4" Submersible Pumps

4" Submersible Pumps

4" Submersible Pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

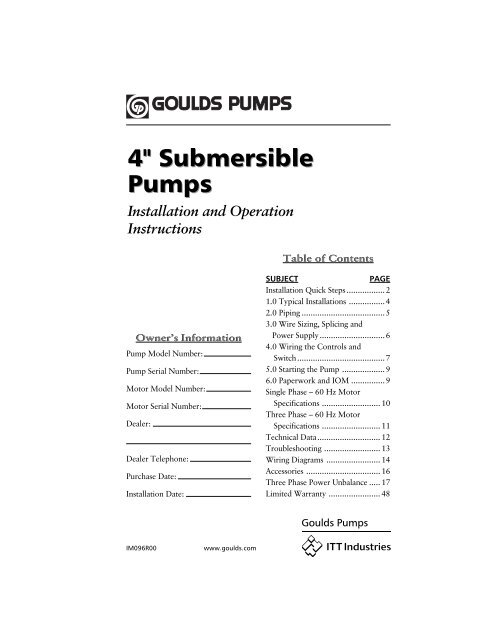

4" <strong>Submersible</strong><br />

<strong>Pumps</strong><br />

Installation and Operation<br />

Instructions<br />

Owner’s Information<br />

Pump Model Number:<br />

Pump Serial Number:<br />

Motor Model Number:<br />

Motor Serial Number:<br />

Dealer:<br />

Dealer Telephone:<br />

Purchase Date:<br />

Installation Date:<br />

IM096R00 www.goulds.com<br />

Table of Contents<br />

SUBJECT PAGE<br />

Installation Quick Steps .................2<br />

1.0 Typical Installations ................4<br />

2.0 Piping .....................................5<br />

3.0 Wire Sizing, Splicing and<br />

Power Supply .............................6<br />

4.0 Wiring the Controls and<br />

Switch .......................................7<br />

5.0 Starting the Pump ...................9<br />

6.0 Paperwork and IOM ...............9<br />

Single Phase – 60 Hz Motor<br />

Specifications .......................... 10<br />

Three Phase – 60 Hz Motor<br />

Specifications .......................... 11<br />

Technical Data............................ 12<br />

Troubleshooting ......................... 13<br />

Wiring Diagrams ........................ 14<br />

Accessories ................................. 16<br />

Three Phase Power Unbalance ..... 17<br />

Limited Warranty ....................... 48

INSTALLATION<br />

INSTALLATION<br />

QUICK QUICK STEPS! STEPS!<br />

1The well should be clean and<br />

disinfected before the<br />

pump is installed. You should<br />

always develop the well before<br />

pump installation.<br />

2Write the pump model<br />

number, pump serial number,<br />

and motor serial number in<br />

the space provided in this<br />

Instruction Manual (IOM).<br />

Leave the completed IOM<br />

attached to the tank or control<br />

box in a dry area or give it to the<br />

owner. We suggest you attach<br />

your business card to promote<br />

referral business.<br />

3<br />

Inspect all components for<br />

shipping damage and insure<br />

that you have all the<br />

components that are required:<br />

Pump with Motor, Motor<br />

Control Box (1∅ / 3-wire) or<br />

Starter w/Overloads (3∅),<br />

Hydro-Pro Tank, Pressure<br />

Switch, Copper Wire, Pressure<br />

Relief Valve (if required),<br />

Torque Arrestor (if required),<br />

Pipe, and Fittings. See 1.0<br />

4Verify that motor voltage and<br />

power supply voltage match.<br />

See 4.2<br />

NOTE: Do not power the unit or<br />

run the pump until all<br />

electrical and plumbing<br />

connections are completed and<br />

the pump is filled with water.<br />

Under no circumstance should<br />

the pump be run dry to test it.<br />

2<br />

Doing so will void the warranty<br />

and damage the impellers! We<br />

suggest you check the rotation on<br />

a three phase motor before<br />

assembling it to the water end<br />

(pump). All 4" motors should<br />

rotate counterclockwise when<br />

viewed from the shaft end. See<br />

4.3 C and 4.4<br />

5Select a well-ventilated,<br />

shaded location in which to<br />

vertically mount the motor<br />

control box. See 4.1<br />

DANGER<br />

Hazardous<br />

voltage<br />

6Connect the pump motor<br />

leads (wires) to the drop<br />

cable using a heat shrink kit<br />

or waterproof electrical tape.<br />

Match the drop cable wire colors<br />

to the pump motor leads or<br />

identify the leads to insure<br />

correct connections at the threewire<br />

motor control box where<br />

used. See 3.1 A&B and 4.3<br />

7If using unthreaded discharge<br />

pipe install a stainless steel<br />

adapter fitting into the pump<br />

discharge head. Consult your<br />

pump supplier for other available<br />

adapter materials. Connect the<br />

discharge pipe to the pump. Do<br />

not use galvanized connections<br />

on stainless steel discharge heads<br />

as galvanic corrosion may occur.<br />

See 2.4<br />

8You can now lower the pump<br />

into the well. Set the pump at<br />

least 10' off the bottom.<br />

Protect the wires from chafing on<br />

the well casing. Never lower the<br />

pump by the wires. See 2.5

CAUTION<br />

Hazardous<br />

Pressure<br />

9Connect the discharge pipe<br />

to the pressure tank and the<br />

house plumbing. Install the<br />

pressure switch at the tank cross<br />

tee. See 2.2<br />

CAUTION<br />

Hazardous<br />

Pressure<br />

what system<br />

pressure you want to<br />

10Decide<br />

use. Adjust the pressure<br />

switch to the desired range.<br />

Typically a 20 pound differential<br />

is used, eg.: 30-50 or 40-60 psi.<br />

Furnas switches have adjustment<br />

instructions on the inside of the<br />

cover.<br />

CAUTION<br />

Hazardous<br />

Pressure<br />

the pressure tank<br />

pre-charge 2 psi lower<br />

11Set<br />

than the pump cut-in<br />

pressure. Check tank pre-charge<br />

only when tank is completely<br />

empty. See 2.3<br />

CAUTION<br />

Hazardous<br />

Pressure<br />

12<br />

Install a pressure relief<br />

valve in any system<br />

capable of over 100 psi<br />

or 230' TDH. Install and set per<br />

relief valve manufacturers<br />

instructions. See 2.2<br />

DANGER<br />

Hazardous<br />

voltage<br />

13<br />

Connect the motor leads<br />

to the control box<br />

(3-wire), pressure<br />

switch (2-wire), or starter on<br />

3 phase systems. See 4.3<br />

DANGER<br />

Hazardous<br />

voltage<br />

DANGER<br />

Hazardous<br />

voltage<br />

14<br />

Connect the leads<br />

between the control<br />

box or starter and the<br />

pressure switch. See 4.3<br />

all piping<br />

connections before<br />

15Check<br />

starting pump.<br />

See 2.0 and 5.0<br />

CAUTION<br />

Hazardous<br />

Pressure<br />

flow between<br />

pump and tank if well<br />

16Restrict<br />

has a high static level or<br />

there is a long discharge pipe<br />

between well and tank. A<br />

partially closed ball or globe<br />

valve works well for throttling.<br />

See 5.1<br />

a faucet in the<br />

discharge piping. This<br />

17Open<br />

will allow air to escape<br />

the system and water to flow<br />

without filling the tank with<br />

dirty water. See 5.3<br />

DANGER<br />

Hazardous<br />

voltage<br />

breaker ON to<br />

power system. Pump<br />

18Turn<br />

should run. Allow water<br />

to flow until well clears. You can<br />

then close the faucet and allow<br />

the tank to fill and pressure to<br />

build. Switch should go ON and<br />

OFF without any chatter. See 5.3<br />

a few cycles to<br />

check pump and switch<br />

19Run<br />

operation. See 5.3<br />

DANGER<br />

Hazardous<br />

voltage<br />

20 Check<br />

amps and insure<br />

they are within<br />

nameplate amp range<br />

from motor data sheet or motor<br />

nameplate. Amps should be<br />

between Rated Input and Service<br />

Factor Amps. Enter the amp<br />

reading in this manual along<br />

with the model number.<br />

See Motor Specifications<br />

3

HYDRO-PRO TANK INSTALLATION<br />

NOTICE: TANK PRE-CHARGE PRESSURE CHANGES MUST BE<br />

MADE USING THE AIR VALVE ON TOP OF THE TANK.<br />

Protected Power Supply<br />

To House Piping<br />

Disconnect Switch<br />

Figure 1<br />

GALVANIZED TANK INSTALLATION<br />

Disconnect Switch<br />

Protected Power Supply<br />

4<br />

1.0 TYPICAL INSTALLATIONS<br />

Control Box Pressure<br />

Gauge To House<br />

Piping<br />

Pitless Adapter<br />

Frost Level<br />

Drain and Y Fitting AV11<br />

Figure 2<br />

Shut-off Valve<br />

Union<br />

Drain Tap<br />

Shut-off Valve<br />

Union<br />

Pressure Relief Valve AV12 _ _ _<br />

Drain Tap<br />

Tank Tee<br />

Pressure Switch AS4FX or AS4<br />

Pressure Relief Valve AV12_ _ _<br />

Air Escape Control AA4<br />

Pressure Switch AS4FX or AS4<br />

Line Check Valve with Snifter AV9<br />

Union<br />

Approximate Drain Fitting Setting<br />

Distance Drain and “Y”<br />

Tank Capacity Fitting Below the Line Check<br />

42 gallon (159 L) 7 feet (2.1m)<br />

82 gallon (310 L) 10 feet (3m)<br />

120 gallon (454 L) 15 feet (4.6m)<br />

220 gallon (833 L) 15 feet (4.6m)<br />

315 gallon (1192 L) 20 feet (6.1m)<br />

525 gallon (1981 L) 20 feet (6.1m)

2.0 PIPING<br />

Notice: All 4" Goulds <strong>Pumps</strong><br />

submersibles have left-hand<br />

discharge head threads, hold the<br />

pump only at the “discharge head”<br />

with a wrench when installing<br />

fittings or threaded pipe.<br />

CAUTION<br />

Hazardous pressure can<br />

cause personal injury or<br />

property damage.<br />

2.1 General<br />

The pump discharge<br />

piping should be sized<br />

for efficient pump<br />

operation. We suggest<br />

using the Friction Loss<br />

Tables to calculate Total Dynamic<br />

Head using different pipe sizes. As<br />

a rule of thumb use 1" for up to<br />

10 gpm, 1 1 ⁄4" for up to 30 gpm, 1 1 ⁄2"<br />

for up to 45 gpm, and 2" for up to<br />

80 gpm. In the case of long pipe<br />

runs it is best to increase pipe size.<br />

Some pumps are capable of very<br />

high discharge pressures, please<br />

select pipe accordingly. Since<br />

Goulds <strong>Pumps</strong> does not sell pipe,<br />

we suggest you consult with your<br />

pipe supplier to determine the best<br />

type of pipe for each installation.<br />

CAUTION<br />

Hazardous pressure can<br />

cause personal injury or<br />

property damage.<br />

2.2Pressure Tank,<br />

Pressure Switch<br />

and Pressure<br />

Relief Valve<br />

Select an area in which<br />

the ambient temperature<br />

is always above 34° F (1° C) in<br />

which to install the tank, pressure<br />

switch, and pressure relief valve.<br />

The tank should be located in an<br />

area where a leak will not damage<br />

property.<br />

The pressure switch should be<br />

located at the tank cross tee and<br />

never more than 4' from the tank.<br />

Locating the switch more than<br />

4' from the tank will cause<br />

switch chatter.<br />

There should be no valves, filters,<br />

or high loss fittings between the<br />

switch and the tank(s) as switch<br />

chatter may result. As an example,<br />

a 1 1 ⁄4" spring check valve has<br />

friction loss equal to 12' of pipe,<br />

placing the valve between the<br />

pressure switch and the pressure<br />

tank is the same as moving the<br />

pressure switch 12' away from the<br />

tank. It will create switch chatter.<br />

On multiple tank installations the<br />

switch should be as close to the<br />

center of the tanks as possible.<br />

Multiple tank installations should<br />

have a manifold pipe at least 1 1 ⁄2<br />

times the size of the supply pipe<br />

from the pump. This is to reduce<br />

the Friction Head in the manifold<br />

and to reduce the possibility of<br />

switch chatter.<br />

The cut-in setting on a 30 - 50<br />

pressure switch is 30 psi. Cut-in is<br />

the lower of the pressure settings.<br />

Pressure relief valves are required<br />

on any system that is capable of<br />

producing 100 psi or 230' TDH. If<br />

in an area where a water leak or<br />

blow-off may damage property<br />

connect a drain line to the pressure<br />

relief valve. Run it to a suitable<br />

drain or an area where the water<br />

will not damage property.<br />

2.3 Adjusting Tank<br />

Pre-Charge<br />

Insure that the tank is empty of<br />

water. Use a high quality pressure<br />

gauge to check the tank pre-charge<br />

pressure. The pressure should be<br />

2 psi below the pump cut-in<br />

pressure. As an example, a<br />

30-50 psi system would use<br />

a tank pre-charge of 28 psi.<br />

5

2.4 Discharge Pipe and<br />

Check Valve<br />

Note: The discharge head is<br />

threaded into the casing with lefthand<br />

threads. Please hold the pump<br />

only at the discharge head with a<br />

pipe wrench when installing<br />

fittings. Failure to hold the<br />

discharge head will loosen it and<br />

pump damage will result on<br />

start-up.<br />

If your pipe requires an adapter we<br />

strongly recommend using stainless<br />

steel. Galvanized fittings or pipe<br />

should never be connected directly<br />

to a stainless steel discharge head as<br />

galvanic corrosion may occur.<br />

Plastic or brass pumps can use any<br />

material for this connection. Barb<br />

type connectors should always be<br />

double clamped.<br />

The pump discharge head has a<br />

loop for attaching a safety cable.<br />

The use of a safety cable is at the<br />

discretion of the installer.<br />

2.5 Installing Pump in Well<br />

If you are using a torque arrestor,<br />

install it per the manufacturer’s<br />

installation instructions. Goulds<br />

<strong>Pumps</strong> does not sell torque<br />

arrestors and has no installation<br />

instructions, please consult the<br />

seller for information.<br />

Connect the discharge pipe to the<br />

discharge head or adapter you<br />

previously installed. Barb style<br />

connectors should always be double<br />

clamped. You can install the pump<br />

into the well using a pitless adapter<br />

or similar device at the wellhead.<br />

Consult the fitting manufacturer or<br />

pitless supplier for specific<br />

installation instructions.<br />

Using waterproof electrical tape<br />

fasten the wires to the drop pipe at<br />

6<br />

10' intervals. Make sure that the<br />

tape does not loosen as it will block<br />

the pump suction if it falls down<br />

the well. Pump suppliers also sell<br />

clip-on style wire connectors that<br />

attach to the drop pipe.<br />

2.6 Special Piping For<br />

Galvanized Tank<br />

Systems<br />

When using a galvanized tank you<br />

should install an AV11 Drain &<br />

Y fitting in the well and an AV9<br />

check valve with snifter valve at the<br />

tank. This will add air to the tank<br />

on each pump start and prevent<br />

water logging the tank. Use an AA4<br />

Air Escape on the tank to allow<br />

excess air to escape. The distance<br />

between the AV11 and AV9<br />

determines the amount of air<br />

introduced on each cycle. See the<br />

table for recommended settings.<br />

See Fig. 2 in Sec 1.0.<br />

Gaseous wells should use<br />

galvanized tanks with AA4 air<br />

escapes to vent off excess air and<br />

prevent “spurting” at the faucets.<br />

Methane and other explosive or<br />

dangerous gases require special<br />

water treatment for safe removal.<br />

Consult a water treatment specialist<br />

to address these issues.<br />

Installations with top feeding wells<br />

should use flow sleeves on the<br />

pump.<br />

DANGER<br />

Hazardous voltage<br />

can shock, burn or<br />

cause death.<br />

3.0 WIRE<br />

SIZING,<br />

SPLICING and<br />

POWER SUPPLY<br />

Always follow the National Electric<br />

Code (N.E.C.), Canadian Electrical<br />

Code, and any state, provincial, or<br />

local codes.

We suggest using only copper wire.<br />

Size wire from the charts found in<br />

your Goulds <strong>Pumps</strong> catalog - Jet &<br />

Sub Accessories - Electrical Section,<br />

in the Franklin Electric AIM<br />

manual, or an N.E.C.( National<br />

Electric Code) code book. If<br />

discrepancies exist the N.E.C. book<br />

takes precedence over a<br />

manufacturer’s recommendations.<br />

3.1 Splicing Wire to<br />

Motor Leads<br />

When the drop cable must be<br />

spliced or connected to the motor<br />

lead it is necessary that the splice be<br />

watertight. The splice can be done<br />

with heat shrink kits or waterproof<br />

tape.<br />

A. Heat Shrink Splice Instructions<br />

To use a typical heat shrink kit:<br />

strip 1 ⁄2" from the motor wires and<br />

drop cable wires, it is best to<br />

stagger the splices. Place the heat<br />

shrink tubes on the wires. Place the<br />

crimps on the wires and crimp the<br />

ends. Slide the heat shrink tubes<br />

over the crimps and heat from the<br />

center outward. The sealant and<br />

adhesive will ooze out the ends<br />

when the tube shrinks. The tube,<br />

crimps, sealant, and adhesive create<br />

a very strong, watertight seal.<br />

B. Taped Splice Instructions<br />

A) Strip individual conductor of<br />

insulation only as far as<br />

necessary to provide room for a<br />

stake type connector. Tubular<br />

connectors of the staked type are<br />

preferred. If connector O.D. is<br />

not as large as cable insulation,<br />

build-up with rubber electrical<br />

tape.<br />

B) Tape individual joints with<br />

rubber electrical tape, using two<br />

layers; the first extending two<br />

inches beyond each end of the<br />

conductor insulation end, the<br />

second layer two inches beyond<br />

the ends of the first layer. Wrap<br />

tightly, eliminating air spaces as<br />

much as possible.<br />

C) Tape over the rubber electrical<br />

tape with #33 Scotch electrical<br />

tape, or equivalent, using two<br />

layers as in step "B" and making<br />

each layer overlap the end of the<br />

preceding layer by at least two<br />

inches.<br />

In the case of a cable with three<br />

conductors encased in a single<br />

outer sheath, tape individual<br />

conductors as described, staggering<br />

joints.<br />

Total thickness of tape should be<br />

no less than the thickness of the<br />

conductor insulation.<br />

DANGER<br />

Hazardous voltage<br />

can shock, burn or<br />

cause death.<br />

4.0 4.0 WIRING WIRING<br />

THE THE<br />

CONTROLS CONTROLS and and<br />

SWITCH SWITCH<br />

4.1 Mounting the Motor<br />

Control Box<br />

Franklin and Goulds <strong>Pumps</strong> single<br />

phase 3-wire control boxes meet<br />

U.L. requirements for Type 3R<br />

enclosures. They are suitable for<br />

vertical mounting in indoor and<br />

outdoor locations. They will<br />

operate at temperatures between<br />

14°F (-10°C) and 122°F (50°C).<br />

Select a shaded, dry place to mount<br />

the box. Insure that there is enough<br />

clearance for the cover to be<br />

removed.<br />

7

4.2 Verify Voltage and Turn<br />

Supply Power Off<br />

Insure that your motor voltage and<br />

power supply voltage are the same.<br />

Place the circuit breaker or<br />

disconnect switch in the OFF<br />

position to prevent accidentally<br />

starting the pump before you are<br />

ready.<br />

Three-phase starter coils are very<br />

voltage sensitive; we suggest you<br />

always verify actual supply voltage<br />

with a voltmeter.<br />

High or low voltage, greater than<br />

± 10%, will damage motors and<br />

controls and is not covered under<br />

warranty.<br />

4.3 Connecting Motor Leads<br />

to Motor Control Box,<br />

Pressure Switch, or<br />

Starter<br />

8<br />

DANGER<br />

Hazardous voltage<br />

can shock, burn or<br />

cause death.<br />

Caution Do not power the<br />

unit or run the pump until<br />

all electrical and plumbing<br />

connections are<br />

completed. Verify that the<br />

disconnect or breaker is<br />

OFF before connecting the pressure<br />

switch line leads to the power<br />

supply. Follow all local and<br />

national codes. Use a disconnect<br />

where required by code.<br />

A. Three-Wire Single Phase Motor<br />

Connect the color coded motor<br />

leads to the motor control box<br />

terminals - Y (yellow), R (red), and<br />

B (black); and the Green or bare<br />

wire to the green ground screw.<br />

Connect wires between the Load<br />

terminals on the pressure switch<br />

and control box terminals L1 and<br />

L2. Run a ground wire between the<br />

switch ground and the control box<br />

ground. See Figure 4 or 5<br />

B. Two-Wire Single Phase Motor<br />

Connect the black motor leads to<br />

the Load terminals on the pressure<br />

switch and the green or bare<br />

ground wire to the green ground<br />

screw. See Figure 3<br />

C. Three phase motors<br />

Connect the motor leads to T1, T2,<br />

and T3 on the 3 phase starter.<br />

Connect the ground wire to the<br />

ground screw in the starter box.<br />

Follow starter manufacturers<br />

instructions for connecting pressure<br />

switch or see Figure 6.<br />

DANGER<br />

Hazardous voltage<br />

can shock, burn or<br />

cause death.<br />

4.4 Connect To<br />

Power Supply<br />

Complete the wiring by<br />

making the connection<br />

from the single phase<br />

pressure switch Line terminals to<br />

the circuit breaker panel or<br />

disconnect where used.<br />

On three phase installations make<br />

the connections between L1, L2,<br />

L3, and ground on the starter to<br />

the disconnect or circuit breaker.<br />

Three phase submersible motors<br />

require Class 10 Quick-Trip<br />

overloads. Our ESP100 starters use<br />

adjustable overloads which you<br />

must adjust during installation.<br />

Goulds <strong>Pumps</strong> sells Furnas starters<br />

which use “K” heaters for Class 10<br />

ambient compensated overload<br />

protection. Use of Class 20<br />

overloads voids the motor<br />

warranty.<br />

Three phase installations must be<br />

checked for motor rotation and<br />

phase unbalance. To reverse motor<br />

rotation switch (reverse) any two

leads. See the instructions for<br />

checking three phase unbalance in<br />

the Technical Section of this<br />

manual. Failure to check phase<br />

unbalance can cause premature<br />

motor failure and nuisance overload<br />

tripping. If using a generator,<br />

see Technical Data for generators.<br />

5.0 STARTING<br />

THE PUMP<br />

CAUTION<br />

Hazardous pressure can<br />

cause personal injury or<br />

property damage.<br />

5.1 Throttling<br />

Discharge On<br />

Start-Up<br />

If the pump will be<br />

operated to clear the well<br />

and/or operate with no pressure or<br />

very little head we strongly suggest<br />

you throttle the discharge. Install a<br />

ball valve in the discharge line.<br />

Open the valve to approximately<br />

1 ⁄3 open on system start-up. After<br />

starting, use the valve to adjust the<br />

flow. This will prevent upthrust<br />

damage to the pump and motor<br />

bearings. It will also keep the pump<br />

running in its recommended<br />

operating range. Starting or running<br />

a pump with little or no head is a<br />

major cause of premature failure.<br />

CAUTION<br />

Hazardous pressure can<br />

cause personal injury or<br />

property damage.<br />

5.2 Throttling A<br />

High Static<br />

Level Well To<br />

Prevent Upthrust<br />

Any well with a high<br />

static water level may allow the<br />

pump to operate off the curve to<br />

the right or outside the<br />

“Recommended Range” shown on<br />

the pump curve. We recommend<br />

using a “Dole” flow restrictor or<br />

throttling with a ball valve to<br />

prevent upthrust damage to the<br />

pump and motor. The maximum<br />

flow must be restricted to be within<br />

the pumps recommended operating<br />

range. If you use a ball valve, set it,<br />

remove the handle, tape the handle<br />

to the pipe, and tag the valve with a<br />

note saying, “Do not open this<br />

valve or pump may be damaged”.<br />

The easiest way to “set” the flow is<br />

to fill a 5 gallon bucket and time<br />

how long it takes to produce 5<br />

gallons. Calculate the flow in gpm<br />

based on this value. As the water<br />

level drops in the well the flow will<br />

be reduced due to increased head<br />

and the valve will not interfere with<br />

performance.<br />

5.3 Start the Pump<br />

Partially open a valve (faucet) in the<br />

system and turn the breaker to the<br />

ON position.<br />

Check all fittings for leaks.<br />

Close the valve when the water<br />

clears and allow the pressure to<br />

build. If properly adjusted the<br />

switch should turn the pump off at<br />

the preset pressure. Open a few<br />

faucets and allow the pump to run<br />

through a few cycles. Check switch<br />

operation and verify that pressure<br />

settings are correct.<br />

Recheck all fittings for leaks.<br />

6.0 PAPERWORK<br />

and IOM<br />

Please give the owner all warranty<br />

and IOM paperwork. It is wise to<br />

include your business card with the<br />

Goulds <strong>Pumps</strong> supplied paperwork.<br />

A sticker with your name and<br />

phone number on the tank or<br />

control box is a great sales tool for<br />

future business!<br />

Congratulations on completing a<br />

professional installation of a Goulds<br />

Pump.<br />

9

SINGLE PHASE – 60 HZ MOTOR SPECIFICATIONS<br />

Type, Goulds Franklin HP, Volts, Amps, S.F<br />

Tipo, # # CV, Voltios, Hz S.F. Amperios, Amps Ohms Std. Delay Control<br />

Type Goulds n<br />

10<br />

o Franklin no hp V FS A A avec FS M=Main S=Start Cir. Br. Fuse Box<br />

S04932 2445040 1<br />

⁄2 115 60 1.60 10.0 12.0 1.0 – 1.3 30 15 N/R, NR<br />

S04942 2445050 1<br />

⁄2 230 60 1.60 5.0 6.0 4.2 – 5.2 15 7 N/R, NR<br />

S05942 2445070 3<br />

⁄4 230 60 1.50 7.2 8.4 3.0 – 3.6 25 10 N/R, NR<br />

S06942 2445081 1 230 60 1.40 8.2 9.8 2.2 – 2.7 25 12 N/R, NR<br />

S07942 2445091 11 ⁄2 230 60 1.30 10.6 13.1 1.5 – 1.9 35 15 N/R, NR<br />

S04930 2145044 1<br />

⁄2 115 60 1.60 Y=10.0 Y=12.0 M = 1.0 – 1.3 30 15 00043<br />

B=10.0 B=12.0 S = 4.1 – 5.1<br />

R=0.0 R=0.0<br />

S04940 2145054 1<br />

⁄2 230 60 1.60 Y=5.0 Y=6.0 M = 4.2 – 5.2 15 7 00044<br />

B=5.0 B=6.0 S = 16.7 – 20.5<br />

R=0.0 R=0.0<br />

S05940 2145074 3<br />

⁄4 230 60 1.50 Y=5.0 Y=6.0 M = 3.0 – 3.6 25 10 00054<br />

B=5.0 B=6.0 S = 11.0 – 13.4<br />

R=0.0 R=0.0<br />

S06940 2145081 1 230 60 1.40 Y=8.2 Y=9.8 M = 2.2 – 2.7 25 12 00064<br />

B=8.2 B=9.8 S = 10.1 – 12.3<br />

R=0.0 R=0.0<br />

S07940 2243001 11 SINGLE PHASE – 60 HZ MOTOR SPECIFICATIONS<br />

1<br />

5 6 7 8<br />

⁄2 230 60 1.30 Y=10.0 Y=11.6 M = 1.5 – 2.3 30 15 00074<br />

B=9.9 B=11.0 S = 6.2 – 12.0<br />

R=1.3 R=1.3<br />

S08940 2243011 2 230 60 1.25 Y=10.0 Y=13.2 M = 1.6 – 2.3 30 15 00084<br />

B=9.9 B=11.9 S = 5.2 – 7.15<br />

R=2.6 R=2.6<br />

S09940 2243027 3 230 60 1.15 Y=14.0 Y=17.0 M = 0.9 – 1.5 45 20 00094<br />

B=12.2 B=14.5 S = 3.0 – 4.9<br />

R=4.7 R=4.5<br />

S10940 2243037 5 230 60 1.15 Y=23.0 Y=27.5 M = 0.68 – 1.0 70 30 00104<br />

B=19.1 B=23.2 S = 2.1 – 2.8<br />

R=8.0 R=7.8<br />

9 M = Main Winding – Black to Yellow, S = Start Winding – Red to Yellow<br />

10 Y = Yellow lead – line amps, B = Black lead – main winding amps, R = Red lead, start or auxiliary winding amps<br />

FS = facteur de surcharge ; NR = non requise.<br />

6. Cortacircuitos estándar<br />

1. ESPECIFICACIONES DE MOTOR DE 60 HZ, MONOFÁSICO 6. Disjoncteur standard<br />

1. CARACTÉRISTIQUES DES MOTEURS MONOPHASÉS, 60 Hz 7. Fusible de retardo<br />

2. 4" de tres alambres con capacitor de funcionamiento<br />

2. 4 po, 3 fils et condensateur de marche<br />

3. 4" de tres alambres<br />

3. 4 po, 3 fils<br />

4. 4" de dos alambres<br />

4. 4 po, 2 fils<br />

5. L1-L2 Resistencia – M=Principal, S=Arranque<br />

5. Voir le renvoi 9. Le 10 est en p. 11.<br />

7. Fusible à action retardée<br />

8. Caja de control<br />

8. Boîte de commande<br />

9. M=Devanado principal – Negro a amarillo;<br />

S=Devanado de arranque – Rojo a Amarillo<br />

9. M = enroulement principal – entre le fil noir et le jaune ;<br />

S = enroulement de démarrage – entre le fil rouge et le jaune.<br />

2 4" 3W 3 4" 2W 4<br />

4" 3W with RunCap

THREE PHASE – 60 HZ MOTOR SPECIFICATIONS<br />

Type, Goulds Franklin HP, Volts, Amps, S.F Locked KVA FURNAS Class 16<br />

Tipo, # # CV Voltios Hz S.F. Amperios, Amps Ohms Rotor Code Std. Delay Starter Htrs.<br />

Type Goulds n<br />

11<br />

o Franklin no hp V FS A A avec FS Amps Cir. Br. Fuse Size<br />

S04978 234501 1 ⁄2 200 60 1.6 2.8 3.4 6.64 – 7.3 17.3 N 10 5 16AD K29<br />

S04970 234511 1 ⁄2 230 60 1.6 2.4 2.9 9.5 – 10.4 15.0 N 8 4 16AG K28<br />

S04975 234521 1 ⁄2 460 60 1.6 1.2 1.5 38.4 – 41.6 7.5 N 4 2 16AH K21<br />

S05978 234502 3 ⁄4 200 60 1.5 3.6 4.4 4.66 – 5.12 24.6 N 12 6 16AD K34<br />

S05970 234512 3 ⁄4 230 60 1.5 3.1 3.8 7.24 – 7.84 21.4 N 11 5 16AG K32<br />

S05975 234522 3 ⁄4 460 60 1.5 1.6 1.9 27.8 – 30.2 10.7 N 5 3 16AH K23<br />

S06978 234503 1 200 60 1.4 4.5 5.4 4.1 – 4.5 31.0 M 15 6 16AD K37<br />

S06970 234513 1 230 60 1.4 3.9 4.7 5.2 – 5.6 27.0 M 12 6 16AG K34<br />

S06975 234523 1 460 60 1.4 2.0 2.4 21.2 – 23.0 13.5 M 6 3 16AH K26<br />

S07978 234504 11 ⁄2 200 60 1.3 5.8 6.8 2.5 – 3.0 38.1 K 20 8 16AD K42<br />

S07970 234514 11 ⁄2 230 60 1.3 5.0 5.9 3.2 – 4.0 33.1 K 15 7 16AG K39<br />

S07975 234524 11 ⁄2 460 60 1.3 2.5 3.1 13.0 – 16.0 16.6 K 8 4 16AH K29<br />

S07979 234534 11 ⁄2 575 60 1.3 2.0 2.4 20.3 – 25.0 13.2 K 6 3 16AE K26<br />

S08978 234305 2 200 60 1.25 7.7 9.3 1.9 – 2.4 53.6 L 25 10 16AD K50<br />

S08970 234315 2 230 60 1.25 6.7 8.1 2.4 – 3.0 46.6 L 20 10 16AG K43<br />

S08975 234325 2 460 60 1.25 3.4 4.1 9.7 – 12.0 23.3 L 15 5 16AH K33<br />

S08979 234335 2 575 60 1.25 2.7 3.2 15.1 – 18.7 18.6 L 15 4 16AE K29<br />

S09978 234306 3 200 60 1.15 10.9 12.5 1.3 – 1.7 71 K 35 15 16AD K55<br />

S09970 234316 3 230 60 1.15 9.5 10.9 1.8 – 2.2 62 K 30 12 16AG K52<br />

S09975 234326 3 460 60 1.15 4.8 5.5 7.0 – 8.7 31 K 15 6 16AH K37<br />

S09979 234336 3 575 60 1.15 3.8 4.4 10.9 – 13.6 25 K 12 5 16AE K34<br />

S10978 234307 5 200 60 1.15 18.3 20.5 .70 – .94 122 K 50 25 16AD K62<br />

S10970 234317 5 230 60 1.15 15.9 17.8 .93 – 1.2 106 K 45 20 16AG K61<br />

S10975 234327 5 460 60 1.15 8.0 8.9 3.6 – 4.4 53 K 25 10 16AH K49<br />

S10979 234337 5 575 60 1.15 6.4 7.1 5.6 – 6.9 43 K 20 8 16AE K42<br />

S119784 234308 71 ⁄2 200 60 1.15 26.5 30.5 .46 – .57 188 K 80 35 16CD K70<br />

S119704 234318 71 ⁄2 230 60 1.15 23.0 26.4 .61 – .75 164 K 70 30 16BG K67<br />

S119754 234328 71 11<br />

13<br />

12<br />

6 7<br />

14 15 16<br />

⁄2 460 60 1.15 11.5 13.2 2.4 – 3.4 82 K 35 15 16AH K55<br />

S129724 234339 10 460 60 1.15 13.6 15.0 2.8 – 3.5 93 K 40 20 16AH K61<br />

10. Y=Conductor amarillo - amperios de línea. B=Conductor<br />

12. Ohmios 13. Rotor frenado amperios<br />

negro - amperios del devanado principal. R=Conductor 12. Ω 13. A avec rotor bloqué<br />

rojo - amperios del devanado de arranque o auxiliar.<br />

10. Y=fil jaune ; B=fil noir – enroulement principal ;<br />

R=fil rouge – enroulement de démarrage ou auxiliaire.<br />

11.ESPECIFICACIONES DE MOTOR DE 60 HZ,<br />

TRIFÁSICO<br />

11.CARACTÉRISTIQUES DES MOTEURS TRIPHASÉS,<br />

60 Hz<br />

14. KVA Código 15. FURNAS Class 16 Arrancador<br />

14. Code kV . THREE PHASE – 60 HZ MOTOR SPECIFICATIONS<br />

A 15. Démarreur Furnas, classe 16<br />

16. FURNAS Class 16 Calentador<br />

16. Dispositif de protection contre la surcharge Furnas,<br />

classe 16<br />

FS = facteur de surcharge<br />

4" 3450 RPM, 4 po, 3 450 r/min

Technical Data<br />

MOTOR INSULATION RESISTANCE READINGS<br />

Normal Ohm/Megohm readings, ALL motors, between all leads and ground<br />

To perform insulation resistance test, open breaker and<br />

CAUTION disconnect all leads from QD control box or pressure switch.<br />

Connect one ohmmeter lead to any motor lead and one to metal drop pipe<br />

or a good ground. R x 100K Scale<br />

Condition of Motor and Leads OHM Value Megohm Value<br />

New motor, without power cable 20,000,000 (or more) 20.0<br />

Used motor, which can be reinstalled in well 10,000,000 (or more) 10.0<br />

Motor in well – Readings are power cable plus motor<br />

New motor 2,000,000 (or more) 2.0<br />

Motor in reasonably good condition<br />

Motor which may be damaged or have<br />

500,000 to 2,000,000 0.5 – 2.0<br />

damaged power cable<br />

Do not pull motor for these reasons<br />

Motor definitely damaged or with<br />

20,000 to 500,000 0.02 – 0.5<br />

damaged power cable<br />

Pull motor and repair<br />

10,000 to 20,000 0.01 – 0.02<br />

Failed motor or power cable<br />

Pull motor and repair<br />

Less than 10,000 0 – 0.01<br />

Generator Operation<br />

• For externally regulated generator kilovolt amperes (KVA) ratings see<br />

Table 1. Electrical voltage, frequency, phase and ampacity, MUST match<br />

that shown on the motor nameplate, or pump control box.<br />

DANGER<br />

Hazardous voltage<br />

can shock, burn or<br />

cause death.<br />

FAILURE TO USE A MANUAL OR AUTOMATIC<br />

TRANSFER SWITCH WHEN GENERATOR IS USED AS<br />

STANDBY OR BACKUP CAN CAUSE SHOCK, BURNS OR<br />

DEATH.<br />

Min.<br />

Generator<br />

Rating 1<br />

⁄3<br />

Pump Motor Horsepower ➀<br />

1 3 1<br />

⁄2 ⁄4 1 1 ⁄2 2 3 5<br />

KVA 1.9 2.5 3.8 5.0 6.3 9.4 12.5 18.8<br />

KW 1.5 2.0 3.0 4.0 5.0 7.5 10.0 15.0<br />

➀ NOTE: For two-wire motors, minimum generator ratings 50% higher<br />

than shown are necessary.<br />

NOTICE: FOLLOW THE GENERATOR MANUFACTURER’S<br />

INSTRUCTIONS CAREFULLY.<br />

Courtesy of Franklin Electric Company<br />

12

Troubleshooting<br />

DANGER<br />

Hazardous voltage<br />

can shock, burn or<br />

cause death.<br />

DISCONNECT AND LOCKOUT ELECTRICAL POWER<br />

BEFORE ATTEMPTING ANY SERVICE. FAILURE TO DO SO<br />

CAN CAUSE SHOCK, BURNS OR DEATH.<br />

Symptom Probable Cause Recommended Action<br />

PUMP MOTOR<br />

NOT RUNNING<br />

LITTLE OR<br />

NO LIQUID<br />

DELIVERED<br />

BY PUMP<br />

1. Motor thermal protector tripped<br />

a. Incorrect control box<br />

b. Incorrect or faulty electrical<br />

connections<br />

c. Faulty thermal protector<br />

d. Low voltage<br />

e. Ambient temperature of control<br />

box/starter too high<br />

f. Pump bound by foreign matter<br />

g. Inadequate submergence<br />

2. Open circuit breaker or blown fuse<br />

3. Power source inadequate for load<br />

4. Power cable insulation damage<br />

5. Faulty power cable splice<br />

1. Faulty or incorrectly installed<br />

check valve<br />

2. Pump air bound<br />

3. Lift too high for pump<br />

4. Pump bound by foreign matter<br />

5. Pump not fully submerged<br />

6. Well contains excessive amounts<br />

of air or gases<br />

7. Excessive pump wear<br />

8. Incorrect motor rotation<br />

– three phase only.<br />

1. Allow motor to cool, thermal<br />

protector will automatically reset<br />

a – e. Have a qualified electrician<br />

inspect and repair, as required<br />

f. Pull pump, clean, adjust set<br />

depth as required<br />

g. Confirm adequate unit<br />

submergence in pumpage<br />

2. Have a qualified electrician inspect<br />

and repair, as required<br />

3. Check supply or generator capacity<br />

4 – 5. Have a qualified electrician<br />

inspect and repair, as required<br />

1. Inspect check valve, repair as<br />

required<br />

2. Successively start and stop pump<br />

until flow is delivered<br />

3. Review unit performance, check<br />

with dealer<br />

4. Pull pump, clean, adjust set depth<br />

as required<br />

5. Check well recovery, lower pump if<br />

possible<br />

6. If successive starts and stops does<br />

not remedy, well contains excessive<br />

air or gases<br />

7. Pull pump and repair as required<br />

8. Reverse any two motor electrical<br />

leads<br />

13

14<br />

(1) Incoming Supply from Fuse Box or<br />

L1 L2<br />

Circuit Breaker<br />

Disconnect<br />

Switch<br />

Line<br />

Load<br />

Load<br />

Line<br />

Pressure<br />

Switch<br />

(5)<br />

NOTE: Pumptec or<br />

Motor Minder (6)<br />

(1) Incoming Supply from Fuse Box or Circuit Breaker<br />

L1 L2<br />

L1 L2<br />

R Y Blk<br />

Red<br />

Yellow<br />

Black<br />

(8)<br />

9) (10)<br />

(3)<br />

Disconnect<br />

Switch<br />

(2)<br />

Two Wire – Direct Connected to<br />

Pressure Switch<br />

Bifilar – conectado directamente al<br />

interruptor por caída de presión<br />

Moteur à deux fils – connecté<br />

directement au pressostat<br />

(3)<br />

Figure (Figura) 3<br />

(2)<br />

(4)<br />

(4)<br />

Line<br />

Load<br />

Load<br />

Line<br />

Pressure<br />

Switch (5)<br />

NOTE: Pumptec or<br />

Motor Minder (6)<br />

Three Wire<br />

Control Box (7)<br />

Three Wire – Direct Connected to<br />

Pressure Switch<br />

Trifilar – conectado directamente al<br />

interruptor por caída de presión<br />

Moteur à trois fils – connecté<br />

directement au prossostat<br />

Figure (Figura) 4<br />

1. Suministro de entrada de la caja de fusibles o<br />

del cortacircuitos<br />

2. Interruptor de desconexión<br />

3. Línea<br />

4. Carga<br />

5. Interruptor por caída de presión<br />

6. NOTA: Pumptec o Motor Minder<br />

7. Caja de control trifilar<br />

8. Rojo<br />

9. Amarillo<br />

10. Negro<br />

1. Courant d’entrée provenant de la boîte à fusibles<br />

ou du disjoncteur<br />

2. Sectionneur<br />

3. Ligne<br />

4. Charge<br />

5. Pressostat<br />

6. Protection Pumptec ou Motor Minder<br />

7. Boîte de commande à trois fils<br />

8. Rouge<br />

9. Jaune<br />

10. Noir

(1) Incoming Supply from Fuse Box or<br />

Circuit Breaker<br />

L1 L2<br />

L1 L2<br />

T1 T2<br />

L1 L2<br />

R Y Blk<br />

Red<br />

Yellow<br />

Black<br />

Disconnect<br />

Switch (2)<br />

(3)<br />

Three Wire<br />

Control Box<br />

Magnetic<br />

Contactor<br />

(6)<br />

Line<br />

Load<br />

Load<br />

Line<br />

(1) Incoming Supply from Fuse Box or<br />

Circuit Breaker<br />

(4)<br />

(3)<br />

3<br />

L1 L2 L3<br />

T1 T2 T3<br />

Disconnect<br />

Switch (2)<br />

(11)<br />

Heaters<br />

(7)<br />

(4)<br />

(8)<br />

(9) (10)<br />

Three Wire – Connected through<br />

Magnetic Contactor<br />

Trifilar – conectado a través del<br />

contactador magnético<br />

Moteur à trois fils – relié au pressostat<br />

par un contacteur magnétique<br />

Figure (Figura) 5<br />

Line<br />

Load<br />

Load<br />

Line<br />

Pressure Switch<br />

(5)<br />

Ambient Compensated<br />

Magnetic Starter with<br />

Quick-Trip Heaters (12)<br />

Three Phase Connections<br />

Tres conexiones de fase<br />

Circuit triphasé<br />

Figure (Figura) 6<br />

Pressure<br />

Switch<br />

(5)<br />

1. Suministro de entrada de la caja de<br />

fusibles o del cortacircuitos<br />

2. Interruptor de desconexión<br />

3. Línea<br />

4. Carga<br />

5. Interruptor por caída de presión<br />

6. Contactador magnético<br />

7. Caja de control trifilar<br />

8. Rojo<br />

9. Amarillo<br />

10. Negro<br />

11. Calentadores<br />

12. Arrancador magnético con compensación<br />

ambiental con calentadores de disparo<br />

rápido<br />

1. Courant d’entrée provenant de la boîte à<br />

fusibles ou du disjoncteur<br />

2. Sectionneur<br />

3. Ligne<br />

4. Charge<br />

5. Pressostat<br />

6. Contacteur magnétique<br />

7. Boîte de commande à trois fils<br />

8. Rouge<br />

9. Jaune<br />

10. Noir<br />

11. Dispositifs de protection contre la<br />

surcharge (DPS)<br />

12. Démarreur magnétique compensé<br />

(température ambiante) avec DPS à<br />

déclenchement rapide<br />

15

PUMPTEC<br />

WIRING<br />

16<br />

PRESSURE<br />

SWITCH<br />

GND<br />

L1<br />

L2<br />

PRESSURE<br />

SWITCH<br />

GND<br />

L1<br />

L2<br />

GND<br />

GND<br />

230 Volt Installation<br />

230 115 L2 SIGNAL<br />

(1 A MAX)<br />

115 Volt Installation<br />

230 115 L2 SIGNAL<br />

(1 A MAX)<br />

ACCESSORIES<br />

ACCESSORIES<br />

MOTOR<br />

MOTOR<br />

GND<br />

TO<br />

2 WIRE<br />

MOTOR<br />

OR 3 WIRE<br />

CONTROL<br />

BOX<br />

GND<br />

TO<br />

2 WIRE<br />

MOTOR<br />

OR 3 WIRE<br />

CONTROL<br />

BOX<br />

Hydro-Pro Tanks<br />

Tanks should be sized to allow<br />

pumps between 1 ⁄2 and 1 1 ⁄2 hp to run<br />

for at least 1 minute. Two (2) hp<br />

and larger pumps should run at<br />

least 2 minutes. If the pump<br />

averages 10 gpm and you run it for<br />

1 minute you need a 10 gallon<br />

“drawdown” tank. See your Goulds<br />

<strong>Pumps</strong> Products catalog for Hydro-<br />

Pro Tank data.<br />

Low Water Protection<br />

Goulds <strong>Pumps</strong> offers Franklin<br />

Electric Pumptec, Pumptec Plus,<br />

QD Pumptec for single phase, and<br />

Subtrol for 3 ∅ low water<br />

protection. We also sell Integra<br />

Motor Check and Motor Minders<br />

which are available for single and<br />

three phase low water protection.<br />

See the Jet & <strong>Submersible</strong><br />

MOTOR MINDER<br />

WIRING<br />

DISCONNECT<br />

SWITCH<br />

L1 L2<br />

GROUND 230VAC<br />

MOTOR MINDER<br />

1 2 3 4 5 6<br />

M1 M2<br />

PRESSURE SWITCH<br />

OR FLOAT SWITCH<br />

(IF USED)<br />

MOTOR<br />

CONTROL<br />

(IF USED)<br />

GREEN<br />

MOTOR<br />

Accessories -Electrical Section in<br />

your catalog or contact your pump<br />

supplier for information.<br />

Electrical Panels<br />

Goulds <strong>Pumps</strong> will build custom<br />

pump control panels. We will build<br />

custom panels only with written<br />

specifications. Please send written<br />

specifications to your authorized<br />

distributor. They will forward it to<br />

the Goulds <strong>Pumps</strong> Customer<br />

Service Group that supports their<br />

product line. Specifications should<br />

include pump HP, voltage, phase,<br />

Nema enclosure type, sequence of<br />

operation, special options needed,<br />

and a brief statement describing any<br />

special logic for alarms, timers, or<br />

duplexing features. The name and<br />

number of a contact person to<br />

answer questions is also appreciated<br />

and will speed the quote.

THREE PHASE POWER UNBALANCE<br />

A full three phase supply consisting<br />

of three individual transformers or<br />

one three phase transformer is<br />

recommended. “Open” delta or wye<br />

connections using only two transformers<br />

can be used, but are more<br />

likely to cause poor performance,<br />

overload tripping or early motor<br />

failure due to current unbalance.<br />

Check the current in each of the<br />

three motor leads and calculate the<br />

current unbalance as explained<br />

below.<br />

If the current unbalance is 2% or<br />

less, leave the leads as connected.<br />

If the current unbalance is more than<br />

2%, current readings should be<br />

checked on each leg using each of<br />

the three possible hook-ups. Roll the<br />

motor leads across the starter in the<br />

same direction to prevent motor<br />

reversal.<br />

To calculate percent of current<br />

unbalance:<br />

A. Add the three line amp values<br />

together.<br />

B. Divide the sum by three,<br />

yielding average current.<br />

C. Pick the amp value which is<br />

furthest from the average<br />

current (either high or low).<br />

D. Determine the difference<br />

between this amp value (furthest<br />

from average) and the average.<br />

E. Divide the difference by the<br />

average.<br />

Multiply the result by 100 to<br />

determine percent of<br />

unbalance.<br />

Current unbalance should not<br />

exceed 5% at service factor load or<br />

10% at rated input load. If the<br />

unbalance cannot be corrected by<br />

rolling leads, the source of the<br />

unbalance must be located and<br />

corrected. If, on the three possible<br />

hookups, the leg farthest from the<br />

average stays on the same power<br />

lead, most of the unbalance is<br />

coming from the power source.<br />

Contact your local power company<br />

to resolve the imbalance.<br />

Hookup 1 Hookup 2 Hookup 3<br />

Starter Terminals L1 L2 L3 L1 L2 L3 L1 L2 L3<br />

Motor Leads R B Y Y R B B Y R<br />

Example:<br />

T3 T1 T2 T2 T3 T1 T1 T2 T3<br />

T3-R = 51 amps T2-Y = 50 amps T1-B = 50 amps<br />

T1-B = 46 amps T3-R = 48 amps T2-Y = 49 amps<br />

T2-Y = 53 amps T1-B = 52 amps T3-R = 51 amps<br />

Total = 150 amps Total = 150 amps Total = 150 amps<br />

÷ 3 = 50 amps ÷ 3 = 50 amps ÷ 3 = 50 amps<br />

— 46 = 4 amps — 48 = 2 amps — 49 = 1 amps<br />

4 ÷ 50 = .08 or 8% 2 ÷ 50 = .04 or 4% 1 ÷ 50 = .02 or 2%<br />

17