Model 1835-C - Newport Corporation

Model 1835-C - Newport Corporation

Model 1835-C - Newport Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Model</strong> <strong>1835</strong>-C<br />

Multi-Function<br />

Optical Meter<br />

OPERATOR’S<br />

MANUAL

<strong>Model</strong> <strong>1835</strong>-C<br />

Multi-Function Optical Meter

Warranty<br />

<strong>Newport</strong> <strong>Corporation</strong> warrants this product to be free from defects in material<br />

and workmanship for a period of 1 year from the date of shipment. If found to<br />

be defective during the warranty period, the product will either be repaired or<br />

replaced at <strong>Newport</strong>’s option.<br />

To exercise this warranty, write or call your local <strong>Newport</strong> representative, or<br />

contact <strong>Newport</strong> headquarters in Irvine, California. You will be given prompt<br />

assistance and return instructions. Send the instrument, transportation<br />

prepaid, to the indicated service facility. Repairs will be made and the instrument<br />

returned, transportation prepaid. Repaired products are warranted for<br />

the balance of the original warranty period, or at least 90 days.<br />

Limitation of Warranty<br />

This warranty does not apply to defects resulting from modification or misuse<br />

of any product or part. This warranty also does not apply to fuses, batteries,<br />

or damage from battery leakage.<br />

This warranty is in lieu of all other warranties, expressed or implied, including<br />

any implied warranty of merchantability or fitness for a particular use.<br />

<strong>Newport</strong> <strong>Corporation</strong> shall not be liable for any indirect, special, or<br />

consequential damages.<br />

Statement of Calibration<br />

This instrument has been inspected and tested in accordance with specifications<br />

published by <strong>Newport</strong> <strong>Corporation</strong>.<br />

The accuracy and calibration of this instrument and photodetector (where<br />

applicable) is traceable to the National Institute for Standards and Technology<br />

through equipment which is calibrated at planned intervals by comparison to<br />

the certified standards maintained at <strong>Newport</strong> <strong>Corporation</strong>.<br />

Copyright 1993, <strong>Newport</strong> <strong>Corporation</strong><br />

Part No. 20061-01, Rev. D<br />

IN-05931 (02-00)<br />

ii

EC DECLARATION OF CONFORMITY<br />

<strong>Model</strong> <strong>1835</strong>-C<br />

We declare that the accompanying product, identified with the<br />

" " mark, meets the intent of the Electromagnetic Compatability<br />

Directive, 89/336/EEC and Low Voltage Directive 73/23/EEC.<br />

Compliance was demonstrated to the following specifications:<br />

EN50081-1 EMISSIONS:<br />

Radiated and conducted emissions per EN55011, Group 1,<br />

Class A<br />

EN50082-1 IMMUNITY:<br />

Electrostatic Discharge per IEC 1000-4-2, severity level 3<br />

Radiated Emission Immunity per IEC 1000-4-3, severity level 2<br />

Fast Burst Transients per IEC 1000-4-4, severity level 3<br />

Surge Immunity per IEC 1000 4-5, severity level 3<br />

IEC SAFETY:<br />

Safety requirements for electrical equipment specified in<br />

IEC 1010-1.<br />

Alain Danielo<br />

Jeff Cannon<br />

VP European Operations<br />

General Manager-Precision Systems<br />

Zone Industrielle<br />

1791 Deere Avenue<br />

45340 Beaune-la-Rolande, France Irvine, Ca. USA<br />

iii

Table of Contents<br />

Warranty ................................................................................................................. ii<br />

EC Declaration of Conformity ............................................................................... iii<br />

List of Figures ........................................................................................................ vii<br />

List of Tables ........................................................................................................ viii<br />

Safety Symbols and Terms .................................................................................... ix<br />

Definitions ............................................................................................................... x<br />

Specifications ......................................................................................................... xi<br />

Section 1 – General Information<br />

1.1 System Overview ...................................................................................... 1<br />

1.2 Scope of this manual ................................................................................ 2<br />

1.3 Unpacking and Inspection ........................................................................ 2<br />

1.4 Preparation for Use .................................................................................. 2<br />

1.5 Optional Accessories and Services ......................................................... 2<br />

Section 2 – System Operation<br />

2.1 Introduction .............................................................................................. 3<br />

2.2 Display ....................................................................................................... 3<br />

2.3 Top Level Key Functions .......................................................................... 5<br />

O I<br />

2.3.1 , Power .................................................................................... 6<br />

2.3.2 SHIFT.............................................................................................. 6<br />

2.3.3 DISP , Display Brightness .......................................................... 6<br />

2.3.4 FILTER, Signal Filtering ................................................................. 6<br />

2.3.5 ZERO, Offset Subtraction ............................................................. 7<br />

2.3.6 AUTO, Automatic Gain Ranging................................................... 7<br />

2.3.7 STO REF, Store Reference Value .................................................. 7<br />

2.3.8 ATTN, Attenuator ......................................................................... 8<br />

2.3.9 λ, Wavelength................................................................................ 8<br />

2.3.10 RANGE, Signal Range .................................................................... 8<br />

2.3.11 R/S, Run-Stop................................................................................. 8<br />

2.3.12 MODE, Measurement Mode ......................................................... 9<br />

2.3.13 UNITS, Display Units ................................................................... 10<br />

2.3.14 STATS, Moving Statistics ........................................................... 10<br />

2.3.15 EXT, External Trigger ................................................................. 11<br />

2.3.16 MENU ........................................................................................... 11<br />

2.3.17 ENTER .......................................................................................... 11<br />

2.3.18 ESC, Escape ................................................................................. 11<br />

2.3.19 , , , Adjust..................................................................... 11<br />

2.4 Menu Level Functions ............................................................................ 12<br />

2.4.1 Menu Access and Movement ..................................................... 12<br />

2.4.2 Data Store .................................................................................... 14<br />

iv

2.4.3 Meter Configuration ................................................................... 15<br />

2.4.4 Auto Cal ....................................................................................... 16<br />

2.4.5 User Calibration .......................................................................... 17<br />

2.4.6 DC Sampling ................................................................................ 17<br />

2.4.7 Trigger Output ............................................................................ 18<br />

2.4.8 Trigger Input ............................................................................... 19<br />

2.4.9 Bar Graph .................................................................................... 19<br />

2.4.10 Tone ............................................................................................. 20<br />

2.4.11 Detector Switch Position............................................................ 20<br />

2.4.12 Remote Setup .............................................................................. 20<br />

2.4.13 General Information Functions .................................................. 20<br />

2.5 Connecting AC Power ............................................................................. 21<br />

2.6 Detector Connection and Setup............................................................. 22<br />

2.7 Power Up ................................................................................................. 22<br />

2.8 Performing Basic Measurements ........................................................... 23<br />

2.8.1 Making a DC Power Measurement ............................................ 23<br />

2.8.2 Making a Peak-to-Peak Power Measurement ............................ 23<br />

2.8.3 Making a Pulse Energy Measurement ....................................... 24<br />

2.8.4 Making a Signal Integration Measurement................................ 24<br />

2.8.5 Measuring a Laser Pulse Energy with a Thermopile Detector 24<br />

2.8.6 Using the <strong>Model</strong> <strong>1835</strong>-C as an Exposure Controller ................. 26<br />

Section 3 – Principles of Operation<br />

3.1 Introduction ............................................................................................ 27<br />

3.2 Analog Signal Flow .................................................................................. 27<br />

3.3 Digitized Signal Flow ............................................................................... 28<br />

3.4 Typical Detector Signals......................................................................... 30<br />

3.5 Thermopile Detector Signals ................................................................. 30<br />

3.6 Pulse Energy Detector Signals ............................................................... 31<br />

3.7 Peak-to-Peak (Photodiode) Detector Signals ........................................ 32<br />

3.8 Integration of Detector Signals .............................................................. 33<br />

3.9 Analog Output ......................................................................................... 34<br />

3.10 Measurement Considerations ................................................................ 34<br />

3.10.1 Detector Calibration and Accuracy ........................................... 34<br />

3.10.2 Quantum Detector Temperature Effects .................................. 35<br />

3.10.3 Thermopile Detector Temperature Effects .............................. 35<br />

3.10.4 Energy Detector Temperature Effects ...................................... 35<br />

3.10.5 Ambient and Stray Light ............................................................ 35<br />

3.10.6 Common Measurement Errors .................................................. 36<br />

Section 4 – Computer Interfacing<br />

4.1 General Guidelines .................................................................................. 37<br />

4.2 Computer Interface Terminology .......................................................... 37<br />

4.3 Entering Remote Computer Interface Mode ......................................... 39<br />

4.4 RS-232C Communication ........................................................................ 39<br />

4.4.1 Setting Baud Rate and Echo Mode from the Keypad. .............. 40<br />

4.4.2 Setting Baud Rate and Echo Mode from a Remote Interface .. 40<br />

v

4.5 RS-232C XON/XOFF Handshaking Protocol .......................................... 41<br />

4.6 GPIB Communication ............................................................................. 41<br />

4.6.1 Setting the GPIB Address ........................................................... 42<br />

Section 5 – Remote Command Reference<br />

5.1 <strong>Model</strong> <strong>1835</strong>-C Remote Interface Commands ......................................... 43<br />

5.2 Device Independent Commands ............................................................ 45<br />

5.3 Device Dependent Commands............................................................... 54<br />

Section 6 – Maintenance, Test and Troubleshooting<br />

6.1 Maintenance Procedures ....................................................................... 82<br />

6.2 Power Up Self Test .................................................................................. 82<br />

6.3 Troubleshooting Guide .......................................................................... 82<br />

Section 7 – Factory Service<br />

7.1 Introduction ............................................................................................ 85<br />

7.2 Obtaining Service .................................................................................... 85<br />

Service Form ........................................................................................... 87<br />

Appendices<br />

A Syntax and Definitions ............................................................................ 89<br />

B Error Messages ....................................................................................... 93<br />

C Status Reporting System ........................................................................ 96<br />

D Sample Programs .................................................................................. 100<br />

vi

List of Figures<br />

1. <strong>Model</strong> <strong>1835</strong>-C Controller and Accessories ..................................................... 1<br />

2a. <strong>Model</strong> <strong>1835</strong>-C VFD Display .............................................................................. 3<br />

2b. Description of <strong>Model</strong> <strong>1835</strong>-C Display Regions ............................................... 4<br />

3. Front Panel Key Pad ........................................................................................ 5<br />

4. Decimal Point Indication of Menu Hierarchy Position ................................ 12<br />

5. Rear Panel Power Supply Voltage Switches in Positions L, R .................... 21<br />

6. Connecting a Detector with its Calibration Module .................................... 22<br />

7. <strong>Model</strong> <strong>1835</strong>-C Detector Calibration Module Input Port .............................. 22<br />

8. Measuring Laser Pulse Energy via a Thermopile in INTG Mode ................ 25<br />

9. <strong>Model</strong> <strong>1835</strong>-C Analog Signal Flow Diagram .................................................. 27<br />

10. <strong>Model</strong> <strong>1835</strong>-C Digitized Signal Flow Block Diagram..................................... 28<br />

11. Thermopile Signals ........................................................................................ 30<br />

12. Energy Detector Signal from a Single Optical Pulse .................................... 31<br />

13. Negative Baseline Drift Voltage to a Pulse Train ......................................... 31<br />

14. Time Varying Signal Measurements ............................................................. 32<br />

15. Integrated Energy Via a Trapezoid Approximation .................................... 33<br />

16. Measuring Laser Pulse Energy with a Thermopile...................................... 34<br />

17. RS 232 Cable Connections ............................................................................. 40<br />

vii

List of Tables<br />

Table 1. <strong>Model</strong> <strong>1835</strong>-C Display Annunciators .................................................... 4<br />

Table 2. <strong>Model</strong> <strong>1835</strong>-C Top Level Key Functions and<br />

Associated Remote Commands ........................................................... 5<br />

Table 3. <strong>Newport</strong> Detector Families and Available Measurement Modes ...... 9<br />

Table 4. <strong>Model</strong> <strong>1835</strong>-C Measurement Modes ..................................................... 9<br />

Table 5. Valid Display Units Available to Detector Families by MODE.......... 10<br />

Table 6. Displayed Unit Abbreviations versus Actual Measurement Units .. 10<br />

Table 7. Menu Level Key Functions and Parameters ...................................... 13<br />

Table 8. Data Store Operations ......................................................................... 14<br />

Table 9. Configuration Parameters and Default Conditions ........................... 15<br />

Table 10. Meter Configuration Operations ........................................................ 16<br />

Table 11. User Calibration Operations ............................................................... 17<br />

Table 12. SAMPLE PREC States and Limits ........................................................ 18<br />

Table 13. DC SAMPLING Operations .................................................................. 18<br />

Table 14. TRIGGER OUT Operations .................................................................. 19<br />

Table 15. EXT TRIGGER IN Operations .............................................................. 19<br />

Table 16. BAR GRAPH Operations ...................................................................... 19<br />

Table 17. TONE Operations ................................................................................ 20<br />

Table 18. DET SWITCH POS Operations ............................................................ 20<br />

Table 19. REMOTE SETUP Operations ............................................................... 20<br />

Table 20. GENERAL INFO Operations ................................................................ 21<br />

Table 21. Power Supply Voltage Switch Positions ............................................ 21<br />

Table 22. Analog Signal Flow Paths .................................................................... 28<br />

Table 23 Common Measurement Errors ........................................................... 36<br />

Table 24 <strong>Model</strong> <strong>1835</strong>-C IEEE-488.1 Capabilities Summary ............................... 41<br />

Table 25 Device Independent Status Commands ............................................. 43<br />

Table 26 Device Dependent Commands .................................................... 44 - 45<br />

Table 27. Symptom/Fault Troubleshooting Guide ..................................... 83 - 84<br />

viii

Safety Symbols and Terms<br />

The following safety terms are used in this manual:<br />

The WARNING heading in this manual explains dangers that could result in<br />

personal injury or death.<br />

The CAUTION heading in this manual explains hazards that could damage<br />

the instrument.<br />

In addition, a NOTES heading gives information to the user that may be<br />

beneficial in the use of this instrument.<br />

GENERAL WARNINGS AND CAUTIONS<br />

The following general warnings and cautions are applicable to this<br />

instrument:<br />

WARNING<br />

This instrument is intended for use by qualified personnel who recognize<br />

shock hazards or laser hazards and are familiar with safety precautions<br />

required to avoid possible injury. Read the instruction manual<br />

thoroughly before using, to become familiar with the instrument’s<br />

operations and capabilities.<br />

WARNING<br />

The American National Safety Institute (ANSI) states that a shock hazard<br />

exists when probes or sensors are exposed to voltage levels greater then<br />

42VDC or 42V peak AC. Do not exceed 42V between any portion of the<br />

<strong>Model</strong> <strong>1835</strong>-C (or any attached detector or probe) and earth ground or a<br />

shock hazard will result.<br />

CAUTION<br />

There are no user serviceable parts inside the <strong>Model</strong> <strong>1835</strong>-C. Work<br />

performed by persons not authorized by <strong>Newport</strong> may void the warranty.<br />

For instructions on obtaining warranty repair or service please<br />

refer to Section 5 of this manual.<br />

ix

Definitions<br />

A amps<br />

AC alternating current<br />

ADC analog-to-digital converter<br />

BAT battery option<br />

BIC biconic fiber connector<br />

BNC standard coaxial connector type<br />

°C degrees Centigrade<br />

DC direct current<br />

°F degrees Fahrenheit<br />

Hz hertz (cycles per second)<br />

I-V current-to-voltage converter<br />

kHz kilohertz<br />

kΩ kiloOhms<br />

mA milliamps<br />

mV millivolts<br />

nA nanoamps<br />

nF nanofarads<br />

nm nanometers<br />

P-P peak-to-peak<br />

RH relative humidity<br />

S/N serial number<br />

µA microamps<br />

µS microsecond<br />

V volts<br />

W watts<br />

x

Specifications<br />

Physical Specifications:<br />

Dimensions:<br />

Weight:<br />

Enclosure:<br />

Connectors:<br />

Power:<br />

Display:<br />

Display Update Rate:<br />

Gain Ranges:<br />

Operating Environment:<br />

Storage Environment:<br />

Compatible Detectors:<br />

4.2 × 8.8 × 13.9 in (107 × 224 × 353 mm)<br />

8 lb, 3 oz. (3.7 kg)<br />

Metal case, painted<br />

8-Pin Sub Mini DIN CAL MODULE Input;<br />

BNC Analog Output, Trigger Output and<br />

Trigger Input; 9 Pin D-Sub RS-232,<br />

24 Conductor GPIB<br />

100/120/220/240 VAC ± 10%, 50/60 Hz<br />

5.5 digit annunciated VFD<br />

10 Hz<br />

Up to 7 decades (Detector and MODE<br />

dependent)<br />

0°C – 40°C; < 70% RH noncondensing<br />

-20°C – 60°C; < 90% RH noncondensing<br />

Low-Power (Semiconductor) Family<br />

High-Power (Thermopile) Family<br />

Energy (Pyroelectric) Family<br />

xi

Electrical Specifications:<br />

DC Current Measurement (Low-Power, Semiconductor Photodiode CAL MODULE)<br />

Signal Range: 1,2 0 1 2 3 4 5 6<br />

Full-Scale Current: 2.51 nA 25.1 nA 251 nA 2.51 µA 25.1 µA 251 µA 2.50 mA<br />

A/D Resolution: 126 FA 1.26 pA 12.6 pA 126 pA 1.26 nA 12.6 nA 126 nA<br />

(20,000 Count Precision)<br />

Display Noise Floor: ≤ 8 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD<br />

(Input Open, Filter Off)<br />

Full-Scale Accuracy: 3 ± 0.1% 0.05% 0.05% 0.05% 0.05% 0.05% 0.05%<br />

(Typical)<br />

Full-Scale Accuracy: 3 ±0.48% .30% .30% .30% .30% .30% .30%<br />

(Worst-Case)<br />

Peak-Peak Current Measurement (Low-Power, Semiconductor Photodiode CAL MODULE)<br />

Signal Range: 1, 2 0 1 2 3 4 5 6 7 8<br />

Full Scale (P-P) Current: 253 nA 797 nA 2.52 µA 7.97 µA 25.1 µA 79.3 µA 251 µA 793 µA 2.51 mA<br />

A/D Resolution: 61.7 pA 195 pA 616 pA 1.95 nA 6.13 nA 19.4 nA 61.3 nA 194 nA 613 nA<br />

Full-Scale Accuracy: 3 ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1%<br />

(Typical)<br />

Full-Scale Accuracy: 3 ±2% ±2% ±2% ±2% ±2% ±2% ±2% ±2% ±2%<br />

(Worst Case)<br />

Bandwidth (3db): (5 Hz - 1 KHz) (5 Hz - 10 KHz) (5 Hz - 47 KHz)<br />

Frequency Range for<br />

±2% (Typ) Accuracy: (50 Hz - 100 Hz) (50 Hz - 1.4 KHz) (50 Hz - 7 KHz)<br />

Trigger Level: 4% of full scale (fixed) above ground.<br />

D.C. Voltage Measurement (Thermopile CAL MODULE)<br />

Signal Range: 1, 2 0 1 2 3<br />

Full Scale Voltage: 2.49 mV 24.9 mV 249 mV 2.49 V<br />

(20,000 Count Precision)<br />

Resolution: 125 nV 1.25 µV 12.5 µV 125 µV<br />

(20,000 Count Precision)<br />

Display Noise Floor: ≤ 8 LSD ≤ 1 LSD ≤ 1 LSD ≤ 1 LSD<br />

(Input Shorted)<br />

Full Scale Accuracy (Typ.): 3 ± .3% ± .2% ± .1% ± .05%<br />

Full Scale Accuracy: ± .56% ± .36% ± .18% ± .1%<br />

(Worst Case)<br />

Bandwidth (3db): 5 Hz 5 Hz 5 Hz 5 Hz<br />

1<br />

Listed signal ranges specify meter capability. Available signal ranges are detector dependent.<br />

2<br />

Maximum measurable signal is detector dependent. See description of detector saturation message “SA”, page 83.<br />

3<br />

After 60 min warm-up, followed by execution of AUTOCAL command. See Section 2.4.4.<br />

xii

Pulse Voltage Measurement (Energy, Pyroelectric CAL MODULE)<br />

Signal Range: 1 0 1 2 3 4 5 6 7 8 9<br />

Full Scale 2 Voltage: 789 µV 2.50 mV 7.89 mV 25.0 mV 78.9 mV 250 mV 789 mV 2.50 V 7.91 V 25.0 V<br />

A/D Resolution: 193 nV 610 nV 1.93 µV 6.10 µV 19.3 µV 61.0 µV 193 µV 610 µV 1.93 mV 6.10 mV<br />

Full-Scale Accuracy: 3 ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1% ±1%<br />

(Typical)<br />

Full-Scale Accuracy: 3 ± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2% ± 2%<br />

(Worst Case)<br />

Maximum Pulse Repetition Rate: 2 kHz<br />

Trigger Level: 8% of Full Scale 1 (fixed)<br />

1<br />

Listed signal ranges specify meter capability. Available signal ranges are detector dependent.<br />

2<br />

Full scale voltage is measured relative to baseline voltage.<br />

3<br />

After 60 min warm-up, followed by AUTOCAL command. See Section 2.4.4.<br />

Analog Output<br />

Full Scale Voltage: 0 - 2.5V into 50Ω<br />

Accuracy: ± 2.5%<br />

xiii

Detector Signals and Calculations:<br />

S<br />

Represents the most recent signal value obtained<br />

from the A/D converter. It may represent<br />

amps or volts and may be analog and or digitally<br />

filtered.<br />

S d<br />

Represents the value stored as a reference signal<br />

for subsequent use in signal offset, i.e. ZERO<br />

calculations. Sd=0 when ZERO is off.<br />

S−<br />

S d<br />

( S−<br />

Sd)<br />

R<br />

λ<br />

10 log ⎜<br />

⎝<br />

⎛ ( ) d<br />

( S−<br />

Sd)/ Rλ<br />

STO-REF<br />

S−<br />

S / R<br />

1mW<br />

⎛ ( )<br />

λ<br />

⎞<br />

⎟<br />

⎠<br />

S−<br />

S / R ⎞<br />

d λ<br />

10 log ⎜<br />

⎟<br />

⎝ STO-REF ⎠<br />

Represents the most recent net signal value.<br />

This is the value that is displayed when units are<br />

set to Amps or Volts. Note that Sd = 0 when<br />

ZERO is off.<br />

Measurement calculation when the display units<br />

are Watts or Joules. R λ is the detector<br />

responsivity associated with the current wavelength<br />

setting.<br />

Measurement calculation when the display<br />

units are ten times the (base ten) logarithm of the<br />

ratio of the measured power to 1 mW, i.e. dBm.<br />

Measurement calculation when the display units<br />

are the ratio of measured power to the value<br />

stored by the STO-REF function.<br />

Measurement calculation when the display units<br />

are ten times the (base ten) logarithm of the<br />

ratio of measured power to the value stored by<br />

the STO-REF function.<br />

xiv

■ <strong>Model</strong> <strong>1835</strong>-C<br />

INPUT<br />

Section 1<br />

General Information<br />

1.1 System Overview<br />

The <strong>Model</strong> <strong>1835</strong>-C Multi-Function Optical Meter is a high performance instrument<br />

with a wealth of measurement and triggering features designed to<br />

provide measurement sensitivity, flexibility and speed. In spite of its power,<br />

<strong>Model</strong> <strong>1835</strong>-C is also designed to provide simple operation with direct panel<br />

access to basic features and a shallow menu for access to advanced features.<br />

Great flexibility exists within the command structure of the <strong>Model</strong> <strong>1835</strong>-C so<br />

that even complex measurements can be set up quickly and easily. The <strong>1835</strong>-C<br />

can react to or provide triggering, act as an exposure or noise meter, or data log<br />

up to 2,500 measurements!<br />

The <strong>Model</strong> <strong>1835</strong>-C is compatible with all of <strong>Newport</strong>’s Low-Power, High-Power<br />

and Energy detector families. A family tree of the <strong>1835</strong>-C, compatible detectors<br />

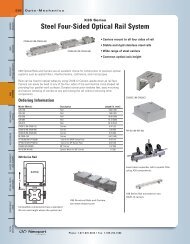

and accessories is shown in Figure 1 below.<br />

818T-10/CM<br />

818T-30/CM<br />

818T-150/CM<br />

818T-150X/CM<br />

FP3-FH1<br />

818J-S10/CM<br />

818J-09/CM<br />

818J-09B/CM<br />

818J-25/CM<br />

818J-25B/CM<br />

818J-50/CM<br />

818J-50B/CM<br />

818-UV/CM<br />

818-SL/CM<br />

818-IR/CM<br />

818-FA3-SMA<br />

818-FA3-ST<br />

818-FA3-FC<br />

818-FA2<br />

818-ST/CM<br />

818-F-SL<br />

818-F-IR<br />

■ Multi-Function Optical Meter<br />

Figure 1. <strong>Model</strong> <strong>1835</strong>-C Controller and Accessories<br />

The <strong>Model</strong> <strong>1835</strong>-C connects to detectors through a calibration module containing<br />

information unique to the detector being used. Calibration modules<br />

are ordered with a detector at the time of purchase and are labeled with the<br />

detector’s model number and serial number. Detectors with calibration<br />

modules have a “/CM” appended to their model number.<br />

EXAMPLE: 818-SL (no calib. module) 818-SL/CM (with calibration module)<br />

1

1.2 Scope of this manual<br />

Please carefully read this instruction manual before using the <strong>Model</strong> <strong>1835</strong>-C<br />

Multi-Function Optical Meter. Be especially careful to observe the warnings<br />

and cautions throughout this manual. If any operating instructions are not<br />

clear, contact <strong>Newport</strong> <strong>Corporation</strong>.<br />

This instruction manual contains the necessary information for operation and<br />

maintenance of the <strong>Newport</strong> <strong>Model</strong> <strong>1835</strong>-C Multi-Function Optical Meter as<br />

well as information for troubleshooting and obtaining service if necessary.<br />

This information is divided into the following sections:<br />

Section 1<br />

General Information and Functional Description<br />

Section 2<br />

System Operation<br />

Section 3<br />

Principles of Operation<br />

Section 4<br />

Computer Interfacing<br />

Section 5<br />

Computer Command Reference<br />

Section 6<br />

Maintenance and Troubleshooting<br />

Section 7<br />

Factory Service<br />

Appendix A<br />

Syntax and Definitions<br />

Appendix B<br />

Error Messages<br />

Appendix C<br />

Status Reporting System<br />

1.3 Unpacking and Inspection<br />

All <strong>Model</strong> <strong>1835</strong>-C Multi-Function Optical Meters are carefully assembled,<br />

tested and inspected before shipment. Upon receiving this instrument, check<br />

for any obvious signs of physical damage that might have occurred during<br />

shipment. Report any such damage to the shipping agent immediately. Retain<br />

the original packing materials in case reshipment becomes necessary.<br />

1.4 Preparation for Use<br />

The <strong>Model</strong> <strong>1835</strong>-C Multi-Function Optical Meter should have some operations<br />

performed before measurements are made. These include:<br />

Connecting AC Power (Section 2.5)<br />

Detector Connection and Setup (Section 2.6)<br />

1.5 Optional Accessories and Services<br />

The <strong>Newport</strong> Catalog presents up to date information on the detectors,<br />

detector accessories and detector calibration services available for use with<br />

the <strong>Model</strong> <strong>1835</strong>-C Multi-Function Optical Meter. Refer to Figure 1 for where a<br />

given detector or accessory fits within the <strong>Model</strong> <strong>1835</strong>-C family tree.<br />

2

Section 2<br />

System Operation<br />

2.1 Introduction<br />

The <strong>Model</strong> <strong>1835</strong>-C is designed to provide quick operation and to avoid a steep<br />

learning curve. This section starts by giving a brief listing of display, key pad<br />

and menu command features. Much of the <strong>Model</strong> <strong>1835</strong>-C’s operation will be<br />

obvious after these descriptions. The manual then explains each key operation<br />

and menu command in detail. Reference each of these detailed explanations<br />

as required when getting started.<br />

2.2 Display<br />

The <strong>Model</strong> <strong>1835</strong>-C incorporates a vacuum fluorescent display, VFD, which can<br />

be clearly observed with most laser goggles and at high angles of incidence.<br />

Figure 2 illustrates and identifies the primary regions and annunciators within<br />

the <strong>Model</strong> <strong>1835</strong>-C’s display.<br />

Figure 2a. <strong>Model</strong> <strong>1835</strong>-C VFD Display<br />

3

Measurement<br />

Activity<br />

Annunciator<br />

Measurement Display Area<br />

Units Display<br />

Measurement<br />

Mode<br />

Annunciators<br />

MODE<br />

= P-P DC INTG SNGL CONT PULSE FLTR = ANLG + DIG<br />

Bar Graph, Menu and Message Display Area<br />

Signal Filtering<br />

Annunciators<br />

SHIFT MENU EDIT STORE USRCAL EXT ATTN ZERO AUTO<br />

Status<br />

Annunciators<br />

Figure 2b. Description of <strong>Model</strong> <strong>1835</strong>-C Display Regions —<br />

Annunciator<br />

DC<br />

INTG<br />

P-P<br />

SNGL<br />

CONT<br />

PULSE<br />

ANLG<br />

DIG<br />

SHIFT<br />

MENU<br />

STORE<br />

USRCAL<br />

EXT<br />

AUTO<br />

ZERO<br />

ATTN<br />

Table 1. <strong>Model</strong> <strong>1835</strong>-C Display Annunciators<br />

Comment<br />

Blinking indicates that the meter is making measurements.<br />

Meter is set to make DC signal measurements.<br />

Meter is set to make INTEGRATED signal measurements.<br />

Meter is set to make Peak-to-Peak signal measurements.<br />

Meter will make only one measurement per front<br />

panel or external trigger.<br />

Meter will continuously make measurements until<br />

stopped.<br />

Meter is set to make pulse energy measurements.<br />

Analog signal filtering is on.<br />

Digital signal filtering is on.<br />

Indicates that the next key press will execute a blue<br />

key function.<br />

Meter and display are in menu mode. Measurement<br />

is stopped.<br />

Meter is logging measurements into memory, i.e.<br />

data logging.<br />

User (versus calibration module) has supplied the<br />

detector responsivity in use.<br />

External trigger input is enabled.<br />

Automatic signal gain ranging is on.<br />

Background signal subtraction, (zeroing), is on.<br />

The responsivity in use includes the affect of the<br />

detector’s attenuator.<br />

4

2.3 Top Level Key Functions<br />

Operating controls for the <strong>Model</strong> <strong>1835</strong>-C are found on both the front and rear<br />

panels of the <strong>Model</strong> <strong>1835</strong>-C. For measurement operation, only the front panel<br />

controls are used. Rear panel controls are used for AC line power setup,<br />

Section 2.5.<br />

The front panel key pad of the <strong>Model</strong> <strong>1835</strong>-C, Figure 3, provides quick access<br />

to measurement functions and menu access to advanced features and setup<br />

parameters. Table 2 and Sections 2.3.1 through 2.3.12 list and describe each<br />

top level key function. Menu level key functions are discussed in Section 2.4.<br />

(LOCAL)<br />

SHIFT<br />

STO REF<br />

DISP<br />

ATTN<br />

FILTER<br />

λ<br />

ZERO<br />

RANGE<br />

AUTO<br />

O<br />

I<br />

EXT<br />

R/S<br />

MENU<br />

MODE<br />

ENTER<br />

UNITS<br />

ESC<br />

STATS<br />

5<br />

Figure 3. Front Panel Key Pad<br />

Table 2. Top Level Key Functions and Associated Remote Commands<br />

Keypad Remote Commands Description<br />

O I<br />

None<br />

Turn the <strong>Model</strong> <strong>1835</strong>-C on and<br />

off.<br />

SHIFT None Enable the blue key functions.<br />

DISP DISP, DISP? Cycle display brightness: OFF,<br />

LOW, NORM and HIGH.<br />

FILTER FILTER, FILTER? Cycle signal filtering: OFF,<br />

ANLG, DIG and ANLG+DIG.<br />

ZERO ZERO, ZERO?, STOZERO, Zero the display via offset<br />

ZEROVAL?<br />

subtraction.<br />

AUTO AUTO, AUTO? Turn automatic gain ranging on<br />

and off.<br />

STO REF STOREF, STOREF? Store last reading for future dB<br />

and REL measurements.<br />

ATTN ATTN, ATTN? Set responsivity to detector or<br />

detector-with-attenuator.<br />

λ LAMBDA, LAMBDA? Display and edit the calibration<br />

wavelength in use.<br />

RANGE RANGE, RANGE? Display signal gain range in use.<br />

R/S RUN, STOP Starts and stops signal<br />

acquisition.<br />

MODE MODE, MODE? Cycle meter between allowed<br />

measurement modes.<br />

UNITS UNITS, UNITS? Cycle display measurement<br />

units between those allowed.<br />

STATS STSIZE, STSIZE?, STMAX? Display statistics.: Max, Min,<br />

STMIN?, STMXMN? STMEAN Max-Min, Mean and Std. Dev.<br />

STSDEV?

EXT EXT Enable or disable external<br />

triggering.<br />

MENU None Enter or exit MENU command<br />

mode.<br />

ENTER None Select next lower menu level or<br />

enter edit mode.<br />

ESC None Escape to next higher menu<br />

level or escape edit mode.<br />

, None Adjust gain range or parameter<br />

values or move through a list.<br />

, None Zooms bargraph in or out. When<br />

in Edit mode, selects the digit to<br />

be edited by the , keys.<br />

2.3.1<br />

O<br />

I<br />

, Power<br />

The O I key toggles the <strong>Model</strong> <strong>1835</strong>-C on and off. To turn the meter on,<br />

O I<br />

depress the key in until it clicks and stays in its depressed position. To<br />

turn the meter off, press the key again until it clicks and rebounds to its<br />

original length.<br />

2.3.2 SHIFT<br />

When SHIFT is pressed, the SHIFT display annunciator lights and the blue key<br />

functions (such as STOREF) are enabled. The next key press will cause that<br />

blue function to be executed and the “shift status” to disable. If a no blue<br />

function is the next pressed, then the ‘shift status’ reverts to disabled.<br />

2.3.3 DISP , Display Brightness<br />

This key cycles the display and the backlit key pad through: OFF, LOW,<br />

NORM and HIGH brightness levels. This allows a user to operate in a dark<br />

environment without light pollution from the display, (except for one dim<br />

scanning decimal point and the measurement activity annunciator).<br />

When the display is OFF, the R/S key may be used to manually trigger measurements.<br />

Any other key press returns the display to the LOW brightness<br />

state while ignoring the key function.<br />

2.3.4 FILTER, Signal Filtering<br />

Press this key to cycle input signal filtering between: OFF, ANLG, DIG,<br />

ANLG+DIG. This function provides methods of lowering the noise observed in<br />

the measurement data and the analog output.<br />

When the ANLG annunciator is lit, a 5Hz low pass filter lowers the noise floor<br />

by attenuating high frequency signal components. ANLG filtering is not<br />

available to High Power detectors, Energy detectors or any P-P modes.<br />

When the DIG display annunciator is lit, measurements pass through a moving<br />

10-sample averaging buffer before being further processed, stored or communicated<br />

to the display or computer interfaces. With DIG on, all observable<br />

values represent digitally averaged results relative to the original A/D conversions.<br />

This averaging is independent of the subsequent processing available<br />

through the STATS buffer, Section 2.3.14.<br />

6

2.3.5 ZERO, Offset Subtraction<br />

This key turns offset subtraction on and off. When turned on, the ZERO<br />

annunciator lights and the last signal reading is saved as S d<br />

and subtracted<br />

from all subsequent signal readings S. This causes subsequent signal calculations<br />

(and the display) to use the value S-S d<br />

instead S.<br />

Offset subtraction allows one to remove the effects of ambient DC signals, by<br />

zeroing the display before making a measurement. A second ZERO key press<br />

turns off the ZERO annunciator and stops offset subtraction.<br />

2.3.6 AUTO, Automatic Gain Ranging<br />

The AUTO key toggles automatic signal ranging on and off. When on, the<br />

AUTO annunciator lights and the signal range (amplifier gain) is adjusted to<br />

utilize maximum analog-to-digital converter resolution. When AUTO is turned<br />

off, the AUTO annunciator is turned off and the signal range is left in its<br />

current state.<br />

Signal range can be manually controlled by the , arrow keys. Pressing an<br />

, arrow key when AUTO is on (and STATS, MENU and λ are off), turns<br />

AUTO off and executes the manual range change. See RANGE, Section 2.3.10.<br />

Signal range changes will not often coincide with observable changes to the<br />

display value as the display is scaled by the detector responsivity and so must<br />

adjust independently. Signal range gains will occur in 1 decade steps when<br />

auto ranging and 1 or 1 ⁄2 decade steps (depending on MODE) when manual<br />

ranging.<br />

When auto ranging in CONT PULSE mode, the arrival rate of pulses must be<br />

above 1 Hz. In P-P CONT mode, the arrival rate of peaks must be above 50 Hz.<br />

AUTO gain ranging is not allowed in SNGL measurement modes. When exiting<br />

a SNGL measurement MODE, AUTO will turn back on if it was on when the<br />

SNGL measurement mode was entered. (See MODE, Section 2.3 12)<br />

2.3.7 STO REF, Store Reference Value<br />

STO REF causes the last measurement D to be stored as D ref<br />

for subsequent<br />

use in relative measurement calculations. When units are relative, REL, the<br />

displayed value is the ratio D/D ref.<br />

When units are logarithmic relative, dB, the<br />

displayed value is the function 10 log (D/D ref<br />

). D ref<br />

is always a power reading<br />

stored in the units of Watts.<br />

Press STO REF to cause a new D ref<br />

to overwrite the existing D ref<br />

value and show<br />

this new D ref<br />

in the message display area. D ref<br />

will be displayed until overridden<br />

by an ESC, λ, RANGE or MENU keypress. STO REF can be pressed at any<br />

time.<br />

NOTE<br />

When not using remote interface operation and when displaying relative dB<br />

or REL measurements, the message display area will show the STO REF value<br />

used in the calculation.<br />

7

2.3.8 ATTN, Attenuator<br />

The ATTN key toggles the responsivity value, R λ<br />

, between the value for the<br />

detector alone and the value for the detector-with-attenuator. When ATTN is<br />

on, the ATTN annunciator is lit and the responsivity of the detector-withattenuator<br />

is used. When ATTN is off, the annunciator is off and the detectoralone<br />

responsivity is used. If the detector does not have an attenuator, or if<br />

USR CAL is on (Section 2.4.5) the ATTN key has no effect.<br />

2.3.9 λ, Wavelength<br />

A detector calibration module contains responsivity data for its assigned<br />

detector at discrete wavelengths. By telling the meter which wavelength is<br />

being measured, the correct responsivity value is used in calculating the<br />

measured power or energy. When a wavelength falls between two calibration<br />

points, linear interpolation is used to approximate the true responsivity value.<br />

Press the λ key to display the measurement wavelength in the message<br />

display area. Press ENTER to light the EDIT annunciator and cause the last<br />

digit of the wavelength to blink. Press , to adjust the blinking digit up<br />

or down and , to change which digit blinks. Press the ENTER a second<br />

time to accept the new wavelength and exit the wavelength edit/display mode.<br />

Press λ or ESC to exit without changing the wavelength.<br />

2.3.10 RANGE, Signal Range<br />

RANGE key allows the user to view the amplifier signal range. Signal ranges step<br />

in 1 or 1 ⁄2 decade gain increments (MODE dependent) as the RANGE is changed<br />

in order to utilize maximum resolution from the meter’s analog-to-digital<br />

converters. The available signal ranges are detector and mode dependent.<br />

Press RANGE to display the signal range number in the message display area.<br />

If AUTO is on, then the signal range number will change if the detector signal<br />

varies more than a decade in magnitude. Signal range changes can occur<br />

without an effect on the displayed measurement value. Press RANGE a<br />

second time to exit the signal range display mode.<br />

Press the , arrow keys to increase or decrease the signal range. If AUTO<br />

is on, pressing the , arrow keys will disable AUTO and cause the signal<br />

range to change. Manual ranging is useful when working with external analog<br />

recording equipments.<br />

NOTE<br />

Pressing the , arrow keys will disable AUTO ranging and change the<br />

signal range even when the signal range is not being displayed via the<br />

RANGE key.<br />

2.3.11 R/S, Run-Stop<br />

The R/S run-stop key provides front panel control over data acquisition.<br />

When in SNGL measurement mode, each R/S key press causes one reading to<br />

be taken. In CONT measurement mode, each R/S key press toggles continuous<br />

data acquisition on and off.<br />

The activity annunciator (Figure 2b) flashes to indicate that readings are being<br />

taken. A steady glow indicates that the meter is armed and waiting for a pulse<br />

or P-P waveform to arrive. The indicator is off when data acquisition has been<br />

stopped.<br />

8

2.3.12 MODE, Measurement Mode<br />

The <strong>Model</strong> <strong>1835</strong>-C provides a number of measurement modes for acquiring<br />

data. At power on, the meter checks the detector’s calibration module to<br />

determine which measurement modes the detector supports. Table 3 describes<br />

the measurement modes available for each family of detector.<br />

Table 3. <strong>Newport</strong> Detector Families and Available Measurement Modes<br />

Low-Power High-Power Energy<br />

DC CONT X X<br />

DC SNGL x x<br />

INTG x x<br />

P-P CONT<br />

x<br />

P-P SNGL<br />

x<br />

CONT PULSE<br />

X<br />

SNGL PULSE<br />

x<br />

X marks the default mode for the detector family<br />

Press the MODE key repeatedly until the desired mode is indicated in the<br />

mode annunciator area of the display, see Table 4. When selecting a new<br />

mode, the display units will change to appropriate default units if they are not<br />

compatible with the new measurement mode, Section 2.3.13.<br />

Mode<br />

DC CONT<br />

DC SNGL<br />

INTG<br />

P-P CONT<br />

P-P SNGL<br />

CONT PULSE<br />

SNGL PULSE<br />

Table 4. <strong>Model</strong> <strong>1835</strong>-C Measurement Modes<br />

Description<br />

Measurement occurs at a programmable sample rate,<br />

Section 2.4.6.<br />

A measurement is taken every time the meter receives a<br />

trigger up to a 1000Hz. rate. (AUTO is disabled in SNGL<br />

mode.)<br />

Measurements occur at 500Hz and are trapezoidally<br />

integrated to get an energy result. An R/S key press or<br />

external trigger sets the display to 0.0000 and sampling<br />

starts. A second R/S keypress or external trigger terminates<br />

integration.<br />

Acquisition is driven by the arrival of high-low peak<br />

pairs. A measurement is processed for every high-low<br />

peak pair up to a frequency of 1000 Hz. Above 1000 Hz,<br />

pair captures experience a minimum 1 ms separation.<br />

A trigger 1 arms the meter to capture the next high-low<br />

peak pair. Triggers can occur at a rate of up to 1000 Hz.<br />

(AUTO is disabled in SNGL mode.)<br />

The meter captures every energy pulse up to a frequency<br />

of 1000 Hz. Above 1000 Hz, pulse acquisitions experience<br />

a minimum 1 ms separation.<br />

A trigger 1 arms the meter to capture the next energy<br />

pulse. Triggers can occur at a rate of up to 1000 Hz.<br />

(AUTO is disabled in SNGL mode.)<br />

9

1<br />

“Trigger” refers to a command to start or stop signal acquisition. Trigger<br />

sources are the R/S key, the external trigger input and remote interface<br />

commands.<br />

2.3.13 UNITS, Display Units<br />

Measurements can be displayed in various units. The set of units available at<br />

any given time is determined by the detector type and the measurement<br />

mode. Press the UNITS key repeatedly to cycle the display units through the<br />

set of available units. Table 5 describes the sets of available units for each<br />

detector family as a function of the measurement mode.<br />

Table 5. Valid Display Units Available to Detector Families by MODE.<br />

FAMILY MODE V A W W/cm 2 J J/cm 2 Erg Erg/cm 2 dBm dB REL<br />

Low-Power DC CONT x X x x x x<br />

Low-Power DC SNGL x X x x x x<br />

Low-Power INTG X x x x<br />

Low-Power P-P CONT x X x x x x<br />

Low-Power P-P SNGL x X x x x x<br />

High-Power DC CONT x X x x x x<br />

High-Power DC SNGL x X x x x x<br />

High-Power INTG X x x x<br />

Energy CONT PULSE x X x x x x<br />

Energy SNGL PULSE x X x x x x<br />

X denotes the default units for the detector family in the given measurement<br />

mode.<br />

Some display units are abbreviated. Table 6 lists displayed units versus actual<br />

measurement units. Display units are limited to four characters in order to<br />

provide for display engineering prefixes such as: p, n, µ, m and k. (pico, nano,<br />

micro, milli and kilo respectively).<br />

Table 6. Displayed Unit Abbreviations Versus Actual Measurement Units.<br />

Actual Units V A W J Erg W/cm 2 J/cm 2 Erg/cm 2 dBm dB REL<br />

Displayed Units V A W J ERG W/cm J/cm E/cm dBm dB E±dd<br />

2.3.14 STATS, Moving Statistics<br />

The STATS key causes a list of statistical results from the stats buffer to be<br />

displayed in the message display area. The stats buffer is a moving data<br />

window containing the most recent measurements to a depth 1 ″ N ″ 100. The<br />

default value is N = 10. Display occurs without disrupting data acquisition or<br />

storage and results are continuously updated.<br />

Press the STATS key to enter the stats display list. The first statistic displayed<br />

will be the stats buffer depth N. Press the , adjust keys to move through<br />

the list. The following statistics are available: N, MAX, MIN, MAX-MIN, MEAN<br />

and STD DEV.<br />

When the STATS buffer depth, N, is displayed, it can be adjusted by pressing<br />

ENTER and using the , keys to set a new value for N. Press the ENTER<br />

key to adopt the new value for N and escape the edit mode. The STATS buffer<br />

is cleared whenever a new stats buffer depth N, or MODE or UNITS is established.<br />

Press the STATS key a second time to exit the stats display mode.<br />

10

2.3.15 EXT, External Trigger<br />

EXT enables and disables the triggering of data acquisition through the rear<br />

panel trigger input BNC connector. The meter can be configured to be<br />

triggered by either a rising or falling edge TTL signal. See Section 2.4.8.<br />

Press EXT to light the EXT annunciator and enable the external trigger input.<br />

The <strong>Model</strong> <strong>1835</strong>-C will still respond to triggers from the R/S key even when the<br />

EXT trigger is enabled. Press the EXT key a second time to turn off the<br />

annunciator and disable the external trigger input.<br />

2.3.16 MENU<br />

The MENU key provides access to advanced features and parameters. Press<br />

the MENU key to stop all data acquisition, light the MENU annunciator, and<br />

display the first item of the top level menu list. Press the MENU key a second<br />

time to immediately exit the menu. Menu structure and functions are presented<br />

in Section 2.4.<br />

The menu consists of a series of lists and parameter values. Most parameter<br />

values can be edited to configure the meter. Lists are moved through via the<br />

, keys. To move to a lower level list, press the ENTER key. To escape a<br />

lower level list, press the ESC key.<br />

In the menu, all key functions are ignored except for the MENU, ENTER, ESC<br />

and the , keys. Each key will act without having to initially press SHIFT.<br />

Pressing SHIFT will toggle the SHIFT annunciator, but it will not effect anything<br />

else when in MENU mode.<br />

To edit a displayed parameter press ENTER. This enables the edit mode and<br />

causes the parameter (or a digit) to blink. Press the , keys to adjust the<br />

parameter through its allowed list or to count the blinking digit up and down.<br />

When adjusting a numerical value, the , keys can be used to change<br />

which decimal digit blinks. Press ENTER to adopt the new value and escape<br />

the editing mode. Press ESC to leave the editing mode without adopting the<br />

new value.<br />

2.3.17 ENTER<br />

ENTER allows one to move lower into the menu when in menu mode, to enter<br />

editing mode when an editable parameter is being displayed and to adopt a<br />

new parameter value after it has been edited. Editable parameters can be<br />

found both in and out of the menu mode. If ENTER is pressed when a noneditable<br />

parameter is being displayed, the key press is ignored.<br />

2.3.18 ESC, Escape<br />

ESC allows one to escape to the next higher level when in menu mode and to<br />

escape editing mode when editing a parameter value without adopting any<br />

changes to the parameter. At the top level of the menu, the ESC key causes<br />

one to escape menu mode. The ESC key also allows one to escape various<br />

other display modes such as STATS or wavelength display or amplifier signal<br />

gain range display modes. When there is nothing to escape from, the ESC key<br />

is ignored.<br />

2.3.19 , , , Adjust<br />

The , , , , keys allow one to adjust various parameter states and<br />

values. In normal operation, the , keys turn AUTO off and adjust the<br />

amplifier signal gain. In any other mode, the , keys cause one to move<br />

11

through a list or to adjust a blinking digit. The , keys zoom the bargraph<br />

( in, out) and in edit mode, select which digit of a numerical value will<br />

blink.<br />

2.4 Menu Level Functions<br />

Menu functions provide control over parameter values and methods of<br />

making measurements, The menu consists of a number of lists and parameter<br />

values. Table 7 presents a quick summary of the hierarchy of the menu<br />

functions and parameters.<br />

2.4.1 Menu Access and Movement<br />

To access the menu press MENU. The MENU annunciator will light and data<br />

acquisition will stop.<br />

Menu labels and parameter values are displayed in the message display area.<br />

The first, second and third leftmost decimal points within this area indicate a<br />

current position at the top, second, third or fourth level of the menu hierarchy,<br />

Figure 4. Table 7 presents the menu functions and their hierarchy.<br />

Top Level<br />

Second Level<br />

Third Level<br />

Fourth Level<br />

Figure 4. Decimal Point Indication of Menu Hierarchy Position<br />

In the menu, valid keys are limited to those needed to perform operations to<br />

move through the menu or edit a parameter value. In the menu, it is not<br />

necessary to hit the SHIFT key to invoke the action of the menu keys: MENU,<br />

ENTER, ESC or . , , , . The SHIFT key will toggle the SHIFT annunciator,<br />

but with no effect on subsequent pressings of other keys. Once in the<br />

menu, the rules for moving through the menu are as follows:<br />

i. Press ENTER to move to the next level down or to enter the edit mode if a<br />

editable parameter is being displayed and to accept a parameter value in<br />

its currently displayed state and exit edit mode.<br />

ii. Press ESC to move to the next level up or to escape the menu when at the<br />

top level or to exit edit mode without changing the parameter value being<br />

edited.<br />

iii. Press MENU to immediately escape the menu regardless of current level<br />

within the menu.<br />

iv. Use the , keys to move up or down through a menu list on a given<br />

level. Also use these keys to adjust a parameter or decimal value when in<br />

edit mode.<br />

v. Use the , keys to select the digit being adjusted when in edit mode.<br />

12

Table 7. Menu Level Key Functions and Parameters<br />

Top Level Second Level Third Level<br />

DATA STORE DATA STORE OFF DATA STORE ON, OFF<br />

CLR DATA BUFFER<br />

(or DATA BUFFER CLR)<br />

SLIDE BUFFER SLIDE, FIX BUFFER<br />

D_BUF SIZE dddd D_BUF_SIZE dddd<br />

VIEW DATA dddd OF dddd<br />

SAVE CONFIG SAVE TO d<br />

RECALL CONFIG RCL DEFAULT, d<br />

AUTO CAL<br />

DET SWITCH POS SWITCH POS S, I, L<br />

USER CALIB USR CAL OFF USR CAL ON, OFF<br />

USR RESP d.dddE±d A/W †<br />

PRESENT RESP d.dddE±d A/W †<br />

DC SAMPLING SAMPLE PREC PREC= 20000, 4096<br />

CNT<br />

SAMPLE FREQ FREQ = ddd.ddd HZ<br />

TRIGGER OUT TRIG ON CMPLT TRIG ON CMPLT,<br />

TRIG AT FREQ ,<br />

TRIG ON LEVEL,<br />

TRIG ON INTG,<br />

TRIG OUT OFF<br />

TRIG POLARITY TRIG ACTIVE LO, HI<br />

TRIGGER FREQ FREQ= dddd.ddd HZ<br />

TRIGGER LEVEL LVL= ±d.ddd E±dd W<br />

TRIGGER INTG INTG= ±d.ddd E±dd J<br />

EXT TRIGGER IN FALLING , RISING EDGE<br />

BAR GRAPH ON BAR GRAPH ON, OFF<br />

TONE OFF TONE ON, OFF<br />

REMOTE SETUP GPIB ADDR dd GPIB ADDR dd<br />

BAUD RATE 9600 BAUD RATE 1200,<br />

2400, 4800, 9600,<br />

19.2K<br />

RS-232 ECHO OFF RS-232 ECHO ON, OFF<br />

GENERAL INFO MODEL <strong>1835</strong>-C<br />

SW VERSION d.d<br />

DETECTOR INFO MODEL xxxxxx<br />

DET SN ddddd<br />

ATTN SN ddddd<br />

CAL ddMONyyyy<br />

†<br />

Units may be in A/W, V/W or V/J.<br />

Items in bold italics type are editable states or decimal values. Decimals are<br />

denoted by d. Move vertically via the , keys. Move horizontally via<br />

ENTER and ESC.<br />

13

2.4.2 Data Store<br />

The <strong>Model</strong> <strong>1835</strong>-C allows a user to save up to 2500 measurements in an<br />

internal buffer for subsequent viewing or transmission over a computer<br />

interface. Data is maintained on power down, but lost when a new configuration<br />

is loaded, Section 2.4.3, or when the buffer is cleared via the CLR DATA<br />

BUFFER command or when data with new units is being stored.<br />

The data store buffer operates in two ways: SLIDE or FIX. In SLIDE configuration,<br />

the buffer slides along storing the most recent measurements up to the<br />

size of the buffer. Beyond this, as data enters the buffer, the oldest data is<br />

pushed out and lost. In FIX configuration, data storing continues until the data<br />

buffer is full. After this, data acquisition stops and no additional data can be<br />

stored without first clearing the buffer via the CLR DATA BUFFER command.<br />

DATA BUFFER CLR is displayed when the buffer is empty.<br />

The size of the buffer is set by the D_BUF_SIZE dddd menu function. Edit the<br />

value dddd to establish the number of data points that the buffer will hold<br />

before dropping old data or stopping data storage.<br />

Data storing is enabled by the user via the DATA STORE menu function. Edit<br />

the ON, OFF condition to enable or disable data storing and the associated<br />

STORE annunciator.<br />

When in CONT mode, data acquisition and storage is resumed immediately<br />

upon exiting the menu if acquisition was active as the menu was entered.<br />

When acquisition was not active when the menu was entered, or when in<br />

SNGL or INTG mode, data acquisition and storage requires an initiating R/S<br />

key press, external trigger or a remote RUN command after exiting the menu.<br />

Buffer data can be viewed via the VIEW DATA menu command. Data are<br />

displayed in the measurement area while the message area displays the<br />

position within the buffer: dddd of dddd. Use the , keys to move through<br />

the buffer data. The value dddd = 0001 is the first, i.e. the oldest datum.<br />

NOTE<br />

When DATA STORE is off, CONT acquisition mode behavior defaults to the<br />

condition where data acquisition is begun without the requirement of a<br />

starting trigger. SNGL acquisition modes always require a trigger for each<br />

acquisition.<br />

Table 8. Data Store Operations<br />

Menu Operation Keypad Commands Associated Remote Commands<br />

DATA STORE ON, OFF Edit ON, OFF status. DSE, DSE?<br />

DATA BUFFER CLR or<br />

CLR DATA BUFFER If CLR DATA BUFFER, DSCLR<br />

press ENTER to clear buffer.<br />

SLIDE, FIX BUFFER Edit SLIDE, FIX BUFFER DSBUF DSBUF?<br />

D_BUF_SIZE dddd Edit D_BUF_SIZE dddd DSSZ, DSSZ?<br />

VIEW DATA Press ENTER and use DS?, DSCNT?, DSUNITS?<br />

, keys.<br />

14

2.4.3 Meter Configuration<br />

The <strong>Model</strong> <strong>1835</strong>-C provides a method to save the configuration of the meter<br />

and to recall that configuration for later use even if the meter has been turned<br />

off. This is accomplished through configuration buffers maintained in nonvolatile<br />

memory. Configuration buffers are numbered 0 to 9 with buffer 0<br />

being a DEFAULT buffer which can only be recalled but not saved to. The<br />

reset state of all the buffers except the default buffer is empty. Empty buffers<br />

cannot be recalled.<br />

A recalled configuration becomes the current configuration of the meter. Any<br />

changes to the current configuration must be saved via SAVE CONFIG or they<br />

will be lost when a new configuration is recalled.<br />

The meter will not recall a configuration that is not compatible with the<br />

detector calibration module currently plugged into the meter. Configurations<br />

using the same model of detector are compatible while configurations using<br />

different models of detectors are incompatible.<br />

The default configuration of the meter depends upon the detector family. The<br />

list of configuration parameters stored in a configuration buffer as well as<br />

their default values versus detector family are listed in Table 9 below:<br />

Table 9. Configuration Parameters and Default Conditions<br />

Parameter Detector Family Default Condition<br />

MODE Low-Power, High-Power DC CONT<br />

Energy<br />

CONT PULSE<br />

UNITS Low-Power, High-Power W<br />

Energy<br />

J<br />

λ, Lambda Lowest available<br />

PRESENT RESP<br />

PRESENT RESP<br />

USR CAL<br />

OFF<br />

ATTN<br />

OFF<br />

FILTER<br />

OFF<br />

DC SAMPLE PREC Low-Power, High-Power 20,000 CNT<br />

DC SAMPLE FREQ<br />

25 Hz<br />

AUTO<br />

ON<br />

RANGE 0<br />

ZERO 0.000<br />

Zero Value 0<br />

Reference Value 0.001<br />

STATS Buffer Size 10<br />

DET SWITCH POS Energy I, (Intermediate)<br />

DATA STORE<br />

OFF<br />

DATA STORE BUFFER<br />

SLIDE<br />

D_BUF_SIZE 100<br />

15

Parameter Detector Family Default Condition<br />

Data Store Units<br />

Same as UNITS<br />

EXT<br />

OFF<br />

EXT TRIG IN<br />

FALLING<br />

TRIGGER OUT<br />

TRIG ON CMPLT<br />

TRIG OUT POL<br />

TRIG ACTIVE LO<br />

TRIG OUT FREQ<br />

FREQ = 30 Hz<br />

TRIG LEVEL Low-Power, LVL = 0.001 W<br />

High-Power, Energy LVL = 0.001 J<br />

TRIG INTG LVL Low-Power, High-Power INTG = 0.001 J<br />

BAR GRAPH<br />

ON<br />

TONE<br />

OFF<br />

GPIB ADDR 05<br />

BAUD RATE 9600<br />

RS-232 ECHO<br />

OFF<br />

These parameters adopt the following default values at power up and are not<br />

affected by recalling a configuration or by setting the configuration to default.<br />

Local Lockout<br />

OFF<br />

Display Brightness<br />

NORMAL<br />

Table 10. below lists the menu commands effecting the saving and recalling of<br />

meter configurations.<br />

Table 10. Meter Configuration Operations<br />

Menu Operation Keypad Commands Associated Remote Commands<br />

SAVE CONFIG Adjust SAVE TO d, *SAV<br />

and ENTER<br />

RECALL CONFIG Adjust RECALL d, *RCL, *RST<br />

and ENTER<br />

2.4.4 AUTO CAL<br />

The AUTO CAL command causes the <strong>1835</strong>-C to perform A/D conversions of<br />

amplifier offset voltages (zero errors) arising from aging and temperature<br />

effects. These conversions are then used in subtracting the appropriate error<br />

voltage from each reading during normal operation. The <strong>1835</strong>-C automatically<br />

performs this procedure every time it powers up (or is reset). To achieve<br />

stable reading at the specified accuracy, AUTO CAL should be executed after a<br />

minimum 60 minute warm-up period from power-up.<br />

16

Executing AUTO CAL with High Power (Thermopile) detectors:<br />

1. With the detector connected to the <strong>1835</strong>-C, remove the detector from the<br />

radiation source and allow a minimum of 60 seconds for the detector<br />

surface temperature to stabilize.<br />

2. Press ENTER when AUTO CAL is displayed. The display message area will<br />

display “ONE MOMENT”, followed by a buzzer sound indicating that AUTO<br />

CAL is complete.<br />

Executing AUTO CAL with Low Power (Photodiode) or Energy detectors:<br />

Simply press ENTER when AUTO CAL is displayed. The display message area<br />

will display “ONE MOMENT”, followed by a buzzer sound indicating that<br />

AUTO CAL is complete. Low Power and Energy detectors do no have to be<br />

connected to the <strong>1835</strong>-C or removed from the radiation source to effectively<br />

execute AUTO CAL.<br />

2.4.5 User Calibration<br />

The <strong>Model</strong> <strong>1835</strong>-C allows one to create a detector responsivity which overrides<br />

the responsivities obtained from the detector’s calibration module. This<br />

allows one to account for the effects of additional optics and filters in the<br />

measurement path.<br />

When USR CAL is on, the USR CAL annunciator is lit and the meter adopts the<br />

responsivity value displayed by the editable USR RESP value. Use the<br />

PRESENT RESP function to display the current calibration module<br />

responsivity.<br />

The USR RESP units are the same as the PRESENT RESP units. Table 11 lists<br />

the possible user calibration operations.<br />

Table 11. User Calibration Operations<br />

Menu Operation Keypad Commands Associated Remote Commands<br />

USR CALIB ON, OFF Edit USR CALIB USRCAL, USRCAL?<br />

ON, OFF<br />

USR RESP Edit d.dddE±dd A/W * USRRESP, USERRESP?<br />

PRESENT RESP ENTER to view RESP?<br />

d.dddE±dd A/W *<br />

*<br />

Units of A/W, V/W or V/J may be displayed. These units are not editable.<br />

2.4.6 DC Sampling<br />

The <strong>Model</strong> <strong>1835</strong>-C incorporates two analog-to-digital, (A/D) converters, one<br />

with 20,000 count resolution and a second with 4096 count resolution. The<br />

user may select which A/D will be used during DC CONT and DC SNGL acquisition<br />

modes. All other modes use the 4096 count A/D. The 20,000 count A/D<br />

converter, can operate at sample rates up to 25 Hz. The 4,096 count A/D<br />

converter, can operate at sample rates up to 1000 Hz.<br />

The SAMPLE PREC menu command, Table 12, selects which analog-to-digital<br />

converter is used. Sampling frequency can be adjusted within the limits<br />

imposed by the SAMPLE PREC state, see Table 13. When the SAMPLE PREC<br />

state changes, the sampling frequency defaults to 25 Hz if the existing SAMPLE<br />

FREQ is incompatible with the new SAMPLE PREC state.<br />

17

Table 12. SAMPLE PREC States and Limits.<br />

SAMPLE PREC A/D Accuracy Sample Frequency Range<br />

20000 CNT 20,000 counts 0.001 Hz to 25.0 Hz<br />

4096 CNT 4,096 counts 0.001 Hz to 1000.0 Hz<br />

Table 13. DC SAMPLING Operations.<br />

Menu Function Keypad Commands Associated Remote Commands<br />

SAMPLE PREC Edit PREC= 20,000, SPREC, SPREC?<br />

4096 CNT<br />

SAMPLE FREQ Edit FREQ= SFREQ, SFREQ?<br />

ddd.ddd HZ<br />

2.4.7 Trigger Output<br />

The <strong>Model</strong> <strong>1835</strong>-C’s rear panel TTL trigger output allows it to coordinate<br />

activities among other instruments. The trigger output can operate in several<br />

ways: conversion complete, periodic output, comparator output and integrating<br />

comparator output. In addition, the polarity of the trigger output can be<br />

specified.<br />

In TRIG ON CMPLT mode, a pulse is output after each reading has been<br />

acquired and completely processed. It indicates that the <strong>1835</strong>-C is ready to<br />

take another reading. The width of this pulse is at least 8 µS.<br />

In TRIG AT FREQ mode, a pulse is output at a user defined frequency or rate.<br />

Each pulse width is at least 8 µS and the programmable frequency range of the<br />

pulses is 0.001 Hz to 1000.0 Hz.<br />

In TRIG ON LEVEL mode, each measurement is compared to a programmable<br />

trigger level. The units of the trigger level always equal Watts for power<br />

detectors or Joules for energy detectors. If a measurement is less than the<br />

specified value, then the trigger output is inactive. If the measurement<br />

exceeds the specified value then the trigger output becomes active. The TRIG<br />

ON LEVEL output is a shift in level rather than a pulse.<br />

In TRIG ON INTG mode, continuous measurements from a power detector are<br />

integrated and compared against a programmable value. The units of the<br />

programmable value are Joules. If the calculated integral is less than the<br />

specified value, then the trigger output is active. If the calculated integral<br />

exceeds the specified value, then the integration stops and the trigger output<br />

becomes inactive. The TRIG ON INTG trigger is a shift in level rather than a<br />

pulse.<br />

The polarity of the trigger output is programmable as active high or active<br />

low. If the polarity is active high then the output will idle low. If the polarity is<br />

active low then the line will idle high.<br />

18

Table 14. TRIGGER OUT Operations.<br />

Menu Function Keypad Commands Associated Remote Commands<br />

TRIGGER OUT Edit TRIG ON CMPLT TRIGOUT, TRIGOUT?<br />

TRIG AT FREQ<br />

TRIG ON LEVEL<br />

TRIG ON INTG<br />

TRIG OUT OFF<br />

TRIG POLARITY Edit ACTIVE HI, LO TRIGOUTPOL, TRIGOUTPOL?<br />

TRIGGER FREQ Edit FREQ= ddd.ddd Hz TRIGOUTFREQ, TRIGOUTFREQ?<br />

TRIGGER LEVEL Edit LVL= d.dddE±dd W * TRIGOUTLVL, TRIGOUTLVL?<br />

TRIGGER INTG Edit INTG= d.dddE±dd J TRIGOUTINTG, TRIGOUTINTG?<br />

*<br />

Displayed units may be W or J depending upon the detector in use.<br />

2.4.8 Trigger Input<br />

The <strong>Model</strong> <strong>1835</strong>-C’s rear panel TTL external trigger input can be enabled or<br />

disabled, Section 2.3.15, and have its edge polarity set. The edge polarity is<br />

accessed via the EXT TRIGGER IN menu function and can be set to rising or<br />

falling edge triggering.<br />

The external trigger (and R/S key) acts like an acquisition trigger when in<br />

SNGL modes and acts like a toggled acquisition gate when in CONT modes. In<br />

Peak-to-Peak or Pulse acquisition modes the external trigger (and R/S key) act<br />

as single or continuous acquisition enabled rather than forcing an acquisition<br />

to occur at the moment the trigger (or keypress) occurs.<br />

The external trigger pulse width must be ≥200 ns. In DC SNGL mode, the delay<br />

from the trigger input going active to the start of the A/D conversion is

2.4.10 Tone<br />

The <strong>1835</strong>-C has a speaker that can emit a short tone or tick to indicate when a<br />

peak or pulse is detected in P-P or PULSE measurement modes. The audible<br />

output is enabled or disabled via the TONE menu function. TONE is not<br />

available in INTG measurement mode.<br />

Table 17. TONE Operations.<br />

Menu Function Keypad Commands Associated Remote Commands<br />

TONE Edit TONE ON, OFF TONE, TONE?<br />

2.4.11 Detector Switch Position<br />

Some <strong>Newport</strong> Energy detectors have a switch that sets an electronic decay<br />

time constant to optimize operation for various pulse repetition rates. As this<br />