1 Annex AGRI - 2 Enhanced Domestic Food Production Sector ...

1 Annex AGRI - 2 Enhanced Domestic Food Production Sector ...

1 Annex AGRI - 2 Enhanced Domestic Food Production Sector ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

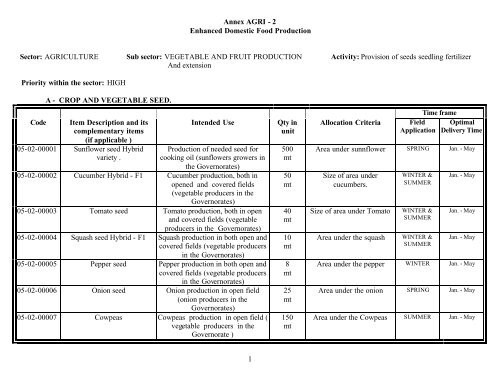

<strong>Annex</strong> <strong>AGRI</strong> - 2<br />

<strong>Enhanced</strong> <strong>Domestic</strong> <strong>Food</strong> <strong>Production</strong><br />

<strong>Sector</strong>: <strong>AGRI</strong>CULTURE Sub sector: VEGETABLE AND FRUIT PRODUCTION<br />

And extension<br />

Priority within the sector: HIGH<br />

A - CROP AND VEGETABLE SEED.<br />

Code Item Description and its<br />

complementary items<br />

(if applicable )<br />

05-02-00001 Sunflower seed Hybrid<br />

variety .<br />

Intended Use Qty in<br />

unit<br />

<strong>Production</strong> of needed seed for<br />

cooking oil (sunflowers growers in<br />

the Governorates)<br />

05-02-00002 Cucumber Hybrid - F1 Cucumber production, both in<br />

opened and covered fields<br />

(vegetable producers in the<br />

Governorates)<br />

05-02-00003 Tomato seed Tomato production, both in open<br />

and covered fields (vegetable<br />

producers in the Governorates)<br />

05-02-00004 Squash seed Hybrid - F1 Squash production in both open and<br />

covered fields (vegetable producers<br />

in the Governorates)<br />

05-02-00005 Pepper seed Pepper production in both open and<br />

covered fields (vegetable producers<br />

in the Governorates)<br />

05-02-00006 Onion seed Onion production in open field<br />

(onion producers in the<br />

Governorates)<br />

05-02-00007 Cowpeas Cowpeas production in open field (<br />

vegetable producers in the<br />

Governorate )<br />

1<br />

500<br />

mt<br />

50<br />

mt<br />

40<br />

mt<br />

10<br />

mt<br />

8<br />

mt<br />

25<br />

mt<br />

150<br />

mt<br />

Activity: Provision of seeds seedling fertilizer<br />

Allocation Criteria Field<br />

Application<br />

Time frame<br />

Optimal<br />

Delivery Time<br />

Area under sunnflower SPRING Jan. - May<br />

Size of area under<br />

cucumbers.<br />

Size of area under Tomato<br />

Area under the squash<br />

WINTER &<br />

SUMMER<br />

WINTER &<br />

SUMMER<br />

WINTER &<br />

SUMMER<br />

Jan. - May<br />

Jan. - May<br />

Jan. - May<br />

Area under the pepper WINTER Jan. - May<br />

Area under the onion SPRING Jan. - May<br />

Area under the Cowpeas SUMMER Jan. - May

05-02-<br />

00008<br />

05-02-<br />

00009<br />

05-02-<br />

00010<br />

05-02-<br />

00011<br />

05-02-<br />

00012<br />

05-02-<br />

00013<br />

05-02-<br />

00014<br />

05-02-<br />

00015<br />

Bean Bean production in open field<br />

( vegetable producers in the<br />

Governorate )<br />

Eggplant Eggplant production in open field<br />

( vegetable producers in the<br />

Brodbean<br />

Governorate )<br />

Brodbean production in open field<br />

( vegetable producers in the<br />

Governorate )<br />

Water Melon Water melon production in the<br />

open field (water melon producers<br />

Different Hybrid Seed for<br />

green Houses<br />

Soybean<br />

Replaced by<br />

potato seed<br />

Rape<br />

* amended 17 August 2000<br />

in the Governorates)<br />

covered vegetable field and green<br />

houses (vegetable producers in the<br />

Governorates)<br />

<strong>Production</strong> of needed seed for<br />

cooking oil (sunflowers growers in<br />

the Governorates)<br />

Safflower <strong>Production</strong> of needed seed for<br />

cooking oil (sunflowers growers in<br />

the Governorates)<br />

<strong>Production</strong> of potato seed type A<br />

and A+ for winter and spring<br />

season .<br />

2<br />

150<br />

mt<br />

10<br />

mt<br />

50<br />

mt<br />

37 *<br />

mt<br />

150<br />

kg<br />

200<br />

mt<br />

200<br />

mt<br />

700<br />

Ton<br />

Area under the Bean<br />

SPRING<br />

SUMMER<br />

Jan. - May<br />

Area under the Eggplant SUMMER Jan. - May<br />

Area under the Brodbean WINTER Jan. - May<br />

Area under the water<br />

melon<br />

SUMMER Jan. - May<br />

Area under the crop WINTER Jan. - May<br />

Area under the crop WINTER Jan. - May<br />

Area under the crop WINTER Jan. - May<br />

Seeds will be multiplicated<br />

in specialised nursery , the<br />

produced A and A+<br />

varaiety will be distributed<br />

to the potato growers<br />

all year<br />

round .<br />

Aug.

B – FRUIT SEED AND SEEDLINGS :<br />

Code Item Description and its<br />

complementary items<br />

(if applicable )<br />

05-02-00016 Malus Communis Seed Stock production for production of<br />

seedling to be distributed to the<br />

farmers (orchards owners in the<br />

Intended Use Qty in unit Allocation Criteria Field<br />

application<br />

Governorates growing the crop)<br />

05-02-00017 Pyrus Communis Seed Stock production for production of<br />

seedling to be distributed to the<br />

farmers (orchards owners in the<br />

Governorates growing the crop)<br />

05-02-00018 Prunus Cerasifera Seed following seeding, production of<br />

stocks in specialized nurseries then<br />

seedling distribution to the farmers<br />

(orchards owners in the<br />

Governorates favorable for this<br />

type)<br />

05-02-00019 Mauls Communes Seedling Stock production for production of<br />

seedling to be distributed to the<br />

farmers (orchards owners in the<br />

Governorates growing the fruit)<br />

05-02-00020 Pyres communes seedling Stock production for production of<br />

seedling to be distributed to the<br />

farmers (orchards owners in the<br />

Governorates favorable for this<br />

type)<br />

05-02-00021 Pyres communes seedling Stock production for production of<br />

seedling to be distributed to the<br />

farmers (orchards owners in the<br />

Governorates favorable for this<br />

type)<br />

3<br />

50<br />

kg<br />

50<br />

kg<br />

50<br />

kg<br />

100000<br />

seeding<br />

100000<br />

seeding<br />

100000<br />

seeding<br />

Seed will be multiplicated<br />

in specialized nurseries, the<br />

seedling will be distributed<br />

to farmers<br />

Seed will be multiplicated<br />

in specialized nurseries, the<br />

seedling will be distributed<br />

to farmers<br />

Seedling will be distributed<br />

to farmer on request, size<br />

of planted areaunder the<br />

fruit.<br />

Seedling will be distributed<br />

to farmer on request area.<br />

Seedling will be distributed<br />

to farmer on request area.<br />

Seedling will be distributed<br />

to farmer on request area/<br />

and size of area under the<br />

crop.<br />

DECEMBER -<br />

JANUARY<br />

DECEMBER -<br />

JANUARY<br />

DECEMBER -<br />

JANUARY<br />

DECEMBER -<br />

JANUARY<br />

DECEMBER -<br />

JANUARY<br />

DECEMBER -<br />

JANUARY<br />

Time frame<br />

Optimal<br />

Delivery Time<br />

Jan. – Feb.<br />

Jan. – Feb.<br />

Jan. – Feb.<br />

Jan. – Feb.<br />

Jan. – Feb.<br />

Jan. – Feb.

Code Item Description and its<br />

complementary items<br />

(if applicable )<br />

05-02-00022 Olive rooted-stem cutting To install olive orchid project and<br />

serving olive producers<br />

05-02-00023 Routing hormones powder To be used by farmer and growers<br />

of orchids<br />

05-02-00024 Pruning saw To be used by the state board of<br />

orchids and growers in the 15<br />

governorates in pruning activities<br />

05-02-00025 Mulching polyathelene To be used by the state board of<br />

orchids and growers in the<br />

05-02-00026 Black plastic sac<br />

30 X 30 CM<br />

15 X 30 CM<br />

seedling tray<br />

05-02-00027 Netting shade<br />

Sheding 50%<br />

Sheding 75%<br />

05-02-00028 Chessel<br />

65 Cm<br />

70 Cm<br />

05-02-00029 Green houses structure<br />

500 M 2 with accessories<br />

180 M 2 with accessories<br />

Intended Use Qty in unit Allocation Criteria Field<br />

application<br />

nurseries<br />

=<br />

=<br />

To be used in land preparation in<br />

the state company of orchids and<br />

growers<br />

To be used by farmers in winter<br />

protected vegetable production and<br />

also for orchid nurseries<br />

4<br />

4000000<br />

50 X1 KG<br />

100 X ½<br />

KG<br />

500 X 100<br />

Gm<br />

Routed stem will be<br />

distributed to farmer on<br />

request area and size of<br />

area under the crop<br />

The hormone will be<br />

distributed by the state<br />

company of orchids to the<br />

growers in the<br />

governorates<br />

500 The saws will be<br />

distributed to the company<br />

orchids and growers in the<br />

15 governorates<br />

15 MT It will be distributed to the<br />

company and the growers<br />

in the 15 governorates<br />

10 MT<br />

10 MT<br />

500000 Pcs<br />

250000 M 2<br />

250000 M 2<br />

50<br />

50<br />

200 houses<br />

200 houses<br />

Optimal<br />

Delivery Time<br />

All year round January – may<br />

All year round January – may<br />

All year round January – may<br />

All year round January – may<br />

= = =<br />

= = =<br />

= = =<br />

Horticulture and forestry<br />

company , potato seed<br />

producers , vegetable<br />

growers in the 15<br />

governorates<br />

= =

C - FERTILIZERS<br />

Code Item Description and its<br />

complementary items<br />

(if applicable )<br />

Intended Use Qty in<br />

unit<br />

05-02-00030 Di ammonium phosphate Will be spread in different fields<br />

crops (farmers)<br />

05-02-00031 Potassium sulphate Will be spread in vegetable fields<br />

both opened and covered (farmers)<br />

05-02-00032 Magnesium Sulphate Will be used in vegetable fields<br />

(farmers)<br />

50–02-00033 Ferrous Sulfate Will be spread in vegetable fields<br />

FeSo4 (Min 19-20 %) both opened and covered (farmers)<br />

05-02-00034 Zinc Sulfate Will be spread in vegetable fields<br />

ZnSO4 ( 35%) both opened and covered (farmers)<br />

05-02-00035 Micro Neturen fouler Will be spread in vegetable fields<br />

fertiliser<br />

both opened and covered (farmers)<br />

05-02-00036 Cupper sulphate Will be spread in vegetable fields<br />

CuSO4H2o (35 % Cu ) both opened and covered (farmers)<br />

05-02-00037 Manganese sulphate Will be spread in vegetable fields<br />

MnSO4 3H2O ( 28 % Mn ) both opened and covered (farmers)<br />

05-02-00038 ( TSP )<br />

Will be spread in vegetable fields<br />

Citrate and water solubility<br />

46 % P2O5 .<br />

P2O5 soluble in water not<br />

less than 30 %<br />

Humidity 1.7 Max.<br />

both opened and covered (farmers)<br />

5<br />

40000<br />

mt<br />

5000<br />

mt<br />

100<br />

mt<br />

20<br />

mt<br />

20<br />

mt<br />

50<br />

mt<br />

10<br />

mt<br />

25<br />

mt<br />

10000<br />

mt<br />

Allocation Criteria Field<br />

Application<br />

State of soil fertility/size<br />

of cultivated area.<br />

State of soil fertility/size<br />

of cultivated area<br />

State of soil fertility/size<br />

of cultivated area<br />

State of soil fertility/size<br />

of cultivated area<br />

State of soil fertility/size<br />

of cultivated area<br />

State of soil fertility/size<br />

of cultivated area<br />

State of soil fertility/size<br />

of cultivated area<br />

State of soil fertility/size<br />

of cultivated area<br />

State of soil fertility/size<br />

of cultivated area<br />

ALL YEAR<br />

ROUND<br />

ALL YEAR<br />

ROUND<br />

ALL YEAR<br />

ROUND<br />

ALL YEAR<br />

ROUND<br />

Time frame<br />

Optimal<br />

Delivery<br />

Time<br />

January – may<br />

January – may<br />

January – may<br />

January – may<br />

All year round January – may<br />

All year round January – may<br />

All year round January – may<br />

All year round January – may<br />

All year round January – may

D - The installation of new banana nursery for seedling production and extension :<br />

05-02-00039 Complete green house For ( 5 ) ha To install pilot project<br />

for banana plantation (<br />

nursery )<br />

05-02-00040 Drip irrigation unit For ( 5 ) ha To install pilot project<br />

for banana plantation (<br />

05-02-00041 Heating and cooling<br />

system<br />

05-02-00042 Fibre glass for green<br />

house<br />

nursery )<br />

For ( 5 ) ha To install pilot project<br />

for banana plantation (<br />

nursery )<br />

For ( 5 ) ha To install pilot project<br />

for banana plantation (<br />

nursery )<br />

05-02-00043 Shading net For ( 5 ) ha To install pilot project<br />

for banana plantation (<br />

05-02-00044 Tractor 33 HP with<br />

accessories<br />

nursery )<br />

2 To install pilot project<br />

for banana plantation (<br />

nursery )<br />

05-02-00045 80 KVA generators 1 To install pilot project<br />

for banana plantation (<br />

05-02-00046 4 cylinder 2000 cc field<br />

car<br />

nursery )<br />

2 To install pilfor banana<br />

plantation ( nursery )<br />

05-02-00047 Mini bus 2 To install pilot project<br />

for banana plantation (<br />

nursery )<br />

05-02-00048 Banana seedling 12000 To install pilot project<br />

for banana plantation (<br />

nursery )<br />

05-02-00049 Foliar fertiliser 5<br />

mt<br />

To install pilot project<br />

for banana plantation (<br />

nursery )<br />

6<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May<br />

Jan. – May

05-02-00050 Growth regulators As required<br />

To install pilot project<br />

for banana plantation (<br />

nursery )<br />

7<br />

Articulator and forestry<br />

company and banana<br />

plantation owners<br />

The farm will be established in<br />

the central part of the country to<br />

serve banana producer<br />

Jan. – May

E : Rehabilitation of the main and district extension centers<br />

Item Description Qty<br />

05-02-<br />

00051<br />

05-02-<br />

00052<br />

05-02-<br />

00053<br />

05-02-<br />

00054<br />

05-02-<br />

00055<br />

05-02-<br />

00056<br />

05-02-<br />

00057<br />

05-02-<br />

00058<br />

05-02-<br />

00059<br />

Digital Betacam SP camera complete<br />

(DXC-D30P) with portable video<br />

cassette recorder (PVV-3P).<br />

Includes : 1.5” viewfinder ; tripod<br />

adapter; rain cover; extender board and<br />

operation / maintenance manual .<br />

Intended use Allocation<br />

criteria<br />

2 To support the<br />

activity of the<br />

state board of<br />

extension<br />

services in the<br />

different<br />

extension centers<br />

located in the<br />

following<br />

governorates<br />

8<br />

According<br />

to the<br />

requirement<br />

s of<br />

extension<br />

centers in<br />

baghdad ,<br />

Nenava ,<br />

Tameem ,<br />

Wasit ,<br />

Basrah<br />

Field<br />

application<br />

Optimal delivery<br />

time<br />

All year round From February to<br />

May<br />

AC Adapter. (AC550CE) 4 = = = =<br />

Battery Charger for (NI-CD) batteries<br />

(BC-1WDCE).<br />

4 = = = =<br />

Video Cassette recorder Betacam SP<br />

(PVW-2800P) .<br />

2 = = = =<br />

Video Cassette player Betacam SP<br />

(PVW-2650P) for editing .<br />

2 = = = =<br />

Remote Control Editor (RM- 1 = = = =<br />

450CE),editing control unit .<br />

Color Monitor with quad decoder and<br />

standard resolution in line slot mask<br />

CRT. Digital. (CVS-37-PS) 14” .<br />

4 = = = =<br />

(NI-CD) Batteries (NP1A). 30 = = = =<br />

Metal type cassettes SP with 20 minute<br />

;<br />

30 minute ; 60 minute<br />

150 = = = =

Item Description Qty<br />

05-02-<br />

00060<br />

05-02-<br />

00061<br />

05-02-<br />

00062<br />

05-02-<br />

00063<br />

05-02-<br />

00064<br />

05-02-<br />

00065<br />

05-02-<br />

00066<br />

05-02-<br />

00067<br />

05-02-<br />

00068<br />

05-02-<br />

00069<br />

05-02-<br />

00070<br />

05-02-<br />

00071<br />

05-02-<br />

00072<br />

05-02-<br />

00073<br />

05-02-<br />

00074<br />

05-02-<br />

00075<br />

Intended use Allocation<br />

criteria<br />

9<br />

Field<br />

application<br />

Optimal delivery<br />

time<br />

Cables for connections to the editing Rou = = = =<br />

system<br />

nd<br />

Dynamic microphone (NEKMIC). 4 = = = =<br />

Video Cassette recorder V.H.S (multisystem)<br />

.<br />

5 = = = =<br />

Television ( multi-system) with remote<br />

control .<br />

10 = = = =<br />

Photograph Camer motors , auto focus .<br />

(recently) .<br />

3 = = = =<br />

Portable Loudspeakers operate with<br />

batteries .<br />

5 = = = =<br />

Portable Audio Recorder . 2 = = = =<br />

Computer with all the accessories.<br />

(recently) .<br />

2 = = = =<br />

Laser Printer for teaching . 10 = = = =<br />

Spare parts for all the Audio and Video Rou = = = =<br />

Equipments .<br />

nd<br />

Slide projector with the screens . 5 = = = =<br />

Overhead projector with the screens . 5 = = = =<br />

Editing Unit for Radio Programm 1 = = = =<br />

Data Show 1 = = = =<br />

Overhead Transparencies 10 = = = =<br />

Field Vehicle 10 = = = =

Item Description Qty<br />

05-02-<br />

00076<br />

05-02-<br />

00077<br />

05-02-<br />

00078<br />

05-02-<br />

00079<br />

05-02-<br />

00080<br />

05-02-<br />

00081<br />

05-02-<br />

00082<br />

05-02-<br />

00083<br />

Intended use Allocation<br />

criteria<br />

10<br />

Field<br />

application<br />

Optimal delivery<br />

time<br />

Field Vehicle for video show 2 = = = =<br />

Video Unit 40” 2 = = = =<br />

Field Soil Analysis Unit 5 = = = =<br />

Portable<br />

humidity.<br />

Units to measure grain 5 = = = =<br />

Tractor 2 = = = =<br />

Tractor mounted sprayer 400 litters . 2 = = = =<br />

Color Photo Copying machine with a<br />

computer<br />

1 = = = =<br />

Electric Generator 150 K.V. 2 = = = =

F : Rehabilitation of Phosphate and Nitrogen Fertilizer Plants :<br />

Rehabilitation of phosphate fertilizer plant :<br />

CODE ITEM DESCRIPTION AND ITS COMPLEMEENTRAY INTENDED USE QTY. ALLOCA - TIME FRAME<br />

05-02-00084<br />

ITEMS (IF APPLICABLE) (AND TARGETED IN TION FILED OPTIMAL<br />

THESE MODELS SHOULD BE DESIGNED TO ALLOW US<br />

CONTINUOSLY LEVEL<br />

MEASURMENT INDICATE THE ACTUAL LEVEL AND PROVIDE<br />

AN ANALOG INDICATION<br />

ASWELL AS OPERATION OF SWITCHING CONTACT AT<br />

PREDTERMINED LEVEL.<br />

THE ((CHEMICAL+THERMAL+ABRASION)) ENVIROMENT OF<br />

THE AREA IN WHICH THE<br />

INSTRUMENT IS USED SHOULD BE TAKEN IN TO ACCOUNT<br />

AND ALSO SIGIFICANT<br />

11<br />

END USER) UNIT CRITERIA APPLICA- DELIVERY<br />

TO REHABILIATE 1 TO<br />

UTILITY PLANT<br />

TO BE USED AS RAW<br />

MATERIAL FOR<br />

PRODUCING<br />

INCREAS<br />

E<br />

CAPACIT<br />

Y<br />

OF<br />

PHOSPHATE FERTILIZER UTILITY<br />

CHANGES CAUSED BY(MOSTURE + CONDENSIT + FUME)) PLANT<br />

WITH FORM AND LIQUID MOVEMENT CAUSED BY THE<br />

AGITATORS.FOR THE<br />

RESION ABOVE<br />

WE PREFER ((NON CONTACT INSTRUMENTS WITH LIQUID<br />

PLEASE FOR MORE INFORMATION SEE BELOW<br />

MEASURING RANG :- 1-12 M ETER FOR INDICATION 5%-100%<br />

CURRENT OUT PUT 4-20MA<br />

POWER SUPPLY 24 VDC<br />

TEMP.OF THE LIQUID 90C DEG. ABOVE<br />

LIQUID :- PHOSPHORIC ACID + ROCKPHOSPHET<br />

PRESSURE :- OPEN TANK<br />

TION<br />

All Year<br />

Round<br />

AS SOON<br />

AS<br />

POSSIBLE

PROTECTION IP66<br />

AMBIENT TEMP.0C DEG.-60C DEG.<br />

ACCURACY :- 1% OR 2CM (TYPICAL)<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00085 HANSSON GEAR BOX FOR BENIFICIATION UNIT BENIFICIATION PLANT<br />

INCREAS<br />

E<br />

ROUND AS<br />

COMPLETE GEAR BOX TYPE NL24L1 ANN -16 TO BE USED AS RAW 2 EA<br />

CAPACIT<br />

Y<br />

POSSIBLE<br />

MARERIAL FOR OF<br />

MANUFATURING NO. 15.11084/87 PRODUCING<br />

BENIFICI<br />

ATION<br />

PHOSPHATE FIRTILIZER PLANT<br />

FOR ROCK SLURRY TANK<br />

05-02-00086 COMPLETE GEAR BOX TYPE NH24L1 ANN - 16 = 2 EA = = =<br />

MANUFATURING NO. 15.11088/90<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00087 SPARE PART FOR PISTON COMPRESSOR TYPE K160-2B AMONIA PLANT<br />

INCREAS<br />

E<br />

ROUND AS<br />

TO BE USED AS RAW<br />

CAPACIT<br />

Y<br />

POSSIBLE<br />

MARERIAL FOR OF<br />

MEDUIM :- NH3 PRODUCING AMONIA<br />

OPERATING SPEED :- 700 RPM<br />

SUCTION PRESSURE :- 4.2 BAR<br />

SUCTION VOLUME :- 1608 +/- 5% M3/H<br />

TEMP. :- 10 DEG.<br />

INTERMEDATE PRESSURE :- 9.2 BAR<br />

DISCHARGE PRESSURE :- 16.4 BAR<br />

SUCTION TEMP. :- FIRST STAGE :- 80 DEG.<br />

DISCHARGE TEMP. :- 120 DEG.<br />

NO. OF STAGES :- 2<br />

N0. OF CYLENDER :- 2<br />

KIND OF OPERATING :- DOUBLE ACTING STROCKE<br />

DIMENTION :- 160 MM<br />

PHOSPHATE FIRTILIZER PLANT<br />

PISTON 1ST STAGE COMPLETE 1EA<br />

12

PISTON SKIRT 2EA<br />

LOWER HALF OF PISTON 2EA<br />

UPPER HALF OF PISTON COMPLE. 2EA<br />

PISTON 2ND STAGE COMPLE. 1EA<br />

PISTON SKIRT 2EA<br />

LOWER HALF OF PISTON 2EA<br />

UPPER HALF OF PISTON 2EA<br />

SET OF SHIMS FOR 1756 4SET<br />

SECTION VALVE 1ST 3EA<br />

LANTREN 2EA<br />

DISTANCE RINGS 38EA<br />

DISCHARGE VALVE 1ST STAGE COMPLETE. 4EA<br />

LANTREN 2EA<br />

SECTION VALVE 2ND STAGE COMPLETE. 2EA<br />

LANTREN 2EA<br />

DISCHARGE VALVE 2ND STAGE COMPLETE 2EA<br />

LANTREN 2EA<br />

VALVE DISC 12EA<br />

DAMPER DISC 6EA<br />

13

SPLIT PIN FOR KEY (1705) 8EA<br />

TO REHABILIATE 2 EA TO ALL YEAR AS SOON<br />

05-02-00088 COMPLETE HORIZONTAL CENTRIFUGAL PUMP TYPE 12/10 FM FERTILIZER PLANT INCREAS<br />

E<br />

ROUND AS<br />

*LIQUID TO BE HANDLED-:- SLURRY AT 40 DEG. PHOSPHORIC ACID<br />

CAPACIT<br />

POSSIBLE<br />

PLANT<br />

Y<br />

*SP. GR. :-1.23 BENIFICIATION PLANT OF<br />

HEAD :- 16.7 M.C.L FERTELIZ<br />

ER<br />

Q :-860 M/HR PLANT;<br />

NPSH :-5.6 M PHOSPHO<br />

RIC<br />

PUMP SPEED :-700 RPM ACID<br />

PLANT;<br />

NO. OF STAGES :- 1 BENIFICI<br />

ATION<br />

MOTOR POWER :-110 KW<br />

MOTOR SPEED :-1500 RPM<br />

MATERIAL :-<br />

*IMPLER :-DIA.550 MM C.I RUBBER LINED<br />

*INNER CASE :-C.I RUBBER LINED<br />

PLANT<br />

2 EA<br />

05-02-00089 COMPLETE HORIZONTAL CENTRIFUGAL PUMP TYPE 10/8 FM<br />

*LIQUID TO BE HANDLED:- SLURRY AT 40 DEG.<br />

*SP. GR. :-1.12<br />

Q :-645 M3/HR<br />

HEAD :- 16 M.C.L<br />

PUMP SPEED :-583 RPM<br />

= = = =<br />

MOTOR POWER :-75KW<br />

MATERIAL :-<br />

*IMPELLR :-C.I RUBBERE LINED<br />

*INNER CASE :-C.I RUBBER LINED<br />

05-02-00090 COMPLETE HORIZONTAL CENTRIFUGAL PUMP TYPE 8/6 EAM = 3 EA = = =<br />

*LIQUID TO BE HANDLED:- SLURRY AT 40 DEG.<br />

*SP. GR. :-1.17<br />

14

Q :-364 M3/HR<br />

NPSH :-3 M<br />

HEAD :- 19.2 M<br />

PUMP SPEED :-653 RPM<br />

MOTOR POWER :-55 KW<br />

MOTOR SPEED :-1500RPM<br />

MATERIAL :-<br />

*IMPELLR :-C.I RUBBERE LINED<br />

*INNER CASE :-C.I RUBBER LINED<br />

05-02-00091 COMPLETE HORIZONTAL CENTRIFUGAL PUMP TYPE 6/4 DAM 3 EA<br />

*LIQUID TO BE HANDLED:- SLURRY AT 40 DEG.<br />

*SP. GR. :-1- 1.14 = = = =<br />

Q :-148M3/HR<br />

NPSH :-1.8 M<br />

PUMP SPEED :-779 RPM<br />

HEAD :- 17.9 M.C.L<br />

MOTOR POWER :-15 KW<br />

MOTOR SPEED :- 1500 RPM<br />

MATERIAL :-<br />

*IMPELLR :-C.I RUBBERE LINED<br />

*INNER CASE :-C.I RUBBER LINED<br />

05-02-00092 COMPLETE HORIZONTAL CENTRIFUGAL PUMP TYPE 300FL 1 EA<br />

*LIQUID TO BE HANDLED:-GYPSUM SLURRY 20% SOLED = = = =<br />

HEAD :-20 M<br />

Q:- 1600 M3/HR<br />

05-02-00093 COMPLETE HORIZONTAL CENTRIFUGAL PUMP TYPE 3/2 DHH 3 EA<br />

*LIQUID TO BE HANDLED:-PRCES PHOSPHORIC ACID 54%<br />

P2O5<br />

AND 5% SOLED<br />

Q :-25 M3/HR<br />

PUMP SPEED :-1450 RPM<br />

HEAD :- 60M.C.L<br />

MOTOR POWER :-45 KW , 1475 RPM<br />

MATERIAL ALL PARTES ATTACHED WITH FLUID NUST UB6<br />

MATERIAL<br />

= = = =<br />

15

05-02-00094 COMPLETE HORIZONTAL CENTRIFUGAL PUMP TYPE 4/3 CAM<br />

*LIQUID TO BE HANDLED:- 54%P2O5 + 5% SOLED AT 40 - 70<br />

DEG.<br />

2 EA<br />

HEAD :- 30M.C.L<br />

Q :-48 M3/HR<br />

NPSH :-0.2M<br />

MOTOR SPEED :-1450 RPM<br />

MOTOR POWER :-30KW<br />

MATERIAL ALL PARTES ATTACHED WITH FLUID NUST UB6<br />

MATERIAL<br />

= = = =<br />

TO REHABILITATE TO ALL YEAR AS SOON<br />

05-02-00095 OFF HIGH WAY TRUCKS OF LOADING CAPACITY AKASHAT MINE 3EA INCREAS<br />

E<br />

ROUND AS<br />

TO BE USED AS RAW CAPACIT<br />

Y<br />

POSSIBLE<br />

(60-80) TONS MARERIAL FOR OF<br />

PRODUCING MINE<br />

PHOSPHATE FERTILIZER<br />

SPECIFICATION:-<br />

----------------<br />

HAULING HEIGHT UP TO 320 CM (MAXIMUM)<br />

DUMPING HEIGHT UP TO 720 CM (MAXIMUM)<br />

TRUCK WIDTH (NOT MORE THAN) 350CM (MAXIMUM)<br />

LOADING CAPACITY 75 TONS<br />

MAJOR TRUCK WIDTH 4900 MM<br />

LOADING BODY HEIGHT 4500 MM<br />

CAB HEIGHT WITH SHADE 4900 MM<br />

TRUCK LENGTH 9010 MM<br />

MAJOR DUMPING HEIGHT 9000 MM<br />

HEIGHT OF REAR BODY 600 MM<br />

FROMGR LEVEL DURING DUMPING.<br />

AIR CONDITIONED CAB.<br />

ORGINAL SUPPLIER LIKE<br />

EUCLID , CATER PILLER<br />

16

CODE INTENDED USE QTY. ALLOCATION TIME<br />

FRAME<br />

(AND TARGETED IN CRITERIA FILED OPTIMAL<br />

END USER) UNIT APPLICA- DELIVERY<br />

05-02-00096 H.V MOTOR,6.6KV ,1500 R.P.M ,220KW ,TYPE<br />

:AK355M26,B3,50MA 19561<br />

05-02-00097 H.V MOTOR,6.6KV ,1500 R.P.M ,260KW<br />

,TYPE:AK355M28,B3,50MA 19564<br />

05-02-00098 H.V MOTOR,6.6KV ,750 R.P.M ,755KW ,TYPE<br />

:AVRT2560L48,V1,50MA 19561<br />

05-02-00099 H.V MOTOR,6.6KV ,1500 R.P.M ,295KW<br />

,TYPE:AK400L20,B3,S.N:50MA19559<br />

05-02-00100 H.V MOTOR,6.6KV,3000 R.P.M ,460KW<br />

,TYPE:AK400L14,B3,S.N:50MA19565<br />

05-02-00101 H.V MOTOR,6.6KV,1000 R.P.M ,300KW<br />

,TYPE:AK400L36,B3,S.N:50MA19558<br />

TO REHABILIATE 2 TO<br />

TION<br />

ALL YEAR AS SOON<br />

FELTILIZER PRODUCTION INCREASE ROUND AS<br />

TO BE USED AS RAW CAPACITY POSSIBLE<br />

MARERIAL FOR OF<br />

PRODUCING FELTILIZER<br />

PHOSPHATE FIRTILIZER PRODUCTION<br />

= 2 = = =<br />

17<br />

= 1 = = =<br />

= 1 = = =<br />

= 1 = = =<br />

= 1 = = =<br />

05-02-00102 VIBRATOR MOTOR TO REHABILITATE TO INCREASE ALL YEAR AS SOON<br />

FOR BENIFICIATION PLANT CAPACITY ROUND AS<br />

TYPE CS260-6 AND FERTILIZER PLANT 6 OF POSSIBLE<br />

BENIFICIATION<br />

POWER 1.2KW PLANT<br />

AND<br />

ROTATION 980 RPM, S.N : 710139 PLANT<br />

FRAME CS260-6<br />

IP 65 (DELTA)/STAR<br />

VOLITAGE 220/380V<br />

AMP.3.6/2.1 - 50HZ

SHAFT ON TWO SIDE<br />

HEAVY DUTY<br />

STRUCTURE : SHAFT ON TWO SIDE<br />

MANUFACTURED BY VIMARC.<br />

05-02-00103 TYPE: FS800-6 ,4KW ,980 R.P.M<br />

FRAME :FS800-6 ,IP;65 ,VOLTAGE 220/380V<br />

DELTA/STAR , I=13/7.5 AMP .S.N=709105 ,B3 MOUNTING<br />

HEAVY DUTY ,SHAFT ON TWO SIDE<br />

MANUFACTURED BY VIMARC.<br />

18<br />

= 6 = = =<br />

COMPLETE GEAR BOXES +MOTOR +COPLING +<br />

AGITATOR<br />

TO REHABILITATE TO INCREASE ALL YEAR AS SOON<br />

FOR SULPHORIC ACID<br />

PLANT<br />

CAPACITY ROUND AS<br />

05-02-00104 FLAT GEAR BOX COMPLETE WITH AGITATOR TO BE USED AS RAW 4 OF POSSIBLE<br />

TYPE:- SFG 11-172 PHSPHATE FERTILIZER SULPHORIC<br />

SERIAL NO: 30.3717<br />

I=17,2<br />

INLET SPEED 1450 R.P.M AND OUT LET SPEED 85 R.P.M<br />

ACID PLANT<br />

05-02-00105 MOTOR NOMINAL POWER 37KW TYPE AKN225.7S.04N 4<br />

INSTALLED POWER 22KW<br />

ABSORBED POWER 15KW<br />

VERTICAL ARRANGEMNT IP55<br />

05-02-00106 Sprinkler irrigation units 100 SET<br />

05-02-00107 KIT FLEXIBLE COUPLING 10 SET<br />

GEAR 28X2.5M (7031667) 10 EA<br />

GEAR 67X2.5M (7031667) 10 EA<br />

GEAR WITH SHAFT (DIA 8MM) {7036175} 10 EA<br />

GEAR {7036175} 10 EA

05-02-00108 FLAT GEAR BOX COMPLETE WITH AGITATOR = 4 EA<br />

TYPE : -SFG 11-214<br />

SERIAL NO: 30-3718<br />

I-21,2 = = =<br />

INLET SPEED :1450 R.P.M<br />

OUTLET SPEED :69 R.P.M<br />

05-02-00109 MOTOR ABSORBED POWER 11KW 10 EA<br />

INSTALLED POWER 18.5 KW<br />

NOMINAL POWER 30KW<br />

AKN 200.7L.04N<br />

VERTICAL ARANGMENT IP55<br />

= = = =<br />

GEAR WHEEL M2.5 X Z=24 5 EA<br />

GEAR WITH SHAFT (DIA 8MM) 10 EA<br />

GEAR 10 EA<br />

KIT FLEXIBLE COPLING 10 SET<br />

05-02-00110 GEAR BOX:-DAVID BROWN FOOT MOUNTED IN LINE TO REHABILIATE 2EA TO ALL YEAR AS SOON<br />

HELLCON SPEED REDUCER FELTILIZER PRODUCTION INCREASE ROUND AS<br />

SERIES HD 870 TO BE USED AS RAW CAPACITY POSSIBLE<br />

ACTUAL RATIO 9.595/1 MARERIAL FOR OF<br />

CAST IRON BASE STANDARD SHAFT EXTENTION PRODUCING FELTILIZER<br />

DAVY MKEE STEM NO 3355 PHOSPHATE FIRTILIZER PRODUCT ION<br />

SET GEARS 2 SET<br />

05-02-00111 GEAR BOX :- DAVID BROWN H3-450 TRIPLE REDUCER 1EA<br />

HELICAL GEAR UNIT RATIO 48-796/1<br />

ITEM NO= 3454 = = = =<br />

SET GEARS 1 SET<br />

05-02-00112 GEAR BOX:- DAVID BROWN REDUCTION HELICAL<br />

GEAR<br />

REDUCER RATIO 12.958/1 FAN COOLED SIZE H2-250<br />

1EA<br />

ITEM NO = 3454 = = = =<br />

SET GEARS 1 SET<br />

19

05-02-00113 GEAR BOX:- DAVID BROWN 2000 REDICON WARM<br />

REDUCER<br />

GEAR BOX STANDARD RATIO 10/1<br />

1EA<br />

ITEM NO = 3456 = = = =<br />

SET GEARS 1 SET<br />

05-02-00114 GEAR BOX:- DAVID BROWN H2-315 FOOT MOUNTED<br />

GEAR<br />

BOX SPEED RATIO 25.575/1<br />

ITEM NO 3455<br />

1 EA<br />

= = = =<br />

SET GEARS 1 SET<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00115 COMPLETE GEAR BOX UNIT AND SPARE PARTS FERTILIZER PLANT INCREASE ROUND AS<br />

CAPACITY POSSIBLE<br />

GEAR BOX UNIT ,COMPLET TYPE HA21 AN18 2 EA OF fertilizer<br />

Plant<br />

GEAR BOX UNIT ,COMPLET TYPE HA21 BN18 = 4 EA<br />

= = =<br />

GEAR BOX UNIT ,COMPLET TYPE HB21 AN18 2 EA<br />

= = =<br />

GEAR BOX UNIT ,COMPLET TYPE HB21 BN18 = 1 EA = = =<br />

MANUFATURING NO. 15.11084/90<br />

SPARE PART FOR THREE YEARS OPERATION FOR ANY<br />

GEAR BOX IN ITEM 1,2,3 AND 4<br />

TO REHABILITATE TO ALL YEAR AS SOON<br />

05-02-00116 HORIZONTAL CENTERFUGAL PUMP UTILITYS PLANT 1EA INCREASE ROUND AS<br />

CAPACITY OF POSSIBLE<br />

Q=2.88 M3/H (TO BE ADJESTED 0.92-1.88-2.88 M3/H) UTILITYS<br />

PLANT<br />

H=2.7 BAR LIQUID H2SO4 66 DEG BE TEMP.20 DEG.<br />

MOTOR 380/220.1.KW 2770 1EA<br />

MOTOR = ECEC<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00117 COMPLETE PUMP PHOSPHORIC ACID PLANT 2 INCREASE ROUND AS<br />

TO BE USED AS RAW CAPACITY POSSIBLE<br />

AXIAL FLOW PUMP TYPE CAV 1250 MARERIAL FOR OF<br />

PRODUCING PHOSPHORIC<br />

FAB 77.17330 PHOSPHATE FIRTILIZER ACID PLANT<br />

20

D.NO. 225.592/4<br />

WITH GEAR BOX TYPE HTI-ND 22-L1 HANSSEN-PATENT<br />

WITH MOTOR SEMENS TYPE 1LA4186 4AA70Z FORM V6<br />

22KW , 1500 R.P.M<br />

MEDIUM :-<br />

H3PO4 40 - 50%<br />

H2SO4 1-5%<br />

H2SiF6 1-3% F<br />

GYPSOM 25-40%<br />

CAPACITY 5.77-6.5 M3/H<br />

RATED POWER 18.4 KW<br />

SPEED 114 RPM<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00118 SPARE PARTS FOR HYDROSEAL HORIZONTAL PHOSPHORIC ACID PLANT INCREASE ROUND AS<br />

(ASH PUMP TYPE GH 9.5 SIZE 20" X20"X40" TO BE USED AS RAW CAPACITY POSSIBLE<br />

LIQUID TO BE HANDELD :- INDUS PHOSPHORIC ACID MARERIAL FOR OF<br />

25-40%<br />

GYPSUM PRODUCING PHOSPHORIC<br />

Q=4041 M3/HR PHOSPHATE FIRTILIZER ACID PLANT<br />

DIFF. HEAD =5.72 - 7.71 M.C.L<br />

300 RPM<br />

MOTOR POWER = 300 KW ,1000 RPM<br />

SHELL HALF SECTION SIDE 2EA<br />

SHELL HALF ENG.SIDE 2EA<br />

MECHANICAL SEAL COMPLETE 6EA<br />

SHELL LINER SUCTION-SIDE 6EA<br />

SHELL LINER ENG.-SIDE 6EA<br />

IMPELLER 3EA<br />

SIDE LINER SUCTION SIDE 6EA<br />

21

SIDE LINER ENGINE SIDE 6EA<br />

SHAFT SLEEVE 4EA<br />

THROAT BUSHING 4EA<br />

END COVER 4EA<br />

END COVER 4EA<br />

BEARING THRUST 4EA<br />

O.RING 10EA<br />

O.RING 10EA<br />

O.RING 10EA<br />

05-02-00119 COMPLETE FAN WITH MOTOR ASPER INFORMATION<br />

BELOW<br />

TO REHABILIATE 1 TO ALL YEAR AS SOON<br />

UTILITY PLANT INCREASE ROUND AS<br />

FAN TO BE USED AS RAW CAPACITY POSSIBLE<br />

----- MARERIAL FOR OF<br />

TYPE:- 2DX DIA 1485 ARG T 8 PRODUCING UTILITY<br />

REF:- 46009/584 606/77<br />

DESIGN :- CENTRIFUGAL<br />

DRAWING NO :- 77-DX-6A<br />

OPERATING TEMP. 50C DEG.MAX.<br />

ROTATION SPEED :- 1485 R.P.M<br />

SHAFT DIA = 100MM<br />

PHOSPHATE FIRTILIZER PLANT<br />

MOTOR<br />

-------<br />

TYPE :- AK 400L20<br />

MARKER : ACEC<br />

NOMINAL POWER :- 295 KW<br />

SPEED :- 1489 R.P.M<br />

CLASS :- IP55 B3<br />

ELECTRICAL MAIN : 6600 VOLT,3PHASE ,50HZ<br />

ELECTRIAL HEATING :- 220V ,200 WATT WITH<br />

THRMOSTATE<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00120 COMPLETE HORIZONTAL ACID PUMP.381P01 A/B. PHOSPHORIC ACID PLANT 2EA INCREASE ROUND AS<br />

22

TO BE USED AS RAW CAPACITY POSSIBLE<br />

TYPE OF PUMP :- CWA 80-40 MARERIAL FOR OF<br />

PRODUCING PHOSPHORIC<br />

FAB.NO :- 77-17460 PHOSPHATE FIRTILIZER ACID PLANT<br />

DRAWING NO:- 329-477<br />

Q :- NORMAL:- 59 M3/H<br />

RATED :- 80 M3/H<br />

H :- 31 M.C.L<br />

RPM :- 1470<br />

LIQUID TO BE HANDELED :- H3PO4 54% P2O5<br />

2.5% H2SO4 , 1.2% FLORIN<br />

TEMP. :- 85- 90 DEG.<br />

DENSITY :- 1.7<br />

NPSH :- 4.8 M<br />

CROSSEN / EROSSEN CAUSED BY ACIDS GYPSOM<br />

K2SiF6 SOLDS<br />

05-02-00121 COMPLETE VERTICAL LIQUID SULPHUR PUMP WITH<br />

MOTOR ASPER<br />

TO REHABILITATE 2 TO INCREASE YEAR AS SOON<br />

DATA SHEET BELOW:- SULPHORIC ACID PLANT SILPHRIC ACID ROUND AS<br />

OPERATION CONDITION:- TO BE USED AS RAW<br />

MATERIAL<br />

CAPACITY POSSIBLE<br />

--------------------- FOR REDUSING PHOSPHATE<br />

FLUID :- LIQUID SULPHUR AT 140C DEG.<br />

SPECIFIC WEIGHT :- 1.784 KG/DM3<br />

FLOW :- 40 M3/HR<br />

TOTAL HEAD :- 25 M.C.L<br />

FERTILIZER<br />

DESIGN CONDITION<br />

---------------------<br />

DESIGN FLOW :- 40 M3/HR<br />

TOTAL PRESSURE RISE :- 26.5 M.C.L<br />

PUMP<br />

----------<br />

PUMP SPEED 1450 R.P.M<br />

POWER ABSORBED 7.2KW<br />

MOTOR<br />

----------<br />

MOTOR SPEED 1450 R.P.M VOLTAGE 38V HZ 50<br />

ABSORBED POWER 7.2KW ,INSTALLED POWER 12.6KW<br />

23

DIMENSION<br />

----------<br />

DISTANCE BETWEEN BASE PLATE AND ASPIRATION<br />

PIPE 3.3 MTR.<br />

MATERIAL AND CONSTRUCTION<br />

---------------------<br />

CASING, SUSPENSIONS , COLUMNS :- CAST IRON +<br />

STEEL<br />

DISCHARGE , SECTION :- STEEL<br />

BEARING SLEEVE . :- CAST IRON<br />

SHAFT :- STEEL<br />

IMPELLER :- CAST IRON<br />

NOTES:-INTERNAL ELBOW BY-PASS HOLE BY<br />

SUPPLIER WILL<br />

------- PASS 1.53 M3/HR<br />

05-02-00122 COMPLETE VERTICAL LIQUID SULPHUR PUMP WITH<br />

MOTOR<br />

ASPER DATA SHEET BELOW:- 2<br />

FLUID :- LIQUID SULPHUR AT 140C DEG.<br />

FLOW :- 15 M3/HR<br />

TOTAL HEAD :- 39 M.C.L<br />

TOTAL PRESSURE RISE :- 44.5 M.C.L = = = =<br />

POWER ABSORBED :- 7-6 KW<br />

INSTALLED POWER :- 11.6 KW<br />

MOTOR SPEED :- 2900 R.P.M<br />

DISTANCE BETWEEN BASE PLATE AND ASPIRATION<br />

PIPE 3 METER<br />

TO REHABILITATE 8 TO INCREASE ALL YEAR AS SOON<br />

05-02-00123 FILTER CLOTH FOR DISCHARGE ROLLER FOR BENIFICIATION PLANT CAPACITY ROUND AS<br />

CHEMICAL COMPOSITION TO BE USED AS RAW OF POSSIBLE<br />

LENGTH = 43 M PHSPHATE FERTILIZER BENIFICIATION<br />

WIDTH = 4.32 M PLANT<br />

BELT FILTER AREA = 50 M2<br />

MANUFACTURER : FILTERS PHILIPPE (FRANCE)<br />

THE FILTER IS USED FOR ROCK PHOSPHATE<br />

FILTERATION<br />

TYPE OF FILTER CLOTH = MONO FILAMENT<br />

POLYESTER 9623<br />

MATERIAL = POLYESTER OR EQUIVALENT<br />

REFRENCE NO : 9623<br />

24

CURVED SPREADER ROLL<br />

NOTE:-<br />

--------<br />

OUR REF. 101/3303/100<br />

FILTER NO= 3303/90<br />

TYPE A50 B40<br />

SERIAL NO= 4<br />

SPARE PART FOR THREE YEAR OPERATION REQUIRED<br />

(FOR COMPELTE FILTER)<br />

EQUIPMENT MANUL 1/2 , 2/2<br />

05-02-00124 HYDRAULIC SETTING CASTABLE TO REHABILITATE 50 TN TO INCREASE ALL YEAR AS SOON<br />

CHEMICAL COMPOSITION FOR BENIFICIATION PLANT CAPACITY ROUND AS<br />

TO BE USED AS RAW OF POSSIBLE<br />

AL2O3 > 90% PHSPHATE FERTILIZER BENIFICIATION<br />

PLANT<br />

Fe2O3 _ 40/1900 SK/C DEG.<br />

SERVICE TEMPERATURE LIMIT > 1750C DEG.<br />

COLD CRUSHING STRENGTH AFTER HEATING TO<br />

110C DEG. > 800KG/CM2<br />

500C DEG. > 800 KG/CM2<br />

1000C DEG.> 850KG/CM2<br />

UNIT WEIGHT 3.2 KG/DM3<br />

GRAIN SIZE 0-6MM<br />

PACKING :- TIN CONTAINERS COMPLETLY CLOSED.<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

25

05-02-00125 ANTI ACID MORTAR WITH FOLLOWING DESCRIPTION: FELTILIZER PRODUCTION 30 TON INCREASE ROUND AS<br />

TO BE USED AS RAW CAPACITY POSSIBLE<br />

AL2O3 :- 35% MARERIAL FOR OF<br />

PRODUCING FELTILIZER<br />

FIRECLAY :- 25% PHOSPHATE FIRTILIZER PRODUCTION<br />

QUARTZ :- 40%<br />

FIRE POWDER<br />

GRAIN SIZE :- 0-0.5 MM<br />

PACKING :- WITH STRONG CLOSED BAGS<br />

05-02-00126 ANTI-ACID BRICKS FOR TOWERS OF SULPHURIC ACID<br />

PLANT<br />

CHEMICAL ANALYSIS:-<br />

SIO2 : 68% -75%<br />

AL203+TIO2:- 21% -27% = = = =<br />

FE203:- 1%-2%<br />

PHYSICAL PROPERTIES:-<br />

BULK DENSITY:- 2.15 G/CM3<br />

POROSITY:

FE203:- 0.8%-1.1%<br />

PHYSICAL PROPERTIES:-<br />

DENSITY:-<br />

POROSITY: 14% -16%<br />

WATER ABSORBATION =600KG/CM2<br />

ACID SOLUBILITY :- 0.7% -0.9% IN WEIGHT<br />

DIA.100/130MM X 1M LENGTH 4EA<br />

DIA.150/180 X 1MLENGTH 4EA<br />

DIA.200/240 X 1M LENGTH 4EA<br />

05-02-00128 ADHISIVE MATERIAL FOR LINING TOWERS OF<br />

SULPHURIC ACID<br />

PLANT = = = =<br />

RHEPANOL-ORG SHEETING TH.1.5MM,WID.1.05MM.ONE<br />

30M<br />

ROLL=15M<br />

RHEPANOL- PRIMER 20KG<br />

RHEPANOL- GLUE PH 20KG<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00129 FIRE NORMAL BRICKS SULPHORIC ACID PLANT 40 000 EA INCREASE ROUND AS<br />

AL2O3 = 35% TO BE USED AS RAW CAPACITY POSSIBLE<br />

SIO2 = 61% MARERIAL FOR OF<br />

Fe2O3 = 1.2% PRODUCING SULPHORIC<br />

BULK DENSITY = 0.6 gr/cm3 PHOSPHATE FIRTILIZER ACID PLANT<br />

REFRACTORINESS UNDER LOAD = 1250C DEG.<br />

POROSITY = 67%<br />

COLD CRUSHING STRENGTH = 80kg/cm2<br />

SIZE = 230 X 114 X 64 mm<br />

05-02-00130 FIRE BRICKS<br />

AL2O3 = 40% - 42%<br />

SIO2 = 54% - 56%<br />

Fe2O3 = 1.9%<br />

BULK DENSITY = 2.25 gm/cm3 = = = =<br />

REFRACTORINESS UNDER LOAD = 1400C DEG.<br />

POROSITY = 18% - 20%<br />

COLD CRUSHING STRENGTH = 400 - 450 kg/cm2<br />

RADIAL BRICKS NO. 1 680 EA<br />

RADIAL BRICKS NO. 2 3150 EA<br />

RADIAL BRICKS NO. 3 1368 EA<br />

RADIAL BRICKS NO. 4 380 EA<br />

27

RADIAL BRICKS NO. 5 8 EA<br />

RADIAL BRICKS NO. 7 300 EA<br />

RADIAL BRICKS NO. 8 450 EA<br />

RADIAL BRICKS NO. 9 4 EA<br />

RADIAL BRICKS NO. 10 2 EA<br />

RADIAL BRICKS NO. 11 2 EA<br />

RADIAL BRICKS NO. 12 2 EA<br />

RADIAL BRICKS NO. 13 2 EA<br />

RADIAL BRICKS NO. 14 4 EA<br />

RADIAL BRICKS NO. 15 4 EA<br />

RADIAL BRICKS NO. 16 4 EA<br />

RADIAL BRICKS NO. 17 4 EA<br />

RADIAL BRICKS NO. 18 4 EA<br />

RADIAL BRICKS NO. 19 4 EA<br />

RADIAL BRICKS NO. 20 4 EA<br />

RADIAL BRICKS NO. 21 4 EA<br />

RADIAL BRICKS NO. 22 4 EA<br />

RADIAL BRICKS NO. 23 4 EA<br />

RADIAL BRICKS NO. 24 4 EA<br />

RADIAL BRICKS NO. 25 4 EA<br />

RADIAL BRICKS NO. 26 4 EA<br />

RADIAL BRICKS NO. 27 4 EA<br />

RADIAL BRICKS NO. 28 4 EA<br />

RADIAL BRICKS NO. 29 4 EA<br />

RADIAL BRICKS NO. 30 4 EA<br />

RADIAL BRICKS NO. 31 4 EA<br />

RADIAL BRICKS NO. 32 4 EA<br />

RADIAL BRICKS NO. 33 40 EA<br />

SIDE ARCH BRICKS CT(24) 536 EA<br />

SIDE ARCH BRICKS CT(10) 948 EA<br />

SIDE ARCH BRICKS CT(6) 1064 EA<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00131 BRAZING-ELECTRODE FOR COPPER-PHOSPHORUS-<br />

SILVER<br />

ALKAIM FERTELIZER 100KG INCREASE ROUND AS<br />

FILLER METAL AWS (B CUP-5) COMPLEX CAPACITY POSSIBLE<br />

NOMINAL COMPOSSTION OF<br />

AG = 1.5% ALKAIM<br />

CU = 80% FERTELIZER<br />

P = 5% COMPLEX<br />

05-02-00132 WELDING ELECTRODE ((HASTE ALLOY CU))<br />

O.K 92-35 DIA 2.5MM 200KG = = =<br />

O.K 92-35 DIA 3.25MM 250KG<br />

28

05-02-00133 WELDING ELECTRODE ((WELD CAST IRON META L))<br />

O.K 92-18 DIA 2.5MM = 500KG = = =<br />

O.K 92-18 DIA 3.25MM 500KG<br />

05-02-00134 WELDING ELECTRODE AUSTENITIC RUTTLE (BASIC<br />

20.25,4-5)<br />

O.K 69-33 DIA 2MM 200KG<br />

O.K 69-33 DIA 2.5MM = 300KG = = =<br />

O.K 69-33 DIA 3.25MM 400KG<br />

05-02-00135 WELDING ELECTRODE AUSTENITIC STAINLESS STEEL<br />

& ACID<br />

RESISTING (E316L-16 DIN 8556.13 32926)<br />

O.K 63.30 DIA 2.5MM 400KG<br />

O.K 63.30 DIA 3.25MM = 600KG = = =<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

ALKAIM FELTELIZER INCREASE ROUND AS<br />

05-02-00136 LIGHT-LATHE CNC MACHINE WITH ACCESSORIES COMPLEX 1 EA CAPACITY POSSIBLE<br />

OF<br />

STANDARD : ALKAIM<br />

--------- FELTELIZER<br />

HIGHT OF CENTERS = 366 MM COMPLEX<br />

DISTANCE BETWEEN TWO CENTERS = 1M<br />

SWING OVER CROSS SLIDE = 470MM<br />

SWING OVER BED = 720MM<br />

MAIN SPINDLE BOR DIA = 80MM<br />

SPINDLE DIA.OF FRONT BEARING = 120MM<br />

SPECD RANGE = 2NR.<br />

05-02-00137 BORING & MALLING CNC MACHINE<br />

THE MACHINE IS SUITABLE FOR PRECISION<br />

COORDINATE<br />

1 EA<br />

DRILLING ,BORING ,MILLING ,FACE TURNING AND<br />

= = = =<br />

THREAD<br />

CUTTING ON MEDIUM SIZE AND LARGE WORKPIECES<br />

UP TO<br />

AWEIGHT OF 6,000 KG.<br />

THE TABLE IS EQUIPRD WITH ALONGITUDINAL,<br />

TRANSVERSE,<br />

AND CIRCULAN HAND AND POWER FECD.<br />

THE TABLE IS PROVIDED WITH A 0 TO 360C DEG.<br />

SCALE.<br />

29

THE LUBRICATION OF THE BEARING AND GEARS IN<br />

THE HEAD<br />

STOCK IS AUTOMATIC ,CIRCULATING.<br />

CAPACITY<br />

----------<br />

- DIAMCTER OF GROUND AND NITRIDED SPINDLE<br />

150MM<br />

- TAPERIN SPINDLE<br />

- MAX.DIAMETER OF FACE TURNING 2500MM<br />

- MAX. BORING DEPTH 1000MM<br />

- CLAMPING SURFACE OF TABLE UP TO 2500 X 2500MM<br />

- LONGITUDINAL TRAVEL OF TABLE 6000MM<br />

ACCESSORIES:-<br />

--------------<br />

BACK REST<br />

FACE PLATE<br />

TOOL POST FOR FACE PLATE<br />

SUSPENSION SCREW FOR FITTING OF HEAD STOCK.<br />

DIAL GAUGE AND MECHANISM FOR 90C DEG. SETTING<br />

OF TABLE.<br />

MAGNIFYING LLASS FOR READING OF VERTICAL<br />

SCALE OF HEAD<br />

STOCK.<br />

CLAMPING FLANGE OF SPINDLE STANDRAD<br />

CLAMPING SUPPORT OF SPINDLE.<br />

GUIDING SUPPORT OF SPINDLE.<br />

COOLING EQUIPMENT .<br />

VERTICAL MILLING HEAD WITH FITTING ATTACH<br />

SET OF GEARS FOR THREADING.<br />

BORING BAR SUPPORT BUSH<br />

ADJUSTABLE LAMP 24V WITH TRANSFORMER,SWITCH<br />

AND FUSES.<br />

SERVICING AND MAINTENACE TOOL<br />

INSTRUCTIONS FOR OPERATION AND MAINTANCE OF<br />

MACHINE.<br />

05-02-00138 SEMI-HAVEY LATH CNC MACHINE WITH ACCESSORIES = 1 EA = = =<br />

STANDARD<br />

----------<br />

HIGHT OF CENTERS = 366 MM<br />

DISTANCE BETWEEN TWO CENTERS = 3M<br />

SWING OVER CROSS SLIDE = 470MM<br />

SWING OVER BED = 720MM<br />

MAIN SPINDLE BOR DIA = 80MM<br />

30

SPINDLE DIA.OF FRONT BEARING = 120MM<br />

SPECD RANGE = 2NR.<br />

05-02-00139 SEMI-HAVEY LATH CNC MACHINE WITH ACCESSORIES = 1 EA = = =<br />

STANDARD<br />

----------<br />

CAPACITY:<br />

DISTANCE BETWEEN TWO CENTERS =4M<br />

ALL CAPACITY AS ABOVE.<br />

05-02-00140 HYDRAULIC SHEARS PRESS = 1 EA<br />

CAPACITY MILD STEEL THICKNESS =40MM = = =<br />

CUTTING LENGTH =2550MM<br />

OPENING BETWEEN UP RIGHTS =2550MM<br />

05-02-00141 AUTOMATIC TUBE BENDING MACHINE = 1 EA<br />

CAPAITY:<br />

---------<br />

-BENDING MILD STEEL PIPE DIA 80 X 3.5MM<br />

-USFEL LENGTH =3600MM<br />

-MAX.BENDING RADIUS =300MM<br />

-MIN.BENDING RADIUS = 35MM<br />

-MAX. BENDING ANGLE =190C DEG.<br />

-BENDING SPEED = 2-10 R.P.M<br />

-BENDING PRECISION =0.1<br />

05-02-00142 RADIAL DRILLI NG MACHINE = 1 EA<br />

------------------------ = = =<br />

DRILLING CAPACITY IN STEEL = 50MM<br />

MORSE TAPER IN SPINDLE = 4<br />

SPINDLE SPEEDS NUMBER =12<br />

SPINDLE SPEEDS RANGE AT 60 CYCLES 62-2400 R.P.M<br />

SPINDLE SPEED RANGE AT 50 CYCLES 52-2000 R.P.M<br />

FEED FOR SPINDLE REVOLUTION =4 IN NO.<br />

MAX.DRILLING RADIUS =1640MM<br />

MIN. DRILLING RADIUS =425 MM<br />

ARM ROTATION =360 C DEG.<br />

MAX.DISTANCE SPINDLE TO BASE =1510 MM<br />

MIN DISTANCE SPINDLE TO BASE = 480MM<br />

ACCESSORIES:<br />

--------------<br />

1 COMPLETE COOLANT SYSTEM COMPRISING<br />

TANK,PUMP,SUCTION<br />

31

AND DISCHARGE PIPING WITH ALL NECESSARY<br />

VALVES,<br />

STRAINERS.<br />

ADJUSTABLE LAMP 24V WITH TRANSFORMER,<br />

SWITCHAND FUSES<br />

1 FIXED CUBICLE TABLE WITH SLOTES<br />

700X550X400MM<br />

ALL NECESSARY KEYS AND SPANNERS.<br />

1 HYDRAULIC CLAMPING HEAD AND COLUME<br />

SHOCK ABSORBER<br />

SPECIFIC EQUIPMENT OR ACCESSORIES FOR<br />

OPERATOR PROTECTION<br />

1 SET AT DRILL<br />

05-02-00143 POWER HACK SAWS 1 EA<br />

--------------<br />

NUMBER OF STROCK 35/45/56/70/90/112M = = =<br />

AVERAGE CUTTING SPEED 10/13/17/20/26/34M<br />

CUTTING RANGE RUND 350MM =<br />

SAW BLADE DIMENSIONS 550X45X2.25MM<br />

WITH STANDARD ACCESSORIES<br />

05-02-00144 PORTABLE SCREW COMPRESSOR 1 EA<br />

----------------------------<br />

ATLAS COPCO PR700 CUD WITH CUMMINS DIESEL<br />

ENGINE<br />

COMPRESSOR TYPE :<br />

-----------------<br />

NUMBER OF COMPRESSION STAGE =2<br />

MAX.WORKING PRESSURE = 8.8 BAR =<br />

MARMAL WORKING PRESSURE =7 BAR<br />

MAX. OPERATING SPEED =2100 R/MIN<br />

MIN. OPERATING SPEED =330 R/MIN<br />

FREE AIR DELIVERY AT NORMAL WORKING PR.AND<br />

MAX<br />

SPEED 19.8 M3/MIN<br />

COOLING SYSTEM = OIL<br />

ENGINE<br />

---------<br />

MANUFACTURE = CUMMINS ENGINE<br />

COMPANY<br />

TYPE 4 STROKE DIESEL =N 8SSC250<br />

32<br />

= = =

NUMBER OF CYLINDERS = 6<br />

COOLING SYSTEM = WATER<br />

ELECTRICAL SYSTEM ,NEGATIVE EARTH =24V<br />

BATTERIER =90 AH<br />

UNIT<br />

---------<br />

AIR RECCIUES CAPACITY = 342L<br />

TYRE MICHELIN TYPE =650-16R10XC<br />

MAX.ANBIENT TEMP.AT SEA LEVEL AT FULL LOAD<br />

=50C DEG.<br />

05-02-00145 ENERPAE HYDRAULIC POWER 1 EA<br />

--------------------- = = = =<br />

PUMP & CYLINDER SET<br />

MODEL CAPACITY PUMP CYLINDER HOSE HOSE<br />

QTY.<br />

NO TONNES MODEL MODEL MODEL M<br />

---- ------ ----- ------ ------ -------- ------<br />

SL-30 30 P-80 RCS-302 HC-913 1.8 5<br />

SL-50 45 P-80 RCS-502 HC-913 1.8 5<br />

SL-100 90 P-80 RCS-1002 HC-913 1.8 5<br />

BHP-30G 30 P-80 RCH-302 HC-913 1.8 1<br />

BHP-60G 60 P-80 RCH-603 HC-913 1.8 1<br />

HYDRAULIC CYLINDER<br />

-----------------<br />

CYLINDER MODEL QTY.<br />

TONNES NO<br />

-------- --------- --------<br />

30 RSM -300 1<br />

200 RR-20013 1<br />

200 CLL-20010 2<br />

500 CLL-50010 2<br />

ELECTRIC DRIVE PUMP<br />

-----------------<br />

A-MODEL BPE 30423 2EA<br />

B-MODEL BPE 50423 1EA<br />

THE PUMP VALVE OPTIONS FOUR-WAY BVS-4 FOR<br />

DOUBLE<br />

ACTING CYLINDER<br />

33

GAUGE MODEL NO GGF-200 4EA<br />

SPARE PART FOR ALL EQUIPMENT ABOVE<br />

MULTI-PURPUSE PULLER SET<br />

- MODEL NUMBER BHP-5750G<br />

- MAX. TONNE CAPACITY 50<br />

- GRID ARMS 2 SET<br />

05-02-00146 ESAB WELDING EQUIPMENT 1 EA<br />

---------------------<br />

HIGH PERFORMANCE THYRISTOR CONTROLLED<br />

RECTIFIERS TYPE:<br />

LHF 400 2EA = = = =<br />

LHF 630 1EA<br />

LHF 800 1EA<br />

TIG-AID 3/S (AC-DC) WITH COMPLETE PIECE OF<br />

EQUIPMENT FOR<br />

TIG-WELDING 2EA<br />

ACCESSORIES<br />

--------------<br />

PHB1 REMOTE CONTROL UNIT<br />

PHC2<br />

PHA 2HOT-START UNIT<br />

25M CONNECTION CABLE PHB 1/2 ,PHA 2/5<br />

ARC-AIR GOUGING TORCH FLAIR 2<br />

TORCH FOR TIG-WELDING AND SPARE PART FOR<br />

MANUAL ARC.<br />

TORCH WELDING 500A<br />

TUNGSTEN ELECTRODE.<br />

PLASMA CUTTING : TYPE AWAC12<br />

ACCESSORIES<br />

--------------<br />

MECHANIZED CUTTING WITH AGUIDE CARRIAGE<br />

CUTTING TORCH PTC 200S<br />

CUTTING TORCH PM 200<br />

05-02-00147 GAS CUTTING MACHINE CADER2001A-ESAB 1 EA<br />

MAX.TORCH INTERAL ADJUSTMENT =120MM<br />

MAX. PARALLET CUT =120MM<br />

MIN. PARALLET CUT =60MM<br />

MAX. CIRCLE CUT DIA 1800MM = = =<br />

MIN. CIRCLE CUT DIA 60MM =<br />

34

CUTTING THICKNESS (1 TORCH) =3-125MM<br />

CUTTING THICKNESS (2 TORCH) =3-75MM<br />

MAX.NUMBER OF TORCH =2<br />

FUEL GASES =PROPANE<br />

CONNECTION VOLTAGE =220/50-60V/112<br />

INPUT POWER =55VA<br />

ACCESSORIES<br />

--------------<br />

DRIVING MACHINE<br />

CROSS SUPPORT<br />

LATERAL GUIDE ROLLER<br />

CABLE MAINR<br />

ENGLISH DOCUMENTATION<br />

ALL NOZZLES TO BE USED<br />

CUTTING TORCH WITH INJECTOR<br />

TORCH HOLDER<br />

HOSES AND CONNECTING PART<br />

35

CODE NO . DESCRIPTION INTENDED USE<br />

(AND<br />

TARGETED END<br />

05-02-00148 Thickness measurement type DM4<br />

with (3) sensior and cable and<br />

complete accesories<br />

05-02-00149 Shock pulse meter with complete<br />

accessories<br />

05-02-00150 Industrial radiology equipment pai to spot<br />

200 KW with complete accessories<br />

05-02-00151 Thermometer with complete accessories<br />

and (3 sensier – liquid , gas , material)<br />

USER)<br />

To rehabilitate<br />

fertilizer plant<br />

To rehabilitate<br />

fertilizer plant<br />

To rehabilitate<br />

fertilizer plant<br />

To rehabilitate<br />

fertilizer plant<br />

36<br />

QTY. IN<br />

UNIT<br />

ALLOCATION<br />

CRITERIA<br />

2 EA To increase capacity<br />

of fertilizer<br />

2 EA To increase capacity<br />

of fertilizer<br />

1 EA To increase capacity<br />

of fertilizer<br />

3 EA To increase capacity<br />

of fertilizer<br />

TIME FRAME<br />

FILED<br />

APPLICATION<br />

OPTIMAL<br />

DELIVERY<br />

All year round As soon as<br />

possible<br />

All year round As soon as<br />

possible<br />

All year round As soon as<br />

possible<br />

All year round As soon as<br />

possible

05-02-00152 UB6 Round Bars<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 8MM FOR MANUFACTERING FOR ALL YEAR AS SOON<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 12MM SPARE PARTS 20M<br />

MANUFACTERI<br />

NG<br />

ROUND AS<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 16MM of fertilizer plant 20M SPARE PARTS POSSIBLE<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 20MM 20M of different units in fertilizer plant<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 25MM 30M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 30MM 50M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 35MM 50M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 45MM 50M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 50MM 56M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 60MM 50M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 70MM 100M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 80MM 68M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 90MM 50M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 100MM 62M<br />

UB6 ROUND BARS MTRS NO.1.4539 L= 6M , DIA = 160MM 50M<br />

UB6 ROUND BARS MTRS NO.1.4539 , DIA =210 X L<br />

3650MM<br />

50M<br />

-------------- 3EA<br />

05-02-00153 UB6 HOLLOW BAR<br />

UB6 HOLLOW BAR SIZE 40/20MM MAT.NO.1.4539<br />

= = = = 45/25MM = = = 2M<br />

= = = = 50/25MM = = = L= 6M 2M<br />

= = = = 60/30MM = = = L= 6M 6M<br />

= = = = 80/45MM = = = L= 6M = 6M = = =<br />

= = = = 100/60MM = = = L= 6M 12M<br />

= = = = 150/110MM = = = L= 6M 12M<br />

= = = = 190/150MM = = = L= 6M 12M<br />

6M<br />

05-02-00154 PLT UB6<br />

PLT UB6 2000X1500X2MM PLATE URANUS B6 DIN 1.4539<br />

OR ASTM 904L<br />

PLT UB6 2000X1500X3MM PLATE URANUS B6 DIN 1.4539<br />

OR ASTM 904L<br />

15EA<br />

PLT UB6 2000X1500X4MM PLATE URANUS B6 DIN 1.4539<br />

OR ASTM 904L<br />

15EA<br />

PLT UB6 2000X1500X5MM PLATE URANUS B6 DIN 1.4539<br />

=<br />

OR ASTM 904L<br />

15EA = = =<br />

PLT UB6 2000X1500X6MM PLATE URANUS B6 DIN 1.4539<br />

OR ASTM 904L<br />

10EA<br />

PLT UB6 2000X1500X8MM PLATE URANUS B6 DIN 1.4539<br />

OR ASTM 904L<br />

10EA<br />

37

PLT UB6 2000X1500X10MM PLATE URANUS B6 DIN<br />

1.4539 OR ASTM 904L<br />

05-02-00155 PLT 316L<br />

PLT 316L 3000 X 1500 X 2MM<br />

= = 3000 X 1500 X 3MM 75EA<br />

= = 3000 X 1500 X 4MM 75EA<br />

= = 3000 X 1500 X 5MM = 75EA = = =<br />

= = 3000 X 1500 X 6MM 75EA<br />

= = 3000 X 1500 X 8MM 75EA<br />

= = 3000 X 1500 X 10MM 75EA<br />

50EA<br />

05-02-00156 PLT HASTEALLOY C4<br />

PLT HASTEALLOY C4 3MM<br />

PLT HASTEALLOY C4 4MM 15EA<br />

PLT HASTEALLOY C4 6MM = 10EA = = =<br />

10EA<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00157 STEAM TRAP FLANGED TYPE: SULPHORIC ACID PLANT INCREASE ROUND AS<br />

TO BE USED AS RAW CAPACITY POSSIBLE<br />

PRESSURE RANG. 1-8 BAR MARERIAL FOR OF<br />

PRODUCING SULPHORIC<br />

TEMP. 130C-180C DEG. PHOSPHATE FIRTILIZER ACID PLANT<br />

05-02-00158<br />

SIZE 1/2" 250<br />

SIZE 3/4" 250<br />

FOR ALKAIM TO ALL YEAR AS SOON<br />

FIRE FIGHTING VEHICLE WITH TWO CABINATE WATER<br />

FELTILIZER COMPLEX<br />

VESSEL<br />

3EA INCREASE ROUND AS<br />

CAPACITY 5000L CAPACITY POSSIBLE<br />

FOAM VESSEL CAPACITY 2000L OF<br />

POWDER VESSEL CAPACITY 1500KG ALKAIM<br />

THE PUMP SHOUDER BE NOT LESS THAN 30 BAR FERTELIZER<br />

-WITH TWO FIRE FIGHTING GUN.<br />

-WITH FOUR NOZELS SOURCE FOR FIRE FIGHTING<br />

HOSE<br />

COMPLEX<br />

SPARE PART FOR THREE YEAR OPERATION REQUIRED<br />

05-02-00159 FORK LIFT CAPACITY 10 TON 4EA<br />

38<br />

5EA<br />

5EA

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00160 COMPLETE CONTROL VALVE SULPHORIC ACID PLANT 4 INCREASE ROUND AS<br />

MODEL AZ 1915 TO BE USED AS RAW CAPACITY POSSIBLE<br />

MARERIAL FOR OF<br />

BODY : TYPE WEDGE GATE PRODUCING SULPHORIC<br />

PHOSPHATE FIRTILIZER ACID PLANT<br />

- SIZE : 300MM<br />

05-02-00161<br />

- END CONNECTION : DN 300 , PN10<br />

ACTUATOR :- MODEL AZ 000.23T<br />

------------<br />

1-PNEUMATIC DUAL ACTION CYLINDER<br />

ARRANGMENT WITH AUXILARY AIR TANK<br />

2-PNEUMATIC DUAL ACTION POSITIONER INPUT 0.2-1<br />

BAR<br />

3-ELECTRO- PNUMATIC CONVERTER<br />

INPUT :- 4-20 MA<br />

OUTPUT :- 0.2-1 BAR<br />

4- HAND WHEEL.<br />

5- FAIL POSITION CLOSE<br />

SERVICE:-<br />

-----------<br />

FLUID : H2SO4 98.5%<br />

MAX.PRESSURE: 6 BAR<br />

MAX.FLOW : 180 M3/H<br />

MAX.TEMP : 60C DEG.<br />

OPER.VISCOCITY : 13 CP<br />

PNEUMATIC DUAL ACTION POSITIONER 5<br />

2<br />

MAINTENANCE AND PARTS CATALOGUE<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

SPARE PARTS FOR CONTROL SYSTEM FOR<br />

BENIFICATION<br />

AMONIA PLANT INCREASE ROUND AS<br />

FARNECE TO BE USED AS RAW CAPACITY POSSIBLE<br />

CONTROLLER 1700RZ MOD 30 WITH HOUSING MARERIAL FOR 15EA OF<br />

39

05-02-00162<br />

05-02-00163<br />

05-02-00164<br />

PRODUCING AMONIA<br />

RECORDER 1700J MOD 30 SYSTEM PHOSPHATE FIRTILIZER 15EA PLANT<br />

RECORDER CHART FOR TAYLOR RECORDER 1700S2<br />

1400L<br />

CABLE FOR CONTROLLER 1700R TYPE 1750F 3EA<br />

UNIVERSAL FIELD IN PUT BOARD TYPE 1722E 4EA<br />

40<br />

50EA<br />

KEY BOARD DX912011 FOR MOD 30 CONTROLLER 40EA<br />

PORTABLE CONFIGERATOR FOR MOD 30. 11EA<br />

GLOBE VALVE NOMINAL DIA.DN=15=22 X<br />

3MM.NOMINAL<br />

TO REHABILIATE 70 TO ALL YEAR<br />

PRESSURE=100BAR.WITH BUTT WELD ENDS DIN 3239<br />

FORM D<br />

SULPHORIC ACID PLANT INCREASE ROUND AS<br />

ACC.TO DIN 2559.FACE TO FACE DIMENSION:- DIN 3202 TO BE USED AS RAW CAPACITY POSSIBLE<br />

LINE F2.ACCORDING TO ATTACHED DRAWING. MARERIAL FOR OF SULPHURIC<br />

PRODUCING ACID PLANT<br />

GLOBE VALVE NOMINAL DIA.DN=25=34 X<br />

3MM.NOMINAL<br />

PHOSPHATE FIRTILIZER 32<br />

PRESSURE=100BAR.WITH BUTT WELD ENDS DIN 3239<br />

FORM D<br />

ACC.TO DIN 2559.FACE TO FACE DIMENSION:- DIN 3202<br />

LINE F2.<br />

= = =<br />

GLOBE VALVE NOMINAL DIA.DN=50=60.3 X<br />

4MM.NOMINAL<br />

PRESSURE=100BAR.WITH BUTT WELD ENDS DIN 3239<br />

FORM D<br />

8<br />

ACC.TO DIN 2559.FACE TO FACE DIMENSION:- DIN 3202<br />

LINE F2.<br />

= = = =<br />

05-02-00165 GLOBE VALVE NOMINAL DIA.DN= 80MM.NOMINAL 2<br />

PRESSURE=100BAR.WITH BUTT WELD ENDS DIN 3239<br />

FORM D<br />

ACC.TO DIN 2559.FACE TO FACE DIMENSION:- DIN 3202 = = = =<br />

LINE F2.<br />

05-02-00166<br />

GLOBE VALVE NOMINAL DIA.DN=100=120 X<br />

7.5MM.THICKNESS<br />

5

05-02-00167<br />

05-02-00168<br />

05-02-00169<br />

05-02-00170<br />

05-02-00171<br />

05-02-00172<br />

05-02-00173<br />

05-02-00174<br />

NOMINAL PRESSURE PN=100BAR.WITH BUTT WELD<br />

ENDS<br />

DIN 3239 FORM D.ACC.TO DIN 2559.FACE TO FACE<br />

DIMENSION:-<br />

DIN 3202 LINE F2<br />

41<br />

= = = =<br />

GLOBE VALVE NOMINAL DIA.DN=150=176 X<br />

9.5MM.NP=100BAR<br />

WITH BUTT WELD ENDS DIN 3239 FORM D.ACC.TO DIN<br />

2559.<br />

1<br />

FACE TO FACE DIMENSION:-3202 LINE F2<br />

DIN 3202 LINE F2<br />

= = = =<br />

GLOBE VALVE DN=200=228 X 11.5MM.NP=100BAR WITH<br />

BUTT<br />

WELD ENDS DIN 3239 FORM D.ACC.TO DIN 2559. FACE<br />

TO<br />

FACE DIMENSION:-DIN 3202 LINE F2<br />

Y-TYPE GLOBE VALVE DN=200=228 X<br />

11.5MM.NP=100BAR<br />

WITH BUTT WELD ENDS DIN 3239 FORM D.ACC.TO DIN<br />

2559.<br />

FACE TO FACE DIMENSION:-DIN 3202 LINE F2<br />

CHECK VALVE Y-TYPE ND =200, NP=100BAR.WITH<br />

BUTT WELD<br />

END DIN 3239 FORM D.ACC.TO DIN 2559.BEGINNING<br />

SIDE<br />

NP 100 SMOOTH FINISH ONE SIDE FLANGE END.<br />

3<br />

= = = =<br />

4<br />

= = = =<br />

2<br />

= = = =<br />

CHECK VALVE (NRV) ND=50MM, PN=100.WITH BUTT<br />

WELD ENDS<br />

1<br />

ACC TO DIN 2559 = = = =<br />

CHECK VALVE (NRV) ND=80MM , PN=100BAR<br />

.FLANGED<br />

=<br />

CHECK VALVE (NRV) STRAIGHT TYPE<br />

ND=100MM,PN=100<br />

ACC TO DIN 2559 =<br />

THREE WAY VALVE (MIXING COCK)<br />

ND=150MM,PN=100BAR<br />

1 = = =<br />

3 = = =<br />

1

05-02-00175<br />

05-02-00176<br />

05-02-00177<br />

05-02-00178<br />

05-02-00179<br />

05-02-00180<br />

05-02-00181<br />

05-02-00182<br />

05-02-00183<br />

05-02-00184<br />

WITH BUTT WELD ENDS DIN 3239 FORM D ACC.TO DIN<br />

2559<br />

FACE TO FACE DIA.DIN =3202 LINE F2<br />

42<br />

= = = =<br />

THREE WAY VALVE (MIXING COCK)<br />

ND=200MM,PN=100BAR<br />

2<br />

WITH BUTT WELD ENDS DIN 2559 FACE TO FACE<br />

DIA.DIN 3202 LINE F2<br />

= = = =<br />

GLOBE VALVE DN=15,PN=64 BAR.WITH BUTT WELD<br />

ENDS<br />

3<br />

DIN 2559. FACE TO FACE DIA.DIN 3202 = = = =<br />

GLOBE VALVE DN=15,PN=16 BAR.FLANGED END ,TO PN<br />

16<br />

3<br />

FACE OF END FLANG RF FACE TO FACE DIA..DIN 3202 = = = =<br />

GLOBE VALVE DN=25MM,PN=40 WITH BUTT WELD<br />

ENDS DIN<br />

1<br />

2559.FACE TO FACE DIA.DIN 3202 = = = =<br />

GLOBE VALVE DN=50MM,PN=16 BAR,END FLANGS TO<br />

16 BAR<br />

2<br />

= = = =<br />

GLOBE VALVE DN=80MM,PN=100BAR,FLANGED ENDS<br />

TO<br />

2<br />

100BAR.FACE TO FACE LENGTH L=380MM. = = = =<br />

CHECK VALVE ND 80MM.PN=100 BAR.FLANGED ENDS<br />

TO<br />

1<br />

PN=100,L=380MM = = = =<br />

GLOBE VALVE DN=200MM=228 X 11.5,PN=100BAR.ONE<br />

END<br />

1<br />

WITH BUTT WELD TO DIN 2559.ANOTHER END WITH<br />

FLANGE<br />

=<br />

DRILLED TO PN=100 BAR.FACE TO FACE L=650MM = = =<br />

GLOBE VALVE FOR STEAM ND=15MM=1/2" PN=16BAR<br />

FLANGED<br />

1<br />

DRILLED PN 16. = = = =<br />

GLOBE VALVE FOR STEAM ND=20MM=3/4" PN=16BAR<br />

FLANGED<br />

200

DRILLED PN 16. = = =<br />

=<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00185 1.2KW ,980 R.P.M ,220/380V DELTA/STAR ,3.6/2.1 A<br />

VIBRATOR<br />

ALKAIM FERTELIZER 3 INCREASE ROUND AS<br />

MOTOR HAVING SHAFT FRAM TWO SIDES WITH COMPLEX CAPACITY POSSIBLE<br />

BALANCING WEIGHT<br />

TYPE :CS260-6,B3 MOUNTING IP65. OF<br />

FERLTILIZER<br />

PRODUCTION<br />

05-02-00186 4KW ,980 R.P.M ,220/380V ,DELTA/STAR<br />

,13/7.5A,VIBRATOR<br />

2<br />

MOTOR HAVING SHAFT FRAM TWO SIDES WITH<br />

BALANCING WEIGHT<br />

TYPE :FS800-6 ,B3 MOUNTING IP65.<br />

= = = =<br />

05-02-00187 1.5KW ,3000 R.P.M ,V1 MOUNTING ,DELTA/STAR<br />

220/380V,5-7/3-3A,<br />

1<br />

TYPE MT90S24F115-2 ,IP55 = = = =<br />

05-02-00188 4.2KW ,1500 R.P.M DRUM MOTOR,380V,TYPE: R90DT-<br />

112M4 IP55<br />

= 2 = = =<br />

05-02-00189 5.5KW ,1500 R.P.M ,B3,380V,TYPE: D 132S, IP55<br />

=<br />

2 = = =<br />

05-02-00190 15KW,1500 R.P.M,FRAME V1/160L,TYPE:1LA3 166-4AA4-<br />

2,380V,IP55<br />

=<br />

2 = = =<br />

05-05-00191 7.4KW,1500/39 R.P.M DRUM<br />

MOTOR,380V/660V,TYPE:JOKI65N 17.5/10A,IP55<br />

2<br />

IP55 = = = =<br />

05-02-00192 18.5KW,1000 R.P.M,FRAME B3/180L,TYPE:1LA4 186, IP55<br />

=<br />

1 = = =<br />

05-02-00193 18.5KW,1500 R.P.M,B3,380V,TYPE:BF5-160L62, IP55 = 3<br />

= = =<br />

05-02-00194 22KW,1500 R.P.M,B3,380V,TYPE: FA180LX34<br />

= 2 = = =<br />

05-02-00195 22KW,1500 R.P.M,B3,SLIP RING MOTOR<br />

,220/380V,DELTA/STAR<br />

TYPE FB200LV/4 IP55<br />

= 1 = = =<br />

05-02-00196 * 60/14.5KW,1475/730 R.P.M,FRAME B3/280 S,380V, = 2<br />

TYPE: AK1-280S2/44,IP55 STAR/STAR = = =<br />

* amended 29 March 2000<br />

43

05-02-00197 110KW,1500 R.P.M,FRAME B3/280M,380V,S.N:H717L, IP55 = 2<br />

= = =<br />

05-02-00198 0.75KW,1500<br />

= 5 = = =<br />

R.P.M,B3,DELTA/STAR,220/380V,3.6/2.1A,IP55<br />

= = =<br />

05-02-00199 150KW,1500 R.P.M,B3,380V,FRAME D315M,IP55<br />

1 = = =<br />

= = = =<br />

05-02-00200 75KW,1500 R.P.M,B3,220/380 DELTA/STAR SLIP-RING<br />

,S.N:15392/1<br />

= 1 = = =<br />

= = =<br />

05-02-00201 132KW,B3,380V DELTA CONNEC.1475<br />

R.P.M,TYPE:FA315M4 ,IP55<br />

1 = = =<br />

= = = =<br />

05-02-00202 22KW,380V,B3/5,1460 R.P.M,TYPE:FA180L4 ,IP55<br />

= 1 = = =<br />

= = =<br />

05-02-00203 7.5KW,380V,1445 R.P.M,TYPE:FA132M/4 ,B3,IP55<br />

1 = = =<br />

= = = =<br />

05-02-00204 160KW,380V,1480 R.P.M,B3,TYPE:FA335L/4 ,IP55<br />

1 = = =<br />

= = = =<br />

05-02-00205 4KW,380V,B3,2850 R.P.M,IN=8.7 AMP = 1 = = =<br />

05-02-00206 DC MOTOR,72KW,MAKE : SIEMENS<br />

ARMATURE VOLTAGE : 440VMAX,DC FIELD<br />

VOLTAGE:310V,<br />

ADJUSTABLE SPEED 1000 R.P.M,V1,IP55,WITH TACHO<br />

GENERATOR , AND WITH FLANGED.<br />

TYPE : GF315-M4.1<br />

NO.124939/40<br />

SCHALTBILD : MSB4-474-09<br />

INSULATION CLASS : F<br />

SPEED VARIABLE :300-1000 R.P.M<br />

DRIVEN EQUIPMENT : SLURRY TO FILTER PUMP<br />

COUPLING : DIRECT<br />

SERVICE CONDITION :50C DUTY 24 HR<br />

STARTING METHOD : FROM THYRISTOR UNIT<br />

COLLING SYSTEM : AIR<br />

= 1 = = =<br />

05-02-00207 TO REHABILIATE TO ALL YEAR AS SOON<br />

TRANSMISSION SHAFT,TURBOFLEX. UTILITY PLANT 3 SET INCREASE ROUND AS<br />

TYPE : GC/CTF 530-LENGTH 2250MM TO BE USED AS RAW CAPACITY POSSIBLE<br />

MARERIAL FOR OF<br />

SHIMS 180 X 180 X0.3 MM PRODUCING 420 EA UTILITY<br />

SPRING STEEL PHOSPHATE FIRTILIZER PLANT<br />

PLUMMER BLOCK SKFN SNA519TA 3 SET<br />

44

BOLT + NUTS+ BOUSH 150 EA<br />

GEAR REDUCERS WITH SHAFT 3 EA<br />

SPEED REDUCTION 11/146<br />

TYPE: HAUSEN NH24 BNR<br />

OIL BATH<br />

FANS TYPE HELICOIDAL 1SET=3EA<br />

HOOF BLADS 3<br />

DIAMETER 9.9M<br />

SPEED 134 R.P.M<br />

POWER ABSORBED & AT MOTOR SHAFT<br />

INDIVIDUAL 195 KW<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />

05-02-00208 CARBON BRICKS-EQUIVELENT TO DIDIER-NERACID-Z PHOSPHORIC ACID PLANT INCREASE ROUND AS<br />

CHIEMICAL ANALYSIS:- TO BE USED AS RAW CAPACITY POSSIBLE<br />

PITCH COKE ; 92%-94% MARERIAL FOR OF<br />

ASES : 6%-8% PRODUCING PHOSPHORIC<br />

PHOSPHATE FIRTILIZER ACID PLANT<br />

PHYSICAL PROPERTIES:-<br />

BULK DENSITY :- 1.45 G/CM3<br />

POROSITY :-

SHAPE NO.8 = = 26 EA<br />

SHAPE NO.9 = = 215 EA<br />

SHAPE NO.10 DRAWING NO 2 70 EA<br />

SHAPE NO.11 DRAWING NO 2 170 EA<br />

SHAPE NO.12 DRAWING NO 2 320 EA<br />

RESACID - CL<br />

TWO COMPONENT BEDDING AND JOINTING CMENT<br />

COLD SETTING LIQUID PHENOLIC RESIN USED FOR<br />

BEDDING<br />

AND JOINTING FOR ACID RESISTANT BRICK WORK<br />

AND TILES<br />

IN PHOSPHORIC ACID PLANT P2O5 54%<br />

SERVICE TEMPERATURE 170C-180C DEG.<br />

COMPONENTS AND PACKING:-<br />

RESACID-CL SOLUTION,ASPECT,BROWN LIQUID<br />

PACKING IN DRUMS<br />

OR CANS<br />

RESACID-CL POWDER,ASPECT, BLACK GRANUIAL<br />

POWDER PACKING<br />

IN BAGS.<br />

46<br />

600KG<br />

1000KG<br />

ANCORLUTE P.E 500KG<br />

FLEXIBLE PITCH EPOXY TYPE EXPANSION JOINT FOR<br />

PHOSPHORIC<br />

ACID PLANT P2O5 54% SERVICE TEMPERATURE 170C-<br />

180C DEG.<br />

PACKING DESCRIPTION<br />

ANCORLUTE P.E IS SUPPLIED IN A 4KG KIT AND AS<br />

FOLLOW:<br />

PART 1 CONTAINING HARDENER IN 5 LITRE METAL<br />

CONTAINER<br />

PART 2 LIQUID RESIN CONTAINED IN A PLASTIC<br />

CONTAINER<br />

THE FILLER IN A POLYTHENE BAG.<br />

STELLALIT VF 60 2000KG<br />

BITUMEN:- 40%<br />

BARITE:- 40%<br />

CARBON POWDER:- 20%<br />

STELLALIT VF60 BEDDING COMPOUNDS FOR ACID<br />

RESISTANT<br />

BRICKS AND TILES OF PHOSPHORIC ACID PLANT,P2O5<br />

54%

SERVICE TEMPERATURE 170C-180C DEG.<br />

PACKING:-<br />

----------<br />

STELLALIT VF60 ASPECT,GREY GRANULAR POWDER<br />

PACKING IN<br />

BAGS.<br />

STELLALIT VARNISH ASPECT BLACK LIQUID PACKING<br />

IN DRUMS<br />

OR CANS<br />

STELLALIT V60 2000KG<br />

BITUMEN:- 30%<br />

BARITE:- 40%<br />

CARBON POWDER:- 30%<br />

BEDDING COMPOUNDS FOR ACID RESISTANT BRICKS<br />

AND TILES OF<br />

PHOSPHORIC ACID PLANT P2O5 54%<br />

SERVICE TEMPERATURE 170C-180C DEG.<br />

PACKING:-<br />

----------<br />

STELLALIT V60 ASPECT,GREY GRANULAR POWDER<br />

PACKING IN BAGS<br />

STELLALIT VARNISH ASPECT BLACK LIQUID PACKING<br />

IN DRUMS<br />

TO REHABILIATE TO ALL YEAR AS SOON<br />