MacArthur Copper Project - Quaterra Resources Inc

MacArthur Copper Project - Quaterra Resources Inc

MacArthur Copper Project - Quaterra Resources Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

M3-PN 110127<br />

May 23, 2012<br />

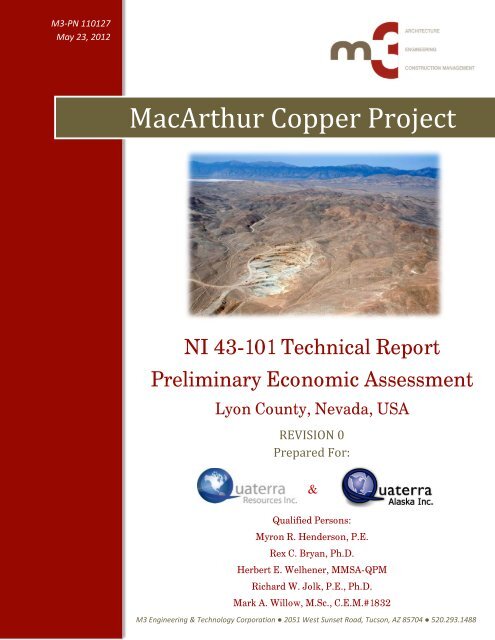

<strong>MacArthur</strong> <strong>Copper</strong> <strong>Project</strong><br />

NI 43-101 Technical Report<br />

Preliminary Economic Assessment<br />

Lyon County, Nevada, USA<br />

REVISION 0<br />

Prepared For:<br />

Qualified Persons:<br />

Myron R. Henderson, P.E.<br />

Rex C. Bryan, Ph.D.<br />

Herbert E. Welhener, MMSA-QPM<br />

Richard W. Jolk, P.E., Ph.D.<br />

Mark A. Willow, M.Sc., C.E.M.#1832<br />

M3 Engineering & Technology Corporation ● 2051 West Sunset Road, Tucson, AZ 85704 ● 520.293.1488<br />

&

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

DATE AND SIGNATURES PAGE<br />

The Qualified Persons contributing to this report are noted below. The Certificates and Consent<br />

forms of the qualified persons are located in Appendix A, Certificate of Qualified Persons<br />

(“QP”) and Consent of Authors.<br />

• Mr. Myron R. Henderson. P.E.; <strong>Project</strong> Manager with M3Engineering & Technology<br />

Corporation; principal author of this technical report and responsible for Sections 1<br />

through 3, Sections 17 through 19, Sections 21 and 22, and Sections 24 through 26.<br />

• Dr. Rex C. Bryan, Ph.D.; Senior Geostatistician with Tetra Tech MM, <strong>Inc</strong>.; responsible<br />

for Sections 4 through 12, Section 14, and Section 23.<br />

• Mr. Herbert E. Welhener, MMSA-QPM; Vice President of Independent Mining<br />

Consultants, <strong>Inc</strong>.; responsible for Section 16 – Mining Methods.<br />

• Dr. Richard W. Jolk, P.E., Ph.D., Principal Mine Engineer, Metallurgical Engineer, and<br />

Certified Minerals Appraiser with Tetra Tech MM, <strong>Inc</strong>.; responsible for Section 13 -<br />

Mineral Processing and Metallurgical Testing.<br />

• Mr. Mark A. Willow, M.Sc., C.E.M., Practice Leader with SRK Consulting (U.S.), <strong>Inc</strong>.;<br />

responsible for Section 20 – Environmental Studies, Permitting and Social or Community<br />

Impact.<br />

This Technical Report is current as of May 23, 2012<br />

(Signed) “Myron R. Henderson” June 26, 2012<br />

Myron R. Henderson, P.E. Date<br />

(Signed) “Rex C. Bryan” June 26, 2012<br />

Rex C. Bryan, Ph.D. Date<br />

(Signed) “Herbert E. Welhener” June 26, 2012<br />

Herbert E. Welhener, MMSA-QPM Date<br />

(Signed) “Richard W. Jolk” June 25, 2012<br />

Richard W. Jolk, P.E., Ph.D. Date<br />

(Signed) “Mark A. Willow” June 25, 2012<br />

Mark A. Willow, M.Sc., C.E.M. #1832 Date<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 i

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

TABLE OF CONTENTS<br />

SECTION PAGE<br />

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

DATE AND SIGNATURES PAGE ................................................................................................... i<br />

TABLE OF CONTENTS.................................................................................................................... ii<br />

LIST OF FIGURES AND ILLUSTRATIONS ............................................................................... ix<br />

LIST OF TABLES ............................................................................................................................ xii<br />

LIST OF APPENDICES .................................................................................................................. xv<br />

1 SUMMARY ............................................................................................................................. 1<br />

1.1 PROPERTY DESCRIPTION AND OWNERSHIP ............................................................... 1<br />

1.2 HISTORY ....................................................................................................................... 2<br />

1.3 GEOLOGY AND MINERALIZATION .............................................................................. 2<br />

1.3.1 Geophysics ............................................................................................... 3<br />

1.4 EXPLORATION STATUS ................................................................................................ 4<br />

1.4.1 Exploration Drilling Program ............................................................... 4<br />

1.5 RESOURCE ESTIMATE .................................................................................................. 5<br />

1.5.1 Block Model Definition .......................................................................... 5<br />

1.5.2 Assay Database ....................................................................................... 6<br />

1.5.3 Compositing ............................................................................................ 6<br />

1.5.4 Geostatistical Analysis and Variography ............................................. 7<br />

1.5.5 Kriging and Resource Classification .................................................... 7<br />

1.5.6 Estimated <strong>Resources</strong> .............................................................................. 9<br />

1.6 METALLURGY ............................................................................................................ 11<br />

1.7 ECONOMIC ASSESSMENT ........................................................................................... 12<br />

1.8 CONCLUSIONS AND RECOMMENDATIONS................................................................. 13<br />

2 INTRODUCTION ................................................................................................................ 14<br />

2.1 GENERAL .................................................................................................................... 14<br />

2.2 PURPOSE OF REPORT ................................................................................................. 14<br />

2.3 SOURCES OF INFORMATION ...................................................................................... 14<br />

2.4 CONSULTANTS AND QUALIFIED PERSONS ................................................................ 15<br />

2.5 DEFINITION OF TERMS USED IN THIS REPORT ........................................................ 16<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 ii

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

3 RELIANCE ON OTHER EXPERTS ................................................................................. 20<br />

4 PROPERTY DESCRIPTION AND LOCATION ............................................................ 21<br />

4.1 LOCATION .................................................................................................................. 21<br />

4.2 PROPERTY OWNERSHIP ............................................................................................. 21<br />

4.3 MINERAL TENURE AND TITLE .................................................................................. 21<br />

4.4 RELEVANT INFORMATION ......................................................................................... 22<br />

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE<br />

AND PHYSIOGRAPHY ...................................................................................................... 26<br />

5.1 ACCESSIBILITY ........................................................................................................... 26<br />

5.2 CLIMATE .................................................................................................................... 26<br />

5.3 LOCAL RESOURCES AND INFRASTRUCTURE ............................................................ 26<br />

6 HISTORY .............................................................................................................................. 28<br />

6.1 PROPERTY HISTORY .................................................................................................. 28<br />

6.2 HISTORICAL RESOURCES .......................................................................................... 30<br />

6.3 HISTORIC MINING ..................................................................................................... 30<br />

6.4 HISTORIC METALLURGICAL TESTWORK AND MINERAL PROCESSING .................. 30<br />

7 GEOLOGICAL SETTING AND MINERALIZATION ................................................. 31<br />

7.1 REGIONAL GEOLOGY ................................................................................................ 31<br />

7.2 LOCAL GEOLOGY ...................................................................................................... 33<br />

7.3 PROPERTY GEOLOGY ................................................................................................ 33<br />

7.3.1 Alteration ............................................................................................... 36<br />

7.4 MINERALIZATION ...................................................................................................... 38<br />

8 DEPOSIT TYPES ................................................................................................................. 40<br />

8.1 OXIDE ZONE EXPLORATION ..................................................................................... 43<br />

8.2 CHALCOCITE/OXIDE ZONE EXPLORATION .............................................................. 43<br />

8.3 PRIMARY SULFIDE ZONE EXPLORATION ................................................................. 43<br />

9 EXPLORATION ................................................................................................................... 45<br />

9.1 GEOPHYSICS ............................................................................................................... 45<br />

9.1.1 IP/Resistivity Surveys ........................................................................... 45<br />

9.1.2 Airborne Magnetic Surveys................................................................. 60<br />

10 DRILLING ............................................................................................................................ 63<br />

10.1 HISTORICAL ............................................................................................................... 63<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 iii

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

10.2 EXPLORATION & DRILLING HISTORY ...................................................................... 63<br />

10.3 HISTORIC MINING ..................................................................................................... 68<br />

10.4 CURRENT DRILLING .................................................................................................. 68<br />

10.5 SURVEYING DRILL HOLE COLLARS .......................................................................... 69<br />

10.6 DOWNHOLE SURVEYS ................................................................................................ 71<br />

10.7 CURRENT DRILLING METHODS AND DETAILS ......................................................... 71<br />

10.8 REVERSE CIRCULATION DRILLING SAMPLING METHOD ....................................... 72<br />

10.9 CORE DRILLING SAMPLING METHOD ...................................................................... 73<br />

10.10 DRILLING, SAMPLING, AND RECOVERY FACTORS .................................................. 73<br />

10.11 SAMPLE QUALITY ...................................................................................................... 73<br />

11 SAMPLE PREPARATION, ANALYSES AND SECURITY ......................................... 75<br />

11.1 RC SAMPLE PREPARATION AND SECURITY ............................................................. 75<br />

11.2 CORE SAMPLE PREPARATION AND SECURITY ......................................................... 75<br />

11.3 SAMPLE ANALYSIS ..................................................................................................... 76<br />

11.4 LEACH ASSAY ANALYSIS ........................................................................................... 77<br />

11.5 QUALITY CONTROL ................................................................................................... 79<br />

11.6 REVIEW OF ADEQUACY OF SAMPLE PREPARATION, ANALYSES, AND<br />

SECURITY ................................................................................................................... 80<br />

12 DATA VERIFICATION ...................................................................................................... 82<br />

12.1 HISTORIC DATA CHECK ............................................................................................ 82<br />

12.2 CURRENT DATA CHECK ............................................................................................ 82<br />

12.2.1 Adequacy of Data ................................................................................. 84<br />

13 MINERAL PROCESSING AND METALLURGICAL TESTING ............................... 85<br />

13.1 OXIDE ORE COPPER EXTRACTION ........................................................................... 86<br />

13.2 OXIDE ORE ACID CONSUMPTION ............................................................................. 87<br />

13.3 TRANSITION ORE EXTRACTION AND ACID CONSUMPTION ..................................... 87<br />

13.4 LEACH CYCLE TIME .................................................................................................. 88<br />

13.5 LEACH SOLUTION APPLICATION RATE .................................................................... 88<br />

13.6 PAD HEIGHT ............................................................................................................... 89<br />

13.7 PLS FLOW RATE AND PLS GRADE .......................................................................... 89<br />

13.8 PARTICLE SIZE TO HEAP LEACH .............................................................................. 89<br />

13.9 HEAP LEACH DESIGN CRITERIA ............................................................................... 89<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 iv

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

14 MINERAL RESOURCE ESTIMATES ............................................................................. 92<br />

14.1 INTRODUCTION .......................................................................................................... 92<br />

14.2 MACARTHUR RESOURCE ESTIMATION .................................................................... 93<br />

14.3 MACARTHUR BLOCK MODEL ................................................................................... 95<br />

14.4 ASSAY DATA ............................................................................................................... 98<br />

14.5 COMPOSITE DATA .................................................................................................... 104<br />

14.6 GEOSTATISTICAL ANALYSIS AND VARIOGRAPHY.................................................. 109<br />

14.7 KRIGING ................................................................................................................... 112<br />

14.8 KRIGING ERROR AND RESOURCE CLASSIFICATION .............................................. 118<br />

14.9 VALIDATION OF BLOCK MODEL: VISUAL AND STATISTICAL CHECKS ................ 122<br />

14.10 MINERAL RESOURCE ESTIMATE ............................................................................ 127<br />

15 MINERAL RESERVE ESTIMATES .............................................................................. 132<br />

16 MINING METHODS ......................................................................................................... 133<br />

16.1 GEOTECHNICAL PARAMETERS ............................................................................... 133<br />

16.2 DILUTION MODELING AND FACTORS ..................................................................... 133<br />

16.3 OPEN PIT MINING .................................................................................................... 133<br />

16.4 MINING SCHEDULE .................................................................................................. 143<br />

16.5 WASTE DUMPS ......................................................................................................... 147<br />

16.6 MINING EQUIPMENT ................................................................................................ 154<br />

16.7 MINE LABOR ............................................................................................................ 155<br />

16.8 MINE CAPITAL COSTS ............................................................................................. 156<br />

16.9 MINE OPERATING COSTS ........................................................................................ 156<br />

17 RECOVERY METHODS .................................................................................................. 158<br />

17.1 OVERVIEW OF PLANNED FACILITIES ...................................................................... 158<br />

17.2 HEAP LEACH PAD .................................................................................................... 158<br />

17.3 SOLVENT EXTRACTION ........................................................................................... 159<br />

17.4 ELECTROWINNING ................................................................................................... 160<br />

17.5 SULFURIC ACID PLANT ............................................................................................ 161<br />

17.6 POWER PLANT .......................................................................................................... 162<br />

17.7 ANCILLARY FACILITIES ........................................................................................... 162<br />

18 PROJECT INFRASTRUCTURE ..................................................................................... 164<br />

18.1 SITE LOCATION ........................................................................................................ 164<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 v

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

18.2 PROCESS BUILDINGS ................................................................................................ 164<br />

18.3 ANCILLARY BUILDINGS ........................................................................................... 164<br />

18.3.1 Administration Building .................................................................... 165<br />

18.3.2 Warehouse / Plant Maintenance Building ....................................... 165<br />

18.3.3 Analytical Laboratory ........................................................................ 165<br />

18.3.4 Mine Truck Shop ................................................................................ 165<br />

18.3.5 Change House ..................................................................................... 165<br />

18.3.6 Main Gatehouse .................................................................................. 165<br />

18.3.7 Fuel Storage and Dispensing ............................................................. 166<br />

18.4 ACCESS ROADS......................................................................................................... 166<br />

18.5 RAILROAD FACILITIES............................................................................................. 166<br />

18.6 POWER SUPPLY & DISTRIBUTION ........................................................................... 166<br />

18.7 WATER SUPPLY & DISTRIBUTION .......................................................................... 166<br />

18.8 WASTE MANAGEMENT ............................................................................................ 167<br />

18.9 SURFACE WATER CONTROL ................................................................................... 167<br />

18.10 TRANSPORTATION & SHIPPING............................................................................... 167<br />

18.11 COMMUNICATIONS .................................................................................................. 168<br />

19 MARKET STUDIES AND CONTRACTS ...................................................................... 170<br />

20 ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR<br />

COMMUNITY IMPACT .................................................................................................. 172<br />

20.1 ENVIRONMENTAL LIABILITIES ............................................................................... 172<br />

20.2 PERMITS ................................................................................................................... 172<br />

20.2.1 Federal Permitting .............................................................................. 174<br />

20.2.2 State Permitting .................................................................................. 176<br />

20.2.3 Local Permitting ................................................................................. 178<br />

20.3 ENVIRONMENTAL STUDIES ...................................................................................... 178<br />

20.4 WASTE AND TAILINGS DISPOSAL ............................................................................ 179<br />

20.5 PROJECT PERMITTING REQUIREMENTS ................................................................. 179<br />

20.6 SOCIAL OR COMMUNITY RELATED REQUIREMENTS ............................................ 179<br />

20.7 MINE CLOSURE REQUIREMENTS ............................................................................ 180<br />

21 CAPITAL AND OPERATING COSTS ........................................................................... 182<br />

21.1 CAPITAL COST ......................................................................................................... 182<br />

21.1.1 Mine Capital Cost ............................................................................... 182<br />

21.1.2 SX/EW Capital Cost ........................................................................... 182<br />

21.1.3 Sulfuric Acid Plant Capital Cost....................................................... 185<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 vi

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

21.1.4 Exclusions ............................................................................................ 188<br />

21.2 RECLAMATION COST ESTIMATE ............................................................................ 188<br />

21.3 OPERATING COST .................................................................................................... 189<br />

21.3.1 Mine Operating Cost .......................................................................... 190<br />

21.3.2 SX/EW Operating Cost ...................................................................... 190<br />

21.3.3 Sulfuric Acid Plant Operating Cost .................................................. 191<br />

21.3.4 General and Administrative Costs ................................................... 193<br />

22 ECONOMIC ANALYSIS .................................................................................................. 195<br />

22.1 INTRODUCTION ........................................................................................................ 195<br />

22.2 MINE PRODUCTION STATISTICS ............................................................................. 195<br />

22.3 HEAP LEACH PAD AND SX/EW PRODUCTION STATISTICS ................................... 195<br />

22.3.1 Cathode Shipping ............................................................................... 195<br />

22.4 CAPITAL EXPENDITURE ........................................................................................... 196<br />

22.4.1 Initial Capital ...................................................................................... 196<br />

22.4.2 Sustaining Capital .............................................................................. 196<br />

22.4.3 Working Capital ................................................................................. 196<br />

22.4.4 Salvage Value ...................................................................................... 196<br />

22.5 REVENUE .................................................................................................................. 197<br />

22.6 OPERATING COST .................................................................................................... 197<br />

22.7 TOTAL CASH COST .................................................................................................. 197<br />

22.7.1 Royalty ................................................................................................. 197<br />

22.7.2 Reclamation and Closure ................................................................... 198<br />

22.8 DEPRECIATION AND DEPLETION ............................................................................. 198<br />

22.9 TAXATION ................................................................................................................. 198<br />

22.9.1 <strong>Inc</strong>ome Tax and Mineral Tax ............................................................ 198<br />

22.10 PROJECT FINANCING ............................................................................................... 198<br />

22.11 NET INCOME AFTER TAX ........................................................................................ 199<br />

22.12 NPV AND IRR .......................................................................................................... 199<br />

22.13 SENSITIVITIES........................................................................................................... 199<br />

23 ADJACENT PROPERTIES .............................................................................................. 203<br />

23.1 SINGATSE PEAK SERVICES PROPERTIES ................................................................ 203<br />

23.2 OTHER PROPERTIES ................................................................................................ 204<br />

24 OTHER RELEVANT DATA AND INFORMATION ................................................... 207<br />

24.1 RE-PROCESSING OF YERINGTON RESIDUALS ........................................................ 207<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 vii

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

24.1.1 Introduction ........................................................................................ 207<br />

24.1.2 Residual <strong>Copper</strong> <strong>Resources</strong> ............................................................... 207<br />

24.1.3 Mining Methods .................................................................................. 209<br />

24.1.4 Capital Cost Summary ....................................................................... 210<br />

24.1.5 Operating Costs .................................................................................. 211<br />

24.1.6 Economic Analysis .............................................................................. 213<br />

25 INTERPRETATION AND CONCLUSIONS ................................................................. 215<br />

25.1 RESOURCES .............................................................................................................. 215<br />

25.2 MINING METHODS ................................................................................................... 215<br />

25.3 METALLURGY .......................................................................................................... 216<br />

25.3.1 Run-of-Mine Heap Leaching ............................................................. 216<br />

25.3.2 Spatial Variability of In-Situ Size Distribution ............................... 216<br />

25.3.3 Chemical Degradation of the Ore during Leaching ....................... 216<br />

25.3.4 Permeability and Agglomeration ...................................................... 217<br />

25.3.5 Spatial Variability of <strong>Copper</strong> Extraction and Acid<br />

Consumption ....................................................................................... 217<br />

25.3.6 Relationship of Total Iron Mineralization to Acid<br />

Consumption ....................................................................................... 217<br />

25.4 ECONOMIC ASSESSMENT ......................................................................................... 217<br />

25.5 RISKS ........................................................................................................................ 218<br />

26 RECOMMENDATIONS ................................................................................................... 219<br />

26.1 METALLURGY TEST PROGRAM .............................................................................. 219<br />

26.1.1 Stage I- Sample Preparation ............................................................. 219<br />

26.1.2 Stage II- Acid Bottle Roll and Acid Characterization Testing ...... 219<br />

26.1.3 Stage III- Small Column Leach Tests .............................................. 220<br />

26.1.4 Stage IV- Large Column Leach Tests .............................................. 220<br />

26.1.5 Stage V- Study Preparation and Recommendations for a<br />

Final Feasibility ................................................................................... 220<br />

26.2 BUDGET AND SCHEDULE .......................................................................................... 220<br />

27 REFERENCES.................................................................................................................... 222<br />

APPENDIX A: CERTIFICATE OF QUALIFIED PERSON (“QP”) AND CONSENT<br />

OF AUTHOR ...................................................................................................................... 224<br />

APPENDIX B: PROPERTY LISTING ........................................................................................ 240<br />

APPENDIX C: EXPLORATION HISTORY OF THE MACARTHUR OXIDE<br />

COPPER PROPERTY ....................................................................................................... 255<br />

APPENDIX D: EXPLORATION DRILL HOLES WITH INTERCEPTS ............................. 260<br />

APPENDIX E: RESOURCE MODEL DRILL HOLE LISTING ............................................ 300<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 viii

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

LIST OF FIGURES AND ILLUSTRATIONS<br />

FIGURE DESCRIPTION PAGE<br />

Figure 1-1: <strong>Quaterra</strong> Exploration Drilling by Year .........................................................................4<br />

Figure 4-1: General Location Map ................................................................................................23<br />

Figure 4-2: Regional Layout May..................................................................................................24<br />

Figure 4-3: <strong>MacArthur</strong> Property May ............................................................................................25<br />

Figure 6-1: Major Physiographic Features ....................................................................................29<br />

Figure 7-1: Regional Geology .......................................................................................................32<br />

Figure 7-2: Generalized Alteration Types .....................................................................................38<br />

Figure 8-1: Datamine© View of Resource Block Model Looking West ......................................40<br />

Figure 8-2: East-West Section 14,691,000N (Looking North) ......................................................41<br />

Figure 8-3: North- South Section 2,438,324 (Looking West) .......................................................42<br />

Figure 9-1: IPR line locations over the central <strong>MacArthur</strong> <strong>Project</strong> area. ......................................47<br />

Figure 9-2: Line 4300 (304300E) IP pseudo-section and inverted phase/depth model .................48<br />

Figure 9-3: Line 4300 Resistivity pseudo-section and inverted resistivity/depth model...............49<br />

Figure 9-4: Line 4900 IP pseudo-section and inverted phase/depth model ...................................50<br />

Figure 9-5: Line 4900 Resistivity pseudo-section and inverted resistivity/depth model...............51<br />

Figure 9-6: Line 7500 IP pseudo-section and inverted phase/depth model ...................................52<br />

Figure 9-7: Line 7500 Resistivity pseudo-section and inverted resistivity/depth model...............53<br />

Figure 9-8: QM-164 down hole electrode to remote electrode transmitter pair ............................54<br />

Figure 9-9: QM-177 down hole electrode to remote electrode transmitter pair ............................55<br />

Figure 9-10: Line location of the 1960’s Kennecott lines (in black) and the 2009 replacement line<br />

(in white). ...............................................................................................................57<br />

Figure 9-11: Historic and 2009 IP data on a modeled magnetic susceptibility depth slice ...........58<br />

Figure 9-12: Inversion model and pseudo-sections for line 6075 recorded in 2009. ....................59<br />

Figure 9-13: Location of the 2012 detailed helicopter magnetic survey .......................................61<br />

Figure 10-1: Location of Historic Drill holes ................................................................................65<br />

Figure 10-2: Drill hole Location Map ............................................................................................70<br />

Figure 10-3: <strong>Quaterra</strong> Exploration Drilling by Year .....................................................................72<br />

Figure 10-4: Letter from Mr. Henry Koehler .................................................................................74<br />

Figure 11-1: <strong>MacArthur</strong> Check Assay Results ..............................................................................80<br />

Figure 11-2: Reviewing Established Protocol for Data Entry .......................................................80<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 ix

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Figure 11-3: Manually Creating Geologic Sections from the Drill Data .......................................81<br />

Figure 12-1: Twin Hole Charted Results .......................................................................................84<br />

Figure 13-1: Comparison of Grade versus <strong>Copper</strong> Recovery Oxide Leach Ore ...........................86<br />

Figure 14-1: Drill Location and Search Zones for the <strong>MacArthur</strong> 2011 Model ............................95<br />

Figure 14-2: Side-by-Side Histograms – TCu% Assay SE-PIT area and NW-OUT area ...........104<br />

Figure 14-3: Side-by-Side Histograms – TCu% Composites SE-PIT area & NW area ..............109<br />

Figure 14-4: 0.12% Indicator Variograms (Omni Direction) For NW-Out and SE-Pit Areas ....110<br />

Figure 14-5: Selected Cu% Correlograms For SE-Pit And NW-Out Areas ................................111<br />

Figure 14-6: Side-by-Side Histograms M&I vs INF for (a) SE and (b) NW-Out .......................117<br />

Figure 14-7: Probability plot of kriging error ..............................................................................119<br />

Figure 14-8: Jackknife Method of Model Validation ..................................................................120<br />

Figure 14-9: Jackknife validation of kriging model (SE Area, MinZones 10 and 11) ................121<br />

Figure 14-10: Side-by-Side Samples, Composites and Blocks ...................................................122<br />

Figure 14-11: East West Cross Section Looking North (Cu blocks) ...........................................123<br />

Figure 14-12: East-West Cross Section Looking North (Resource Class) ..................................124<br />

Figure 14-13: North-South Cross Section Looking West (Cu Blocks) .......................................125<br />

Figure 14-14: North South Cross Section Looking West (Resource Class) ................................126<br />

Figure 16-1: Final Pits .................................................................................................................136<br />

Figure 16-2: Mining Phase 1 in <strong>MacArthur</strong> Pit ...........................................................................137<br />

Figure 16-3: Mining Phase 2 in <strong>MacArthur</strong> Pit ...........................................................................138<br />

Figure 16-4: Mining Phase 3 in North Pit Area ...........................................................................139<br />

Figure 16-5: Mining Phase 4 in North Pit Area ...........................................................................140<br />

Figure 16-6: Mining Phase 5 (Gallagher Pit) ...............................................................................141<br />

Figure 16-7: Mining Phase 6 in <strong>MacArthur</strong> Pit ...........................................................................142<br />

Figure 16-8: Final Pit and Dumps (including pit backfill) ..........................................................148<br />

Figure 16-9: End of Year 1 ..........................................................................................................149<br />

Figure 16-10: End of Year 3 ........................................................................................................150<br />

Figure 16-11: End of Year 5 ........................................................................................................151<br />

Figure 16-12: End of Year 7 ........................................................................................................152<br />

Figure 16-13: End of Year 10 ......................................................................................................153<br />

Figure 17-1: Overall Process Flowsheet ......................................................................................163<br />

Figure 18-1: <strong>MacArthur</strong> Heap Leach and Process Facilities .......................................................169<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 x

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Figure 19-1: Historic <strong>Copper</strong> Price ..............................................................................................170<br />

Figure 22-1: <strong>MacArthur</strong> <strong>Project</strong> NPV Sensitivities .....................................................................200<br />

Figure 23-1: Adjacent Properties .................................................................................................206<br />

Figure 24-1: Yerington Mine Residuals ......................................................................................214<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 xi

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

LIST OF TABLES<br />

TABLE DESCRIPTION PAGE<br />

Table 1-1: Exploration Drilling History ..........................................................................................2<br />

Table 1-2: <strong>MacArthur</strong> Model Parameters ........................................................................................5<br />

Table 1-3: MinZone Codes and Density ..........................................................................................6<br />

Table 1-4: Kriging and Search Parameters ......................................................................................8<br />

Table 1-5: Measured + Indicated <strong>Copper</strong> <strong>Resources</strong> .....................................................................10<br />

Table 1-6: Inferred <strong>Copper</strong> <strong>Resources</strong> ...........................................................................................11<br />

Table 10-1: Historic Exploration Drilling......................................................................................63<br />

Table 10-2: U.S. Bureau of Mines 1947-1950 Drilling Highlights ...............................................64<br />

Table 10-3: Anaconda Company 1955-1957 Drilling Highlights .................................................66<br />

Table 10-4: Pangea Exploration 1987-1991 Drilling Highlights ...................................................67<br />

Table 11-1: Sequential <strong>Copper</strong> Leach Assay Results ....................................................................78<br />

Table 11-2: Ferric Sulfate Leach (QLT) Assay Results ................................................................79<br />

Table 11-3: <strong>MacArthur</strong> 2011 QA/QC Program Results ................................................................79<br />

Table 12-1: List of Twin Holes Drilled By <strong>Quaterra</strong> .....................................................................83<br />

Table 13-1: <strong>MacArthur</strong> Historical Test Work ...............................................................................91<br />

Table 14-1: <strong>MacArthur</strong> Model Parameters ....................................................................................95<br />

Table 14-2: MinZone Codes and Density ......................................................................................96<br />

Table 14-3: MinZone Interval Data Count and Drill hole Assay Statistics ...................................97<br />

Table 14-4: Statistics of Cu Assay Data (All Areas) .....................................................................99<br />

Table 14-5: SE-Pit Area Cu Assay Statistics ...............................................................................102<br />

Table 14-6: NW Area TCu Assay Statistics ................................................................................103<br />

Table 14-7: MinZone Composite Count (All Areas) ...................................................................105<br />

Table 14-8: All Cu Assay Statistics for <strong>Quaterra</strong> Composites ....................................................106<br />

Table 14-9: SE Area Cu Assay Statistics for <strong>Quaterra</strong> Composites ............................................107<br />

Table 14-10: NW Area Cu Assay Statistics for <strong>Quaterra</strong> Composites ........................................108<br />

Table 14-11: Variogram and Search Parameters .........................................................................112<br />

Table 14-12: MinZone Block Count (All Areas) .........................................................................113<br />

Table 14-13: SE-Pit and NW Areas Cu Block Statistics .............................................................114<br />

Table 14-14: SE Area Cu Block Statistics ...................................................................................115<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 xii

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Table 14-15: NE Area Cu Block Statistics ..................................................................................116<br />

Table 14-16: Measured <strong>Copper</strong> <strong>Resources</strong> ..................................................................................128<br />

Table 14-17: Indicated <strong>Copper</strong> <strong>Resources</strong> ...................................................................................129<br />

Table 14-18: Measured + Indicated <strong>Copper</strong> <strong>Resources</strong> ...............................................................130<br />

Table 14-19: Inferred <strong>Copper</strong> <strong>Resources</strong> .....................................................................................131<br />

Table 16-1: Pit Definition Inputs .................................................................................................134<br />

Table 16-2: Floating Cone Geometries Used for Pit Designs......................................................135<br />

Table 16-3: Phase Tonnage and Grade Available for Mine Production Schedule ......................135<br />

Table 16-4: Production Schedule .................................................................................................143<br />

Table 16-5: Ore Production Schedule by Mining Phase ..............................................................144<br />

Table 16-6: Ore Production Schedule by Mining Phase and Resource Classification ................145<br />

Table 16-7: Waste Tonnage by Source and Destination ..............................................................147<br />

Table 16-8: Mine Equipment .......................................................................................................155<br />

Table 16-9: Mine Capital Estimate ..............................................................................................156<br />

Table 16-10: Mine Operating Costs .............................................................................................157<br />

Table 18-1: Products & Consumables .........................................................................................168<br />

Table 20-1: Summary of Major Permits for Future Mining ........................................................173<br />

Table 20-2: Future Baseline Studies ............................................................................................176<br />

Table 21-1: SX/EW Capital Cost .................................................................................................182<br />

Table 21-2: SX/EW Sustaining Capital .......................................................................................183<br />

Table 21-3: Sulfuric Acid Plant Capital Cost ..............................................................................186<br />

Table 21-4: Reclamation Cost Estimate ......................................................................................189<br />

Table 21-5: <strong>MacArthur</strong> SX/EW and Mine Operating Cost .........................................................190<br />

Table 21-6: SX/EW Operating Cost ............................................................................................190<br />

Table 21-7: Reagent Cost.............................................................................................................191<br />

Table 21-8: Sulfuric Acid Plant Operating Cost ..........................................................................192<br />

Table 21-9: General & Administrative Cost Summary ...............................................................193<br />

Table 21-10: General & Administrative Labor Cost Summary ...................................................194<br />

Table 22-1: Life of Mine Ore, Waste Quantities, and Ore Grade ................................................195<br />

Table 22-2: Initial Capital ............................................................................................................196<br />

Table 22-3: Life of Mine Operating Cost ....................................................................................197<br />

Table 22-4: Economic Indicators .................................................................................................199<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 xiii

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Table 22-5: Sensitivity Analysis ..................................................................................................199<br />

Table 22-6: Discounted Cash Flow Model ..................................................................................201<br />

Table 23-1: Singatse Peak Services, LLC – Yerington Mine <strong>Resources</strong>, Feb. 2012 ..................203<br />

Table 23-2: Yerington Mine Residual <strong>Copper</strong> <strong>Resources</strong>, SRK March, 2012 (Non NI43-101<br />

Compliant) ...........................................................................................................204<br />

Table 23-3: Adjacent Property Resource Estimates ....................................................................205<br />

Table 24-1: Yerington Residual Oxide <strong>Copper</strong> <strong>Resources</strong>, SRK March 2012 ............................209<br />

Table 24-2: Combined Yerington Oxide Residuals / <strong>MacArthur</strong> Mine Capital & Sustaining<br />

Costs .....................................................................................................................211<br />

Table 24-3: Combined Yerington Oxide Residuals / <strong>MacArthur</strong> Mine Operating Costs............212<br />

Table 24-4: Combined Yerington Oxide Residuals / <strong>MacArthur</strong> Mine Economic Indicators ....213<br />

Table 26-1: Budget for <strong>MacArthur</strong> Follow on Test Work ...........................................................221<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 xiv

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

APPENDIX DESCRIPTION<br />

LIST OF APPENDICES<br />

A Certificate of Qualified Person (“QP”) and Consent of Author<br />

B Property Listing<br />

C Exploration History of the <strong>MacArthur</strong> Oxide <strong>Copper</strong> Property<br />

D Exploration Drill Holes with Intercepts<br />

E Resource Model Drill Hole Listing<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 xv

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

1 SUMMARY<br />

<strong>Quaterra</strong> Alaska, <strong>Inc</strong>. (<strong>Quaterra</strong>), a wholly owned subsidiary of <strong>Quaterra</strong> <strong>Resources</strong>, <strong>Inc</strong>.<br />

commissioned M3 Engineering and Technology Corporation (M3) to prepare a Canadian<br />

National Instrument 43-101 (NI 43-101) compliant Preliminary Economic Assessment (PEA) for<br />

the <strong>MacArthur</strong> <strong>Copper</strong> <strong>Project</strong> in Lyon County, Nevada. Tetra Tech <strong>Inc</strong>. (Tt) and Independent<br />

Mining Consultants, <strong>Inc</strong>. (IMC) prepared several sections of the PEA. This report includes an<br />

update of the January 2011 <strong>MacArthur</strong> technical report and reflects changes to the resource<br />

estimate as a result of the 2011 exploration drilling and continued geologic investigations.<br />

The Qualified Person for Sections 4 through 12, Section 14, and Section 23 of this report is Mr.<br />

Rex Bryan, PhD, Senior Geostatistician for Tetra Tech, Golden Colorado. The Qualified Person<br />

for Section 13 of this report is Mr. Richard W. Jolk, P.E., PhD, Principal Minerals Engineer for<br />

Tetra Tech, Golden Colorado. The Qualified Person for Section 16 of this report is Mr. Herb<br />

Welhener, Principal Mining Engineer for Independent Mining Consultants, <strong>Inc</strong>., Tucson,<br />

Arizona.<br />

The <strong>MacArthur</strong> <strong>Copper</strong> Property is located near the geographic center of Lyon County, Nevada,<br />

USA along the northeastern flank of the Singatse Range approximately seven miles northwest of<br />

the town of Yerington, Nevada. The property is accessible from Yerington by approximately five<br />

miles of paved roads and two miles of maintained gravel road. Topographic coverage is on US<br />

Geological Survey “Mason Butte” and “Lincoln Flat” 7.5’ topographic quadrangles. The nearest<br />

major city is Reno, Nevada approximately 75 miles to the northwest.<br />

The Preliminary Economic Assessment within this Technical Report is based upon the oxide /<br />

chalcocite portion of the updated resource. This oxide / chalcocite portion includes a measured<br />

and indicated resource of 159.1 million tons averaging 0.21% Cu (percent total copper or TCu)<br />

containing 676 million pounds of copper at a 0.12% Cu cutoff and an inferred resource of 243<br />

million tons averaging 0.20% Cu at a 0.12% Cu cutoff containing 980 million pounds of copper.<br />

It should also be noted that integration of some 120 million tons of resource piles (non-compliant<br />

NI 43-101 “Residuals”) from <strong>Quaterra</strong> <strong>Resources</strong> 2011 acquisition of the historic, neighboring<br />

Yerington copper mine, could provide a significant positive impact on the economics of the<br />

<strong>MacArthur</strong> <strong>Project</strong>. Residuals consist of oxide-copper bearing sub-grade material representing<br />

stripped material from the Yerington mine, vat leach tailings representing oxide tailings from<br />

copper oxide vat leaching, and partially leached tailings and ore previously mined by Arimetco.<br />

The residuals are currently being characterized to elevate to a NI 43-101 status.<br />

1.1 PROPERTY DESCRIPTION AND OWNERSHIP<br />

The <strong>MacArthur</strong> <strong>Copper</strong> Property is located near the geographic center of Lyon County, Nevada,<br />

USA along the northeastern flank of the Singatse Range approximately seven miles northwest of<br />

the town of Yerington, Nevada. The property is accessible from Yerington by approximately five<br />

miles of paved roads and two miles of Lyon County maintained gravel road. Topographic<br />

coverage is on US Geological Survey “Mason Butte” and “Lincoln Flat” 7.5’ topographic<br />

quadrangles. The nearest major city is Reno, Nevada approximately 75 miles to the northwest.<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 1

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

The property consists of 470 unpatented lode claims totaling approximately 9700 acres on lands<br />

administered by the US Department of Interior - Bureau of Land Management (BLM). All<br />

required annual payments to the BLM and Lyon County have been paid in a timely manner and<br />

the claims are current.<br />

1.2 HISTORY<br />

Over the history of the project, previous operators have contributed more than 300 holes to the<br />

current drill hole database. Table 1-1 summarizes the exploration history of the <strong>MacArthur</strong> area.<br />

Of the historic holes, 280 of those holes drilled by the Anaconda Company (Anaconda) during<br />

1972-73 have been deemed acceptable under NI 43-101 standards and have been used during the<br />

resource estimation.<br />

Operator<br />

Table 1-1: Exploration Drilling History<br />

MACARTHUR PROJECT<br />

February 2009<br />

Drill Program<br />

Date Range<br />

Number of<br />

Holes Drilled<br />

Feet Drilled<br />

U.S. Bureau of Mines 1947-50 8 3,414<br />

Anaconda Company 1955-57 14 3,690<br />

Bear Creek Mining Company 1963-?? ~14 Unknown<br />

Superior Oil Company 1967-68 11 13,116<br />

Anaconda Company 1972-73 280 55,809<br />

Pangea Explorations, <strong>Inc</strong>. 1987-1991 15 2,110<br />

Arimetco International, <strong>Inc</strong>. Unknown Unknown Unknown<br />

Total ~342 ~78,139<br />

1.3 GEOLOGY AND MINERALIZATION<br />

The <strong>MacArthur</strong> property is one of several copper deposits and prospects located near the town of<br />

Yerington that collectively comprise the Yerington Mining District. The property is underlain by<br />

Middle Jurassic granodiorite and quartz monzonite intruded by west-northwesterly-trending,<br />

moderate to steeply north-dipping quartz porphyry dike swarms. These dikes host a large portion<br />

of the primary copper mineralization at the nearby Yerington mine and are associated with all<br />

porphyry copper occurrences in the district.<br />

The <strong>MacArthur</strong> copper deposit consists of a 50-150 foot thick, tabular zone of secondary copper<br />

(oxides and/or chalcocite) covering an area of approximately two square miles. This mineralized<br />

zone has yet to be fully delineated and remains open to the west and north. Limited drilling has<br />

also intersected underlying primary copper mineralization open to the north, but only partially<br />

tested to the west and east.<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 2

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Oxide copper mineralization is most abundant and particularly well exposed in the walls of the<br />

<strong>MacArthur</strong> pit. The most common copper mineral is chrysocolla; also present is black copper<br />

wad (neotocite) and trace cuprite and tenorite. The flat-lying zones of oxide copper mirror<br />

topography, exhibit strong fracture control and range in thickness from 50 to 100 feet. Secondary<br />

chalcocite mineralization forms a blanket up to 50 feet or more in thickness that is mixed with<br />

and underlies the oxide copper. Primary chalcopyrite mineralization has been intersected in<br />

several locations mixed with and below the chalcocite. The extent of the primary copper is<br />

unknown as many of the drill holes bottomed at 400 feet or less. The primary copper is currently<br />

not included in the mine plan for the PEA.<br />

The <strong>MacArthur</strong> deposit is part of a large, partially defined porphyry copper system that has been<br />

complicated by complex faulting and post-mineral tilting. Events leading to the current geometry<br />

and distribution of known mineralization include 1) Middle Jurassic emplacement of primary<br />

porphyry copper mineralization by quartz monzonite dikes intruding the Yerington Batholith; 2)<br />

Late Tertiary westward tilting of the porphyry deposit 60-90° by Basin and Range extensional<br />

faulting; 3) secondary (supergene) enrichment resulting in the formation of a widespread, tabular<br />

zone of secondary chalcocite mineralization below outcrops of oxidized rocks called leached<br />

cap; 4) oxidation of outcropping and near-surface parts of this chalcocite blanket, as well as<br />

oxidation of the primary porphyry sulfide system.<br />

1.3.1 Geophysics<br />

<strong>Quaterra</strong> contracted three surveys at the <strong>MacArthur</strong> <strong>Project</strong> in 2011 and 2012. A borehole<br />

geophysical survey and a surface IP/resistivity (IPR) survey were carried out by Zonge<br />

International in 2011, and a detailed helicopter magnetic survey was flown by Geosolutions Pty.<br />

Ltd. in 2012. These surveys supplement previous geophysical work on the property that includes:<br />

a 2009 IPR survey carried out by Zonge; a 2007 helicopter magnetic survey carried out by<br />

EDCON-PRJ; a series of historic aeromagnetic surveys (1966 to 1975) available in analog form<br />

from the Anaconda Archives; and a series of historic IPR surveys (1963 – 1964) carried out by<br />

Kennecott Exploration Services/Bear Creek Mining Company and Superior Oil.<br />

The mineralized system at <strong>MacArthur</strong> has an anomalous IP and resistivity response first detected<br />

in the Kennecott and Superior Oil IPR surveys in the 1960’s. The <strong>Quaterra</strong> 2009 and 2011 IPR<br />

surveys confirmed the reliability of the earlier surveys and further defined the depth extent of the<br />

IP anomalies. The 2009 and 2011 <strong>Quaterra</strong> surveys confirmed that the 1963-64 Kennecott data is<br />

of good quality and is useful for mapping anomalous IP zones within the upper 1,000-1,200 feet<br />

from the surface. Below this depth, the older data cannot effectively resolve the bottom of the IP<br />

anomalies nor determine if any of the anomalies extend to great depths.<br />

The 2009 and 2011 data sets show this increased depth of exploration is important. Portions of<br />

the IP response are flat lying with limited depth extent. However both the 2009 and 2011 surveys<br />

have identified anomalous IP responses with depth extent in excess of 2000 feet and possibly<br />

feeder zones of the near surface zones. In 2011 two borehole IP surveys were run that<br />

demonstrate <strong>Quaterra</strong>’s ability to explore for deep sulfide responses below the depth of<br />

exploration of surface techniques. The modern data maps subtle low resistivity features which<br />

are interpreted to be porphyry alteration systems and have identified anomalous IP responses that<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 3

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

extend under post-mineral volcanic cover to the north and west of the main <strong>MacArthur</strong> system.<br />

These buried anomalies are high priority drill targets.<br />

Two high resolution helicopter magnetic surveys were flown over the <strong>MacArthur</strong> <strong>Project</strong> in 2007<br />

(EDCON-PRJ) and 2012 (Geosolutions). The modern, high resolution data has a broad<br />

frequency bandwidth and will be used for 3D modeling and exploring beneath the magnetic<br />

volcanic cover.<br />

1.4 EXPLORATION STATUS<br />

1.4.1 Exploration Drilling Program<br />

<strong>Quaterra</strong> has completed 204,656 feet of drilling in 401 holes since beginning drilling in 2007.<br />

Core holes total 40,233 feet in 58 holes and reverse circulation holes total 164,423 feet in 343<br />

holes. (Note that one previously listed, but abandoned 115 foot drill hole, has now been removed<br />

from the database and reported totals). Figure 1-1 show <strong>Quaterra</strong>'s yearly exploration drilling<br />

footage by year.<br />

Figure 1-1: <strong>Quaterra</strong> Exploration Drilling by Year<br />

<strong>Quaterra</strong>’s initial objective was to verify and expand the <strong>MacArthur</strong> oxide resource as had been<br />

defined by the 1972-1973 Anaconda drilling program and, importantly, to follow up chalcocite<br />

intercepts in several Anaconda holes as well as in a few outlying early 1960’s holes drilled by<br />

Bear Creek Mining Company, in late 1960’s drilling by Superior Oil, and holes drilled by the US<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 4

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Bureau of Mines in 1950. <strong>Quaterra</strong>’s drilling through 2010 successfully expanded the oxide<br />

mineralization outbound from the <strong>MacArthur</strong> pit and encountered a widespread, underlying<br />

tabular blanket of mixed oxide-chalcocite mineralization as well as primary copper intercepts<br />

that remain incompletely tested.<br />

During 2011, exploration and infill drilling focused north of the <strong>MacArthur</strong> pit where earlier<br />

drilling encountered better grades of oxide and chalcocite mineralization. Holes were angled<br />

both southerly and northerly to test high angle fractures common in the west-northwest structural<br />

grain. Strong chalcocite and chalcopyrite mineralization was intersected in several holes in the<br />

North Ridge zone including QM-183: 1.37% Cu over 40 feet and QM-187: 1.66% Cu over 90’.<br />

These results were followed by a tightened drill spacing from 500 feet to 250 feet over an<br />

approximate 2,500 feet by 2,500 feet area north of the <strong>MacArthur</strong> pit, forming the basis for the<br />

2011 resource.<br />

Deep drilling north of the North Ridge Zone intersected significant primary sulfide<br />

mineralization grading 1.32% Cu over 64 feet in hole QM-164 which is open to the north and<br />

partially open to the west and east. Although the mineralization at <strong>MacArthur</strong> has yet to be<br />

completely closed off to the west and north, the 2011 drilling program expanded and in-filled<br />

earlier drill results and defined the footprint for the mineral resource estimation published in this<br />

document.<br />

1.5 RESOURCE ESTIMATE<br />

An updated mineral resource estimate has been generated using drill hole sample assays results<br />

and the interpretation of a geologic model which relates to the spatial distribution of copper in<br />

the <strong>MacArthur</strong> deposit. Interpolation characteristics have been defined based on geology, drill<br />

hole spacing and geostatistical analysis of the data.<br />

1.5.1 Block Model Definition<br />

The block model parameters for <strong>MacArthur</strong> were defined to best reflect both the drill hole<br />

spacing and current geologic model. Table 1-2 shows the block model parameters used for the<br />

2011 estimates.<br />

Table 1-2: <strong>MacArthur</strong> Model Parameters<br />

<strong>MacArthur</strong> East Model Parameters X (Columns) Y (Rows) Z (Levels)<br />

Origin (lower left corner): 2,429,300 14,685,800 2,800<br />

Block size (feet) 25 25 20<br />

Number of Blocks 548 400 150<br />

Rotation 0 degrees azimuth from North to left boundary<br />

Composite Length 10 feet (Zone)<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 5

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

1.5.2 Assay Database<br />

An Excel database provided by <strong>Quaterra</strong> contained the pertinent drill hole and assay information<br />

for the <strong>MacArthur</strong> <strong>Copper</strong> deposit. The database contained 737 drill holes of which 676 drill<br />

holes from <strong>Quaterra</strong> and Anaconda (sometimes referred to as the Metech holes) were used. The<br />

61 holes removed included holes with limited or no information on the assays (Pangea Gold<br />

1991, Superior, USBM 1952, Anaconda 1955-57), and six <strong>Quaterra</strong> holes outside the model<br />

limits. Of the 676 holes used, there are 280 Anaconda (Metech) RC holes and 396 <strong>Quaterra</strong> holes<br />

(58 core and 338 RC holes). These drill holes traversed 257,895 feet, producing 51,258 total<br />

copper sample assay values at a nominal five feet in length.<br />

A total of 151 drill holes totaling 80,800 feet were added to the database used for the resource<br />

estimation. These included two holes for which data was unavailable at the time of the last<br />

estimate, but did not include three 2011 holes which were outside the model limits.<br />

The variables available in the database are for total copper from <strong>Quaterra</strong> and Anaconda<br />

intervals, and acid-soluble copper, a limited number of ferric sulfate soluble (QLT) copper<br />

assays and a very limited number of cyanide leach copper assays from <strong>Quaterra</strong> holes.<br />

1.5.3 Compositing<br />

The assay data was composited using a 10-foot “zone method”. The zone method is a variant of<br />

down hole compositing, with the distinction that the composite begins as the drill interval enters<br />

a rock code zone. This method tends to reduce averaging composites across zones. The process<br />

first used DataMine ® to assign a MinZone to each 25x25x20-foot block within the model<br />

specified in Table 1-3. When the majority of a block fell within the interpreted MinZone<br />

wireframe it was assigned the appropriate code. These coded blocks were then imported into<br />

MicroModel ® and used to “back-mark” each composite using a simple majority rule. No capping<br />

was applied. Table 1-3 presents the MinZone codes used in the model. Initial codes of alluvium,<br />

oxide, oxide and chalcocite mix, and sulfide were 10, 20 and 30 respectively. These codes were<br />

altered by the addition of 1 if the assays, composites or blocks fell within a 0.12% Cu grade<br />

envelope predicted by indicator kriging. The codes were also altered by the addition of 100 if the<br />

data was within a modeled dike.<br />

Table 1-3: MinZone Codes and Density<br />

MinZone Code Description Density (cu.ft/ton)<br />

0 Air and previously mined pit<br />

Air (0) and Mined<br />

(12.5)<br />

5, 6, 105, 106 Alluvium 12.5<br />

10, 11, 110, 111 Oxide zone 12.5<br />

20, 21, 120, 121 Chalcocite mix zone 12.5<br />

30, 31, 130, 131 Sulfide zone 12.5<br />

9999 Undefined 12.5<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 6

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

1.5.4 Geostatistical Analysis and Variography<br />

A total of twenty-two (21 directional and a omni-directional) variograms were calculated using<br />

MicroModel® for each MinZone within each area. The program searches along each direction<br />

for data pairs within a 12.5-degree window angle and 5-feet tolerance band. All experimental<br />

variograms are inspected so that spatial continuity along a primary, secondary and tertiary<br />

direction can be modeled.<br />

Each variogram model was then validated using the “jackknifing” method. This method<br />

sequentially removes values and then uses the remaining composites to krige the missing value<br />

using the proposed variogram.<br />

1.5.5 Kriging and Resource Classification<br />

Table 1-4 presents the search and kriging parameters employed in the resource model. The<br />

composite and block codes were used to determine which composites were selected to estimate a<br />

particular block.<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 7

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Table 1-4: Kriging and Search Parameters<br />

Tt used a two-part approach to classify the total copper resources. This approach takes into<br />

account the spatial distribution of the drilling, the distance to the nearest data points used to<br />

estimate a block, and finally the relative kriging error generated by the estimate. Tt has found<br />

this approach to be very robust and provide highly reproducible results. The following points<br />

detail this approach:<br />

1. A measured block requires 16 samples, with a maximum of five samples per sector in a<br />

six sector search pattern and a maximum of 2 composites coming from a single drill hole.<br />

This implies that in most cases, for a block to be classified as measured there must be a<br />

least 8 drill holes in four cardinal directions.<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 8

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

2. The constraints for an indicated block are not as stringent for a measured block. An<br />

indicated block requires a minimum of 6 samples, with a maximum of 4 samples per<br />

sector in a sector search pattern and a maximum number of 2 samples coming from a<br />

single drill hole. This implies that for most cases an indicated block must have at least 3<br />

drill holes in three of the four cardinal directions.<br />

3. Relaxing the constraints even more, a inferred block requires a minimum of 2 samples,<br />

with a minimum of 2 samples per sector in a sector search pattern and a maximum of 2<br />

composites from a single drill hole. This implies that an inferred block must have a least<br />

one drill hole from one of the four cardinal directions.<br />

In addition to the search parameters, kriging error comes into play when determining if a block<br />

falls into a particular class. Tt has found that by plotting the kriging error as a log-probability<br />

plot, there is a natural break in the distribution which signifies when the error is too great to<br />

allow a block to be classified as measured or indicated. In the case of the <strong>MacArthur</strong> deposit,<br />

any block with a kriging error of 0.75 or greater was classified as inferred.<br />

1.5.6 Estimated <strong>Resources</strong><br />

Table 1-5 presents the measured + indicated resources, and Table 1-6 presents the inferred<br />

resources. The base case cutoff grade for the leachable resource is 0.12% Cu (or TCu) while the<br />

base case cutoff grade for the primary sulfide resources is 0.15% Cu. Both of these values are<br />

representative of actual operating cutoff grades in use as of the date of this report. It is Tt’s<br />

opinion that the <strong>MacArthur</strong> Mineral <strong>Resources</strong> meet current CIM definitions for classified<br />

resources.<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 9

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Oxide and Chalcocite<br />

Material<br />

(MinZone 10 and 20)<br />

Primary Material<br />

(MinZone 30)<br />

Table 1-5: Measured + Indicated <strong>Copper</strong> <strong>Resources</strong><br />

MEASURED+INDICATED COPPER RESOURCES<br />

MACARTHUR COPPER PROJECT –YERINGTON, NEVADA<br />

May 2011<br />

Cutoff Grade Tons Average Grade Contained <strong>Copper</strong><br />

%TCu (x1000) %TCu (lbs x 1000)<br />

0.50 3,401 0.720 48,974<br />

0.40 6,730 0.583 78,485<br />

0.35 10,092 0.513 103,544<br />

0.30 16,251 0.441 143,171<br />

0.25 29,859 0.364 217,075<br />

0.20 65,421 0.286 374,601<br />

0.18 89,306 0.260 465,106<br />

0.15 125,659 0.233 585,822<br />

0.12 159,094 0.212 675,513<br />

0.50 98 0.720 1,411<br />

0.40 193 0.586 2,263<br />

0.35 273 0.523 2,857<br />

0.30 354 0.478 3,382<br />

0.25 507 0.416 4,216<br />

0.20 670 0.369 4,938<br />

0.18 796 0.340 5,414<br />

0.15 1,098 0.292 6,408<br />

M3-PN110127<br />

23 May 2012<br />

Revision 0 10

MACARTHUR COPPER PROJECT<br />

FORM 43-101F1 PRELIMINARY ECONOMIC ASSESSMENT<br />

Table 1-6: Inferred <strong>Copper</strong> <strong>Resources</strong><br />

TABLE 1-6: INFERRED COPPER RESOURCES<br />

MACARTHUR COPPER PROJECT –YERINGTON, NEVADA<br />

May 2011<br />

Oxide and Chalcocite<br />

Material<br />

(MinZone 10 and 20)<br />

Primary Material<br />

(MinZone 30)<br />

1.6 METALLURGY<br />

Cutoff<br />

Grade<br />

%TCu<br />

Tons<br />

(x1000)<br />

Average<br />