Full - Reed Catalog - Reed Manufacturing Co.

Full - Reed Catalog - Reed Manufacturing Co.

Full - Reed Catalog - Reed Manufacturing Co.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

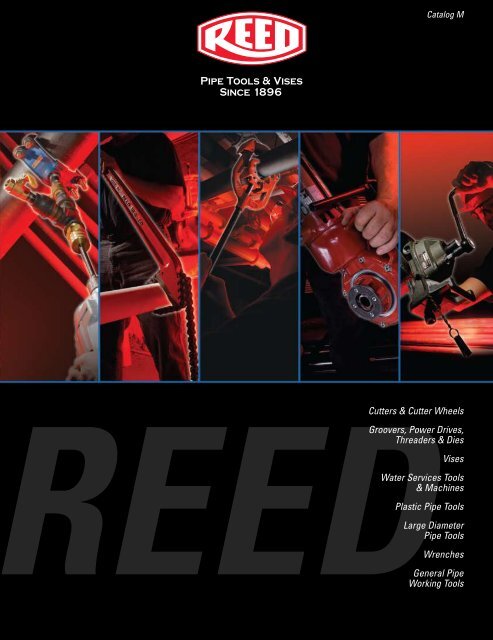

<strong>Catalog</strong> M<br />

Cutters & Cutter Wheels<br />

Groovers, Power Drives,<br />

Threaders & Dies<br />

Vises<br />

Water Services Tools<br />

& Machines<br />

Plastic Pipe Tools<br />

Large Diameter<br />

Pipe Tools<br />

Wrenches<br />

General Pipe<br />

Working Tools

<strong>Reed</strong> <strong>Manufacturing</strong> has been producing fine tools for worldwide<br />

professional trades since its founding, in 1896, by Carl <strong>Reed</strong>.<br />

Purchased in 1902 by Reuben Wright with money he made selling<br />

water and hardware during the 1849 California Gold Rush, the<br />

company continues to be operated by his descendants: fifth<br />

generation members of the Wright family. Standing in front of the<br />

portraits of the 1st, 2nd, and 3rd generations of Wrights at <strong>Reed</strong> are<br />

(L-R) Scott Wright (5th generation), Ralph Wright (4th), and Mark<br />

Wright (5th). Scott and Mark are co-presidents of <strong>Reed</strong> and uphold<br />

the family traditions of product innovation, highest quality pipe tools,<br />

great customer service, a cutting-edge factory (P. 20), and extra<br />

value to customers. Ralph continues as chairman of the board.<br />

Five generations of Wrights have also provided a great place to work<br />

and exceptional contributions to the community. For example, all<br />

<strong>Reed</strong> associates averaged $2850 each to the United Way 2008-2009<br />

campaign, by far the highest in the region.<br />

1<br />

2<br />

CUTTERS & CUTTER WHEELS.......................................... 5<br />

Cutter Wheels........................................................................................6 - 9<br />

Cutter Wheel Headquarters ................................................................... 10<br />

Quick Release Tubing Cutters................................................... 11<br />

Tubing Cutters....................................................................................11 - 12<br />

Telescoping Tubing Cutters......................................................... 11<br />

Mini Tubing Cutters................................................................................... 12<br />

Repair Kits................................................................................................. 12<br />

Deburring Tools......................................................................................... 12<br />

CSST Tubing Cutters.................................................................... 13<br />

Steel Pipe Cutters..................................................................................... 14<br />

Pipe Reamer.............................................................................................. 14<br />

Soil Pipe Cutters........................................................................................ 15<br />

Pipe Descalers........................................................................................... 16<br />

Saw It ® ...................................................................................................... 16<br />

Universal Pipe Cutters................................................................. 17<br />

Hinged Cutters ........................................................................................ 18<br />

Rotary Cutters & Low Clearance Rotary Cutters................................ 19<br />

GROOVERS, POWER DRIVES, THREADERS & DIES. 21<br />

<strong>Co</strong>mbo Roll Groovers................................................................... 22<br />

Roll Groovers............................................................................................. 23<br />

5301PD Power Drives.................................................................. 24<br />

700PD Power Drives................................................................................. 24<br />

701PD Power Drives................................................................................. 25<br />

601PD Power Drives................................................................................. 25<br />

Ground Fault Interrupter........................................................................... 25<br />

R12+ Segmental Dies, Dropheads & Threader Sets..........26 - 27<br />

Dropheads <strong>Co</strong>mplete for PVC-<strong>Co</strong>ated Pipe & <strong>Co</strong>nduit........................... 27<br />

Universal Dies........................................................................................... 28<br />

Universal Die Head................................................................................... 28<br />

Enclosed Ratchet Threader Sets.............................................................. 29<br />

Enclosed Dropheads................................................................................. 29<br />

Oilers.......................................................................................................... 30<br />

Threadguard Cutting Oil............................................................................ 30<br />

Adjustable Guide Threader Sets.............................................................. 31<br />

Block Dies.................................................................................................. 31<br />

We are dedicated to earning and<br />

keeping your business.<br />

Reach us at:<br />

Phone: 800-666-3691 (US/Canada) or 814-452-3691<br />

7:30 am - 5:30 pm U.S. Eastern Time<br />

Fax: 800-456-1697 (US/Canada) or 814-455-1697<br />

e-mail:<br />

reedsales@reedmfgco.com<br />

www.reedmfgco.com<br />

For the latest information on NEW REED Tools!<br />

<strong>Reed</strong> Mission Statement P. 45<br />

<strong>Reed</strong> Lifetime Warranty P. 76<br />

3<br />

VISES.................................................................................................. 32<br />

Tripod Vises.................................................................................. 33<br />

Pipe Jacks.................................................................................................. 34<br />

Chain Vises................................................................................................ 34<br />

Field Pipe Vise........................................................................................... 34<br />

Yoke Pipe Vises......................................................................................... 35<br />

Clamping Vises & Jaws for PVC-<strong>Co</strong>ated Pipe & <strong>Co</strong>nduit....................... 35<br />

Utility Workshop Vises.............................................................................. 36<br />

Mid-Line Vises........................................................................................... 36<br />

<strong>Co</strong>mbination Bench & Pipe Vises............................................................. 36<br />

Machinists’ Vises...................................................................................... 37<br />

Vise Accessories........................................................................................37<br />

Pipe Welding Vise..................................................................................... 37<br />

UNIVERSAL PRODUCT CODE MANUFACTURER ID NUMBER - 757033 © 2009<br />

2

4<br />

5<br />

LARGE DIAMETER PIPE TOOLS..............................38 - 39<br />

WATER SERVICES TOOLS & MACHINES................ 40<br />

Direct Tapping Machine............................................................................ 41<br />

Drilling Machines...................................................................................... 42<br />

<strong>Co</strong>mbination Drilling / Tapping Machines................................. 44<br />

PVC/PE Drilling Machines........................................................................ 44<br />

Power Tapping & Drilling Machines........................................... 45<br />

Feed Tap Drilling Machines...................................................... 46<br />

PE Water Service Shut-Off Tool............................................................... 47<br />

Standing Shut-Off Tool............................................................................. 47<br />

<strong>Co</strong>pper Shut-Off Tools............................................................................... 47<br />

Hammer & Flare Tools.............................................................................. 48<br />

Rerounding Tools....................................................................................... 48<br />

Round It ® Straightener/Rerounders........................................... 48<br />

Electric Hydrostatic Test Pumps.................................................. 49<br />

Hydrostatic Test Pumps............................................................................ 49<br />

Meter Pit Pump......................................................................................... 49<br />

Valve & Curb Keys....................................................................... 50<br />

Ratcheting Valve Keys..........................................................50 - 51<br />

Valve Operators............................................................................ 51<br />

Valve Key Socket Kit.................................................................... 52<br />

Meter Box & Curb Box Lid Keys............................................................... 52<br />

Valve Box Cleaners...................................................................... 52<br />

Manhole Hooks......................................................................................... 52<br />

PLASTIC PIPE TOOLS............................................................ 53<br />

Quick Release Cutters............................................................................ 54<br />

Internal Pipe Cutters................................................................................. 54<br />

Ratchet Shears............................................................................. 55<br />

Scissor Shears........................................................................................... 55<br />

Plastic Pipe Saws........................................................................ 56<br />

PLAS In-Line Rotary Cutter ..................................................... 56<br />

Bevelers..................................................................................................... 57<br />

Plastic Pipe Joiners................................................................................... 57<br />

PE Squeeze-Off Tools................................................................... 58<br />

Guillotine Pipe Cutters.............................................................................. 59<br />

Grounding Accessory................................................................................ 59<br />

Static Discharge Alarm............................................................................. 59<br />

PEX Crimpers................................................................................ 60<br />

PEX Shut-Off Tools....................................................................... 60<br />

Flare Tools for PE Water Service Lines.................................................... 60<br />

Deburring Tools for Plastic........................................................................ 61<br />

Chain Vises for Plastic Pipe...................................................................... 61<br />

6<br />

7<br />

WRENCHES.................................................................................... 62<br />

Pipe Wrenches.......................................................................................... 63<br />

Aluminum Pipe Wrenches........................................................................ 63<br />

Chain Tongs............................................................................................... 64<br />

Adjustable Wrenches............................................................................... 64<br />

<strong>Co</strong>mfort Grip Wrenches............................................................................ 64<br />

Strap Wrenches........................................................................................ 65<br />

Hydrant Wrenches.................................................................................... 65<br />

Chain Wrenches........................................................................................ 65<br />

Ratchet Wrenches & Sockets.................................................................. 66<br />

Square Drive Ratchet Wrenches.............................................................. 66<br />

Larger Ratchet Wrench & Sockets............................................. 67<br />

Extended Sockets...................................................................................... 67<br />

Dual Socket Ratchet Wrenches.................................................. 67<br />

Basin Wrenches........................................................................................ 68<br />

Torque Wrenches...................................................................................... 68<br />

One Hand Wrenches................................................................................. 68<br />

<strong>Co</strong>mfort Grip One Hand Wrenches.......................................................... 68<br />

Operator’s Wrench.................................................................................... 69<br />

Valve Packing Wrenches.......................................................................... 69<br />

Valve Wheel Wrenches............................................................... 69<br />

Internal Wrench......................................................................................... 70<br />

Smooth Jaw Wrenches............................................................... 70<br />

Meter Nut Wrenches.................................................................. 70<br />

GENERAL PIPE WORKING TOOLS...................................... 71<br />

Mechanical Hot Tapping Machine........................................................... 72<br />

Hole Master ® Hole Cutting Base............................................... 72<br />

Hole Saws for DM3MECH & Hole Master ® ........................................... 72<br />

Self-Feed Bits .............................................................................. 73<br />

Bit Extensions............................................................................................ 73<br />

Ship Augers.................................................................................. 74<br />

Hack Saw & Blades.................................................................................. 74<br />

Portable Power Hack Saw Blades.............................................. 74<br />

Stud Punches............................................................................................. 75<br />

Dam It ® Soldering Aids............................................................................ 75<br />

Bi-Metal Hole Saws.................................................................................. 75<br />

Flaring Tools............................................................................................... 76<br />

Tubing Benders.......................................................................................... 77<br />

Torpedo Level............................................................................................ 77<br />

Multi-Purpose Pipe Joiner........................................................................ 77<br />

Pipe Wrench Pliers ® ................................................................................. 78<br />

Water Pump Pliers.................................................................................... 78<br />

Smooth Jaw Pliers....................................................................... 78<br />

Positive Grip Pliers.................................................................................... 78<br />

3

<strong>Reed</strong> Special Features<br />

Throughout the catalog, various symbols are used to help the reader identify key points:<br />

TOOL<br />

FEATURES<br />

SIZES<br />

<strong>Reed</strong> Exclusive Tool – The tool is unique,<br />

available only from <strong>Reed</strong>, offers operational<br />

cost savings or safety features, and at least<br />

one advantage to buying <strong>Reed</strong>.<br />

<strong>Reed</strong> Exclusive Features – The tool has<br />

special features available only from <strong>Reed</strong>.<br />

These meaningful features are advantages<br />

to buying <strong>Reed</strong>.<br />

<strong>Reed</strong> Exclusive Sizes – The tool is<br />

available in certain capacities only from<br />

<strong>Reed</strong>. These unique capacities are<br />

advantages to buying <strong>Reed</strong>.<br />

<strong>Reed</strong> Best Ever – The tool has been<br />

improved over all previous versions. These<br />

continuous improvements are advantages<br />

to buying <strong>Reed</strong>.<br />

Next to many of the tools in this catalog,<br />

there is a brief statement headed by the<br />

term: ”WHY REED ” This statement<br />

explains why that particular <strong>Reed</strong> tool is<br />

superior to any other on the market, and<br />

can be used with confidence to compare<br />

<strong>Reed</strong> products with the competition.<br />

New Tool Families are indicated by<br />

symbol, while models added to the <strong>Reed</strong><br />

line are highlighted in Red Ink. To <strong>Reed</strong>,<br />

”New ” means the tool was introduced<br />

within the last 12 months.<br />

<strong>Reed</strong> Extra Value – The tool offers extra<br />

cost savings over the previous <strong>Reed</strong> version<br />

– or the competitions’.<br />

Truck Freight Required – These tools<br />

require truck freight due to size or weight.<br />

AVAILABLE<br />

<strong>Reed</strong> Training Available –<br />

Demonstrations of all <strong>Reed</strong> products are<br />

available on request. Many of the more<br />

complex tools are featured on the <strong>Reed</strong><br />

Piping Solutions video on DVD, CD, or<br />

on-line at www.reedmfgco.com.<br />

<strong>Reed</strong> encourages<br />

responsible recycling.<br />

<strong>Reed</strong> - Registered and Trademarked<br />

REED Education and Training<br />

Why <strong>Reed</strong> Training Services are better...<br />

Best Service + Best Quality +<br />

Best People = The Lowest Total <strong>Co</strong>st<br />

<strong>Reed</strong> <strong>Manufacturing</strong> believes in the importance of continuing education and training. To<br />

provide our customers with the best service, all <strong>Reed</strong> Regional Managers, Manufacturer’s<br />

Representatives, and <strong>Reed</strong> Associates are extensively trained in-house. The Product<br />

Development department engineers, senior Regional Managers, and <strong>Reed</strong> management<br />

give hands-on tool training sessions annually in addition to the formal, one-on-one,<br />

two-week session for new Regional Managers. <strong>Reed</strong> people know the products inside and<br />

out. They assemble them and disassemble them in addition to working with the tools in<br />

simulated and field situations. The <strong>Reed</strong> sales team understands tool applications and<br />

recommends to customers how to achieve the best results with <strong>Reed</strong> pipe tools and vises.<br />

These trained salespersons, the <strong>Reed</strong> Piping Solutions DVD (#01070), and on-line training<br />

videos extend the training beyond <strong>Reed</strong>’s Erie, Pennsylvania classrooms.<br />

Clean Cut ®<br />

Cutter Wheel Headquarters <br />

Dam It ®<br />

Feed Tap <br />

Hinged Cutter <br />

Hole Master ®<br />

Quality First ®<br />

Quick Release Cutter<br />

Rotary Cutter<br />

Round It ®<br />

Saw It ®<br />

Thru-Bolt <br />

AVAILABLE<br />

To request a tool demonstration or consultation, contact <strong>Reed</strong>: 800-666-3691 (US/Canada),<br />

814-452-3691 (International) or reedsales@reedmfgco.com.<br />

www.reedmfgco.com<br />

For the latest information on NEW REED Tools!<br />

4

Cutters &<br />

Cutter Wheels<br />

1<br />

SECTION<br />

Cutter Wheels<br />

Quick Release TM<br />

Tubing Cutters<br />

Tubing Cutters<br />

Telescoping Tubing Cutters<br />

Tubing Cutters for Stainless Steel<br />

Mini Tubing Cutters<br />

Repair Kits<br />

Deburring Tools<br />

CSST Tubing Cutters<br />

Steel Pipe Cutters<br />

Pipe Reamer<br />

Soil Pipe Cutters<br />

Pipe Descalers<br />

Saw It ®<br />

Universal Pipe Cutters<br />

Hinged Cutters<br />

Rotary Cutters & Low<br />

Clearance Rotary Cutters<br />

5

Cutters &<br />

Cutter Wheels<br />

DESIGNED FOR PERFORMANCE<br />

Thinness of<br />

<strong>Reed</strong> Wheels<br />

CUTTER WHEELS ARE BETTER…<br />

All <strong>Reed</strong> cutter wheels are made from high shock-resistant tool steel, while competitive<br />

wheels are made from carbon steel or still lower quality tool steel. By using this higher<br />

quality raw material, <strong>Reed</strong> cutter wheels can be made thinner and can therefore cut pipe<br />

more easily and leave less burr. Also, because of their higher<br />

quality, certified material, only <strong>Reed</strong> wheels can be heat-treated<br />

for the perfect balance between hardness and toughness to<br />

make the wheels resist breakage and last longer.<br />

<strong>Reed</strong> pioneered the development of wheels for plastic pipe<br />

and today has the widest variety and highest quality wheels for<br />

various types and wall thicknesses of plastic pipe and tubing.<br />

Thickness of<br />

All Other Wheels<br />

<strong>Reed</strong> offers the largest cutter wheel line for all types of pipe,<br />

tubing and conduit. <strong>Reed</strong> wheels are the best value for use in<br />

<strong>Reed</strong> cutters, or in the cutters of any other manufacturer.<br />

cutter wheel interchangeability p. 6 - 9<br />

Item<br />

<strong>Co</strong>de<br />

<strong>Reed</strong> 2-Pack Replacement Cutter Wheels<br />

<strong>Reed</strong> Standard Blade Exposure**<br />

<strong>Catalog</strong> No. Pack* <strong>Reed</strong> Cutter inches mm<br />

Application<br />

2-Pack Replacement WHeels<br />

63655 2PK-OSS 2 TC1Q; TC1.6Q; TC2Q; T10; T15; T20 0.160 4.1 Stainless Steel<br />

63660 2PK-O 2 TC1Q; TC1.6Q; TC2Q; T10; T15; T20; MC3; 0.180 4.6 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

RT15T1; RT15T2; RT15T3; RTC1.1;RTC1.4<br />

63665 2PK-30-40 2 TC3Q; TC4Q; TC5Q; TC6Q; TC8Q 0.250 6.4 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

63670 2PK-R2558 2 TC3Q; TC4Q; TC5Q; TC6Q; TC8Q 0.188 4.8 Muffler Systems Tubing<br />

63671 2PK-30-40SS 2 TC3Q; TC4Q; TC5Q; TC6Q; TC8Q 0.160 4.1 Stainless Steel<br />

64180 2PK-OP2 2 TC1Q; TC1.6Q; TC2Q; T10; T15; T20 0.275 7.0 ABS; PE; PEX; PP; PEX/AL/PEX<br />

64184 2PK-1-2PVC 2 TC1Q; TC1.6Q; TC2Q; T10; T15; T20 0.160 4.1 Stainless Steel<br />

64190 2PK-30-40P 2 TC3Q; TC4Q; TC5Q; TC6Q 0.343 8.7 ABS; PE; PP<br />

64194 2PK-3-6PVC 2 TC3Q; TC4Q; TC5Q; TC6Q 0.377 9.6 3”-6” PVC; 4” Heavy Wall; CPVC<br />

63662 2PK-75015 2 TC11; TC17 0.125 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

63663 2PK-75046 2 TC11; TC17 0.125 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel; Stainless Steel<br />

63690 2PK-73505 2 TC14 0.170 4.3 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

63691 2PK-73515 2 TC14 0.170 4.3 Stainless Steel Only<br />

63661 2PK-32633 2 MC1 0.127 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

63666 2PK-345T 2 MC2 0.146 3.7 <strong>Co</strong>pper; Aluminum; Brass<br />

63659 2PK-OCSST-2 2 TC1.6QRGT; TC2Q; TC2QRGT 0.281 7.1 CSST Tubing<br />

63612 2PK-2RBS 2 2-1; 2-1Q; 2-4WG; 2-3; 2-3Q; 2-4 0.300 7.6 Steel; Stainless Steel<br />

63613 2PK-2RBHD 2 2-1; 2-1Q; 2-4WG; 2-3; 2-3Q; 2-4 0.296 7.5 HD for Steel; Stainless Steel<br />

63634 2PK-ACWR 2 GENERAL - ATC12; ATC34; ATC100 0.125 3.2 <strong>Co</strong>pper<br />

6

<strong>Reed</strong> Replacement Cutter Wheels<br />

Item<br />

<strong>Co</strong>de<br />

<strong>Reed</strong> Standard Blade Exposure**<br />

<strong>Catalog</strong> No. Pack* <strong>Reed</strong> Cutter inches mm<br />

Application<br />

For Tubing Cutters – Metal<br />

03655 OSS 12 TC1Q; TC1.6Q; TC2Q; T10; T15; T20 0.160 4.1 Stainless Steel<br />

03657 3T23 4 T23 0.125 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

03659 OCSST-2 12 TC1Q; TC2Q; TC2QRGT 0.281 7.1 CSST Tubing<br />

03660 O 12 TC1Q; TC1.6Q; TC2Q; T10; T15; T20; MC3; 0.180 4.6 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

RT15T1; RT15T2; RT15T3; RTC1.1; RTC1.4<br />

03661 32633 12 MC1 0.127 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

03662 75015 12 TC11; TC17 0.125 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

03663 75046 12 TC11; TC17 0.125 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel; Stainless Steel<br />

03665 30-40 12 TC3Q; TC4Q; TC5Q; TC6Q; TC8Q 0.250 6.4 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

03666 345T 12 MC2 0.146 3.7 <strong>Co</strong>pper; Aluminum; Brass<br />

03668 R4546 6 MC2 0.161 4.1 Steel; Stainless Steel<br />

03670 R2558 12 TC3Q; TC4Q; TC5Q; TC6Q; TC8Q 0.188 4.8 Muffler Systems Tubing<br />

03671 30-40SS 12 TC3Q; TC4Q; TC5Q; TC6Q; TC8Q 0.250 6.4 Stainless Steel Tubing<br />

03690 73505 12 TC14; TC166 0.170 4.3 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

03691 73515 12 TC14; TC166 0.170 4.3 Stainless Steel Only<br />

For Tubing Cutters – Plastic<br />

04180 OP2 12 TC1Q; TC1.6Q; TC2Q; T10; T15; T20 0.275 7.0 ABS; PE; PEX; PP; PEX/AL/PEX<br />

04181 2CON 4 TC2Q 0.180 4.6 2” PE <strong>Co</strong>nduit<br />

04184 1-2PVC 12 TC1Q; TC1.6Q; TC2Q; T10; T15; T20 0.280 7.1 PVC; CPVC; PVDS<br />

04187 R10279 4 TC3Q; TC4Q; TC5Q; TC6Q 0.221 5.6 Thin Wall PVC<br />

04188 R1740 4 MC2 0.148 3.7 Soft Flexible Plastic<br />

04190 30-40P 12 TC3Q; TC4Q; TC5Q; TC6Q 0.343 8.7 ABS; PE; PP<br />

04192 680PVC 4 TC6Q; TC8Q 0.575 14.6 PVC – Standard & Heavy Wall; CPVC<br />

04194 3-6PVC 12 TC3Q; TC4Q; TC5Q; TC6Q 0.377 9.6 3”-6” PVC; 4” Heavy Wall; CPVC<br />

04198 6QP 4 TC4Q; TC5Q; TC6Q; TC8Q 0.550 14.0 Thick Wall PE<br />

04199 80P 4 TC6Q; TC8Q 0.750 19.1 ABS; PE; PP<br />

For Pipe Cutters<br />

03504 HS4 4 3-1; 3-3; 3-4 0.383 9.7 Steel; Stainless Steel<br />

03522 HI4 4 3-1; 3-3; 3-4 0.258 6.6 Cast Iron; Ductile Iron<br />

03612 2RBS 12 2-1; 2-1Q; 2-4WG; 2-3; 2-3Q; 2-4; 5301PD 0.300 7.6 Steel; Stainless Steel<br />

03613 2RBHD 12 2-1; 2-1Q; 2-4WG; 2-3; 2-3Q; 2-4; 5301PD 0.296 7.5 HD for Steel; Stainless Steel<br />

03620 REU2 4 2-1; 2-3; 2-4; 2-4WG 0.295 7.5 Steel; Stainless Steel<br />

03624 2RBCI 4 2-1; 2-1Q; 2-4WG; 2-3; 2-3Q; 2-4 0.172 4.4 Cast Iron<br />

03532 R1032/S 6 5301PD 0.450 11.4 Steel; Stainless Steel; Schedule 80<br />

For Hinged Cutters<br />

03502 HS21/2 4 H21/2 0.312 7.9 Steel; Stainless Steel<br />

03504 HS4 4 H4 0.320 8.1 Steel; Stainless Steel<br />

03505 HSI4 4 H4 0.275 7.0 Steel; Stainless Steel; Cast Iron; Ductile Iron<br />

03506 HS6 4 H6 0.390 9.9 Steel; Stainless Steel<br />

03507 HSI6-8 4 H6; H8 0.350 8.9 Steel; Stainless Steel; Cast Iron; Ductile Iron<br />

03508 HS8-12 4 H8; H12 0.450 11.4 Steel; Stainless Steel<br />

03510 HX21/2 4 H21/2 0.383 9.7 Steel; Stainless Steel; Schd 80<br />

03512 HX4 4 H4 0.383 9.7 Steel; Stainless Steel; Schd 80<br />

03514 HX6 4 H6 0.476 12.1 Steel; Stainless Steel; Schd 80<br />

03516 HX8 4 H8; H12 0.567 14.4 Steel; Stainless Steel; Schd 80<br />

03518 HXX8 4 H8; H12 0.682 17.3 Steel; Stainless Steel; Schd 100<br />

03522 HI4 4 H4 0.258 6.6 Cast Iron; Ductile Iron<br />

03524 HI6 4 H6; H8; H12 0.410 10.4 Cast Iron; Ductile Iron<br />

03525 H6PSE5 4 H6; H8; H12 0.400 10.2 Steel; Cast Iron; Ductile Iron<br />

03624 2RBCI 4 H21/2 0.172 4.4 Cast Iron; Ductile Iron<br />

For Rotary Cutters<br />

03530 RCS8-36 4 LCRC8; LCRC12; LCRC16; RC20; RC24; RC30; RC36 0.635 16.1 Steel; Stainless Steel<br />

03531 RC58-36 7MM 4 LCRC8; LCRC12; LCRC16; RC20; RC24; RC30; RC36 0.512 13.0 Spiral Weld Pipe<br />

03533 RCS8-36 6MM 4 LCRC8; LCRC12; LCRC16; RC20; RC24; RC30; RC36 0.394 10.0 Spiral Weld Pipe<br />

03535 RCI8-30 4 LCRC8; LCRC12; LCRC16; RC20; RC24; RC30; RC36 0.500 12.7 Cast Iron; Ductile Iron (manual)<br />

03545 RCDX 4 LCRC8; LCRC12; LCRC16; RC20; RC24; RC30; RC36 0.531 13.5 Heavy Cast Iron; Ductile Iron (PRC)<br />

03550 RCX 4 LCRC8; LCRC12; LCRC16; RC20; RC24; RC30; RC36 0.800 20.3 Heavy Wall Steel; Stainless Steel<br />

REQUIRES: ONE SET (8) OF THE RC8-30XR ROLLERS WHEN USING RCX WHEELS<br />

* Cutter wheels sold to distributors in standard package quantities only. ** Blade Exposure determines wall thickness capacity of cutter wheel.<br />

7

Cutter Wheel <strong>Co</strong>nversions<br />

Manufacturer Cutter No.<br />

Manufacturer <strong>Reed</strong> <strong>Reed</strong> Standard Blade Exposure**<br />

Wheel <strong>Catalog</strong> No. Item <strong>Co</strong>de Pack* inches mm Application<br />

RIDGID ®<br />

50 M-50 R2558 03670 12 0.188 4.8 Muffler Systems Tubing<br />

315 E-2990 R2990 03667 6 0.117 3.0 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

10; 15; 20 E-1240 OSS 03655 12 0.160 4.1 Stainless Steel<br />

10; 15; 20 E-1240 O 03660 12 0.180 4.6 Steel<br />

10; 15; 20 F-158 O 03660 12 0.180 4.6 <strong>Co</strong>pper; Aluminum<br />

101; 103; 104; 105; 150; 131P; 132P; E-1740 R1740 04188 4 0.148 3.7 Soft Flexible Plastic<br />

151P; 152P; 153P; 205P; 150L<br />

101; 103; 104; 105; 118; 150; 150L; 131; E-3469 345T 03666 12 0.146 3.7 <strong>Co</strong>pper; Aluminum; Brass<br />

132; 151; 152; 153; 205<br />

105; 150; 150L; 131; 132; 151; 152; 153; 205 E-4546 R4546 03668 6 0.161 4.1 Steel; Stainless Steel<br />

131P; 132P; 151P; 152P; 153P; 205P E-2155 R2155 04185 6 0.295 7.5 PE; PP – Standard & Heavy Wall<br />

131P; 132P; 151P; 152P; 153P; 205P E-5272 R5272 04186 6 0.295 7.5 PVC; ABS – Standard Wall<br />

134P; 136P; 154P; 156P E-702 680PVC 04192 4 0.575 14.6 PVC – Standard & Heavy Wall; CPVC<br />

134P; 136P; 154P; 156P E-2157 6QP 04198 4 0.550 14.0 Thick Wall PE<br />

134P; 154P; 136P; 156P E-10279 R10279 04187 4 0.221 5.6 Thin Wall PVC<br />

136P; 156P E-2880 80P 04199 4 0.750 19.1 ABS; PE; PP<br />

1A; 2A; 42A; 202; 360; 820; 364; 732; 300 power drive E-1032S R1032/S 03532 6 0.450 11.4 Steel; Stainless Steel; Schedule 80<br />

1A; 2A; 42A; 202; 360; 820; 364; 732 F-514 2RBS 03612 12 0.300 7.6 Steel; Stainless Steel<br />

1A; 2A; 42A; 202; 360; 820; 364; 732 F-3 2RBHD 03613 12 0.296 7.5 HD for Steel; Stainless Steel<br />

1A; 2A; 42A; 202; 360; 820; 364; 733 F-3S 2RBHD 03613 12 0.296 7.5 HD for Steel; Stainless Steel<br />

1A; 2A; 42A; 206; 360; 820; 364; 732 F-119 2RBCI 03624 4 0.172 4.4 Cast Iron<br />

30; 40; 106; 108; 109; 133; 134; 136; 154; 156 E-2191 30-40 03665 12 0.250 6.4 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

30; 40; 106; 108; 109; 133; 134; 136; 154; 156 E-2558 30-40 03665 12 0.250 6.4 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

30; 40; 106; 108; 109; 133; 134; 154; 136; 156 E-2558 R2558 03670 12 0.188 4.8 Muffler Systems Tubing<br />

30P; 40P; 106; 108; 109P; 133P; 134P; E-5299 3-6PVC 04194 12 0.377 9.6 3”-6” PVC; 4” Heavy Wall<br />

136P; 154P; 156P<br />

30P; 40P; 106; 108; 109P; 133P; 134P; E-5299 30-40P 04190 12 0.343 8.7 ABS; PE; PP<br />

154P; 136P; 156P<br />

30P; 40P; 133P; 134P; 136P; 154P; 156P E-2156 30-40P 04190 12 0.343 8.7 ABS; PE; PP<br />

3S; 4S; 44S; 466S; 466C; 466HWS; 468C; F-229 3RG 03616 4 0.399 10.1 Steel; Stainless Steel<br />

468S; 468HWS; 472C; 472S; 472HWS; 764<br />

3S; 4S; 44S; 466S; 466C; 466HWS; 468C; F-229S 3RG 03616 4 0.399 10.1 Steel; Stainless Steel<br />

468S; 468HWS; 472C; 472S; 472HWS; 764<br />

3S; 4S; 44S; 466S; 466C; 466HWS; 468C; F-515 3RG 03616 4 0.399 10.1 Steel; Stainless Steel<br />

468S; 468HWS; 472C; 472S; 472HWS; 764<br />

42A; 202; 360; 820; 364; 732; 300 power drive E-1032 R1032/S 03532 6 0.450 11.4 Steel; Stainless Steel; Schedule 80<br />

466; 468; 472; 1224 E-1962 3RGCI 03617 4 0.285 7.2 Cast Iron; Ductile Iron<br />

466C; 466S; 466HWS; 468C; 468S; E-3186 R3186 03526 4 0.680 17.3 Steel; Ductile Iron Heavy Wall<br />

468HWS; 472C; 472S; 472HWS<br />

6S; 208; 209 F-367 R367 03639 6 0.480 12.2 Steel; Ductile Iron Heavy Wall<br />

ARMSTRONG ®<br />

1T; 2T; 2TA 2RBS 03612 12 0.300 7.6 Steel; Stainless Steel<br />

1T; 2T; 2TA 2RBHD 03613 12 0.296 7.5 HD for Steel; Stainless Steel<br />

4A 3RG 03616 4 0.399 10.1 Steel; Stainless Steel<br />

4A 3RGCI 03617 4 0.285 7.2 Cast Iron; Ductile Iron<br />

GASTITE ®<br />

RT15T1; RT15T3; RT15T2; T15T1; T15T2 O 03660 12 0.180 4.6 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing; CSST<br />

GENERAL WIRE SPRING ®<br />

ATC12; ATC34; ATC100 ATCW ACWR 03634 12 0.125 3.2 <strong>Co</strong>pper<br />

Imperial Eastman ®<br />

127-F/FA/FB; TC1050; 227-FA S32633 32633 03661 12 0.127 3.2 <strong>Co</strong>pper; Aluminum; Brass<br />

TC1000; TC1020; 374; 312-FC/FB; S75015 75015 03662 12 0.125 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

274-FC/FB; 174-F<br />

TC1000; TC1020; 374; 312-FC/FB; S75046 75046 03663 12 0.125 3.2 <strong>Co</strong>pper; Aluminum; Brass; Steel; Stainless Steel<br />

274-FC/FB; 174-F<br />

Ridgid ® is a registered trademark of Ridgid, Inc. and is not associated with <strong>Reed</strong> <strong>Manufacturing</strong> <strong>Co</strong>mpany.<br />

8

Cutter Wheel <strong>Co</strong>nversions<br />

Manufacturer <strong>Reed</strong> <strong>Reed</strong> Standard Blade Exposure**<br />

Manufacturer Cutter No. Wheel <strong>Catalog</strong> No. Item <strong>Co</strong>de Pack* inches mm Application<br />

LENOX ®<br />

21010-TC11/8; 21011-TC13/8; 21017-TCW158C O 03660 12 0.180 4.6 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

21012-TC13/4<br />

21010-TC11/8; 21012-TC13/4; 21011-TC13/8; 21015-TCW158SS OSS 03655 12 0.160 4.1 Brass; Stainless Steel<br />

21013-TC25/8<br />

21013-TC25/8 21016-TCW158P 1-2PVC 04184 12 0.280 7.1 PVC; Plastic<br />

Stahlwille ®<br />

2” PIPE CUTTER REU2 03620 4 0.295 7.5 Steel; Stainless Steel<br />

Swagelok ®<br />

MS-TC-308 MS-TCW-308 OSS 03655 12 0.160 4.1 Stainless Steel<br />

Virax ®<br />

2101 10; 2101 20; 2101 30 REU2 03620 4 0.295 7.5 Steel; Stainless Steel<br />

Wheeler Rex ®<br />

95041 8050 HS4 03504 4 0.320 8.1 Steel; Stainless Steel<br />

95041 8078 HS4 03504 4 0.320 8.1 Steel; Stainless Steel<br />

95061 8052 HS6 03506 4 0.390 9.9 Steel; Stainless Steel<br />

95081; 95121 8054 HS8-12 03508 4 0.450 11.4 Steel; Stainless Steel<br />

8002 HX21/2 03510 4 0.383 9.7 Steel; Stainless Steel; Schd 80<br />

95041 8051 HI4 03522 4 0.258 6.6 Cast Iron; Ductile Iron<br />

95061; 95081; 95121 8053 HI6 03524 4 0.410 10.4 Cast Iron; Ductile Iron<br />

95061; 95081; 95121 8076 H6PSE5 03525 4 0.400 10.2 Steel; Cast Iron; Ductile Iron<br />

8839 RCS8-36 03530 4 0.635 16.1 Steel; Stainless Steel<br />

6090; 7090; 6190; 6290; 6390; 6490; 6590; 60324 RXM 03534 1 0.432 11 Steel Pipe<br />

6790; 6793; 6794; 6890<br />

8838 RCI8-30 03535 4 0.500 12.7 Cast Iron; Ductile Iron<br />

9590 8001 2RBHD 03613 12 0.296 7.5 HD for Steel; Stainless Steel<br />

8004 3RG 03616 4 0.399 10.1 Steel; Stainless Steel<br />

8016 3RG 03616 4 0.399 10.1 Steel; Stainless Steel<br />

8006 R367 03639 6 0.480 12.2 Steel; Ductile Iron Heavy Wall<br />

9290; 9291 8012 OSS 03655 12 0.160 4.1 Stainless Steel<br />

9290; 9291 8015 O 03660 12 0.180 4.6 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

8021 30-40 03665 12 0.250 6.4 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

9490 8025 30-40 03665 12 0.250 6.4 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

8034 345T 03666 12 0.146 3.7 <strong>Co</strong>pper; Aluminum; Brass<br />

8045 R4546 03668 6 0.161 4.1 Steel; Stainless Steel<br />

90735; 90728; 90750 8071 73505 03690 12 0.170 4.3 <strong>Co</strong>pper; Aluminum; Brass; Steel Tubing<br />

8065 OP2 04180 12 0.275 7 ABS; PE; PEX; PP; PEX/AL/PEX<br />

8036 30-40P 04190 12 0.343 8.7 ABS; PE; PP<br />

8037 3-6PVC 04194 12 0.377 9.6 3”-6” PVC; 4” Heavy Wall; CPVC<br />

* Cutter wheels sold to distributors in standard package quantities only. ** Blade Exposure determines wall thickness capacity of cutter wheel.<br />

<strong>Reed</strong> has the widest variety of high-quality wheels<br />

for more cutters and more brands than any other manufacturer!<br />

9

Replacement wheels for every pipe and<br />

every pipe cutter<br />

Be on the cutting edge with <strong>Reed</strong>!<br />

DESIGNED FOR PERFORMANCE<br />

Thinness of<br />

<strong>Reed</strong> Wheels<br />

Thickness of<br />

All Other Wheels<br />

<strong>Reed</strong> offers the largest<br />

cutter wheel line for all<br />

types of pipe, tubing<br />

and conduit.<br />

The most popular<br />

types of genuine <strong>Reed</strong><br />

cutter wheels (P. 6) are<br />

also sold in convenient,<br />

two-pack display bags<br />

for quick and easy<br />

showroom purchases.<br />

Optimally thin tool profile cuts<br />

pipe easily, leaves less burr<br />

and lasts longer!<br />

Front<br />

Your distributorship can become a<br />

Cutter wheel<br />

headquarters<br />

Back<br />

<br />

Distributors participating in Cutter Wheel<br />

Annual <strong>Co</strong>ntracts are eligible for this<br />

durable, metal display case that makes<br />

choosing the right wheel easy. Additional<br />

showroom support includes our large<br />

counter mat with handy wheel conversion<br />

charts. Wheel conversions are also<br />

available at www.reedmfgco.com.<br />

<strong>Co</strong>ntact your <strong>Reed</strong> Rep or Regional<br />

Manager for program details.<br />

10

Quick Release Tubing Cutters<br />

Best tracking, easiest cutting tubing cutters available. Cut copper, aluminum, light<br />

wall steel, and stainless steel tubing. With alternate wheels it will cut a wide variety<br />

of plastic pipe and tubing. Three new cutters feature the R2558 wheel for muffler<br />

systems tubing. TC1Q, TC1.6Q and TC2Q sliding bars are die-cast zinc aluminum<br />

for greater strength. Each of these three also features a built-in reamer and spare<br />

cutter wheel in the knob. Xtra Value – just change the wheel to cut a wide<br />

variety of tubing.<br />

Reamer<br />

FEATURES<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Actual<br />

Inches<br />

O.D. Capacity Length Weight<br />

Actual<br />

Ø mm<br />

in mm lbs kg<br />

Wheel<br />

TC1.6Q<br />

Spare Cutter<br />

Wheel Storage<br />

TC1Q* 03410 1 /8 - 1 5 /16 3 - 33 6 152 0.6 0.3 O<br />

TC1.6Q* 03416 1 /4 - 1 5 /8 6 - 42 6.5 165 0.8 0.4 O<br />

TC2Q* 03420 1 /4 - 2 5 /8 6 - 63 8 203 1.2 0.5 O<br />

TC3Q 03430 3 /8 - 3 1 /2 10 - 90 11 279 2.5 1.1 30 - 40<br />

TC3Q2558 03439 3 /8 - 3 1 /2 10 - 90 11 279 2.5 1.1 R2558<br />

TC4Q 03440 1 7 /8 - 4 1 /2 48 - 114 12 305 2.8 1.3 30 - 40<br />

TC5Q2558 03459 2 1 /2 - 5 63 - 125 13 330 3.0 1.4 R2558<br />

TC6Q 03460 4 - 6 5 /8 102 - 168 15 381 3.9 1.8 30 - 40<br />

TC6Q2558 03469 4 - 6 5 /8 102 - 168 15 381 3.9 1.8 R2558<br />

NEW<br />

*Spare ”O” Cutter Wheel in Knob.<br />

Cutter wheels on p. 6 - 7<br />

Quick Release Cutters for Plastic on p. 54<br />

Quick Release cutter is a <strong>Reed</strong> invention and still the<br />

industry standard! First used by <strong>Reed</strong>, the ball detent wheel<br />

pin makes cutter wheel change easy. No other cutter on the<br />

market tracks or cuts as well!<br />

1<br />

Tubing Cutters<br />

Popular copper tubing cutters are long-lasting due to quality construction and have<br />

a large grip knob for comfort during use. A reamer is built inside grip knob for<br />

convenience and safety. Wide rollers yield a square cut while thin cutter wheel<br />

profile ensures a quick, clean cut. When structures, equipment, or ditch walls get in<br />

the way, the three wheel T23 requires only 3” clearance and a 150° cutting radius.<br />

Large capacity (2” nominal) means the T23 gets the job done when mini cutters are<br />

too small. Includes large knob with built-in reamer for comfort and convenience,<br />

plus large reamer in body for larger tubing clean-up.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

O.D. Capacity<br />

Actual<br />

Inches<br />

Actual<br />

Ø mm<br />

Weight<br />

Plastic<br />

T10 03483 1/8 - 1 3 - 25 0.9 0.4 O OP2 1 - 2PVC<br />

T15 03485 3/16 - 1 1 /4 4 - 32 1.3 0.6 O OP2 1 - 2PVC<br />

T20* 03487 5/8 - 2 1 /8 15 - 54 1.5 0.7 O OP2 1 - 2PVC<br />

T23* 03496 3/4 - 2 1 /8 19 - 54 1.4 0.6 3T23 – –<br />

*Exclusive<br />

**Ships with wheel for copper. To cut plastic pipe, order recommended cutter wheel separately.<br />

*AWWA Approved for Tapping <strong>Co</strong>ntest.<br />

Cutter wheels on p. 6 - 7<br />

TC11 03480 1 /8 - 1 1 /8 3 - 28 0.7 0.3 75015 75046<br />

TC14* 03475 1 /4 - 1 3 /8 6 - 35 1.1 0.5 73505 73515<br />

TC166 03465 1 /4 - 1 5 /8 6 - 42 1.2 0.5 73505 73515<br />

NEW<br />

*Replacement deburring blade available (Item <strong>Co</strong>de #03473 or #94437 for 10 pack).<br />

**Ships with regular wheel. Order heavy-duty wheels separately.<br />

Cutter wheels on p. 6 - 7<br />

lbs<br />

Telescoping Tubing Cutters<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Actual<br />

Inches<br />

O.D. Capacity<br />

Actual<br />

Ø mm<br />

lbs<br />

kg<br />

Weight<br />

kg<br />

<strong>Co</strong>pper<br />

Cutter Wheel**<br />

Telescoping Tubing Cutters are a good choice for tight spaces as their feed screw<br />

keeps them a consistent size throughout the cut. TC11 tubing cutter with strong,<br />

aluminum alloy body and nickel-chrome finish, makes a clean, square cut. Cutters<br />

have easy action, enclosed feed screw, fold-out reamer, grooved rollers, and spare<br />

cutting wheel. TC14 and TC166 move smoothly and offer a pencil reamer. TC14<br />

features a spare cutter wheel.<br />

PE<br />

Cutter<br />

Wheel**<br />

PVC<br />

Heavy-<br />

Duty<br />

Wheel<br />

T15<br />

TC166<br />

Pencil Reamer In<br />

The T23 is the only close-quarters<br />

tubing cutter with good leverage and<br />

a large knob for faster cutting. Its<br />

design requires only 150° for rotation.<br />

TC14<br />

Pencil Reamer Out<br />

T20<br />

Internal Reamer<br />

Fold-Out<br />

Reamer<br />

TC11<br />

TOOL<br />

Spare Cutter<br />

Wheel Storage<br />

T23<br />

Fold-Out<br />

Reamer<br />

Fold-Out Reamer<br />

and Spare<br />

Cutter Wheel<br />

Storage<br />

11

1<br />

T15SS<br />

Fold-Out<br />

Reamer<br />

MC3<br />

TC11SS<br />

MC2Grip<br />

MC1 features smallest cutting radius in the industry and<br />

finer screw thread for easier tightening. MC2 is heavyduty<br />

– the strongest mini cutter available. MC2GRIP also<br />

includes a larger, high-torque<br />

feed. Larger, deeply knurled knob<br />

allows easier tightening.<br />

Repair cutters on-site<br />

for less lost time!<br />

1-2 PARTS<br />

DEB3<br />

Spare Cutter<br />

Wheel Storage<br />

DEB0<br />

MC2<br />

Only <strong>Reed</strong> offers<br />

such a wide variety of<br />

professional-quality<br />

cutters with wheels<br />

for stainless installed.<br />

No more early<br />

replacement of the<br />

first wheel!<br />

MC1<br />

RPR Kit<br />

3-4-6 PARTS<br />

Tubing Cutters for Stainless Steel<br />

<strong>Reed</strong> tubing cutters are equipped with special wheels for stainless steel. <strong>Reed</strong><br />

wheels for stainless tubing use specialized steel for toughness and heat dissipation,<br />

resulting in long wheel life. T10SS, T15SS, and T20SS offer a large knob for<br />

firm grip and easy turning, along with an internal reamer in the knob. TC11SS<br />

telescoping cutter includes a fold-out reamer and spare wheel for stainless tubing.<br />

<strong>Catalog</strong><br />

No.<br />

T10SS 03476 1/8 - 1 3 - 25 OSS 0.9 0.4<br />

T15SS 03477 3/16 - 1 1 /4 4 - 32 OSS 1.4 0.6<br />

T20SS 03479 5/8 - 2 1 /8 15 - 54 OSS 1.5 0.7<br />

TC11SS* 03481 1/8 - 1 1 /8 3 - 28 75046* 0.7 0.3<br />

*Includes spare cutter wheel.<br />

Cutter wheels on p. 6 - 7<br />

Mini Tubing Cutters<br />

For use in extremely tight places, these tubing cutters require minimal swing around<br />

the tubing. Mini cutters can be used on copper, steel, stainless steel, and aluminum<br />

tubing. MC2GRIP has rounded corners and edges of the body for a more comfortable<br />

grip when rotating the cutter around tubing. MC3SL contains a self-feeding cutter<br />

wheel. After tightening the feed screw, the tool cuts faster by providing a more<br />

consistent cutting force on the wheel.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Actual in<br />

Actual<br />

Inches<br />

O.D. Capacity<br />

Actual<br />

Ø mm<br />

Actual mm<br />

lbs<br />

Weight<br />

kg<br />

Cutter<br />

Wheel<br />

Cutter<br />

Swing<br />

Inches<br />

MC1 03470 1/8 - 5 /8 3 - 15 0.2 0.1 32633 1 1 /4<br />

MC2 03490 1/8 - 15 /16 3 - 24 0.3 0.1 345T 1 11 /16<br />

MC2GRIP 03493 1/8 - 15 /16 3 - 24 0.4 0.2 345T 1 11 /16<br />

MC3 03495 1/8 - 1 1 /8 3 - 28 0.4 0.2 O 1 7 /8<br />

MC3SL 03341 1/8 - 1 1 /8 3 - 28 0.4 0.2 O 1 7 /8<br />

Cutter wheels on p. 6 - 7<br />

Deburring Tools<br />

These feature a long-lasting, hardened tool steel deburring blade. DEBO eliminates<br />

internal burrs in copper tubing. It has an aluminum handle and handy pocket clip. DEB3<br />

deburrs aluminum, copper, and steel tubing. It has a plastic body and three spare blades<br />

stored in its handle, giving this tool extra value.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Item<br />

<strong>Co</strong>de<br />

Capacity<br />

Repair Kits for Tubing Cutters<br />

Nominal Pipe Capacity<br />

Cutter<br />

Wheel<br />

lbs<br />

Weight<br />

DEB0 04434 unlimited 0.1 0.05<br />

DEB3* 04437 unlimited 0.1 0.05<br />

*Reamer replacement blade #94437 fits DEB3, TC1.6Q, and TC14.<br />

deburring tools for plastic on p. 61<br />

lbs<br />

Weight<br />

RPR Kit contains the parts, except body, for all <strong>Reed</strong> TCQ and TCQP sizes 1 through<br />

6. It also contains blades for ratchet and scissor shears. It is a great choice for<br />

distributor counter repairs or maintenance departments. Simple field repairs can<br />

be handled with 1-2 Parts and 3-4-6 Parts kits which are plastic bags containing<br />

the most popular parts for Quick Release Cutters. <strong>Co</strong>mmon spare parts for T10,<br />

T15, and T20 cutters are contained in T10-T15-T20 Parts kit.<br />

<strong>Catalog</strong> No.<br />

Item <strong>Co</strong>de<br />

Weight<br />

1-2 Parts 03009 2.2 oz 0.1<br />

3-4-6 Parts 03010 3.3 oz 0.1<br />

RPR Kit 03011 5.5 lbs 2.5<br />

T10-T15-T20 Parts 03014 3.0 oz 0.1<br />

lbs<br />

kg<br />

kg<br />

kg<br />

12

CSST Tubing Cutters †<br />

<strong>Reed</strong> offers CSST (corrugated stainless steel tubing) Tubing Cutters in different<br />

models for cuts with the outer plastic wrapper jacket on or off. They fit 1 /4” up to<br />

2 1 /2” CSST flexible gas piping. For cuts with the jacket off, <strong>Reed</strong> recommends the<br />

RT15T1 and the RT15T2 which feature a special nylon roller design allowing square<br />

and central cuts for optimal flaring in various CSST systems. The TC1.6QCSST is a<br />

great option for cutting CSST tubing up to 1 5 /8” with the jacket on. For cuts of 1 1 /4”<br />

up to 2 1 /2” with the jacket either off or on, <strong>Reed</strong> recommends the TC2QRGT.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Capacity<br />

Weight<br />

lbs kg<br />

Roller<br />

Jacket<br />

FEATURES<br />

Change the rollers and cutter wheel<br />

to use as a regular tubing cutter.<br />

RT15T2<br />

RT15T1 03497 3 /8'' & 1 /2'' 1.3 0.6 RT15T1R Off<br />

RT15T2 03498 3 /4'' & 1'' 1.3 0.6 RT15T2R Off<br />

TC1.6QCSST 03418 1 /4’’ - 1 5 /8’’ 0.8 0.4 CORRUGATED On<br />

TC2QRGT 03426 1 /4'' - 2 1 /2'' 1.2 0.5 RGT2QLR Off or On<br />

NEW<br />

† <strong>Reed</strong>’s tested cutters are suitable for Gastite ® , Parker Parflex ® ,<br />

WARDFLEX ® , TracPipe ® , and Pro-Flex ® systems.<br />

ACCESSORIES<br />

ROLLERS<br />

RT15T2R<br />

<strong>Co</strong>rrugated<br />

Rollers<br />

RT15T1R<br />

<strong>Co</strong>rrugated Rollers<br />

1<br />

Item<br />

<strong>Co</strong>de<br />

Roller<br />

Description<br />

93628 TC16QR Regular Roller for TC1.6Q/TC1.6QCSST<br />

93438 RT15T1R <strong>Co</strong>rrugated Rollers for 1 /2” and 3 /8” CSST tubing<br />

93439 RT15T2R <strong>Co</strong>rrugated Rollers for 3 /4” and 1” CSST tubing<br />

93444 RGT2QSR Small Roller for TC2QRGT<br />

93446 RGT2QLR Large Roller for TC2QRGT<br />

<strong>Reed</strong> works with pipe and tube<br />

manufacturers to constantly<br />

improve piping solutions.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Blade Exposure<br />

O 03660 0.180 4.6 RT15T1, RT15T2<br />

OCSST-2 03659 0.281 7.1 TC1.6QCSST, TC2QRGT<br />

Cutter wheels on p. 6-7<br />

CSST CUTTER WHEELS<br />

in<br />

mm<br />

Fits<br />

TC2QRGT<br />

Left Photo - Top Row, L to R - Mike<br />

Pruzinsky, Pat Reinke, Bill Stevens,<br />

Debbie Sulecki, Steve Angermeier<br />

Seated L to R - Joyce Carr,<br />

Todd Gilpatrick, LaVerna Ritchie<br />

Above Photo - Top Row, L to R -<br />

Gene Lachman, Minnie <strong>Co</strong>nfer,<br />

Tom Fess, Marnie Caldwell<br />

Seated L to R - Julie Machinski,<br />

Patty Soderberg, Rich Stummer<br />

Left Photo - Top Row, L to R -<br />

Carrie Applequist, Sophia Liuxuelian,<br />

Matt Harvey, Michael Balliett<br />

Seated L to R - Brian Gunderson,<br />

Wan-Xin Werstler, Tim Donohue<br />

From our family to yours...<br />

<strong>Reed</strong> Associates have produced fine tools for professional trades around<br />

the world since 1896. <strong>Reed</strong> engineers developed many of the most<br />

innovative and effective tools in the industry – such as the<br />

Quick Release Tubing Cutter, the Hinged Cutter , the Rotary <br />

Cutter, and the Universal Pipe Cutter. Many of these tools have<br />

been copied by others, but through continuous improvements<br />

and everyday dedication to quality workmanship, <strong>Reed</strong><br />

products remain the finest in the world.<br />

The goals of each <strong>Reed</strong> Associate are to ship 98% of orders<br />

within three working days, to provide immediate, informed<br />

responses to customer inquiries and to produce 100% errorfree<br />

work. <strong>Reed</strong> works diligently to cultivate relationships with<br />

dependable distributors to reach the end-user market. Selling<br />

through traditional, local distributors is the best avenue to strengthen ties<br />

with <strong>Reed</strong> tool users. The strong links in the customer service chain – from<br />

product development and manufacturing, through order processing and<br />

inquiry fulfillment, to distribution – make <strong>Reed</strong> a leader in customer<br />

satisfaction. <strong>Reed</strong> identifies the best people to provide the best quality<br />

tools which results in the best service available.<br />

Best Service + Best Quality +<br />

Best People = The Lowest Total <strong>Co</strong>st<br />

13

Steel Pipe Cutters<br />

Guide bars are exclusive to <strong>Reed</strong> and<br />

the best way to get a square cut on<br />

stainless steel and corroded pipe.<br />

Guide bars also reduce wheel<br />

90 o - 140 o breakage.<br />

SWING<br />

4-Wheel With Guides – Spring-tensioned guide bars of 2-4WGA provide square<br />

alignment for 4-wheel cutters. The short handle allows for close-quarter work.<br />

Thinnest wheels of highest quality tool steel make cutting easier and faster. Sharper<br />

wheels allow shorter handles for work in smaller spaces.<br />

Standard – Strong malleable iron frames and wide rollers ensure square cuts.<br />

Thinnest wheels of highest quality tool steel make cutting easier and faster. Sharper<br />

wheels allow shorter handles for work in smaller spaces. The 2-1 cutter leaves no<br />

burr, which is great for threading jobs; the 2-3 with three wheels means more<br />

cutting surface and less handle swing.<br />

1<br />

2-4WGA<br />

TOOL<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Pipe Capacity<br />

Inches-<br />

Nom.<br />

Actual<br />

OD Ø mm<br />

Length<br />

Weight<br />

in mm lbs kg<br />

Wheel*<br />

4-WHEEL WITH GUIDES<br />

2-4WGA* 03338 1 /2 - 2 21 - 63 14.3 362 7.2 3.3 2RBS<br />

STANDARD 1-WHEEL<br />

2-1 03320 1 /8 - 2 10 - 63 15.8 400 6.9 3.1 2RBS<br />

With rollers on the side away from the operator and<br />

the cutter wheel closer, <strong>Reed</strong> Steel Pipe Cutters are the<br />

easiest to line up with the cut-off mark. Wheel change is<br />

quick as the ring on the top of the wheel pin makes it<br />

convenient to find and center the pin through<br />

the second hole.<br />

STANDARD 3-WHEEL<br />

2-3 03305 1 /8 - 2 10 - 63 15.8 400 6.8 3.1 2RBS<br />

STANDARD 4-WHEEL<br />

2-4 03335 1 /2 - 2 21 - 63 14.3 362 6.8 3.1 2RBS<br />

*EXCLUSIVE<br />

*2RBCI wheels available for cast iron. 2RBHD heavy-duty wheels available for steel and stainless steel.<br />

Cutter wheels on p. 6 - 7<br />

2-1<br />

Replacement Wheel Pins available for Ridgid ® cutters: 1-A, 2-A, 42-A, 202, 2000A.<br />

Order <strong>Reed</strong> pin R34780 #93320 5/pk. to replace Ridgid ® pin No. 34780 (Old #F-9).<br />

FEATURE<br />

2-3<br />

<strong>Co</strong>nvert 2-1 and 2-3 back<br />

and forth simply by changing<br />

wheels and rollers.<br />

2-4<br />

Pawls<br />

Pipe Reamer<br />

Pipe Reamers are used to deburr steel pipe before threading. <strong>Co</strong>ne is made from<br />

tool steel and hardened for maximum life. Unique cutting edge makes this spiral<br />

reamer self-feeding and easy to start and operate.<br />

This <strong>Reed</strong> invention has<br />

two pawls for faster<br />

action and for work<br />

in tight places – requires<br />

half the handle swing<br />

space of competitive<br />

reamers.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Inches-<br />

Nom.<br />

Pipe Capacity<br />

Weight<br />

Actual<br />

ID Ø mm lbs kg<br />

2-71 06060 1 /8 - 2 3 - 50 6.7 3.0<br />

FEATURE<br />

Ridgid ® is a registered trademark of Ridgid, Inc. and is not associated with <strong>Reed</strong> <strong>Manufacturing</strong> <strong>Co</strong>mpany.<br />

14

Soil Pipe Cutters<br />

The fastest way to cut cast iron soil pipe, clay pipe, and small diameter concrete pipe<br />

is with a chain pipe cutter. Great for gray water applications! <strong>Reed</strong> has improved the<br />

original manufacturer’s design by providing stronger jaws and more durable adjusting<br />

screws which are interchangeable with the original tools. <strong>Reed</strong> soil pipe cutters are<br />

available in a single stroke SC59 model and a ratcheting SC49 model for close<br />

quarter work. Multiple use 1 /2” ratchet wrench ships with SC49 models. No-Hub ®<br />

Roller Kit is standard on all models.<br />

For cutting ductile iron pipe, <strong>Reed</strong> recommends Hinged cutters on p. 18 and<br />

Low Clearance rotary cutters on p. 19<br />

RATCHET<br />

SC49<br />

SC59<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Pipe Capacity**<br />

Inches-<br />

Nom.<br />

Actual<br />

Ø mm<br />

Length<br />

Weight<br />

in mm lbs kg<br />

SC49-6* 08049 1 1 /2 - 6 160 26 660 17.6 8.0<br />

SC49-8* 08050 1 1 /2 - 8 212 26 660 19.4 8.8<br />

SC49-10* 08051 1 1 /2 - 10 268 26 660 21.2 9.6<br />

SC49-12* 08052 1 1 /2 - 12 317 26 660 23.0 10.5<br />

SC49-15* 08053 1 1 /2 - 15 403 26 660 24.8 11.3<br />

1<br />

SINGLE STROKE<br />

SC59-6 08059 1 1 /2 - 6 160 43 1,092 23.8 10.8<br />

SC59-8 08060 1 1 /2 - 8 212 43 1,092 25.6 11.6<br />

SC59-10 08061 1 1 /2 - 10 268 43 1,092 27.4 12.5<br />

SC59-12 08062 1 1 /2 - 12 317 43 1,092 29.2 13.3<br />

SC59-15 08063 1 1 /2 - 15 403 43 1,092 31.0 14.1<br />

*Ratchet Wrench (#40208) included with all SC49 cutters.<br />

**Maximum Pipe Capacities (determined by maximum pressure applied):<br />

• Extra heavy cast iron soil pipe ..............2-4” (62-125 mm)<br />

• Service weight cast iron soil pipe ...........2-8” (62-212 mm)<br />

• <strong>Co</strong>ncrete pipe ...........................4-6” (125-160 mm)<br />

• No-Hub ® cast iron soil pipe ................1 1 /2”-8” (38-212 mm)<br />

• Clay pipe ...............................2-15” (62-403 mm)<br />

AVAILABLE<br />

Captured Screw<br />

Extension chains available to increase capacity of smaller cutters.<br />

NOTE: Jaw sets and cutter chains are interchangeable with Wheeler-Rex ® models. Pressure Screw<br />

Assembly available offering heavy-duty parts for current and prior <strong>Reed</strong> models, along with Wheeler-<br />

Rex ® 490. Order #98046 for <strong>Reed</strong> SC49 models and Wheeler-Rex ® 490 series; use #98047 for <strong>Reed</strong><br />

SC59 models.<br />

ACCESSORIES<br />

<strong>Catalog</strong> No.<br />

Item <strong>Co</strong>de<br />

Description<br />

SCEXT 40336 10” Extension Chain with 8 pitches at 1.25” per pitch<br />

TW516 02298 5 /16” Torque Wrench<br />

TW38 02300 3 /8” Torque Wrench<br />

First introduced by <strong>Reed</strong>, the captured<br />

screw makes the SC49 close-quarter soil<br />

pipe cutters both easy to use and less<br />

costly. The screw does not have to be<br />

manipulated into place which reduces<br />

screw and cutter breakage.<br />

* 1 /2” Ratchet Wrench<br />

ships with all SC49<br />

Cutters.<br />

TW38<br />

TW516<br />

Torque Wrenches for Cast Iron Soil Pipe on p. 68<br />

www.reedmfgco.com<br />

For the latest information on NEW REED Tools!<br />

15

DS12<br />

Roller<br />

Handles<br />

Pipe Descalers<br />

<strong>Reed</strong> pipe descalers feature wide, tough scrapers that remove scale, dirt, and corrosion<br />

cleanly and quickly from the pipe surface to allow more effective cutting, joining,<br />

gasket/valve seating, or other operations. Descalers are faster and more effective than<br />

chisels, chains or files and need only 2” of clearance around the pipe. Use descalers to<br />

clean pipe before cutting or water tapping or drilling. Roller handles allow smoother<br />

movement in use. DS12 and DS36 chain descalers are made entirely of steel that is<br />

zinc-plated for corrosion resistance and toughness. The scrapers are welded on for<br />

long life and can be sharpened. Also, <strong>Reed</strong> produces a heavy-duty power transmission<br />

belting pipe descaler, DS12B. Its handles and scrapers are blackened for good rust<br />

protection. Belt descaler benefits include lighter weight than all-metal descalers or<br />

chains, longer length to ease back strain during use, and high-profile scrapers that don’t<br />

clog with dirt as readily. <strong>Reed</strong> also offers replacement belts with scrapers attached;<br />

simply bolt the new belt onto the handles.<br />

1<br />

DS12B<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Type<br />

Pipe Capacity Length Weight<br />

Inches-<br />

Nom.<br />

mm in mm lbs kg<br />

DS12 08000 Steel Chain 3 - 12 70 - 300 32 810 5.7 2.6<br />

DS36 08006 Steel Chain 3 - 36 70 - 910 44 1110 8.2 3.7<br />

DS12B 08008 Belt 3 - 12 70 - 300 50 1257 4.2 1.9<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

REPLACEMENT BELT<br />

Description<br />

Length<br />

in mm<br />

Weight<br />

DS12BRB 98008 Replacement belt fits REED DS12B or 45 1143 3.0 1.4<br />

Wheeler-Rex ® 1300<br />

Saw It ® Pneumatic Saw<br />

lbs<br />

kg<br />

In Use on<br />

Plastic<br />

Saw It ® Vise<br />

Great for work on<br />

process piping!<br />

Saw It ® provides pneumatic power and reciprocating motion to blades. Saw<br />

improvements allow the tool to turn and work more freely, along with starting<br />

easier and running smoother. <strong>Reed</strong> offers blades to cut plastic, steel, stainless steel,<br />

and C900 PVC pipe.* Saw It ® needs a 6” clearance beyond the pipe to accommodate<br />

blade movement. Cuts up to 20” (500 mm) diameter pipe with a single setup. The Saw<br />

It ® must have a means to hold it in place. The recommended Saw It ® Vise (sold<br />

separately) fits 4” - 12” diameter pipe (up to 24” with chain extensions), and provides<br />

stability and safety for the cut. Pneumatic saws are less likely to ignite materials than<br />

gas-powered saws and even some electrical-powered saws. However, the Saw It ® is<br />

not recommended for gas lines.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Diameter Capacity*<br />

In - Nom.<br />

mm Nom.<br />

Maximum<br />

Power<br />

Speed<br />

Weight<br />

Strokes/Min. lbs kg<br />

SAWIT 07600 up to 24” max. up to 610 max. 1.5 HP, 1100 watts 50 cfm @ 90 psi 300 17.0 7.7<br />

1.4 cu. m/min. @ 6.2 BAR<br />

SAWITVISE 04600 4” – 12” 102 - 305 — — — 14.0 6.4<br />

*Capacity is dependent on blade and chain extensions.<br />

NOTE: Saw It ® , Saw It ® Vise, and Blades are all sold separately.<br />

Portable Power Hack Saw Blades on p. 74<br />

ACCESSORIES<br />

CHAIN EXTENSIONS<br />

Item <strong>Co</strong>de<br />

Air<br />

<strong>Co</strong>nsumption<br />

Description<br />

40628 6” diameter increment plus pin<br />

40629 12” diameter increment plus pin<br />

This saw is safer and cuts straighter than a<br />

gas-powered chop saw. The Saw It ® Vise<br />

allows the saw to pivot straight into the pipe,<br />

giving the operator better control over the cut.<br />

Used together, this saw is EASY to handle.<br />

Process Piping<br />

Application<br />

16

Universal Pipe Cutters (6”-48” or 150-1300 mm)<br />

These lightweight, easy-to-use Universal Pipe Cutters (UPC) are available<br />

to cut 6” - 48” (150-1300 mm) outside diameter ductile iron, cast iron, clay, concrete,<br />

steel, PVC, or PE pipe. The cutters are pneumatic powered. The lower cost<br />

UPC616A uses the same motor as the others, but does not need connecting<br />

frames. The UPC616 is shipped in a steel toolbox with a three-gallon, formed-steel<br />

water tank. The UPC636A and UPC648A come in a steel toolbox with a sevengallon,<br />

stainless steel water tank and cart.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

PNEUMATIC<br />

Inches-<br />

Pipe Diameter<br />

Nom. mm<br />

UPC616A 07512 6 - 16 150 - 450 89 40.5<br />

UPC636A 07510 6 - 36 150 - 1000 131 59.5<br />

UPC648A 07511 6 - 48 150 - 1300 138 62.7<br />

O.D.<br />

Net Weight*<br />

*NET WEIGHT includes all components that may be part of any given tool item code, but does not<br />

include packing materials.<br />

Must order REQUIRED blades SEPARATELY.<br />

lbs<br />

kg<br />

1<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

UPCARB4 97510 4” BLADES cut up to 23 /32” (18.3 mm) wall thickness 6” (150 mm) PVC<br />

UPBEVEL 97512 Available by special order. Minimum order applies. PVC<br />

UPCARB6 97514 6” BLADES cut up to 1 23 /32” (43.7 mm) wall thickness 8” - 48” (200-1300 mm) PVC<br />

UPCSTEEL4 97519 4” BLADES cut up to 23 /32” (18.3 mm) wall thickness 6” - 8” (150-200 mm) Steel, PE<br />

UPCSTEEL6 97520 6” BLADES cut up to 1 23 /32” (43.7 mm) wall thickness 8” - 48” (200-1300 mm) Steel, PE<br />

UPDIA6C 97524 6” BLADES cut up to 1 23 /32” (43.7 mm) wall thickness 8” - 48” (200-1300 mm) Cast Iron, Pit Cast, Ductile Iron<br />

Clay, <strong>Co</strong>ncrete<br />

UPDIA4C 97528 4” BLADES cut up to 23 /32” (18.3 mm) wall thickness 6” (150 mm) Cast Iron, Pit Cast, Ductile Iron<br />

Clay, <strong>Co</strong>ncrete<br />

NEW<br />

pipe descalers on p. 16<br />

ACCESSORIES<br />

UPC POWER REQUIREMENTS<br />

Accessory<br />

BLADE SELECTION CHART<br />

Pneumatic<br />

Horsepower = 1.7 H.P.<br />

Maximum R.P.M. = 3675<br />

Air <strong>Co</strong>nsumption = 50 cu. ft./min. (1.4 cu. m/min.)<br />

Pressure = 90 P.S.I. Maximum (6 BAR)<br />

Shut-Off = 3 /4” Ball Valve<br />

Air Supply Fittings = 3 /4” Dixon ”Air King” <strong>Co</strong>upling<br />

Item <strong>Co</strong>de<br />

Air-Line Oil 97583<br />

Arbor Locknut 97543<br />

Arbor Wrench 97590<br />

Chain Hooks 97546<br />

Diamond Blade Sharpening Stone 97595<br />

Filter for the FRL 40139<br />

Hex Key Set 40156<br />

Motor Grease, 2 oz. 97588<br />

Release Pins 97545<br />

Water Tank Hose System 97581<br />

Wedges 97589<br />

service<br />

Description<br />

UPC motor reconditioning/refurbishing is available. <strong>Co</strong>mplete UPC cutters can also<br />

be reconditioned/refurbished.<br />

BEFORE shipping items, contact <strong>Reed</strong> by phone, fax, or email for a return<br />

authorization number.<br />

All items should arrive freight prepaid at the <strong>Reed</strong> factory. Quotes, including any<br />

labor charges, will be issued upon inspection of the unit.<br />

Pipe Diameter<br />

AVAILABLE<br />

Pipe Material<br />

The <strong>Reed</strong> UPC is lightweight; cuts fast;<br />

requires only 12” (300 mm) clearance around<br />

the pipe; provides a square cut virtually<br />

every time; and can be operated underwater.<br />

It is by far the safest, easiest and fastest<br />

power cutter to setup, operate and maintain,<br />

which nets a low operating cost.<br />

UPC636A<br />

Blades for Steel Pipe<br />

NOW available!<br />

17

Hinged Cutters (1”-12” or 32-356 mm)<br />

Four wheels cut steel, stainless steel, cast and ductile iron with only 90° to 110°<br />

handle swing. Only 4” (125 mm) clearance required around pipe. Strong guide<br />

fingers ensure perfect wheel alignment for square cuts. A closed 360° frame<br />

forces all energy into cutting the pipe for maximum efficiency. There is no shower<br />

of sparks in this cold cut. This is the only hinged cutter that tracks every time and<br />

the only one recommended for ductile iron, steel, and stainless steel to Schedule<br />

100. This tool is a <strong>Reed</strong> invention.<br />

1<br />

AVAILABLE<br />

90° - 110°<br />

SWING<br />

Hinged Cutters are a <strong>Reed</strong><br />

invention! They are lighter, track<br />

better for square cuts, and require<br />

less clearance, yet provide better<br />

torque so the cut is made faster<br />

and with less effort. Can be<br />

used anywhere – in the ditch,<br />

underwater, in explosive<br />

atmospheres (cold cut), in<br />

noise-free zones, over head,<br />

in racks of pipes, etc.<br />

SIZE<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Inches-<br />

Nom.<br />

Pipe Capacity Length Weight<br />

Actual<br />

Ø mm<br />

in mm lbs kg<br />

H21/2S* 03110 1 - 2 1 /2 32 - 76 17 419 7.2 3.3<br />

H21/2I* 03112 1 - 2 1 /2 32 - 76 17 419 7.2 3.3<br />

H21/2X* 03114 1 - 2 1 /2 32 - 76 17 419 7.2 3.3<br />

H4S 03120 2 - 4 60 - 125 22 559 12.8 5.8<br />

H4I 03122 2 - 4 60 - 125 22 559 12.8 5.8<br />

H4X 03124 2 - 4 60 - 125 22 559 12.8 5.8<br />

H6S 03130 4 - 6 114 - 182 28 711 19.4 8.8<br />

H6I 03132 4 - 6 114 - 182 28 711 19.4 8.8<br />

H6X 03134 4 - 6 114 - 182 28 711 19.4 8.8<br />

H8S 03140 6 - 8 168 - 240 32 813 24.4 11.1<br />

H8I 03142 6 - 8 168 - 240 32 813 24.4 11.1<br />

H8X 03144 6 - 8 168 - 240 32 813 24.4 11.1<br />

H8XX 03146 6 - 8 168 - 240 32 813 24.4 11.1<br />

H12S 03150 8 - 12 219 - 356 34 864 34.9 15.9<br />

H12I 03152 8 - 12 219 - 356 34 864 34.9 15.9<br />

H12X 03154 8 - 12 219 - 356 34 864 34.9 15.9<br />

H12XX 03156 8 - 12 219 - 356 34 864 34.9 15.9<br />

*EXCLUSIVE<br />

1<br />

4”<br />

CLEARANCE<br />

NOTE: S= includes cutter wheels for steel; I= includes cutter wheels for cast and ductile iron;<br />

X= includes cutter wheels for schedule 80 steel; XX= for schedule 100 steel.<br />

Wheels for same size cutters are interchangeable. Recommend only <strong>Reed</strong> cutter wheels be used with<br />

these Hinged Cutters . <strong>Reed</strong> wheels are made from high shock-resistant tool steel on computerized<br />

(CNC) machines and then precisely heat-treated. This allows for a thinner profile yet stronger blade,<br />

so they:<br />

• Cut easier and faster, especially stainless steel and ductile pipe<br />

• Last much longer<br />

• Allow for shorter cutter handle for work in tight spaces<br />

• Provide the best value<br />

cutter wheels on p. 7<br />

Pipe descalers on p. 16<br />

Replacement Wheel Pins for Ridgid ® cutters: 3S, 4S, 6S, 44S, 466, 468, 472. Order <strong>Reed</strong> pin<br />

R34790 #93322 5/pk. to replace Ridgid ® pin No. 34790 (Old #F-14).<br />

Ridgid ® is a registered trademark of Ridgid, Inc. and is not associated with <strong>Reed</strong> <strong>Manufacturing</strong> <strong>Co</strong>mpany.<br />

www.reedmfgco.com<br />

For the latest information on NEW REED Tools!<br />

18

Rotary Cutters & Low Clearance Rotary Cutters (6”-36” or 159-915 mm)<br />

<strong>Co</strong>ld cut large diameter steel, most stainless steel, ductile, and cast iron pipe in<br />

close quarters. The low profile design of the LCRC models needs only 4” clearance<br />

for up to 16” pipe diameter; only 8” clearance for the RC20 and RC24; and just<br />

11.8” clearance for the RC30 and RC36 large diameter pipe cutters. Each cutter is<br />

supplied with a slip-on handle that is used to turn the cutter around the pipe in<br />

one direction. The handle is also used to tighten the cutter every 1/2 revolution.<br />

Best manual cutters for ductile iron. With good leverage from long handle, pipe<br />

snaps off squarely before wheel penetrates halfway through pipe. Cutters have<br />

heavy-duty frames.<br />

All sizes use the same cutter wheels: either<br />

RCS8-36 for steel and RCI8-30 for ductile and<br />

cast iron. RCX wheels cut up to 25 /32” wall<br />

thickness for steel pipe.<br />

Rotary cutters are a <strong>Reed</strong> invention! <strong>Reed</strong><br />

Rotary cutters cut pipe safely, easily, quickly,<br />

and at a low cost. Provides a square cut and can<br />

be used anywhere – in the ditch, underwater, in<br />

explosive atmospheres (cold cut), in noise-free<br />

zones, over head, in racks of pipes, etc. <strong>Reed</strong><br />

Rotary cutters last for decades.<br />

<strong>Catalog</strong><br />

No.<br />

Item<br />

<strong>Co</strong>de<br />

Steel**<br />

Inches-<br />

Nom.<br />

Pipe Capacity<br />

Cast Iron<br />

& Ductile<br />

Inches-<br />

Nom.<br />

Actual<br />

Ø mm<br />

†CONVERSION KITS<br />

<strong>Catalog</strong> No.<br />

Item<br />

<strong>Co</strong>de<br />

<strong>Co</strong>nverts<br />

RC30CONV 03267 RC36 to RC30<br />

RC36CONV 03268 RC30 to RC36<br />

Length<br />

Weight<br />