Professional Documents

Culture Documents

APQP Internal Assessment Checklist: Management

Uploaded by

Kapil Harchekar0 ratings0% found this document useful (0 votes)

358 views3 pagesThis document is an internal assessment checklist for evaluating a company's Advanced Product Quality Planning (APQP) processes. It contains 23 questions across 3 pages assessing whether the company has defined project planning personnel and their training, utilizes system-level project plans with key elements, holds regular project review meetings, involves manufacturing engineering appropriately, maintains open issue tracking, and incorporates quality planning and risk assessment tools like FMEAs into their new product development process. The checklist is intended to be completed during an APQP internal audit.

Original Description:

Original Title

APQP-Checklist-Project-Planning

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is an internal assessment checklist for evaluating a company's Advanced Product Quality Planning (APQP) processes. It contains 23 questions across 3 pages assessing whether the company has defined project planning personnel and their training, utilizes system-level project plans with key elements, holds regular project review meetings, involves manufacturing engineering appropriately, maintains open issue tracking, and incorporates quality planning and risk assessment tools like FMEAs into their new product development process. The checklist is intended to be completed during an APQP internal audit.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

358 views3 pagesAPQP Internal Assessment Checklist: Management

Uploaded by

Kapil HarchekarThis document is an internal assessment checklist for evaluating a company's Advanced Product Quality Planning (APQP) processes. It contains 23 questions across 3 pages assessing whether the company has defined project planning personnel and their training, utilizes system-level project plans with key elements, holds regular project review meetings, involves manufacturing engineering appropriately, maintains open issue tracking, and incorporates quality planning and risk assessment tools like FMEAs into their new product development process. The checklist is intended to be completed during an APQP internal audit.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

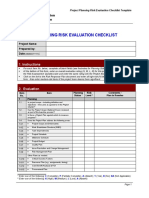

APQP Internal Assessment Checklist

Customer: Audit Date:

Audit Type: APQP Internal Assessment Auditor:

APQP Phase / Support Process: Project Planning / Project / Platform:

Management Department:

Checklist: Page 1 of 3 Area :

Author: Quality-One Date Created:

Requirements 1 2 3 4 5 Notes

1. Are there personnel defined with the responsibility of

Project Planning and Management of Projects?

2. Is adequate training or skill available to Project

Planning and Management personnel?

Deliverables may include: skill assessments, training

plans.

Skills and Training may include: Project Management

Techniques, Timing / Critical Path Planning, Team

Building, Budgeting

3. Are System Level Project Plans utilized? Do plans

consist of the following:

o Team identification for major product

systems

o Definition of major milestone timing

o Identification of System level risk

assessment review criteria with review

schedules

o Identification of analytical studies and

testing with timing

o Training Plans

o Deliverable Identification (Deliverable

Matrix)

o Responsibilities defined for each deliverable

(Responsibility Matrix)

o System Level Design Verification Plans

o Include a feedback and Corrective Action

4. Do project teams meet on a regular basis to review

project timing, targets/objectives versus status, risk

and opportunities, roadblocks, and open design and

manufacturing issues?

Deliverables may include: meeting minutes, open issue

reporting, etc.

5. Are Manufacturing Engineering personnel:

o Involved in all phases of the design

development?

o Included in all management design reviews?

o Included on all Risk Assessments sign-offs?

6. Does the project team maintain an Open Issues

record, which identifies: Item Description, Actions,

Status, Priority, Required and Actual Completion

Dates, and Responsibilities?

7. Are risk and opportunity lists maintained?

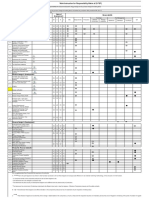

APQP Internal Assessment Checklist

Customer: Audit Date:

Audit Type: APQP Internal Assessment Auditor:

APQP Phase / Support Process: Project Planning / Project / Platform:

Management Department:

Checklist: Page 2 of 3 Area :

Author: Quality-One Date Created:

Requirements 1 2 3 4 5 Notes

8. Is the project Manager accountable for

communication between the product and

manufacturing team members?

9. Does the project team participate in early stages to

support cost assumptions associated with quality,

warranty, and customer satisfaction?

10. Does the project team utilize metrics to monitor it’s

performance?

11. Are suppliers included in project team meetings?

12. Is there a documented Product Development

Process? Is the Process complete and methodical? Is

it published and instituted at the beginning of each

project and is it being followed? Does the process

continue through launch, including Product

Development Launch support?

13. Does the Product Development Process include:

o Regular design reviews?

o Reliability reviews?

o Risk Assessments to evaluate deliverables,

outstanding issues with recovery plans?

o Senior Management sign-off’s at key

milestones?

o Manufacturing Feasibility?

o Identification and addressing of significant and

critical characteristics?

o Prototype development and testing time-lines

with prove out evaluation time?

o Manufacturing Engineering (ME) responsibilities

and key deliverables?

o Product Development approval of manufacturing

process plans and control plans?

o Consideration and sign-off of serviceability?

14. Does Management provide visible leadership of the

Quality Planning effort?

15. Are Design and Process FMEA development and

application a documented part of the Product

Development process which include:

o Sign-off approval from Product Development

o Development and use of Generic FMEA’s for

each commodity or system

o A library of FMEA’s which is maintained and

which can be easily retrieved

APQP Internal Assessment Checklist

Customer: Audit Date:

Audit Type: APQP Internal Assessment Auditor:

APQP Phase / Support Process: Project Planning / Project / Platform:

Management Department:

Checklist: Page 3 of 3 Area :

Author: Quality-One Date Created:

Requirements 1 2 3 4 5 Notes

16. Are test plans developed for each design level and

formalized in a Design Verification Plan? Are they

reviewed and updated to meet all customer

expectations as part of the Product Development

Process? Do Test Plans originate from DFMEA’s

17. Are Control Plans utilized for Prototype, Pre-Launch

(Pilot), and Production?

18. Do all high-risk failure modes identified on the FMEA’s

have prevention methods designed into the respective

processes?

19.

20.

21.

22.

23.

Auditor Additional Notes:

You might also like

- Apqp MiniDocument14 pagesApqp MiniSudhagarNo ratings yet

- APQP Timing Plan TemplateDocument9 pagesAPQP Timing Plan TemplatemuthuselvanNo ratings yet

- Productr Process Quality ChecklistDocument8 pagesProductr Process Quality ChecklistSenthil_KNo ratings yet

- Apqp TrackerDocument17 pagesApqp TrackerKrunal PandyaNo ratings yet

- Unlocked - Supplier Audit Checklist ExampleDocument68 pagesUnlocked - Supplier Audit Checklist ExampleVi KraNo ratings yet

- Project Planning Risk Evaluation Checklist: 1. InstructionsDocument6 pagesProject Planning Risk Evaluation Checklist: 1. InstructionsnsadnanNo ratings yet

- APQP MatrixDocument4 pagesAPQP MatrixVikas KashyapNo ratings yet

- Supplier Quality System Audit Checklist - Elbit Systems of AmericaDocument8 pagesSupplier Quality System Audit Checklist - Elbit Systems of Americaamirkhakzad498No ratings yet

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- Iso IATF 16949 Upgrade Planner and Delta ChecklistDocument14 pagesIso IATF 16949 Upgrade Planner and Delta ChecklistHomero Januncio100% (1)

- PPAP FundamentalsDocument21 pagesPPAP FundamentalsRajdeep SinghNo ratings yet

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- Operations Management, Compelte Slides, Supply Chain ManagementDocument919 pagesOperations Management, Compelte Slides, Supply Chain ManagementSadiq Sagheer100% (12)

- Supplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberDocument1 pageSupplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberBESNo ratings yet

- Apqp PDFDocument2 pagesApqp PDFChandru JattiNo ratings yet

- Procedure For NPD HandoverDocument1 pageProcedure For NPD HandoverTushar Wagh100% (1)

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- Issued Action Item Category Root Cause Resp. Target Action Taken Status Record of EffectivenessDocument4 pagesIssued Action Item Category Root Cause Resp. Target Action Taken Status Record of EffectivenessBharathNo ratings yet

- Quality Control: A Brief Introduction About QUALITY SYSTEMS in M/s. AADHIRA CNC Product PVT LTDDocument25 pagesQuality Control: A Brief Introduction About QUALITY SYSTEMS in M/s. AADHIRA CNC Product PVT LTDsridharanNo ratings yet

- CQI19 FormsDocument7 pagesCQI19 FormsEmre TekinNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Planning Risk Evaluation ChecklistDocument6 pagesPlanning Risk Evaluation ChecklistHussain ElarabiNo ratings yet

- Introduction To Advanced Product Quality PlanningDocument14 pagesIntroduction To Advanced Product Quality PlanningAbraham GuerraNo ratings yet

- What Is Apqp & PpapDocument5 pagesWhat Is Apqp & PpapprafakeNo ratings yet

- Cost of Poor Quality COPQ CalculatorDocument2 pagesCost of Poor Quality COPQ Calculatorrgrao85No ratings yet

- Copy of APQP Check List - Ford (Blank)Document9 pagesCopy of APQP Check List - Ford (Blank)feiraluremaNo ratings yet

- Enquiry No: Part Name: Customer: Part No.:: S.No. Feasibility Conceren Yes No Remark'sDocument2 pagesEnquiry No: Part Name: Customer: Part No.:: S.No. Feasibility Conceren Yes No Remark'saslamNo ratings yet

- 7.2.5 APQP Phase 2 Checklist Dec 2013Document21 pages7.2.5 APQP Phase 2 Checklist Dec 2013Mani Rathinam RajamaniNo ratings yet

- Responsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsDocument4 pagesResponsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsAL BARAKAH GRAINS100% (1)

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- Design and Development ISODocument7 pagesDesign and Development ISObrenda smith100% (1)

- 7.5 - Types of Cost, Revenue and Profit, Short-Run and Long-Run Production (S)Document150 pages7.5 - Types of Cost, Revenue and Profit, Short-Run and Long-Run Production (S)l PLAY GAMESNo ratings yet

- GS-0002D, Design FMEADocument26 pagesGS-0002D, Design FMEAmesa142100% (1)

- List of QMS Process PDFDocument2 pagesList of QMS Process PDFkarthikkandaNo ratings yet

- The 5 Core ToolDocument17 pagesThe 5 Core ToolRajesh GhoshNo ratings yet

- Quality Planning ProcessDocument36 pagesQuality Planning ProcessBhaswati PandaNo ratings yet

- 9001 Audit Checklist - Quality Planning and DesignDocument14 pages9001 Audit Checklist - Quality Planning and DesignAmer RahmahNo ratings yet

- Apqp & PpapDocument63 pagesApqp & Ppapjd4u100% (1)

- APQP Internal Assessment Checklist: Development PhaseDocument3 pagesAPQP Internal Assessment Checklist: Development PhaseRandhir Kanwar100% (1)

- Process Turtle Diagram - Assignment EngineeringDocument1 pageProcess Turtle Diagram - Assignment EngineeringShara Jane DelmoNo ratings yet

- Project Review ChecklistDocument21 pagesProject Review Checklistmsaad2100% (2)

- APQP Checklist Combined Rev 5 - 2Document17 pagesAPQP Checklist Combined Rev 5 - 2Neil SarkarNo ratings yet

- What Is APQPDocument2 pagesWhat Is APQPshanramaNo ratings yet

- APQPDocument18 pagesAPQPMy Dad My World100% (1)

- Test Bank For Accounting Information Systems Hall 8th EditionDocument23 pagesTest Bank For Accounting Information Systems Hall 8th Editioncynthiaacostabsjeiaxmqk100% (38)

- QAP 4.0 - Design Control - Rev B (G) PDFDocument13 pagesQAP 4.0 - Design Control - Rev B (G) PDFPrakash TiwariNo ratings yet

- Guidelines For Making PFMEA - A PDFDocument10 pagesGuidelines For Making PFMEA - A PDFKalimuthu PsNo ratings yet

- Control PlansDocument12 pagesControl Plansaman_ranhotra67% (6)

- ISO 9001 Implementation PlanDocument2 pagesISO 9001 Implementation PlanbevarsiNo ratings yet

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocument2 pagesISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- Nykaa BRM Report PDFDocument23 pagesNykaa BRM Report PDFKANIKA SACHANNo ratings yet

- Global Supplier Quality 15 Key ProcessesDocument1 pageGlobal Supplier Quality 15 Key ProcessesalexrferreiraNo ratings yet

- 7 FmeaDocument25 pages7 Fmeaprx4177No ratings yet

- Entrep Summative 1 & 2Document4 pagesEntrep Summative 1 & 2Vengie PamanNo ratings yet

- Blast FurnaceDocument32 pagesBlast FurnaceShailesh SharmaNo ratings yet

- Quality Management Plan (Large Projects) : Template and GuideDocument17 pagesQuality Management Plan (Large Projects) : Template and Guidesreekanthsasidharan100% (1)

- Apqp Ppap TrainingDocument2 pagesApqp Ppap TrainingAnkur DhirNo ratings yet

- APQP Checklist Design PDFDocument3 pagesAPQP Checklist Design PDFShiva SNo ratings yet

- ControlTek - New Product Introduction Flow ChartDocument1 pageControlTek - New Product Introduction Flow ChartControl_TekNo ratings yet

- APQP OS Procedure ExampleDocument8 pagesAPQP OS Procedure Exampleali qaNo ratings yet

- Project Quality ManagementDocument53 pagesProject Quality Managementatularvin231849168No ratings yet

- Check List For FMEA Evaluation SupplierDocument7 pagesCheck List For FMEA Evaluation SupplierNavnath TamhaneNo ratings yet

- Quality Assurance Plan DocumentDocument6 pagesQuality Assurance Plan Documentachari_swapnil100% (1)

- Excel Tool Prozessaudit VDA 6.3 2010 enDocument29 pagesExcel Tool Prozessaudit VDA 6.3 2010 enHokuto No KenNo ratings yet

- Project 4: Section A Develop Quality Management Plan, Process Improvement Plan, Quality Metrics and Quality ChecklistDocument7 pagesProject 4: Section A Develop Quality Management Plan, Process Improvement Plan, Quality Metrics and Quality ChecklistPNG networksNo ratings yet

- Software Quality Engineering BS (SE) - VI: Dr. Assad AbbasDocument26 pagesSoftware Quality Engineering BS (SE) - VI: Dr. Assad AbbasAssad AbbasNo ratings yet

- Astm A788 (M) - 13Document14 pagesAstm A788 (M) - 13Kapil HarchekarNo ratings yet

- Astm A855 - 03 R2014Document5 pagesAstm A855 - 03 R2014Kapil HarchekarNo ratings yet

- Astm A563-15Document9 pagesAstm A563-15Kapil HarchekarNo ratings yet

- Astm B633 - 19Document8 pagesAstm B633 - 19Kapil HarchekarNo ratings yet

- Astm F3393 - 20Document6 pagesAstm F3393 - 20Kapil Harchekar100% (1)

- Astm B209M - 14Document26 pagesAstm B209M - 14Kapil HarchekarNo ratings yet

- 8D Report For Eye Bolt Internal DiaDocument1 page8D Report For Eye Bolt Internal DiaKapil HarchekarNo ratings yet

- 8D Report For Eye Bolt Thickness ProblemDocument1 page8D Report For Eye Bolt Thickness ProblemKapil HarchekarNo ratings yet

- Asme B1.1-2019Document194 pagesAsme B1.1-2019Kapil Harchekar100% (1)

- 8D Report For Eye Bolt Dim 0.625Document1 page8D Report For Eye Bolt Dim 0.625Kapil HarchekarNo ratings yet

- Astm A536 - 84 R2009Document6 pagesAstm A536 - 84 R2009Kapil HarchekarNo ratings yet

- Midterm Activity 1: (For Asynchronous) : I. Multiple ChoiceDocument6 pagesMidterm Activity 1: (For Asynchronous) : I. Multiple ChoiceArven FrancoNo ratings yet

- Bossard Asia Pacific Can It Make Its CRM Strategy Work?: Presented byDocument24 pagesBossard Asia Pacific Can It Make Its CRM Strategy Work?: Presented byprabirjaisNo ratings yet

- Akanksha Performance Appraisal (1) Project ReportDocument47 pagesAkanksha Performance Appraisal (1) Project Reportabhaskant100% (1)

- Download pdf Business Driven Technology Eighth Edition Paige Baltzan ebook full chapterDocument53 pagesDownload pdf Business Driven Technology Eighth Edition Paige Baltzan ebook full chapterrosie.reaves902100% (1)

- 5 Forces WorksheetDocument5 pages5 Forces WorksheeteleanorattuquayeNo ratings yet

- PP Qsu PR 0002 r0 Scar Procedure PDFDocument8 pagesPP Qsu PR 0002 r0 Scar Procedure PDFHoàng Việt NguyễnNo ratings yet

- Allocation of Support Activity Costs and Joint CostsDocument15 pagesAllocation of Support Activity Costs and Joint CostsMark CoachNo ratings yet

- Eleanor Cronin's ResumeDocument2 pagesEleanor Cronin's ResumejugglingjonNo ratings yet

- Defense QuestionsDocument4 pagesDefense QuestionsWilliam RañosaNo ratings yet

- Oracle Transportation Management: Key CapabilitiesDocument8 pagesOracle Transportation Management: Key CapabilitiesPardha Saradhi JanyavulaNo ratings yet

- Advertising ManagementDocument16 pagesAdvertising Managementnishant ranjanNo ratings yet

- Sap Pi Idea & AutomationDocument5 pagesSap Pi Idea & AutomationSuruchi BhowmikNo ratings yet

- Product Roadmap Template LightDocument8 pagesProduct Roadmap Template LightDaniel MachadoNo ratings yet

- Business Plan For FreshwearDocument4 pagesBusiness Plan For FreshwearUt TAm ThAgunnaNo ratings yet

- English Cual - ConDocument5 pagesEnglish Cual - ConWAINTSNo ratings yet

- JewllaryDocument47 pagesJewllaryfreak badNo ratings yet

- UntitledDocument3 pagesUntitledBhebz Erin Mae0% (1)

- Activity Based ManagementDocument62 pagesActivity Based ManagementJoswa CaxtonNo ratings yet

- Network Design ProblemsDocument5 pagesNetwork Design ProblemsAnkit GoyalNo ratings yet

- Incoterms 2020Document3 pagesIncoterms 2020Vladyslav KalchevskiiNo ratings yet

- Information Technology For Managers 2nd Edition Reynolds Test Bank DownloadDocument23 pagesInformation Technology For Managers 2nd Edition Reynolds Test Bank Downloadodiletoanhyx2p3100% (23)

- Social Studies ReviewerDocument2 pagesSocial Studies ReviewerVaughn Siegfried FuertezNo ratings yet

- CA4101 Lecture 3 Business Architecture - BPMNDocument40 pagesCA4101 Lecture 3 Business Architecture - BPMNManoj VenkatNo ratings yet

- U7 - Lesson 2Document33 pagesU7 - Lesson 2Alejandra HuaytaNo ratings yet