Composite dry sliding bearings â maintenance-free and space-saving

Composite dry sliding bearings â maintenance-free and space-saving

Composite dry sliding bearings â maintenance-free and space-saving

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

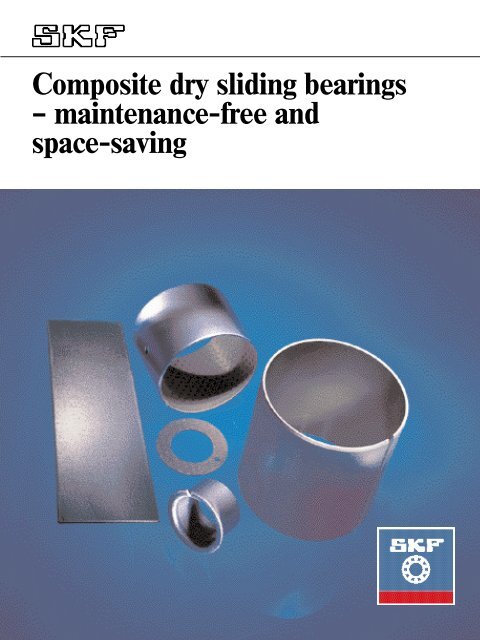

<strong>Composite</strong> <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>– <strong>maintenance</strong>-<strong>free</strong> <strong>and</strong><strong>space</strong>-<strong>saving</strong>

ContentsMaintenance-<strong>free</strong> <strong>and</strong> <strong>space</strong>-<strong>saving</strong>...........................3Materials .........................................................................6Machinability of composite materials .............................8Friction ............................................................................8Chemical properties........................................................9Selection of bearing size ............................................10Basic load ratings .........................................................10Service life.....................................................................11Requisite bearing size...................................................11Calculation of service life ..............................................13Application of <strong>bearings</strong> ..............................................14Design of associated components ...............................22Seals .............................................................................23Lubrication...................................................................24Mounting......................................................................25Bearing data – general................................................26Product tables .............................................................27<strong>Composite</strong> bushings with metric dimensions...............27<strong>Composite</strong> bushings with inch dimensions ..................34<strong>Composite</strong> flanged bushings ........................................38<strong>Composite</strong> thrust washers............................................39<strong>Composite</strong> strip ............................................................40Other related products ...............................................41Application examples .................................................44The SKF Group – a worldwide corporation...............542

Maintenance-<strong>free</strong> <strong>and</strong><strong>space</strong>-<strong>saving</strong>Dry <strong>sliding</strong> <strong>bearings</strong> of compositematerial are primarily used for bearingarrangements where heavy loads haveto be supported but where rotationalor oscillating movements are relativelyslow. Because of their good <strong>sliding</strong>properties <strong>and</strong> compact design, theseplain <strong>bearings</strong> are particularly suitablefor bearing arrangements where• <strong>free</strong>dom from <strong>maintenance</strong> isrequired,• there is a risk of lubricant starvation,• lubricants should not be used or areforbidden, or• very limited <strong>space</strong> is available.Typical application areas for SKFcomposite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> <strong>and</strong>examples will be found on pages 44to 52.CharacteristicsThe important characteristics of SKFcomposite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> include• <strong>free</strong>dom from <strong>maintenance</strong>• no lubrication required(PTFE composite)• initial lubrication required(POM composite)• minimum wall thickness, minimum<strong>space</strong> requirements• can support heavy loads• wide operating temperature range• good <strong>sliding</strong> properties• practically without stick-slip• little wear• insensitive to edge loads(POM composite)• no machining requiredThe assortmentThe st<strong>and</strong>ard range of SKF composite<strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> is very comprehensive<strong>and</strong> meets most needs for thistype of product. The range is shown inthe product overview (➔ Table 1 ) <strong>and</strong>comprises• bushings,• flanged bushings,• thrust washers, <strong>and</strong>• strip.3

Maintenance-<strong>free</strong> <strong>and</strong> <strong>space</strong>-<strong>saving</strong>Bearing Series Bore Lubrication Permissiblediameter needed temperature rangePlain bushingsPTFE composite PCM .. B 3 – 300 mm No –200 to +250 °CPCZ .. B 0,125 – 7 inch No –200 to +250 °CPOM composite PCM .. M 8 – 300 mm Yes, –40 to +110 °Con mounting short periods +130 °CPCZ .. M 0,375 – 4 inch Yes, –40 to +110 °Con mounting short periods +130 °CFlanged bushingsPTFE composite PCMF .. B 6 – 35 mm No –200 to +250 °CThrust washersPTFE composite PCMW .. B 15 – 52 mm No –200 to +250 °CPOM composite PCMW .. M 15 – 52 mm Yes, –40 to +110 °Con mounting short periods +130 °CStripPTFE composite PCMS .. B 500 × 100 mm No –200 to +250 °CHeight1 to 2,5 mmPOM composite PCMS .. M 500 × 100 mm Yes, –40 to +110 °CHeight on mounting short periods +130 °C1 to 2,5 mm4

Table1Series Characteristics PagePCM .. B Dry <strong>sliding</strong> bushings with metric dimensions of triple-layer PTFE composite 27material (➔ page 6).Suitable for slow rotational <strong>and</strong> oscillating movements under radial load <strong>and</strong><strong>maintenance</strong>-<strong>free</strong> operation. No lubrication required.PCZ .. B Dry <strong>sliding</strong> bushings with inch dimensions of triple-layer PTFE composite 34material (➔ page 6).Suitable for slow rotational <strong>and</strong> oscillating movements under radial load <strong>and</strong><strong>maintenance</strong>-<strong>free</strong> operation. No lubrication required.PCM .. M Dry <strong>sliding</strong> bushings with metric dimensions of triple-layer POM composite 27material (➔ page 6).Suitable for slow rotational <strong>and</strong> oscillating movements <strong>and</strong> also linear movementsunder radial load <strong>and</strong> <strong>maintenance</strong>-<strong>free</strong> operation but also where there is a risk of errorsof alignment, edge loading or moderate contamination. Initial lubrication required.PCZ .. M Dry <strong>sliding</strong> bushings with inch dimensions of triple-layer POM composite 34material (➔ page 6).Suitable for slow rotational <strong>and</strong> oscillating movements <strong>and</strong> also linear movementsunder radial load <strong>and</strong> <strong>maintenance</strong>-<strong>free</strong> operation but also where there is a risk of errorsof alignment, edge loading or moderate contamination. Initial lubrication required.PCMF .. B Dry <strong>sliding</strong> bushings with flange on one side <strong>and</strong> metric dimensions of triple-layer 38PTFE composite material (➔ page 6).Suitable for slow rotational <strong>and</strong> oscillating movements under radial <strong>and</strong> single directionaxial loads. For <strong>maintenance</strong>-<strong>free</strong> operation. No lubrication required.PCMW .. B Dry <strong>sliding</strong> thrust washers with metric dimensions of triple-layer PTFE composite 39material (➔ page 6).Suitable for <strong>space</strong>-<strong>saving</strong> arrangements for axial location. For slow rotational <strong>and</strong>oscillating movements under axial load <strong>and</strong> <strong>maintenance</strong>-<strong>free</strong> operation.No lubrication required.PCMW .. M Dry <strong>sliding</strong> thrust washers with metric dimensions of triple-layer POM composite 39material (➔ page 6).Suitable for <strong>space</strong>-<strong>saving</strong> arrangements for axial location. For slow rotational <strong>and</strong>oscillating movements under axial load <strong>and</strong> <strong>maintenance</strong>-<strong>free</strong> operation <strong>and</strong> wherethere is a risk of edge loading or moderate contamination. Initial lubrication required.PCMS .. B Dry <strong>sliding</strong> strip of triple-layer PTFE composite material (➔ page 6). 40The strip can be bent, pressed, cut etc. to fit the particular application. Suitable for<strong>space</strong>-<strong>saving</strong>, <strong>maintenance</strong>-<strong>free</strong> arrangements of all types. No lubrication required.PCMS .. M Dry <strong>sliding</strong> strip of triple-layer POM composite material (➔ page 6). 40The strip can be bent, pressed, cut etc. to fit the particular application. Suitable for<strong>space</strong>-<strong>saving</strong>, <strong>maintenance</strong>-<strong>free</strong> arrangements of all types <strong>and</strong> where there isa risk of moderate contamination or edge loading. Initial lubrication required.5

Maintenance-<strong>free</strong> <strong>and</strong> <strong>space</strong>-<strong>saving</strong>MaterialsThere are two st<strong>and</strong>ard types of compositematerial for SKF <strong>dry</strong> <strong>sliding</strong><strong>bearings</strong>: PTFE composite <strong>and</strong> POMcomposite, which differ in their <strong>sliding</strong>layers. They are suitable in differentbearing applications.PTFE compositeThe PTFE composite material has acopper-plated sheet steel backing onto which a 0,2 to 0,4 mm thick porouslayer of tin bronze is sintered (➔ fig 1 ).The pores of the sintered layer arefilled with a mixture of PTFE (polytetrafluoroethylene)<strong>and</strong> lead by a rollingprocess. The sintered bronze layer iscovered by a 5 to 30 µm thick runninginlayer of the same mixture.There is an optimum combination ofthe mechanical properties of the sinteredbronze <strong>and</strong> the good <strong>sliding</strong> <strong>and</strong>lubricating properties of the PTFE mixturein PTFE composite <strong>bearings</strong>. Ithas good dimensional stability <strong>and</strong>thermal conductivity.PTFE composite <strong>bearings</strong> are identifiedby designation suffix B, e.g.PCM 101212 B.POM compositeThe POM composite material also hasa sheet steel backing which is copperplated, <strong>and</strong> also a 0,2 to 0,4 mm thicklayer of sintered tin bronze (➔ fig 2 ).The principal characteristic of these<strong>bearings</strong> is their relatively thick (0,3 mm)covering layer of acetal resin (POM –polyoxymethylene) which is firmlyanchored in the sintered bronze layer.The covering layer has pockets toretain lubricating grease.The thickness of the covering layermakes <strong>bearings</strong> insensitive to a certaindegree of misaligment <strong>and</strong> the edgeloading associated with misalignment.POM composite <strong>bearings</strong> are identifiedby designation suffix M, e.g.PCM 101212 M.PTFE composite <strong>dry</strong> <strong>sliding</strong> materialPOM composite <strong>dry</strong> <strong>sliding</strong> materialFig1Fig2polytetrafluoroethylene(PTFE) + leadpolyoxymethylene(POM)tin bronzetin bronzecopper layersheet steel backingcopper layertin layercopper layersheet steel backingcopper layertin layer6

Summary of characteristics of SKFPTFE composite <strong>and</strong> POM composite<strong>dry</strong> <strong>sliding</strong> materialsTable2Characteristics PTFE composite POM compositeComposition steel backing with sintered layer of tin steel backing with sintered layer of tinbronze; pore filling <strong>and</strong> covering layer bronze; pore filling <strong>and</strong> covering layer(5 to 30 µm) of PTFE with lead (0,3 mm) of POMadditivesPermissible specific static 250 250bearing load (N/mm 2 )Permissible specific dynamic 80 120load (N/mm 2 )Maximum <strong>sliding</strong> velocity (m/s) 2 2,5Operating temperature range (°C) –200 to +250 –40 to +110 (+130 for brief periods)Coefficient of friction 0,03 to 0,25 0,02 to 0,20Stick-slip effect negligible negligibleWear layer thickness (mm) 0,2 0,3Lubrication not required initial lubrication requiredAbility to support edge loads fair good(e.g. resulting from misalignment)Ability to carry alternating loads good fairAbility to accommodate linear fair goodmovementMachining of <strong>sliding</strong> surface calibration drilling, turning, (reaming)after moutingRecommended housing tolerance H7 H7for bushingsRecommended shaft tolerance f7 (for d ≤ 75 mm) h8for bushings h8 (for d > 75 mm) h8Required surface roughness R z ≤ 3 R z ≤ 6of mating surface (µm) R a ≤ 0,4 R a ≤ 0,8Permissible surface machining ground drawnof mating surface(drawn)7

Maintenance-<strong>free</strong> <strong>and</strong> <strong>space</strong>-<strong>saving</strong>Machinability ofcomposite materialsSKF composite <strong>dry</strong> <strong>sliding</strong> bearingmaterials – with the exception of the<strong>sliding</strong> layer – can be machined usingconventional methods.If bushings are required to have asmaller width than the st<strong>and</strong>ard size,this can easily be achieved by turningor parting-off. It is also possible to drilllubrication holes. Care must be takento see that any burrs are removed,particularly from the <strong>sliding</strong> surface.Strip can be bent, coined, pressed,cut, bored or drilled to shape to fit theindividual application. When cutting ordrilling it is advisable to work from the<strong>sliding</strong> surface side to avoid creatingburrs in the <strong>sliding</strong> layer.Any bright metal surfaces producedas a result of machining should begiven protection against corrosion.PTFE composite bushingsThese bushings are supplied in aready-to-mount condition. Any subsequentmachining of the bore, i.e. the<strong>sliding</strong> surface, should only be undertakenin exceptional cases as it willreduce the service life. If necessary,however, the bore should be calibratedusing a m<strong>and</strong>rel (➔ fig 3 ). If a PTFEFig3composite bushing having an outsidediameter D is to be mounted in a steelhousing having an outside diameterD G , guideline values for the requisitediameter d K of the calibrating m<strong>and</strong>rel(= d + ∆d K ) will be found in Diagram 1 .This diagram gives the requisite interference∆d K of the calibrating m<strong>and</strong>relas a function of the desiredexpansion ∆d of the bushing bore forvarious nominal bushing bore diametersd. The diagram is valid for theratio D G /D = 2. No values are given forbushings installed in light alloy housingsas the influence of design parameters<strong>and</strong> the housing material is toogreat. In such cases, the requisitediameter of the calibrating m<strong>and</strong>relmust be established by trials.POM composite bushingsBushings made of the POM compositematerial are supplied in a ready-tomountcondition but can be machinedin the bore, for example, by turning.When machining the bore an R a valueof 2,5 µm should be aimed at for the<strong>sliding</strong> surface. The following machiningrecommendations have beenfound to give good results:• a cutting speed > 150 m/min,• a slow feed rate (0,05 to0,1 mm/revolution),• a cutting depth ≤ 0,1 mm, <strong>and</strong>• a cutting tool of poly-crystallinediamond.In addition, cooling must be efficientto prevent excessive heating of theplastic with an attendant risk of smearing.The swarf produced must be removedduring machining. Both cooling<strong>and</strong> swarf removal can usually beachieved using compressed air.FrictionThe friction in composite <strong>dry</strong> <strong>sliding</strong><strong>bearings</strong> is primarily determined by theload, the <strong>sliding</strong> velocity <strong>and</strong> the operatingtemperature. It is also influencedby the roughness of the surface onwhich the bearing runs, the degree ofcontamination <strong>and</strong> the lubrication conditions.For PTFE composite <strong>bearings</strong>, thevalue of the coefficient of friction µ liesbetween 0,03 <strong>and</strong> 0,25 depending onthe operating conditions. Similar valuesare found for the POM composite material,but the influence of lubrication isstronger. The lowest values are normallyobtained under high specificloads <strong>and</strong> low <strong>sliding</strong> velocities, seeguideline values for µ in Diagram 2 .Under particularly unfavourable operatingconditions as well as under lightloads, the maximum guideline valuesmay even be exceeded. The friction ofPTFE composite <strong>bearings</strong> is increasedat temperatures above +100 °C.Stick-slip effects are negligibly smallin <strong>bearings</strong> of both materials.M<strong>and</strong>reld K = diameter of calibrating m<strong>and</strong>relB = bushing widthMinimum hardness: 50 HRCSurface roughness: R z ≈ 1 µm8

Chemical propertiesThe chemical resistance of SKF composite<strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> is primarilydetermined by the chemical resistanceof the steel backing <strong>and</strong> the sinteredtin bronze layer, as the <strong>sliding</strong> (covering)layers are chemically resistant tomany substances. The covering layerof the PTFE composite material is virtuallyinert because of its PTFE content,although at elevated temperaturesmolten alkali metals <strong>and</strong> <strong>free</strong>fluorine will attack it. The acetal resincovering layer of the POM composite<strong>bearings</strong> is largely resistant to organicsubstances.At room temperature the sintered tinbronze structure has good resistanceto sea water, steam, atmospheric influences,salt solutions <strong>and</strong> sulphuricacid, but not to oxidising acids ormedia containing ammonia.All exposed surfaces of the steelbacking are electrolytically tin platedbut this gives only limited protectionagainst corrosion in most applications.In cases where the <strong>bearings</strong> are to beexposed to corrosive media, or wherethere is a danger of corrosion in thecontact between the steel backing <strong>and</strong>the housing material, the backing canbe protected by a nickel, chromium orzinc coating applied electrolytically.Further details can be supplied onrequest.Valid for steel housings with D G /D = 2DiagramDiagram12Requisiteinterference ofthe m<strong>and</strong>relGuideline valuesfor coefficient offriction of PTFEcomposite <strong>dry</strong><strong>sliding</strong> <strong>bearings</strong>9

Selection of bearing sizeThe load carrying ability <strong>and</strong> wearbehaviour of SKF composite <strong>dry</strong> <strong>sliding</strong><strong>bearings</strong> are governed by the specificconditions pertaining in a particularapplication. Therefore, any calculationcan only provide approximatevalues. In order to determine the requiredsize of bearing, the load carryingcapacity, the applied loads, the servicelife requirements <strong>and</strong> operationalreliability are all considered. The loadcarrying capacity is expressed by thebasic dynamic load rating C <strong>and</strong> thebasic static load rating C 0 . Values ofthe load ratings will be found in theproduct tables.Basic load ratingsBasic dynamic load ratingsThe basic dynamic load rating C isused when calculating <strong>dry</strong> <strong>sliding</strong><strong>bearings</strong> which are to be dynamicallyloaded. It is defined as that load, constantin magnitude <strong>and</strong> direction,under which a given basic rating life(corresponding to a given total distancetravelled) can be achieved underconstant rotation or oscillating movementat a defined <strong>sliding</strong> velocity atroom temperature. It is assumed inthis definition that the load acting onbushings <strong>and</strong> flanged bushings ispurely radial, <strong>and</strong> the load acting onthrust washers is purely axial <strong>and</strong>applied at the centre. Dynamic loadconditions are essentially oscillatingmovement or rotation under load, butalso include micro-<strong>sliding</strong> under variableload (e.g. as a result of vibration)or operation under high-frequencyalternating loads. Often a combinationof these conditions will be encountered.Whereas oscillating movementor rotation under load usually produceswear, the other conditions mayresult in fatigue.The actual load ratings quoted byvarious manufacturers depend on theway in which they are defined so thatit is not always possible to make directcomparisons between them.Basic static load ratingsThe basic static load rating C 0 isdefined as the maximum load whichan SKF composite bushing, flangedbushing or thrust washer can supportwhen stationary at room temperaturewithout permanent deformation of the<strong>sliding</strong> layer being produced whichwould jeopardise its performance. It isassumed here that the componentssurrounding the bearing prevent itsdeformation. At elevated temperaturesit is necessary to modify the basicload ratings of the various materials bymultiplying the C 0 value by the temperaturefactor c 3 , which is also valid fordynamically loaded <strong>bearings</strong> (➔ Diagram5 ). The permissible operatingtemperature range should also beconsidered (➔ Table 2 ), page 7).Diagram1pv operating rangespv operating rangefor PTFE composite<strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>IIIIIIBasic rating service life equation validQuasi-static range;SKF should be consulted before life equation is usedOperation possible, e.g. if heat removal very good;SKF should be consulted before life equation is used10

Service lifeThe service life of a <strong>dry</strong> <strong>sliding</strong> bearingis expressed as a number of oscillationsor revolutions, or in operatinghours. It depends on the clearanceincrease occurring under boundary or<strong>dry</strong> lubrication conditions because ofthe continuing wear of the <strong>sliding</strong> contactsurfaces, plastic deformation ofthe <strong>sliding</strong> layer or fatigue. Dependingon the application <strong>and</strong> <strong>sliding</strong> layervarious degrees of wear or increasesin friction may be acceptable. Thismeans that even under apparentlysimilar operating conditions, the servicelife achieved in practice will differ,simply because the requirementsplaced on the bearing differ.In contrast, the lives actuallyachieved by seemingly identical <strong>bearings</strong>under identical operating conditionsfor identical dem<strong>and</strong>s are not thesame. This scatter of results has beenfound both in laboratory endurancetests as well as in field tests. Obviouslythe actual lives will also beaffected by the actual operating conditions– not only the magnitude <strong>and</strong>type of load but also many other influenceswhich are difficult or evenimpossible to quantify. These includecontamination, corrosion, high frequencyload <strong>and</strong> movement cycles<strong>and</strong> shock loads.However, the basic rating service lifeis a guideline value which is attainedor exceeded by the majority of <strong>bearings</strong>under the test conditions.Diagram2Requisite bearing sizeThe type <strong>and</strong> mode of action of theload, the expected operating temperature,lubrication <strong>and</strong> <strong>maintenance</strong>requirements etc. all influence thechoice of bearing type <strong>and</strong> design.To determine the requisite size ofcomposite <strong>dry</strong> <strong>sliding</strong> bearing to beused, it is necessary to know the basicrating service life which is required for,or appropriate to, a given application.This depends on the type of machine,the duration of operation, the operatingconditions <strong>and</strong> the degree of operationalreliability required.pv operating rangeWhen selecting a suitable size of <strong>dry</strong><strong>sliding</strong> bearing Diagrams 1 <strong>and</strong> 2can be used to check whether a proposedbearing can be used under thegiven load <strong>and</strong> at the given <strong>sliding</strong>velocity. The data required – p (specificbearing load) <strong>and</strong> v (<strong>sliding</strong> velocity)– can be calculated using the equationsoverleaf. If it is found that theoperating data lie within range I of thepv diagram, the basic rating servicelife of the bearing can be determinedusing the equation given in the followingsection. If the data lie within rangeII or III of the diagram, either SKFshould be contacted, or pre-trialsmade to see whether the bearing canbe used. Alternatively, a different <strong>bearings</strong>hould be chosen so that thevalues for p <strong>and</strong> v fall within therange I.For flanged bushings it is necessaryto check the suitability of thebushing <strong>and</strong> flange separately.pv operating rangesIIIIIIBasic rating service life equation validQuasi-static range;SKF should be consulted before life equation is usedOperation possible, e.g. if heat removal very good;SKF should be consulted before life equation is usedpv operating rangefor POM composite<strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>11

Selection of bearing sizeDiagram3Determination of specific bearingloadThe specific bearing load can bedetermined fromPOM compositePTFE compositeFp = K –– CLoad factor c 1Diagram4wherep = specific bearing load, N/mm 2F = dynamic bearing load, NC = basic dynamic load rating, NK = specific load factor, N/mm 2= 80 for PTFE composite material= 120 for POM composite materialPOM compositePTFE compositeFor flanged bushings it is necessary tocalculate the specific load of the bushing<strong>and</strong> flange separately. When calculatingthe specific bearing load for theflange the axial basic dynamic loadrating C a should be used instead of Cin the above equation. Values of C a willbe found in the product tables.Speed factor c 2Diagram5Determination of <strong>sliding</strong> velocityThe <strong>sliding</strong> velocity for SKF compositebushings <strong>and</strong> thrust washers can beobtained fromv = 5,82 × 10 –7 d β fTemperature factor c 3POMcompositePTFE compositePTFE compositePOM compositeDiagram6wherev = <strong>sliding</strong> velocity, m/sd = bore diameter of bushings <strong>and</strong>flanged bushings, mm= mean diameter of flange of flangedbushings = 0,5 (d + D 1 ), mm= mean diameter of thrust washers= 0,5 (d + D), mm (= dimension Jin product table)f = frequency of oscillation, min –1 ,or rotational speed, r/minβ = half the angle of oscillation,degrees (➔ fig 1 )A complete oscillation (from point0 to point 4) = 4 β. For rotation,use β = 90°.Surface roughness factor c 412

Calculation of servicelifeMany factors influence the life of a <strong>dry</strong><strong>sliding</strong> bearing, e.g. load, <strong>sliding</strong> velocity,operating temperature, surfaceroughness of the surface on which the<strong>dry</strong> <strong>sliding</strong> layer runs etc. Any calculationis therefore only approximate.The values obtained using the equationsgiven below for the basic ratingservice life are attained by the majorityof <strong>bearings</strong> <strong>and</strong> are often exceeded.This has been confirmed by rig tests<strong>and</strong> field experience.The basic rating service life for SKFPTFE composite <strong>and</strong> POM composite<strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> can be calculatedfromK MG h = c 1 c 2 c 3 c 4 c 5 ––––(pv) nwhereG h = basic rating service life, operatinghoursc 1 = load factor (➔ Diagram 3 )c 2 = speed factor (➔ Diagram 4 )c 3 = temperature factor(➔ Diagram 5 )c 4 = surface roughness factor(➔ Diagram 6 )c 5= factor for the type of load= 1 for point load (i.e. the loadedzone is always at the same positionon the bearing circumference)= 1,5 for rotating load (i.e. theloaded zone moves round thecircumference of the bearing)K M = factor depending on material<strong>and</strong> bearing type= 480 for PTFE composite bushings= 300 for PTFE compositethrust washers= 1 900 for POM compositebushings <strong>and</strong> thrust washersp = specific bearing load, N/mm 2vn= <strong>sliding</strong> velocity, m/s= an exponent= 1 for PTFE composite bushings<strong>and</strong> thrust washers= 1 for pv ≤ 1 for POM compositebushings <strong>and</strong> thrust washers= 3 for pv > 1 for POM compositebushings <strong>and</strong> thrust washersIf loads are very light <strong>and</strong>/or <strong>sliding</strong>velocities very low <strong>and</strong> the value of theproduct pv• for PTFE composite <strong>bearings</strong> is lessthan the limiting value of 0,025 thenthe limiting value pv = 0,025 shouldbe used for the life calculations.• for POM composite <strong>bearings</strong> is lessthan the limiting value of 0,1 thenthe limiting value pv = 0,1 should beused for the life calculations.Calculation exampleThe suspension of a rail vehicle is tobe equipped with composite <strong>dry</strong> <strong>sliding</strong><strong>bearings</strong> at the linkage position ofthe springs; in this case bushingsarranged in pairs are to be used.Design data:Pin diameter: d = 30 mmSurface roughness of pin: R a = 0,4 µmOperating data:Radial load at the linkage point:F r = 18 750 NHalf angle of oscillation: β = 1°(➔ fig 1 )Frequency of oscillation: f = 180 min –1Operating temperature: t = 30 °CBased on the design characteristics,PTFE composite bushing PCM 303420B having a basic dynamic load ratingC = 46 500 N is chosen. It is necessaryto check that the bushing can beused under the given operating conditions<strong>and</strong> then to calculate the basicrating service life.As a first check that the bearing sizeis suitable (➔ Diagram 1 ) the specificbearing load p is calculated usingF 18 750p = K –– = 80 × ––––––––– ≈ 16 N/mm 2C 2× 46 500(with the specific load factor K = 80 forPTFE composite).The <strong>sliding</strong> velocity is calculated usingv = 5,82 × 10 –7 d β f= 5,82 × 10 –7 × 30 × 1 × 180= 0,0031 m/sAngle of oscillationϕ = angle of oscillation = 2 βA complete oscillation = 4 β(from point 0 to point 4)Fig1These values are within the permissiblerange I of the pv diagram for PTFEcomposite <strong>bearings</strong>. Furthermorethe load factor c 1 = 1 (➔ Diagram 3 ),the speed factor c 2 = 1(➔ Diagram 4 ),the temperature factor c 3 = 1(➔ Diagram 5 ),the surface roughness factor c 4 = 0,6(➔ Diagram 6 ), <strong>and</strong>the factor for the type of load c 5 = 1,5as the load is rotating.The value of K M for PTFE compositebushings = 480. Thus using thebasic rating service life equation forSKF composite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>K MG h = c 1 c 2 c 3 c 4 c 5 ––––(pv) n 480G h = 1 × 1 × 1 × 0,6 ×1,5 × ––––––––––16 × 0,0031G h = 8 700 operating hours13

Application of <strong>bearings</strong>Material <strong>and</strong> surface finish ofcounterfacesThe factors which are most importantto consider when selecting the material<strong>and</strong> surface finish of the counterface(the surface on which the <strong>bearings</strong>lides) are the loading conditions (load,angle of oscillation, type of movementetc.) <strong>and</strong> the environmental influences.Where there is a risk of corrosion,the counterface must be sufficientlyresistant. Corrosion scars in the counterface<strong>and</strong> the products of corrosion(particulate contamination) increasethe surface roughness or are abrasive,thus increasing wear. In such casesthe use of stainless steel or a surfacetreatment such as hard chromium ornickel plating or electrolytic oxidationshould be considered.For PTFE composite <strong>and</strong> POM composite<strong>dry</strong> <strong>sliding</strong> bearing arrangementssoft carbon steels having aground surface are usually adequatefor the counterface. The surface roughnessR a (to DIN 4768:1990) should notexceed 0,4 µm for PTFE composite<strong>bearings</strong> <strong>and</strong> 0,8 µm for POM composite<strong>bearings</strong>. The corresponding R zvalues are 3 <strong>and</strong> 6 µm, respectively. Formore dem<strong>and</strong>ing applications the useof hardened shafts is recommended.These should have a surface hardnessof at least 50 HRC. Alternatively, hardchromium or nickel plating or someother form of surface treatment shouldbe considered. In all cases R a shouldnot be greater than 0,3 µm (R z ≤ 2 µm).The better the surface finish, the betterthe running properties <strong>and</strong> the less thewear (➔ Surface roughness factorc 4 , Diagram 6 , page 12).14Shaft <strong>and</strong> housing tolerancesIt is recommended that the seating inthe housing bore is machined to toleranceH6 for PTFE composite <strong>and</strong>POM composite <strong>dry</strong> <strong>sliding</strong> bushings(including flanged bushings) having abore diameter up to <strong>and</strong> including4 mm, <strong>and</strong> to tolerance H7 for larger<strong>bearings</strong>. If this is done, after mounting,the bore diameter of the bushing<strong>and</strong> the clearance in the bearingarrangement will lie within the limitsquoted in Tables 1 <strong>and</strong> 3 for metricsizes of PTFE composite <strong>and</strong> POMcomposite <strong>dry</strong> <strong>sliding</strong> bushings, respectively,provided the shaft seatingalso has the recommended tolerance.The shaft <strong>and</strong> housing limits for inchsizedbushings are given in Tables 2<strong>and</strong> 4 , respectively, together with thecorresponding limits for the bushingbore diameter after mounting <strong>and</strong> theoperating clearance.The values quoted are for the operatingclearance at room temperature.If the operating temperature is higherthan this it is expected that the operatingclearance of• PTFE composite bushings will bereduced by 0,0016 mm <strong>and</strong>• POM composite bushings will bereduced by 0,005 mmfor every 20 °C temperature increase.The actual operating clearance can beincreased or decreased within the recommendedlimits by matching shaft<strong>and</strong> housing bores having appropriatevalues within the specified limits.If in certain applications very easyrunning is required, for example, or ifthe bearing is only lightly loaded, it isrecommended that maximum valuesfor the operating clearance should beaimed for.The recommended tolerances <strong>and</strong>guideline limits quoted in the tables arevalid for steel <strong>and</strong> cast iron housings.Where light alloy housings are used, agreater degree of interference may berequired because of the different thermalexpansion characteristics. There isotherwise a risk that the greater thermalexpansion of the housing would nolonger provide radial location for thebushing <strong>and</strong> that the operating clearancewould be too large.If it is not possible to adopt agreater interference for mounting reasons,or because of the force requiredto press the bushing into the housingbore, it is possible to use an adhesiveto retain the bushing in position. Inspecial cases it may be necessary, byselecting a suitable tolerance for theshaft, to prevent an inadmissibleincrease in operating clearance.

PTFE composite bushings (metric sizes)Shaft <strong>and</strong> housing tolerances, bearing clearanceTable1Bushing dimensions Diameter limits OperatingBore Outside Wall Shaft Housing Bore diameter of clearancediameter diameter thickness (f7 for d ≤ 75 mm) bore mounted bushing or preload (–)(h8 for d > 75 mm) (H7)d D max min max min max min max min min maxmm mm µm3 4,5 0,750 0,730 3,000(h6) 2,994(h6) 4,508(H6) 4,500(H6) 3,048 3,000 0 544 5,5 0,750 0,730 4,000(h6) 3,992(h6) 5,508(H6) 5,500(H6) 4,048 4,000 0 565 7 1,007 0,981 4,990 4,978 7,015 7,000 5,053 4,986 –4 756 8 1,007 0,981 5,990 5,978 8,015 8,000 6,053 5,986 –4 757 9 1,007 0,981 6,987 6,972 9,015 9,000 7,053 6,986 –1 818 10 1,007 0,981 7,987 7,972 10,015 10,000 8,053 7,986 –1 8110 12 1,007 0,981 9,987 9,972 12,018 12,000 10,056 9,986 –1 8412 14 1,007 0,981 11,984 11,966 14,018 14,000 12,056 11,986 2 9013 15 1,007 0,981 12,984 12,966 15,018 15,000 13,056 12,986 2 9014 16 1,007 0,981 13,984 13,966 16,018 16,000 14,056 13,986 2 9015 17 1,007 0,981 14,984 14,966 17,018 17,000 15,056 14,986 2 9016 18 1,007 0,981 15,984 15,966 18,018 18,000 16,056 15,986 2 9017 19 1,007 0,981 16,984 16,966 19,021 19,000 17,059 16,986 2 9318 20 1,007 0,981 17,984 17,966 20,021 20,000 18,059 17,986 2 9320 23 1,507 1,475 19,980 19,959 23,021 23,000 20,071 19,986 6 11222 25 1,507 1,475 21,980 21,959 25,021 25,000 22,071 21,986 6 11224 27 1,507 1,475 23,980 23,959 27,021 27,000 24,071 23,986 6 12025 28 1,507 1,475 24,980 24,959 28,021 28,000 25,071 24,986 6 12028 32 2,007 1,971 27,980 27,959 32,025 32,000 28,083 27,986 6 12430 34 2,007 1,971 29,980 29,959 34,025 34,000 30,083 29,986 6 12432 36 2,007 1,971 31,975 31,950 36,025 36,000 32,083 31,986 11 13335 39 2,007 1,971 34,975 34,950 39,025 39,000 35,083 34,986 11 13337 40 1,507 1,475 36,975 36,950 40,025 40,000 37,075 36,986 11 12540 44 2,007 1,971 39,975 39,950 44,025 44,000 40,083 39,986 11 13345 50 2,508 2,462 44,975 44,950 50,025 50,000 45,101 44,984 9 15150 55 2,508 2,462 49,975 49,950 55,030 55,000 50,106 49,984 14 16655 60 2,508 2,462 54,970 54,940 60,030 60,000 55,106 54,984 14 16660 65 2,508 2,462 59,970 59,940 65,030 65,000 60,106 59,984 14 16665 70 2,508 2,462 64,970 64,940 70,030 70,000 65,106 64,984 14 16670 75 2,508 2,462 69,970 69,940 75,030 75,000 70,106 69,984 14 16675 80 2,508 2,462 74,970 74,940 80,030 80,000 75,106 74,984 14 16680 85 2,490 2,440 80,000 79,954 85,035 85,000 80,155 80,020 20 20185 90 2,490 2,440 85,000 84,946 90,035 90,000 85,155 85,020 20 20690 95 2,490 2,440 90,000 89,946 95,035 95,000 90,155 90,020 20 20695 100 2,490 2,440 95,000 94,946 100,035 100,000 95,155 95,020 20 206100 105 2,490 2,440 100,000 99,946 105,035 105,000 100,155 100,020 20 206105 110 2,490 2,440 105,000 104,946 110,035 110,000 105,155 105,020 20 206110 115 2,490 2,440 110,000 109,946 115,035 115,000 110,155 110,020 20 206115 120 2,490 2,440 115,000 114,946 120,035 120,000 115,155 115,020 20 206120 125 2,465 2,415 120,000 119,946 125,040 125,000 120,210 120,070 70 264125 130 2,465 2,415 125,000 124,937 130,040 130,000 125,210 125,070 70 273130 135 2,465 2,415 130,000 129,937 135,040 135,000 130,210 130,070 70 273135 140 2,465 2,415 135,000 134,937 140,040 140,000 135,210 135,070 70 273140 145 2,465 2,415 140,000 139,937 145,040 145,000 140,210 140,070 70 273150 155 2,465 2,415 150,000 149,937 155,040 155,000 150,210 150,070 70 27315

Application of <strong>bearings</strong>PTFE composite bushings (metric sizes)Shaft <strong>and</strong> housing tolerances, bearing clearanceContinuation of Table1Bushing dimensions Diameter limits OperatingBore Outside Wall Shaft Housing Bore diameter of clearancediameter diameter thickness (h8) bore mounted bushing or preload (–)(H7)d D max min max min max min max min min maxmm mm µm160 165 2,465 2,415 160,000 159,937 165,040 165,000 160,210 160,070 70 273180 185 2,465 2,415 180,000 179,937 185,046 185,000 180,216 180,070 70 279200 205 2,465 2,415 200,000 199,928 205,046 205,000 200,216 200,070 70 288210 215 2,465 2,415 210,000 209,928 215,046 215,000 210,216 210,070 70 288220 225 2,465 2,415 220,000 219,928 225,046 225,000 220,216 220,070 70 288250 255 2,465 2,415 250,000 249,928 255,052 255,000 250,222 250,070 70 294300 305 2,465 2,415 300,000 299,919 305,052 305,000 300,222 300,070 70 30316

PTFE composite bushings (inch sizes)Shaft <strong>and</strong> housing tolerances, bearing clearanceTable2Bushing dimensions Diameter limits OperatingBore Outside Wall Shaft Housing Bore diameter of clearancediameter diameter thickness bore mounted bushing or preload (–)d D max min max min max min max min min maxinch/mm inch/mm µinch/µm0,125 0,1875 0,0316 0,0308 0,1243 0,1236 0,1878 0,1873 0,1261 0,1241 –0,24 2,563,175 4,763 0,803 0,783 3,157 3,139 4,770 4,757 3,204 3,151 –6 650,1562 0,2188 0,0316 0,0308 0,1554 0,1547 0,2191 0,2186 0,157 0,1554 –0,04 2,763,969 5,556 0,803 0,783 3,947 3,929 5,565 5,552 3,999 3,946 –1 700,1875 0,25 0,0316 0,0308 0,1865 0,1858 0,2503 0,2497 0,1887 0,1865 –0,04 2,874,763 6,35 0,803 0,783 4,737 4,719 6,358 6,342 4,792 4,736 –1 730,25 0,3125 0,0316 0,0308 0,2490 0,2481 0,3128 0,3122 0,251 0,2490 –0,04 3,036,35 7,938 0,803 0,783 6,325 6,302 7,945 7,930 6,379 6,324 –1 770,3125 0,375 0,0316 0,0308 0,3115 0,3106 0,3753 0,3747 0,3137 0,3115 –0,04 3,077,938 9,525 0,803 0,783 7,912 7,889 9,533 9,517 7,967 7,911 –1 780,375 0,4687 0,0472 0,0461 0,3740 0,3731 0,4691 0,4684 0,3768 0,3741 0,04 3,709,525 11,906 1,198 1,172 9,500 9,477 11,915 11,897 9,571 9,501 1 940,4375 0,5312 0,0472 0,0461 0,4365 0,4355 0,5316 0,5309 0,4393 0,4366 0,08 3,8211,113 13,494 1,198 1,172 11,087 11,062 13,503 13,485 11,159 11,089 2 970,5 0,5937 0,0472 0,0461 0,4990 0,4980 0,5941 0,5934 0,5018 0,4991 0,04 3,8212,7 15,081 1,198 1,172 12,675 12,649 15,090 15,072 12,746 12,676 1 970,5625 0,6562 0,0472 0,0461 0,5615 0,5605 0,6566 0,6559 0,5643 0,5616 0,08 3,8214,288 16,669 1,198 1,172 14,262 14,237 16,678 16,660 14,334 14,264 2 970,625 0,7187 0,0472 0,0461 0,6240 0,6230 0,7192 0,7184 0,6269 0,6241 0,04 3,9415,875 18,256 1,198 1,172 15,850 15,824 18,268 18,247 15,924 15,851 1 1000,6875 0,7812 0,0472 0,0461 0,6865 0,6865 0,7817 0,7809 0,6894 0,6866 0,08 3,9017,463 19,844 1,198 1,172 17,437 17,412 19,855 19,835 17,511 17,439 2 990,75 0,875 0,0627 0,0614 0,7491 0,7479 0,8755 0,8747 0,7527 0,7493 0,24 4,7619,05 22,225 1,592 1,560 19,027 18,997 22,238 22,217 19,118 19,033 6 1210,875 1 0,0627 0,0614 0,8741 0,8729 1,0005 0,9997 0,8777 0,8743 0,24 4,7622,225 25,4 1,592 1,560 22,202 22,172 25,413 25,392 22,293 22,208 6 1211 1,125 0,0627 0,0614 0,9991 0,9979 1,1256 1,1246 1,0028 0,9993 0,16 4,8425,4 28,575 1,592 1,560 25,377 25,347 28,590 28,565 25,470 25,381 4 1231,125 1,2812 0,0784 0,077 1,1238 1,1226 1,2818 1,2808 1,1279 1,1240 0,20 5,2828,575 32,544 1,991 1,955 28,545 28,514 32,558 32,532 28,648 28,550 5 1341,25 1,4062 0,0784 0,077 1,2488 1,2472 1,4068 1,4058 1,2529 1,2490 0,20 5,5731,75 35,719 1,991 1,955 31,720 31,679 35,733 35,707 31,823 31,725 5 1441,375 1,5312 0,0784 0,077 1,3738 1,3722 1,5318 1,5308 1,3779 1,3740 0,20 5,5734,925 38,894 1,991 1,955 34,895 34,854 38,908 38,882 34,998 34,900 5 1441,5 1,6562 0,0784 0,077 1,4988 1,4972 1,6568 1,6558 1,5029 1,4990 0,20 5,5738,1 42,069 1,991 1,955 38,070 38,029 42,083 42,057 38,173 38,075 5 1441,625 1,7812 0,784 0,077 1,6238 1,6222 1,7818 1,7808 1,6279 1,6240 0,20 5,5741,275 45,244 1,991 1,955 41,245 41,204 45,258 45,232 41,348 41,250 5 1441,75 1,9375 0,0939 0,0921 1,7487 1,7471 1,9381 1,9371 1,7539 1,7492 0,51 6,7744,45 49,213 2,386 2,340 44,417 44,376 49,228 49,202 44,548 44,430 13 17217

Application of <strong>bearings</strong>PTFE composite bushings (inch sizes)Shaft <strong>and</strong> housing tolerances, bearing clearanceContinuation of Table2Bushing dimensions Diameter limits OperatingBore Outside Wall Shaft Housing Bore diameter of clearancediameter diameter thickness bore mounted bushing or preload (–)d D max min max min max min max min min maxinch/mm inch/mm µinch/µm1,875 2,0625 0,0939 0,0921 1,8737 1,8721 2,0633 2,0621 1,8791 1,8742 0,51 6,9747,625 52,388 2,386 2,340 47,592 47,551 52,408 52,377 47,728 47,605 13 1772 2,1875 0,0939 0,0921 1,9987 1,9969 2,1883 2,1871 2,0041 1,9992 0,51 7,1750,8 55,563 2,386 2,340 50,767 50,721 55,583 55,552 50,903 50,780 13 1822,25 2,4375 0,0925 0,0906 2,2507 2,2489 2,4377 2,4365 2,2566 2,2515 0,75 7,7257,15 61,913 2,35 2,30 57,168 57,122 61,918 61,887 57,318 57,187 19 1962,5 2,6875 0,0925 0,0906 2,5011 2,4993 2,6881 2,6869 2,5070 2,5019 0,75 7,7263,5 68,263 2,35 2,30 63,528 63,482 68,278 68,247 63,678 63,547 19 1962,75 2,9375 0,0925 0,0906 2,7500 2,7482 2,9370 2,9358 2,7559 2,7507 0,75 7,7269,85 74,613 2,35 2,30 69,850 69,804 74,600 74,569 70,000 69,869 19 1963 3,1875 0,0925 0,0906 3,0000 2,9982 3,1872 3,1858 3,0061 3,0007 0,75 7,9176,2 80,963 2,35 2,30 76,200 76,154 80,955 80,919 76,355 76,219 19 2013,5 3,6875 0,0925 0,0906 3,5000 3,4978 3,6872 3,6858 3,5061 3,5007 0,75 8,3188,9 93,663 2,35 2,30 88,900 88,844 93,655 93,615 89,055 88,919 19 2114 4,1875 0,0925 0,0906 4,0000 3,9978 4,1872 4,1858 4,0061 4,0007 0,75 8,31101,6 106,363 2,35 2,30 101,600 101,544 106,355 106,319 101,755 101,619 19 2115 5,1875 0,0915 0,0896 4,9986 4,9961 5,186 5,1844 5,0067 5,0013 2,6 10,7127 131,763 2,325 2,275 126,964 126,901 131,724 131,684 127,174 127,034 70 2736 6,1875 0,0915 0,0896 6,0000 5,9975 6,1874 6,1858 6,0083 6,0027 2,72 10,7152,4 157,163 2,325 2,275 152,400 152,337 157,160 157,119 152,610 152,469 69 2737 7,1875 0,0915 0,0896 6,9954 6,9929 7,1830 7,1812 7,0039 6,9981 2,76 10,9177,8 182,563 2,325 2,275 177,683 177,620 182,448 182,403 177,888 177,753 70 27818

POM composite bushings (metric sizes)Shaft <strong>and</strong> housing tolerances, bearing clearanceTable3Bushing dimensions Diameter limits OperatingBore Outside Wall Shaft Housing Bore diameter of clearancediameter diameter thickness (h8) bore mounted bushing(H7)d D max min max min max min max min min maxmm mm µm8 10 0,980 0,955 8,000 7,978 10,015 10,000 8,105 8,040 40 12710 12 0,980 0,955 10,000 9,978 12,018 12,000 10,108 10,040 40 13012 14 0,980 0,955 12,000 11,973 14,018 14,000 12,108 12,040 40 13513 15 0,980 0,955 13,000 12,973 15,018 15,000 13,108 13,040 40 13514 16 0,980 0,955 14,000 13,973 16,018 16,000 14,108 14,040 40 13515 17 0,980 0,955 15,000 14,973 17,018 17,000 15,108 15,040 40 13516 18 0,980 0,955 16,000 15,973 18,018 18,000 16,108 16,040 40 13518 20 0,980 0,955 18,000 17,973 20,021 20,000 18,111 18,040 40 13820 23 1,475 1,445 20,000 19,967 23,021 23,000 20,131 20,050 50 16422 25 1,475 1,445 22,000 21,967 25,021 25,000 22,131 22,050 50 16424 27 1,475 1,445 24,000 23,967 27,021 27,000 24,131 24,050 50 16425 28 1,475 1,445 25,000 24,967 28,021 28,000 25,131 25,050 50 16428 32 1,970 1,935 28,000 27,967 32,025 32,000 28,155 28,060 60 18830 34 1,970 1,935 30,000 29,967 34,025 34,000 30,155 30,060 60 18832 36 1,970 1,935 32,000 31,961 36,025 36,000 32,155 32,060 60 19435 39 1,970 1,935 35,000 34,961 39,025 39,000 35,155 35,060 60 19437 40 1,475 1,445 37,000 36,961 40,025 40,000 37,135 37,050 50 17440 44 1,970 1,935 40,000 39,961 44,025 44,000 40,155 40,060 60 19445 50 2,460 2,415 45,000 44,961 50,025 50,000 45,195 45,080 80 23450 55 2,460 2,415 50,000 49,961 55,030 55,000 50,200 50,080 80 23955 60 2,460 2,415 55,000 54,954 60,030 60,000 55,200 55,080 80 24660 65 2,460 2,415 60,000 59,954 65,030 65,000 60,200 60,080 80 24665 70 2,450 2,385 65,000 64,954 70,030 70,000 65,260 65,100 100 30670 75 2,450 2,385 70,000 69,954 75,030 75,000 70,260 70,100 100 30675 80 2,450 2,385 75,000 74,954 80,030 80,000 75,260 75,100 100 30680 85 2,450 2,385 80,000 79,954 85,035 85,000 80,265 80,100 100 31185 90 2,450 2,385 85,000 84,946 90,035 90,000 85,265 85,100 100 31990 95 2,450 2,385 90,000 89,946 95,035 95,000 90,265 90,100 100 31995 100 2,450 2,385 95,000 94,946 100,035 100,000 95,265 95,100 100 319100 105 2,450 2,385 100,000 99,946 105,035 105,000 100,265 100,100 100 319105 110 2,450 2,385 105,000 104,946 110,035 110,000 105,265 105,100 100 319110 115 2,450 2,385 110,000 109,946 115,035 115,000 110,265 110,100 100 319115 120 2,450 2,385 115,000 114,946 120,035 120,000 115,265 115,100 100 319120 125 2,450 2,385 120,000 119,946 125,040 125,000 120,270 120,100 100 324125 130 2,450 2,385 125,000 124,937 130,040 130,000 125,270 125,100 100 333130 135 2,450 2,385 130,000 129,937 135,040 135,000 130,270 130,100 100 333135 140 2,450 2,385 135,000 134,937 140,040 140,000 135,270 135,100 100 333140 145 2,450 2,385 140,000 130,937 145,040 145,000 140,270 140,100 100 333150 155 2,450 2,385 150,000 149,937 155,040 155,000 150,270 150,100 100 333160 165 2,450 2,385 160,000 159,937 165,040 165,000 160,270 160,100 100 333180 185 2,450 2,385 180,000 179,937 185,046 185,000 180,276 180,100 100 339190 195 2,450 2,385 190,000 189,928 195,046 195,000 190,276 190,100 100 348210 215 2,450 2,385 210,000 209,928 215,046 215,000 210,276 210,100 100 348280 285 2,450 2,385 280,000 279,919 285,052 285,000 280,282 280,100 100 36319

Application of <strong>bearings</strong>POM composite bushings (inch sizes)Shaft <strong>and</strong> housing tolerances, bearing clearanceTable4Bushing dimensions Diameter limits OperatingBore Outside Wall Shaft Housing Bore diameter of clearancediameter diameter thickness bore mounted bushingd D max min max min max min max min min maxinch/mm inch/mm µinch/µm0,375 0,4687 0,051 0,050 0,3648 0,3639 0,4694 0,4687 0,3694 0,3667 1,93 5,519,525 11,906 1,295 1,270 9,266 9,243 11,923 11,905 9,383 9,315 49 1400,4375 0,5312 0,051 0,050 0,4273 0,4263 0,5319 0,5312 0,4319 0,4293 1,97 5,5911,113 13,494 1,295 1,270 10,853 10,828 13,510 13,493 10,970 10,903 50 1420,5 0,5937 0,051 0,050 0,4897 0,4887 0,5944 0,5937 0,4944 0,4917 2,05 5,7112,7 15,081 1,295 1,270 12,438 12,413 15,098 15,080 12,558 12,490 52 1450,5625 0,6562 0,051 0,050 0,5522 0,5512 0,6569 0,6562 0,5569 0,5543 2,05 5,6714,288 16,669 1,295 1,270 14,026 14,001 16,685 16,667 14,145 14,078 52 1440,625 0,7187 0,051 0,050 0,6146 0,6136 0,7195 0,7187 0,6195 0,6167 2,13 5,9115,875 18,256 1,295 1,270 15,611 15,585 18,275 18,255 15,735 15,665 54 1500,6875 0,7812 0,051 0,050 0,6770 0,6760 0,7820 0,7812 0,6820 0,6793 2,24 6,0217,463 19,844 1,295 1,270 17,196 17,170 19,863 19,843 17,323 17,253 57 1530,75 0,875 0,0669 0,0657 0,7390 0,7378 0,8758 0,8750 0,7444 0,7412 2,20 6,5719,05 22,225 1,699 1,669 18,771 18,740 22,245 22,225 18,907 18,827 56 1670,875 1 0,0669 0,0657 0,8639 0,8627 1,0008 1,0000 0,8694 0,8662 2,32 6,6522,225 25,4 1,699 1,669 21,943 21,913 25,420 25,400 22,082 22,002 59 1691 1,125 0,0669 0,0657 0,9888 0,9876 1,1258 1,1250 0,9944 0,9912 2,40 6,7725,4 28,575 1,699 1,669 25,116 25,085 28,595 28,575 25,257 25,177 61 1721,125 1,2812 0,0824 0,081 1,1138 1,1126 1,2822 1,2812 1,1202 1,1164 2,60 7,6428,575 32,544 2,093 2,057 28,291 28,260 32,568 32,543 28,454 28,357 66 1941,25 1,4062 0,0824 0,081 1,2387 1,2371 1,4072 1,4062 1,2452 1,2414 2,72 8,1531,75 35,719 2,093 2,057 31,463 31,422 35,743 35,718 31,629 31,532 69 2071,375 1,5312 0,0824 0,081 1,3635 1,3619 1,5322 1,5312 1,3702 1,3664 2,91 8,3534,925 38,894 2,093 2,057 34,633 34,592 38,918 38,893 34,804 34,707 74 2121,5 1,6562 0,0824 0,081 1,4884 1,4868 1,6572 1,6562 1,4952 1,4914 3,03 8,4338,1 42,069 2,093 2,057 37,805 37,765 42,093 42,068 37,979 37,882 77 2141,625 1,7812 0,0824 0,081 1,6133 1,6117 1,7822 1,7812 1,6202 1,6164 3,11 8,5441,275 45,244 2,093 2,057 40,978 40,937 45,268 45,243 41,154 41,057 79 2171,75 1,9375 0,098 0,0962 1,7383 1,7367 1,9385 1,9375 1,7461 1,7415 3,23 9,4544,45 49,213 2,489 2,443 44,153 44,112 49,238 49,213 44,352 44,235 82 2401,875 2,0625 0,098 0,0962 1,8632 1,8616 2,0637 2,0625 1,8713 1,8665 3,35 9,7247,625 52,388 2,489 2,443 47,325 47,285 52,418 52,388 47,532 47,410 85 2472 2,1875 0,098 0,0962 1,9881 1,9863 2,1887 2,1875 1,9963 1,9915 3,43 10,050,8 55,563 2,489 2,443 50,498 50,452 55,593 55,563 50,707 50,585 87 2552,25 2,4375 0,098 0,0962 2,2378 2,2360 2,4387 2,4375 2,2463 2,2415 3,74 10,457,15 61,913 2,489 2,443 56,840 56,794 61,943 61,913 57,057 56,935 95 2632,5 2,6875 0,098 0,0962 2,4875 2,4857 2,6887 2,6875 2,4963 2,4915 4,02 10,663,5 68,263 2,489 2,443 63,183 63,137 68,293 68,263 63,407 63,285 102 2702,75 2,9375 0,0991 0,0965 2,7351 2,7333 2,9387 2,9375 2,7457 2,7393 4,21 12,469,85 74,613 2,517 2,451 69,472 69,426 74,643 74,613 69,741 69,579 107 31520

POM composite bushings (inch sizes)Shaft <strong>and</strong> housing tolerances, bearing clearanceContinuation of Table4Bushing dimensions Diameter limits OperatingBore Outside Wall Shaft Housing Bore diameter of clearancediameter diameter thickness bore mounted bushingd D max min max min max min max min min maxinch/mm inch/mm µinch/µm3 3,1875 0,0991 0,0965 2,9849 2,9831 3,1889 3,1875 2,9959 2,9893 4,41 12,876,2 80,963 2,517 2,451 75,817 75,771 80,998 80,963 76,096 75,929 112 3253,5 3,6875 0,0991 0,0965 3,4844 3,4822 3,6889 3,6875 3,4959 3,4893 4,92 13,788,9 93,663 2,517 2,451 88,504 88,448 93,698 93,663 88,796 88,629 125 3484 4,1875 0,0991 0,0965 3,9839 3,9817 4,1889 4,1875 3,9959 3,9893 5,43 14,2101,6 106,363 2,517 2,451 101,191 101,135 106,398 106,363 101,496 101,329 138 36121

Application of <strong>bearings</strong>Design of associatedcomponentsBushingsThe surface of the shaft on which thebushing runs, i.e. the counterface,should always be wider than the actualbushing – particularly where axialdisplacement of the shaft relative tothe housing may occur as a result ofchanges in shaft length – in order toprevent step formation in the <strong>sliding</strong>surface.To ease mounting, shaft ends <strong>and</strong>housing bores should have a lead-inchamfer with an angle of 10 to 15°(➔ fig 1 ). It is then easier to press thebushings into the housing bore <strong>and</strong> toinsert the shaft into the bushing borewithout the risk of damaging the <strong>sliding</strong>surface.The housing shoulders intended foraxial location of the bushing shouldhave a diameter which is equal to orgreater than d + 0,8 mm.Where PTFE composite bushingsoperate without lubricant it is especiallyimportant to accurately align bearingpositions. If misalignment betweenthe positions cannot be avoided, it isnecessary to take steps at the designstage to prevent inadmissibly highedge stresses from occurring. Forexample, the housing bore seatingshould be relieved at both sides, or awider bushing should be used so thatit extends beyond the housing boreseating at both sides (➔ fig 2 ).If errors of alignment have to becompensated for <strong>and</strong> the operatingconditions permit the use of POM composite,then bushings of this materialshould be chosen. The covering layerof this material can be machined to aminimum degree after the bushing hasbeen mounted in a housing bore.Flanged bushings <strong>and</strong> thrustwashersFor shafts which not only need radialsupport, but also require axial location,flanged bushings or a combinationof bushing <strong>and</strong> thrust washer(➔ fig 3 ) can be used, depending onthe magnitude of the axial load. Theuse of flanged bushings or thrustwashers is advantageous even whereaxial loads are small, particularlywhere suitable surfaces are not availableto take the thrust, either becausethe material or its finish is unsuitable.It should be remembered that thecounterface should completely coverthe <strong>sliding</strong> surface of the thrust washer<strong>and</strong> the flange of a flanged bushing(➔ fig 4 ). For bearing arrangementswhere flanged bushings are used thetransition from housing bore to abutmentshould be chamfered so that itdoes not contact the bushing at thetransition to the flange (➔ fig 5 ).Thrust washers are generally locatedradially in a turned recess in thehousing (➔ fig 3 ) <strong>and</strong> secured by adowel pin or grub screw to preventthem from rotating. The appropriatedimensions for this type of location aregiven in the product tables. If a recesscannot be provided in the housing forsome reason, the thrust washer canbe attached to the housing by twopins or screws (➔ fig 6 ) or by glueing.The heads of the pins or screwsmust be recessed to at least 0,3 mmbelow the <strong>sliding</strong> surface <strong>and</strong> the entiresurface of the thrust washer mustbe supported.Lead-in chamfers for housing bores <strong>and</strong>shaft endsBushing extending beyond the <strong>bearings</strong>eating in the housing at both sides toprevent inadmissibly high edge stressesCombination of bushing <strong>and</strong> thrustwasherFig 1Fig 2Fig322

Fig4Fig5Fig6The mating surface should cover theentire surface of the flangeThe transition between housing bore<strong>and</strong> support surface must be sufficientlylargeThrust washer secured by two grubscrewsSealsThe service life of composite <strong>dry</strong> <strong>sliding</strong><strong>bearings</strong> is decisively influencedby the seals used. When selectingsuitable seals it is necessary to consider,for example, the design, theavailable <strong>space</strong> <strong>and</strong> the justifiableexpense.<strong>Composite</strong> <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>, inparticular those of the POM composite,are able to embed contaminantparticles <strong>and</strong> are thus relatively insensitiveto contamination. They generallyrequire no special protection againstnormal airborne dirt. If, however, thebearing position is subjected to heaviercontamination it should be sealedoff from the outside. Simple <strong>and</strong> efficientsealing can be obtained if adjacentcomponents can also serve asseals (➔ fig 7 ). Radial shaft sealswith low cross section, e.g. of the Gdesign, provide adequate protectionfor composite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> innormal cases (➔ fig 8 ). If the dem<strong>and</strong>splaced on the sealing arrangementare high, it may be necessaryto resort to special seals of rubber,plastic or similar materials (➔ fig 9 ).Under very rough conditions, particularlywhere s<strong>and</strong> or clay contaminantsoccur, rubber or plastic sealsusually have a very short life. Good“sealing” will be achieved in suchcases by periodic relubrication, if theoperating conditions permit.Adjacent components serve as sealsA shaft seal with low cross sectionalheight can be usedSealing with a wiper-scraper seal ofnitrile rubberFig7Fig8Fig923

LubricationFig1POM composite bushing with lubricationholePTFE composite <strong>bearings</strong>PTFE composite <strong>bearings</strong> have good<strong>dry</strong> <strong>sliding</strong> characteristics <strong>and</strong> do notrequire lubrication. The presence orcontinuous supply of oil or other fluidmay be advantageous, however. Evenfluids not normally associated with lubrication,such as water, kerosene orparaffin, may be used.Lubrication improves the removal ofheat from the bearing position <strong>and</strong> theformation of a hydrodynamic lubricatingfilm has a very favourable effect onthe wear behaviour of the bearing <strong>and</strong>considerably extends bearing life.If periodic relubrication with greaseis used to enhance sealing or to protectthe counterface against corrosion,bearing life will also be extended. Asingle initial application of grease whenmounting PTFE composite <strong>bearings</strong>may, however, have a negative influenceon bearing life, as the grease willform a paste-like mixture with the wearparticles produced during running in.This “paste” will increase bearingwear.Age-resistant lithium base greasesare preferred for operating temperaturesup to 80 °C, while at higher temperatures,silicone greases should beused. Greases containing solid lubricantssuch as molybdenum disulphideare totally unsuitable.POM composite <strong>bearings</strong>POM composite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>require an initial application of greaseon mounting. Relubrication is notrequired but the presence or constantsupply of lubricating fluid or periodicgrease relubrication serve to extendbearing life considerably.For this reason POM compositebushings having a bore diameter of 10mm <strong>and</strong> above <strong>and</strong> a width of 12 mmor more are supplied as st<strong>and</strong>ard witha lubrication hole (➔ fig 1 ). The holedimensions <strong>and</strong> position are in accordancewith DIN 1434-3:1983. The samegreases as those recommended abovecan be used.24

MountingSkill <strong>and</strong> care in mounting are prerequisitesfor the successful performanceof <strong>bearings</strong> <strong>and</strong> the avoidance ofpremature wear.The counterface (shaft seating) <strong>and</strong>other components of the bearingarrangement should be carefullycleaned <strong>and</strong> deburred before mountingis begun. Unmachined surfaces incast iron housings must be <strong>free</strong> ofs<strong>and</strong>. The condition of the shaftshould be carefully checked so thatthere are no sharp edges or burrs orsurface defects which would damagethe <strong>sliding</strong> surface of the bushings asthey are mounted.A mounting dolly is the most suitabletool for mounting PTFE composite<strong>and</strong> POM composite <strong>dry</strong> <strong>sliding</strong>bushings <strong>and</strong> flanged bushings (➔ fig1 ). An O-section rubber ring placedon the dolly is a simple means ofretaining the bushing in position. Theuse of a mounting ring (➔ fig 2 ) isrecommended for larger bushings asit aligns <strong>and</strong> centres the bushing sothat it will not tilt or skew when beingpressed in. A light oiling or greasingof the seating in the housing makesmounting easier. When mounting largerbushings it has been found that usinga solid lubricant paste on the seating isbeneficial in reducing the risk of frettingcorrosion <strong>and</strong> also reducing the forcerequired for mounting.<strong>Composite</strong> <strong>dry</strong> <strong>sliding</strong> bushings <strong>and</strong>flanged bushings which are to beheavily loaded in operation should bemounted so that the butt joint is at90° to the loaded zone in operation(➔ fig 3 ), otherwise life will be reduced.When mounting thrust washers careshould be taken that they are correctlypositioned, i.e.the steel backing shouldabut the housing wall.If composite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> areto be located in the housing usingadhesive, it should be rememberedthat the adhesive used should be suitablefor the expected operating temperature<strong>and</strong> should have suitableexpansion, ageing resistance, strength<strong>and</strong> curing properties. If no operationalexperience is available, it is recommendedthat the adhesive manufacturerbe contacted for advice. Whenapplying adhesive care must be takento see that no adhesive reaches the<strong>sliding</strong> surface.Mounting with a m<strong>and</strong>relMounting with a m<strong>and</strong>rel<strong>and</strong> mounting ringFig 1Fig 2The main direction of the load must beat 90° to the plane of the butt jointFig325

Bearing data – generalDimensionsThe dimensions of the metric sizes ofPTFE composite <strong>and</strong> POM composite<strong>dry</strong> <strong>sliding</strong> bushings in the bore diameterrange 4 to 160 mm, inclusive,are in accordance, with a few exceptions,with those specified in ISO3547-1976 <strong>and</strong> DIN 1494/1:1983.The dimensions of the inch-sizebushings, the flanged bushings <strong>and</strong>the thrust washers have not beenst<strong>and</strong>ardised.TolerancesBushings: The tolerances for the outsidediameter of the metric sizes ofSKF PTFE composite <strong>and</strong> POM composite<strong>dry</strong> <strong>sliding</strong> bushings correspondto DIN 1494/1:1983. To check thevalues, the procedure given in DIN1494/2:1983 should be used. For allsizes, the tolerances for the width Bare a uniform ± 0,25 mm.Flanged bushings: For all sizes,when mounted, the tolerances are auniform ±0,5 mm for the flange diameterD 1 <strong>and</strong> for the width B 1+0,05/–0,20 mm.Thrust washers: The tolerances forthe diameters are given in the producttable. The tolerances for the height are• 0/–0,05 mm for PTFE compositethrust washers• 0/–0,10 mm for POM compositethrust washers.Strip: The tolerances for the height are• 0/–0,05 mm for PTFE compositestrip• 0/–0,10 mm for POM compositestripOperating clearanceThe operating clearance of bushingsdepends on the recommended shaft<strong>and</strong> housing tolerances. Guidelinevalues for bushings in metric sizes are26given in Tables 1 <strong>and</strong> 3 <strong>and</strong> forinch-sized bushings in Tables 2 <strong>and</strong>4 .Excessive clearance may have anegative influence on the service life ofPTFE composite bushings if they arenot lubricated.Permissible operating temperaturerangePTFE composite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>can be used at temperatures between–200 <strong>and</strong> +250 °C.The operating temperature range forPOM composite <strong>bearings</strong> is –40 to+110 °C, although brief periods ofoperation at +130 °C are permissible.The service life of SKF composite<strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong> will be shortenedwhen operating at temperatures abovea given value. This is taken intoaccount when calculating the basicrating service life by the temperaturefactor c 3 (➔ Diagram 5 , page 12).Running-inDuring a short running-in phase therewill be some transfer of material fromthe covering layer of <strong>bearings</strong> madefrom PTFE composite to the counterface.After this transfer has taken place,the characteristic low friction <strong>and</strong> wearproperties of these <strong>bearings</strong> will beobtained.Electrical propertiesBearings made from POM composite,because of their acetal resin coveringlayer, may act as electrical insulatorswhen new. To avoid the build-up ofstatic electricity, components at riskshould be earthed.Product designationsSKF metric composite <strong>dry</strong> <strong>sliding</strong> <strong>bearings</strong>are identified by designationsmade up of a prefix PCM which mayhave a fourth letter indicating the typeof bearing (e.g. PCMW for a thrustwasher) followed by 6 to 9 figures givingthe dimensions (d, D, B/H) in millimetresuncoded. The small bushingscarrying the additional suffix /VB055are an exception to this: the outsidediameter is 0,5 mm larger than indicatedin the designation. The actualmaterial used is identified by a suffix:B for PTFE composite <strong>and</strong> M for POMcomposite. For example, PCM 081008M is a POM composite bushing withd = 8 mm, D = 10 mm <strong>and</strong> B = 8 mm.The inch-size <strong>bearings</strong> have similardesignations, but in this case the prefixis PCZ <strong>and</strong> the size (d, B) is shownin 1/16ths of an inch, e.g. PCZ 1208 Bis a PTFE composite bushing with d =12/16˝ = 3/4˝ <strong>and</strong> B = 8/16˝ = 1/2˝.

<strong>Composite</strong> bushings with metric dimensionsd 3 – 12 mmButt jointDimensions Basic load ratings Mass Designationsdynamic static PTFE POMcompositecomposited D B M C C 0mm N g –3 4,5 3 – 720 2 240 0,2 PCM 030403 B/VB055 –4,5 5 – 1 200 3 750 0,3 PCM 030405 B/VB055 –4,5 6 – 1 430 4 500 0,4 PCM 030406 B/VB055 –4 5,5 3 – 965 3 000 0,2 PCM 040503 B/VB055 –5,5 4 – 1 270 4 000 0,3 PCM 040504 B/VB055 –5,5 6 – 1 930 6 000 0,6 PCM 040506 B/VB055 –5,5 10 – 3 200 10 000 0,8 PCM 040510 B/VB055 –5 7 5 – 2 000 6 200 0,7 PCM 050705 B –7 8 – 3 200 10 000 1,1 PCM 050708 B –7 10 – 4 000 12 500 1,4 PCM 050710 B –6 8 6 – 2 900 9 000 1,0 PCM 060806 B –8 8 – 3 800 12 000 1,3 PCM 060808 B –8 10 – 4 800 15 000 1,6 PCM 060810 B –7 9 10 – 5 600 17 600 1,8 PCM 070910 B –8 10 6 – 3 800 12 000 1,2 PCM 081006 B –10 8 – 5 100 16 000 1,7 PCM 081008 B –10 8 – 7 650 16 000 1,3 – PCM 081008 M10 10 – 6 400 20 000 2,1 PCM 081010 B –10 10 – 9 650 20 000 1,6 – PCM 081010 M10 12 – 7 650 24 000 2,5 PCM 081012 B –10 12 – 11 600 24 000 1,9 – PCM 081012 M10 12 8 – 6 400 20 000 2,0 PCM 101208 B –12 10 – 8 000 25 000 2,5 PCM 101210 B –12 10 – 12 000 25 000 1,9 – PCM 101210 M12 12 – 9 650 30 000 3,0 PCM 101212 B –12 12 3 14 300 30 000 2,3 – PCM 101212 M12 15 – 12 000 37 500 3,8 PCM 101215 B –12 15 3 18 000 37 500 2,9 – PCM 101215 M12 20 – 16 000 50 000 5,1 PCM 101220 B –12 20 3 24 000 50 000 3,9 – PCM 101220 M12 14 8 – 7 650 24 000 2,4 PCM 121408 B –14 10 – 9 650 30 000 3,0 PCM 121410 B –14 10 3 14 300 30 000 2,3 – PCM 121410 M14 12 – 11 600 36 000 3,6 PCM 121412 B –14 12 3 17 300 36 000 2,8 – PCM 121412 M14 15 – 14 300 45 000 4,5 PCM 121415 B –14 15 3 21 600 45 000 3,5 – PCM 121415 M14 20 – 19 300 60 000 6,0 PCM 121420 B –14 20 3 29 000 60 000 4,6 – PCM 121420 M14 25 – 24 000 75 000 7,6 PCM 121425 B –14 25 3 36 000 75 000 5,8 – PCM 121425 M27

<strong>Composite</strong> bushings with metric dimensionsd 13 – 32 mmButt jointDimensions Basic load ratings Mass Designationsdynamic static PTFE POMcomposite composited D B M C C 0mm N g –13 15 10 – 10 400 32 500 3,2 PCM 131510 B –15 10 3 15 600 32 500 2,4 – PCM 131510 M15 20 – 20 800 65 500 6,3 PCM 131520 B –14 16 10 – 11 200 34 500 3,5 PCM 141610 B –16 12 – 13 400 41 500 4,2 PCM 141612 B –16 15 – 16 600 52 000 5,2 PCM 141615 B –16 15 3 25 000 52 000 4,0 – PCM 141615 M16 20 – 22 400 70 000 7,0 PCM 141620 B –16 20 3 33 500 70 000 5,3 – PCM 141620 M16 25 – 28 000 88 000 8,7 PCM 141625 B –16 25 3 41 500 88 000 6,6 – PCM 141625 M15 17 10 – 12 000 37 500 3,7 PCM 151710 B –17 10 3 18 000 37 500 2,8 – PCM 151710 M17 12 – 14 300 45 000 4,4 PCM 151712 B –17 12 3 21 600 45 000 3,4 – PCM 151712 M17 15 – 18 000 56 000 5,6 PCM 151715 B –17 15 3 27 000 56 000 4,3 – PCM 151715 M17 20 – 24 000 75 000 7,4 PCM 151720 B –17 25 – 30 000 93 000 9,3 PCM 151725 B –16 18 10 – 12 900 40 000 3,9 PCM 161810 B –18 12 – 15 300 48 000 4,7 PCM 161812 B –18 15 – 19 300 60 000 5,9 PCM 161815 B –18 15 3 29 000 60 000 4,5 – PCM 161815 M18 20 – 25 500 80 000 7,9 PCM 161820 B –18 20 3 38 000 80 000 6,0 – PCM 161820 M18 25 – 32 000 100 000 9,9 PCM 161825 B –18 25 3 48 000 100 000 7,5 – PCM 161825 M18 20 15 – 21 600 67 000 6,6 PCM 182015 B –20 15 3 32 500 67 000 5,0 – PCM 182015 M20 20 – 29 000 90 000 8,8 PCM 182020 B –20 20 3 43 000 90 000 6,7 – PCM 182020 M20 25 – 36 000 112 000 11 PCM 182025 B –20 25 3 54 000 112 000 8,4 – PCM 182025 M28

Dimensions Basic load ratings Mass Designationsdynamic static PTFE POMcomposite composited D B M C C 0mm N g –20 23 10 – 14 600 45 500 7,4 PCM 202310 B –23 10 3 22 000 45 500 6,4 – PCM 202310 M23 15 – 22 800 71 000 11 PCM 202315 B –23 15 3 34 000 71 000 9,7 – PCM 202315 M23 20 – 30 500 96 500 15 PCM 202320 B –23 20 3 46 500 96 500 13 – PCM 202320 M23 25 – 39 000 120 000 19 PCM 202325 B –23 25 3 58 500 120 000 16 – PCM 202325 M23 30 – 46 500 146 000 23 PCM 202330 B –23 30 3 69 500 146 000 19 – PCM 202330 M22 25 15 – 25 000 78 000 12 PCM 222515 B –25 15 3 37 500 78 000 11 – PCM 222515 M25 20 – 34 000 106 000 16 PCM 222520 B –25 20 3 51 000 106 000 14 – PCM 222520 M25 25 – 42 500 134 000 21 PCM 222525 B –25 25 3 64 000 134 000 18 – PCM 222525 M25 30 – 51 000 160 000 25 PCM 222530 B –25 30 3 76 500 160 000 21 – PCM 222530 M24 27 15 – 27 500 85 000 13 PCM 242715 B –27 20 – 36 500 116 000 18 PCM 242720 B –27 20 4 55 000 116 000 15 – PCM 242720 M27 25 – 46 500 146 000 22 PCM 242725 B –27 30 – 56 000 176 000 26 PCM 242730 B –25 28 15 – 28 500 88 000 14 PCM 252815 B –28 15 4 42 500 88 000 12 – PCM 252815 M28 20 – 38 000 120 000 18 PCM 252820 B –28 20 4 57 000 120 000 16 – PCM 252820 M28 25 – 48 000 150 000 23 PCM 252825 B –28 25 4 72 000 150 000 20 – PCM 252825 M28 30 – 58 500 183 000 28 PCM 252830 B –28 30 4 88 000 183 000 24 – PCM 252830 M28 40 – 78 000 245 000 37 PCM 252840 B –28 50 – 98 000 310 000 47 PCM 252850 B –28 50 4 146 000 310 000 40 – PCM 252850 M28 32 20 – 43 000 134 000 28 PCM 283220 B –32 20 4 64 000 134 000 25 – PCM 283220 M32 25 – 54 000 170 000 35 PCM 283225 B –32 25 4 81 500 170 000 32 – PCM 283225 M32 30 – 65 500 204 000 42 PCM 283230 B –32 30 4 98 000 204 000 38 – PCM 283230 M30 34 15 – 34 000 106 000 22 PCM 303415 B –34 20 – 46 500 143 000 30 PCM 303420 B –34 20 4 69 500 143 000 27 – PCM 303420 M34 25 – 58 500 180 000 37 PCM 303425 B –34 30 – 69 500 220 000 45 PCM 303430 B –34 30 4 106 000 220 000 41 – PCM 303430 M34 40 – 95 000 300 000 60 PCM 303440 B –34 40 4 140 000 300 000 54 – PCM 303440 M32 36 20 – 49 000 153 000 31 PCM 323620 B –36 20 4 73 500 153 000 29 – PCM 323620 M36 30 – 75 000 232 000 48 PCM 323630 B –36 30 4 112 000 232 000 43 – PCM 323630 M36 40 – 100 000 315 000 64 PCM 323640 B –36 40 4 150 000 315 000 57 – PCM 323640 M29

<strong>Composite</strong> bushings with metric dimensionsd 35 – 95 mmButt jointDimensions Basic load ratings Mass Designationsdynamic static PTFE POMcomposite composited D B M C C 0mm N g –35 39 20 – 54 000 166 000 34 PCM 353920 B –39 20 4 80 000 166 000 31 – PCM 353920 M39 30 – 81 500 255 000 52 PCM 353930 B –39 30 4 122 000 255 000 47 – PCM 353930 M39 40 – 110 000 345 000 68 PCM 353940 B –39 50 – 137 000 430 000 87 PCM 353950 B –39 50 4 208 000 430 000 78 – PCM 353950 M37 40 20 – 57 000 176 000 27 PCM 374020 B –40 20 4 85 000 176 000 23 – PCM 374020 M40 30 4 129 000 270 000 35 – PCM 374030 M40 44 20 – 61 000 193 000 39 PCM 404420 B –44 20 4 91 500 193 000 36 – PCM 404420 M44 30 – 93 000 290 000 59 PCM 404430 B –44 30 4 140 000 290 000 53 – PCM 404430 M44 40 – 125 000 390 000 78 PCM 404440 B –44 40 4 190 000 390 000 66 – PCM 404440 M44 50 – 156 000 490 000 98 PCM 404450 B –44 50 4 236 000 490 000 89 – PCM 404450 M45 50 20 – 69 500 216 000 65 PCM 455020 B –50 20 5 104 000 216 000 52 – PCM 455020 M50 30 – 106 000 325 000 83 PCM 455030 B –50 30 5 156 000 325 000 78 – PCM 455030 M50 40 – 140 000 440 000 110 PCM 455040 B –50 40 5 212 000 440 000 105 – PCM 455040 M50 50 – 176 000 550 000 140 PCM 455050 B –50 50 5 265 000 550 000 130 – PCM 455050 M50 55 20 – 76 500 240 000 62 PCM 505520 B –55 30 – 116 000 365 000 93 PCM 505530 B –55 30 5 176 000 365 000 86 – PCM 505530 M55 40 – 156 000 490 000 125 PCM 505540 B –55 40 5 236 000 490 000 115 – PCM 505540 M55 60 – 236 000 735 000 185 PCM 505560 B –55 60 5 355 000 735 000 170 – PCM 505560 M30

Dimensions Basic load ratings Mass Designationsdynamic static PTFE POMcomposite composited D B M C C 0mm N g –55 60 20 – 85 000 265 000 67 PCM 556020 B –60 20 6 127 000 265 000 63 – PCM 556020 M60 25 – 106 000 335 000 84 PCM 556025 B –60 25 6 160 000 335 000 78 – PCM 556025 M60 30 – 129 000 400 000 100 PCM 556030 B –60 30 6 193 000 400 000 94 – PCM 556030 M60 40 – 173 000 540 000 135 PCM 556040 B –60 40 6 260 000 540 000 125 – PCM 556040 M60 50 – 216 000 680 000 170 PCM 556050 B –60 50 6 325 000 680 000 155 – PCM 556050 M60 60 – 260 000 815 000 200 PCM 556060 B –60 65 20 – 91 500 290 000 75 PCM 606520 B –65 30 – 140 000 440 000 110 PCM 606530 B –65 30 6 212 000 440 000 100 – PCM 606530 M65 40 – 190 000 585 000 145 PCM 606540 B –65 40 6 280 000 585 000 135 – PCM 606540 M65 60 – 285 000 880 000 220 PCM 606560 B –65 60 6 425 000 880 000 205 – PCM 606560 M65 70 – 335 000 1 040 000 255 PCM 606570 B –65 70 6 500 000 1 040 000 240 – PCM 606570 M65 70 30 – 153 000 475 000 120 PCM 657030 B –70 50 – 255 000 800 000 200 PCM 657050 B –70 50 6 380 000 800 000 185 – PCM 657050 M70 70 – 360 000 1 120 000 275 PCM 657070 B –70 70 6 540 000 1 120 000 255 – PCM 657070 M70 75 40 – 220 000 680 000 170 PCM 707540 B –75 50 – 275 000 865 000 210 PCM 707550 B –75 50 6 415 000 865 000 195 – PCM 707550 M75 70 – 390 000 1 220 000 300 PCM 707570 B –75 70 6 585 000 1 220 000 275 – PCM 707570 M75 80 40 6 355 000 735 000 170 – PCM 758040 M80 50 – 300 000 930 000 230 PCM 758050 B –80 60 – 355 000 1 100 000 270 PCM 758060 B –80 60 6 530 000 1 100 000 255 – PCM 758060 M80 80 – 475 000 1 500 000 365 PCM 758080 B –80 80 6 710 000 1 500 000 340 – PCM 758080 M80 85 40 6 375 000 780 000 180 – PCM 808540 M85 60 – 375 000 1 180 000 290 PCM 808560 B –85 60 6 560 000 1 180 000 270 – PCM 808560 M85 80 6 750 000 1 560 000 360 – PCM 808580 M85 100 – 630 000 1 960 000 485 PCM 8085100 B –85 100 6 950 000 1 960 000 450 – PCM 8085100 M85 90 30 – 196 000 610 000 150 PCM 859030 B –90 30 6 290 000 610 000 145 – PCM 859030 M90 60 – 400 000 1 250 000 305 PCM 859060 B –90 60 6 600 000 1 250 000 285 – PCM 859060 M90 100 – 670 000 2 080 000 510 PCM 8590100 B –90 100 6 100 0000 2 080 000 475 – PCM 8590100 M90 95 60 – 425 000 1 320 000 325 PCM 909560 B –95 60 6 640 000 1 320 000 300 – PCM 909560 M95 100 – 710 000 2 240 000 540 PCM 9095100 B –95 100 6 1 060 000 2 240 000 505 – PCM 9095100 M95 100 30 6 325 000 680 000 160 – PCM 9510030 M100 60 – 450 000 1 400 000 340 PCM 9510060 B –100 60 6 670 000 1 400 000 320 – PCM 9510060 M100 100 – 750 000 2 360 000 570 PCM 95100100 B –100 100 6 1 120 000 2 360 000 530 – PCM 95100100 M31

<strong>Composite</strong> bushings with metric dimensionsd 100 – 300 mmButt jointDimensions Basic load ratings Mass Designationsdynamic static PTFE POMcompositecomposited D B M C C 0mm N g –100 105 30 6 345 000 720 000 170 – PCM 10010530 M105 50 – 390 000 1 220 000 305 PCM 10010550 B –105 50 6 585 000 1 220 000 280 – PCM 10010550 M105 60 – 475 000 1 460 000 360 PCM 10010560 B –105 60 6 710 000 1 460 000 335 – PCM 10010560 M105 80 6 950 000 1 960 000 445 – PCM 10010580 M105 115 – 915 000 2 850 000 690 PCM 100105115 B –105 115 6 1 370 000 2 850 000 640 – PCM 100105115 M105 110 60 – 490 000 1 530 000 375 PCM 10511060 B –110 60 8 735 000 1 530 000 350 – PCM 10511060 M110 115 – 950 000 3 000 000 725 PCM 105110115 B –110 115 8 1 430 000 3 000 000 675 – PCM 105110115 M110 115 50 8 640 000 1 340 000 305 – PCM 11011550 M115 60 – 520 000 1 630 000 395 PCM 11011560 B –115 60 8 780 000 1 630 000 370 – PCM 11011560 M115 115 – 1 000 000 3 150 000 760 PCM 110115115 B –115 115 8 1 500 000 3 150 000 705 – PCM 110115115 M115 120 50 – 450 000 1 400 000 340 PCM 11512050 B –120 50 8 670 000 1 400 000 320 – PCM 11512050 M120 70 – 630 000 1 960 000 480 PCM 11512070 B –120 70 8 950 000 1 960 000 450 – PCM 11512070 M120 125 60 – 560 000 1 760 000 430 PCM 12012560 B –125 60 8 850 000 1 760 000 400 – PCM 12012560 M125 100 – 950 000 3 000 000 715 PCM 120125100 B –125 100 8 1 430 000 3 000 000 665 – PCM 120125100 M125 120 – 1 140 000 3 550 000 880 PCM 120125120 B –125 130 100 – 980 000 3 100 000 745 PCM 125130100 B –130 100 8 1 500 000 3 100 000 695 – PCM 125130100 M130 135 60 – 610 000 1 900 000 465 PCM 13013560 B –135 60 8 915 000 1 900 000 435 – PCM 13013560 M135 100 – 1 020 000 3 200 000 775 PCM 130135100 B –135 100 8 1 530 000 3 200 000 720 – PCM 130135100 M135 140 60 – 640 000 2 000 000 480 PCM 13514060 B –140 60 8 950 000 2 000 000 450 – PCM 13514060 M140 80 – 850 000 2 650 000 645 PCM 13514080 B –140 80 8 1 270 000 2 650 000 600 – PCM 13514080 M140 145 60 – 655 000 2 040 000 500 PCM 14014560 B –145 60 8 980 000 2 040 000 465 – PCM 14014560 M145 100 – 1 100 000 3 450 000 835 PCM 140145100 B –145 100 8 1 660 000 3 450 000 775 – PCM 140145100 M145 120 – 1 340 000 4 150 000 1 000 PCM 140145120 B –32

Dimensions Basic load ratings Mass Designationsdynamic static PTFE POMcompositecomposited D B M C C 0mm N g –150 155 60 – 710 000 2 200 000 535 PCM 15015560 B –155 60 8 1 060 000 2 200 000 500 – PCM 15015560 M155 80 – 950 000 3 000 000 715 PCM 15015580 B –155 80 8 1 430 000 3 000 000 665 – PCM 15015580 M155 100 – 1 200 000 3 750 000 890 PCM 150155100 B –155 100 8 1 800 000 3 750 000 830 – PCM 150155100 M160 165 80 – 1 000 000 3 150 000 780 PCM 16016580 B –165 80 8 1 500 000 3 150 000 710 – PCM 16016580 M165 100 – 1 270 000 3 900 000 970 PCM 160165100 B –165 100 8 1 900 000 3 900 000 885 – PCM 160165100 M180 185 80 – 1 140 000 3 550 000 870 PCM 18018580 B –185 80 8 1 700 000 3 550 000 795 – PCM 18018580 M185 100 – 1 430 000 4 400 000 1 100 PCM 180185100 B –185 100 8 2 120 000 4 400 000 995 – PCM 180185100 M190 195 60 8 1 340 000 2 800 000 630 – PCM 19019560 M195 100 8 2 240 000 4 650 000 1 050 – PCM 190195100 M200 205 100 – 1 600 000 4 900 000 1 200 PCM 200205100 B –205 100 8 2 360 000 4 900 000 1 100 – PCM 200205100 M210 215 100 – 1 660 000 5 200 000 1 250 PCM 210215100 B –215 100 8 2 500 000 5 200 000 1 150 – PCM 210215100 M220 225 100 – 1 730 000 5 400 000 1 350 PCM 220225100 B –225 100 8 2 600 000 5 400 000 1 200 – PCM 220225100 M250 255 100 – 1 960 000 6 100 000 1 500 PCM 250255100 B –255 100 8 3 000 000 6 100 000 1 400 – PCM 250255100 M280 285 80 – 1 760 000 5 500 000 1 350 PCM 28028580 B –285 80 8 2 650 000 5 500 000 1 250 – PCM 28028580 M300 305 50 – 1 180 000 3 650 000 900 PCM 30030550 B –305 50 8 1 760 000 3 650 000 825 – PCM 30030550 M305 100 – 2 360 000 7 350 000 1 800 PCM 300305100 B –305 100 8 3 550 000 7 350 000 1 650 – PCM 300305100 M33