friction clutches - Arten Freios e Embreagens Industriais

friction clutches - Arten Freios e Embreagens Industriais

friction clutches - Arten Freios e Embreagens Industriais

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Table of ContentsPRODUCTCAT ALOG10-060 BRAKES, CLUTCHES, CLUTCH/BRAKES,TENSION CONTROL CLUTCHES & BRAKES,SERVOMOTOR BRAKES, TORQUE LIMITERS,WEB TENSION & WEB AUXILIARY CONTROLS.Distribuidor Autorizado e Importador<strong>Arten</strong> <strong>Freios</strong> e <strong>Embreagens</strong> LtdaFone: (11) 5594-8333 • Fax (11) 5589-2422E-mail: arten@arten.com.br • Site: www.arten.com.br

Table of ContentsPRODUCTSPRODUCT PAGE NUMBER INDEXThis Section Contains: . . . . . . . .PageProduct Numbers 1876 to 801638 . . . . . . . . . . . . .4Product Numbers 801639 to 812500 . . . . . . . . . . .5Product Numbers 812600 to 828400 . . . . . . . . . . .6Product Numbers 828500 to 846974 . . . . . . . . . . .7Product Numbers 847000 to 912300 . . . . . . . . . . .8Product Numbers 912302 to 927432 . . . . . . . . . . .9Product Numbers 927434 to 963600 . . . . . . . . . .10Product Numbers 963700 to 965320 . . . . . . . . . .113

Table of Contents◗PRODUCT NUMBER INDEXPRODUCTSProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbers1876: 3441877: 3441878: 3441879: 3441880: 125, 3441881: 3441882: 3441883: 3441885: 3441887: 3442138: 2978365: 2979428: 2979429: 2979430: 29715596: 30317167: 29717168: 29730518: 303170012: 345170013: 345170014: 345170017: 345170020: 345170021: 345170023: 345170024: 345800000: 32-33800004: 32-33800100: 32-33, 137800107: 32-33800111: 32-33, 137800200:32800300: 32-33800400: 32-33800500: 32-33800900:32801200: 137801300: 156-157801305: 156-157801310: 156-157801321: 156801322: 156801323: 156801324: 156801331: 156801332: 156801333: 156801334: 156801335: 156801336: 156801337: 156801341: 156801342: 156801343: 156801344: 156801345: 156801350: 357801351: 357801352: 357801364: 224801365: 224801368: 225801400: 274-275801401: 358801402: 358801403: 274-275801405: 358801424: 274-275, 280-281,286-287801425: 274-275, 280-281,286-287801427: 274-275, 280-281,286-287801428: 358801430: 358801431: 226-227, 230-232,236-237, 240-241801432: 288801433: 280-281, 288801434: 280-281, 286-287801435: 280-281, 286-287801436: 358801440: 230-231801444: 280-281801445: 280-281, 286-287801447: 358801448: 358801451: 286-287801452: 286-287801454: 280-281, 286-287801455: 280-281, 286-287801458: 282-283, 288-289801460: 282-285, 288-291801463: 284-285, 290-291801464: 280-281801466: 286-287801467: 286-287801469: 286-287801470: 286-287801472: 288-289801473: 288-289801474: 358801475: 288-289801476: 288-289801477: 358801478: 290-291801479: 290-291801480: 230-231801481: 290-291801482: 290-291801484: 280-281801485: 281-283801487: 358801489: 240-241801493: 240-241801495: 282-283801496: 284-285801497: 284-285801498: 280-281, 286-287801499: 280-281, 286-287801500: 116801502: 112-113, 118801504: 116801506: 112-113, 118801508: 353801510: 116801512: 112-113, 118801516: 112-113, 118801518: 355801520: 116801522: 112-113, 118, 377801524: 116, 237801526: 112-113, 118801528: 353801530: 116801532: 112-113, 118801536: 112-113, 118801538: 355801540: 116801542: 112-113, 118801544: 116801546: 112-113, 118801548: 355801550: 116801552: 112-113, 118801554: 116801556: 112-113, 118801558: 355801560: 116801562: 112-113, 118801564: 116801566: 112-113, 118801568: 355801575: 282-283, 288-289801578: 111801579: 111801600: 234-235801601: 284-285, 290-291801602: 284-285, 290-291801603: 228-229, 234-235238-240801604: 358801605: 358801606: 234, 238801608: 282-283, 288-289801610: 276-277801613: 276-277801616: 278-279801619: 278-279801622: 234-235801623: 236-237, 381801624: 236-237801625: 238-239801626: 238-239801627: 276-277,282-283, 288-289801628: 276-277, 282-283288-289801629: 278-279, 284-285290-291801630: 278-279, 284-285290-291801631: 234801632: 276-277, 282-283,289801633: 276-279, 282-285,289-291801634: 278-279, 284-285,290-291801637: 358801638: 3584

Table of ContentsPRODUCTSPRODUCT NUMBER INDEX ◗ProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbers801639: 358801640: 358801644: 358801645: 358801646: 358801647: 358801648: 358801649: 358801650: 358801651: 358801652: 358801653: 358801654: 358801655: 234801656: 236801657: 236801658: 238801659: 238801660: 280-281801661: 358801662: 358801663: 280-281801664: 358801666: 282-283801669: 282-283801672: 284-285801675: 284-285801677: 232-233801680: 232-233801705: 226-227801706: 226-227801709: 228-229801711: 228-229801731: 234-235801802: 112801808: 355801812: 112801900:42802100:42802300:42802311:42802500: 34, 260, 264802600: 34, 260, 64802700: 34-35, 254260-261, 264-265802800:34802810: 34-35, 42264-265802820: 34-35, 42802830: 34-35, 42802840: 34-35, 42802850: 34-35, 42264-265802855: 34-35, 42264-265802864: 34-35802865: 34-35802870: 32-33, 137802880: 354802902: 114-115, 118802904: 120-121802906: 114-115, 118802908: 355802912: 114-115, 118802914: 120-121802916: 114-115, 118802918: 355802922: 114-115, 118802924: 120-121802926: 114-115, 118802928: 355802932: 114-115, 118802934: 120-121802936: 114-115, 118802938: 355802942: 114-115, 118802944: 120-121802946: 114-115, 118802948: 355803000:34803100: 34, 260, 264803351: 303803352: 303803353: 303803354: 303803355: 303803356: 303803900:42804000:42804300:42804513:42804600: 34, 266804700: 34, 266804800: 34, 266804900: 34-35, 258260-261, 266-267805000: 34, 266805100: 34, 266805200:34805210: 34-35, 42266-267805220: 34-35, 42805230: 34-35, 42805240: 34-35, 42805250: 34-35, 42805260: 34-35, 42805270: 34-35, 42266-267, 374805275: 34-35, 42266-267805280: 354805300:34805400:34805500:34805600: 36, 270805700: 152, 155805800: 152, 155805900: 152, 154806000: 152, 154806100:42806400:42806600:42806612:42806700: 36, 268806800: 36, 268806900: 36, 268807000: 36, 268807100: 36, 268807200: 36, 268807300: 36, 268807400: 36-37, 258,262-263, 268-269807500: 36, 268807600:36807610: 36-37, 42268-269807620: 36-37, 42807630: 36-37, 42807640: 36-37, 42807650: 36-37, 42,268-269 380807655: 36-37, 42,268-269807680: 354807700:36807800:36807900:36808000:36808100:36808200: 152, 154808300: 152, 154808400: 357808471: 357808500: 357808600:42808900:42809100:42809200: 36, 270809300: 36, 270809400: 36, 270809500: 36, 270809600: 36, 270809700: 36-37,262-263,270-271809900: 36, 270810000:36810010: 36-37, 42,270-271810020: 36-37, 42810030: 36-37, 42810040: 36-37, 42810050: 36-37, 42,270-271810055: 36-37, 42,270-271810080: 354810300:36810400:36810500:36810600:36810900: 40-41811100: 40-41811200:40811300:40811400:40811500:40811600:40811700: 40-41811800:40811900:40812000:405

Table of Contents◗PRODUCT NUMBER INDEXPRODUCTSProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbers812500: 152, 155812600: 152, 155812700: 357812771: 357812800: 357817700: 138-139, 142-143,146-147, 192-195,218-219818300: 138-139, 142-143,146-147, 192-195,218-219818800: 146818830: 194-195818861: 146-147818862: 146-147818865: 194-195818866: 194-195818870: 357818910: 356818971: 356818972: 356818974: 356-357818975: 356818976: 356819000: 142-143819001: 142-143819003: 142-143, 218819004: 142-143, 218819200: 138819300: 138819400: 138819900: 138-139 142-143,146-147, 192-195,218820000: 138820300: 146-147820330: 194-195820361: 146-147820362: 146-147820365: 194-195820366: 194-195820370: 357820510: 356820571: 356820572: 356820574: 356-357820575: 356820576: 356820577: 356820600: 142-143820601: 142-143820604: 142-143, 218820605: 142-143, 218820800: 72, 138820800: 72, 138820900: 72, 138821000: 72, 138821100: 72, 138821200: 72, 138821400: 138-139, 142-143,146-147, 192-195,218821800: 72, 138821900: 72, 138822465: 196-197822466: 196-197822470: 357822494: 146-147822495: 146-147822496: 146-147822500: 148-149822510: 144-145822514: 140-141822515: 140-141, 144-145,148-149822516: 140-141, 144-145,148-149822517: 140-141822518: 144-145822519: 140-141822520: 144-145822523: 141, 144-145822525: 140-141, 144-145,148-149822526: 140-141,144- 145,148-149822530: 196-197822561: 148-149822562: 148-149822565: 196-197822566: 196-197822570: 357822700: 72, 138822710: 148-149822713: 148-149822714: 148-149822720: 148-149822723: 148-149822724: 148-149822800: 72, 138822900: 72, 138823000: 72, 138823100: 72, 138823200: 72, 138823400: 138-139, 142-143,146-147, 192-193,196-197, 218823800: 72, 138824200: 142-143824201: 142-143824202: 142-143, 218824203: 142-143, 218824300: 144-145824301: 144-145824305: 144-145, 218824306: 144-145, 218824700: 72, 140824800: 72, 140824900: 72, 140825000: 72, 140825100: 72, 140825200: 72, 140825300: 72, 140825500: 140-141, 144-145,148-149, 192-193,196-197, 218825800: 72, 140825900: 72, 140826000: 254-255826050: 254-255826051: 254-255826070: 358826300: 138-139, 142-143,146-147, 192-193196-197, 218-219826700: 260-261, 375826800: 260-261826900: 260-261827100: 260-261827111: 260-261827200: 34, 260, 264827250: 225827251: 225, 232, 236827260: 225827261: 225, 232, 236827270: 225, 232, 236827272: 232-233827280: 225, 232, 236827282: 232-233827320: 150-151827323: 150-151827340: 150-151827343: 150-151827344: 150-151827360: 150-151827380: 150-151827410: 356827471: 356827472: 356827474: 356-357827475: 356827476: 356827477: 356827510: 356827571: 356827572: 356827574: 356-357827575: 356827576: 356827577: 356827578: 356827579: 356827800: 138-139827801: 138-139827810: 192-193827811: 192827818: 218827819: 218827820: 218827821: 218827900: 138-139827901: 138-139827904: 218827905: 218827907: 218827908: 218827910: 192-193827911: 192828000: 138-139828001: 138-139828006: 218828007: 2186

Table of ContentsPRODUCTSPRODUCT NUMBER INDEX ◗ProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbers828008: 218828010: 192-193828012: 192828023: 218828100: 140-141828101: 140-141828108: 218828109: 218828110: 192-193828111: 192828121: 218828122: 218828200: 140-141, 144-145,148-149. 192-193,196-197, 218-219828300: 260-261828400: 260-261828500: 260-261828600: 260-261828700: 260-261828800: 260-261828900: 260-261829000: 260829100: 260829200: 260830300: 262-263830400: 262-263830500: 262-263830600: 262-263830700: 262-263830800: 262-263830811: 262-263830900: 262831000: 262831100: 262831200: 262831300: 262832400: 262-263832500: 262-263832600: 262-263832700: 262-263832900: 262-263832913: 262-263833000: 262833100: 262833200: 262833300: 262833400: 262835000: 160, 264-271835030: 160835071: 160835111:73835112:73835113:73835120: 307835121:73835122: 203835123: 71, 203835124: 71, 203835125: 71, 203835127: 71, 203835128: 71, 203835129: 203835131: 158-159835132: 158-159835133: 158-159835134: 307835139: 71, 73835140:73835141:73835142:73835143:73835144:73835145:73835146:73835147:73835148:73835150:72835151:72835152:72835156:72835157:72835158:72835165: 203835166:71835168:71835175: 201835200: 162-163835210: 162-163835220: 164-165835230: 164-165835271: 356835272: 356835273: 356835274: 356835275: 356835400: 160, 264, 266,268, 270835401: 205835402: 205835403: 205835404: 205835405: 205835411: 207835412: 207835413: 207835414: 207835415: 207835416: 207835421: 209835422: 209835423: 209835424: 209835425: 209835426: 209835431: 211835432: 211835433: 211835434: 211835435: 211835436: 211, 209, 211835451: 205. 207, 209,211835463: 205, 207, 209,211835471: 205, 207, 209,211835491: 211835492: 211835493: 211835494: 211835495: 211835496: 211835500: 211835540: 213835541: 213835542: 213835543: 213835544: 213835545: 213835550: 213835551: 213835552: 213835553: 213835554: 213835555: 213835560: 213835570: 213835580: 213835581: 213835600: 356835601: 356835602: 356835631: 205, 207, 209,211835643: 205, 207, 209,211835650: 205835651: 205835652: 205835653: 205835654: 205835655: 205835656: 207835657: 207835658: 207835659: 207835660: 207835661: 207835662: 209835663: 209835664: 209835665: 209835666: 209835667: 209835668: 211835669: 211835670: 211835671: 211835672: 211835673: 211837000: 158-159837100: 158-159837400: 172-173837450: 170837471: 356837472: 356837473: 356837500: 172837600: 173841600: 176-177842000: 176-1777

Table of Contents◗PRODUCT NUMBER INDEXPRODUCTSProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbers842100: 176-177842300: 176-177843200: 176-177843600: 176-177,180-181843700: 176-177844000: 176-177, 180-181845100: 180-181845200: 178-179845300: 178-181845400: 180-181845500: 178-179845600: 178-181845700: 180-181846800: 354, 356846871: 354, 356846900: 354846971: 354846972: 354846974: 354847000: 354847071: 354847072: 354, 358847074: 354847100: 354847171: 354847172: 354, 358847174: 354847200: 354847271: 354847272: 354847274: 354847800: 358847900: 358848000: 358848100: 358848200: 354848271: 354848272: 354848273: 354853900: 354854000: 307, 344, 375855500: 160, 266-267855600: 160, 268-269855700: 160, 268-269855800: 160, 270-271855900: 264-265856000: 266-267856100: 160856200: 160856300: 160856700: 136856800: 31, 136857000: 158883000: 152-153, 155887000: 330887001: 330887002: 330887003: 330887005: 330887009: 330887010: 330887011: 330887012: 330887013: 330887014: 330887017: 330887111: 330887112: 330906700: 80-81906701: 96-97906703: 98-99906704:98906800: 80-81906802: 98-99906900: 80-81906902: 98-99907000: 80-81907002: 98-99907003:98907100: 80-81907101: 96-97907103: 98-99907104:98907200: 80-81907202: 98-99907300: 80-81907302: 98-99909900: 82-84909902: 100-101909903: 100909912: 82, 84909980: 64, 66-67, 8284-86, 88. 90-92,114, 118-119, 369909981: 64, 66-67, 82,84-86, 88, 90-92114, 118-119, 369909984: 66, 84, 90, 118909985: 66, 84, 90, 118910000: 82-84910002: 100-101910003: 100910011: 82, 84910080: 64, 66-67, 82,84-86. 88. 90-92114, 118-119, 369910081: 64, 66-67, 82,84-86, 88, 90-92,114, 118-119, 369910084: 66, 84, 90, 118910085: 66, 84, 90, 118910091: 96-97910093: 96-97910094: 96-97910100: 82-84910102: 100-101910103: 100910112: 82, 84910180: 64, 66-67, 82, 84-86, 88, 90-92, 369910181: 64, 66-67, 82, 84-86, 88, 90-92, 369910184: 66, 84, 90910185: 66, 84, 90910200: 82-84910202: 100-101910203: 100910204: 96-97910211: 82, 84910280: 64, 66-67, 82, 84-86, 88, 90-92, 114,118-119, 369910281: 64, 66-67, 82, 84-86, 88, 90-92, 114118-119, 369910284: 66, 84, 90910285: 66, 84, 90, 118910300: 82-84910302: 100-101910303: 100910304: 96-97910311: 82, 84910380: 64, 66-67, 8284-86, 88, 90-92,114, 118-119, 369910381: 64, 66-67, 82, 84-86, 88, 90-92, 114,118-119, 369910384: 66, 84, 90, 118910385: 66, 84, 90, 118910400: 82-84910402: 100-101910403: 100910404: 96-97910407: 96-97910480: 64, 66-67, 82,84-86, 88, 90-92,114, 118-119, 369910481: 64, 66-67, 82,84-86, 88, 90-92,114, 118-119, 369910484: 66, 84, 90910485: 66, 84, 90, 118910500: 82-84910503: 100-101910504: 100910580: 64, 66-67, 82,84-85, 88, 90-91,118-119, 369910581: 64, 66-67, 82,84-85, 88, 90-91,118-119, 369911300: 82-83911700: 82-84911702: 100-101911703: 100911780: 82, 84-85, 88,90-91, 118-119,369911781: 82, 84-85, 88, 90-91, 118-119, 369911784: 84, 90, 118911785: 84, 90, 118911889: 297911991: 297911995: 297911996: 297911998: 297911999: 297912000: 2978

Table of Contents◗PRODUCT NUMBER INDEXPRODUCTSProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbersProductNumberPageNumbers927206: 217927207: 217927208: 357927209: 357927210: 217927211:77927240: 357927249: 357927250: 357927252: 357927407: 215927408: 215927409: 215927420: 215927421: 215927422: 215927423: 215927424: 215927425: 215927426: 215927427: 215927428: 215927429: 215927430: 215927431: 215927432: 215927434: 357927435: 357927521: 357927522: 357927523: 215927524: 215927525: 215927526: 215927527: 215927528: 215927529: 215927530: 215927531: 215927532: 215927533: 215927534: 215927535: 215927536: 215927537: 215927538: 215927539: 357927540: 357928000: 246, 249928100: 246, 248928400: 226-227, 230-233,236-237,240-241,246, 248928500: 246, 249, 382928600: 246, 248, 382928700: 246, 249928800: 246, 249929300: 246929600: 226-227, 230-233,236-237, 240-241,246, 248930000: 358930100: 358930200: 358930272: 358930276: 358930277: 358930278: 358930300: 358931000: 246932600: 152, 154932700: 152, 154932800: 346932900: 152, 155933000: 152, 154933100: 152, 154933200: 152, 155933500: 168-169 373933600: 166-167933800: 346933900: 356934000: 356934001: 356934200: 174-175 375934201: 174-175934202: 174-175934203: 174-175934204: 174-175934205: 174-175934206: 174-175934207: 174-175934219: 175934220: 175934221: 175934222: 175934223: 175934224: 175934225: 175934300: 174-175934400: 174-175935000: 228-229, 234-235,238-240, 247-248935041: 234, 238935100: 247-248 378935200: 247, 249, 378935300: 247, 249936000: 228-229, 234-235,238-240, 247-248936001: 234-235936041: 234, 238936100: 247-248936200: 247, 249936300: 247, 249936900: 247937000: 247, 251, 253937100: 358937200: 358937300: 358937400: 358937500: 358937600: 358937700: 358939101: 342, 374-378,380-383939201: 342, 374, 376-378, 380-383939300: 346, 375939400: 346, 374, 376-378, 381940001: 343, 374, 376-376, 380-383940011: 348940012: 350940013: 350940014: 350940017: 350940018: 349940019: 349940020: 351940021: 348940412: 346940425: 346944400: 347944900: 347945100: 347, 375945125: 347, 374, 376-378, 381948801: 344948802: 133, 150, 344948803: 344948804: 133, 150, 344948805: 133, 150948806: 133, 150948807: 133, 150948808: 133, 150948809: 133, 150948810: 133, 150949001: 344949002: 344, 374, 380-383949003: 344949004: 344950050: 38-39950061:38950070: 354950072: 354950150: 38-39950161:38950171: 354950172: 354950373: 354950250: 38-39950261:38950271: 354950272: 354950350: 38-39950361:38950371: 354950372: 354950700: 38-39951203: 120951213: 120951222: 121951223: 120951232: 121951233: 120951242: 121951243: 120951302: 120-12110

Table of Contents◗FAMILY OF PRODUCTS◗ AIR CHAMP ® FEATURES AND BENEFITSFor nearly one-half century, Nexen has been designing andmanufacturing Clutches, Brakes and other products to supportyour motion control requirements. Each product is a result ofyears of innovative design and engineering, precisemanufacturing and most importantly - understanding therequirements of motion control applications.Whether your application requirements are simple or extensive,you will find our Air Champ ® product family will service yourmotion control needs time and time again. You will findspecific product features, benefits and specifications for everyAir Champ ® product in this catalog. However, there is acommon thread of features and benefits throughout the AirChamp ® product line.Simple design, durability, efficiency and economy makeAir Champ ® products the best choice for your motioncontrol applications.“Air Champ” ®Simple DesignEasy to understand • Easy to installAir ActivatedIncreased efficiency and productivity • Inexpensive to operateHigh Thermal DissipationLess torque fade • High cyclic rates • Long product lifeSelf AdjustingAutomatic torque maintenance • Worry-free operationLow MaintenanceLong product life • Less down time • Easily servicedWide SelectionApplication and Operational versatility • Mounting flexibilityVersatile product characteristics • Imperial & Metric designsReady to ShipReadily available stock • Quick service12

Table of Contents“Air Champ” ®In accordance with Nexen’s establishedpolicy of constant product improvement,the specifications contained in this documentare subject to change without notice.Technical data listed in this document arebased on the latest information availableat the time of printing and are also subjectto change without notice. For currentinformation, please consult:www.nexengroup.comNEXEN FAMILY OF PRODUCTSThis Section Contains: . . . . .Page“AIR CHAMP” ® FAMILY OF PRODUCTSFriction Clutches . . . . . . . . . . . . . . . . . . . . .14Tooth Clutches . . . . . . . . . . . . . . . . . . . .14-15Multiple Disc Clutches . . . . . . . . . . . . . . . . .15Dual Plate Clutches & Brakes . . . . . . . . . . .16High Capacity Clutches & Brakes . . . . . . . . .16Overload Protection Devices . . . . . . . . . . . .17Flexible Couplings . . . . . . . . . . . . . . . . . . . .17Friction Brakes . . . . . . . . . . . . . . . . . . . . . . .18Caliper Brakes . . . . . . . . . . . . . . . . . . . . . . .18Drum Brakes . . . . . . . . . . . . . . . . . . . . . . . .18Spring Engaged Brakes . . . . . . . . . . . . . . . .19Thru-Shaft Mount Clutch-Brakes . . . . . . . . .19Clutch-Disc Caliper Brakes . . . . . . . . . . . . .20NEMA “C” Flange Clutch-Brakes . . . . . . . . .20Modular System forNEMA “C” Flange Clutch-Brakes . . . . . .21This Section Contains: . . . . .PageWEB PRODUCTS APPLICATION GUIDEWeb Products Application Guide . . . . . . . . .22Web Control Products,Everything you need . . . . . . . . . . . .23Tension Control Systems . . . . . . . . . . .24Web Tension Systems . . . . . . . . . . . . .25Tension Control Brakes and Clutches . .25Tension Meters and Amplifiers . . . . . . .26Web Guiding Systems . . . . . . . . . . . . . .26Web Guide Sensors and Controllers . . .27Auxiliary Products . . . . . . . . . . . . . . . . .2713

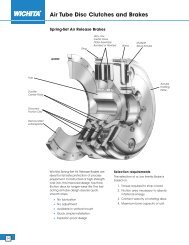

Table of Contents◗FAMILY OF PRODUCTSDISENGAGED“Air Champ” ®◗ DUAL PLATE CLUTCHES & BRAKESDual Plate Clutches and Brakes each come in 4 StandardModels, whose modular design makes custom design easyand less expensive. For applications requiring up to 36,000In Lb of torque, speeds up to 2200 rpm, thermal horsepowervalues up to 9.0, motor horsepower ratings from 5 hp to 150hp. Clutches are designed for either shaft-end mounting orthru-shaft mounting. Brakes can either mount rigidly or nonrigidly.As many as 8 Bore sizes per Clutch Model, 7 Boresizes per Brake Model with further customization possible.Sheave Mount options are also available for Clutches. DualPlate Clutches are perfect for these functions:◗ Controlled Acceleration◗ Inching/Jogging◗ Rapid Cycling/Indexing◗ Positioning◗ Reversing/Multiple Speed◗ Tension Control◗ Overload Protection◗ Torque LimitingDual Plate Brakes address these functions:◗ Controlled Deceleration◗ Stopping/HoldingDISENGAGED◗ HIGH CAPACITY CLUTCHES & BRAKES16 Standard Models of air-actuated Clutch & Brake Elementsare designed for heavy duty industrial applications thatrequire high torque and low inertia. Used as either Clutchesor Brakes, these elements are available in disc sizes from11.50 to 25 inches. Torque capacities for these elementsrange from 12,000 to 300,000 In Lb, with speeds up to 2200rpm and thermal horsepower values up to 14.7. Elements areavailable in two styles: Dual Faced Models, having single discassemblies; and Quad Faced Models, having double discassemblies. Each style is available in an S Model (standardcoefficient <strong>friction</strong> lining), and an H Model (high coefficient<strong>friction</strong> lining). Bore sizes range from 1to 6.50 inches. HighCapacity Clutches address these functions:◗ Controlled Acceleration◗ Inching/Jogging◗ Rapid Cycling/Indexing◗ Positioning◗ Reversing/Multiple SpeedHigh Capacity Brakes address these functions:◗ Stopping/Holding16

Table of Contents◗FAMILY OF PRODUCTS“Air Champ” ®ENGAGED◗ FRICTION BRAKESLow inertia, high thermal dissipation and self-adjustingfacings make these ideal for many applications. Choosebetween Straight or Tapered Bore units in a wide range ofoperational specifications. Each Model comes in a StandardBore size, with customization possible through the use ofBushings. You'll find 24 Standard Models and 4 MetricModels from which to choose. Friction Brakes address thesefunctions:◗ Controlled Deceleration◗ Rapid Cycling/Indexing◗ Positioning◗ Tension Control◗ Stopping/HoldingDISENGAGED◗ CALIPER BRAKES10 Standard Models address a wide range of Caliper Brakerequirements. Choose between Spring or Air Actuation, 10Disc diameters and a variety of design styles. Caliper spacingis movable and shoes are adjustable on many Models. CaliperBrakes address these functions:◗ Controlled Deceleration◗ Tension Control◗ Stopping/HoldingDISENGAGED◗ DRUM BRAKES7 Standard Models offer maximum efficiency anddependability. All can mount on the shaft, a few can alsobracket mount. 3 Models have a hinge top design for use withremovable brake drums. Drums available in Standard Boresizes or without bore customization. Operationalspecifications provide a wide range of application criteria.Drum Brakes address these functions:◗ Controlled Deceleration◗ Tension Control◗ Stopping/Holding18

Table of Contents“Air Champ” ®FAMILY OF PRODUCTS ◗◗ SPRING ENGAGED BRAKESSpring Engaged Brakes are available in 18 Standard Modelswith either Straight or Tapered Bore and 4 Metric Models witha Straight Bore. A variety of Standard Bore sizes are available,some Models provide bore size customization. Productspecifications cover a broad range of operational criteria.Spring Engaged Brakes address these functions:◗ Stopping/HoldingDISENGAGED◗ THRU-SHAFT MOUNT CLUTCH-BRAKESThru-Shaft Mounted Clutch/Brakes combine the features of aFriction Clutch with a Friction Brake into a single unit. 9Standard Models offer Pilot Mount, Sheave Mount and PilotMount with Coupling Half options. Pilot Mount units areavailable in 2 Standard Bores sizes with customizationpossible with Bushings and Couplings. Thru-Shaft Mountunits come in a range of bore sizes and Sheave styles.Operation specifications throughout the category will addressalmost any need. Thru-Shaft Mount Clutch-Brakes addressthese functions:◗ Controlled Acceleration◗ Controlled Deceleration◗ Inching/Jogging◗ Stopping/Holding◗ DisconnectCLUTCH DISENGAGEDBRAKE DISENGAGED19

Table of Contents◗APPLICATION GUIDEWeb ProductsWEB PRODUCTS APPLICATION GUIDEEverything you need to control web quality and productivityfrom unwind through windup, roll after roll.Nexen offers you a wide rangeof web control systems andcomponents, supported by ourexpert technical support andservice team.With Nexen, you can beassured of consistent, highqualityoutput from your webprinting or converting process.Nexen controls are usedsuccessfully with applicationsas diverse as:• paper • paperboard• film • metal strip• rubber • non-wovens• labels • foil• textiles • plastics• laminates • wirePrecise enough for thelaboratory, yet rugged enoughfor the mill, Nexen controlsystems are delivered andbacked by the recognizedleader in web controlequipment for almost 50 years.22

Table of Contents◗APPLICATION GUIDEWeb ProductsTENSION CONTROL SYSTEMSPneumatic BrakeElectric BrakePrecise tension control is vital to any web- or stripfedoperation, the product – whether paper, plastics,metal strip, rubber sheet or wire – must be fedunder tension, processed under tension and woundup again under tension.Factors such as poorly wound rolls, elasticity, rolldiameter change and irregularities in web thicknesscause significant variations in web tension.ClosedLoopLoad CellBrakeControlSystemsElectric ClutchPSSome applications require taper tension on windup.Winding begins at relatively high tension, with agradual reduction, or tapering, in tension as the rollbuilds in diameter.At the very least, your tension control systemmust compensate for the change in roll diameter. Forprecise control and high line speeds, it must alsobe capable of measuring and controlling tensionwithin very close tolerances.ClosedLoopLoad CellRewindControlSystemsMMCPneumatic ClutchPSNexen systems are available to control variablespeed motors and pneumatic and electric brakesand <strong>clutches</strong>.Load Cell Based Tension ControlNexen’s load cell based tension control system is aclosed loop system which senses tension in a web andcompares it to a set point, or desired tension level andautomatically adjusts air pressure to a pneumaticclutch or brake to maintain appropriate web tension.The load cell based system can also control electric<strong>clutches</strong> and brakes.ClosedLoopLoad CellInternalControlSystemsMMCPneumaticClutchMMCThe load cell based systems also can be used withvariable speed drives to maintain proper tension ininternal tension zones or at the windup stand.• Control accuracy of 1-2 percent –highest of any web control systems• Ideal for use with brakes, drives and <strong>clutches</strong>• Simple to operate –set the tension leveland let the controller do the rest• Allows remote computer to determinethe tension and set points for each jobOpen Loop Tension ControlThe open loop tension control system electronicallymeasures or estimates the diameter of the unwindor windup roll. It then modulates a brake to controlthe unwind, or a clutch or variable speed drive forwindup applications to maintain tension as thediameter varies. Accuracy is typically about8-10 percent.OpenLoopUnwindBrakeControlSystemsTensionRead OutRewindControlSystemsTROTension Read OutOptical EncoderPneumatic BrakeTRMCUMMCMotor ControllerTension SensorOpenLoopRewindControlSystemsOptical EncoderOutputControl*Electric BrakeProximity SwitchPP*For pneumatic clutch: I to DFor electric clutch: power supplyFor variable-speed motor: motor controlPPSOPPSMProximity SwitchPower SupplyOpen Loop ControlsMotorClosed Loop LoadCell Based ControllerI to P TransducerDancer PositionSensor24

Table of Contents◗APPLICATION GUIDETension MeterOften you need to only measurethe tension in a web, not controlit. Nexen has a variety of solutionsto meet these needs.Web ProductsTENSION METERS AND AMPLIFIERSTension MeterNexen tension meters preciselymeasure web tensions with adigital tension display on thefront panel. Their 0-10 VDC or4-20 mA analog output is alsowell suited as a proportional tensiondata signal to process controllers,data loggers and variable-speedmotor controls.You can also use one of thesensors for narrow webs, singlestrands of wire, or any other narrowmaterial where tension will notvary from one side to the other.Nexen tension meters are alsouseful as a tension readout-onlydevice to measure intermediatezonetension.Tension AmplifiersNexen tension amplifiers interfacewith load cell or straingauge sensors. They provide anexcitation signal to the sensorsand separately amplify the returnsignal from each sensor beforecombining them to provide asignal proportional to the totaltension.Tension amplifiers are ideal foraccurate, low-cost tensionmeasurement of a web processinterfaced with machine controlssuch as data loggers, processcontrollers, drive controls, hostcomputers and other applicationsrequiring a precise tensioninterface.Tension Amplifiers Offer:• Low cost signal conditioningfor LVDT or strain gaugetension sensors• Wide tension range forflexible installation• Ideal for use with machinecontrols where localreadout is not required• Includes both 0-10 VDCand 4-20 mA outputsControlled lateral alignment of the web isabsolutely essential to providing high qualityproduct and reducing scrap and waste.Nexen web guiding systems are designed,tested and proven to give you that alignmentWeb Guiding ApplicationsWEB GUIDING SYSTEMSUnwind Guiding (See Figure 1)As material is unwound and fed into amachine, it must be properly aligned with theprocess to be performed upon it.Unwind guiding is accomplished by sensingthe web as it enters the machine. The sensoris mounted as part of the main machineframe and placed so that its center is locatedat the desired position of the web. Thecontroller directs movement of the actuator,which moves the roll stand laterally acrossthe machine to bring the edge of the roll intothe center of the sensor.Intermediate GuidingThis method is normally used in the intermediatezone to make minor corrections inposition. The steering rolls pivot, directingthe web to the left or right to bring it intocenter position within the sensor.26Displacement Guides (See Figure 2)Displacement guides consist of a pair ofpivoting rollers with a pair of stationery idlerollers, one lead-in roller before the guideand a lead-out roller after the guide. Thistype of guide induces pure, out-of-planetwisting of the web, which is gentler on aweb than a steering guide. Much shorterfree spans are required before and afterguiding when compared to a steering guide.Displacement guides are often used onprinting presses and other applicationswhere space is at a premium.Windup Guiding (See Figure 3)The position of the web is monitored by asensor mounted on the moveable windup rollstand, positioned before the last roll on themachine. As the web shifts laterally, thecontroller signals the actuator to move thewindup roll into line with the web edge.Chase GuidingChase guiding is a technique used to alignthe edge of two or more webs or to align aprocess to a web. The sensor is moved bythe actuator to “chase” the edge of the web.In the case of aligning several web edges,the sensors for the second and subsequentwebs are aligned with the chase sensor andmove in tandem with it. This moves the targetor center of the sensor for allsubsequent webs, which in turn causes theguides to align their webs to the target.To align the process to the web, the sensoris mounted to the moveable processcomponent. The actuator then moves thecomponent, causing the sensor to chase theweb edge or printed line.

Table of ContentsWeb ProductsGUIDE SENSING OPTIONSWEB GUIDE SENSORS AND CONTROLLERSPosition Control ConfigurationsAPPLICATION GUIDE ◗Ultrasonic Web Guide SensorLED Infrared Web Guide SensorEdge Position ControlOne edge of the material isaligned with the process at alltimes. The position of this edgeremains constant throughout allprocesses. The opposite edge ispermitted to run free and iseventually edge-trimmed to meetthe final specified web width.Center Position ControlThis technique requires one sensoron each side of the web. Theobjective is to maintain the centerof the web on the mean centerlineof the machine. If the webvaries in width, center positioncontrol will maintain an equaledge trim on each side of theweb, to be removed later in theprocessing.Line Follower ControlLine follower control is alwaysemployed for previouslyprocessed materials, using asensor to follow a line or theedge of a pattern of print orcoating material previously laiddown on the web.Ultrasonic SensorsUltrasonic sensors are used particularlyfor edge or center controlof photosensitive materialssuch as photographic film andprint paper, and with transparentor translucent films bearing acoating, printing or an opaquesurface near the edge. A highfrequency sound is transmittedacross an air gap to a receivingunit. Interruption of the signal isinterpreted as a change in positionof the web material. Theycan also be used with opaquematerials.Infrared SensorsA pulsed LED transmits aninfrared signal across the webedge to a light sensitive sensor;edge position of the material isSplice Detector SystemSplice DetectorSystem ControllerThe Splice Detector System is avisible light system used tosense splices or double thicknessesin translucent materials.It provides both a visual indicationand a relay signal at each splice.determined from the amount oflight sensed at the receiving unit.Infrared sensors can also beconfigured in pairs for centerposition control. The infrared signalis not affected by ambientlight and is useful for processingof certain photosensitive materials.Infrared sensors are usedfor opaque materials only.Line Follower SensorsA line following sensor bounceslight off a web as it passesaround a transport roll in themachine. It is received by asensing element contained inthe same housing. This type ofsensor is normally used to followa printed line or the edge of aprinted pattern on the web.This system is ideally suited foruse where high nippingpressure in a machine must bemomentarily relaxed to allow asplice to pass through withoutdamaging the web, printing blanketor other components.This system typically does notrequire operator intervention. Achange in web thickness ofmore than three seconds durationwill cause the system’s controllerto recalibrate to the newweb thickness.Web Guide ControllerSelf ContainedWeb Guide ControllerAUXILIARY PRODUCTSPaper Checker SystemPaper CheckerThe Paper Checker Systemdetects web breaks and spliceson web machines.This system makes use of anultrasonic sensor to prevent thefalse triggering that can resultfrom the presence of print orWeb Guide ControllersA Nexen web guide controllerreceives signals from a webposition sensor and translatesthem into control signals for webposition drive motors. With theappropriate sensor, they offercontrol accuracy to within±0.004 inches (±0,01mm) of anedge or centerline position.The purpose of the controller isto provide automatic positioningof the web in relation to the sensor.Web position information fromthe sensor is fed to the webguide controller. The controller’smotor control drives anelectrical linear actuator tocorrect the web position byadjusting the roll stand or guideroll mechanism.other patterns on the web materialand for use with photo sensitivematerials. Each break orsplice is indicated by a separaterelay signal and front panel indicatorlights.This Nexen Paper CheckerSystem can be used on transparentto fully opaque webs andwith laminates of paper, film andfoil. It handles web speeds from30 to more than 3000 feet perminute, (10 to 1000 meters perminute).27

Table of Contents◗CLUTCHES“Air Champ” ®◗ PRODUCT FUNCTION/SELECTION CHARTProduct Groups Friction Tooth Multi-Disc Dual Plate High CapacityClutches Clutches Clutches Clutches ClutchesGeneral FeaturesNumber of Model Options 15 Standard 40 Standard 7 Standard 4 Standard 16 Standard5 Metric 35 Metric 0 Metric 0 Metric 0 MetricFunctionsControlled Acceleration Yes Yes YesInching/Jogging Yes Yes YesCycling/Indexing Yes Yes YesPositioning Yes Yes Yes Yes YesReversing/Multiple Speed Yes Yes Yes Yes YesTension Control, Rewind Yes YesOverload Protection Yes Yes YesDisconnect/Connect Yes Yes Yes Yes YesPositive DriveYes28

Table of Contents“Air Champ” ®In accordance with Nexen’s establishedpolicy of constant product improvement,the specifications contained in this documentare subject to change without notice.Technical data listed in this document arebased on the latest information availableat the time of printing and are also subjectto change without notice. For currentinformation, please consult:www.nexengroup.comFRICTION CLUTCHESThis Section Contains: . . . . .PageThis Section Contains: . . . . .PageCLUTCHESClutch Product Function/Selection Chart . . .28Friction Clutch Selection Chart . . . . . . . . . .30Micro Model (M) . . . . . . . . . . . . . . . . . . . . .31Bantam Weight (BW & B-275) . . . . . . . .32-33F-450 & L-600 Models . . . . . . . . . . . . .34-35M-800 & H-1000 Models . . . . . . . . . . . .36-37Extra Heavy Weight Models (XHW) . . . .40-41FW, LW, MW & HW Models . . . . . . . . . . . .42METRIC FRICTION CLUTCHESBW, B-275,F-450, L-600, M-800, H-1000 . . .38-39DUAL PLATE CLUTCHESDPC Selection Chart . . . . . . . . . . . . . . . . . .43DPC Model Overview . . . . . . . . . . . . . . .44-45DPC-9T Model . . . . . . . . . . . . . . . . . . . .46-47DPC-11T Model . . . . . . . . . . . . . . . . . . .48-49DPC-13T Model . . . . . . . . . . . . . . . . . . .50-51DPC-15T Model . . . . . . . . . . . . . . . . . . .52-53DFC-1650 & 2200 Models . . . . . . . . . . .54-55HIGH CAPACITY CLUTCHESDFE & QFE Model Overview . . . . . . . . . .56-57DFE Model Clutch & Brake Elements . . .58-59QFE Model Clutch & Brake Elements . . .60-61CONVEYOR CLUTCHESLSCC-32, 44, 54 Models Straight Bore . . .62-63MULTI-DISC CLUTCHES4HP Model Multe-Disc . . . . . . . . . . . . . .64-654HP Flexible Couplings . . . . . . . . . . . . . .66-6729

Table of Contents◗CLUTCHESFRICTION CLUTCH SELECTION CHARTFriction clutch recommendation is based upon air pressure of 50 psi, transmitted horsepower and speed.“Air Champ” ®1800 2200 2600 3000 3600100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700RPM1 ⁄ 36 M M M M M M M M M M M M M M M M M1 ⁄ 20BW /B-275BW /B-275 M M M M M M M M M M M M M M M1 ⁄ 18BW /B-275BW /B-275 M M M M M M M M M M M M M M M1 ⁄ 15BW /B-275BW /B-275 M M M M M M M M M M M M M M1 ⁄ 12BW /B-275BW /B-275 M M M M M M M M M M M M M M1 ⁄ 10BW /B-275BW /B-275BW /B-275 M M M M M M M M M M M M M1 ⁄ 9BW /B-275BW /B-275BW /B-275BW/ B-275 M M M M M M M M M M M MM M M M MM M M M MM M M M MM M M M MM M M M MM M M M MM M M M MTRANSMITTED HORSEPOWER1 ⁄ 8 F-450 F-450 BW /BW B-275 /B-275BW/BW B-275 / B-275 M M M M M M M M M M M1 ⁄ 6 F-450 F-450 F-450 BW /BW B-275 /BW B-275 /BW B-275 /BW B-275 / B-275 M M M M M M M M M1 ⁄ 4 L-600 F-450 F-450 F-450 BW /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 / B-275 M M M M M1 ⁄ 3 L-600 F-450 F-450 F-450 F-450 F-450 BW /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 / B-275M M M M MM M M M MM M M M MM M M M M1 ⁄ 2 M-800 L-600 L-600 F-450 F-450 F-450 F-450 F-450 BW /BW BW/BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 /BW B-275 / B-275 B-275 / B-275 M M M1 H-1000 H-1000 L-600 L-600 L-600 L-600 F-450 F-450 F-450 F-450 F-450 F-450 F-450 F-450 F-450 F-450 F-4502 H-1000 H-1000 M-800 M-800 M-800 L-600 L-600 L-600 L-600 L-600 L-600 L-600 L-600 L-600 L-600 L-600 L-6003 H-1000 H-1000 H-1000 M-800 M-800 M-800 M-800 M-800 L-600 L-600 L-600 L-600 L-600 L-600 L-600 L-600 L-6005 XHW H-1000 H-1000 H-1000 H-1000 M-800 M-800 M-800 M-800 M-800 M-800 M-800 M-800 M-800 L-600 L-600 L-600BW/ B-275BW/ B-275BW/ B-275BW/ B-275BW/ B-275F-450 F-450 F-450 F-450 F-450L-600 F-450 F-450 F-450 F-450L-600 L-600 L-600 L-600 F-4507 1 ⁄ 2 XHW H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 M-800 M-800 M-800 M-800 M-800 M-800 M-800 M-800 M-80010 XHW XHW H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 M-800 M-800 M-800 M-800 M-800 M-80015 XHW XHW H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-100020 XHW XHW H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000M-800 L-600 L-600 L-600 L-600M-800H-1000H-100025 XHW XHW XHW H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000 H-1000REFER TO DUAL PLATECLUTCH PRODUCTSPAGE 4330 XHW XHW XHW XHW40 XHW XHW XHW XHW50 XHW XHWH-1000REFER TO DUAL PLATE CLUTCHPRODUCTS PAGE 43IMPORTANT NOTES:1. For static torque ratings at different air pressures, refer to individual models to ensure conformity.2. For operating speeds over 1800 rpm, refer to individual models or consult Nexen to ensure conformity.3. Limited to peak thermal input rates of .9 HP T per square inch of interface area.4. Bars equal PSI x 0.0689.30

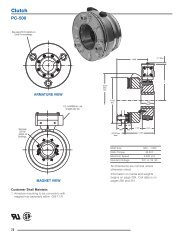

Table of Contents◗ MICRO FRICTION CLUTCHMounting Product Bore Shipping Wt.Style Number (In) (Lbs)Pilot 856800 0.375 3For Inertia Values of components, see page 359.Required shaft insertion into clutch hub = minimum of 1 inch from Pilot side.MICRO MODEL–APPROXIMATE DIMENSIONS (INCHES)◗ PILOT MOUNTØAJBF4 X AT 90°CWPRODUCT +.000 +.001NUMBER AJ AK -.001 BB BF CR CS CT CW CZ P PA PB U -.000CRCSPBB CZCS2 X .164-32SET SCREW.127-27 NPTAIR INLET“Air Champ” ®CTU PB5" FLEXIBLE HOSEMICRO FRICTION CLUTCHThe Micro Friction Clutch provideshigh performance in a smallpackage:◗ Static Torque capacity up to 18In. Lbs. @ 80 psi◗ Maximum Operating Speed up to3600 rpm◗ Transmitted Horsepower valuesfrom 0.06 to 0.50◗ Thermal Horsepower rating of0.06 @ 1800 rpm◗ Heat Sink capacity of 1900 Ft.Lbs.This Pilot Mount clutch mountseasily and comes with:◗ 0.375 inch Standard BoreCLUTCHES ◗◗ 5 inch hose with .190-32 by .125NPT included.856800 1.562 1.374 0.19 .138-32 2.27 0.09 0.72 0.32 0.20 1.75 0.59 0.88 0.375◗ TORQUE VS. AIR PRESSURE20.0Static Torque in Inch-Pounds15.010.05.00 10 20 30 40 50 60 70 80Air Pressure in PSINOTE: Dynamic torque is approximately 85% of static torque.31

Table of Contents◗CLUTCHES“Air Champ” ®BANTAM WEIGHT MODEL BWFRICTION CLUTCHThe BW Friction Clutch providesexcellent performance:◗ Static Torque capacity up to 100In. Lbs. @ 80 psi◗ Maximum Operating Speed up to3600 rpm◗ Transmitted Horsepower valuesfrom 0.05 to 1.00◗ Thermal Horsepower rating of0.13 @ 1800 rpm◗ Heat Sink capacity of 5650 Ft. Lbs.◗ Corrosion-Resistant Modelavailiable for damp environmentsThis clutch is thru-shaft mountedto provide design versatility in 5Models:◗ 4 Sheave Mount units provide1-“3V” or 1-“A” Groove options◗ 5 Pilot Mount units withdifferent standard bore sizes◗ Standard Bore sizes of 0.500and 0.625 inches◗ Customize the bore to your shaftdiameter with a Bushing orCoupling Half◗ Tapped holes provided for easymounting in applications withpulleys, sprockets or gears◗ 8.25 inch hose included◗ BW is equipped with ThrustBearings and a Single Key SplinedHub.◗ B-275 is equipped with Sealed,Radial Bearings and a Multi-toothSplined Hub.32◗ BW AND B-275 MODEL CLUTCHESProduct Sheave Bore Key Size Shipping Wt.Clutch Style Number Diameter (In) (SQ) (Lbs)Pilot Mount, BW 800100 -- 0.625 0.188 4Pilot Mount, BW 800111 -- 0.500 0.125 4Pilot Mount Corrosion-Resistant, BW 800107 -- 0.625 0.188 4Pilot Mount, B-275 802870 -- 0.625 0.188 4Pilot Mount, B-275 802871 -- 0.500 0.125 4Sheave Mount, B-275, 1-“A” 802872 3.00 PD 0.625 0.188 4Sheave Mount, B-275, 1-“3V” 802873 2.750 OD 0.625 0.188 4Sheave Mount, 1-“3V” 800000 2.750 OD 0.625 0.188 4Sheave Mount, 1-“A” 800004 3.000 PD 0.625 0.188 4Pilot w/Coupling Half Select a Pilot Mount and a Coupling Half to achieve this style of mount.For Inertia Values of components, see page 359.Keys are included. Required shaft insertion into clutch hub = minimum of 1.50 inches from Pilot side.◗ BUSHING OPTIONS (FOR 0.625 BORE CLUTCHES ONLY)Bushings fit within the bore of the clutch, reducing the bore to the amount indicated.Product Reduces Clutch Shipping Wt.Number Bore Size to (In) (Lbs)800200 0.500 1800900 No Bore/Customer machines 1◗ COUPLING HALF OPTIONSA Coupling Half is used for in-line applications. To achieve a Pilot Mount withCoupling Half mounting configuration:1. Select a Pilot Mount Clutch from above;2. Select a Coupling Half from the chart below which fits your shaft requirements;3. Order Clutch and Coupling Half separately.Product Key Size Shipping Wt.Number Bore Size (In) (SQ) (Lbs)800300 0.500 0.125 1800307 0.500 0.125 1 ➀800400 0.625 0.188 1800500 0.750 0.188 1➀ Nickle Plated◗ PULLEYS, SPROCKETS, GEARSTapped holes are provided for ease of mounting. Nexen does not furnish theseitems. For minimum sprocket requirements, see page 369.◗ TORQUE VS. AIR PRESSUREStatic Torque in Inch-Pounds112988470564228140 10 20 30 40 50 60 70 80Air Pressure in PSIB-275, BWNOTE: Dynamic torque is approximately 85% of static torque.

Table of Contents“Air Champ” ®CLUTCHES ◗BW AND B-275 MODEL CLUTCHES - APPROXIMATE DIMENSIONS (INCHES)◗ PILOT MOUNTØ A JB F4 X A T 9 0 °2 X .164-32S E T S C R E W SC WC SK LC RB BK E YC ZA KP APUP B8 . 2 5 " F L E X I B L E H O S E. 1 2 5 - 2 7 N P TA I R I N L E TPRODUCT KEY +.001NUMBER AJ AK ±.001 BB BF CR CS CT CW CZ KL (SQ) P PA PB U -.000800100 2.437 2.124 0.25 .190-32 3.51 0.11 0.50 0.49 0.18 0.62 0.188 2.89 0.98 1.19 0.625800107 2.437 2.124 0.25 .190-32 3.51 0.11 0.50 0.49 0.18 0.62 0.188 2.89 0.98 1.19 0.625800111 2.437 2.124 0.25 .190-32 3.51 0.11 0.50 0.49 0.18 0.62 0.125 2.89 0.98 1.19 0.500802870 2.437 2.124 0.25 .190-32 3.51 0.11 0.50 0.49 0.18 0.62 0.188 2.89 0.98 1.19 0.625802871 2.437 2.124 0.25 .190-32 3.51 0.11 0.50 0.49 0.18 0.62 0.125 2.89 0.98 1.19 0.500C T◗ PILOT MOUNTW/COUPLING HALFC O U P L I N GS H A F TK L 2K E Y 2P I L O T M O U N TC L U T C H S H A F TC XK L 12 X .164-32S E T S C R E W SK E Y 1C ZP A U 2U 1 P B P2 X .190 - 3 2S E T S C R E W SC SC W8 . 2 5 " F L E X I B L EH O S EC RCOUPLINGPRODUCT KEY 1 KEY 2 +.001 +.001NUMBER CR CS CW CX CZ KL1 KL2 (SQ) (SQ) P PA PB U1 -.000 U2 -.000800300 4.20 0.11 0.69 0.07 0.18 0.62 0.62 0.188 0.125 2.89 1.87 1.19 0.625 0.501800307 4.20 0.11 0.69 0.07 0.18 0.62 0.62 0.188 0.125 2.89 1.87 1.19 0.625 0.501800400 4.20 0.11 0.69 0.07 0.18 0.62 0.62 0.188 0.188 2.89 1.87 1.19 0.625 0.625800500 4.20 0.11 0.69 0.07 0.18 0.62 0.62 0.188 0.188 2.89 1.87 1.19 0.625 0.751◗ SHEAVE MOUNT2 X .164-32S E T S C R E W S. 1 2 5 - 2 7 N P TA I R I N L E TK LC WC SC RK E YC TC ZO DP DP AP B PUC X. 1 2 5 - 2 7 N P TA I R I N L E T8 . 2 5 " F L E X I B L EH O S EPRODUCT SHEAVE KEY +.001NUMBER BELT GROOVE OD PD CR CS CT CW CX CZ KL (SQ) P PA PB U -.000C T802872 “A” 1 3.250 3.000 3.51 0.11 0.50 0.18 0.55 0.18 0.62 0.188 2.89 0.98 1.19 0.625800000 “3V” 1 2.750 -- 3.51 0.11 0.50 0.24 0.58 0.18 0.62 0.188 2.89 0.98 1.19 0.625802873 “3V” 1 2.750 -- 3.51 0.11 0.50 0.25 0.59 0.18 0.62 0.188 2.89 0.98 1.19 0.625800004 “A” 1 3.250 3.000 3.51 0.11 0.50 0.17 0.54 0.18 0.62 0.188 2.89 0.98 1.19 0.62533

Table of Contents◗CLUTCHES“Air Champ” ®FRICTION CLUTCH MODELSF-450 & L-600◗ Static Torque capacity up to:F-450/140 In. Lbs. @ 80 psiL-600/370 In. Lbs. @ 80 psi◗ Maximum Operating Speed up to3600 rpm◗ Transmitted Horsepower values from:F-450/0.125 to 5.00L-600/0.25 to 10.00◗ Thermal Horsepower rating of:F-450/0.30 @ 3600 rpmL-600/0.75 @ 3600 rpm◗ Heat Sink capacity of:F-450/30,000 Ft. Lbs.L-600/60,000 Ft. Lbs.8 F-450 & 8 L-600 Models offer designflexibility:◗ Sheave Mount Units:F-450/4 in 1-“3V” or 1-“A” Groovestyles, each in 2 sizesL-600/6, 4 sizes of 2-“3V” and 2 sizesof 2-“A”◗ 2 Pilot Mount units with differentstandard bore sizes◗ 2 Rewind Clutches Half-Torque,Precise Interface. Standard or LOCOfacing, 0.875 bore size.◗ Standard Bore Sizes:F-450/0.750 and 0.875 inchesL-600/1.00 and 1.125 inches◗ Customize the bore to your shaft diameterwith a Bushing or Coupling Half◗ Includes:F-450/Air Inlet Adapter and 8.25 in. hose.L-600/8.25 inch hose.◗ 1 802864 & 802865Percision Interface Clutches.For reduced pulsation in tension controlapplications.◗ TORQUE VS. AIR PRESSUREF-450140Static Torque in Inch-Pounds3412010080604020F-450802864 1802865 1◗ F-450 & L-600 MODEL CLUTCHESProduct Bore Key Size Shipping Wt.Model Clutch Style Number Sheave Diameter (In) (SQ) (Lbs)F-450 Pilot Mount 802850 -- 0.875 0.188 12F-450 Pilot Mount, Rewind (Std) 802864 1 -- 0.875 0.188 10F-450 Pilot Mount, Rewind (LOCO) 802865 1 -- 0.875 0.188 10F-450 Pilot Mount 802855 -- 0.750 0.188 10F-450 Sheave Mount 1-“3V” 802810 3.35 OD 0.875 0.188 10F-450 Sheave Mount, 1-“3V” 802820 4.50 OD 0.875 0.188 11F-450 Sheave Mount, 1-“A” 802830 3.80 PD 0.875 0.188 10F-450 Sheave Mount, 1-“A” 802840 4.40 PD 0.875 0.188 10L-600 Pilot Mount 805270 -- 1.125 0.250 17L-600 Pilot Mount 805275 -- 1.000 0.250 17L-600 Sheave Mount, 2-“3V” 805210 4.50 OD 1.125 0.250 18L-600 Sheave Mount, 2-“3V” 805220 5.30 OD 1.125 0.250 19L-600 Sheave Mount, 2-“3V” 805230 6.00 OD 1.125 0.250 21L-600 Sheave Mount, 2-“3V” 805240 8.00 OD 1.125 0.250 25L-600 Sheave Mount, 2-“A” 805250 4.40 PD 1.125 0.250 18L-600 Sheave Mount, 2-“A” 805260 5.40 PD 1.125 0.250 20Both Pilot w/Coupling Half Select a Pilot Mount and a Coupling Half to achieve this style of mount.For Inertia Values of components, see page 359. Keys are included. Required shaft insertion into clutchhub = minimum of F-450/2.00 inches, L-600/2.50 inches from Pilot side.◗ BUSHING OPTIONS(FOR 0.875 & 1.125 BORE CLUTCHES ONLY)Bushings fit within the bore of theexisting clutch, reducing the bore tothe amount indicated.Bore Product Reduces Clutch ShippingSize Number Bore Size to (In) Wt. (Lbs)0.875 827200 0.500 10.875 802500 0.625 10.875 802600 0.750 10.875 803100 No Bore/Customer machines 11.125 805100 0.625 11.125 804600 0.750 11.125 804700 0.875 11.125 804800 1.000 11.125 805000 No Bore/Customer machines 1◗ PULLEYS, SPROCKETS AND GEARSThese can be attached to the clutch foroffset shaft applications. Tapped holes areprovided for ease of mounting. Nexen doesnot furnish these items. For minimumsprocket requirements, see page 369.0 10 20 30 40 50 60 70 800 10 20 30 40 50 60 70 80Air Pressure in PSIAir Pressure in PSINOTE: Dynamic torque is approximately 85% of static torque.Static Torque in Inch-Pounds40035030025020015010050L-600L-600◗ COUPLING HALF OPTIONS(SEE PAGE 367 FOR COUPLING SPECIFICATIONS)A Coupling Half is used for in-lineapplications. To achieve a Pilot Mountwith Coupling Half mountingconfiguration:1. Select a Pilot Mount Clutch;2. Order Clutch and Coupling Halfseparately.3. Coupling Half is less taper lockbushing. Use Dodge Taper Lock ®#1008/F-450, #1215/L-600,(0.500 to 1.000/F-450, 0.500 to1.125/L-600, inch bore range).Customer furnished.Product Maximum ShippingModel Number Bore Size (In) Wt. (Lbs)F-450 802700 1.000 3L-600 804900 1.125 64. Select a Shaft Extension when thedriving shaft is smaller in diameterand shorter than the length of theclutch. The Shaft Extension is thesame length as the clutch and engageswith the key on the pilot end. Extensionsfit the driving shaft diameter.Only for Product Driving Shaft ShippingBore Size Number DIA. Wt. (Lbs)0.875 802800 0.500 10.875 803000 0.625 11.125 805200 0.500 1.51.125 805300 0.625 1.51.125 805400 0.750 1.51.125 805500 0.875 1.5

Table of Contents“Air Champ” ®CLUTCHES ◗F-450 & L-600 MODEL CLUTCHES - APPROXIMATE DIMENSIONS (INCHES)◗ PILOT MOUNTS E T S C R E W SB F 22 A T 9 0 °6 A T 6 0 °Ø A J 2K E YK E YC W 1B B 1C SA K 2P AA K 1UC RK LPB F 14 A T 9 0 °Ø A J 1B B 2C W 2. 1 2 5 - 2 7 N P TA I R I N L E TC T ( D I S E N G A G E D )C T 1 ( M A X E N G A G E D )8 . 2 5 " F L E X I B L E H O S EMODELF-450F-450L-600L-600PRODUCT KEY SET +.001NUMBER AJ1 AJ2 AK1 ±.001 AK2 ±.001 BB1 BB2 BF1 BF2 CR CS CT CT1 CW1 CW2 KL (SQ) P PA SCREWS U -.000802850 3.000 4.000 2.498 3.498 0.60 0.19 .250-20 .190-24 4.75 0.25 1.33 1.42 1.04 1.23 1.062 0.188 4.56 1.38 .250-20 0.875802855 3.000 4.000 2.498 3.498 0.60 0.19 .250-20 .190-24 4.75 0.25 1.33 1.42 1.04 1.23 1.062 0.188 4.56 1.38 .250-20 0.750805270 3.500 5.500 2.998 4.498 0.62 0.07 .250-20 .190-24 5.56 0.25 1.79 1.94 1.23 1.55 1.37 0.250 6.06 1.84 .312-18 1.125805275 3.500 5.500 2.998 4.498 0.62 0.07 .250-20 .190-24 5.56 0.25 1.79 1.94 1.23 1.55 1.37 0.250 6.06 1.84 .312-18 1.000◗ PILOT MOUNTW/COUPLING HALFC WC W 1C RP BP AT A P E RL O C KC XC O U P L I N GS H A F TCOUPLINGDODGEPRODUCTTAPERMODEL NUMBER CR CW CW1 CX PA PB LOCK ®P I L O T M O U N TC L U T C H S H A F T◗ SHEAVE MOUNTB F 26 A T 6 0 °C XC YC X 1F-450 802700 6.45 0.12 2.75 0.70 2.62 3.50 #1008L-600 804900 7.70 0.94 3.37 0.64 2.62 4.38 #1215Ø A J 2O DP DA K 2B B 2C W 2PRODUCT SHEAVEMODEL NUMBER BELT G’VE OD PD AJ2 AK2 ±.001 BB2 BF2 CW2 CX CX1 CYF-450 802810 “3V” 1 3.35 -- 4.000 3.498 0.06 .190-24 1.22 0.75 -- 0.44F-450 802820 “3V” 1 4.50 -- -- -- -- -- -- 0.88 -- 0.44F-450 802830 “A” 1 4.05 3.80 -- -- -- -- -- 0.88 -- 0.44F-450 802840 “A” 1 4.65 4.40 -- -- -- -- -- 0.88 -- 0.44L-600 805210 “3V” 2 4.50 -- 5.500 4.498 0.29 .190-24 1.55 0.68 0.41 0.43L-600 805220 “3V” 2 5.30 -- -- -- -- -- -- 0.86 0.41 0.55L-600 805230 “3V” 2 6.00 -- -- -- -- -- -- 0.86 0.41 0.55L-600 805240 “3V” 2 8.00 -- -- -- -- -- -- 0.86 0.41 0.55L-600 805250 “A” 2 4.65 4.40 -- -- -- -- -- 0.62 0.63 0.24L-600 805260 “A” 2 5.65 5.40 -- -- -- -- -- 0.62 0.63 0.2435

Table of Contents◗CLUTCHES“Air Champ” ®FRICTION CLUTCH MODELSM-800 & H-1000◗ Static Torque capacity up to:M-800/975 In. Lbs. @ 80 psiH-1000/2800 In. Lbs. @ 80 psi◗ Maximum Operating Speed up to1800 rpm◗ Transmitted Horsepower values from:M-800/0.50 to 10.00H-1000/1.00 to 25.00◗ Thermal Horsepower rating of:M-800/1.00 @ 1800 rpmH-1000/2.25 @ 1800 rpm◗ Heat Sink capacity of:M-800/110,000 Ft. Lbs.H-1000/230,000 Ft. Lbs.6 M-800 & 6 H-1000 Models offerdesign flexibility:◗ Sheave Mount Units:M-800/2 sizes of 3-“3V” and 2 sizes of2-“B” Groove styles.H-1000/2 sizes of 3-“5V” and 2 sizesof 2-“B”◗ 2 Pilot Mount units with differentstandard bore sizes◗ Standard Bore Sizes:M-800/1.438 and 1.625 inchesH-1000/1.688 and 1.875 inches◗ Customize the bore to your shaft diameterwith a Bushing or Coupling Half◗ Includes:M-800/8.25 in. hose.H-1000/8.25 inch hose.◗ PULLEYS, SPROCKETS AND GEARSThese can be attached to the clutch foroffset shaft applications. Tapped holes areprovided for ease of mounting. Nexen doesnot furnish these items. For minimumsprocket requirements, see page 369.◗ TORQUE VS. AIR PRESSUREM-8001000 1000Static Torque in Inch-Pounds368757506255003752501258757506255003752501250M-800◗ M-800 & H-1000 MODEL CLUTCHESProduct Bore Key Size Shipping Wt.Model Clutch Style Number Sheave Diameter (In) (SQ) (Lbs)M-800 Pilot Mount 807650 -- 1.625 0.375 38M-800 Pilot Mount 807655 -- 1.438 0.375 38M-800 Sheave Mount, 3-“3V” 807610 5.30 OD 1.625 0.375 37M-800 Sheave Mount, 3-“3V” 807620 6.00 OD 1.625 0.375 40M-800 Sheave Mount, 2-“B” 807630 5.80 PD 1.625 0.375 39M-800 Sheave Mount, 2-“B” 807640 6.80 PD 1.625 0.375 43H-1000 Pilot Mount 810050 -- 1.875 0.500 61H-1000 Pilot Mount 810055 -- 1.688 0.375 63H-1000 Sheave Mount, 3-“5V” 810010 7.10 OD 1.875 0.500 69H-1000 Sheave Mount, 3-“5V” 810020 8.00 OD 1.875 0.500 74H-1000 Sheave Mount, 3-“B” 810030 7.40 PD 1.875 0.500 72H-1000 Sheave Mount, 3-“B” 810040 8.60 PD 1.875 0.500 82Both Pilot w/Coupling Half Select a Pilot Mount and a Coupling Half to achieve this style of mount.For Inertia Values of components, see page 359. Keys are included. Required shaft insertion into clutchhub = minimum of M-800/3.75inches, H-1000/4.00 inches from Pilot side.◗ BUSHING OPTIONS(FOR 1.625 & 1.875 BORE CLUTCHES ONLY)Bushings fit within the bore of theexisting clutch, reducing the bore tothe amount indicated.Bore Product Reduces Clutch ShippingSize Number Bore Size to (In) Wt. (Lbs)1.625 806700 1.000 21.625 806800 1.125 21.625 806900 1.188 21.625 807000 1.250 21.625 807100 1.375 21.625 807200 1.438 21.625 807300 1.500 21.625 807500 No Bore/Customer machines 21.875 805600 1.000 21.875 809200 1.375 21.875 809300 1.438 21.875 809400 1.500 21.875 809500 1.625 21.875 809600 1.750 21.875 809900 No Bore/Customer machines 20 0 10 20 30 40 50 60 70 800 10 20 30 40 50 60 70 80Air Pressure in PSIAir Pressure in PSINOTE: Dynamic torque is approximately 85% of static torque.Static Torque in Inch-Pounds300026252250187515001125750375H-1000H-1000◗ COUPLING HALF OPTIONS,SEE PAGE 367 FOR COUPLING SPECIFICATIONSA Coupling Half is used for in-lineapplications. To achieve a Pilot Mountwith Coupling Half mountingconfiguration:1. Select a Pilot Mount Clutch;2. Order Clutch and Coupling Halfseparately.3. Coupling Half is less taper lockbushing. Use Dodge Taper Lock ®#2517 (1.000 to 2.500 inch borerange). Customer furnished.Product Maximum ShippingModel Number Bore Size (In) Wt. (Lbs)M-800 807400 2.500 25H-1000 809700 2.500 334. Select a Shaft Extension when thedriving shaft is smaller in diameterand shorter than the length of theclutch. The Shaft Extension is thesame length as the clutch and engageswith the key on the pilot end. Extensionsfit the driving shaft diameter.Only for Product Driving Shaft ShippingBore Size Number DIA. Wt. (Lbs)1.625 807600 0.750 41.625 807700 0.875 41.625 807800 0.938 41.625 807900 1.000 41.625 808000 1.125 41.625 808100 1.250 41.875 810000 1.000 61.875 810300 1.125 61.875 810400 1.250 61.875 810500 1.375 61.875 810600 1.500 6

Table of Contents“Air Champ” ®CLUTCHES ◗M-800 & H-1000 MODEL CLUTCHES - APPROXIMATE DIMENSIONS (INCHES)◗ PILOT MOUNTS E T S C R E W SB F 22 A T 9 0 °6 A T 6 0 °Ø A J 2K E YC W 1B B 1C SA K 2P AA K 1UC RK LPB F 14 A T 9 0 °Ø A J 1B B 2C W 2. 1 2 5 - 2 7 N P TA I R I N L E TC T ( D I S E N G A G E D )C T 1 ( M A X E N G A G E D )8 . 2 5 " F L E X I B L E H O S EMODELPRODUCT KEY SET +.001NUMBER AJ1 AJ2 AK1 ±.001 AK2 ±.001 BB1 BB2 BF1 BF2 CR CS CT CT1 CW1 CW2 KL (SQ) P PA SCREWS U -.000M-800 807650 4.750 6.500 3.999 5.498 0.77 0.67 .312-18 .250-20 7.31 0.38 1.62 1.71 1.62 2.31 1.69 0.375 8.06 2.63 .375-16 1.625M-800 807655 4.750 6.500 3.999 5.498 0.77 0.67 .312-18 .250-20 7.31 0.38 1.62 1.71 1.62 2.31 1.69 0.375 8.06 2.63 .375-16 1.438H-1000 810050 5.625 9.000 4.873 7.098 1.47 0.12 .375-16 .250-20 8.50 0.31 1.92 2.14 1.97 2.90 2.56 0.500 10.06 3.25 .375-16 1.875H-1000 810055 5.625 9.000 4.873 7.098 1.47 0.12 .375-16 .250-20 8.50 0.31 1.92 2.14 1.97 2.90 2.56 0.375 10.06 3.25 .375-16 1.688◗ PILOT MOUNTW/COUPLING HALFC WC W 1C RP BP AT A P E RL O C KC XC O U P L I N GS H A F TP I L O T M O U N TC L U T C H S H A F TCOUPLINGDODGEPRODUCTTAPERMODEL NUMBER CR CW CW1 CX PA PB LOCK ®◗ SHEAVE MOUNTB F 26 A T 6 0 °C XC YC X 1M-800 807400 9.93 0.81 4.25 0.87 5.00 7.00 #2517H-1000 809700 11.43 0.63 4.90 1.18 5.00 8.00 #2517Ø A J 2O DP DA K 2B B 2C W 2PRODUCT SHEAVEMODEL NUMBER BELT G’VE OD PD AJ2 AK2 ±.001 BB2 BF2 CW2 CX CX1 CYM-800 807610 “3V” 3 5.30 -- 6.500 5.498 0.06 .250-20 2.30 0.96 0.41 0.68M-800 807620 “3V” 3 6.00 -- -- -- -- -- -- 0.96 0.41 0.68M-800 807630 “B” 2 6.15 5.80 -- -- -- -- -- 1.18 0.75 0.68M-800 807640 “B” 2 7.15 6.80 -- -- -- -- -- 1.18 0.75 0.68H-1000 810010 “5V” 3 7.10 -- 9.000 7.098 0.29 .250-20 2.90 0.91 0.69 0.47H-1000 810020 “5V” 3 8.00 -- -- -- -- -- -- 1.03 0.69 0.50H-1000 810030 “B” 3 7.75 7.40 -- -- -- -- -- 1.03 0.75 0.50H-1000 810040 “B” 3 8.95 8.60 -- -- -- -- -- 1.03 0.75 0.5037

Table of Contents◗CLUTCHES“Air Champ” ®METRIC SERIESFRICTION CLUTCHESThe Metric Model Friction ClutchSeries provides:◗ Static Torque capacity up to 330Nm◗ Maximum Operating Speed up to3600 rpm◗ Heat Sink capacity of 312,000Joules.This clutch comes in 5 Modelsfor design flexibility:◗ 6 Pilot Mount units withdifferent standard bore sizes◗ 6 Standard Bore sizes rangingfrom 15 to 50 millimeters◗ 4 Minimum Bore sizes rangingfrom 0 to 19 millimeters–youmachine and assemble◗ BW is equipped with ThrustBearings and a Single Key SplinedHub.◗ B-275 is equipped with Sealed,Radial Bearings and a Multi-tooth,Involute Spline.◗ METRIC SERIES FRICTION CLUTCHES, PILOT MOUNT ONLYStandard Bore Clutch:Speeds MIN. Shaft Heat SinkProduct Up to Bore Insertion into Hub Capacity Shipping Wt.Model Number RPM (mm) Key Size from Pilot Side (Joules) (kg)BW 950700 3600 15 5 x 5 38 7660 1,8B-275 950705 3600 15 5 x 5 38 7660 1,8F-450 950050 3600 20 6 x 6 51 41000 4,7L-600 950150 3600 25 7 x 8 64 81000 7,8M-800 950250 1800 40 8 x 12 95 149000 17H-1000 950350 1800 50 9 x 14 102 312000 28Keys are included.Minimum Bore Clutch:Minimum bore <strong>clutches</strong> are supplied unassembled with machinable hubs.Speeds MIN. Shaft Heat SinkProduct up to MIN. Bore Insertion into Hub Capacity Shipping Wt.Model Number RPM (mm) from Pilot Side (Joules) (kg)F-450 950061 3600 0 51 41000 4,7L-600 950161 3600 13 64 81000 7,8M-800 950261 1800 18 95 149000 17H-1000 950361 1800 19 102 312000 28◗ TORQUE VS. AIR PRESSUREStatic Torque in NmBW, B-275, F-450 & L-60048403224168L-600F-450B-275BWStatic Torque in Nm36030024018012060M-800 & H-1000H-1000M-8000 1 2 3 4 5 6Air Pressure in BarTorque (In. Lbs.) = Nm x 8.849PSI = Bar ÷ .06890 1 2 3 4 5 6Air Pressure in Bar38

Table of Contents“Air Champ” ®CLUTCHES ◗BW, B-275 PILOT MOUNT - APPROXIMATE DIMENSIONS (MILLIMETERS)PRODUCTKEYNUMBER AC AE AF D H7 (SQ) KL LD LE LG LH LK M S T N h8950700 73 25 30 15 5 16 89 3 13 13 5 63 M5 6 54950705 73 25 30 15 5 16 89 3 13 13 5 63 M5 6 54F-450, L600, M-800 & H-1000 PILOT MOUNT - APPROXIMATE DIMENSIONS (MILLIMETERS)Ø M 2S 26 A T 6 0 °S E T S C R E W S2 A T 9 0 °K E YL H 1T 1L EK LL DNN 2N 1A EDA CS 1 Ø M 14 A T 9 0 °L H 2T 2. 250 B S P TL G ( D I S E N G A G E D )L G 1 ( M A X E N G A G E D )A I R I N L E TMODELPRODUCTNUMBERSETAC AE D H7 KEY KL LD LE LG LG1 LH1 LH2 M1 M2 N1 h8 N2 h8 S1 S2 T1 T2 SCREWSF-450 950050L-600 950150M-800 950250H-1000 950350116 35 20 6 SQ 27 121 6 34 36 26 31 78.00 101.60 62.00 88.87 M6 M5 15 5 M6154 47 25 8 x 7 35 141 6 41 43 31 39 90.00 139.70 75.00 114.27 M6 M5 16 2 M6D205 67 40 12 x 8 43 186 10 46 50 42 58 120.00 165.10 100.00 139.67 M8 M6 19 16 M10256 83 50 14 x 9 65 216 9 49 54 50 73 144.00 228.60 120.00 180.31 M10 M6 37 3 M10NOTE: Drawings are expressed in third angle projection.39

Table of Contents◗CLUTCHES“Air Champ” ®XHW, EXTRA HEAVY-WEIGHTMODEL FRICTION CLUTCHThe XHW Friction Clutch provides:◗ Static Torque capacity up to5000 In. Lbs. @ 80 psi◗ Maximum Operating Speed up to1200 rpm◗ Transmitted Horsepower valuesfrom 5.00 to 50.00◗ Thermal Horsepower rating of2.25 @ 1200 rpm◗ Heat Sink capacity of 200,000 Ft.Lbs.2 Models offer design flexibility:◗ 1 Sheave Mount unit in a5-“5V” Groove design◗ 1 Pilot Mount unit◗ Standard Bore size of 2.375inches◗ Customize the bore to your shaftdiameter with a Bushing orCoupling Half◗ 8.25 inch hose included.◗ TORQUE VS. AIR PRESSUREStatic Torque in Inch-Pounds50004375375031252500187512506250 10 20 30 40 50 60 70 80XHW◗ XHW MODEL CLUTCHProduct Bore Key Size Shipping Wt.Clutch Style Number Sheave Diameter (In) (SQ) (Lbs)Pilot Mount 811100 -- 2.375 0.625 110Sheave Mount, 5-“5V” 810900 8.00 OD 2.375 0.625 110Pilot w/Coupling Half Select a Pilot Mount and a Coupling Half to achieve this style of mount.For Inertia Values of components, see page 359.Keys are included. Required shaft insertion into clutch hub = minimum of 5.625 inches from Pilot side.◗ BUSHING OPTIONS (FOR 2.375 BORE CLUTCHES ONLY)Bushings fit within the bore of the existing clutch, reducing it to the amount indicated.Product Reduces Clutch Shipping Wt.Number Bore Size to (In) (Lbs)811800 1.625 4811900 1.688 4811200 1.750 4811300 1.875 4811400 1.938 4812200 2.125 4811500 2.188 4811600 2.250 4812000 No Bore/Customer machines 4◗ COUPLING HALF OPTIONS, SEE PAGE 367 FOR COUPLING SPECIFICATIONSA Coupling Half used for in-line applications. To achieve a Pilot Mount withCoupling Half mounting configuration:1. Select a Pilot Mount Clutch from above;2. Order Clutch and Coupling Half separately.3. Coupling Half is less taper lock bushing. Use Dodge Taper Lock ® #3030(1.500–3.000 inch bore range). Customer furnished.Product Maximum Shipping Wt.Number Bore Size (In) (Lbs)811700 3.000 63◗ PULLEYS, SPROCKETS AND GEARSThese can be attached to the clutch for offset shaft applications. Tapped holes areprovided for ease of mounting. Nexen does not furnish these items.For minimum sprocket requirements, see page 369.Air Pressure in PSINOTE: Dynamic torque is approximately 85%of static torque.40

Table of Contents“Air Champ” ®CLUTCHES ◗XHW MODEL CLUTCH - APPROXIMATE DIMENSIONS (INCHES)◗ PILOT MOUNTS E T S C R E W S1 O V E R K E Y W A Y2 A T 1 2 0 °K E YC WB BC SK LC RC ZØ 0 . 5 0 ( F O RT O R Q U E P I N )A KP AUPØ A JB F 6 A T 6 0 °. 1 2 5 N P T A I R I N L E TPRODUCT KEY SET +.001NUMBER AJ AK ±.001 BB BF CR CS CT CW CZ KL (SQ) P PA SCREWS U -.000811100 8.500 6.997 1.94 .625-11 10.25 0.38 1.12 2.47 1.09 3.81 0.625 11.06 3.35 .375-16 2.3754 5 °C T8 . 2 5 " F L E X I B L EH O S E◗ PILOT MOUNTW/COUPLING HALFC WC W 1C RP BP AT A P E RL O C KC XC O U P L I N GS H A F TCOUPLINGPRODUCTDODGENUMBER CR CW CW1 CX PA PB TAPER LOCK ®P I L O T M O U N TC L U T C H S H A F T811700 14.72 1.63 6.69 1.47 6.00 10.00 #3030◗ SHEAVE MOUNTC YC XC X 1O DPRODUCT SHEAVENUMBER BELT GROOVE OD CX CX1 CY810900 “5V” 5 8.00 1.03 0.69 0.5341

Table of Contents◗CLUTCHES“Air Champ” ®FW, LW, MW & HWMODEL SERIESThe design of this Series FrictionClutches has been improved:◗ The comparable replacement canbe found in each table◗ Accessories for FW, LW, MW &HW Friction Clutches can befound on the comparable Clutchcatalog page.◗ Torque values are the same asthe replacement <strong>clutches</strong>.◗ FW, FLY-WEIGHT MODEL CLUTCH SERIESProduct Clutch Sheave Bore Shipping Comparable ComparableNumber Style DIA (IN) Wt. (Lbs) Model Product Number802300 Pilot Mount -- 0.875 7 F-450 802850802311 Pilot Mount -- 0.750 7 F-450 802855801900 Sheave Mount, 1-“3V” 3.35 OD 0.875 7 F-450 802810802200 Sheave Mount, 1-“3V” 4.50 OD 0.875 8 F-450 802820802100 Sheave Mount, 1-“A” 3.80 PD 0.875 8 F-450 802830-- Sheave Mount, 1-“A” 4.40 PD 0.875 -- F-450 802840Required shaft insertion into clutch hub = minimum of 2.00 inches from Pilot side.◗ LW, LIGHT-WEIGHT MODEL CLUTCH SERIESProduct Clutch Sheave Bore Shipping Comparable ComparableNumber Style DIA (IN) Wt. (Lbs) Model Product Number804513 Pilot Mount -- 1.000 11 L-600 805275804500 Pilot Mount -- 1.125 11 L-600 805270803900 Sheave Mount, 2-“3V” 4.50 OD 1.125 13 L-600 805210804000 Sheave Mount, 2-“3V” 5.30 OD 1.125 14 L-600 805220-- Sheave Mount, 2-“3V” 6.00 OD 1.125 -- L-600 805230-- Sheave Mount, 2-“3V” 8.00 OD 1.125 -- L-600 805240804300 Sheave Mount, 2-“A” 4.40 PD 1.125 13 L-600 805250-- Sheave Mount, 2-“A” 5.40 PD 1.125 -- L-600 805260Required shaft insertion into clutch hub = minimum of 2.50 inches from Pilot side.◗ MW, MIDDLE-WEIGHT MODEL CLUTCH SERIESProduct Clutch Sheave Bore Shipping Comparable ComparableNumber Style DIA (IN) Wt. (Lbs) Model Product Number806600 Pilot Mount -- 1.625 26 M-800 807650806612 Pilot Mount -- 1.437 26 M-800 807655806100 Sheave Mount, 3-“3V” 5.30 OD 1.625 27 M-800 807610-- Sheave Mount, 3-“3V” 6.00 OD 1.625 -- M-800 807620806400 Sheave Mount, 2-“B” 5.80 PD 1.625 29 M-800 807630-- Sheave Mount, 2-“B” 6.80 PD 1.625 -- M-800 807640Required shaft insertion into clutch hub = minimum of 3.75 inches from Pilot side.◗ HW, HEAVY-WEIGHT MODEL CLUTCH SERIESProduct Clutch Sheave Bore Shipping Comparable Comparableumber Style DIA (IN) Wt. (Lbs) Model Product Number809100 Pilot Mount -- 1.875 48 H-1000 810050809111 Pilot Mount -- 1.687 48 H-1000 810055808600 Sheave Mount, 3-“5V” 7.10 OD 1.875 55 H-1000 810010-- Sheave Mount, 3-“5V” 8.00 OD 1.875 -- H-1000 810020808900 Sheave Mount, 3-“B” 7.40 PD 1.875 60 H-1000 810030-- Sheave Mount, 3-“B” 8.60 PD 1.875 -- H-1000 810040Required shaft insertion into clutch hub = minimum of 4.00 inches from Pilot side.42

Table of Contents“Air Champ” ®CLUTCHES ◗DUAL PLATE FRICTION CLUTCH SELECTION CHARTFriction clutch recommendation is based upon air pressure of 50 psi, transmitted horsepower and speed.RPM100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800TRANSMITTED HORSEPOWER57 1 ⁄ 21015202530405075100125150DPC-9TDPC-11TDPC-11TDPC-9TDPC-9TDPC-13T DPC-11T DPC-9T DPC-9TDPC-13T DPC-11T DPC-11T DPC-9T DPC-9TDPC-15T DPC-13T DPC-11T DPC-11T DPC-9T DPC-9T DPC-9TREFER TO FRICTION CLUTCH PRODUCTS ON PAGE 30 FOR SPECIFICATIONSIN THIS AREA OR HORSEPOWER RATINGS LESS THAN 5DPC-15T DPC-13T DPC-11T DPC-11T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9TDPC-15T DPC-13T DPC-13T DPC-11T DPC-11T DPC-11T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9TDPC-15T DPC-13T DPC-13T DPC-11T DPC-11T DPC-11T DPC-11T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9TDPC-15T DPC-15T DPC-13T DPC-13T DPC-13T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9T DPC-9TDPC-15T DPC-15T DPC-13T DPC-13T DPC-13T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-9TDPC-15T DPC-15T DPC-15T DPC-13T DPC-13T DPC-13T DPC-13T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11TDPC-15T DPC-15T DPC-15T DPC-15T DPC-13T DPC-13T DPC-13T DPC-13T DPC-13T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11T DPC-11TIMPORTANT NOTES:1. For static torque ratings at different air pressures, refer to individual models to ensure conformity.2. For operating speeds over 1800 rpm, refer to individual models or consult Nexen to ensure conformity.3. Limited to peak thermal input rates of .9 HP T per square inch of interface area.4. Bars equal PSI x 0.0689.43

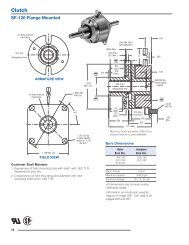

Table of Contents◗CLUTCHES“Air Champ” ®DPC SERIESDUAL PLATE CLUTCHESThis Series, specified bycomponent, allows you to customdesign for specific applicationrequirements:◗ Static Torque capacity up to36,000 In. Lbs. @ 80 psi◗ Maximum Operating Speed up to2200 rpm◗ Thermal Horsepower values of3.3 to 9.0 at rated speeds◗ Components combine in a varietyof options to fit almost any need◗ Choose from Thru-Shaft orShaft-End Mounting◗ Choose between Sheave or Pilotstyle configurations◗ Rotary Air Union is included witheach Clutch Assembly.With the DPC Model Series, toughapplications are made easy. Each ofthe 4 Models and their manyoptions are detailed on the next fewpages.The DPC Series Clutches are designed for applications involving high inertia startsand stops. The Peak Input Rate may be the limiting factor in high inertia starts orstops, even though the Heat Sink Capacity is sufficient. The Peak Input Rate capacityis the rate at which the clutch absorbs heat at the <strong>friction</strong> interface during theacceleration period, while the interfaces are slipping or until the load and clutch areoperating at the same speed. See page 368 in the Engineering Data Section forinformation explaining how to calculate the Peak Input Rate and how to avoidpotential problems.◗ HOW TO SPECIFY AND ORDER DPC CLUTCHES:1. Determine if you require Shaft-End Mounting or Thru-Shaft Mounting;2. Determine if you require a Pilot Mount or Sheave Mount configuration;3. Determine which bore size you will need;4. Order each component individually, based upon your requirements.◗ MOTOR FRAME, SHAFT DIAMETERS & LENGTHSThis chart can be used for quick selection of many criteria.If you are using a standard motor frame and are within the rpm and horsepowerrequirements, the chart indicates a clutch and shaft to use.If you know the rpm, horsepower and desired clutch, the chart will indicate astandard motor frame and shaft to use.HORSEPOWER 600RPM 900RPM 1200RPM 1800RPM50 DPC13T DPC11T DPC9T DPC9TMotor Frame 445T 404T 365T 326TShaft DIA./LGTH 3.375 / 8.25 2.875 / 7.0 2.375 / 5.625 2.125 / 5.060 -- DPC11T DPC11T DPC9TMotor Frame -- 405T 404T 364TS, 364TShaft DIA./LGTH -- 2.875 / 7.0 2.875 / 7.0 2.375 / 5.62575 DPC13T DPC13T DPC11T DPC9TMotor Frame D5005 444T 405T 365TS, 365TShaft DIA./LGTH 3.5/ 10.25 3.375 / 8.25 2.875 / 7.0 2.375 / 5.625100 DPC15T DCP13T DPC13T DPC11TMotor Frame D5008 445T 444T 405TS, 404TShaft DIA./LGTH 4.0 / 11.75 3.375 / 8.25 3.375 / 8.25 2.875 / 7.0125 -- DPC13T DPC13T --Motor Frame -- D5005 444T --Shaft DIA./LGTH -- 3.5/ 10.25 3.375 / 8.25 --150 -- DPC15T DPC13T --Motor Frame -- D5005 445T, D5005 --Shaft DIA./LGTH -- 3.5/ 10.25 3.5/ 10.25 --◗ CLUTCH APPLICATION DATAMODEL DPC-9T DPC-11TPeak Input Rate 50 hp 84 hpEffective Friction Areas 55 in 2 93 in 2MODEL DPC-13T DPC-15TPeak Input Rate 131 hp 149 hpEffective Friction Areas 145 in 2 166 in 2◗ TORQUE VS. AIR PRESSUREStatic Torque in Inch-PoundsDPC-9T & DPC-11T12000105009000750060004500300015000 10 20 30 40 50 60 70 80DP-11TDP-9TStatic Torque in Inch-PoundsDPC-13T & DPC-15T40000DPC-15T35000300002500020000DPC-13T150001000050000 10 20 30 40 50 60 70 80Air Pressure in PSIAir Pressure in PSINOTE: Dynamic torque is approximately 85% of static torque.44

Table of Contents“Air Champ” ®CLUTCHES ◗◗ CLUTCH ASSEMBLYROTARY AIR UNION(SUPPLIED WITHCLUTCH ASSEMBLY)◗ DPC CLUTCHESShown are the typical components of aDPC Clutch:SHEAVE◗ SHAFT-END MOUNTINGSUPPORTBUSHINGCLUTCHASSEMBLYENDCAPQDBUSHINGAIR INLET◗ The Clutch Assembly comes with theRotary Air Union◗ Rotary Air Union, supplied with eachclutch, is required for both Shaft-End and Thru Shaft mounting◗ The optional End Cap is onlyrequired for Shaft-End Mounting◗ The customer supplied QD Bushingis required for both Shaft-End andThru-Shaft Mounting◗ The Support Bushing is usedwhenever the shaft size is less thanthe maximum clutch bore.AIR INLET CONNECTION:1. Attach the End Cap to the end of the Hubwith three cap screws.2. Install the Rotary Air union and elbowfittings in the End Cap.3. Connect the cylinder hoses to the elbowfittings.AIR INLET4. Use the flexible hose (supplied) toconnect air supply to the Rotary Air Union(do not use rigid pipe or tubing for thisconnection).5. Make sure that of these hoses do notinterfere with the rotating parts of the unit.◗ MOUNTING/AIR INLETCONNECTIONSDPC Clutches are very flexible unitsbecause of their many mounting possibilities.Four of the more common applicationsare shown at left. Also refer to the AirInlet Connection information (at left)for each mounting style.◗ THRU-SHAFT MOUNTINGAIR INLET CONNECTION:1. Drill a 0.375 inch diameter hole in thecenter of the shaft, long enough to reachthe air outlets.2. Tap drill the air outlet holes straightthrough the shaft, intersecting the 0.375diameter hole, and tap the 0.125-27 NPTon both ends.3. The air outlet holes should be located0.375 of an inch from the end of the Hub.4. Tap a .625-18 inch hole, 0.625 inchesdeep in the end of the shaft for the RotaryAir Union.5. Install the two elbow fittings in the airoutlet holes and connect the cylinderhoses to them.6. Install the Rotary Air Union in the end ofthe shaft and use the flexible hose(supplied) to connect the air supply to theshaft (do not use rigid pipe or tubing forthis connection).45

Table of Contents◗CLUTCHES“Air Champ” ®DPC-9T MODELDUAL PLATE CLUTCHThis Model, specified bycomponent, allows you to customdesign for specific applicationrequirements:◗ Static Torque capacity up to5500 In. Lbs. @ 80 psi◗ Maximum Operating Speed up to2200 rpm◗ Thermal Horsepower ratings upto 3.3 @ 2200 rpm◗ Pilot Mount clutch assemblywith standard support bushingbore of 2.375 inches◗ Sheave options: 5-“5V” or 4-“C” Groove◗ Support Bushings provide 6additional bore sizes rangingfrom 1.87 to 2.125 inches◗ Heat Sink capacity of 220,000 Ft. Lbs.◗ 8.25 inch hose included◗ Rotary Air Union is supplied withthe clutch assemblyReview the information on this andthe next page to determine therequired components to build yourclutch.REQUIRED COMPONENTS:Shaft-End Thru-ShaftMounting Mounting1 Clutch 1 ClutchAssembly Assembly1 End Cap 1 QD Bushing1 QD Bushing(QD Bushing customer furnished)OPTIONAL COMPONENTS:Shaft-EndMountingThru-ShaftMounting1 Support 1 SupportBushing Bushing1 Sheave 1 Sheave◗ DPC-9T, DUAL PLATE CLUTCHProduct Support Bushing Shaft Insertion Shipping Wt.Clutch Component Number Bore (O.D.)(In) MIN. MAX. (Lbs)Shaft-End Mounting (1 of each required)Clutch Assembly 960200 2.375 4.69 6.57 64End Cap 960700 -- -- -- 3QD Bushing Customer Supplied SK Bore Range = 0.500 - 2.375 inchesThru-Shaft Mounting (1 of each required)Clutch Assembly 960200 -- -- -- 64QD Bushing Customer Supplied SK Bore Range = 0.500 - 2.375 inches◗ SUPPORT BUSHING/BORE OPTIONSSupport Bushings are used to reduce the clutch bore for the driven shaft.Product Reduce Bore Shipping Wt.Clutch Component Number Size to/ (In) (Lbs)Support Bushing 960419 1.187 1Support Bushing 960423 1.437 1Support Bushing 960427 1.687 1Support Bushing 960430 1.875 1Support Bushing 960431 1.937 1Support Bushing 960434 2.125 1Bushing-Blank/No Bore 960400 1.131 ID MIN. 1◗ SHEAVE OPTIONSProduct Type of Shaft Insertion Shipping Wt.Clutch Component Number Sheave Groove MIN. MAX. (Lbs)Sheave, “5V” 956700 8.0 OD, 5-“5V” 5.32 7.20 16Sheave, “4C” 960600 9.0, OD, 4 “C” 5.51 7.39 22◗ PULLEYS, SPROCKETS, GEARSThese can be attached to the clutch for thru-shaft applications. Tapped holes areprovided for ease of mounting. Nexen does not supply these items.For minimum sprocket requirements, see page 369.◗ TORQUE VS. AIR PRESSUREStatic Torque in Inch-Pounds600050004000300020001000DPC-9T0 10 20 30 40 50 60 70 80Air Pressure in PSIDP-9TNOTE: Dynamic torque is approximately 85% of static torque.46

Table of Contents“Air Champ” ®CLUTCHES ◗DPC-9T, DUAL PLATE CLUTCH - APPROXIMATE DIMENSIONS (INCHES)◗ PILOT MOUNTC WC R 1C RQ DB U S H I N GB BE N DC A PPA KUC T. 2 5 0 N P TA I R I N L E T8 . 2 5 " F L E X I B L E H O S EB F6 A T 6 0 ° Ø A JS U P P O R TB U S H I N GS H A F TI N S E R T I O NW I T H E N D C A PH U B L E N G T HCLUTCHPRODUCT HUB SHAFT INSERTION +.002NUMBER AJ AK ±.001 BB BF CR CR1 CT CW P LENGTH MIN. MAX. U -.000960200 5.562 4.874 0.75 .375-16 7.42 10.76 0.38 1.62 10.75 6.82 4.69 6.57 2.375◗ SHEAVE MOUNT; CLUTCH AND SHEAVE COMBINEDO DP DC YC XC X 1SHEAVEPRODUCT SHEAVENUMBER BELT GROOVE OD PD CX CX1 CY956700 “5V” 5 8.00 -- 0.50 0.69 0.63960600 “C” 4 9.00 8.60 0.56 1.00 0.8247