Clemtex Parts Catalog

Clemtex Parts Catalog

Clemtex Parts Catalog

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CLEMTEX<br />

Corrosion Control<br />

Equipment and Supplies<br />

<strong>Parts</strong> <strong>Catalog</strong><br />

Products Manufactured by:<br />

<strong>Clemtex</strong> • Clemco • Bullard • DeVilbiss<br />

Binks • Graco • Zero • Econoline<br />

RPB/Nova • Reed • Green Diamond<br />

DeFelsko •ElektroPhysik<br />

COMPLETE — DEPENDABLE — KNOWLEDGEABLE<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

1-800-CLEMTEX<br />

www.clemtex.com<br />

clemtex@clemtex.com

CLEMTEX<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

!<br />

Nozzle<br />

Orifice<br />

No. 2<br />

(1/8")<br />

No. 3<br />

(3/16")<br />

No. 4<br />

(1/4")<br />

No. 5<br />

(5/16")<br />

No. 6<br />

(3/8")<br />

No. 7<br />

(7/16")<br />

No. 8<br />

(1/2")<br />

Nozzle<br />

No. 4<br />

No. 5<br />

No. 6<br />

No. 7<br />

No. 8<br />

Compressed Air and Abrasive Consumption<br />

Pressure at the Nozzle (psi)<br />

50 60 70 80 90 100<br />

Air, Abrasive and<br />

HP Requirements<br />

11 13 15 17 18.5 20 Air (cfm)<br />

0.67 0.77 0.88 1.01 1.12 1.23 Abrasive (cu.ft./hr<br />

67 77 88 101 112 123 & lbs/hr)<br />

2.5 3 3.5 4 4.5 5 Compressor hp<br />

26 30 33 38 41 45 Air (cfm)<br />

1.5 1.71 1.96 2.16 2.38 2.64 Abrasive (cu.ft./hr<br />

150 171 196 216 238 264 & lbs/hr)<br />

6 7 8 9 10 10 Compressor hp<br />

47 54 61 68 74 81 Air (cfm)<br />

2.68 3.12 3.54 4.08 4.48 4.94 Abrasive (cu.ft./hr<br />

268 312 354 408 448 494 & lbs/hr)<br />

11 12 14 16 17 18 Compressor hp<br />

77 89 101 113 126 137 Air (cfm)<br />

4.68 5.34 6.04 6.72 7.4 8.12 Abrasive (cu.ft./hr<br />

468 534 604 672 740 812 & lbs/hr)<br />

18 20 23 26 28 31 Compressor hp<br />

108 126 143 161 173 196 Air (cfm)<br />

6.68 7.64 8.64 9.6 10.52 11.52 Abrasive (cu.ft./hr<br />

668 764 864 960 1052 1152 & lbs/hr)<br />

24 28 32 36 39 44 Compressor hp<br />

147 170 194 217 240 254 Air (cfm)<br />

8.96 10.32 11.76 13.12 14.48 15.84 Abrasive (cu.ft./hr<br />

896 1032 1176 1312 1448 1584 & lbs/hr)<br />

33 38 44 49 54 57 Compressor hp<br />

195 224 252 280 309 338 Air (cfm)<br />

11.6 13.36 15.12 16.8 18.56 20.24 Abrasive (cu.ft./hr<br />

1160 1336 1512 1680 1856 2024 & lbs/hr)<br />

44 50 56 63 69 75 Compressor hp<br />

System Air Volume Requirements at 100 psig<br />

Material<br />

Orifice<br />

Size<br />

Volume<br />

of Air<br />

Plus<br />

Helmet<br />

Plus 50%<br />

(reserve)<br />

Minimum<br />

Air Required<br />

1/4" 81 20 50 151 cfm<br />

6.5mm 2.3 0.5 1.4 4.2 m 3 /min<br />

5/16" 137 20 79 236 cfm<br />

8.0mm 3.9 0.5 2.2 6.6 m 3 /min<br />

3/8" 196 20 108 324 cfm<br />

9.5mm 5.5 0.5 3 9.0 m 3 /min<br />

7/16" 254 20 137 411 cfm<br />

11.0mm 7.2 0.5 3.9 11.6 m 3 /min<br />

1/2" 338 20 179 537 cfm<br />

12.5mm 9.6 0.5 5 16.1 m 3 /min<br />

Mesh<br />

Size<br />

Shape<br />

Abrasive Comparison<br />

! !<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

Density<br />

lbs/ft 3 Mohs Friability Source<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

!<br />

I.D.<br />

Pressure Production<br />

Loss Loss<br />

3/4" 1.1 psi 16.6%<br />

1" 2.4 psi 3.6%<br />

1-1/4" 0.7 psi 1.0%<br />

1-1/2" 0.2 psi 0.3%<br />

Nozzle Orifice Size<br />

Increase in Air<br />

Consumption<br />

No. 4 1/4" 6.5mm<br />

No. 5 5/16" 8.0mm 60% more than No. 4<br />

No. 6 3/8" 9.5mm 38% more than No.5<br />

No. 7 7/16" 11.0mm 36% more than No. 6<br />

No. 8 1/2" 12.5mm 33% more than No. 7<br />

Typical<br />

Applications<br />

Slag 8-80 Angular 85-112 7.0-7.5 high By-Product Outdoor blast cleaning<br />

Steel Grit<br />

10-<br />

325<br />

Angular 230 8.0 low Manufactured Removing heavy scale<br />

Steel Shot 8-200 Spherical 280 8.0 low Manufactured Cleaning, Peening<br />

Al. Oxide<br />

Glass<br />

Beads<br />

12-<br />

325<br />

10-<br />

400<br />

Angular 125 8.9-9.0+ med Manufactured<br />

Cleaning, Finishing,<br />

Deburring, Etching<br />

Spherical 85-90 5.5 med Manufactured Cleaning, Finishing<br />

Garnet 12-80 Angular 45-60 3.0-4.0 low/med Manufactured<br />

Green<br />

Lightening<br />

120 Angular 115 7.0 med Natural<br />

Corn Cob 8-40 Angular 35-45 2.0-4.5 med By-Product<br />

Pressure Loss in Air Hose<br />

Minimum Compressor Air Line Sizes<br />

The importance of nozzle pressure is illustrated<br />

above. Proper nozzle pressure (90-100 psi)<br />

results in high production cleaning and low<br />

abrasive use in the same amount of time.<br />

Paint Stripping,<br />

Deflashing, Cleaning<br />

Paint Stripping,<br />

Cleaning<br />

Removing paint from<br />

delicate surfaces<br />

Minimum Compressor<br />

Air Line Sizes<br />

Nozzle<br />

No. 3<br />

No. 4<br />

No. 5<br />

No. 6<br />

No. 7<br />

No. 8<br />

No. 10<br />

No. 12<br />

Nozzle<br />

Orifice<br />

Size<br />

Minimum<br />

Air Line<br />

ID<br />

3/16" 1"<br />

5.0mm 25.0mm<br />

1/4" 1"<br />

6.5mm 25.0mm<br />

5/16" 1-1/4"<br />

8.0mm<br />

32.0mm<br />

3/8" 1-1/2"<br />

9.5mm 38.0mm<br />

7/16" 2"<br />

11.0mm 50.0mm<br />

1/2" 2"<br />

12.5mm 50.0mm<br />

5/8" 2-1/2"<br />

16.0mm 64.0mm<br />

3/4" 3"<br />

19.0mm 76.0mm<br />

“We stock the most complete line of Corrosion-

!<br />

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

Corrosion Control<br />

Equipment and Supplies<br />

10 Essential Components to Succeed in<br />

Todayʼs Economy!<br />

1. Compressed Air ......................................... 2!<br />

2. Air Supply Hose ......................................... 2!<br />

3. Moisture ..................................................... 3!<br />

4. Blast Machine ............................................ 3!<br />

5. Blast Hose.................................................. 4!<br />

6. Blast Nozzle ............................................... 4!<br />

7. Abrasive ..................................................... 5!<br />

8. Operator Comfort and Safety ..................... 5!<br />

9. Blaster Technique ...................................... 6!<br />

10. Supervision and Communication ............. 6!<br />

Blasting Abrasives .......................................... 7!<br />

<strong>Clemtex</strong> Anchor Pattern Standards................ 8!<br />

Couplings and Blast Hose .............................. 9!<br />

Nozzles ........................................................... 10!<br />

Blast Machines!<br />

6 Bag & 3 Bag Blast Machine - Clemco....... 11!<br />

TLR 100/300 Remote Control Systems........ 12!<br />

Exhaust Muffler......................................... 12!<br />

1-1/2” Inlet Valve ...................................... 13!<br />

1” Inlet Valve............................................. 13!<br />

Abrasive Trap ........................................... 14!<br />

1” Diaphragm Outlet Valve ....................... 14!<br />

1” Piston Outlet Valve............................... 14!<br />

Combo Valve: 2223-002........................... 15!<br />

Schmidt G2 Deadman Valve .................... 15!<br />

Abrasive Metering Valves ............................ 16!<br />

Flat Sand Valve: FSV02427 ..................... 16!<br />

Micro Valve: 2127-108.............................. 17!<br />

Sentinel Valve........................................... 18!<br />

<strong>Clemtex</strong> Bulk Machine ................................. 20!<br />

Pneumatic Remote Controls..................... 21!<br />

Electric Remote Controls.......................... 21!<br />

Pinch Valve: CLCPV................................. 22!<br />

Schmidt 3.5-10 cf Blast Pot.......................... 23!<br />

Thompson Valve Large Bore.................... 24!<br />

Thompson II Valve: 2152-007 .................. 25<br />

Table of Contents<br />

!<br />

Internal Diameter Blast Equipment!<br />

Heavy Duty Spinblast Tool: SB-636-B ..........26!<br />

Spinblast Tool: SB-636-A..............................27!<br />

Holloblast Tool: HBS01076...........................28!<br />

Holloblast Junior: HBJ01098.........................29!<br />

Respiratory Equipment!<br />

Clemco Apollo Hood (Red) ...........................30!<br />

CPF 20/80 Particulate Air Filter.................31!<br />

CPF 20 Cap...............................................32!<br />

CPF 80 Cap...............................................32!<br />

Bullard 88VX (Yellow Hood) .........................33!<br />

Bullard 41 Series Airline Filter ...................36!<br />

RPB Nova 2000 (Green Hood) .....................37!<br />

RPB Radex Filter.......................................37!<br />

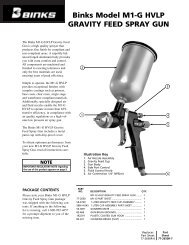

Paint Guns!<br />

Devilbiss MBC-510 .......................................39!<br />

Devilbiss JGA-510 ........................................41!<br />

Devilbiss EGA-503........................................44!<br />

Binks 2100 ....................................................45!<br />

Binks 115 ......................................................47!<br />

Binks Mach 1 ................................................48!<br />

Graco Silver Plus ..........................................51!<br />

Internal Diameter Paint Equipment!<br />

HDCBX-360-2 and HDCBX-360-112 ............59!<br />

HDCBX-360-3 ...............................................59!<br />

HDCBX-360-4 ...............................................60!<br />

HDCBX-360-5 ...............................................60!<br />

Paint Tanks!<br />

Binks 83C Pressure Tank .............................61!<br />

Binks 81-800: 1 Qt. Drip Cup........................63!<br />

Binks 80-295: 2 Qt. Pressure Cup ................64!<br />

Control Equipment and Supplies in the Southwest.”

CLEMTEX<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

10 Essential Components to Succeed in Todayʼs Economy<br />

In today’s business environment, if you’re standing still, you’re moving backwards!<br />

Pursuing the details yields efficiency and competitiveness. Here is a list of the 10<br />

Essential Blasting Components.<br />

1. Compressed Air<br />

!"#$%&'((&)*+,&-./*&01+2/&03/&1.45&.6&7(&)*+,!<br />

Pressure + Volume = Cost Effective<br />

NPG-100<br />

PBAG<br />

Does your compressor maintain pressure<br />

How much air does it TRULY produce<br />

See Page 2 for importance of air pressure<br />

2. Air Supply Hose<br />

!"#$%&'()*&+,&-./*0)12*/&34.&0*)50135&60*))-0*&78&9:;!<br />

Large Nozzle + Large Hose<br />

= High Production<br />

Small hose + Large Nozzle<br />

= Low Production<br />

See Page 2 for importance of air pressure<br />

2 “We stock the most complete line of Corrosion-

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

Corrosion Control<br />

Equipment and Supplies<br />

3. Moisture<br />

!"#$%&#'()*+,,'*,&-+.+*/0+&1+/0&2134+&5'()*+,,3.-&/3*6&<br />

$1+*+&7899&:+&('3,0;*+&3.&

CLEMTEX<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

5. Blast Hose<br />

!"#$%&'())*+&,-)+&.+/+01-2+3&4*53/&6(3+&,-)+!<br />

Large Blast Hose + Small Nozzle<br />

= Loss of Production<br />

Small Blast Hose + Large Nozzle<br />

= Loss of Production<br />

Long Runs of Blast Hose = Loss<br />

in Pressure & Production<br />

See Pressure Drop Information on Page 2<br />

6. Blast Nozzle<br />

!"#$%&"&'())*+&,(-'&./.01&*2-3+-&452'&(-636'2*&76)+&,6**&<br />

89#:9";9&!"#$%&'#()@AB!<br />

Worn Nozzle will yield:<br />

- Increased air consumption<br />

- Increased abrasive consumption<br />

- Increased labor costs<br />

- Decreased abrasive velocity<br />

Test your nozzle<br />

with PBAG and<br />

NPG-100 gauges.<br />

See Nozzles on Page 10<br />

4 “We stock the most complete line of Corrosion-

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

Corrosion Control<br />

Equipment and Supplies<br />

7. Abrasive<br />

!"#$%&'(()*+&,)-./.&"0)-123/&42**&56#76"86&9*/-:2:;&<br />

)-#76"86&-2:

CLEMTEX<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

9. Blaster Technique<br />

!"#$%&'()**&+,&-./&0*12345&6788&9:1(/;&+

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

Corrosion Control<br />

Equipment and Supplies<br />

"#$%&!"'$()*!<br />

"#$%&!"'$()*!+,!$!-+.'/$#!,#$0!)1$)!1$,!,1$/2!<br />

3+$-4.35#+&'!%())+.0!'30',6!$.3!34',!.4)!$))/$%)!<br />

-4+,)(/'6!71+#'!2/48+3+.0!9$,)!%#'$.+.0!/$)',6!$.3!<br />

$.!':%'##'.)!$.%14/!2/49+#'!94/!$!,(2'/+4/!%4$)+.0!<br />

$31',+4.;!+,$-'.!!<br />

-'3+(-6!""5!9+.'6!""5@!':)/$!9+.';!/$%&$0120!BBBC!D(#&!D$0,6!=A!)4.!D(#&!#4$3,!<br />

+,''2!31$452-!<br />

F/''.!G+$-4.3!+,!$!-+.'/$#!,#$0!)1$)!1$,!,1$/2!<br />

%())+.0!'30',6!7'##!0/$3'3!$.3!8'/*!%#'$.6!71+#'!<br />

2/48+3+.0!,(2'/+4/!%#'$.+.0!/$)',6!$.3!$!<br />

%4.)$+.-'.)!9/''!,(/9$%'!94/!,(2'/+4/!%4$)+.0!<br />

$31',+4.;!+,$-'.!BBBC!D(#&!D$0,6!=A!)4.!D(#&!#4$3,;!<br />

+,''2!6107)2120!<br />

F/''.!L+01).+.0!+,!$!.$)(/$##*!4%%(//+.0!-+.'/$#!<br />

MN#+8+.'O!)1$)!+,!7'##!0/$3'3!$.3!+,!0'.'/$##*!(,'3!<br />

+.!D#$,)!/44-,!$.3!%$D+.'),;!+,$-'.!@FUS!<br />

H>@!-',1K6!C@BJIBFUS!H@BJIB!-',1K6!CIBVQ!<br />

HIB!-',1K!0/$3'3!,2'%+9+%$##*!94/!7$)'/5W')!%())+.06!CEABFUS!<br />

HEAB!-',1K;!/$%&$0120!@6!CA6!C@B6CIB6!CEBB6!CE=B6!CEAB6!CEIB6!C==B!H9+.'/!<br />

0/$3',!$/'!':%'##'.)!94/!)(/D+.'!D#$3'!%#'$.+.0K;!!/$%&$0120!"!HE=J=B![',1K6!UG5@"!<br />

H=BJB![',1K6!UG5Z"!HBJEBB![',1K;!/$%&$0120!

CLEMTEX<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

<strong>Clemtex</strong> Anchor Pattern Standards<br />

R1'!XU\Q!HX#'-)':!U.%14/!\$))'/.!Q)$.3$/3,K!$/'!3',+0.'3!94/!)1'!2(/24,'!49!$!Y(+%&!9+'#3!+.,2'%)+4.!49!$!<br />

D#$,)5%#'$.'3!,(/9$%'!)4!3')'/-+.'!$.%14/!2$))'/.!3'2)1!7+)1+.!]![+#;!<br />

R1'!$.%14/!2$))'/.!+,!$##5+-24/)$.)!)4!2/4)'%)+8'!%4$)+.0,!+.!)1$)!+)!2/48+3',!':%'##'.)!%4$)+.0!$31',+4.;!^)!+,!<br />

+-24/)$.)!)1$)!)1'!$.%14/!2$))'/.!D'!(.+94/-!48'/!+),!'.)+/'!,(/9$%';!R1+,!+,!$%%4-2#+,1'3!(,+.0!$!%#'$.6!<br />

7'##50/$3'3!4/!,+_'3!$D/$,+8';!!<br />

R1'!%1$/)!+.%#(3'3!7+##!$+3!+.!4D)$+.+.0!)1'!2/42'/!$D/$,+8'!,+_'!,2'%+9+'3;!!<br />

^)!,14(#3!D'!/'-'-D'/'3!)1$)!$D/$,+8'!,+_',!8$/*!$.3!$!%#4,'!+.,2'%)+4.!49!,+_'!)4#'/$.%'!H$22/4:;!EB`K!<br />

,14(#3!D'!-$+.)$+.'36!',2'%+$##*!71'/'!$D/$,+8',!$/'!/'%#$+-'3!$.3!/'5(,'3;!S'%#$+-'3!$D/$,+8',!,14(#3!D'!<br />

$.0(#$/!$.3!.4)!/4(.3'3!$.3!9/''!9/4-!4+#6!0/'$,'6!+/4.!4:+3'6!')%;!#<br />

#<br />

0.5 MIL<br />

2.0 MIL<br />

2.5 MIL<br />

1.0 MIL<br />

1.5 MIL<br />

3.0 MIL<br />

NOTE: 100 psig should be used for those not already stated.<br />

8 “We stock the most complete line of Corrosion-

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

Corrosion Control<br />

Equipment and Supplies<br />

Hose<br />

I.D.<br />

Hose<br />

O.D.<br />

Couplings and Blast Hose<br />

Couplings<br />

Model No.<br />

Brass Aluminum Nylon<br />

1/2" 1-5/32" QCA00599<br />

3/4" 1-1/2" CQB00563 QCA00568 CQP08412<br />

1" 1-7/8" CQB00564 QCA00569 CQP21711<br />

1-1/4" 2-5/32" CQB00565 QCA00570 CQP08414<br />

1-1/2" 2-3/8" CQB00566 QCA00573 CQP07714<br />

1-1/2" 2-3/8" CQB00567 QCA00574*<br />

* NOTE: QCA00574 is for 1-1/2" I.D. x 2-3/8" O.D. hose. It<br />

wil not interconnect with any other quick coupling.<br />

Threaded Quick Couplings<br />

Thead Size Brass Aluminum<br />

1/2" CFA00558<br />

3/4" CFA00559<br />

1-1/4" CFB00551<br />

1-1/2" CFB00553 CFA00561*<br />

2" CFB00555 CFA00556<br />

2" PAC00562*<br />

* NOTE: These are for 1-1/2" I.D. x 2-3/8"<br />

O.D. hose. It wil not interconnect with any<br />

other quick coupling.<br />

Nozzle Holders<br />

Hose Dimensions<br />

Thread Type<br />

I.D. O.D. 50mm 1-1/4" 3/4"<br />

Nylon<br />

3/4" 1-1/2" NHP04106 HEP07720<br />

1" 1-7/8" NHP04127 HEP07721<br />

1-1/4" 2-5/32" NHP04128 HEP07722<br />

Aluminum<br />

1/2" 1-5/32" CHE00577<br />

3/4" 1-1/2" CHE00578<br />

1" 1-7/8" CHE00579<br />

1-1/4" 2-5/32" CHE00580<br />

1-1/2" 2-3/8" CHE00581<br />

I.D.<br />

O.D.<br />

Blast Hose<br />

Maximum<br />

Working<br />

Pressure<br />

Weight<br />

Per 50'<br />

4 Ply<br />

3/4" 1-1/2" 125 PSIG 33 lbs.<br />

1" 1-7/8" 125 PSIG 45 lbs.<br />

1-1/4" 2-5/32" 125 PSIG 57 lbs.<br />

1-1/2" 2-3/8" 100 PSIG 64 lbs.<br />

2-Braid<br />

1/2" 1-5/32" 175 PSIG 23 lbs.<br />

3/4" 1-1/2" 160 PSIG 33 lbs.<br />

1" 1-7/8" 160 PSIG 53 lbs.<br />

1-1/4" 2-5/32" 160 PSIG 63 lbs.<br />

2-Ply SUPA<br />

1-1/4" 1-7/8" 170 PSIG 35 lbs.<br />

Control Equipment and Supplies in the Southwest.” 9

CLEMTEX<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

Short Barrel Nozzles<br />

Used for blast applications where the operator<br />

must work within 12 inches of the surface.<br />

One Inch Entry<br />

Thread: 1!“ Straight Thread<br />

Jacket: Kirksite<br />

Liner: Tungsten Carbide<br />

Length: 3!“<br />

Nozzles<br />

Long Barrel Nozzles<br />

Used for high production jobs where the<br />

operator can blast more than 12” from the<br />

surface.<br />

One Inch Entry<br />

Thread: 1!“ Straight Thread<br />

Jacket: Kirksite<br />

Liner : Tungsten Carbide<br />

Nozzle<br />

Orifice<br />

Size<br />

Part<br />

Number<br />

No. 3 3/16" CJD01378<br />

No. 4 1/4" CJD01379<br />

No. 5 5/16" CJD01380<br />

No. 6 3/8" CJD01381<br />

No. 7 7/16" CJD01382<br />

No. 8 1/2" CJD01383<br />

Nozzle<br />

Orifice<br />

Size<br />

Length<br />

Part<br />

Number<br />

No. 3 3/16" 4" CSD01384<br />

No. 4 1/4" 5-1/4" CSD01385<br />

No. 5 5/16" 5-5/8" CSD01386<br />

No. 6 3/8" 6-1/2" CSD01387<br />

No. 7 7/16" 7-3/4" CSD01388<br />

No. 8 1/2" 8-13/16" CSD01389<br />

CT style<br />

A Tungsten Carbide Lined straight bore nozzle<br />

for use with small suction gun or blast cabinets.<br />

These are also used with model 1028 and 1042<br />

Blast Machines.<br />

Nozzle<br />

Orifice<br />

Size<br />

Part<br />

Number<br />

No. 2 1/8" CTO01351<br />

No. 3 3/16" CTO01352<br />

No. 4 1/4" CTO01353<br />

No. 5 5/16" CTO01354<br />

No. 6 3/8" CTO01355<br />

No. 8 1/2" CTO01356<br />

CAM style<br />

An angled nozzled designed to blast blind<br />

surfaces such as mold cavities or behind<br />

beams. They are Tungsten Carbide lined, and<br />

available in one or three outlets.<br />

Nozzle<br />

Orifice<br />

Size<br />

No. 4 1/4"<br />

No. 5 5/16"<br />

No. 6 3/8"<br />

Orifice<br />

Holes<br />

Part<br />

Number<br />

1 CAM01442<br />

3 CAM01444<br />

1 CAM01445<br />

3 CAM01447<br />

1 CAM01448<br />

3 CAM01450<br />

10 “We stock the most complete line of Corrosion-

Corpus Christi Branch<br />

4750 Westway<br />

1-800-CLEMTEX P.O. Box 5036<br />

Dallas, TX 75207<br />

Corrosion Control<br />

! "#$%%&"!'#$%(!)$"*&+,!-./0!)$+1$#!"2+(32#% 4567!89!<br />

www.clemtex.com<br />

Equipment and Supplies<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

:;9! '0.7!5@!$>>7==AB.7=C!D.6EB7!F<br />

11. Metering valve, FSV w/ wye.......................... 02427<br />

! "#$%%&"!'#$%(!)$"*&+,!-./0!)$+1$#!"2+(32#%<br />

12. Gasket, CQG coupling, (package<br />

4567!89!<br />

of 10) ..... 00850<br />

&/7G! H7=>B.I/.A! Blast %/A>J!+A;! Machines<br />

13. Wheel and tire, 10 x 2.75, for 2 cu. ft. .......... 20349<br />

! "#$%%&"!'#$%(!)$"*&+,!-./0!)$+1$#!"2+(32#% 14. Axle, 2 cu. ft. 10" Wheel ............................... 4567!89! 20734<br />

1. :;9! Ball '0.7!5@!$>>7==AB.7=C!D.6EB7!F<br />

valve with<br />

6<br />

handle,<br />

Bag & 3 Bag Blast 11. Machine<br />

15. Metering Wheel valve, -<br />

and FSV Clemco<br />

tire, w/ wye.......................... 16 x 400 .............................. 02427 02338<br />

1-inch NPT .................................................... 02396 12. 16. Gasket, Axle CQG and coupling, 16" wheel (package set of for 10) ..... 00850<br />

:;9! &/7G! 1-1/4-inch '0.7!5@!$>>7==AB.7=C!D.6EB7!F<br />

H7=>B.I/.A! NPT ............................................. %/A>J!+A;! .02397 13. 11. Wheel Metering 3 and cu. tire, valve, ft. 10 machine x FSV 2.75, w/ for ............................................02822<br />

wye.......................... 2 cu. ft. 2034902427<br />

2. Handle,<br />

14.<br />

12.<br />

Axle,<br />

Gasket,<br />

26 cu. cu. ft.<br />

CQG ft. 10" machine Wheel<br />

coupling, ............................................02350<br />

(package of 10)<br />

20734<br />

00850<br />

1. Ball with handle,<br />

15. Wheel and tire, 16 x 400 .............................. 02338<br />

&/7G! 1" H7=>B.I/.A! ball valve, .................................................. %/A>J!+A;! 22531 13. 17. Wheel Washer, and tire, 1" 10 thrust x 2.75, .......................................... for 2 cu. ft. 20349 03825<br />

1-inch NPT .................................................... 02396 16. Axle and 16" wheel set for<br />

1-1/4" 1-1/4-inch ball valve.............................................. NPT ............................................. .02397 22532 14. 18. Axle,<br />

3 cu. ft. Retaining 2 cu. ft. 10"<br />

machine ............................................02822<br />

ring, Wheel 1" .......................................... 20734 03824<br />

3. 1.<br />

2. Pop-up Ball<br />

Handle,<br />

valve valve, with 4" handle, with external sleeve ..........03699 15. 19. 6 cu.<br />

Wheel<br />

ft. Inspection machine<br />

and tire,<br />

............................................02350<br />

door 16 x 400 assembly, .............................. 6" x 8" ................ 02338 02377<br />

4. Internal 1-inch 1" ball pop-up NPT valve, .................................................... guide, toe nipple, for 22531 02396 17. 16. 20. Washer, Axle Gasket, and 1" thrust 16" 6" wheel .......................................... x 8" set inspection for door .................... 03825 02369<br />

2 and<br />

1-1/4-inch 1-1/4" 3 cu. ball ft.<br />

NPT valve.............................................. 1-1/4" x 6-1/2" 22532 .02397<br />

01754 18. 21. Retaining 3 cu.<br />

Seat,<br />

ft. ring, machine<br />

pop-up 1" ............................................02822<br />

03824<br />

2. 3. Handle, Pop-up valve, 4" with external sleeve ..........03699 19. Inspection 6 cu. ft. door machine assembly, ............................................02350<br />

6 cu. ft. 1-1/4" x 6" ......................................... 01753<br />

gum rubber, standard 6" x 8" use.............................02325<br />

02377<br />

4. 1" Internal ball valve, pop-up .................................................. guide, toe nipple, for 22531 20. 17. Gasket, Washer, 6" x 8" 1" inspection thrust .......................................... door 0236903825<br />

5. Adaptor, male NPT x male JIC<br />

neoprene, for hot climates ............................02380<br />

1-1/4" 2 and ball 3 cu. valve.............................................. ft. 1-1/4" x 6-1/2" 01754 22532 21. 18. Seat, Retaining pop-up ring, 1" .......................................... 03824<br />

3. 1" Pop-up NPT 6 cu. ........................................................... ft. valve, 1-1/4" 4" x 6" with external sleeve ..........03699 01753 11720 19. 22. gum Inspection rubber, Umbrella, standard door optional, assembly, use.............................02325<br />

4" 6" bolt-on x 8" ....................... 02377 02318<br />

4. 5. 1-1/4" Internal Adaptor, NPT pop-up male ..................................................... NPT guide, x male toe nipple, JIC for 22529 20. 23. neoprene, Gasket, Muffler, for 6" hot x exhaust 8" climates inspection ............................02380<br />

............................................ door 02369 05068<br />

6. Pusher 21" and NPT line, 3 cu. ........................................................... coupled ft. 1-1/4" x 6-1/2" 11720 01754 22. 21. 24. Umbrella, Seat, Metering pop-up optional, valve, 4" bolt-on optional ....................... manual 02318 pinch tube 04321<br />

1" 6 ID 1-1/4" cu. x 21" ft. NPT 1-1/4" (2 cu ..................................................... x ft 6" machine).......................... 22529 01753 22508 23. 25. Muffler, gum Metering exhaust rubber, standard ............................................ valve, for use.............................02325<br />

Lo-pot machines 05068<br />

05680<br />

5. 6. 1" Adaptor, ID Pusher x 28" line, male long coupled NPT (3 cu x ft male & larger)................... JIC<br />

23673 24. 26. Metering neoprene, Metering valve, for optional valve, hot climates manual optional ............................02380<br />

pinch manual tube 04321 Quantum .. 22845<br />

1"<br />

1"<br />

NPT<br />

ID x<br />

...........................................................<br />

21" (2 cu ft machine).......................... 22508<br />

11720<br />

25. Metering valve, for Lo-pot machines ............ 05680<br />

1-1/4" ID x 28" long (3 cu ft & larger) 23674 22. 27. Umbrella, Lock pin, optional, coupling 4" bolt-on (package ....................... of 25) .............. 02318 11203<br />

1" ID x 28" long (3 cu ft & larger)................... 23673 26. Metering valve, optional manual Quantum .. 22845<br />

1" 1-1/4" x NPT ..................................................... 22529<br />

1-1/4" 19" long 23. Muffler, exhaust ............................................ 05068<br />

ID x (Lo-Pot 28" long (3 machines).................... cu ft & larger) 23674 24167 27. 28.* Lock pin, Formed coupling pipe (package pusher of 25) line, .............. 1" ......................... 11203 01865<br />

6. 1-1/4" Pusher line, coupled<br />

24. Metering valve, optional manual pinch tube 04321<br />

1" x 19" long long (Lo-Pot (Lo-Pot machines).................... ............. 24167 24168 28.* 29.* Formed Formed pipe pusher pipe line, pusher 1" ......................... line, 1-1/4" 01865 ................... 01866<br />

7. Coupling,<br />

1"<br />

1-1/4"<br />

ID x 21"<br />

x 1-1/4" 19"<br />

(2<br />

long<br />

cu<br />

CF<br />

ft<br />

(Lo-Pot<br />

machine)..........................<br />

...................................... machines) 24168<br />

22508<br />

00551 29.*<br />

25.<br />

30.* Formed<br />

Metering<br />

Compression pipe<br />

valve,<br />

pusher<br />

for<br />

line, coupling,<br />

Lo-pot<br />

1-1/4"<br />

machines<br />

................... 1" ............................ 01866<br />

05680<br />

01856<br />

7. 1" Coupling, ID x 28" 1-1/4" long (3 CF cu ...................................... ft & larger)................... 00551 23673 30.* 26. Compression Metering valve, coupling, optional 1" ............................ manual Quantum 01856 .. 22845<br />

8. Wye, 1-1/4" standard ....................................01818 31.* Gasket, 1" compression coupling, ............... 01885<br />

8. 1-1/4" Wye, ID 1-1/4" x 28" standard long (3....................................01818<br />

cu ft & larger) 23674 31.* 27. Gasket, Lock 1" pin, compression coupling (package of ............... 25) .............. 0188511203<br />

9. Leg pad, right, for<br />

32.* Compression coupling, 1-1/4" ...................... 01857<br />

9. 1" Leg x 19" pad, long right, (Lo-Pot for machines).................... 24167 32.* 28.* Compression Formed pipe coupling, pusher 1-1/4" line, 1" ......................... 0185701865<br />

1.51-1/4" cu ft, cu x 3<br />

ft, 19" cu<br />

3 cu long ft, and<br />

ft, and (Lo-Pot 6 cu cu machines) ft machine<br />

ft ............. ...........03654<br />

...........03654 24168 33.* 29.* 33.*<br />

Gasket, Formed Gasket,<br />

1-1/4" pipe 1-1/4"<br />

compression pusher compression line, coupling 1-1/4" ................... coupling<br />

0188601866<br />

.......... 01886<br />

7. 2 cu Coupling, 2 ft cu machine ft machine 1-1/4" .............................................. CF 20735 00551 20735 ! 30.* * ! Used * Compression on Used 30” & on larger 30” coupling, machines, & larger 1" ............................ machines, & all machines & all machines 01856<br />

10. 8. 10. Leg Wye, Leg pad, pad, 1-1/4" left, left, for standard for ....................................01818 31.* shipped Gasket, shipped prior 1" to compression Jan prior 2003 to Jan coupling, 2003 ............... 01885<br />

9. 1.5 Leg cu 1.5 pad, ft, cu 3 ft, right, cu 3 cu ft, ft, for and 6 cu ft machine ...........03655 ! 32.* ! Compression coupling, 1-1/4" ...................... 01857<br />

2 cu. 1.5 2 cu. ft. machine ft. ft, 3 cu ft, ............................................ and 6 cu ft machine ...........03654 20736 20736 33.* Gasket, 1-1/4" compression coupling .......... 01886<br />

!<br />

! 2 cu ft machine .............................................. 20735 ! * Used on 30” & larger machines, & all machines<br />

10.<br />

!<br />

! Leg pad, left, for<br />

shipped prior to Jan 2003<br />

1.5 cu ft, 3 cu ft, and 6 cu ft machine ...........03655 !<br />

2 cu. ft. machine ............................................ 20736<br />

22<br />

!<br />

1, 2<br />

34<br />

22<br />

21<br />

!<br />

1, 2<br />

34<br />

3<br />

21<br />

3<br />

1<br />

31, 33<br />

30, 32 1, 2<br />

12<br />

31, 33<br />

5<br />

30, 32<br />

2<br />

28, 29<br />

51<br />

31, 33<br />

30, 32 6<br />

28, 29<br />

2<br />

15<br />

5<br />

17, 18 6<br />

28, 29<br />

15<br />

13<br />

6<br />

17, 18<br />

15<br />

17, 1318<br />

13<br />

16<br />

14<br />

16<br />

9<br />

9<br />

27<br />

34<br />

26 27<br />

27<br />

26<br />

9<br />

14 16<br />

12<br />

25<br />

24<br />

26<br />

© 2005 CLEMCO 14 INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 06160<br />

! 8<br />

7<br />

Figure 5<br />

© 2005 CLEMCO INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 06160<br />

Control Equipment and Supplies in the Southwest.” 11<br />

10<br />

10<br />

10<br />

25<br />

© 2005 CLEMCO INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 06160<br />

19<br />

19<br />

25<br />

19<br />

24<br />

20<br />

20<br />

24<br />

12<br />

20<br />

22<br />

3<br />

12<br />

7<br />

8<br />

7<br />

8<br />

4<br />

11<br />

21<br />

4<br />

11<br />

4<br />

11<br />

!<br />

Figure 5<br />

!<br />

Figure 5

78I) 1:;46)@9A)F96

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

89:) %$%'7;),)4=@6A)BC5DE6)F)<br />

89:) %$%'7;),)4=@6A)BC5DE6)F)<br />

89:) %$%'7;),)4=@6A)BC5DE6)F)<br />

Dallas Branch<br />

4770 Gretna<br />

!"#$%&&'(&&)*+#,+*)-.+/01!,2)#+03!+)23.!#3"*) Dallas, TX 75207<br />

Corrosion Control -456)%7)<br />

(214) 631-0584<br />

!"#$%&&'(&&)*+#,+*)-.+/01!,2)#+03!+)23.!#3"*) Equipment and Supplies -456)%7) -456)%7)<br />

!"#$%&&'(&&)*+#,+*)-.+/01!,2)#+03!+)23.!#3"*) -456)%7)<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

,>6G) H6IJECK>CLLJM).L9) ,>6G) H6IJECK>CLLJM).L9)<br />

,>6G) H6IJECK>CLLJM).L9)<br />

,>6G) H6IJECK>CLLJM).L9)<br />

(-) 1-1/2" Inlet Valve, complete ......................01995<br />

(-) 1-1/2" Inlet Valve, complete ......................01995<br />

(-) 1. (-) Petcock 1.<br />

1-1/2"<br />

Petcock<br />

Inlet 1/4"<br />

1/4"<br />

Valve, NPT ......................................01993<br />

NPT<br />

complete<br />

......................................01993<br />

......................01995<br />

2. 1. 1. Elbow, 2.<br />

Petcock 1/4"<br />

Elbow, 1/4"<br />

1/4" NPT<br />

NPT<br />

NPT adaptor<br />

adaptor<br />

......................................01993<br />

...........................02513<br />

...........................02513<br />

3. 2. 2. Elbow, 1/4" 3. 1/8"<br />

Elbow, 1/4" brass<br />

1/8" NPT street<br />

brass adaptor ............................03993<br />

street ............................03993<br />

...........................02513<br />

4. 3. 3. 4.<br />

Adaptor Elbow, Adaptor<br />

1/8" 1/8"<br />

NPT brass NPT<br />

with street with<br />

1/16"<br />

1/16" ............................03993<br />

orifice<br />

orifice<br />

...........01945<br />

...........01945<br />

5. 4. 4. 1/8" NPT with 1/16" orifice 5. Bottom Adaptor Bottom cap cap 1/8" ................................................02001<br />

NPT with 1/16" orifice ...........01945<br />

6.* 5. 5. 6.* Spring, Bottom Spring, inner, cap cap inner, ................................................02001<br />

5/8" 5/8" x x 1-11/16" long (1) .......01982<br />

7.* 6.* 6.* 7.* Gasket, Spring, Gasket,<br />

inner, bottom inner, bottom<br />

5/8" 5/8" cap cap<br />

x x (1) (1) 1-11/16" ..............................02006<br />

long long (1) (1) .......01982<br />

8.* 7.* 7.* 8.* Spring, Gasket, Spring, outer bottom<br />

outer bottom (1) (1)<br />

cap cap ........................................02000<br />

(1) (1) ..............................02006<br />

9. 8.* 8.* 9. Valve Spring, Spring, Valve body outer<br />

body outer .................................................01996<br />

(1) (1) ........................................02000<br />

10. 9. 10. 9. Valve Valve plug body body plug ..................................................01999<br />

.................................................01996<br />

11.* 10. 10. 11.* Washer, Valve Valve plug plug valve ..................................................01999<br />

plug (2) (2)..............................01998<br />

12.* 11.* 11.* 12.* Retainer, Washer, Washer, valve valve plug plug (2) washer (2) ..............................01998<br />

..............................01998<br />

(1) ................02002<br />

13.*<br />

12.*<br />

12.* 13.* O-Ring,<br />

Retainer,<br />

Retainer, 7/16"<br />

valve valve OD<br />

plug OD plug (1) (1) washer<br />

washer .................................02008<br />

(1)<br />

(1)<br />

................02002<br />

................02002<br />

14.<br />

13.*<br />

13.* 14. Piston<br />

O-Ring,<br />

O-Ring, Piston and<br />

7/16" and 7/16" rod rod OD<br />

assembly OD (1)<br />

(1)<br />

.................................02008<br />

.................................02008<br />

...........................02003<br />

14.<br />

14. 15.* Piston<br />

Piston O-Ring and<br />

and 2-1/4" rod<br />

rod<br />

assembly OD assembly (1) ...........................02003<br />

15.* O-Ring 2-1/4" OD (1) .................................02007<br />

...........................02003<br />

15.* 16. O-Ring Cylinder 2-1/4" cap OD (1) .................................02007<br />

16. 15.* Cylinder O-Ring cap 2-1/4" ..............................................01997<br />

OD (1) .................................02007<br />

16. (-) Cylinder Service cap kit, includes ..............................................01997<br />

(-) 16. Service Cylinder kit, cap includes ..............................................01997<br />

items items marked *, *,<br />

(-) Service quantity kit, is includes shown items ( ) marked *,<br />

(-) quantity Service is kit, shown includes ( items ) ...............................01927<br />

marked *,<br />

quantity is shown in ...............................01927<br />

quantity is shown in ( ) ...............................01927<br />

16<br />

16<br />

16<br />

216<br />

2<br />

2<br />

13*<br />

13*<br />

913*<br />

9<br />

9<br />

12*<br />

12*<br />

10<br />

10<br />

10<br />

8*<br />

8*<br />

8*<br />

5<br />

5<br />

5<br />

12*<br />

8*<br />

1<br />

1 2<br />

1<br />

2<br />

2<br />

15*<br />

15* 15*<br />

14<br />

15*<br />

14 14<br />

14<br />

11*<br />

11*<br />

11*<br />

6*<br />

6* 6*<br />

6*<br />

7*<br />

7*<br />

7*<br />

7*<br />

3<br />

3<br />

43<br />

4<br />

4<br />

Figure 6<br />

Figure 6<br />

Figure 6<br />

Figure 6<br />

89N) %;),)4=@6A)BC5DE6)8)<br />

89N) %;),)4=@6A)BC5DE6)8)<br />

89N) 89N) %;),)4=@6A)BC5DE6)8)<br />

,>6G) H6IJECK>CLLJM).L9)<br />

,>6G) ,>6G) H6IJECK>CLLJM).L9)<br />

(-) 1" Inlet Valve, complete ............................ 01980<br />

(-) 1" Inlet Valve, complete ............................ 01980<br />

(-) 1. 1" Inlet Valve, 01980<br />

1.<br />

(-) Petcock<br />

Petcock<br />

1" Inlet<br />

1/4"<br />

Valve, 1/4" NPT<br />

NPT<br />

complete ......................................<br />

...................................... 01993<br />

01980 01993<br />

1. 2. 1/4" 01993<br />

2.<br />

1. Elbow,<br />

Elbow,<br />

Petcock 1/8"<br />

1/8"<br />

1/4" NPT<br />

NPT<br />

NPT adaptor<br />

adaptor<br />

...................................... 02827<br />

.......................... 02827<br />

01993<br />

2. 3. 1/8" NPT adaptor 02827<br />

3. 2. Elbow,<br />

Elbow, 1/8"<br />

1/8" brass<br />

brass NPT street adaptor street ............................<br />

............................ 03993<br />

03993 02827<br />

3. Elbow, 1/8" brass street 03993<br />

4.<br />

4. 3. Adaptor<br />

Adaptor Elbow, 1/8" 1/8"<br />

NPT brass NPT<br />

with<br />

with street 1/16"<br />

1/16" ............................ orifice<br />

orifice 01945<br />

01945 03993<br />

4. Adaptor 1/8" NPT with 1/16" orifice 01945<br />

5. 5. 4. Bottom Bottom Adaptor cap cap 1/8" ................................................ ................................................ NPT with 1/16" orifice 01985 01945 01985<br />

5.<br />

6.* 6.* 5. Bottom<br />

Spring, Spring, Bottom cap<br />

5/8" 5/8" cap x 1-11/16" x ................................................ 1-11/16" long long (1) (1) 01982<br />

01985 01982 01985<br />

6.*<br />

7.* 7.* 6.* Spring,<br />

Seal, Seal, Spring, bottom bottom 5/8" 5/8" x<br />

cap<br />

1-11/16" x cap 1-11/16" (1) (1) long .................................01989<br />

long (1) (1) 01982 01982<br />

7.*<br />

8. 8. 7.* Seal, Valve Seal, bottom<br />

plug bottom plug cap ................................................. cap (1) (1) .................................01989 01984 01984<br />

8.<br />

9. 9. 8. Valve Valve plug body plug ................................................. 01981<br />

01984 01981 01984<br />

9. 10.* 9. Valve Washer, Valve body body valve ................................................ plug plug (2) (2) 01969 01981 01969 01981<br />

10.* 11.* 10.* Washer, Retainer, Washer, valve valve plug plug (2) (2) washer .............................. .............................. (1) (1) 01986 01969 01986 01969<br />

11.* 12.* 11.* Retainer, O-Ring Retainer, valve 3/16" valve ID plug ID x plug 1/16" x washer 1/16" washer (1) (1) (1) ....................... (1) 01992 01986 01986 01992<br />

12.* 13. 12.*<br />

O-Ring Piston O-Ring and 3/16"<br />

and 3/16" rod rod<br />

ID ID<br />

x<br />

assembly<br />

1/16"<br />

x 1/16"<br />

(1) (1) .......................... 01987 01992<br />

01992 01987<br />

13. 14.* 13.<br />

Piston O-Ring Piston<br />

and and 1-3/4"<br />

rod<br />

rod OD assembly<br />

OD assembly (1) (1) ................................<br />

.......................... 01990 01987<br />

01987 01990<br />

14.* 14.*<br />

O-Ring O-Ring<br />

1-3/4" cap 1-3/4" OD<br />

OD<br />

(1)<br />

(1) 01983 01990<br />

15. Cylinder cap .............................................. 01990 01983<br />

15. (-) Cylinder kit, cap includes .............................................. items marked *, 01983<br />

15. (-) Service Cylinder kit, cap includes .............................................. items marked *, 01983<br />

(-) Service quantity kit, is shown includes items ( ) ............................... marked *,<br />

(-) quantity Service is kit, shown includes ( items ) ............................... marked *, 01929 01929<br />

quantity is shown in ( ) ............................... 01929<br />

quantity is shown in ( ) ............................... 01929<br />

15<br />

15<br />

15<br />

2 15<br />

2 2<br />

2<br />

5<br />

) 5<br />

5<br />

) Figure 7)<br />

)<br />

))<br />

)<br />

) Figure 7)<br />

))) Figure 7)<br />

) Figure 7)<br />

)))<br />

)<br />

)<br />

) )<br />

)<br />

)<br />

Control Equipment and Supplies in the Southwest.” 13<br />

12*<br />

12* 12*<br />

12*<br />

9<br />

9 9<br />

9<br />

11*<br />

11* 11*<br />

11*<br />

8<br />

8 8<br />

8<br />

7*<br />

7* 7*<br />

7*<br />

© 2006 CLEMCO INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 22428<br />

© 2006 CLEMCO INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 22428<br />

1<br />

1<br />

1<br />

1<br />

2<br />

2<br />

14*<br />

14* 14*<br />

14*<br />

13<br />

13 13<br />

13<br />

10* 10*<br />

10*<br />

6*<br />

10*<br />

6* 6*<br />

6*<br />

5<br />

2<br />

2<br />

3<br />

3<br />

4<br />

4<br />

3<br />

3<br />

4<br />

4

CLEMTEX<br />

!"#$%&&'(&&)*+#,+*)-.+/01!,2)#+03!+)23.!#3"*) -456)%()<br />

789) 1:;46)!;4@)A=5B;6)C<br />

Abrasive Trap<br />

1” Piston Outlet Valve<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

,D6E) F6

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

Corrosion Control<br />

Equipment and Supplies<br />

Combo Valve: 2223-002<br />

No. Qty. Part No. Description<br />

1. 1 2223-002-01 Cap<br />

1<br />

6<br />

2. 1 2223-002-02 Pinch Ram<br />

3. 1 2223-002-03 Upper Rod Guide<br />

23<br />

4. 1 2223-002-04 Seal (Upper Rod)<br />

5. 1 2223-002-05 Spring<br />

2<br />

6. 4 7010-511-18 Bolt, 1/2" UNC x 9"<br />

7. 1 2223-002-07 Cylinder<br />

8. 1 2223-002-08 O-ring (Shaft)<br />

3<br />

22<br />

9. 1 2223-002-09 Snap Ring<br />

10. 1 2223-002-10 Seal (Lower Rod)<br />

11. 1 2223-002-11 Piston<br />

7<br />

12. 1 2223-002-12 Shaft<br />

13. 1 2149-000-04 Piston Seal<br />

4<br />

14. 4 2149-000-08 Nut, 1/2" UNC<br />

15. 1 2223-002-15 Lower Rod Guide<br />

16. 1 2223-002-16 O-ring (Lower Rod Guide)<br />

17. 1 2223-002-17 Base<br />

18. 1 2223-002-21 Valve Plug<br />

19. 2 2223-002-20 O-ring (Combo Valve Plug)<br />

20. 1 7016-507 Fender Washer, 3/8"<br />

21. 1 7019-507 Nylock Nut, 3/8" UNC<br />

25<br />

22. 8 7027-504-02 Flat Washer, 1/2" SAE<br />

8 9<br />

23. 1 2223-002-19 Combo Drive Pin<br />

5<br />

13<br />

24. 2 2014-300 Vent, 1/8"<br />

25. 2 4203-504-04 90° Swivel, 1/2" x 1/2"<br />

25<br />

Corrosion Control<br />

CLEMTEX 10<br />

Equipment and Supplies<br />

12 Houston Office<br />

Corrosion Control<br />

Corpus Christi Branch Dallas Branch<br />

248 McCarty Dr. 4750 Westway 4770 Gretna<br />

18<br />

CLEMTEX<br />

P.O. Box 15214 Equipment 1-800-CLEMTEX and Supplies P.O. Box 5036 Dallas, TX 75207<br />

Houston TX, 77220-5214 www.clemtex.com<br />

Corpus Christi, TX 78465 (214) 631-0584<br />

19<br />

(713) 672-8251 (361) 882-8282 Fax (214) 631-5824<br />

Fax (713) 672-6336 Fax (361) 882-6029 1-800-BLAST 97<br />

Houston Office Corpus 11 Christi Branch 20<br />

Dallas Branch<br />

Email clemtex@clemtex.com<br />

248 McCarty Dr. 4750 Westway 4770 Gretna<br />

P.O. Box 15214 1-800-CLEMTEX<br />

P.O. 15Box 5036 Schmidt G2 Dallas, 22Deadman TX 75207 Valve<br />

Houston TX, 77220-5214<br />

www.clemtex.com<br />

Corpus Christi, TX 78465 (214)<br />

16<br />

14 631-0584<br />

(713) 672-8251 (361) 882-8282 Fax (214) 631-5824<br />

Fax (713) 672-6336 Fax (361) 882-6029 21<br />

1-800-BLAST 97<br />

Email clemtex@clemtex.com<br />

24<br />

17<br />

Schmidt G2 Deadman Valve<br />

SECTION VIEW<br />

NOTES:<br />

1) SPRAY INSIDE OF COMBO CYLINDER (ITEM 7) WITH NEVER-SEIZE LUBRICANT.<br />

2) USE HAMMER OR PRESS TO INSTALL DRIVE PIN (ITEM 23) INTO COMBO CAP (ITEM 1).<br />

3) PAY CLOSE ATTENTION TO DIRECTION OF U-CUP SEALS (ITEMS 10&13). BOTH U-CUPS FACE THE<br />

PRESSURE SIDE (RIGHT SIDE) OF THE COMBO VALVE AS SHOWN IN SECTION VIEW.<br />

Schmidt G2 Deadman Valve<br />

1.0. RULES FOR SAFER OPERATION<br />

AXXIOM MANUFACTURING, INC.<br />

1.1. KNOW YOUR EQUIPMENT. Do Not operate this equipment in a manner other than its intended application (see Section<br />

2.0). Do Not operate this equipment without following the Rules for Safer Operation and all the operating procedures. Failure<br />

to do so could result in serious injury or death.<br />

1.2. RECEIVE PROPER TRAINING. Do Not operate or perform maintenance on this equipment unless you have received<br />

operational and maintenance training. Begin by thoroughly reading and understanding this document and any operational and<br />

maintenance manual or instructions for the equipment that will be used in conjunction with the G2 Deadman. Consult an<br />

authorized Schmidt® or Axxiom distributor.<br />

1.3. USE PROPER PERSONAL PROTECTIVE EQUIPMENT. Do Not operate or perform maintenance on this equipment<br />

without wearing OSHA approved eye, ear, foot, and lung protection.<br />

1.4. ADHERE TO ALL REGULATIONS. Do Not operate or perform maintenance on this equipment without observing all local,<br />

state, and federal safety regulations including, but not limited to, OSHA (Occupational Health and Safety Administration).<br />

1.5. USE CORRECT REPLACEMENT PARTS. Do Not use replacement parts that are not manufactured by Axxiom<br />

Manufacturing, “We stock Inc. the and most furnished complete by an line authorized of Corrosion distributor Control of Axxiom Equipment Manufacturing, and Supplies Inc. in Incorrect the Southwest.” replacement parts can<br />

result in equipment failure and cause serious injury or death.<br />

1.6. SAVE THIS OPERATION AND MAINTENANCE MANUAL.<br />

Control Equipment and Supplies in the Southwest.” 15<br />

Refer to this operation and maintenance manual as well as any other manufacturers information included for equipment that is<br />

used in conjunction with the G2 deadman. Never permit anyone to operate this equipment without having him/her first read this<br />

manual and receive proper training. Provisions should be made to have this manual readily available to the operating and<br />

maintenance personnel. If for any reason the manual becomes lost or illegible, have it replaced immediately. This operation and<br />

maintenance manual should be read periodically to maintain the highest skill level; it may prevent a serious accident.<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

5<br />

5

CLEMTEX<br />

! "#$%%&"!'#$%(!)$"*&+,!-./0!)$+1$#!"2+(32#% 4567!89!<br />

Abrasive Metering Valves<br />

Flat Sand Valve: FSV02427<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

! "#$%%&"!'#$%(!)$"*&+,!-./0!)$+1$#!"2+(32#% 4567!89!<br />

! "#$%%&"!'#$%(!)$"*&+,!-./0!)$+1$#!"2+(32#% 4567!89!<br />

:;9! 5@.A7!)7/7.B6!=5CA7D!

1-800-CLEMTEX<br />

www.clemtex.com<br />

Corpus Christi Branch<br />

4750 Westway<br />

P.O. Box 5036<br />

Corpus Christi, TX 78465-5036<br />

(361) 882-8282<br />

Fax (361) 882-6029<br />

Dallas Branch<br />

4770 Gretna<br />

Dallas, TX 75207<br />

(214) 631-0584<br />

Fax (214) 631-5824<br />

1-800-BLAST 97<br />

Corrosion Control<br />

Equipment and Supplies<br />

13 13<br />

Micro Valve: 2127-108<br />

1<br />

3<br />

11<br />

6<br />

No. Part No. Description<br />

2127-100-98 Replacement Part Kit, Seals Only<br />

2127-100-99 Replacement Part Kit<br />

1. 2127-000-01 Knob<br />

2. * 7011-005-06O Socket Head Cap Screw, 5/16" x 1" Lg. Self Sealing<br />

3. 7010-507-06 Hex Bolt, 3/8" x 1" Lg.<br />

5. * 2127-000-05 Plunger<br />

6. 2127-000-06 Body<br />

7. *+ 2149-500-06 Plunger Seal<br />

8. *+ 2127-100-08 Polyurethane Sleeve<br />

9. *+ 2127-000-09 O-Ring<br />

10. 2127-008-10 Base, 1 1/2"<br />

11. 7027-503-02 Flat Washer, 3/8"<br />

12. *+ 2127-000-12 Ball<br />

13. 2127-000-13 Orifice Indicator Decal<br />

14. 2127-000-14 Cleanout Ball Valve Adder<br />

15. 2401-505 Ball Valve, 3/4" Full Port<br />

16. 3006-105 Street Elbow 90°, 3/4" Galv.<br />

17. 3037-105 Pipe Cap, 3/4" Galv.<br />

* Included In Replacement Part Kit<br />

+ Included In Replacement Part Kit, Seals Only<br />

16<br />

7<br />

17<br />

5<br />

15<br />

*Optional<br />

14<br />

9<br />

2<br />

8<br />

12<br />

9<br />

10<br />

AXXIOM MANUFACTURING, INC.<br />

Control Equipment and Supplies in the Southwest.” 17

CLEMTEX<br />

SENTINEL MEDIA METERING VALVE Page 9<br />

6.5 Sentinel Replacement <strong>Parts</strong>, Figure 8<br />

Replacement <strong>Parts</strong><br />

6.5 Item 6.5 Sentinel Description............................................Stock Sentinel Replacement Replacement <strong>Parts</strong>, <strong>Parts</strong>, Figure Figure 8 8 No.<br />

Item Item 1. Cylinder Description............................................Stock cap .............................................. No. 20512 No.<br />

2. Cap screw, 3/8-NC x 1-1/2" ...................... 03267<br />

3.<br />

1.<br />

Adaptor,<br />

Cylinder cap<br />

1/8"<br />

..............................................<br />

NPT 20512<br />

1. Cylinder cap .............................................. 20512 01940<br />

4.<br />

2.<br />

Piston<br />

Cap screw,<br />

cup .................................................<br />

3/8-NC x 1-1/2" ...................... 03267<br />

2. Cap screw, 3/8-NC x 1-1/2" 03267 20515<br />

3. Adaptor, 1/8" NPT ..................................... 01940<br />

3. 5. Piston, shut-off .......................................... 20494<br />

4.<br />

Adaptor,<br />

Piston<br />

1/8"<br />

cup<br />

NPT<br />

................................................. 01940<br />

20515<br />

4. 6. Spring, 2" OD x 4-1/2" 20600<br />

5. Piston Piston, cup ................................................. shut-off .......................................... 20515 20494<br />

5. 7. Upper body ............................................... 20514<br />

6. Piston, Spring, shut-off 2" OD x 4-1/2" .............................. 20494 20600<br />

6. 8.<br />

7. Spring, Cap<br />

Upper 2" screw, OD body x 4-1/2" 5/16-NC<br />

............................................... x 3/4" ....................... 20600 20514<br />

03151<br />

7. 9.<br />

8. Upper Wear<br />

Cap body screw,<br />

sleeve ............................................... 5/16-NC x 3/4" 20514 03151<br />

20495<br />

8. 10. 9. Cap screw, Seat Wear plate sleeve 5/16-NC .................................................. x 3/4" 03151 20495 20497<br />

9. 11. 10. Wear Metering Seat sleeve plate plate .................................................. and stem<br />

20495 20497<br />

10. 11. Seat plate Metering Standard-use, .................................................. plate and coarser stem than 50-mesh 20497 .... 20499<br />

11. Metering Fine-mesh, Standard-use, plate Urethane, stem coarser than 50-mesh 50-mesh & finer .... 20499 . 21438<br />

12.<br />

Standard-use,<br />

Packing Fine-mesh, gland<br />

coarser Urethane, ...........................................<br />

than 50-mesh & .... finer 20499 . 21438 21021<br />

13. 12. Fine-mesh,<br />

Spring, Packing 5/8" gland Urethane,<br />

ID ........................................... x 1-11/16"<br />

50-mesh & finer . 21438 21021 01982<br />

12.<br />

14. 13.<br />

Packing<br />

Close Spring,<br />

gland<br />

nipple, 5/8"<br />

...........................................<br />

ID 1-1/2" x 1-11/16" schedule ......................... 80...............<br />

21021<br />

01982 01791<br />

13.<br />

15. 14.<br />

Spring,<br />

Inspection Close nipple,<br />

5/8" ID x<br />

plate 1-1/2"<br />

1-11/16"<br />

........................................ schedule 80............... 01791<br />

......................... 01982<br />

02440<br />

16. 15. Cap Inspection screw, plate 5/16-NC ........................................ x 1-1/4" 02440 19509<br />

14. Close nipple, 1-1/2" schedule 80............... 01791<br />

17. 16. Cap screw, 5/16-NC 1/2-NC x 2-1/2" 1-1/4" ...................... 19509 03457<br />

15.<br />

17.<br />

Inspection<br />

Cap screw,<br />

plate<br />

1/2-NC<br />

........................................<br />

x 2-1/2" ......................<br />

02440<br />

03457<br />

16. Cap screw, 5/16-NC x 1-1/4" .................... 19509<br />

17. Cap screw, 1/2-NC x 2-1/2" ...................... 03457<br />

37<br />

38<br />

3<br />

37<br />

37<br />

38 38<br />

3<br />

39<br />

1<br />

4<br />

3<br />

39<br />

30<br />

Houston Office<br />

248 McCarty Dr.<br />

P.O. Box 15214<br />

Houston, TX 77220-5214<br />

(713) 672-8251<br />

Fax (713) 672-6336<br />

SENTINEL MEDIA METERING VALVE Page 9<br />

Sentinel Valve<br />

25<br />

16<br />

15<br />

8 25<br />

14 16<br />

15 27<br />

8 27<br />

7<br />

25 7<br />

16<br />

15<br />

81<br />

27<br />

4<br />

3<br />

30<br />

6<br />

5<br />

99<br />

Items not called out are are available in 10<br />

in<br />

service kits only.<br />

Refer<br />

Refer<br />

to<br />

to Page<br />

Page<br />

8 for<br />

for<br />

service<br />

service<br />

kits.<br />

kits.<br />

Items not called out are available in<br />

service kits only.<br />

Refer to Page 8 for service kits.<br />

6<br />

5<br />

9<br />

7<br />

10 10<br />

24 24<br />

24<br />

22<br />

18. Nut, 1/2-NC hex head ............................... 03511<br />

19. Metering handle, heavy duty .................... 20498<br />

18. 18. 20. Nut, Nut, Pin, 1/2-NC valve hex handle head ...................................... 03511<br />

20246<br />

19. 19. 21. Metering Close nipple, handle, 1-1/4" heavy .................................. duty 20498<br />

01717<br />

20. 20. 22. Pin, Pin, Wye, valve valve 1-1/4" handle handle standard ...................................... ................................ 20246 20246 01818<br />

21.<br />

21. 23. Close<br />

Close Set nipple,<br />

nipple, screw, 1-1/4"<br />

1-1/4" 1/4-NC ..................................<br />

.................................. SQ. HD. 01717<br />

01717 03080<br />

22.<br />

24.<br />

Wye,<br />

Lower<br />

1-1/4"<br />

body<br />

standard<br />

............................................... 01818<br />

22. Wye, 1-1/4" standard 01818 20511<br />

23.<br />

25.<br />

Set<br />

Flanged<br />

screw, 1/4-NC<br />

adaptor<br />

SQ.<br />

w/ inspection<br />

HD. ......................<br />

opening<br />

03080<br />

23. Set screw, 1/4-NC SQ. HD. ...................... 03080 ... 20513<br />

24. Lower body ............................................... 20511<br />

24. 26. Nut, 3/8-NC hex head 03311<br />

25.<br />

Lower<br />

Flanged<br />

body<br />

adaptor<br />

...............................................<br />

w/ inspection opening ... 20513<br />

20511<br />

25. 27. Nut, 5/16-NC wing .................................... 03213<br />

26. Flanged Nut, 3/8-NC adaptor hex w/ head inspection ............................... opening 03311 20513<br />

26. 28. Flanged adaptor w/o inspection opening . 20522<br />

27. Nut, Nut, 3/8-NC 5/16-NC hex wing head .................................... 03213 03311<br />

27. 28.<br />

29. Nut, Flanged<br />

Hitch 5/16-NC pin.....................................................<br />

adaptor wing w/o inspection opening . 20522 03213 20245<br />

28. 29. 30. Flanged Hitch Petcock...................................................... pin..................................................... adaptor w/o inspection opening . 20245 20522 01993<br />

29. 30. 31. Hitch Petcock...................................................... Gauge pin..................................................... unit 01993 20245 02433<br />

30. 31. 32. Petcock...................................................... Gauge Stud, unit gauge unit ....................................... 02433 01993 02436<br />

31. 32. 33. Gauge Stud, Spacer, gauge unit ................................................ handle unit bolt ................................... 02436 02433 02431<br />

32. 33. 34. Stud, Spacer, Cap gauge screw, handle unit 1/4-NC bolt ....................................... x 1" ............................ 02431 02436 03053<br />

33. 34. 35.<br />

Spacer, Cap Nut, screw, handle<br />

1/4-NC 1/4-NC bolt<br />

wing<br />

................................... x ......................................03113<br />

1" 03053 02431<br />

34. 35. 36.<br />

Cap Nut, Washer,<br />

screw, 1/4-NC 1/4-NC<br />

1/4 wing flat ......................................03113<br />

x<br />

........................................<br />

1" 03053<br />

03116<br />

35.<br />

36. 37.<br />

Nut,<br />

Washer, Connector,<br />

1/4-NC<br />

1/4<br />

wing<br />

flat 1/8” ........................................<br />

......................................03113<br />

brass 03116 01962<br />

37. 38. Connector, Valve, 3-way 1/8” brass ACS switch........................... ............................... 01962 07658<br />

36. Washer, 1/4 flat ........................................ 03116<br />

38. 39. Valve, Breather, 3-way muffler ACS switch........................... 1/8” ................................ 07658 07657<br />

37. Connector, 1/8” brass ............................... 01962<br />

39. Breather, muffler 1/8” ................................ 07657<br />

38. Valve, 3-way ACS switch........................... 07658<br />

39. Breather, muffler 1/8” ................................ 07657<br />

14<br />

14<br />

21 21<br />

22<br />

2122<br />

2<br />

2<br />

26<br />

26<br />

2 17 17<br />

26<br />

© 2008 CLEMCO INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 20951<br />

© 2008 CLEMCO INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 20951<br />

Figure 8<br />

Figure 8<br />

18 “We stock the most complete line of Corrosion-<br />

18 18<br />

11 11<br />

1812<br />

12<br />

32<br />

32<br />

28<br />

28<br />

© 2008 CLEMCO INDUSTRIES CORP. ! www.clemcoindustries.com ! Manual No. 20951<br />

17<br />

11<br />

32<br />

12<br />

28<br />

13 13<br />

13<br />

31<br />

3133<br />

23<br />

23 34<br />

19<br />

19<br />

20<br />

35<br />

20<br />

35<br />

36 36<br />

29 29<br />

20<br />

35 33<br />

33<br />

36 34<br />

34 29<br />

23<br />

31<br />

19<br />

Figure 8

SENTINEL MEDIA METERING VALVE Page 8<br />

SENTINEL MEDIA METERING VALVE Page 8<br />

SENTINEL MEDIA METERING VALVE Page 8<br />

6.3 Replacement Corpus Christi Valves Branch<br />

SENTINEL Dallas Branch MEDIA METERING (-) Service VALVE kit, lower segment, Figure 7..........22389 Page 8<br />

6.3 Replacement 4750 Westway Valves<br />

4770 Gretna<br />

(-) Service kit, lower segment, Figure 7..........22389<br />

1-800-CLEMTEX 6.3 Replacement P.O. Box 5036 Valves<br />

Dallas, TX 75207 (-) Service<br />

Corrosion<br />

kit, lower<br />

Control<br />

segment, Figure 7..........22389<br />

(-) Sentinel Corpus valve Christi, with TX 78465-5036 attached ACS, (214) standard-use<br />

631-0584<br />

www.clemtex.com (-)<br />

for<br />

Sentinel<br />

abrasives<br />

valve<br />

(361) 882-8282 coarser<br />

with attached<br />

than 50-mesh,<br />

ACS, Fax standard-use<br />

(214) 631-5824 Equipment 22389 and LOWER-SEGMENT Supplies<br />

(-) 6.3 Sentinel Replacement<br />

for abrasives Fax (361) valve 882-6029<br />

1-800-BLAST 97<br />

with inspection<br />

coarser with Valves attached<br />

plate<br />

than<br />

...........................20508<br />

SENTINEL 50-mesh, ACS, standard-use (-) Service<br />

MEDIA METERING VALVE 22389<br />

kit, lower<br />

LOWER-SEGMENT<br />

segment, Figure 7..........22389<br />

SERVICE KIT Page 8<br />

for abrasives with inspection coarser plate than ...........................20508<br />

50-mesh,<br />

22389 SERVICE LOWER-SEGMENT<br />

KIT<br />

(-) Sentinel without inspection opening .................20509<br />

without inspection<br />

valve with<br />

plate<br />

attached<br />

opening ...........................20508<br />

ACS,<br />

.................20509<br />

standard-use<br />

SERVICE KIT<br />

for abrasives Item Qty. Description<br />

Sentinel Continued… without inspection<br />

coarser than<br />

opening<br />

50-mesh,<br />

.................20509 Item Qty. Description 22389 LOWER-SEGMENT<br />

(-) 6.3 Sentinel Replacement valve, Valves w/o attached ACS, standard-use<br />

(-) Sentinel with inspection valve, w/o plate attached ...........................20508<br />

ACS, standard-use (-) Item Service kit, lower segment, Figure 7..........22389<br />

Replacement for abrasives Valves coarser than 50-mesh,<br />

Service 1. Qty. 1 Description<br />

SERVICE KIT<br />

Kits Seat, – rubber<br />

for abrasives without inspection coarser than opening 50-mesh, .................20509<br />

22389 Lower Segment<br />

(-) Sentinel valve, w/o attached ACS, standard-use 1. 1 Seat, rubber<br />

(-) Sentinel with inspection valve with attached plate ............................20608<br />

ACS, standard-use<br />

2. 2 Gasket, seat plate<br />

with inspection plate ............................20608 Item 2. 2 Qty. Gasket, Description<br />

for abrasives coarser than 50-mesh,<br />

1. 1 Seat, rubber seat plate<br />

(-) Sentinel for abrasives without inspection coarser than opening 50-mesh, ..................20609 3. 22389 O-ring, LOWER-SEGMENT<br />

gland, 5/8” ID nom.<br />

without valve, inspection w/o attached opening ACS, ..................20609<br />

standard-use<br />

inspection plate ............................20608<br />

3. 2. 12 O-ring, Gasket, gland, seat 5/8” plate ID nom.<br />

for abrasives with inspection coarser plate than ...........................20508<br />

50-mesh,<br />

4. 1. 4.<br />

2 Gasket, Seat, Gasket, SERVICE rubber shaft<br />

shaft KIT<br />

without without inspection<br />

(-) Sentinel valve w/o attached opening opening<br />

ACS, .................20509<br />

..................20609 3. 1 O-ring, gland, 5/8” ID nom.<br />

fine-mesh<br />

(One is for standard-use [coarse media]<br />

(-) Sentinel inspection valve w/o attached plate ............................20608 2. Gasket,<br />

ACS, fine-mesh<br />

(One is seat for standard-use plate<br />

4. 2 Gasket, shaft<br />

[coarse media]<br />

for Item Qty. Description has a 1-3/8” nominal OD)<br />

for abrasives without inspection 50-mesh opening and finer ..................20609 3. 1 O-ring, has gland, a 1-3/8” 5/8” nominal ID nom. OD)<br />

(-) (-) Sentinel with valve, w/o attached ACS, standard-use<br />

fine-mesh<br />

(One is for standard-use [coarse media]<br />

4. 2 Gasket, (One is for a urethane plate [fine-mesh]<br />

for with inspection<br />

coarser<br />

plate<br />

than<br />

............................21439<br />

50-mesh,<br />

1. 1 Seat,<br />

(One<br />

rubber<br />

is shaft for a urethane plate [fine-mesh]<br />

for abrasives 50-mesh and finer<br />

has a 1-3/8” nominal OD)<br />

(-) Sentinel valve w/o attached ACS, fine-mesh<br />

(One has 1” nominal OD)<br />

............................20608 2. 2 Gasket,<br />

has is<br />

seat<br />

a<br />

plate<br />

1” for nominal standard-use OD) [coarse media]<br />

6.4 5. 1 O-ring, lower body 1” ID<br />

6.4 for Service abrasives<br />

with inspection<br />

without Kits 50-mesh<br />

plate<br />

and<br />

............................21439<br />

(One is for a urethane plate [fine-mesh]<br />

finer<br />

inspection opening ..................20609 3. 5. 1 1 O-ring, O-ring, has<br />

gland, lower a 1-3/8”<br />

5/8” body nominal<br />

ID nom. 1” ID OD)<br />

with inspection plate ............................21439 6. plate, 1-3/4” OD nom.<br />

4. 6. 2 1 Gasket, O-ring, (One<br />

has<br />

shaft Inspection is<br />

a<br />

for<br />

1”<br />

a<br />

nominal<br />

urethane<br />

OD)<br />

plate, 1-3/4” plate [fine-mesh] OD nom.<br />

6.4 Service Kits<br />

5. 1 O-ring,<br />

(-) (-) Service Sentinel kit, valve upper w/o segment, attached ACS, Figure fine-mesh 6 ........22388<br />

has<br />

lower<br />

a 1” nominal<br />

body 1”<br />

OD)<br />

ID<br />

(One is for standard-use [coarse media]<br />

6.4 Service<br />

for abrasives<br />

Kits<br />

5.<br />

6. 1<br />

O-ring,<br />

O-ring,<br />

lower<br />

Inspection<br />

body 1”<br />

plate,<br />

ID<br />

1-3/4” OD nom.<br />

50-mesh and finer<br />

has a 1-3/8” nominal OD)<br />

(-) Service kit, upper segment, Figure 6 ........22388 6. 1<br />

with inspection plate ............................21439<br />

(One<br />

O-ring,<br />

is for<br />

Inspection<br />

a urethane<br />

plate,<br />

plate<br />

1-3/4”<br />

[fine-mesh]<br />

OD nom.<br />

(-) Service 22388 kit, upper UPPER-SEGMENT<br />

segment, Figure 6 ........22388<br />

has a 1” nominal 6 OD) 6<br />

6.4 Service Kits<br />

SERVICE KIT<br />

5. 1 O-ring, lower body 1” ID<br />

Service Kits<br />

22388<br />

– 22388<br />

UPPER-SEGMENT<br />

Upper Segment 6. 1 O-ring, Inspection plate, 6 1-3/4” OD nom.<br />

(-) Item Qty. Service Description 22388 kit, upper<br />

SERVICE UPPER-SEGMENT<br />

segment,<br />

KIT<br />

Figure 6 ........22388<br />

6<br />

SERVICE KIT<br />

Item 1. 1. Qty. 1 Description<br />

Washer, rubber backed<br />

2 2<br />

Item 2. 2. Qty. 1 Description<br />

O-ring, 22388 UPPER-SEGMENT<br />

piston shaft bore, 3/4” ID nom.<br />

6 2<br />

1.<br />

2<br />

3. 3.<br />

1 1<br />