDESUPERHEATERS& NOISE REDUCTIONAPPLICATION GUIDETRAPS & SPECIALTIESUNIFLEX COUPLINGS& GENERAL USE VALVESSTRAINERS- 1 -

SPENCE ENGINEERINGCOMPANY, INC.The Spence Engineering Company was founded in 1926 by Paulsen Spence in Walden,New York. Paulsen Spence developed the original patent for the normally closed externalpilot operated packless pressure regulator. This design is the basis for the products offeredtoday. This technology offers the maximum in application and selection flexibility. Spencestands alone in their ability to produce regulators up to 12 inches in cast iron and cast steel.Their pilots are used to control pressure, temperature, differential pressure or back pressureeither mechanically or with a pneumatic pilot.Spence Engineering is a widely recognized leader in the steam regulator and flow controlfield. Spence regulators are used extensively for heating systems in buildings, institutionsand district heating systems as well as major industrial plants.In 1984, Spence Engineering was acquired by Watts Industries. The company continuedto grow and develop new fluid control and steam specialty products. A new line of pneumaticcontrol valves was introduced in 1986. In 1989, a range of self contained temperature regulatorswas added to the line to meet the demand for an economical temperature regulator.1990 was an active year, with Spence becoming certified by the ASME for the assembly andsetting of safety relief valves manufactured by their sister Watts company in Canada. Spencewas also instrumental in the acquisition and management of the Nicholson Steam TrapCompany. In 1994, Nicholson was integrated into the Spence Plant.Spence continued it’s product development program with the introduction of free floatsteam traps and pressure operated condensate pumps. In 1996, Watts moved the manufacturingresponsibility for safety valves to the Spence Engineering plant in Walden, New York.Spence is now an ASME certified manufacturer of bronze and iron safety relief valves.Watts Industries, <strong>Inc</strong>. split in 1999 and Spence Engineering Company became a divisionof the newly formed corporation, Circor International.Spence Engineering continues to focus their attention on providing single source steamspecialty products for regulating and control of steam and fluids for the institutional andindustrial marketplace. Their growth efforts are to expand the already comprehensiveproduct capabilities to reach new developing markets.For more information on Spence Engineering Co., visit our website atwww.spenceengineering.com or reach us via e-mail at sales@spenceengineering.com- 2 -

THE SPENCE ADVANTAGE ISSERVICELOCAL TECHNICAL SUPPORTSpence Engineering has a network of technically trained Representatives around the world. TheseRepresentatives can direct you to local inventory of our products for fast, fast service. They can alsohelp you in the selection and sizing of Regulators, Pilots, Desuperheaters and Noise SuppressionProducts.TECHNICAL TRAININGWe offer a regular schedule of workshops covering various technical issues in our state of the art ValveTechnology Training Center. We can also schedule customized training sessions to suit your particularneeds.ENGINEERING SEMINARS. These seminars provide the engineer with the skills of regulator selectionand sizing.DISTRIBUTOR SEMINARS. This seminar will provide you with all the information you need to serveyour customers.MAINTENANCE SEMINARS. Maintenance personnel will receive hands-on training in selection,installation, operation, maintenance and troubleshooting.INTERNATIONAL SALESSpence is well equipped to provide product to our customers around the world. We regularly ship ourproducts to all parts of the world. Our experienced international sales group can meet the transportand documentation requirements of our international customers with ease. Our network of InternationalTechnical Sales Representatives will also be able to provide you with product from local inventory.ENGINEERED SOLUTIONSSpence offers a very comprehensive line of specialty options to enhance and optimize valve performance.We can tailor custom solutions for your most unique process applications. Call us for solutions.- 3 -

REGULATORSCONTROL VALVESSAFETY RELIEF VALVESDESUPERHEATERS& NOISE REDUCTIONCONDENSATE PUMPSTRAPS & SPECIALTIESUNIFLEX COUPLINGS& GENERAL USE VALVESSTRAINERSAPPLICATION GUIDEREFERENCESpence Engineering Company, <strong>Inc</strong>. …………………………………2The Spence Advantage is Service ……………………………………3SECTION IREGULATORSED Series Pressure Regulator Features ……………………………10How to Choose a Regulator ………………………………………11The Operating Cycle of a Spence Pressure Regulator ……………12The Operating Cycle of a Spence Temperature Regulator ………13Quick Selection Chart for Steam Pressure Regulators ……………14Quick Selection Chart for Temperature Regulators ………………15Spence Main Valve Specification Table ……………………………16COMBINATION REGULATORSType ED Series Pressure Regulator …………………………………18Type E2D Series Pressure Regulator ………………………………19Type ED & ED2 Integral Mound Pressure Regulator ………………20Type EA Series Pressure Regulator …………………………………21Type ET14 Temperature Regulator …………………………………22Type ET14D Pressure Limiting Temperature Regulator …………23Type ET124/ET134 & E2T134 Temperature & Pressure Regulator …24Type ED210 Regulator ………………………………………………25Type ED208D Pressure Regulator …………………………………26Type E Main Valve ……………………………………………………28Type E2 Main Valve …………………………………………………30Type E5 Main Valve …………………………………………………32Type E6 Main Valve …………………………………………………34Type E8 Main Valve …………………………………………………36Type C34 Main Valve ………………………………………………38MAIN VALVE ACCESSORIESMain Valve Options……………………………………………………42Insulcap Jacket ………………………………………………………44Types A & B Panels …………………………………………………45Auxiliary Fittings ………………………………………………………46PILOTSType D Pressure Reducing Pilot ……………………………………48Type A Air Adjusted Pilot ……………………………………………50Type P60 Pneumatic <strong>Control</strong>ler ……………………………………52Type N Differential Pressure Pilot ……………………………………54Type P Pump Governor Pilot…………………………………………56Type F46 Vacuum Pump Governor Pilot …………………………58Type Q Back Pressure Pilot …………………………………………60Type F Back Pressure Pilot …………………………………………62Type P125 Trip Stop Pilot ……………………………………………64Type SP/P Pressure Safety Pilot ……………………………………66Type M Solenoid Pilot ………………………………………………68TABLE OF CONTENTSREADY TO START?The best way to make a selection is to contact your local Spence Engineering Technical Sales Representative. Our network offactory trained Representatives will offer you a choice of solutions for your application utilizing our Computer Valve SizingProgram. For the name and number of your local Spence Representative, call our Hotline at 1-800-398-2493 or visit our websiteat www.spenceengineering.com.Type D208 Electronic Actuator Pilot…………………………………70Type D210 Electronic Actuator Pilot…………………………………72Type T124/134 Temperature/ Pressure Pilot ………………………74Type T14 Vapor Tension Temperature Pilot …………………………76Type T52 Temperature Pilot …………………………………………78Type T60 Pneumatic Temperature <strong>Control</strong>ler ………………………80Type SP/T Temperature Safety Pilot…………………………………82Type T61, T62, T63, T64 Pneumatic Temperature <strong>Control</strong>ler ……83Material Specifications for Main Valves & Pilots ……………………84PILOT ACCESSORIESThermostat Bulbs & Wells ……………………………………………86Pilot Options …………………………………………………………87DIRECT OPERATED VALVESSeries 2000 Temperature Regulator Features ……………………88Series 2000 Temperature Regulator ………………………………90Capacity Table…………………………………………………………94Sizing Series 2000 Temperature Regulators ………………………95Steam Flow Requirements …………………………………………95Type D50 Pressure Reducing Valve …………………………………96Type N6 Differential Pressure Valve …………………………………98Type D & D2 Differential Pressure Valve …………………………100Type D34 Water Pressure Reducing Valve ………………………102Type D36 Water Pressure Reducing Valve ………………………104REGULATOR SIZINGDefinitions Relating to Regulator Capacity ………………………108Planning Main Valve Installation ……………………………………109Rules for Main Valve Selection ……………………………………110Valve Sizing By Computation ………………………………………111Pressure Reducing Station Design Guidelines ……………………112Pressure Reducing Station General Specification ………………112Regulator Cv Data …………………………………………………113Saturated Steam Flow Table (lb/hr) ………………………………114Selecting Pressure Pilots ……………………………………………116Sizing Pressure Regulators …………………………………………117Selecting Temperature Pilots ………………………………………118Sizing Temperature Regulators ……………………………………119Selecting Differential Pressure Pilots ………………………………120Sizing Differential Pressure Regulators ……………………………121Selecting Back Pressure Pilots ……………………………………122Sizing Back Pressure Regulators …………………………………123Selecting Pump Governor Pilots …………………………………124Rated Steam Capacity Table ………………………………………125Sizing D36 Water Pressure Reducing Valve ………………………133Rated Steam, Air and Water Capacity Table ……………………134Sizing D50 Direct Acting Pressure Regulator ……………………135- 4 -

SECTION IICONTROL VALVESKombat K1 Pneumatic <strong>Control</strong> Valve Features …………………138Intimidator Type J <strong>Control</strong> Valve Features…………………………139Boss Series D <strong>Control</strong> Valve Features ……………………………140Kombat Series K <strong>Control</strong> Valve ……………………………………142Kombat Shutoff & Cv Tables ………………………………………144Kombat Capacity Tables ……………………………………………146Intimidator Type J <strong>Control</strong> Valve …………………………………150Intimidator Shutoff & Cv Tables ……………………………………153Intimidator Capacity Tables …………………………………………154Boss Series D <strong>Control</strong> Valve ………………………………………160Boss Capacity Tables ………………………………………………164Boss Shutoff Tables - Reverse & Direct Acting …………………170Doctor Series MD 3-way <strong>Control</strong> Valve …………………………174Doctor Shutoff & Cv Tables…………………………………………179Doctor Capacity Tables ……………………………………………180CONTROL VALVE OPTIONS &ACCESSORIESActuators ……………………………………………………………184EPC-1 Electro-Pneumatic <strong>Control</strong>ler Features ……………………185EPC-1 Electro-Pneumatic <strong>Control</strong>ler ………………………………186EPC-1 Electro-Pneumatic <strong>Control</strong>ler Options ……………………188Model 65A Air Filter Regulator ……………………………………189Electro-Pneumatic (I/P) Transducer ………………………………189RTD Resistance Probe Thermometer ……………………………190Electronic Pressure Transmitter ……………………………………190Eckardt Positioner …………………………………………………191PMV Positioner ………………………………………………………192Moore Positioner ……………………………………………………193CONTROL VALVE SIZINGValve Sizing By Computation ………………………………………196Intimidator Piping Geometry Factors ………………………………197SECTION IIISAFETY RELIEF VALVESSpence Safety Valve Selection Chart………………………………200Spence/Kunkle Competitive Crossover Chart ……………………201COMMERCIAL/INDUSTRIAL SAFETY RELIEF VALVESFigure 31 / 41 Bronze Series ………………………………………204Figure 31 / 41 Cast Iron Series ……………………………………212Figure 800 Series ……………………………………………………218Figure 10 Series ……………………………………………………230Figure 15 Series ……………………………………………………232Figure 15V Series ……………………………………………………234Figure 50 Series ……………………………………………………236Drip Pan Elbow………………………………………………………238CRYOGENIC SAFETY RELIEF VALVESFigure 710 Series ……………………………………………………242TABLE OF CONTENTSFigure 760/765 Series ………………………………………………244Figure 770/775 Series ………………………………………………246Figure 780 Diverter Valve……………………………………………250Figure 790 Cryotree Assembly …………………………………252SAFETY RELIEF VALVE SIZINGBasics of Relief Valves ………………………………………………256Sizing Guidelines ……………………………………………………258Pipe Data Table ……………………………………………………260Capacity of Saturated Steam Table ………………………………261Safety Valve Sizing By Computation ………………………………262Spence SRV Testing Specifications ………………………………269Summary of ASME Codes & Standards …………………………270Installation, Maintenance & Troubleshooting Guidelines …………272SECTION IVDESUPERHEATERSDesuperheaters ……………………………………………………278Rules for Sizing Desuperheaters …………………………………280NOISE REDUCTIONNoise Suppressor …………………………………………………282Muffling Orifice Plates (MOPS) ……………………………………284Noise Reduction Design Guidelines ………………………………287SECTION VCONDENSATE PUMPSCondensate Commander Pump Features ………………………297Condensate Commander Pump …………………………………298Condensate Commander Classic Pump …………………………299Condensate Commander Big Boy Pump …………………………300Condensate Commander Horizontal Pump ………………………301Condensate Commander Little Boy Pump ………………………302Condensate Commander Pump Skid Mounted System…………304Condensate Commander Pump Primer …………………………306Condensate Commander Pump Checklist ………………………307Condensate Commander Pump Selection Guidelines …………308SECTION VITRAPS &SPECIALTIESNova NFT250 Series Variable Orifice Steam Traps Features ……314Dura-Flo Inverted Bucket Steam Traps Features …………………315Liquidator 450 Series Thermostatic Steam Traps Features ……316Nova NFT250 Series Variable Orifice Steam Traps ………………318Nova NFT650 Series Variable Orifice Steam Traps ………………320FTN Series Float & Thermostatic Steam Traps……………………322Max-Flo Super High Capacity Float & Thermostatic Steam Traps …324Dura-Flo Inverted Bucket Steam Traps ……………………………326Threaded Dura-Flo Inverted Bucket Steam Traps ………………330Universal Mount Dura-Flo Inverted Bucket Steam Traps ………332NTD600 Series Thermodynamic Steam Traps ……………………334Liquidator 450 Series Universal Mount Thermostatic Steam Traps …336REGULATORSCONTROL VALVESSAFETY RELIEF VALVESDESUPERHEATERS& NOISE REDUCTIONCONDENSATE PUMPSTRAPS & SPECIALTIESUNIFLEX COUPLINGS& GENERAL USE VALVESSTRAINERSAPPLICATION GUIDEREFERENCE- 5 -

REGULATORSCONTROL VALVESSAFETY RELIEF VALVESDESUPERHEATERS& NOISE REDUCTIONCONDENSATE PUMPSTRAPS & SPECIALTIESUNIFLEX COUPLINGS& GENERAL USE VALVESSTRAINERSAPPLICATION GUIDEREFERENCELiquidator UMT-TD Universal Mount Thermodynamic Steam Traps 338DS200 Series Thermostatic Steam Traps …………………………340SPECIALTIESBig Block UMT Valve Station Features ……………………………342Big Block Universal Mount Trap Valve Station ……………………344Steam Scrubber Stainless Steel Filter ……………………………346Eliminator Series Steam Separator ………………………………348Drain-Air & Mini-Drains ……………………………………………350TAV Series Thermostatic Air Vent …………………………………352STV Series Combination Trap Test & Blocking Steam Valve ……354TRAPS &SPECIALTIES SIZINGThermostatic Steam Traps …………………………………………359Mechanical Steam Traps ……………………………………………359Thermodynamic Steam Traps………………………………………360Sizing Steam Traps …………………………………………………361Sizing Condensate Return Lines …………………………………366Steam Tracing Design Guidelines …………………………………367Clean Steam Design Guidelines ……………………………………368Piping & Trapping Design Guidelines ………………………………368Sizing Eliminator Steam Separators ………………………………369SECTION VIIUNIFLEX COUPLINGSUniflex Carbon/Stainless Steel Pipe Couplings Features ………372Uniflex Steel/Stainless Pipe Couplings ……………………………374SECTION VIIIIntroducing Spence Strainers International ………………………376Y STRAINERSY Strainer Design Features …………………………………………381125Y1 Series Bronze Y Strainers NPT, Sweat Ends ……………385125Y2 Series Cast Iron Y Strainers Flanged………………………386150Y2 Series Carbon Steel, Stainless Steel Y StrainersFlanged, Buttweld ………………………………………………391150Y2 Series Bronze Y Strainers Flanged ………………………392250Y1 Series Cast Iron Y Strainers NPT …………………………397250Y1 Series Bronze Y Strainers NPT ……………………………398250Y2 Series Ductile Iron Y Strainers Flanged……………………399300Y1 Series Carbon Steel, Stainless Steel Y StrainersNPT, Socketweld …………………………………………………403300Y2 Series Carbon Steel, Stainless Steel Y StrainersFlanged, Buttweld ………………………………………………404600Y1 Series Carbon Steel, Stainless Steel, Low Carbon Steel,Alloy 20 Y Strainers NPT, Socketweld …………………………409600Y2 Series Carbon Steel, Stainless Steel Y StrainersFlanged, Ring joint, Buttweld ……………………………………410900Y Series Carbon Steel, Stainless Steel Y StrainersFlanged, Ring Joint, Buttweld …………………………………414900Y2 Series Carbon Steel, Stainless Steel Y StrainersFlanged, Ring joint, Buttweld ……………………………………415TABLE OF CONTENTS1500Y1 Series Carbon Steel, Stainless Steel Y StrainersNPT, Socketweld …………………………………………………4191500Y2 Series Carbon Steel, Stainless Steel Chrome MolyY Strainers NPT, Socketweld ……………………………………4201500Y2 Series Carbon Steel, Stainless Steel Y StrainersFlanged, Ring joint, Buttweld ……………………………………421FY Series Fabricated Y Strainers …………………………………424Y-STRAINER TECHNICAL INFORMATIONScreen Openings ……………………………………………………430Replacement Cylindrical Screens …………………………………431Pressure Charts ……………………………………………………433BASKET STRAINERSBasket Strainers Features …………………………………………439125B Series Cast Iron Flanged Basket Strainers …………………440150B1 Series Cast Bronze, Carbon Steel, Stainless SteelFlanged Basket Strainers ……………………………………… 444150B2 Series Cast Carbon Steel, Stainless SteelFlanged Basket Strainers ………………………………………448300B Series Cast Carbon Steel, Stainless SteelThreaded Basket Strainers ………………………………………452FB Series – FB1 Fabricated Basket Strainers ……………………457FB Series – FB2 Fabricated Basket Strainers ……………………458FB Series – FB3 Fabricated Basket Strainers ……………………459FB Series – FB4 Fabricated Basket Strainers ……………………460FB Series – FB5 Fabricated Basket Strainers ……………………461BASKET STRAINER TECHNICAL INFORMATIONScreen Openings ……………………………………………………466Replacement Basket Screens ……………………………………470Screen/Basket Checklist …………………………………………470Correction Factors ………………………………………………………471T-STRAINERST-Strainers Features …………………………………………………475FT1 Series Fabricated T-Strainers …………………………………477FT2 Series Fabricated T-Strainers …………………………………478FT3 Series Fabricated T-Strainers …………………………………479T-STRAINER TECHNICAL INFORMATIONScreen Openings ……………………………………………………484Screen Burst Pressure………………………………………………485Installation and Maintenance ………………………………………487SUCTION DIFFUSERSSuction Diffuser Features …………………………………………489S Series Cast Iron Suction Diffusers ………………………………490FF Series Fabricated Suction Diffusers ……………………………494T Series Cast Iron Triple Duty Valves ………………………………498PUMP PROTECTION TECHNICAL INFORMATIONScreen Openings ……………………………………………………502Installation and Maintenance ………………………………………504- 6 -

TEMPORARY STRAINERSTemporary Strainers Features………………………………………505TC Series Temporary Cone Strainer ………………………………507TB Series Temporary Basket Strainer ……………………………508TP Series Temporary Basket Strainers ……………………………509TEMPORARY STRAINER TECHNICAL INFORMATIONScreen Openings ……………………………………………………514Burst Pressure Charts ………………………………………………516Installation and Maintenance ………………………………………519DOUBLE DOOR CHECK VALVESDouble Door Check Valves Features ………………………………521125WT Series Cast Iron Double Door Check Valves ……………524150WT Series Cast Steel and Stainless SteelDouble Door Check Valves………………………………………528300WT Series Cast Steel and Stainless SteelDouble Door Check Valves………………………………………532600WT Series Cast Steel and Stainless SteelDouble Door Check Valves………………………………………536WAFER SILENT CHECK VALVESWafer Silent Check Valves Features ………………………………541125WC Series Cast Iron Wafer Silent Check Valves ……………542150WC Series Cast Steel and Stainless SteelWafer Silent Check Valves ………………………………………546300WC Series Cast Steel and Stainless SteelWafer Silent Check Valves ………………………………………550FLANGED SILENT CHECK VALVESFlanged Silent Check Valves Features ……………………………555125FC Series Cast Iron Flanged Silent Check Valves ……………556150FC Series Cast Steel and Stainless SteelFlanged Silent Check Valves ……………………………………560BUTTERFLY VALVESButterfly Valves Features ……………………………………………565BF Series Butterfly Valves …………………………………………566SECTION IXAPPLICATION GUIDEType ED Single Stage Pressure Reducing Valve …………………574Type ED Parallel (Additive) Pressure Reducing Station …………575Type ED Two-stage Pressure Reducing Station …………………576Type ED Turbine Exhaust Make-up Valve …………………………577Type EF14 and EF14D Steam Allocating Valves …………………578Type ED Remote Shut Off …………………………………………579Type ED Remote Mounted Pilot …………………………………580Type EP125 Trip Valve ………………………………………………581Type D50 Direct Operated Pressure Reducing Valve ……………582Type ED5 Pressure Regulator for Accurate <strong>Control</strong> of a Deaerator 583Type EP Pressure Regulatorfor Self-contained <strong>Control</strong> of an Unfired Steam Generator……584TABLE OF CONTENTSType EP Pressure Regulator Integrally Mountedfor Self-contained control of an Unfired Steam Generator ……584Type E8 Air Adjusted Pressure Reducing Valve …………………585EA Series Air Adjusted Pressure Regulator ………………………586EA95P60 Pneumatically <strong>Control</strong>led Pressure Regulator ………587EA93 Automatic Transfer Pressure Reducing Station …………588Type E2 Slow Opening Valve ………………………………………589Type EA Pressure Regulator with Type B Panel 590for Gaylord Shower <strong>Control</strong> ……………………………………591Type EA Pressure Regulator with Type B Panelfor <strong>Control</strong> of the Plate Sections of a Corrugator ……………592Type E8 EPC Electro-pneumatically <strong>Control</strong>ledPressure Reducing Valve ………………………………………593Type EM33D Electrically Operated Reducing Valve ……………594Type ED208D Electronic Startup <strong>Control</strong> in conjunction witha Time Proportioning Outdoor Reset <strong>Control</strong>ler ………………595Type ED208P14-EF14D Electronic Slow Startup <strong>Control</strong>for Parallel Operation ……………………………………………596Type ED210 Electronic Modulating Regulator ……………………597Type ED208D Electronic Start-up <strong>Control</strong> ………………………598Type EDM33D Pressure Reducing Valvewith Two Set Point <strong>Control</strong> ……………………………………599Type D36 Water Pressure Reducing Valve ………………………600Type C34D Pilot Operated Pressure Reducing Valve ……………601Type ET14 & ET14D Temperature Regulator ……………………602Type ET124 & ET134 Temperature Regulator ……………………603Type C34T52 Cooling Regulator …………………………………604Type ET14D Temperature Regulator ………………………………605Type ET14T14 Temperature Regulator ……………………………606Type ET134 Temperature Regulator for Poultry Scalder ………607Type C34T52 Temperature Regulator for Chilled Water System 608Series 2000 Direct Operated Temperature Regulatorfor Storage Heater ………………………………………………609Series 2000 Direct Operated Temperature Regulatorfor Plate Heater …………………………………………………610Series 2000 Direct Operated Temperature Regulatorfor Engine Jacket Cooling ………………………………………611Series 2000 Direct Operated Temperature Regulatorfor Liquid Cooling Tank …………………………………………612Series 2000 Direct Operated Temperature Regulatorfor Three-way Blending/Mixing …………………………………613Series 2000 Direct Operated Temperature Regulatorfor Three-way Diverting …………………………………………614Type EAT61 Air <strong>Control</strong>led Temperature Regulator ………………615Type EA Temperature Regulator for Remote Thermostat <strong>Control</strong> 616Type ET134 Self-contained Temperature Regulator for Starch Mixer 617Type EAT60 Temperature Regulator for Wax Application <strong>Control</strong> 618Type ET124A Viscosity/Temperature Regulator …………………619Type EQ Back Pressure Regulator ………………………………620Type EF14D Pressure Reducing Valve with Back Pressure <strong>Control</strong> 621Type EQ Back Pressure Valve with Flow <strong>Control</strong> Orifice ………622Type C34Q Back Pressure Pump Bypass <strong>Control</strong> ………………623Type EN Differential Regulator ……………………………………624Type N6 Differential Pressure Valve ………………………………625Type C34N Differential Pressure Regulator ………………………626Type C34N20 Differential Regulator ………………………………627ULATORSCTROL VALVESSAF RELIEF VALVESDPERHEATERS& SE REDUCTIONCONNSATE PUMPSPS & SPECIALTIESNIFLEX COUPLINGSGENERAL USE VALVESSTRAINERSPLICATION GUIDEREFERENCE- 7 -

REGULATORSCONTROL VALVESSAFETY RELIEF VALVESTRAPS & SPECIALTIESUNIFLEX COUPLINGS& GENERAL USE VALVESSTRAINERSType EP14 Pump Governor ………………………………………628Steam Atomizing Air Operated Desuperheater …………………629Steam Atomizing Direct Operated Desuperheater ………………630Mechanical Atomizing Direct Operated Desuperheater …………631Mechanical Atomizing Air Operated Desuperheater ……………632Pressure Regulator with Muffling Orifice …………………………633Pressure Regulator with Noise Suppressor ………………………634Type NFT Free Float Steam Trapfor Fast Start-up in Corrugation Plants ………………………635Type NFT Free Float Steam Trapto Prevent Freezing in Steam Coils ……………………………636Type NFT Free Float Steam Trapto Prevent Freezing of Outside Air Heating Coils ……………637Type NFT Free Float Steam Trap for Reboilers …………………638Intimidator Type J <strong>Control</strong> Valve and P60 Pressure <strong>Control</strong>lerfor Fast Load Changes and Varying Pressures ………………639Intimidator Type J <strong>Control</strong> Valve and P60 Pressure <strong>Control</strong>lerfor Steam Showers ………………………………………………640Intimidator Type J <strong>Control</strong> Valve and Liquid Level <strong>Control</strong>lerfor Boilers …………………………………………………………641Intimidator Type JP60 for Pump Governor ………………………642Intimidator Type J <strong>Control</strong> Valve with P60 <strong>Control</strong>lerfor Turbine Exhaust Make-up …………………………………643Intimidator Type J <strong>Control</strong> Valve and P60 Back Pressure<strong>Control</strong>ler for Pump Discharge …………………………………644Intimidator Type J <strong>Control</strong> Valve with Electro-pneumaticPositioner for computerized Cogeneration <strong>Control</strong> …………645Intimidator Type J <strong>Control</strong> Valve with P60 <strong>Control</strong>lerfor Gaylord Shower <strong>Control</strong> ……………………………………646Intimidator Type J <strong>Control</strong> Valve with P60 <strong>Control</strong>lerfor Plate Sections of a Corrugator ……………………………647Intimidator Type J <strong>Control</strong> Valve with P60 <strong>Control</strong>lerfor Back Pressure <strong>Control</strong> of a Deaerator ……………………648TABLE OF CONTENTSIntimidator Type J <strong>Control</strong> Valve with P60 <strong>Control</strong>lerfor Unfired Steam Generator ……………………………………649Intimidator Type J <strong>Control</strong> Valve with EPC Electro-pneumatic<strong>Control</strong>ler as a Pressure or Back Pressure <strong>Control</strong>ler ………650Intimidator Type J <strong>Control</strong> Valve and T60 <strong>Control</strong>lerfor Instantaneous Heaters ………………………………………651Intimidator Type J <strong>Control</strong> Valve with T60 <strong>Control</strong>lerfor Starch Mixer …………………………………………………652Intimidator Type J <strong>Control</strong> Valve with T60 <strong>Control</strong>lerfor Wax Application <strong>Control</strong> ……………………………………653Intimidator Type J <strong>Control</strong> Valve with EPC Electro-Pneumatic<strong>Control</strong>ler as a Temperature <strong>Control</strong>ler ………………………654Intimidator Type J <strong>Control</strong> Valvefor Level/Make-up on a Deaerator ……………………………655Intimidator Type J <strong>Control</strong> Valve with EPC Electro-pneumatic<strong>Control</strong>ler as a Differential (Level) <strong>Control</strong>ler …………………656SECTION XREFERENCE &PIPING DESIGNGlossary of Terms …………………………………………………658Flow vs. Velocity Chart ……………………………………………659Reference Tables ……………………………………………………660Pressure Temperature Limits ………………………………………667Spence Typical Installation for Sanitary Steam System …………668Spence Single Stage Pressure Reducing Station ………………669Spence Two Stage Pressure Reducing Station …………………670Spence Single Stage Parallel Pressure Reducing Station ………671Spence Two Stage Parallel Pressure Reducing Station …………672Spence Typical Installation for Instantaneous Heater ……………673Spence Typical Installation for Storage Heater ……………………674Product Index ………………………………………………………676Steam Tables ………………………………………………………682DESUPERHEATERS& NOISE REDUCTIONCONDENSATE PUMPSAPPLICATION GUIDEREFERENCEIt is solely the responsibility of the system designer and the user to select products suitable for theirspecific application requirements and to ensure proper installation, operation, and maintenance of theseproducts. Assistance shall be afforded with the selection of the materials based on the technical informationsupplied to Spence Engineering Company, <strong>Inc</strong>. Applicable codes, material compatibility, productratings and application details should be considered in the selection and application. Improper selection,application or use of the products described herein can cause personal injury or property damage. If theproduct is intended for an application or use other than originally specified, the system designer and oruser must reconfirm that the selection is suitable for the new operating conditions.- 8 -

SECTION IREGULATORSREGULATORS- 9 -

REGULATORSApplications● Pressure Regulation for Steam Distribution● Single Point or Multiple Use Applications● Pressure <strong>Control</strong> for Steam Plants● District Heating Systems● Single Stage Reduction Stations● Two Stage Reduction Stations● Parallel Reduction StationsIron HorseED SeriesPressureRegulatorPressures To 600 PSIGTemperatures to 750°FSprings OutsideSteam Pathassure exceptionallylong life on bothMain Valve and PilotEasy Inspectionprovided by externaldiaphragm loadingsteam passagesGuaranteedDead End Shutoffmeets Class IV in steamservice, even on large sizesPatented SECOWELD Optionallows easy repair of seat ringthreads damaged by highpressure applicationsThree Pilot Mounting Optionsinclude standard side mount (shown),integral mount and remote mountSECO Metal Seats and Discsresist wiredraw - not one caseof SECO Metal being cut bysteam in 75 yearsPackless Constructioneliminates leakage andgreatly reduces frictionand stem wearTwo MainSpring Optionsfor superior regulationover a wide rangeof applicationsLarge, ProtectedMetal Diaphragmbathed in condensate,sealed away from steamseldom needs replacementNo Closely Fitted Partsto stick or bind due touneven expansionor foreign matterFew Moving Partsmean long service life- 10 -

HOW TO CHOOSE A REGULATORIf you already know the product that you want information on, find the product page in the Table ofContents. Pages showing popular combinations of Pilot and Regulators are found in the CombinationRegulators Chapter. Detailed product information on materials, ratings, dimensions, weights and applicationsare found in the Products Chapters. All sizing information is contained in the Regulator Sizing Chapter.If you are not sure of what you need, collect all the following information. You will need it to select the rightproduct for your needs.Inlet PressureFlow RateFlow Media (i.e.: Steam, Water, etc.)Desired Delivery PressureNoise Restrictions, if anyType of Pilot <strong>Control</strong> (i.e.: Self Contained, Pneumatic, Electronic, etc.)Application (i.e.: Temperature Regulation, Single Stage Pressure Regulation, etc.)HOW TO CHOOSEA REGULATORApplication data is listed on each Product Page. If you identify the nature of the installation, it will assistyou selecting the proper equipment.DIRECT ACTING OR PILOT OPERATED REGULATOR?You may be able to use a Direct Operated Regulator for your application. They are generally less expensivethan Pilot Operated Regulators. However, they do not provide the same level of accuracy or rangeability.If a Direct Acting Regulator is an option, consult the Direct Operated Valves Chapter to determine whichbest fits your specific needs. Then, consult the appropriate pages in the Regulator Sizing Chapter toselect the exact size you need.If a Pilot Operated Regulator is required, go to Page 14 (for Pressure Regulators) or Page 15 (forTemperature Regulators). These selection charts will help you to quickly determine the type of productthat you need. The Pilot can be self contained, pneumatically or electronically actuated. Consult theappropriate pages in the Regulator Sizing Chapter to select the exact size Regulator and Pilot you need.Overall dimensions of the most popular combinations are provided in the Combination Regulators Chapter.ECONOMICAL, ENGINEERED OR ENGINEERED WITH NOISE SUPPRESSION?The choice of how to size a regulator for an application is up to you. The most economical choice doesnot necessarily take into consideration the optimum loading of the Regulator, which could affect it’sservice life. Properly engineered Spence Regulators have been in continuous service for as much as 50years. In high pressure reduction stations, noise can be a serious environmental problem. Spence offersa number of Noise Suppression products to reduce this problem. You will find comprehensive noisereduction sizing and selection information in the Noise Reduction Chapter.- 11 -

OPERATING CYCLEPRESSURETHE OPERATING CYCLE OF A SPENCE PRESSURE REGULATORThe basic Type ED has been selected to illustrate the operation of a SPENCE Pilot Operated Pressure Regulator.This presentation describes the successive steps in the mechanical cycle of the Regulator.1MAIN VALVE is normally closed.On placing Regulator in service,initial pressure fills the passagesshown in red.2PILOT receivesinitial pressurethrough Nipple andUnion Connection.3CONTROL LINE connectsPilot Diaphragm Chamberto Delivery piping.4ADJUSTING SPRING,when compressed,forces Pilot Valve open.5CONNECTING TUBINGconducts fluid from Pilotto Main Valve Diaphragmand Bleedport. When Pilotopens, fluid flows throughPilot faster than it canescape at Bleedport, creatinga loading pressure (orange)which forces Main Valveopen.KEYHIGH PRESSUREMEDIUM PRESSURELOW PRESSURE- 12 -6DELIVERY PIPE and <strong>Control</strong> Lineare now being filled with fluidflowing through Main Valve.As delivery pressure (yellow) rises,it overcomes the force exerted byAdjusting Spring and Pilot throttles.This , in turn, allows Main Valve tothrottle just enough to maintain theset delivery pressure.If the demand ceases, Pilot closes,allowing the Main Valve to close –effecting a DEAD-END SHUTOFF.

THE OPERATING CYCLE OF A SPENCE TEMPERATURE REGULATORThe Type ET134 has been selected to illustrate the operation of a SPENCE Pilot Operated Temperature Regulator.This presentation describes the successive steps in the mechanical cycle of the Regulator.1MAIN VALVE is normally closed. On placingRegulator in service, initial pressure fills thepassages shown in red.3CONTROL LINE connects Pilot DiaphragmChamber to Delivery piping.OPERATING CYCLETEMPERATURE2PILOT receivesinitial pressurethrough Nipple andUnion Connection.KEYINITIAL STEAM PRESSURELOADING STEAM PRESSUREDELIVERY STEAM PRESSUREVAPOR PRESSUREFLUID HEATED5CONNECTING TUBING conducts steam fromPilot to Main Valve Diaphragm and Bleedport.When Pilot opens, steam flows through Pilot fasterthan it can escape at Bleedport, creating a loadingpressure (orange) which forces Main Valve open.4PRESSURE SPRINGforces Pilot Valve open.6HEATER, Delivery Pipe and <strong>Control</strong>Line are now being filled with steamflowing through Main Valve.As delivery pressure (yellow) rises, itovercomes the force exerted by PressureSpring and Pilot throttles. This, in turnallows Main Valve to throttle just enoughto maintain the set delivery pressure.7THERMOSTAT ELEMENT (vapor tension type) is connected into heater outlet.The rising temperature of the fluid (blue) being heated creates a vapor pressure(green) on the Temperature Diaphragm. When this pressure has reached a pointsufficient to overcome the Temperature Adjusting Spring, it applies a force on theLever so as gradually to decrease the spring loading on the Pressure Diaphragm.This produces a stem-by-step reduction in the delivery pressure as the temperaturerises through several degrees.If the desired temperature is exceeded, the vapor pressure on the PilotTemperature Diaphragm overcomes the forces of the Spring. This allows Pilot andMain Valve to close tight.- 13 -

QUICK SELECTIONCHART - PRESSUREQUICK SELECTION CHARTFOR STEAM PRESSURE REGULATORSReview the application data that you have collected. Consult the chart, starting with the inlet pressure that matches the inletpressure you have. Next, select your outlet pressure (reduced or delivery pressure). Then select the type of pilot control that youwill be using and, finally, the level of accuracy that your system requires. This will lead you to a recommended regulator.Please bear in mind that these recommendations are general in nature and you should check the Product Pages and Sizing Sectionto ensure you have selected the correct product. If you need assistance, contact your local Spence Technical Sales Representative.INITIALPRESSUREREDUCEDPRESSURENORMALREGULATIONACCURACYTYPE OFCONTROLSPENCEREGULATORSELFACTUATEDTYPE ED5PAGE 481 PSIGTO25 PSIG± 1 /2 PSIGPNEUMATICTYPE EA84PAGE 50ELECTRONIC*TYPE ED210PAGE 72SELFACTUATEDTYPE EDPAGE 48ABOVE15 PSIGPAGE 283 PSIGTO150 PSIG± 1 PSIGPNEUMATICTYPE EA43PAGE 50ELECTRONIC*TYPE ED210PAGE 72SELFACTUATEDTYPE ED2PAGE 48ABOVE150 PSIG± 2 PSIGPNEUMATICTYPE EA70PAGE 50ELECTRONIC*TYPE ED210PAGE 72SELFACTUATEDTYPE E2DPAGE 48± 1 PSIGPNEUMATICTYPE E2A84PAGE 5015 PSIGORBELOWPAGE 301 PSIGTO12 PSIGELECTRONIC*SELFACTUATEDTYPE E2D210PAGE 72TYPE E2D5PAGE 48± 1 /2 PSIGPNEUMATICTYPE E2A84PAGE 50ELECTRONIC*TYPE E2D210PAGE 72* Electronic Pilot accuracy is a function of controller accuracy.- 14 -

QUICK SELECTION CHARTFOR TEMPERATURE REGULATORSReview the application data that you have collected. Consult the chart, starting with the inlet pressure that matches the inletpressure you have. Next, select your outlet pressure (reduced or delivery pressure). Then select the type of pilot control that youwill be using and, finally, the level of accuracy that your system requires. This will lead you to a recommended regulator.Please bear in mind that these recommendations are general in nature and you should check the Product Pages and Sizing Sectionto ensure you have selected the correct product. If you need assistance, contact your local Spence Technical Sales Representative.INLETPRESSUREOUTLETPRESSURETYPE OFCONTROLHEATERTYPESPENCEREGULATORQUICK SELECTIONCHART - TEMPERATURENO PRESSUREREDUCTIONSELFCONTAINEDSTORAGE ORINSTANTANEOUSTYPEET14PAGE 76ABOVE15 PSIGPAGE 28SELFCONTAINEDSTORAGEINSTANTANEOUS20 PSI MAXIMUMTYPEET14DPAGE 76TYPEET134PAGE 74REDUCEDPRESSUREINSTANTANEOUS125 PSI MAXIMUMTYPEET124PAGE 74PNEUMATICSTORAGE ORINSTANTANEOUSTYPEEAT61PAGE 8315 PSIGORBELOWPAGE 30NO PRESSUREREDUCTIONREDUCEDPRESSURESELFCONTAINEDPNEUMATICSELFCONTAINEDPNEUMATICSTORAGE ORINSTANTANEOUSSTORAGE ORINSTANTANEOUSSTORAGE ORINSTANTANEOUSSTORAGE ORINSTANTANEOUSTYPEE2T14PAGE 76TYPEJT61*PAGE 83TYPEE2T14DPAGE 76TYPEE2AT61PAGE 83* See <strong>Control</strong> Valve Section, Page 150- 15 -

SPENCE MAIN VALVE SPECIFICATION TABLESIZES, BODY MATERIAL a AND FACINGS OTHER MATERIALS aMAIN VALVESPECIFICATION TABLETYPESCAST IRON CAST CAST STEEL SEAT RINGS DISCSBRONZEFlanged FlangedFlanged Flanged Flanged Diaphragm Steam Water, Oil, Steam Water, Oil, Stem MainScrewed ANSI ANSI Screwed Screwed ANSI ANSI ANSI Service Air or Gas Service Air or Gas SpringEnds 125 250 Ends Ends 150 300 600 Service ServiceSIZES–INCHES3 /8-2 1-12 1-123 /8-23 /8-2 1-12 1-121 /2-8EMax. Initial Pressure–psi 250 125 250 250 300 150 300 600Stainless 316/ 316/ 304/ Stainless CarbonMax. Initial Temperature–°F 450 450 450 400 750 500 750 750 Steel 420 d 420 420 Hycar Steel or or17-4PH e <strong>Inc</strong>onel fMin. Differential c –psi h 10/30/50 10/30/50 10/30/50 10/30/50 10/30/50 10/30/50 10/30/50 30SIZES–INCHES3 /4-2 1-12 —3 /4-2 — — — —E2Max. Initial Pressure–psi 15 15 — 15 — — — —304/ Stainless CarbonMax. Initial Temperature–°F 250 250 — 250 — — — — Hycar 316 — 420 — Steel SteelMin. Differential c –psi 3 3 — 3 — — — —SIZES–INCHES3 /4-2 1-12 1-123 /4-23 /4-2 1-12 1-12 —E5Max. Initial Pressure–psi 250 125 250 250 300 150 300 —316/ 316/ 304/ 304/ Stainless CarbonMax. Initial Temperature–°F 450 450 450 400 600 500 600 — Hycar 420 420 420 420 Steel SteelMin. Differential c –psi 5 5 5 5 5 5 5 —SIZES–INCHES3 /4-2 1-123 /4-2 — — — — —E6Max. Initial Pressure–psi 250 125 250 250 — — — —316/ Stainless CarbonMax. Initial Temperature–°F 200 200 200 200 — — — — Hycar — 420 — Hycar Steel SteelMin. Differential c –psi 10 10 10 10 — — — —SIZES–INCHES 1-2 2-6 2-6 — — — — —C34Max. Initial Pressure–psi 200 165 200 — — — — —303/ Stainless CarbonMax. Initial Temperature–°F 200 200 200 — — — — — Hycar — 304 — Hycar Steel SteelMin. Differential c –psi 10 10 10 — — — — —aMain Valves for corrosive fluids or costly gases requirespecial materials.bBronze body and blind flange only.cMinimum Differential is the smallest permissible differencebetween initial pressure (measured at the inlet) and thedelivery pressure (measured at the outlet) of the main valve.dSecoweld seat construction described in Options Section isregularly furnished for service pressures 400 psi and higher.e17-4 PH stems are furnished for service temperaturesexceeding 600°F.f<strong>Inc</strong>onel springs are furnished for service pressuresexceeding 400 psi and/or temperatures exceeding 600°F.hStandard spring (HP) requires minimum 30PSI differential. 50 PSI is recommendedminimum differential. Use optional Low ∆P(LP) main spring for 15 psi minimumdifferential. 10 psi minimum differential isattainable by adding base bypass and 1 ⁄16"bleedport.- 16 -

COMBINATIONREGULATORSCOMBINATIONREGULATORS- 17 -

TYPE ED & ED2PRESSURE REGULATORTYPE ED SERIESPRESSURE REGULATORCAST IRON or STEELPRESSURES to 600 PSIG at 750°FAPPLICATION DATA● Pressure Regulating for Steam Distribution● Single Point or Multiple use Applications● Pressure <strong>Control</strong> for Steam Plants● District Heating Systems● Single Stage Reductions● Two Stage Reductions● Parallel ReductionTYPE ED PRESSURE REGULATORVALVE INFOPAGE 28PILOT INFOPAGE 48FDIMENSIONSinches (mm)SIZE F G3/8 5 3 /8 1 1 /4(10) (136) (32)1/2 5 3 /8 1 1 /4(15) (136) (32)3/4 5 3 /8 1 3 /8(20) (136) (35)1 5 3 /4 1 1 /2(25) (146) (38)G1 1 /4 6 1 7 /8(32) (152 (48)1 1 /2 6 1 /4 2(40) (159) (51)2 6 5 /8 2 1 /8(60) (168) (54)2 1 /2 6 3 /4 2 3 /8(65) (171) (60)Valve is tapped so thatPilot may be mountedon either side.3 7 1 /4 2 3 /4(80) (184) (70)4 8 3 1 /2(100) (203) (89)5 9 3 1 /2(125) (229) (89)6 9 7 /8 4(150) (251) (102)8 10 1 /2 6 1 /4(200) (267) (159)10 12 1 /2 6(250) (318) (152)12 14 8 1 /2(300) (356) (216)- 18 -

TYPE E2D SERIESPRESSURE REGULATORCAST IRONPRESSURES to 15 PSIG max.APPLICATION DATA● Pressure Regulating for Steam Distribution● Single Point or Multiple use Applications● Single Stage Reduction● Parallel Reduction● Low Pressure Drop to Operate Valve● Instantaneous Hot Water Heaters with lowsupply pressures (with the addition of a T14Pilot)TYPE E2DPRESSURE REGULATORTYPE E2D PRESSURE REGULATORDIMENSIONSinches (mm)SIZE F G3/4 5 5 /8 1 3 /8(20) (143) (35)1 5 3 /4 1 1 /2(25) (146) (38)1 1 /4 6 1 7 /8(32) (152) (48)1 1 /2 6 1 /4 2(40) (159) (51)2 6 5 /8 2 1 /8(50) (168) (54)2 1 /2 6 3 /4 2 3 /8(65) (171) (60)FVALVE INFOPAGE 30PILOT INFOPAGE 483 7 1 /4 2 3 /4(80) (184) (70)G4 7 3 /8 3 1 /2(100) (187) (89)5 8 1 /8 3 1 /2(125) (206) (89)6 8 1 /2 4(150) (216) (102)8 9 3 /8 6 1 /4(200) (238) (159)10 11 6(250) (279) (152)12 11 7 /8 7 1 /4(300) (302) (184)NO. 5B OPEN ELBOWValve is tapped so that Pilotmay be mounted on eitherside.- 19 -

TYPE ED(2) INTEGRALPRESSURE REGULATORTYPE ED & ED2INTEGRAL MOUND PRESSUREREGULATORCAST IRON or STEELfor PRESSURES to 600 PSIG at 750°FAPPLICATION DATA● Pressure Regulation for Steam Distributionwhere space is limitedDIMENSIONSinches (mm)SIZE F G*TYPE ED INTEGRAL MOUNTPRESSURE REGULATORVALVE INFOPAGE 28PILOT INFOPAGE 48G3/8 5 1 /4 15 3 /4(10) (133) (400)1/2 5 1 /4 15 3 /4(15) (133) (400)3/4 5 3 /8 17(20) (136) (432)1 5 1 /2 18 1 /2(25) (140) (470)1 1 /4 5 3 /4 18 1 /2(32) (146) (470)1 1 /2 6 19 1 /2(40) (152) (495)F2 6 1 /2 20 5 /8(50) (165) (524)2 1 /2 7 21 3 /4(65) (178) (552)3 7 3 /8 23 1 /2(80) (187) (597)4 8 7 /8 27 1 /4(100) (225) (692)G*5 10 28 5 /8(125) (254) (727)6 11 3 /8 31 1 /2(150) (289) (800)8 12 3 /4 35 3 /8(200) (324) (899)10 15 1 /2 43 3 /4(250) (394) (1111)F12 18 47 3 /4(300) (457) (1213)* For D2 Pilot, add 5 1 /4"(133) to this dimension.- 20 -

TYPE EA SERIESPRESSURE REGULATORCAST IRON or STEELfor PRESSURES to 600 PSIG at 750°FAPPLICATION DATA● Pressure Regulating for Steam Distribution● Single Point or Multiple use Applications● Pressure <strong>Control</strong> for Steam Plants● District Heating Systems● Single Stage Reductions● Two Stage Reductions● Parallel Reduction● <strong>Control</strong> from Remote Location● Temperature Regulating (with addition of T60Series Pneumatic Temperature Pilot)TYPE EA SERIESPRESSURE REGULATORVALVE INFOPAGE 28TYPE EA SeriesPRESSURE REGULATORDIMENSIONSinches (mm)SIZE F G3/8 5 3 /8 1 1 /4(10) (136) (32)PILOT INFOPAGE 501/2 5 3 /8 1 1 /4(15) (136) (32)No. 8B TeeBleedport BendNo. 4A Bleedport3/4 5 5 /8 1 3 /8(20) (143) (35)1 5 3 /4 1 1 /2(25) (146) (38)1 1 /4 6 1 7 /8(32) (152) (48)1 1 /2 6 1 /4 2(40) (159) (51)F<strong>Control</strong>PipePilotType A85SerialNo. PlateSerial No. PlateDo notinsulatebelowthis line2 6 5 /8 2 1 /8(50) (168) (54)2 1 /2 6 3 /4 2 3 /8(65) (171) (60)RestrictionBend1/4" UnionMain ValveType E or E23 7 1 /4 2 3 /4(80) (184) (70)4 8 3 1 /2(100) (203) (89)5 9 3 1 /2(125) (229) (89)6 9 7 /8 4(150) (251) (102)8 10 1 /2 6 1 /4(200) (267) (159)10 12 1 /2 6(250) (318) (152)12 14 8 1 /2(300) (356) (216)GValve is tapped so thatPilot may be mountedon either side.No. 5A Restriction Elbow—Type ENo. 5B Open Elbow—Type E2- 21 -

TYPE ET14TEMP. REGULATORTYPE ET14TEMPERATURE REGULATORAPPLICATION DATACAST IRON or STEELCONTROLS 20 to 500°F● Temperature Regulation for Batch Process● Storage Heaters (Water, Fuel Oil or Chemical)● Air HeatingTYPE ET14 TEMPERATURE REGULATORPilotType T14VALVE INFOPAGE 28PILOT INFOPAGE 76ThermostatFDIMENSIONSinches (mm)SIZE F G3/8 5 3 /8 1 1 /4(10) (136) (32)1/2 5 3 /8 1 1 /4(15) (136) (32)3/4 5 5 /8 1 3 /8(20) (143) (35)1 5 3 /4 1 1 /2(25) (146) (38)Adjusting SpringAdjustingWheelNo. 8BTeeBleedport BendNo. 4A BleedportSerial No. PlateG1 1 /4 6 1 7 /8(32) (152) (48)1 1 /2 6 1 /4 2(40) (159) (51)2 6 5 /8 2 1 /8(50) (168) (54)2 1 /2 6 3 /4 2 3 /8(65) (171) (60)3 7 1 /4 2 3 /4(80) (184) (70)SerialNo. Plate4 8 3 1 /2(100) (203) (89)RestrictionBend1/4" UnionNo. 5A Restriction Elbow—Type ENo. 5B Open Elbow—Type E2Do not insulatebelow this lineMain ValveType E or E2Valve is tapped so thatPilot may be mountedon either side.5 9 3 1 /2(125) (229) (89)6 9 7 /8 4(150) (251) (102)8 10 1 /2 6 1 /4(200) (267) (159)10 12 1 /2 6(250) (318) (152)12 14 8 1 /2(300) (356) (216)- 22 -

TYPE ET14DPRESSURE LIMITINGTEMPERATURE REGULATORAPPLICATION DATACAST IRON or STEELCONTROLS 20 to 500°F● Temperature & Pressure Regulation for largevolume Heat Exchangers● Storage Heaters● Jacketed Kettles● VatsTYPE ET14DTEMP. REGULATORTYPE ET14D TEMPERATURE& PRESSURE REGULATORDIMENSIONSinches (mm)SIZE F G3/8 5 3 /8 1 1 /4(10) (136) (32)1/2 5 3 /8 1 1 /4(15) (136) (32)VALVE INFOPAGE 28D PILOT INFOPAGE 48T14 PILOT INFOPAGE 763/4 5 5 /8 1 3 /8(20) (143) (35)1 5 3 /4 1 1 /2(25) (146) (38)1 1 /4 6 1 7 /8(32) (152) (48)1 1 /2 6 1 /4 2(40) (159) (51)2 6 5 /8 2 1 /8(50) (168) (54)2 1 /2 6 3 /4 2 3 /8(65) (171) (60)GF 6"Adjusting NutsPilotType DAdjustingSpringPilot Type T14HandwheelNo.8BTeeAdjusting SpringBleedport BendThermostatNo. 4A BleedportSerial No. PlateMain ValveType E or E23 7 1 /4 2 3 /4(80) (184) (70)4 8 3 1 /2(100) (203) (89)5 9 3 1 /2(125) (229) (89)6 9 7 /8 4(150) (251) (102)1/4"<strong>Control</strong>PipeSerialNo. Plate1/4"UnionRestrictionBend1/4"UnionDo not insulatebelow this line8 10 1 /2 6 1 /4(200) (267) (159)10 12 1 /2 6(250) (318) (152)12 14 8 1 /2(300) (356) (216)Valve is tapped so thatPilot may be mounted oneither side.No. 5A Restriction Elbow—Type ENo. 5B Open Elbow—Type E2- 23 -

TYPE E(2)T124/134TEMP. & PRESS. REGULATORTYPE ET124/ET134 &E2T134TEMPERATURE & PRESSUREREGULATORAPPLICATION DATA● Instantaneous Heaters● Jacketed Kettles● Storage Heaters● Oil Heaters● Batch HeatingCAST IRON or STEEL● Process Heaters● Vats● Driers● OvensMODELS● ET124 for heater operating pressures between 20 and 125 psi.● ET134 for heater operating pressures up to 20 psi.● E2T134 for heater operating pressures up to 15 psi.TYPE ET124 TEMPERATURE &PRESSURE REGULATORE VALVE INFOPAGE 28FSIZEDIMENSIONSinches (mm)FEGE2E2 VALVE INFOPAGE 303/8 5 3 /8 1 1 /4 —(10) (136) (32) —PILOT INFOPAGE 741/2 5 3 /8 1 1 /4 —(15) (136) (32) —3/4 5 5 /8 1 3 /8 1 3 /8(20) (143) (35) (35)1 5 3 /4 1 1 /2 1 1 /2(25) (146) (38) (38)1 1 /4 6 1 7 /8 1 7 /8(32) (152) (48) (48)1 1 /2 6 1 /4 2 2(40) (159) (51) (51)2 6 5 /8 2 1 /8 2 1 /8(50) (168) (54) (54)G2 1 /2 6 3 /4 2 3 /8 2 3 /8(65) (171) (60) (60)3 7 1 /4 2 3 /4 2 3 /4(80) (184) (70) (70)4 8 3 1 /2 3 1 /2(100) (203) (89) (89)5 9 3 1 /2 3 1 /2(125) (229) (89) (89)6 9 7 /8 4 4(150) (251) (102) (102)8 10 1 /2 6 1 /4 6 1 /4(200) (267) (159) (159)Valve is tapped so thatPilot may be mountedon either side.10 12 1 /2 6 6(250) (318) (152) (152)12 14 8 1 /2 7 1 /4(300) (356) (216) (184)- 24 -

TYPE ED210REGULATORELECTRONIC MODULATIONDELIVERY PRESSURES to 150 PSIGAPPLICATION DATA● Main Valve adapted to 4-20 mA Signal● Requires balanced Main ValveTYPE ED210 ELECTRONICMODULATING REGULATORDIMENSIONSinches (mm)SIZE F G3/8 5 3 /8 1 1 /4(10) (136) (32)1/2 5 3 /8 1 1 /4(15) (136) (32)TYPE ED210 REGULATORVALVE INFOPAGE 283/4 5 5 /8 1 3 /8(20) (143) (35)1 5 3 /4 1 1 /2(25) (146) (38)1 1 /4 6 1 7 /8(32) (152) (48)1 1 /2 6 1 /4 2(40) (159) (51)2 6 5 /8 2 1 /8(50) (168) (54)2 1 /2 6 3 /4 2 3 /8(654) (171) (60)3 7 1 /4 2 3 /4(80) (184) (70)4 8 3 1 /2(100) (203) (89)5 9 3 1 /2(125) (229) (89)6 9 7 /8 4(150) (251) (102)8 10 1 /2 6 1 /4(200) (267) (159)10 12 1 /2 6(250) (318) (152)12 14 8 1 /2(300) (356) (216)FGValve is tapped so thatPilot may be mounted oneither side.PILOT INFOPAGE 72- 25 -

TYPE ED208DREGULATORTYPE ED208DPRESSURE REGULATORELECTRONIC STARTUPPILOT OPERATEDDELIVERY PRESSURES to 150 PSIGAPPLICATION DATA● Electronic <strong>Control</strong> of Slow Startup and/orSlow Shutdown of Pressure Regulation● Building Heating Systems● Can save more than 4 times it’s cost inbuilding heating in one year.● Requires balanced Main ValveTYPE ED208D PRESSURE REGULATORVALVE INFOPAGE 28D PILOT INFOPAGE 48D208 PILOTINFOPAGE 70DIMENSIONSinches (mm)SIZE F G3/8 5 3 /8 1 1 /4(10) (136) (32)1/2 5 3 /8 1 1 /4(15) (136) (32)3/4 5 5 /8 1 3 /8F 6 1 /2"(165)G(20) (143) (35)1 5 3 /4 1 1 /2(25) (146) (38)1 1 /4 6 1 7 /8(32) (152) (48)1 1 /2 6 1 /4 2(40) (159) (51)2 6 5 /8 2 1 /8(50) (168) (54)2 1 /2 6 3 /4 2 3 /8(65) (171) (60)3 7 1 /4 2 3 /4(80) (184) (70)Valve is tapped so thatPilot may be mounted oneither side.4 8 3 1 /2(100) (203) (89)5 9 3 1 /2(125) (229) (89)6 9 7 /8 4(150) (251) (102)8 10 1 /2 6 1 /4(200) (267) (159)10 12 1 /2 6(250) (318) (152)12 14 8 1 /2(300) (356) (216)- 26 -

MAIN VALVESMAIN VALVES- 27 -

TYPE EMAIN VALVETYPE E MAIN VALVEAPPLICATION DATA● Pressure Regulating for Steam Distribution● Regulating for Process <strong>Control</strong> (Temperature or Pressure)● Maintain Back Pressure or Differential Pressure● For use with Self-contained, Pneumatic or Electronic Pilots● Single Point or Multiple Use Applications● Slow Start-up or ShutdownSIZING INFOPAGE 108VALVE RATINGSValve Ends Pressure TemperatureASME/ANSI PSIG (bar) °F (°C)CAST IRONClass 250 NPT 250 (17.2) @ 450 (232)B16.1 Class 125 Flanged 125 (8.6) @ 450 (232)B16.1 Class 250 Flanged 250 (17.2) @ 450 (232)CAST STEELB16.34 Class 300 NPT 300 (21.0) @ 600 (315)†B16.34 Class 150 Flanged 150 (10.3) @ 500 (260)B16.34 Class 300 Flanged 300 (21.0) @ 600 (315)†B16.34 Class 600 Flanged 600 (41.4) @ 600 (315)††750°F (400°C) construction available on request.Other pressure/temperature ratings available; consult factory.Maximum downstream pressure is 300 psi.Canadian Registration # OC 0591.9CInstallation Tip: Add EZ Connections for ease of maintenanceSEE PAGE 42TYPE E MAIN VALVESIZES 3/8" – 12"PRESSURES to 600 PSIG at 750°F● Normally Closed● Single Seat● Balanced Metal Diaphragms● Protected Main Spring● Fluid, Gas & Vapor Applications● Multiple Trims for Precise Sizing● ANSI/FCI 70-2 Class IV Shutoff● Virtually Frictionless for Long Service Life● Packless Construction● Easy In-line Maintenance● Wide Variety of Pilots for Many Applications● Minimum Operating ∆P 10 psi (.7 bar)● Lifetime Warranty against Wiredrawing ofSeat & Disc*OPTIONS● Composition See Disc page 42 ● Parabolic Disc● Balanced Construction ● Integral Mount Pilot● Insulcap Insulating Jacket ● Secoweld● High Temperature Construction ● Dashpot● Low ∆P (LP) Main Spring ● EZ ConnectionsTYPICAL CONFIGURATIONSPRESSURE REDUCING ……………TYPE ED SERIESAIR ADJUSTED ……………………TYPE EA SERIESBACK PRESSURE…………………TYPE EQ SERIESPUMP GOVERNOR………………TYPE EP SERIESLOAD ALLOCATING………………………TYPE EFDAIR CONTROLLED ……………………TYPE EAP60ELECTRONIC SLOW START …………TYPE ED208DSOLENOID CONTROLLED ………………TYPE EMDSOLENOID ACTUATED ……………………TYPE EMDIFFERENTIAL ……………………………TYPE ENTEMPERATURE CONTROL …………TYPE ET SERIESRATED FLOW COEFFICIENTS (Cv)SEATREGULATOR SIZEFACTOR 3/8 1 /2 3 /4 1 1 1 /4 1 1 /2 2 2 1 /2 3 4 5 6 8 10 12Full 1.5 2.8 5.4 8.8 14.1 19.8 31 44 74 109 169 248 444 706 1113Full 75 % — 2.1 4.0 6.6 10.6 14.8 23.3 33 56 82 127 186 333 530 835Full 50 % — 1.4 2.7 4.4 7.0 9.9 15.5 22 37 55 85 124 222 353 557Normal .65 1.5 4.8 7.5 10.4 14.6 17.6 24 43 78 115 151 249 377 631Normal 75 % — — — — — — — 18 33 59 87 114 187 283 474Normal 50 % — — — — — — — 12 22 39 58 76 125 189 316* When installed according to factory specifications.- 28 -

TYPE E MAIN VALVESPECIFICATIONThe valve shall be self-operated, external pilot type, singleseated, metal diaphragm actuated, normally closed design. Thevalve will function quickly and shut tight on dead end service.Internal parts including seats, discs, stems and diaphragms shallbe of stainless steel. There shall be no springs in the steam spaceand no stuffing box. The valve shall be easy to maintain with allparts accessible without removal from the line.ACTYPE EMAIN VALVEMATERIALS OF CONSTRUCTIONBody, Cast Iron …………………………ASTM A126 Cl. BBody, Cast Bronze ……………ASTM B61 UNS C92200Body, Cast Steel ………………………ASTM A216 WCBStem ……………………………303 St. Stl. ASTM A582Disc 3/4 - 5" ……………420 St. Stl. ASTM A743 CA-40Disc 6 - 12" ………………304 St. Stl. ASTM A167/A240Seat 3/4 - 5" ……………420 St. Stl. ASTM A743 CA-40Seat 6 - 12" …………316 St. Stl. ASTM A743-79 CF-8MGasket ………………………………………Non-asbestosDiaphragm …………………Stainless Steel MIL-S-5059CSpring …………………………………………………SteelBTYPE E MAIN VALVEDIMENSIONS inches (mm) AND WEIGHTS pounds (kg)FACE TO FACE DIMENSIONSCA B Std. Mount Integral Mount D* APPROX. WT.SIZE ANSI ANSI ANSI ANSI ANSI ANSI CI & Brz. Steel Steel ANSI ANSI ANSI ANSINPT 125,150 250 300 600 600 All 600 NPT 125,150 250,300 6003/8 4 3 /8 — — — — 5 7 /8 2 3 /4 — 3 1 /2 3 1 /2 — 5 1 /4 14 — — —(10) (111) — — — — (149) (70) — (89) (89) — (133) (6) — — —1/2 4 3 /8 — — — 6 5 7 /8 2 3 /4 2 3 /4 3 1 /2 3 1 /2 3 5 /8 5 1 /4 14 — — 20(12) (111) — — — (152) (149) (70) (70) (89) (89) (92) (133) (6) — — (9.1)3/4 4 3 /8 — — — 6 3 /8 6 1 /2 2 7 /8 3 7 /8 3 5 /8 3 3 /4 4 1 /2 5 1 /2 18 — — 28(19) (111) — — — (162) (165) (73) (98) (92) (95) (114) (140) (8) — — (13)1 5 3 /8 5 1 /2 6 6 1 /2 6 1 /2 7 3 5 /8 4 1 /4 4 3 /8 4 3 /8 4 3 /4 6 1 /4 23 26 31 32(25) (137) (140) (152) (165) (165) (178) (92) (108) (111) (111) (121) (159) (10) (12) (14) (15)1 1 /4 6 1 /2 6 3 /4 7 1 /4 7 7 /8 7 7 /8 7 7 /8 4 1 /8 4 5 /8 4 4 5 /8 5 6 1 /2 33 37 41 45(32) (165) (171) (184) (200) (200) (200) (105) (117) (102) (117) (127) (165) (15) (17) (19) (20)1 1 /2 7 1 /4 6 7 /8 7 3 /8 8 8 8 3 /4 4 3 /8 5 1 /8 4 3 /8 5 — 7 1 /8 43 47 55 58(38) (184) (175) (187) (203) (203) (222) (111) (130) (111) (127) — (181) (20) (21) (25) (26)2 7 1 /2 8 1 /2 9 10 1 /4 10 1 /4 9 7 /8 5 1 /4 5 3 /4 5 5 5 /8 5 3 /4 7 5 /8 62 73 78 83(51) (191) (216) (229) (260) (260) (251) (133) (146) (127) (143) (146) (194) (28) (33) (35) (38)2 1 /2 — 9 3 /8 10 11 1 /4 11 1 /4 10 7 /8 5 3 /4 7 7 /8 5 1 /2 6 8 1 /4 8 3 /8 — 95 100 130(64) — (238) (254) (286) (286) (276) (146) (200) (140) (152) (210) (213) — (43) (45) (59)3 — 10 10 3 /4 12 1 /4 12 1 /4 11 3 /4 6 5 /8 9 1 /8 6 3 /8 7 1 /8 — 9 1 /4 — 125 140 175(76) — (254) (273) (311) (311) (298) (168) (232) (162) (181) — (235) — (57) (64) (80)4 — 11 7 /8 12 1 /2 12 1 /2 14 1 /2 14 3 /4 7 5 /8 10 5 /8 7 1 /4 8 — 11 7 /8 — 210 230 310(102) — (302) (318) (318) (368) (375) (194) (270) (184) (203) — (302) — (95) (105) (141)5 — 13 5 /8 14 1 /2 14 1 /2 16 1 /2 16 7 /8 8 1 /2 12 1 /2 8 1 /8 8 1 /2 — 12 1 /2 — 295 310 490(127) — (346) (368) (368) (419) (429) (216) (318) (206) (216) — (318) — (134) (141) (223)6 — 15 1 /8 16 16 17 3 /8 19 3 /4 10 13 3 /4 9 1 /2 9 1 /2 13 5 /8 14 1 /8 — 420 470 655(152) — (384) (406) (406) (441) (502) (254) (349) (241 (241) (346) (359) — (191) (214) (298)8 — 19 20 20 21 5 /8 22 1 /2 11 1 /2 15 3 /8 11 1 /4 11 3 /4 — 17 1 /4 — 700 710 1070(203) — (483) (508) (508) (549) (572) (292) (391) (286) (298) — (438) — (318) (323) (486)10 — 23 5 /8 25 25 — 28 13 3 /4 — — — — 23 3 /8 — 1240 1300 —(254) — (600) (635) (635) — (711) (349) — — — — (594) — (563) (591) —12 — 26 1 /2 28 28 — 33 15 7 /8 — — — — 25 1 /4 — 2060 2140 —(305) — (673) (711) (711) — (838) (403) — — — — (641) — (936) (972) —DFITTINGS ONPAGE 46*Add 65% to D dimension for stem removal clearance.- 29 -

TYPE E2MAIN VALVETYPE E2 MAIN VALVEAPPLICATION DATA● Pressure Regulating for Steam Distribution● Regulating for Process <strong>Control</strong> (Temperature or Pressure)● Maintain Back Pressure or Differential Pressure● For use with Self-contained, Pneumatic or Electronic Pilots● Single Point or Multiple Use Applications● Slow Start-up or ShutdownVALVE RATINGSValve Ends Pressure TemperatureASME/ANSI PSIG (bar) °F (°C)CAST IRONB16.4 Class 250 NPT 15 (1.03) 250°F (121°C)B16.1 Class 125 Flanged 15 (1.03) 250°F (121°C)Canadian Registration # OC 0591.9CInstallation Tip: Add EZ Connections for ease of maintenanceSEE PAGE 42SIZING INFOPAGE 108TYPE E2 MAIN VALVELOW PRESSURELOW DIFFERENTIALSIZES 3/4" – 12"PRESSURES to 15 PSIG at 250°F● Normally Closed● Single Seat● Hycar Diaphragm● Protected Main Spring● Gas & Steam Applications● Accurate Regulation Unaffected byService Conditions● ANSI/FCI 70-2 Class IV Shutoff● Virtually Frictionless for Long Service Life● Packless Construction● Easy In-line Maintenance● Wide Variety of Pilots for ManyApplications● Minimum Operating ∆P 3 psi (.2 bar)● Lifetime Warranty against Wiredrawing ofSeat & Disc *OPTIONS See page 42● Composition Disc for liquid, air or gas service● Insulcap Insulating Jacket ● Integral Mount Pilot● EZ ConnectionsTYPICAL CONFIGURATIONSPRESSURE REDUCING…………………TYPE E2DAIR ADJUSTED …………………TYPE E2A SERIESBACK PRESSURE ………………………TYPE E2QLOAD ALLOCATING ……………………TYPE E2FDAIR CONTROLLED …………………TYPE E2AP60ELECTRONIC SLOW START ………TYPE E2D208DSOLENOID CONTROLLED ……………TYPE E2MDSOLENOID ACTUATED …………………TYPE E2MDIFFERENTIAL……………………………TYPE E2NTEMPERATURE CONTROL ……………TYPE E2T14TEMP. & PRESSURE CONTROL……TYPE E2T134RATED FLOW COEFFICIENTS (Cv)SEATREGULATOR SIZEFACTOR 3 /4 1 1 1 /4 1 1 /2 2 2 1 /2 3 4 5 6 8 10 12Full 7.6 11.7 18.9 27.4 44 68 96 143 202 255 465 748 111870%-75% — 8.8 13.2 19.2 30.8 47.6 67.2 100 141 178 — — —45% — — — 12.3 — 30.6 — 64.4 — 11.4 — 336 —* When installed according to factory specifications.- 30 -

TYPE E2 MAIN VALVESPECIFICATIONThe valve shall be self-operated, external pilot type, singleseated, hycar diaphragm actuated, normally closed design. Thevalve will function quickly and shut tight on dead end service.Internal parts including seats, discs and stems shall be ofstainless steel. There shall be no springs in the steam flow pathand no stuffing box. The valve shall be easy to maintain with allparts accessible without removal from the line.MATERIALS OF CONSTRUCTIONBody, Cast Iron …………………………ASTM A126 Cl. BBody, Cast Bronze………ASTM B61-80 61UNSC 92200Stem ……………………………303 St. Stl. ASTM A582Disc 3/4 - 2" ……………420 St. Stl ASTM A743 CA-40Disc 2-1/2 - 12" …………304 St. Stl. ASTM A167/A240Seat………………………420 St. Stl. ASTM A743 CA-40Gasket ………………………………………Non-asbestosDiaphragm ……………………………………………HycarSpring …………………………………………………SteelACDTYPE E2MAIN VALVEBTYPE E2 MAIN VALVEFITTINGS ONPAGE 46DIMENSIONS inches (mm), WEIGHTS pounds (kg)A OTHER DIMENSIONS APPROX. WT.CI,BRZ CI C CI,BRZ CISIZE ANSI ANSI B Std. Integral D* ANSI ANSINPT 125 Mount Mount NPT 1253/4 4 3 /4 — 8 2 7 /8 3 5 /8 7 3 /4 18 —(19) (121) — (203) (73) (92) (197) (8) —1 5 3 /8 5 1 /2 8 3 5 /8 4 3 /8 8 1 /8 19 21(25) (137) (140) (203) (92) (111) (206) (9) (10)1 1 /4 6 1 /2 6 3 /4 9 4 1 /8 4 8 1 /4 30 33(32) (165) (171) (229) (105) (101) (210) (14) (15)1 1 /2 7 1 /4 6 7 /8 9 3 /4 4 3 /8 4 1 /2 8 3 /4 36 40(38) (184) (175) (248) (111) (118) (222) (16) (18)2 7 1 /2 8 1 /2 10 1 /2 5 1 /4 5 10 50 57(51) (191) (216) (267) (133) (127) (254) (23) (26)2 1 /2 — 9 3 /8 10 1 /2 5 3 /4 5 3 /8 11 1 /2 — 70(64) — (238) (267) (146) (136) (292) — (32)3 — 10 11 1 /4 6 5 /8 6 3 /8 12 3 /4 — 98(76) — (254) (286) (168) (162) (324) — (45)4 — 11 7 /8 13 1 /2 6 3 /4 6 5 /8 13 5 /8 — 135(102) — (302) (343) (171) (168) (346) — (61)5 — 13 5 /8 14 1 /4 7 1 /2 7 3 /8 15 — 185(127) — (346) (362) (191) (187) (381) — (84)6 — 15 1 /8 16 7 7 /8 7 16 5 /8 — 250(152) — (384) (406) (200) (178) (422) — (114)8 — 19 20 9 1 /2 9 1 /4 19 7 /8 — 1210(203) — (483) (508) (241) (235) (505) — (550)10 — 23 5 /8 24 10 7 /8 — 23 7 /8 — 690(254) — (600) (610) (276) — (606) — (314)12 — 26 1 /2 28 12 3 /4 — 27 1 /8 — 1060(305) — (673) (711) (324) — (689) — (482)*Add 55% to D dimension for stem removal clearance.- 31 -

TYPE E5MAIN VALVETYPE E5 MAIN VALVEAPPLICATION DATA● Pressure Regulating for Steam Distribution● High Pressure/Low Differential Pressure Regulating● Fluid Regulation● For use with Self-contained, Pneumatic or Electronic Pilots● Slow Start-up or ShutdownSIZING INFOPAGE 108VALVE RATINGSValve Ends Pressure TemperatureASME/ANSI PSIG (bar) °F (°C)CAST IRONClass 250 NPT 250 (17.2) @ 450 (232)B16.1 Class 125 Flanged 125 (8.6) @ 450 (232)B16.1 Class 250 Flanged 250 (17.2) @ 450 (232)CAST STEELB16.34 Class 300 NPT 300 (21.0) @ 600 (315)B16.34 Class 150 Flanged 150 (10.3) @ 500 (260)B16.34 Class 300 Flanged 300 (21.0) @ 600 (315)Other pressure/temperature ratings available; consult factory.Maximum downstream pressure is 300 psi.Canadian Registration # OC 0591.9CInstallation Tip: Add EZ Connections for ease of maintenanceSEE PAGE 42TYPE E5 MAIN VALVEHIGH PRESSURE–HIGH LIFTLOW DIFFERENTIALSIZES 3/4" – 12"PRESSURES to 300 PSIG at 600°F● Normally Closed● Single Seat● Balanced Hycar Diaphragm● Protected Main Spring● Long Main Spring Operates on 5 psiMinimum Differential● Internal & External Condensation Chambers● Fluid, Gas & Vapor Applications● Accurate Regulation Unaffected byService Conditions● ANSI/FCI 70-2 Class IV Shutoff● Virtually Frictionless for Long Service Life● Packless Construction● Easy In-line Maintenance● Wide Variety of Pilots for Many Applications● Lifetime Warranty against Wiredrawing ofSeat & Disc *OPTIONS See page 42● Composition Disc for liquid, air or gas service● Balanced Construction ● Secoweld● Integral Mount Pilot● EZ ConnectionsTYPICAL CONFIGURATIONSPRESSURE REDUCING …………………TYPE E5DAIR ADJUSTED …………………………TYPE E5ABACK PRESSURE ………………………TYPE E5QPUMP GOVERNOR ………………………TYPE E5PLOAD ALLOCATING ……………………TYPE E5FDAIR CONTROLLED …………………TYPE E5AP60ELECTRONIC SLOW START ………TYPE E5D208DSOLENOID CONTROLLED ……………TYPE E5MDSOLENOID ACTUATED …………………TYPE E5MDIFFERENTIAL……………………………TYPE E5NTEMPERATURE CONTROL ………………TYPE E5TRATED FLOW COEFFICIENTS (Cv)SEATREGULATOR SIZEFACTOR 3 /4 1 1 1 /4 1 1 /2 2 2 1 /2 3 4 5 6 8 10 12Full 7.6 11.7 18.9 27.4 43 67 95 159 258 350 665 1018 1611Normal 5.7 10.0 13.4 19.8 25 35 59 120 176 228 366 525 952* When installed according to factory specifications.- 32 -

TYPE E5 MAIN VALVESPECIFICATIONThe valve shall be self-operated, external pilot type, singleseated, diaphragm actuated, normally closed design. The valvewill function quickly and shut tight on dead end service. Internalparts including seats, discs and stems shall be of stainless steel.The diaphragm shall be a balanced Hycar material for high lift.There shall be an external condensation chamber supplied. Themain valve spring shall operate on a 5 psi minimum differential.There shall be no springs in the steam flow path and no stuffingbox. The valve shall be easy to maintain with all parts accessiblewithout removal from the line.ACTYPE E5MAIN VALVEMATERIALS OF CONSTRUCTIONBody, Cast Iron …………………………ASTM A126 Cl. BBody, Cast Steel ………………………ASTM A216 WCBStem ……………………………303 St. Stl. ASTM A582Disc 3/4 - 5"……………420 St. Stl. ASTM A582 Cond ADisc 6 - 12" ………………304 St. Stl. ASTM A167/A240Seat 3/4 - 5" …………420 St. Stl. ASTM A582 Cond ASeat 6 - 12" ……………316 St. Stl. ASTM A743 CF-8MGasket ………………………………………Non-asbestosDiaphragm ……………………………………………HycarSpring …………………………………………………SteelDIMENSIONS inches (mm) AND WEIGHTS pounds (kg)TYPE E5 MAIN VALVECAPPROX.WTA Integral Mount D* Iron,Brz. Iron SteelStd.SIZE ANSI ANSI ANSI B MountANSI SCR Stl.ANSI ANSI ANSI ANSI ANSICI Stl.NPT 125 250125 250 NPT 125 250 150 3003/4 4 3 /4 — — 6 7 /8 2 7 /8 3 5 /8 3 1 /2 11 1 /4 11 1 /4 23 — — — —(19) (111) — — (175) (73) (92) (89) (286) (286) (10) — — — —1 5 3 /8 5 1 /2 6 6 7 /8 3 5 /8 4 3 /8 4 3 /8 11 5 /8 11 5 /8 24 30 33 35 39(25) (137) (140) (152) (175) (92) (111) (111) (295) (295) (11) (14) (15) (16) (18)1 1 /4 6 1 /2 6 3 /4 7 1 /4 9 1 /8 4 1 /8 4 4 5 /8 13 1 /2 13 1 /2 49 46 49 58 63(32) (165) (171) (184) (232) (105) (102) (117) (343) (343) (22) (21) (22) (26) (29)1 1 /2 7 1 /4 6 7 /8 7 3 /8 9 1 /8 4 3 /8 4 1 /2 5 13 5 /8 13 5 /8 53 58 68 67 74(38) (184) (175) (187) (232) (111) (114) (127) (346) (346) (24) (26) (31) (30) (34)2 7 1 /2 8 1 /2 9 11 1 /8 5 1 /4 5 5 5 /8 16 1 /4 16 1 /4 84 90 97 113 120(51) (191) (216) (229) (283) (133) (127) (143) (413) (413) (38) (41) (44) (51) (55)2 1 /2 — 9 3 /8 10 11 1 /8 5 3 /4 5 3 /8 6 16 1 /2 16 1 /2 — 97 112 130 135(64) — (238) (254) (283) (146) (137) (152) (419) (419) — (44) (51) (59) (61)3 — 10 10 3 /4 13 1 /2 6 5 /8 6 3 /8 7 19 1 /4 19 1 /4 — 148 170 210 226(76) — (254) (273) (343) (168) (162) (178) (489) (489) — (67) (77) (95) (103)4 — 11 7 /8 12 1 /2 13 1 /2 7 5 /8 6 5 /8 8 18 3 /8 23 3 /8 — 208 293 307 330(102) — (302) (318) (343) (194) (168) (203) (467) (594) — (95) (133) (139) (150)5 — 13 5 /8 14 1 /2 13 1 /2 8 1 /2 7 3 /8 8 3 /4 18 3 /4 23 3 /4 — 240 333 335 366(127) — (346) (368) (343) (216) (187) (222) (476) (603) — (109) (151) (152) (166)6 — 15 1 /8 16 16 3 /4 10 7 — 23 1 /2 27 3 /8 — 348 616 560 503(152) — (384) (406) (425) (254) (178) — (597) (695) — (158) (280) (254) (274)8 — 19 20 16 3 /4 11 1 /2 9 1 /4 — 23 3 /4 29 5 /8 — 650 814 795 862(203) — (483) (508) (425) (292) (235) — (603) (752) — (295) (370) (361) (392)10 — 23 5 /8 25 20 13 3 /4 — — 30 3 /4 35 3 /8 — 910 1130 1345 1420(254) — (600) (635) (508) (349) — — (781) (899) — (414) (513) (611) (645)12 — 26 1 /2 28 24 3 /4 15 7 /8 — — 39 3 /4 39 3 /4 — 1580 1920 1990 2160(305) — (673) (711) (629) (403) — — (1010) (1010) — (718) (872) (904) (982)- 33 -BFITTINGS ONPAGE 46D*Add 150% to D dimension for stem removal clearance.

TYPE E6MAIN VALVETYPE E6 MAIN VALVEAPPLICATION DATA● Pressure Regulating for Compressed Air Distribution● Pressure Regulating for Gas Service● Maintain Back Pressure or Differential Pressure● For use with Self-contained, Pneumatic or Electronic Pilots● Single Point or Multiple Use Applications● Slow Start-up or ShutdownVALVE RATINGSValve Ends Pressure TemperatureASME/ANSI PSIG (bar) °F (°C)CAST IRONB16.4 Class 250 NPT 250 (17.2) @ 200 (93)B16.1 Class 125 Flanged 125 (8.6) @ 200 (93)Other pressure/temperature ratings available; consult factory.Canadian Registration # OC 0591.9CInstallation Tip: Add EZ Connections for ease of maintenanceSEE PAGE 42SIZING INFOPAGE 108TYPE E6 MAIN VALVEHIGH PRESSURE–HIGH LIFTCOLD SERVICESIZES 3/4" – 12"PRESSURES to 250 PSIG at 200°F● Normally Closed● Single Seat● Balanced Hycar Diaphragm● Protected Main Spring● Composition Disc for Tight Shutoff● Air & Gas Applications● Accurate Regulation Unaffected byService Conditions● ANSI/FCI 70-2 Class VI Shutoff● Virtually Frictionless for Long Service Life● Packless Construction● Easy In-line Maintenance● Wide Variety of Pilots for ManyApplicationsOPTIONS See page 42● Dashpot for Water Service● Insulcap Insulating Jacket● EZ ConnectionsTYPICAL CONFIGURATIONS● Integral Mount Pilot● Balanced ConstructionPRESSURE REDUCING …………………TYPE E6DAIR ADJUSTED …………………………TYPE E6ABACK PRESSURE ………………………TYPE E6QPUMP GOVERNOR ………………………TYPE E6PLOAD ALLOCATING ……………………TYPE E6FDAIR CONTROLLED …………………TYPE E6AP60ELECTRONIC SLOW START ………TYPE E6D208DSOLENOID CONTROLLED ……………TYPE E6MDSOLENOID ACTUATED …………………TYPE E6MDIFFERENTIAL……………………………TYPE E6NTEMPERATURE CONTROL ………………TYPE E6TRATED FLOW COEFFICIENTS (Cv)SEATREGULATOR SIZEFACTOR 3/4 1 1 1 /4 1 1 /2 2 2 1 /2 3 4 5 6 8 10 12Full 7.6 11.7 18.9 27.4 43 67 95 159 258 350 665 1018 1611Normal 5.7 10.0 13.4 19.8 25 35 59 120 176 228 366 525 952- 34 -

TYPE E6 MAIN VALVESPECIFICATIONThe valve shall be self-operated, external pilot type, singleseated, composition disc, hycar diaphragm actuated, normallyclosed design. The valve will function quickly and shut tight ondead end service. Seats and stems shall be of stainless steel.There shall be no springs in the flow space and no stuffing box.The valve shall be easy to maintain with all parts accessiblewithout removal from the line.MATERIALS OF CONSTRUCTIONBody, Cast Iron …………………………ASTM A126 Cl. BBody, Cast Bronze ……………ASTM B61 UNS C92200Stem ……………………………303 St. Stl. ASTM A582Disc …………………………………………Hycar Comp.Seat 3/4 - 5"………………420 St. Stl. ASTM 473 CA-40Seat 6 - 8" ………………316 St. Stl. ASTM A743 CF-8MGasket ………………………………………Non-asbestosDiaphragm ……………………………………………HycarSpring …………………………………………………SteelDisc Holder ……………………ASTM B16 UNS C36000ABTYPE E6 MAIN VALVECD*FITTINGS ONPAGE 46TYPE E6MAIN VALVEDIMENSIONS inches (mm) AND WEIGHTS pounds (kg)DIMENSIONSA C APPROX. WT.SIZE ANSI ANSI ANSI B Std. Integral D* ANSI ANSI ANSINPT 125 250 Mount Mount NPT 125 2503/4 4 3 /4 — — 6 7 /8 2 7 /8 3 5 /8 6 3 /8 18 — —(19) (111) — — (175) (73) (92) (162) (8) — —1 5 3 /8 5 1 /2 6 6 7 /8 3 5 /8 4 3 /8 6 5 /8 18 27 30(25) (137) (140) (152) (175) (92) (111) (168) (8) (129) (14)1 1 /4 6 1 /2 6 3 /4 7 1 /4 9 1 /8 4 1 /8 4 7 3 /4 37 39 44(32) (165) (171) (184) (232) (105) (102) (197) (17) (18) (20)1 1 /2 7 1 /4 6 7 /8 7 3 /8 9 1 /8 4 3 /8 4 1 /2 7 7 /8 42 50 56(38) (184) (175) (187) (232) (111) (114) (200) (19) (23) (25)2 7 1 /2 8 1 /2 9 11 1 /8 5 1 /4 5 8 5 /8 66 73 81(51 191) (216) (229) (283) (133) (127) (219) (30) (33) (37)2 1 /2 — 9 3 /8 10 11 1 /8 5 3 /4 5 3 /8 9 — 83 95(64) — (238) (254) (283) (146) (137) (229) — (38) (43)3 — 10 10 3 /4 13 1 /2 6 5 /8 6 3 /8 9 7 /8 — 124 146(76) — (254) (273) (343) (168) (162) (251) — (56) (66)4 — 11 7 /8 12 1 /2 13 1 /2 7 5 /8 6 5 /8 12 3 /4 — 206 234(102) — (302) (318) (343) (194) (168) (324) — (94) (106)5 — 13 5 /8 14 1 /2 13 1 /2 8 1 /2 7 3 /8 13 1 /4 — 275 287(127) — (346) (368) (343) (216) (187) (337) — (125) (130)6 — 15 1 /8 16 16 3 /4 10 7 15 1 /2 — 363 431(152) — (384) (406) (425) (254) (178) (394) — (165) (196)8 — 19 20 16 3 /4 11 1 /2 9 1 /4 17 5 /8 — 508 610(203) — (483) (508) (425) (292) (235) (448) — (231) (277)- 35 -*Add 100% to D dimension for stem removal clearance.

TYPE E8MAIN VALVETYPE E8 MAIN VALVETYPE E8 MAIN VALVEAIR LOADEDSIZES 3 /8" – 12"PRESSURES to 250 PSIG at 406°F● Normally Closed● Single Seat● Balanced Metal Diaphragms● ANSI/FCI 70-2 Class IV Shutoff● No Minimum Operating DifferentialPressure● Packless Construction● No Pilot Needed● Maximum 50 PSI Air Delivery Pressure● Permits Remote Operation and <strong>Control</strong>● Economical Alternative to <strong>Control</strong> ValveAPPLICATION DATA● Pressure Regulating for Steam Distribution● Regulating for Process <strong>Control</strong> (Temperature or Pressure)● Maintain Back Pressure or Differential Pressure● To use Air Load Pressure to <strong>Control</strong> Delivery Pressure● Single Point or Multiple Use Applications● Slow Start-up or Shutdown● Use where “Dirty Steam” Conditions ExistVALVE RATINGSValve Ends Pressure TemperatureASME/ANSI PSIG (bar) °F (°C)CAST IRONClass 250 NPT 250 (17.2) @ 450 (232)B16.1 Class 125 Flanged 125 (8.6) @ 450 (232)B16.1 Class 250 Flanged 250 (17.2) @ 450 (232)Canadian Registration # OC 0591.9COPTIONS See page 42● Composition Disc● Parabolic Disc● Balanced Construction ● Dashpot● Insulcap Insulating Jacket ● EZ ConnectionsTYPICAL CONFIGURATIONSPRESSURE REDUCING ………………TYPE E8 65APRESSURE REDUCINGPRESSURE REDUCING…………TYPE E8 A PANEL…………TYPE E8 B PANELPRESSURE REDUCING ………………TYPE E8EPCTEMPERATURE CONTROL……………TYPE E8T61TEMPERATURE CONTROL ……………TYPE E8EPCInstallation Tip: Add EZ Connections for ease of maintenanceSEE PAGE 42SIZING INFOPAGE 108RATED FLOW COEFFICIENTS(Cv)SEATREGULATOR SIZEFACTOR 3 /8 1 /2 3 /4 1 1 1 /4 1 1 /2 2 2 1 /2 3 4 5 6 8 10 12Full 1.5 2.8 5.4 8.8 14.1 19.8 31 44 74 109 169 248 444 706 1113Full 75 % — 2.1 4.0 6.6 10.6 14.8 23.3 33 56 82 127 186 333 530 835Full 50 % — 1.4 2.7 4.4 7.0 9.9 15.5 22 37 55 85 124 222 353 557Normal .65 1.5 4.8 7.5 10.4 14.6 17.6 24 43 78 115 151 249 377 631Normal 75 % — — — — — — — 18 33 59 87 114 187 283 474Normal 50 % — — — — — — — 12 22 39 58 76 125 189 316- 36 -

TYPE E8 MAIN VALVESPECIFICATIONThe valve shall be air operated, single seated, metal diaphragmactuated, normally closed design. The valve will function quicklyand shut tight on dead end service. Internal parts including seats,discs, stems and diaphragms shall be of stainless steel. Thereshall be no springs in the steam space and no stuffing box. Thevalve shall be easy to maintain with all parts accessible withoutremoval from the line.ACTYPE E8MAIN VALVEMATERIALS OF CONSTRUCTIONBody, Cast Iron …………………………ASTM A126 Cl. BBody, Cast Bronze ……………ASTM B61 UNS C92200Stem ……………………………303 St. Stl. ASTM A582Disc 3/4 - 5" ……………420 St. Stl. ASTM A743 CA-40Disc 6 - 12" ………………304 St. Stl. ASTM A167/A240Seat 3/4 - 5" ……………420 St. Stl. ASTM A743 CA-40Seat 6 - 12" …………316 St. Stl. ASTM A743-79 CF-8MGasket ………………………………………Non-asbestosDiaphragm …………………Stainless Steel MIL-S-5059CSpring …………………………………………………SteelBTYPE E MAIN VALVEDIMENSIONS inches (mm) AND WEIGHTS pounds (kg)DFITTINGS ONPAGE 46FACE TO FACE DIMENSIONSOTHER DIMENSIONSA B C D E APPROX. WT.SIZE ANSI ANSI ANSI ANSI ANSI ANSI ANSI ANSI ANSI ANSI ANSI ANSINPT 125,150 250 300 600 600 NPT 125 150 250 300 6003/8 4 3 /8 — — — — 5 7 /8 2 3 /4 — 5 1 /4 7 3 /8 14 — — — — —(10) (111) — — — — (149) (70) — (133) (187) (31) — — — — —1/2 4 3 /8 — — — 6 5 7 /8 2 3 /4 2 3 /4 5 1 /4 7 3 /8 14 — — — — 20(12) (111) — — — (152) (149) (70) (70) (133) (187) (31) — — — — (44)3/4 4 3 /8 — — — 6 3 /8 6 1 /2 2 7 /8 3 7 /8 5 1 /2 7 7 /8 18 — — — — 28(19) (111) — — — (162) (165) (73) (98) (140) (200) (40) — — — — (62)1 5 3 /8 5 1 /2 6 6 1 /2 6 1 /2 7 3 5 /8 4 1 /4 6 1 /4 8 7 /8 23 24 26 27 31 32(25) (137) (140) (152) (165) (165) (178) (92) (108) (159) (225) (51) (53) (57) (59) (68) (70)1 1 /4 6 1 /2 6 3 /4 7 1 /4 7 7 /8 7 7 /8 7 7 /8 4 1 /8 4 5 /8 6 1 /2 9 1 /8 33 36 37 40 41 45(32) (165) (171) (184) (200) (200) (200) (105) (117) (165) (232) (73) (79) (81) (88) (90) (99)1 1 /2 7 1 /4 6 7 /8 7 3 /8 8 8 8 3 /4 4 3 /8 5 1 /8 7 1 /8 9 3 /4 43 45 47 51 55 58(38) (184) (175) (187) (203) (203) (222) (111) (130) (181) (248) (95) (99) (103) (112) (121) (128)2 7 1 /2 8 1 /2 9 10 1 /4 10 1 /4 9 7 /8 5 1 /4 5 3 /4 7 5 /8 11 1 /4 62 67 73 72 78 83(51) (191) (216) (229) (260) (260) (251) (133) (146) (194) (286) (136) (147) (161) (158) (172) (183)2 1 /2 — 9 3 /8 10 11 1 /4 11 1 /4 10 7 /8 5 3 /4 7 7 /8 8 3 /8 12 1 /8 — 82 95 100 100 130(64) — (238) (254) (286) (286) (276) (146) (200) (213) (308) — (180) (209) (220) (220) (286)3 — 10 10 3 /4 12 1 /4 12 1 /4 11 3 /4 6 5 /8 9 1 /8 9 1 /4 14 5 /8 — 110 125 130 140 175(76) — (254) (273) (311) (311) (298) (168) (232) (235) (371) — (242) (275) (286) (308) (385)4 — 11 7 /8 12 1 /2 12 1 /2 14 1 /2 14 3 /4 7 5 /8 10 5 /8 11 7 /8 18 1 /4 — 200 210 235 230 310(102) — (302) (318) (318) (368) (375) (194) (270) (302) (464) — (440) (462) (517) (506) (682)5 — 13 5 /8 14 1 /2 14 1 /2 16 1 /2 16 7 /8 8 1 /2 12 1 /2 12 1 /2 20 1 /8 — 280 295 315 310 490(127) — (346) (368) (368) (419) (429) (216) (318) (318) (511) — (616) (649) (693) (682) (1078)6 — 15 1 /8 16 16 17 3 /8 19 3 /4 10 13 3 /4 14 1 /8 22 3 /8 — 385 420 455 470 655(152) — (384) (406) (406) (441) (502) (254) (349) (359) (568) — (847) (924) (1001) (1034) (1441)8 — 19 20 20 21 5 /8 22 1 /2 11 1 /2 15 3 /8 17 1 /4 27 3 /4 — 657 700 735 710 1070(203) — (483) (508) (508) (549) (572) (292) (391) (438) (705) — (1445) (1540) (1617) (1562) (2354)10 — 23 5 /8 25 25 — 28 13 3 /4 — 23 3 /8 36 1 /4 — 1260 1240 1430 1300 —(254) — (600) (635) (635) — (711) (349) — (594) (921) — (2772) (2728) (3146) (2860) —12 — 26 1 /2 28 28 — 33 15 7 /8 — 25 1 /4 41 1 /2 — 2070 2060 2145 2140 —(305) — (673) (711) (711) — (838) (403) — (641) (1054) — (4554) (4532) (4719) (4708) —- 37 -

TYPE C34MAIN VALVETYPE C34 MAIN VALVEAPPLICATION DATA● Pressure Regulating for Liquid Distribution● Regulating for Process <strong>Control</strong> (Temperature or Pressure)● Maintain Back Pressure or Differential Pressure● For use with Self-contained, Pneumatic or Electronic Pilots● Single Point or Multiple Use Applications● Slow Start-up or ShutdownTYPE C34 MAIN VALVEBALANCED SINGLE SEATLIQUID SERVICESIZES 1" – 6"PRESSURES to 200 PSIG at 200°F● Normally Closed● Single Seat● Hycar Diaphragm● Balanced Composition Disc● Protected Main Spring● Balanced Piston Design without Dashpot● Fluid Applications● Accurate Regulation for Non-violent LoadFluctuations● ANSI/FCI 70-2 Class VI Shutoff● Virtually Frictionless for Long Service Life● Packless Construction● Wide Variety of Pilots for ManyApplicationsOPTIONS See page 42● EZ ConnectionsVALVE RATINGSValve Ends Pressure TemperatureASME/ANSI PSIG (bar) °F (°C)CAST IRONB16.4 Class 250 NPT 200 (13.8) @ 200 (93)B16.1 Class 125 Flanged 165 (11.4) @ 200 (93)B16.1 Class 250 Flanged 200 (13.8) @ 200 (93)Canadian Registration # OC 0591.9CInstallation Tip: Add EZ Connections for ease of maintenanceSEE PAGE 42TYPICAL CONFIGURATIONSPRESSURE REDUCING …………TYPE C34DAIR ADJUSTED …………………TYPE C34ABACK PRESSURE ………………TYPE C34QPUMP GOVERNORLOAD ALLOCATINGAIR CONTROLLED……………TYPE C34P……………TYPE C34FD……………TYPE C34AP60ELECTRONIC SLOW START ……TYPE C34D208DSOLENOID CONTROLLED ………TYPE C34MDSOLENOID ACTUATED …………TYPE C34MDIFFERENTIAL …………………TYPE C34NCOOLING CONTROL ……………TYPE C34TSIZING INFOPAGE 108RATED FLOW COEFFICIENTS(Cv)REGULATOR SIZE1 1 1 /4 1 1 /2 2 2 1 /2 3 4 5 65.5 12.5 17.3 24 36 53 86 139 196- 38 -