Professional Documents

Culture Documents

Ansi Awwa C150 A21 PDF

Uploaded by

bladimyr0 ratings0% found this document useful (0 votes)

505 views58 pagesOriginal Title

ANSI AWWA C150 A21.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

505 views58 pagesAnsi Awwa C150 A21 PDF

Uploaded by

bladimyrCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 58

American Water Works Association

ANSIAWWA C150/A21.50-96

(Revision of ANSVAWWA C150/A21.50-91)

a

AMERICAN NATIONAL STANDARD

FOR

THICKNESS DESIGN OF

DUCTILE-IRON PIPE

Gn RATIONAL)

|STANDARD}

Secretariats

AMERICAN GAS ASSOCIATION

AMERICAN WATER WORKS ASSOCIATION

Effective date: Dee. 1, 1996

First edition approved by AWWA Board of Directors June 23, 1965

‘This edition approved Feb 4, 1996.

Approved by American National Standards Institute Sept 6, 1996

AMERICAN WATER WORKS ASSOCIATION

6666 West Quincy Avenue, Denver, Colorado 80235

AWWA Standard

‘This document is an American Water Works Association (AWWA) standard It is not a specification

AWWA standards describe minimum requirements and do not contain all of the engineering and

administrative information normally contained in specifications The AWWA standards usually contain

options that must be evaluated by the user of the standard Until each optional feature is specified

by the user, the product or service is not fully defined AWWA publication of e standard does not

constitute endorsement of any product or product type, nor dos AWWA test, certify, or approve any

product The use of AWWA standards is entirely voluntary AWWA standards are intended to represent a

consensus of the water supply industry that the product described will provide satisfactory service

When AWWA revises or withdraws this standard, an official notice of action will be placed on the

first page of the classified advertising section of Journal AWWA The action becomes effective on the

first day of the month following the month of Journal AWWA publication of the official notice

American National Standard

An American National Standard implies a consensus of those substantially concerned with its scope

and provisions An American National Standard is intended as a guide to aid the manufacturer, the

consumer, and the general public. The existence of an American National Standard does not in any

respect preclude dnyone, whether that person has approved the standard or not, from manufaeturing,

marketing, purchasing, or using products, processes, or procedures not conforming to the standard

‘American National Standards are subject to periodic review, and users are cautioned to obtain the

latest editions Producers of goods made in conformity with an American National Standard are

encouraged to state on their own responsibility in advertising and promotional materials or on tags

or labels that the goods are produced in conformity with particular American National Standards

Caution Nomics: The American National Standards Institute (ANSI) approval date on the front

cover of this standard indicates completion of the ANSI approval process ‘This American National

Standard may be revised or withdrawn at any time ANSI procedures require that action be taken

to reaffirm, revise, or withdraw this standard no later than five years from the date of publication

Purchasers of American National Standards may recoive current information on all standards by

calling or writing the American National Standards Institue, 11 W 4nd St , New York, NY 10036;

(212) 642-4900.

Copyright © 1996 by American Water Works Association

Printed in USA

Committee Personnel

Subcommittee No 1, Pipe, which reviewed this standard, had the following

personnel at the time:

Philip A Selig, Chair

‘Troy F Stroud, Vice-Chair

Consumer Members

E:T Knudsen

J.D Larson

General Interest Members

KM. Bell Harold Kennedy

MG. Hoover JE. McClelland

MB Horsley WH. Smith

Producer Members

DR. Charko CM Luna

David Cleveland ‘TJ. Muntz,

LR. Dunn PA. Selig

Steven Farkas "DF Stroud

AWWA Standards Committee A21, Ductile-Iron Pipe and Fittings, which

reviewed and approved this standard, had the following personnel at the time of

approval:

Edward T Knudsen, Chair

Philip A. Selig, Vice-Chair

John H. Wilber, Secretary

Consumer Members a

Ron Goold, Johnson County Water District, Mission, Kan. cawwa)

RE, Hargraves, IndianaAmerican Water Company, Muncie, Ind (awwa)

ELT. Knudsen Jr, City of St Petersburg, St Petersburg, Fla. (awwa)

G.L. Meyer, City of Sioux Falls, Sioux Falls, .D. cawwa)

‘TC. Moreno, Bexar Metropolitan Water District, San Antonio, Texas (AWWA)

PJ. Schreiber, San Jose Water Company, San Jose, Calif (AWWA)

CR Schwenker, Fairfax County Water Authority, Merrifield, Va. (AWWA)

GA Seibel, Tualatin Valley Water District, Beaverton, Ore. (awwa)

AM. Tinkey, St Louis County Water Company, St. Louis, Mo. (awwa)

DL Tippin, Tampa Water Department, Tampa, Fla. cawwa)

General Interest Members

KM, Bell, Underwriters Laboratories Inc., Northbrook, Il. (wl)

‘Vance Forsgren, Forsgren Associates Ine , Rexburg, Idaho cawwa)

Joseph Goss," Whitman & Howard Corporation, Wellesley, Mass, (NEWWA)

KW Henderson, Malcolm Pirnie Inc , White Plains, NX.” (AWWA)

MG Hoover, HYA Consulting Engineers, Pasadena, Calif cawwa)

MB Horsley, Black & Veatch, Overland Park, Kan cawwa)

WB Jeffcoat, CH2M Hill, Montgomery, Ala (AWWA)

Harold Kennedy Jr, Harold Kennedy & Associates, Eastland, Texas (awwa)

JE, McClelland, Council Liaison, McClelland Consulting Engineers,

Little Rock, Ark (awwa)

E,W. Misichko," Underwriters Laboratories Inc., Northbrook, Ill. (UL)

RL, Scarpa, Metcalf & Eddy Inc , Coral Gables, Fla. cawwa)

WH Smith, Flora, Hl. (AWWA)

J.H. Wilber,* Standards Engineer Liaison, AWWA, Denver, Colo. cawwa)

Producer Members

David Cleveland, Union Foundry Company, Anniston, Ala. (DIPRA)

Larry Dunn, US Pipe and Foundry Company, Birmingham, Ala, (DIPRA)

Steven Farkas, Griffin Pipe Products Company, Lynchburg, Va. (DIPRA)

B.C, Helton,” American Cast Iron Pipe Company, Birmingham, Ala (DIPRA)

O11. Jackson, Tyler Pipe Industries, Tyler, Texas cawwa)

CM. Luma, MeWane Cast Iron Pipe Company, Birmingham, Ala. IPRA)

PI. McGrath Jr,” US Pipe & Foundry Company, Birmingham, Ala. (DIPRA)

PL Robertson, Specification Rubber Products, Alabaster, Ala cawWwa)

PA. Selig, American Cast Iron Pipe Company, Birmingham, Ala. (DIPRA)

Dennis Shumard, EBAA Iron Inc, Eastland, Texas (AWWA)

TE Stroud, Ductile Iron Pipe Research Association, Birmingham, Ala (DIPRA)

“Alternate

Contents

AIL AWWA standards follow the general format indicated subsequently Some variations from this format may be

found in a particular standard

sec PAGE

Foreword

I Introduction.

LA Background

1B History.

IC Acceptance.

TL Special Issues .. ...

I Use of This Standard

TILA Purchaser Options

and Alternatives.

MILB Modification to Standard

IV Major Revisions.

V Comments

Standard

1 General

LL Scope. _

12 Purpose.

13 Application

2 References. 2

3 Definitions .... 2

4 Requirements

41 Procedure for Calculating

Thickness, . 2

42 Design Example for Calculating

Thickness.

4.3 Design Method =

44 — Explanation of Symbols Used in

Design Equations...

4.5 Special Thickness Classes.

spc

PAGE

Delivery

Standard Pipe Laying Conditions .. 11

Earth Loads Ps, Truck Loads Pr,

and Trench Loads Pr—psi.

Design Values for Standard

Laying Conditions

Allowances for Casting Tolerance .. 10

Reduetion Factors R for Truck

‘Load Calculations.

Nominal Thicknesses for

Standard Pressure Classes of

Ductile-Iron Pipe. ..

Surface Load Factors for Single

‘Truck on Unpaved Road...

DiameterThickness Ratios for

Laying Condition Type 1.

DiameterThickness Ratios for

Laying Condition Type 2.

Diameter—Thickness Ratios for

Laying Condition Type 3...

Diameter—Thickness Ratios for

Laying Condition Type 4...

Diameter—Thickness Ratios for

Laying Condition Type 5...

Thickness for Earth Load Plus

‘Truck Load «0»

‘Thickness for Internal Pressure .... 45

Rated Working Pressure and

‘Maximum Depth of Cover...

Special Thickness Classes of

‘Ductile-Iron Pipe.

12

“

Foreword

This foreword is for information only and is not a part of ANSI/AWWA C150/A21.50

1. Introduction

TA. Background The purpose of this standard isto provide pipeline designers

with a recommended design procedure and associated tabular data necessary to

establish the wall thickness(es) required for buried ductile-iron pipe based on the

type of pipe embedment, depths of trench cover, live load conditions, internal working

pressures, and surge conditions appropriate for the specific pipeline project Once

‘the required wall thickness(es) has been established, the ductile-iron pipe should be

specified to be manufactured in accordance with ANSI'/AWWA C151/A21.51

ANSV/AWWA C151/A21.51 contains options that must be addressed in the purchaser's

specifications in response to site-specific project requirements

Although ANSVAWWA C150/A21.50 is commonly used for designing ductile-

iron pipe for services other than water, users are also directed to ASTM A746,

Standard Specification for Ductile Iron Gravity Sewer Pipe

LB. History. American National Standards Committee A21, Cast-Iron Pipe and

Fittings, was organized in 1926 under the sponsorship of the American Gas Association

(AG.A), the American Society for Testing and Materials (ASTM), the American

Water Works Association (AWWA), and the New England Water Works Association

(NEWWA). Between 1972 and 1984, the cosecretariats were A G.A, AWWA, and

NEWWA, with AWWA serving as administrative secretariat. In 1984, the committee

became an AWWA committee with the name of American Water Works Association

Standards Committee A21 on Ductile-Iron Pipe and Fittings In 1988, NEWWA with-

drew as a separate secretariat; however, it contimues to maintain its representation

‘on the AWWA Committee A21. The committee remains cosponsored by AG.A for

gas-related activities.

‘The present scope of AWWA Committee A21 activity is the development of

standards and manuals addressing ductile-iron pressure pipe for gas, water, and

other liquids, and ductile-iron and gray-iron fittings for use with such pipe. These

standards and manuals include design, dimensions, materials, coatings, linings,

joints, accessories, and methods of inspection and testing.

‘The work of AWWA Committee A21 is conducted by subcommittees. The scope

of Subcommittee 1, Pipe, includes the periodic review of all current AZ1 standards

for pipe, the preparation of revisions and new standards when needed, as well as

other matters pertaining to pipe standards.

‘The first edition of A21.50, American National Standard for the Thickness

Design of Ductile-Iron Pipe, was issued in 1966, and revisions were issued in 1971,

1976, 1981, and 1991. The standard was reaffirmed without revision in 1986, Sub-

committee 1 reviewed the 1991 edition and submitted a proposed revision to AWWA

Standards Committee A21 in 1995.

L.C. Acceptance In May 1985, the US Environmental Protection Agency (USEPA)

entered into a cooperative agreement with a consortium led by NSF International

“American National Standards Institute, 11 W 42nd St., New York, NY 10036

tAmerican Society for Testing and Materials, 100 Barr Harbor Dr, West Conshohocken, PA

19428-2959.

(NSF) to develop voluntary third-party consensus standards and a certification pro-

gram for all direct and indirect drinking water additives. Other members of the

original consortium included the American Water Works Association Research Foun-

dation (AWWARF) and the Conference of State Health and Environmental Managers

(COSHEM) The American Water Works Association (AWWA) and the Association of

State Drinking Water Administrators (ASDWA) joined later.

In the United States, authority to regulate products for use in, or in contact,

with, drinking water rests with individual states” Local agencies may choose to

impose requirements more stringent than those required by the state To evaluate

the health effects of products and drinking water additives from such products, state

‘and local agencies may use various references, including

1 An advisory program formerly administered by USEPA, Office of Drinking

‘Water, discontinued on Apr. 7, 1990.

2, Specific policies of the state or local agency

3. Two standards developed under the direction of NSF, ANSI'/NSF! 60,

Drinking Water Treatment Chemicals—Health Effects, and ANSUNSF 61, Drinking

Water System Components—Health Effects.

4 Other references, including AWWA standards, Food Chemicals Codex, Water

Chemicals Codex,§ and other standards considered appropriate by the state or local

agency.

Various certification organizations may be involved in certifying products in

accordance with ANSIINSF 61. Individual states or local agencies have authority to

accept or accredit certification organizations within their jurisdiction Accreditation

of certification organizations may vary from jurisdiction to jurisdiction.

Appendix A, “Toxicology Review and Evaluation Procedures,” to ANS/NSF 61

does not stipulate a maximum allowable level (MAL) of a contaminant for sub-

stances not regulated by a USEPA final maximum contaminant level (MCL). The

MALs of an unspecified list of “unregulated contaminants" are based on toxicity

testing guidelines (noncarcinogens) and risk characterization methodology (carcino-

gens). Use of Appendix A procedures may not always be identical, depending on the

certifier.

AWWA C150-96 does not address additives requirements ‘Thus, users of this

standard should consult the appropriate state or local agency having jurisdiction in

order to

1. Determine additives requirements, including applicable standards

2 Determine the status of certifications by all parties offering to certify prod-

‘ucts for contact with, or treatment of, drinking water

8, Determine current information on product certification

Il. Special Issues. Currently, there are no special issues related to this

standard

"Persons in Canada, Mexico, and non-North American countries should contact the

appropriate authority having jurisdiction

tamerican National Standards Institute, 11 W 42nd St , New York, NY 10036

NSF International, 8475 Plymouth Rd , Ann Arbor, MI 48106.

SBoth publications available from National Academy of Sciences, 2102 Constitution Ave.

NW, Washington, DC 20418

vii

ILL Use of This Standard. AWWA has no responsibility for the suitability or

compatibility of the provisions of this standard to any intended application by any

user. Accordingly, each user of this standard is responsible for determining that the

standard’s provisions are suitable for and compatible with that user's intended

application .

TILA Purchaser Options and Alternatives As noted in'Sec LA of the foreword,

ANSIAWWA C151/A21 51 contains options that must be addressed in the pur-

chaser’s specifications in response to site-specific requirements for ductile-iron pipe

IIB. Modification to Standard Any modification to the provisions, definitions,

or terminology in this standard must be provided in the purchaser's specifications.

IV. Major Revisions. Major revisions made to the standard in this edition

include the following

1. The format, has been changed to AWWA standard style

2. The acceptance clause (Sec 1.C) has been revised to approved wording,

3. The truck load equation (Eq 5) and the surface load factor (Eq 6) have

been modified to allow for a correct distribution of units.

4 Table 6, Surface load factors for single truck on unpaved road, has been

changed to match the revised surface load factor equation (Eq 6)

5. ‘The statement concerning surge allowance in the hoop stress formula (See.

4.12 and Sec. 4.2.2) has heen modified to note that if anticipated surge pressures

are other than 100 psi (689 kPa), the actual anticipated pressure should be used.

V. Comments. If you have any comments or questions about this standard,

please call the AWWA Standards and Materials Development Department,

(803) 794-7711 ext. 6283, FAX (303) 795-1440, or write to the department at 6666 W.

Quiney Ave., Denver, CO 80235

‘American Water Works Association \

ANSUAWWA C150/A21.50-96

(Revision of ANSVAWWA C150/A21.50-91)

AMERICAN NATIONAL STANDARD FOR

THICKNESS DESIGN OF

DUCTILE-IRON PIPE

SECTION 1: GENERAL

Sec. 1.1 Scope

‘This standard covers the thickness design of ductile-iron pipe complying with

the requirements of ANSI'/AWWA C15V/A2151, Ductile-Iron Pipe, Centrifugally

Cast, for Water.

‘Section 4 1 outlines the design procedure and Sec. 4.2 gives a design example,

Section 4.8 explains the basis of design.

As opposed to using procedures in Sec. 4.1 or Sec 4.3, the designer may refer-

ence Tables 12 through 14 directly.

‘Table 12 lists thicknesses for standard laying conditions and certain depths of

cover.

‘Table 13 lists thicknesses for 150 psi-B50 psi (1,034 kPa-2,413 kPa)’ water

working pressure,

‘The greater thickness from Table 12 or Table 13 for given trench load ar internal

pressure should be used.

Table 14 lists working pressures find maximum depths of cover for standard

laying conditions and standard pressure classes.

‘Table 15 lists special thickness classes of ductile-iron pipe.

"American National Standards Institute Inc , 11 W 42nd St, New York, NY 10036

‘tMetrie conversions given in this standard are direct conversions of US customary units

and are not those specified in Intemational Organization for Standardization (ISO)

standards

2 AWWA.Ci50A21 50.96

Sec. 12 Purpose

The main purpose of this standard is to provide the minimum requirements for e

the thickness design of ductile-iron pipe, including basis of design and design procedure,

Sec. 1.3 Application 5

This standard can be referenced in specifications for the thickness design of

ductile-iron pipe. The stipulations of this standard apply when this document has

been referenced and then only to the thickness design of ductile-iron pipe.

SECTION 2: REFERENCES

This standard references the following documents. In thei latest editions,

these documents form a part of this standard to the extent specified within the

' standard In any case of conflict, the requirements of this standard shall prevail.

AASHTO T99—Standard Method of ‘Test for the Moisture-Density Relations of

Soils Using a 5.5 Ib (2.5 kg) rammer, 12 in (805 mm) drop.

ANSVAWWA C151/A21 51—American National Standard for Ductile-Iron Pipe,

Centrifugally Cast, for Water

ASTM” A746—Standard Specification for Ductile Iron Gravity Sewer Pipe ;

SECTION 3:__ DEFINITIONS

|

‘This standard has no applicable information for this section. @

SECTION 4: REQUIREMENTS.

See. 4.1 Procedure for Calculating Thickness

The thickness of ductile-iron pipe is determined by considering trench load and

internal pressure separately. :

4.11 Step 1—Design for trench load.

a Determine trench load F,, Table 1 gives trench load, including earth load

P,, plus track load P, for 2.5 fr-82 ft (0.8 m-9.8 m) cover.

b Determine the standard laying condition from the descriptions in Table 2

and select the appropriate table for diaméter-thickness ratios from Tables 7 through

11, Each table lists diameter-thickness ratios calculated for both bending stress and

deflection over a range of trench loads

¢. For bending-stress design, enter the column headed “Bending-Stress Design”

in the appropriate table of Tables 7 through 11, and locate the tabulated trench load

P, nearest to the calculated P, from See. 4 1.1.a. (If the calculated P, is halfway

between two tabulated values, use the larger P, value.)

“American Society for Testing and Materials, 100 Barr Harbor Dr, West Conshohocken, PA.

10428-2959, ©

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 3

Select the corresponding D/t value for this P,.

Divide the pipe's outside diameter D (Table 5) by the D/e value to obtain net

thickness 2.

4. For deflection design, enter the column headed “Deflection Design” in the

appropriate table of Tables 7 through 11, and locate the tabulated trench load P,

nearest to the calculated P, from Sec 41.1 (If the calculated P, is less than the

minimum P, listed in the table, design for trench load is not controlled by deflection

and this determination need not be completed ) If the calculated P, is halfway between

two tabulated values, use the larger P, value

Select the corresponding D/t; value for this P,

Divide the pipe’s outside diameter D (Table 5) by the D/ty value to obtain min-

imum manufacturing thickness f). Deduct 0.08 in. (2,0 mm) service allowance to obtain

net thickness ¢

NOTE: Service allowance equals 0.08 in, (2.0 mm) for all sizes of ductile-iron

pipe

¢. Compare the net thicknesses from steps ¢ and @ and select the larger of

the two. This will be the net thickness required for trench load

4.12 Step 2—Design for internal pressure. Calculate the net thickness required

for internal pressure using the equation for hoop stress:

iD

Where:

= net thickness, in (mm)

P, = design internal pressure, psi (kPa) = 2 (Py) + P,)

Py = working pressure, psi (kPa)

P, = surge allowance, 100° psi (689 kPa)

D_ = outside diameter of pipe, in. (mm)

‘S__= minimum yield strength in tension = 42,000 psi (289,590 kPa)

“Uf anticipated surge pressures are other than 100 psi (689 kPa), the actual

anticipated pressure should be used )

418 Step 3—Selection of net thickness and addition of allowances.

a Select the net thickness ¢ from step 1 or step 2, whichever thickness is

larger. .

’b Add the service allowance of 0.08 in (2.0 mm) to the net thickness ¢. The

resulting thickness is the minimum manufacturing thickness ¢).

c. Add the casting allowance from Table 3 to the minimum manufacturing

thickness t; The resulting thickness is-the total caleulated thickness

4.14 Step 4—Selection of standard pressure class Use the total calculated

thickness from Sec 413. to select a standard pressure-dass thickness from Table 5.

When the calculated thickness is between two nominal thicknesses, select the larger

of the two,

When specifying and ordering pipe, use the pressure class listed in Table 6 for

this nominal thickness.

NOTE: On specific projects, manufacturers may be willing to furnish pipe with

thicknesses that fall between standard classes.

4.15 Alternative procedure. The appropriate standard pressure class may also

be determined by using the Design Equations in Sec 4.3.

4° Awwacis0/A21 60-96

Sec. 4.2 Design Example for Calculating Thickness

Problem: Calculate the thickness for 80-in, (762-mm) ductile-iron pipe bedded

in loose soil for a minimum depth of 4 in. (100 mm), backfill lightly consolidated to

top of pipe, laying condition Type 3, under 10 ft (3 m) of cover for a working pres-

sure of 150 psi (1,034 kPa)

4.21 Step 1—Design for trench load

a Earth load (Table 1) Pe 88 psi

‘Truck load (Table 1) 0.7 ps

‘Trench load, Pp = Pe+ Pe = 90psi

b. Select Table 9 for diameter-thickness ratios for laying condition Type 3

c Entering P, of 9.0 psi in Table 9, the bending-stress design requires Dit of

163 From Table 5, diameter D of 80-in pipe is 3200 in

Net thickness for bending stress = D/(D/t) = 32 00/163 = 0.20 in.

_ Also, from Table 9, the deflection design requires D/ty of 136.

Minimum manufacturing thickness ty for deflection design

D_ 32.00

024in,

Deduct service allowance 0.08 in,

Net thickness ¢ for deflection control = 016in

e. The larger net thickness is 0.20 in,, obtained by the design for bending

stress.

4.22 Step 2—Design for internal pressure.

P= 2.0 (Py + P,) = 2.0 (working pressure + 100 psi surge allowance)

(If anticipated surge pressures are other than 100 psi [689 kPal, then the actual

anticipated pressures should be used.)

P;

.0 (150 + 100) = 500 psi

PiD _ 500x320

28

2 x 42,000 ~ 0-19 im

Net thickness ¢ for internal pressure is 0.19 in

4.2.3 Step 3—Selection of net thickness and addition of allowances. 'The larger

of the thicknesses is given by the design for trench load, Step 1, and 0.20 in. is

selected.

Net thickness 020in,

Service allowance = 0.08 in,

‘Minimum manufacturing thickness

Casting allowance

‘Total calculated thickness

‘THICKNESS DESIGN OF DUCTILE-IRON PIPE 5

4.24 Step 4—Selection of nominal thickness and standard pressure class. The

@ total calculated thickness of 0.85 in is larger than 0.34 in., Class 150. Therefore,

Class 200 is selected for specifying and ordering

Sec. 4.3 Design Method

431 Ductile-iron pipe thickness The thickness of ductile-iron pipe is deter-

‘mined by considering trench load and internal pressure separately

Calculations are made for the thicknesses required to resist the bending stress

and the deflection caused by trench load The larger of the two is selected as the

thickness required to resist trench load Calculations are then made for the thickness

required to resist the hoop stress of internal pressure

‘The larger of these is selected as the net design thickness. Tb this net thickness

is added a service allowance to obtain the minimum manufacturing thickness and a

casting allowance to obtain the total calculated thickness.

‘The nominal thickness and the standard pressure dass for specifying and ordering

are selected from the table of nominal thicknesses for standard pressure classes

(Table 5).

‘The reverse of the preceding procedure i used to determine the rated working

pressure and maximum depth of cover for pipe of a given pressure class

4.32 Trench load P,, ‘Trench load is expressed as vertical pressure in pounds

per square inch (kilopascals) and is equal to the sum of earth load P, and truck

oad P.

43.3 Earth load P, Earth load is computed by Eq 4 for the weight of the unit

prism of soil with a height equal to the distance from the top of the pipe to the

ground surface. The unit weight of backfill soil is taken to be 120 Ibift®

@ (2885 kNim8) If the designer anticipates additional loads, the design load should be

increased accordingly.

434 Truck load P,. The truck loads shown in Table 1 were computed by Eq 5

using the surface-load factors in Table 6 and the reduction factors R from Table 4 for

a single AASHTO H-20 truck on unpaved road or flexible pavement, 16,000-Ib

(71,170-N) wheel load, and 15 impact factor. The surface-load factors in Table 6

were calculated by Eq 6 for a single concentrated wheel load centered over an effec-

tive pipe length of 8 ft (0.914 m)

4.3.5 Design for trench load. ‘Tables 7 through 11, the diameter-thickness ratios

tables used to design for trench load, were computed with Hs 2 and 3 Equation 2

4s based on the bending stress at the bottom of the pipe. The design-bending stress f

is 48,000 psi (831 x 10° kPa), which provides at least a 1.5 safety factor based on

minimum ring yield strength and a 2.0 safety factor based on ultimate strength.

Equation 3 is based on the deflection of the pipe ring section. The design deflection

Ax is 3 percent of the outside diameter of the pipe, which is well below the deflection

that might damage coment linings. Design values of the trench parameters E', Ki,

and K, are given in Table 2

Tables similar to Tables 7 through 11 may be compiled for laying conditions

other than those shown in this standard by calculating the trench loads P, for a

series of diameter-thickness ratios, D/t and D/ty, using Eqs 2 and 3 with values of

E’, Kb, and K, appropriate to the bedding and backfill conditions.

6 AWWA.C150/A21 50.95

Design Equations e

qd

(Bq 2)

(Bq 3)

Pat (Bq 4)

P= RPoe (Bq 5)

, aa 1 1

|

x oresin a2 5 2) (BP) Jn (ane +B |e mm) vt)

Note; In Eq 6, angles are in radians

Sec. 4.4 Explanation of Symbols Used in Design Equations

A. = Outside radius of pipe For A in feet, D in inches:

(Por A in metres, D in millimetres: A = D/2,000)

a = Conversion factor. For pounds per square foot to pounds per square inch

= 144 (For kilonewtons por square metre to kilopaseals: a = 1)

15 ft (0.457 m)

‘Effective pipe length: 36 in (0.914 m)

Surface load factor: see Table 6.

Outside diameter, in inches (millimetres): see Table 5.

Modulus of elasticity: 24 x 10° psi (165 5 x 106 kPa)

‘Modulus of soil reaction, in pounds per square inch (kilopascals):

see Table 2.

Impact factor. 1.5

Design bending stress: 48,000 psi (831 x 10° kPa)

Depth of cover, in feet (metres)

Bending moment coefficient: see Table 2,

Dis

THICKNESS DESIGN OF DUCTILE-IRON PIPE 7

K, = Deflection coefficient: see Table 2.

@ P. = Wheel load: 16,000 Ib (71,170 N)

P, = Earth load, in pounds per square inch (kilopascals)

P, = Design internal pressure, in pounds per square inch (kilopascals)

P; = 2 (working pressure + 100 psi [689 kPa] surge allowance)

‘Truck load, in pounds per square inch (kilopascals)

‘Trench load, in pounds per square inch (kilopascals) P, = P.+ Pr

Reduction factor, which takes account of the fact that the part of the pipe

directly below the wheels is aided in carrying the truck load by adjacent.

parts of the pipe that receive little or no load from the wheels see Ta-

ble 4.

S_ = Minimum yield strength in tension: 42,000 psi (289,590 kPa)

t = Not thickness, in inches (millimetres)

ty = Minimum manufacturing thickness, in inches: fy = ¢ + 0.08

Gn millimetres: t = ¢ + 2)

w = Soil woight: 120 Ib/ft® (18.85 kN/m®)

qo Ax = Design deflection, in inches (millimetres): Ax = 0.03D

Sec. 4.5 Special Thickness Classes

For design conditions not covered in Tables 12, 13, and 14, special (formerly

standard) thickness classes shown in Table 15 continue to be available.

SECTION 5: VERIFICATION

‘This standard has no applicable information for this section

SECTION 6: DELIVERY

‘This standard has no applicable information for this section.

8 AWWA .C150/A21 50.96

Table 1 Earth loads Pe, truck loads Py, and trench loads Py—ps!

Sel

Depth of

eth in Pe in Pipe in Pipe in Phe

R Pe Pe Pe, Pe Po Py Po Pe Pe

sta

Sear Me rap lect tcc tivoh entre ice! irs etiss

eset OR rsh et aep tot Oat cat em eect ere

5 0az ee 80 Rk Rak

Boker eae tee cere steer

Beers eae ae ete eee acerseeen es

3 0c? stoke

> 0s eB sa

boas 08 «83 «(06st sc

Tcl tcf wsttee selena tcsa eee Tish ea

Moi wl ok ow) kkk

3 oma oo: Me) 08 més eke

a seri atest roche oste eta) atoahe cs tna ale

RUE Eset etost eee nalee forte ttn’ sureate itt alo ato

Se craft oben cte a oct Oe ceate arc ne al cecPeenio Ty tess

sero} ee ato 8a ate

Depth of 10mm Fe ‘win Pipe din Pipe 16m Pipe

ft Pe Pr Po Pr Py Pe Poy Pe Po

rogues Gega 77 page 10 eens sone “pees ren Seu =3Rae 7

Seen rele (orl ttt ote ort et capeauareetosn ac

to ea kta

ep on eo em

$ oe mo 6d ol ok ke

ree ee

3 0oer6 2st

> 0st

2 oo oe kos ok

2 oo 8 «SOS

“uoooaTook kis

ust mes

Dor oa>sk 8a

x mo 0: mi oof ml om ma ot mt

me os (Ok dBA

wer ole O_o

"Nore: To convert inches (in) to millimetres (mm), multiply by 26.4; to convert fet (A) to metres (mn), multiply by 0 3048; to

convert pounds per square inch (ps) to kilopascals (kPa), multiply by 6 805

Table continued next page.

THICKNESS DESIGN OF DUCNLEIRON PIPE 9

@ Table 1 Earth loads Pe, truck loads P,, and trench loads Py—psi (continued)

Depth

of Cover 1B-in Pipe __20-in Pipe __2ein Pipe __Ssin Pipe

RR eR RB wm mh Fw FB bh mB Bm mh PB

25. 21 78 99 75 6 71 92 67 88 62 683

8 25 59 84 57 82 54 79 562 77 49 74

4 33 39 «72 39 72 36 69 385 68 34 67

5 42 26 «68 26 68 24 66 24 66 28 45

6 50 19 69 19 69 17 67 17 67 17 67

1 CB a a a ace ral re

8 67 12 78 41 78 12 78 31 78 11 78

9 75 10 85 09 84 09 84 08 84 08 83

1 = 8838s 91ST: 80780 80 OT 8

pe OO

“4 ont 04 121 04 21 04 321 04 121 04 A

16 18303-1386. :03-s«186}-S:sBKBCOB: «CBSO 186.

2 167 02 169 02 169 02 169 02 169 02 169

24 =200 01-2011 1 tL = od D1 tO

fia) en ie 20 1 28 tee 00 os 0 eet 408 cody 1 ood

82267 «01 HB__—O_—26HB_—01— HBO HBO 6K

of Gane 42in Pipe __4i-in Pipe tin Pipe 60hin Pipe __Gdsin Pipe

@ fh oem mR hm Pe hm Ph Ph me Pm BP

26 oi 68 79 64 75 50 71 48 69 45 66

25 46 71 44 69 41 66 39 64 38 63

33 33 66 31 64 30 68 29 G62 28 61

fade eS) Ghee 29 6 erie (68) ees engl

Ome i7e67) ale a 66uc16) ae 110806) eutibea 66)

3

4

5

6

7 58 18 71 12 70 42 70 12 70 12 70

8 67 10 77 10 77 40 77 10 77 10 97

9 75 08 838 08 88 08 88 08 88 08 83

10 M=@ (0 Ww ( WW 0 t 1 =

2 100 05 105 05 105 05 105 05 105 05 105

Moo uy) 21k a ad.

1% 188 08 136 03 136 08 186 08 136 08 186

2 167 02 169 02 169 02 169 02 169 02 169

ees WO 0 e200 01 01 0 eet 0 19 090 ae 20.

28 «3301341 844 OL BABA

92-267 —Sad «26H OT SBT HHL HB 8B

"Nore To convert inches (in to millimetres (mum, multiply hy 25 4; to convert feet (Rt) to metres (am), multiply by 0 8048; to

convert pounds per square inch (psi) to kilopascals (kPa), multiply by 6 895

10 AWWA c1Sq/A21 50.96

Table 2. Design values for standard laying conditions

Bedding

Laying g ‘Angle

Condition” Deseription psi, deg Ke Ke

‘Type IF Flat-bottom trench # Loose backfill 1860 30 0235 (0.108

‘Type2 Flat-hottom trench Backfill lightly consolidated 300 45 0210 0105

‘to centerline of pipe

‘Type 8 —_Pipe-bedded in 4-in-minimum loose soil § 400 60 0189 0103,

‘Backfill lightly consolidated to top of pipe

‘Type 4 —_Pipe bedded in sand, gravel, or crushed stone to 500 9 0157 (0.098

depth of Y% pipe diameter 4-in minimum,

Backfill compacted to top of pipe.

(Approximately, 80 percent Standard Proctor,

AASHTO 1-99)"

‘Type —_Pipe bedded to its centerline in compacted 700 15001280085

granular material, 4-in, minimum under pipe.

‘Compacted granular or select material to top of

pipe. (Approximately 90 percent Standard

Proctor, AASHTO 299)"

‘Noris:

1) Consideration of the pipe-zo0e embedment conditions included in this table may be influenced by factors other than

pipe strength For additional information eee ANSUAWWA C600, Standard for Installation of Ductile-Iren Water Mains and

‘Their Appurtenancee

2)'To convert pounds per square inch (psi) to kilopascale (kPa), multiply by 6 695

‘See Figure 1

‘For pipe 14 in (956 mm) and larger, eansideration should be given to the use of laying conditions other than ‘Type 2

{Plat-bottom is defined as “undisturbed earth”

‘soil or select matarial is defined as “native soll excavated fram the trench, five of rocks, foreign material, and

frozen earth *

“WAASHTO 799, "Standard Method of Test for the Moisture-Density Relations of Soils Using a 55 Ib (25 kg) Rammer

‘and a 12 in (805 mim) Drop” Available from the American Asrocation of State Highway and Transportation Officials, 444

1N Capital St NW, Washington, DC 20003,

Table 3. Allowances for casting tolerance

Size Casting Allowance

8 0.05

10-12 ‘ 0.06

mae oor

4 008

54-64 009

(Note: To convert inches in) to millimetres (mi, multiply by 25 4

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 11

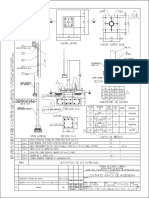

Types

Types

Figure 1 Standard pipe laying conditions (see Table 2)

@

12 Awwa.ci1501A21 50-96

Table 4 Reduction factors R for truck load calculations

Depth of Covert

a T-10 >10

in Reduction Factor

we 100 100 100) 100

rv 92 100 100 100

16 0.88 095 100 100

18 085 090 100 100

20 oss 090 095 100

24-80 ost 085 095 100

36-64 080 085 090 100

"Nort: To convert inches (in) to millimetres (mm), multiply by 25 4; to convert feet (R) to metre (rm), multiply by 0 8048

Table 5 Nominal thicknesses for standard pressure classes of ductile-iron pipe

Nee

- Pressure Class

Outside 5

fier, 150 200 250 300 350

in Nominal Thickness—in,

396 = = = = 025°

480 - - - - 025°

690 - - - - 025"

905 = - - - 025"

1110 - - - - 026

1320 - - - - 028

15.30 - - 028 030 oat

3740 - - 030 oaz oad

1950 - - oa1 034 036

2160 =_ _ 033 036 038

2580 = 033 037 040 043

32.00 0.34 038 042 045, 049

38.30 038 042 047 ost 056

4450 oan oar os2 ost 083

50,80 04s 052 0658 oes 0.70

5756 ost 058 065 on 079

6161 0.64 61 068 076 083.

65.67 058 064 o72 080 087

{Nowe To convert Inches (i) to millimetres (mm), multiply by 25 4

for these sizes and pressure ratings are loss than those shown shove

‘Caleulated thickness

calculated thicknestes) Presently these are the lowest neminal thicknesses available in these sizes

Pressure classae are defined as the rated water working pressure of the pipe i pounds per equare inch (psi) The

thicknesses shown are adequate for the rated water working pressure plus a surge allowance of 100 psi (689 kPa)

Calealations are based on a minimum yield strongth in tension of 42,000 psi (289,590 kPa) and 20 safety factor times the

‘som of working pressure and 100 psi (689 kPa) sarge allowance

(Bee Table 13 for actual

‘Thickness can be calculated for rated water working pressure and surges other than the shove hy use of the formula

shown in See 412

Ductileiron pipe is available for water working pressures greater than 850 pai (2,418 kPa)

Pipe is available with thicknesses greater than Pressure Class 250 See Table 15

Lowest nominal thicknesses shown in Table 15 1 of ANSUAWWA CLIB/A21 15 for threaded flanged pipe are still required

‘Lowest nominal thicknesses shown in ANSVAWWA C805 for pipe with grooved and shouldered joints are still required

‘THICKNESS DESIGN OF DUCTILE-TRON PIPE 13

Table 6 Surface load factors for single truck on unpaved road

Pipe Siae—in

a

ft Surface Load Facior—C

26 00869 00713 O10) 01928 0161S 01001 ODITS 0244302898

3 00437 00590 00759-00990 01207 0424 01687-01843 0.2044

4 00285 0.0321 9.0460 0.0602 00736-0871 01005011860 1265,

5 00176 -—«O0ZI3 0090600401 0048000581 DOG O0761 0.0849

6 00125-00151 .02IT ORB 00948 0413 OKTS 00542 0.0606

7 00088-00113 00162 ~— 90212-9260 00308 00357 0.0105 0.0453

8 00072 0008700125 0164 © 0.0201 0238 00276 00913 0.0350

9 0.0057 00089 © 00099-0130 00160 0.0190 00219 00z49 00279

10 00046 00056-00081 00108-00180 0154 0172 0020300227

+ 12 00032 0008900056 0.0074 0.0001 a.0108. 00125 OOMd2 0.0159

14 00024 0.0028 00042 © 0.0055 00067 0.0080 0.0092 00105 oI?

16 00018-00022 00082 0.0042 00051 0.0061 0.0071 00080 0.0090

20 00012-00014 0.0020 00027 0.0083 0.0089 0.0045 0.0052 020058

24 «00008-00010 «001d © 00019 0.0023 00027 0.0082 © 0.0036 00040

23 0.0006 00007 0.0010 00014-0017 0.0020 0.0028 0.0026 00080

320.0005 00006 00008 __0.0011__00013 0.0015 0.0018 0.0020 0.0028,

Pipe Size—in

opeth 20 24 30, 36 42 43, bt 60 6

ft Burlace Load Factor

25 oni 08000 00062 04497 04813 OBIS 06900 ObABB 06502

3 02287 + 0260203085 0.3507 03857 «04153 OdI2 © O4BAS 0.4857

4 013101635 0.1972 02284-02559 02808-0300 OB164 0.9277

5 00995 O.1106 01347 0.1576 © O.178G 0.1982 0217S 02278 02877

6 00669 00793 00970 -01M3 0.404 0.1458 «0161201698 -01781

7 00500 0.0504 0.0790 00863 0.0988. 0.101235 0130601874

8 00387 0.0461 00567 00872 HUTTE 008710097 010310 1088

9 00300 0.0367 0.0453 00538 0062000700 08784 0.0838 0.0880

10 00251 0.0299 00370 0040 0.0507 00574 0064400585 0.0725

12 00176-00210 0.0259 0030900357 0405 00455 0.0486 0.0515

14 0013000155 0.0192 00229 90265 00301 0.0599 00862 0.0884

16 00100 0.09 0.0147 0017S HORDE 02s .0EA_—0.02T9_0.0297

20 00064 00076-00085 00113011 © 0.0149 O16 0018100192

24 0.0045 00053 0.000. 00079 ©0001 «00TH OTB 00125 00194

28 00083 00039 0.0049 00058 00067 0.0077 0.0087 00083 0.0099

820005 00030 0.0087 __0.0044 00052 0.0059 0.0087 00071 _ 00076

[NOTE convert inches (in) to millimetres (ram), multiply by 25 4; to convert feet (ft) to metres (x), multiply by 0 $048

14 AWWA.Ci50/A21 50.96

Table 7 Diameter-thickness ratios for laying condition Type 1°

‘Trench Load (Pp)—psi ‘Trench Load (Pu)—psi

Bending Stress D,,Dt | Bending Stress DD

Design Deflection Desiom °° Design Deflection Desiem 7 °°

440 346 770 540 408 1

443 348 169 545 406 1a

446 360 168 549 409 us

450 351 167 354 413 12

454 353 166 559 416 ui

457 355 166 565 4.20 vo

461 357 164 510 423 139

464 359 163 315 427 138

468 361 162 580 431 17

47 363 161 5.86 435 136

476 365 160 son 439 135

480 267 159 597 449 104

484 309 168 608 447 133

438 37 157 609 52 12

402 am 156 615 456 it

496 376 155 ear 461 180

500 378 104 627 466 129

504 381 158 633 an 128

508 288 152 640 476 137

513 386 161 646 482 125

537 360 160 653 487 15

Bat 301 149 660 498 124

535 30 48 667 499 13

530 397 ut 674 505 122

525 400 us. 682 5 121

‘Nore: convert pounds per square inch (ps) to Kilopascals (kPa), multiply by 6 895,

“B= 150 pels Ko = 0235; Ke = 0 108

‘tne ? or P forthe tabulated Fe nearest tothe calculated Py is aeleted: when the calculated Po i halfway between two

ablated vate sale 2 or ahd be

‘Table continued next page.

©

‘THICKNESS DESIGN OF DUCTILE-IRON PIPE

Table 7 Diameter-thickness ratios for laying condition Type 1° (continued)

rT

‘Trench Load (P.)—psi ‘Trench Load (P,)—psi

Bending-Stress Bending Stress DDI

Design Deflection Design Design Deflection Design i

689 518 956 789 %

697 525 on 807 3

705 532 987 825 8

713 539 1008 84 2

721 546 3020 864 s1

729 554 5 1037 885 %

738 5.62 m4 1055 908 89

147 571 13 1074 929 88

7.56 5.79 uz 1093 953 81

7.65 588 ul 18 978 86

176 597 uo usa 10.04 85

785 607 109 1155 1031 4

7.95 617 108 178 1060 8

805 627 107 1201 10.90 s

816 638 106 1225 nz 81

827 649 105, 1250 1156 80

838 661 304 1276 ust 19

849 678 10s 1303 1228 13

861 6.86 02 1331 1267 n

84 689 aL 1360 13.08 16

806 12 100 191 1351 15

899 126 9 1493 1397 4

913 Ta 98 1456 1445 73

927 181 a 1491 1496 2

eat 173 9% 1527 15.0 u

‘Note: Tb convert pounds per square inch (pel) to Kilopascals (kPa), multiply by 6896

‘e

150 pai Ke = 0.285; Ke

‘ine? or 2 for the tabulated Ps mont Se cleat Ps is elec; when the ella Fi by tween bo

108

tabulated vata, the smaller? or. should be used

Table continued next page.

16 AWWA CiBO/A22 60.96

Table 7 Diameter-thickness ratios for laying condition Type 1° (continued)

‘Trench Load (P,)—psi ‘Trench Load (P.)—psi

Bending-Stress D,,Dt | Bending Stress D,,D*

Design Deflection Design f° th Design Deflection Design "1

1565 3607 70 2894 4032 0

1605 1668 69 3007 4273 49

1646 3732, 68 3128 4535 48

1689 1800 o7 3257 48.20 a

1735 1873 66 83.95 5131 46

ares 19.50 65 35 42 5472 45

1833 2032 64 3700 58.44 “

18.85 2119 63 3869 6253 43

1940 22.12 ee 40.50 67.03 2

1998 2312 61 42.46 7199 a

2059 2418 60 44.56 AT 0

2123 25.32 69 46.84 8354 39

2191 26 54 58 49.30 90.28 38

2263 27.85 87 5196 9780 aT

23.38 2926 86 54.86 106 20 36

2418 307 55 58.02 115 62 35

2502 32.39 54 6146 126.21 a

2592 34.15 53 6523 138 18 33

2686 3605 52 69.36 16178 cy

2787 3810 51 73.92 167.15 3

‘Note: Tb covert pounda per square inch (pai) to Kllopaccals (kPa), multiply by 6 885

“= 160 pas Kare 0280; Ke = 0108,

‘the 2or2 forthe tabulated Po nerost to the calculated Ps in ecected: when the clcultedP, is halfway between to

tabled van tn amar or ahold be und

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 17

( Table 8 Diameter-thickness ratios for layitig condition Type 2°

‘Trench Load (P))}—psi_ ‘Trench Load (Pp)—psi

Bending-Stress D,,2' | Bending Stress D, Dt

Design Deflection Design ttt Design Deflection Design tt

629 618 To 774 676 is

694 619 169 780 679 14

639 621 168 187 683 143

644 623 161 794 686 12

650 625 166 801 689 vn

655 625 165 808 699 40

600 628 164 815 697 199

60s 630 169 822 701 188

em 622 182 829 705 137

er 634 161 837 709 136

ese 6a7 160 a4 713 135

688 639 159 852 mM 134

604 oat 168 859 722 133

699 642 181 867 726 132

705 646 156 815 731 131

mm eas 16 883 738 120

@ 77 650 154 B91 TAL 129

7283 653 158 899 146 128

729 656 182 907 751 a

195 658 151 936 161 126

742 sor 150 925 763 125

748 664 9 933 768 4

754 867 us 942 75 123

761 670 ut 951 781 1

167 679 6 360 1a Pt

[NOTE T convert pounde por equare inch (psi) to Kilopascale (kPa), multiply by 6 805

300 pal; i = 0.210; Ke = 0105

"ane or Prt alte Ps one cael Py i ec; when he eae aay Btw no

tabla valey, the malr2 or? slo ed .

® Table continued next page

18 AWWA.C150/A21 50.96

Table 8 Diameter-thickness ratios for laying condition Type 2" (continued)

‘Trench Load (P))—psi ‘Trench Load (P,)—psi

Bonding-Stress D,.Dt | Bending-Stress 2,Dt

Design Deflection Design tf Design Deflection Desien "1

970 794 120 1279 1078 95

979 sor ug 1296 sos 94

989 808 us 1313 110 93

999 816 nT 1331 11.29 2

10.09 823 6 1349 1150 a1

1019 gat 15 1368 un 20

1029 840 14 1388 i194 89

1040 848 13 14.08 12.17 88

10.51 857 12 1430 12.42 87

* 1062 8.66 ut M51 1267 86

1073 816 Bo 3474 1294 85

1084 886 309 1497 1322 Be

10.96 8.96 108 1521 1352 88

1108 907 107 1546 13.83 2

121 918 106 16.72 M416 al

1138 929 305 15.99 1450 80

146 on 104 16.28, 1486 7° @

11.59 954 108 1657 16.24 6

u7B 967 102 1687 1564 n

87 9.80 101 v.19 1606 6

1201 994 100 1152 36.51 %

12.16 1009 99 17.86 16.98 “

1231 3024 98 18.22 37.48 3

1246 10.40 oT 18.59 18.00 2

1262 1056 96 18.98 1856 a

[Nom To convert pounds per square inch (pai) to Kllopascals (kPa), multiply by 6895

“B= 800 pai; Ky = 0210; Ke = 0105

‘ane? or? fr th bland Part thet Ps isl when helene ala btwee ne

telat vas he male? or snd be ws zi

Table continued nest page. Qs

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 19

Table 8 Diameter-thickness ratios for laying condition Type 2° (continued)

©

‘Trench Load (Pp)—psi ‘Trench Load (Pp)—psi

Bending Stress D,,Dt | Bending Stress DDI

Design Deflection Design 7 tt Design Deflection Design °°

1959 wi 70 38.84 1409

1982 19.77 6 3508 4656 ro

2027 2043 68 36.41 4926

2073 2118 er 3183 5219 a

2123 2187 66 3004 5540 46

2114 267 6 40.96 5889 4

2228 2351 ot 4270 6273 4“

2285 Baad 6 4451 68.93 4

23.45 2537 e 4657 T1568 2

+ 407 2639 61 4873, T3866 a1

2aT4 2749 ® 5106 8229 40

25.43 2866, 59 53857 8854 39

26.17 2901 53 56.30 95.48 33

26.95 3126 sr 5925 10321 31

2077 3271 56 6246 m185 36

2864 3426 55 6596 12154 3%

® 29.56 35.93 Be 6979 132.44 34

S 3053, 314 53 7398 MaTa 33

3157 3969 52 7857 158.68 2

3267 4180 51 8364 17454 a

‘Noms To convert pounds per square inch (pei) to kilopaseals (kPa), multiply by 6 895

“B= 800 pels Kb = 0210; Ke » 0 105

‘the or? rth bland snare oh cadet when heated alien

aban ag th emaier? ral eed

20 AWWA C1BO/A21 50.08

Table 9 Diameter-thickness ratios for laying condition Type 3°

‘Trench Load (Py)—psi ‘Trench Load (Py}—psi_

Bending Stress D,,D' | Bending Stress D,,Dt

Design Deflection Design 27 Design Deflection Design f°"

325 726 B10 445 738 380

329 a2 308 451 738 258

338 72 306 457 739 256

337 12 304 463 739 254

341 728 302 469 140 252

345 728 300 476 74 250

349 728 298 482 742 248

a4 729 296 489 142 246

258 79 294 496 143 244

363 730 292 503 744 242

367 730 290 510 14s 240

32 730 288 517 146 238

a76 7a 286 524 wat 236

get 7a 284 531 7148 24

3.86 732 22 539 748 232

3a1 792 280 547 149 230

3.96 733 278 554 751 228

401 7133 276 562 752 226

406 734 214 570 158 224

4a 734 22 579 154 22

ant 735 20 587 755 220

422 735 268 5.96 756 28

428 736 266 6.04 758 216

433 7236 264 6.13 159 24

439 1st 262 622 740 212

‘Nore: Tb convert pounds per square inch (ps) to Klopascals (kPa), multiply by 6 895

‘e

400 pais K

ane? or? for the tabulated eae the seated Py

18; Ke = 0108

D.

tabulated vals, the ama P or shouldbe weed

7

ected; when the calculated Pr is halfway between two

Table continued next page.

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 21

Table 9 Diameter-thickness ratios for laying condition Type 3° (continued)

\e

‘Trench Load (P)}—psi ‘Trench Load (Py}—psi_

Bending-Stress D,Dt | Bending Stress DDI

sae ausin nse FOR | UE aim pein FE

a a a oe a i

fal fe a oa ia =

es) a a = a -

. co o - =

ia fe a on pa ce

ca fa i oa fa a

fa a ia oa ea a

en fa fe oad fe a

e a6 198 ve ars oer ie

ea fa a na aes ia

ra ra 4 os oa ta

‘Nort: To eonvert pounds per aquare inch (psi) to Kilopascale (kPa), multiply by 6 695

"R= 400 poi; Ky = 0 189; Ke = 0103

"ame or? tr nnd Ps tre tthe essed ltd won te alent ebay bos no

nad va h ler? oral end :

® Table continued next page.

22 AWWA.C150/A21.50.06

Table 9 Diameter-thickness ratios for laying condition Type 3° (continued)

——————————————————————————E

ere aoe «

Bending Stress D,,D' | Bending Stress D,,Dr

Delgn Deflection Desion 7 °° Design Deflection Desien f°

1088 ead 740 1334 1025 is

092 888 139 1346 1034 4

101 a9 138 1358 1042 13

1110 896 337 Bn 1051 12

nii9 200 195 138 1061 nt

128 904 135 1596 on no

1137 908 134 1409 1081 108

1146 918 133 uz 1091 108

1156 918 132 1495 ne 107

165 923 i 1450 13, 108

16 928 190 ue 125 105

nse 933 139 ue ns 104

14 938 128 1493 1150 108

1204 94s 127 1508 1.88 102

Bu 949 128 1523 a7 101

225 965 125 1529 no 100

1235 961 124 1555 12.08, 23

was oer vs bn wai ee q

1256 om 12 1588 1237 97

1267 980 121 1606 1254 98

x78 987 120 1623 1272 9%

1289 994 19 1642 12.90 %

13.00 1002 ne 1661 1309 99

Bn 1009 qn 16.0 1329 2

1323 117 6 1100 1350 a

TORE: To convert pounds per square inch (psi) to kilopascals (kPa), multiply by 6 896,

“B= 400 pal; Ki ~ 0.189; Ke = 0 108

‘ie 2 or for the tabulated Py nearest tothe ealculated Py is selecte

tabula as, he eer? ost :

then the calculated Py is halfway between two

Table continued next page. (

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 28

Table 9 Diameter-thickness ratios for laying condition Type 3° (continued)

‘Trench Load (P.)~psi ‘Trench Load (P.)—psi

Bending Stress D,,Dt | Bending Stress DD!

Design Deflection Design tot Design Deflection Design tt

W721 1372 90 25 85 24 88 65

1142 1395 89 2643, 2574 ot

164 1418 88 2704 2666 6

1786 1443 a 2768 2764 @

1810 1470 8% 2836 2868 6

18.34 1497 & 29.08 29.80 60

1859 1528 wt 2983 3090 59

18.85 1556 83 3063, 32.27 58

1912 1588 2 3147 33.64 87

, 1940 1621 a 3236 3512 56

19.68 1658 8% 39381 3670 55

1999 1893 7 3430 38.41 54

20.90 1731 ® 3537 40.25 38

20.62 172 7 3649 42.24 6

20.96 1815 76 3769 439 61

2131 1861 6 3897 4672 50

2168 1909 4 4033, 4925 49

2207 19.59 8 4178 5199 “8

22.47 2013 72 4333 54.98 a1

22.88 2069 n 4498 56.25 46

2392 2129 10 4676 e1at 45

2378 2193 6 4865, 6572 “4

24.26 22.60 6 5071 7001 43

476 23.2 67 5291 mun 2

2529 24.08 6 5528 79.92 4

‘Nore Mh covert pounds per equare inch (pt to Kilopascale (kPa), mally by 6895

"B= 400 pes Ho = 0189, Ke = 0108

the? or2 tor the abated nano the anata Py ena when te cleat Fy bf between ow

tabulated vale, the amaer 2 or? shouldbe used 5

® Table continued next page.

24 AWWA C15Q/A21 50.96

Table 9 Diameter-thickness ratios for laying condition Type 3° (continued)

— eee C—C—“ I

‘Trench Load (Ps)—psi ‘Trench Load (P.)—psi

Bending Stress D,,2* | Bending Stress DD?

Design Fiat Design Deflection Design ft

or8e 40 a27 125 67 35

6061 9204 39 1849 13678 ct

6 9911 38 a3 149 32 83

66.86 106 99 37 8819 163 54 32

7040 115 80 36 9379 v9.71 31

Toasts oe pods pr aus Tn Ga os ly yO

"B= 400 pal; Kp = 0 189; Kz = 0103

‘tne? or ane sare th ad eed wn sled ivy ban bo

aaa vat, the nero? steed

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 25

Table 10 Diameter-thickness ratios for laying condition Type 4”

——

‘Trench Load (P.)—psi ‘Trench Load (Py)—psi

Bending Stress D,,Dt | Bending Stross

Design Deflection Design tr Design Deflection Design

598 970 3i0 00 042

600 970 308 810 980 258

607 en 306 820 983 256

ou on 304 eal 984 254

62 on 302 ea 9.85 252

6.29 o72 300 852 986 250

636 ow 298 8.63 986 248

6.43 973 296 ai 987 246

651 ona 204 885 988 244

+ 659 973 292 897 9.89 22

eer 94 290 908 990 240

67a, 97% 288 920 9.01 238

683 9.76 286 992 92 296

6a1 976 204 944 9.93 234

6.99 976 282 957 904 232

708 976 200 9.69 995 230

@ 7.16 977 278 9.82 996 228

735 977 216 9.95 907 226

734 978 214 1008 998 204

743 978 272 1021 999 222

192 979 270 1035 i001 220

761 979 268, 1049 10.02 218

am 9.80 266 1082 10.03 216

780 san 264 107 1005 a4

190 9e1 262 1091 1006 22

‘Nore: To convert pounds per square inch (pi) to Kilopascals (kPa), multiply by 6895

"E’ = 800 pal; Ki = 0 151; Ke = 0096

‘tne? or ter th tate mene it aed Pees; when teas Palen bnboms bo

taultd vas th mar or? hl bind :

@ Table continued next page.

26 AWWA .C150/A21 50-06

Table 10 Diameter-thickness ratios for laying condition Type 4” (continued)

Trench Load (Ps)—psi ‘Trench Load (P.)—psi

Bending Stress DD! | Bending-Stress D,.Dt

Design Deflection Design f°" ts Design Deflection Design f°" tn

1.05) 3008 210 1486 1066 165

1120 1009 208 14968 1069 164

1135 100 206 1505 1071 168

1150 1013, 204 1515 1073 162

16s 1035 202 1525 1075 161

81 1017 200 1534 1078 160

ust 1019 198 1544 1080 159

1218 1021 196 1554 1082 158

1229 1023, 194 1564 1085 167

1245 1025 sz 1674 1087 156

1262 1027 390 15.84 1090 155

279 1030 188 1594 1093, 164

1296 1032 186 16.04 1096 153

1313 1035 184 3614 10.98 152

1330 1037 12 1624 i101 31

13.48 1040 180 16.34 104 160

1366 1043, 118 1645 anor v9

13.84 10.46 x16 1655 uu 48

14.02 1050 am 16.65 1.4 ua

1420 2058 we 16.76 uy vs

439 1087 370 1686 mai us

448 1059 369 36.96 a2 4

M467 1060 368 3707 1128 us

467 1062 367 3718 ust v2

476 10.64 166 3728 11.35, uaa

[Nom Tb avert pounds per square inh pai) to Klopaocale (GPa, multiply by 6685,

"B= 500 pels Ry = 0 157; Ke = 0096,

‘the or P for the tabulated Pe nearest tothe calculated Py i selected; when th ealclated Py is halfway between two

ablated vale the sme or ah be wed

Table continued next page.

®

‘THICKNESS DESIGN OF DUCTILE-IRON PIPE 27

Table 10 Diameter-thickness ratios for laying condition Type 4° (continued)

‘Trench Load (P,)—psi ‘Trench Load (P,)—psi

Bending-Stress D,.Dt | Bending-Stress D,,.Dt

Design Deflection Design #71 Design Deflection Design f°" ts

3789 1189 140 2029 1201 15

3750 143 189 2042 1300 au

3760 1148 138 2055 1309 us

wi 4182 137 2069 1319 m2

3782 11.56 186 20 82 1329 uu

3793 61 135 20.96 1339 a0

1804 166 194 2110 1350 109

18.15 un 133 2124 1361 108,

18.26 176 182 21.39 1373 107

+ 1837 mai 131 21.54 1385 108

1849 11.86 130 21.69 1398 105

18.60 1.92 129 2184 14.1 104

18.72 197 128 2200 1424 108

1888 3203, 127 22.16 1438 102

1895 1209 126 2232 1453 301

1906 32.5 195 2249 1468 300

@ 1918 32.22 14 2266 1484 9

19.30 1228 123 22.88 3501 8

1942 12.35 322 2301 1518 7

19.54 3242 ya 23.20 1536 96

19.68, 12.50 120 23.38 15.55 ®

1978 1287 ug 23.58 1575 4

1991 1265 us 2378 1595 8

2004 273 a7 23.99 3617 2

2016 1282 us 2420 1639, 31,

‘Note: To convert pounds per square inch (psi) to kilopascals (kPa), multiply by 6 895

“Br = 500 pal; Kb = 0 15%; Ke = 0096

‘the or? th table Pero hae esl wha eae haley btn

teulted vl, th mar” or? sl be wd :

‘Table continued next page.

28 AWWA C1B0/A21 50.96

Table 10 Diameter-thickness ratios for laying condition Type 4” (continued)

‘Trench Load (Pe)—psi ‘Trench Load (Pepsi

Bending-Stress D,,Dt | Bending-Stress D,,Bt

Design Deflection Design "ts Design _Deflestion Design. °" ft

2442 1662 0 3395 28.60 6

2464 1687 89 3461 2958 64

2488 1712 8 3530 3051 63

2512 4739 81 3604 3156 e

2587 aer 86 3681 8268 61

2563 ast 85 3763 33.88 cy

25.90 1828 4 3850 35.16 59

26.18 1860 83 3042 36.53 58

26.47 1894 2 4039 3800 Br

+ 2877 1930 81 4142 3958 56

2709 1967 80 4251 4128 85

2742 2007 9 4367 4312 54

2776 20.48 78 4491 45.09 53

28. 20.92 7 46.22 4729 2

28.49 2188 76 4762 4953 51

2887 2187 % aon 5208 50

2928 2288 ™ 5070 5474 49

2970 2293 3 seat 57.69 8

30.15 23.50 2 54.23 60.90 a1

30.62 24 tL na 56.18 64.40 6

sin 2475 70 5827 68.28 45

3162 2543 cy 6052 2.42 “

3216 26.16 8 6293 71.02 43

32.72 26.92 or 6554 82.08 a2

3382 208 66 6835 87.68, a1

Tan cove pounds per eqn GD Has OF apy iy OS

rere

or the bated sere oh cated

i. D

"The t

tabulated values, the small

si bn hese Py re ro

hn .

‘Table continued next page. ®

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 29

Table 10 Diameter-thickness ratios for laying condition Type 4” (continued)

‘Trench Load (Py)—psi ‘Trench Load (Py)}—psi

Bending Stress D,,D* | Bending Stress DDI

Design Deflection Design? Design Deflection Design ft ty

7199 70 9098 13674

7467 39 9597 148.68

7824 38 10149 19212

sou a 10756 w737

86.98 36 11425 19172 a

TT soe pur pe oane nl Gao lpn UFO, mal yO

Saphire 20s

‘ane or? fr he auld Perth eee Plead en heed slay been we

oo D

tabulated vaste amar? or?

B sould be weed

80 AWWA.C150/A21 60.96,

Table 11 Diameter-thickness ratlos for laying condition Type 5°

‘Trench Load (P,)—psi ‘Trench Load (P,)~psi

Bending Stress D,,D! | BendingStress B,D!

Design Deflection Design °" ft Design Deflection Design i

3.06 1509 660 460 16.it 535

310 15.09 655, 469 wn 530

315 1509 650 am wn 55

320 1509 645 486 1u 520

325 15.09 640 495 wu 515,

330 1509 635 505 1s 510

335 15.09 630 514 wu 505

340 15.09 625 524 2 500

346 1509 620 535 1612 495

+ BBL 1509 615 545 1512 490

357 1510 610 556 1512 495,

3.63 15.10 605 567 152 480

3.68 1510 600 578 162 45

315 1510 595 590 15.3 470

381 1510 590 602 1513 465

387 1510 585 615 1513 460

394 1510 580 628 1513 455,

400 1510 515 eat 1513, 450

407 1510 570 654 1614 M5

4u4 16.10 565 668 16.4 440

4m 15.10 560 6.83 1534 435

429 35.10 355 698 15.44 430

4.38 1530 50 713 114 45

4m 15.41 545 729 15.5 420

452 15.1 540 146 15.15 45

‘Nore: To convert pounds per equare lack (pi) wo Kilpascala (KPa, milly by 695

“B= 700 pol; Ks = 0 128; Ke = 0085

‘ape 2 or 2 forthe tabulated P mare nto calelted yi cles hn the eleiated i bafvay betwen wo

tabulated vals, te ealer? or? sod he wed ’

Table continued next page

‘THICKNESS DESIGN OF DUCTILE-IRON PIPE

Table 11 Diameter-thickness ratios for laying condition Type 5° (continued)

BL

‘Trench Load (P.)—psi ‘Trench Load (Py)—psi

Bending Stress D,,D' | Bending-Stress D,,Dt

Design Deflection Design fh Design Deflection Design "1

763 1515 400 1823 1528 300

780 1516 405 1337 1529 298

798 1516 400 33.52 1529 236

817 1516 395 1367 1530 294

836 1637 390 1383 1530 292

856 16 885 1398 1530 290

877 3517 380 us 131 288

898 1518 3% 1480 16.31 286

920 1518 370 M446 15.32 284

+ 948 16.19 365 462 15.33 282

966 15.19 360 479 1533 280

991 1520 355 34.96 1534 218

1016 1520 350 3513 1534 216

1042 1621 345 1530 15 35 24

1069 1522 340 15.48 16.85 22

1097 1522 335 3565 1536 270

126 1523, 30 1583 1537 268

156 1524 825 1602 1537 266

us? 1524 820 1620 1538 204

219 1525 315 1639 3539 262

3252 1526 310 16.58 3540 260

1266 1527 308 16.77 1540 258

3280 1627 306 1697 B41 256

12.94 1527 804 17.16 1542 254

1308 1528 302 1736 1543, 252

‘Noms To eonvert pounds per square inch (pi) to kilopascals (kPa), multiply by 6 695

“Br = 100 ps Ky = 0 128; Ke = 0085,

‘the? or? te aed Ps eres tn eae lend when tell Pie lfey beng wo

saat asthe aaler2 or 2 ed ed

Table continued next page.

82 _AWWAC150/A21 50.96

Table 11 Diameter-thickness ratios for laying condition Type 5° (continued) e

‘Trench Load (Pp)—psi ‘Trench Load (Ps)—psi

Bending-Stress D,,Dt Rending-Stress D,Dt

Design Deflection Design 1" Design Deflection Design 't

87 164d 250 2348 1579 200

un 1845 248 2370 1581 198,

17.98 1545 246 2397 1583 196

119 1546 24 2424 1580 194

1840 1347 242 2450 1588 192

1362 1548 240 2arT 1591 190

13 1549 238 2504 1593 188

1906 1551 236 2531 1598 186

1928 15.52 234 2559 1599 184

: 19.51 1553 232 25 86 1602 182

ws 1554 230 2619 1608 180

19.97 1555 228 2641 16.09 18

2020 1557 228 26.68 1632 x16

2043 1558 224 2698 16.16 m4

2087 1559 222 2723 1620 rm

2091 1561 220 2751 3624 170

2116 1562 218 2765 16.26 169 ©

21.40 1564 216 2778 1628 168

2165 1565 214 2792 1631 167

21.90 1667 212 2808 1633, 366

22.15 1569 210 2819 1635 165

2240 bn 208 2833 1637 164

22.66 678 206 2847 16.40 163

15.78 204 2860 1642 102

67 202 2874 16.45 161

ToT ave punts pr ane nc po Mlopwes Pay mally by 6,

"BY = 700 psi; Ki = 0 128; Kr = 0086

‘ane or2 rte tabulated Peet oth elated Pla when he cae Palen two

nll aaller2or2 bl bed .

&

niiscmimetnecre @

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 33,

ion Type 5° (continued)

e Table 11 Diameter-thickness ratios for laying con

‘Trench Load (Px)—psi ‘Trench Load (P.)—psi

Bonding Stress D,,Dt | Bending Stress D,.Dt

Design Deflection Design °F Desi Deflection Design 2°

2887 1648 160 3213 Tae 135

2901 1650 150 3235 147 134

2915 1653 168, 3238 1753 133

2928 1656 187 3250 1758 132

2941 1659 156 9262 1764 18

2955 1682 155 3275 1170 130

2968 1665 154 3287 1176 129

2982 1668 159 3299 1783 123

2995 1671 182 33m 1789 127

+ 8008 1674 151 9323 1796 125

3021 1678 150 3835 1803 125

3034 1681 “9 3947 18.1 124

3048 1685 3 39.59 1818 123

3061 1689 147 3371 1826 122

3074 16.92 46 39.88 18.34 121

2087 16.96 145 23.95 142 120

r) 3099 3700 146 3407 1o1 9

a1az x704 43 3419 1860 8

3125 1708 2 3431 18.69 u7

3138 M1. ut 3443 1878 116

3150 111 140 3455 1888 15

31.68 1722 139 3468 1898 ne

3176 1101 138 34.80 1909 us

3188 1732 137 3492 1920 ne

8201 1737 136, 35,05 1931 m.

[NOTE To convert pounds por square inch (pel to Kilopascals (kPa), multiply by 6 885

“B= 700 pais Ko = 0128; Ke = 0085

‘the? or? tr th bated sane oth cli Pens when cole avy anes

tabulated vale, the maine 2or2 hl be wed ,

® Table continued next page.

84 AWWA .C150/A21 50-96

Table 11 Diameter-thickness 1

for laying condition Type 5° (continued)

‘Trench Load (P:}—psi_ ‘Trench Load (P:)—psi

Bending Stress D,,D+ | Bending Stress D, De

Design Deflection Design 7°" Design Deflection Design 7°"

3617 1948 0 3941 24 60 3

3520 1955 109 3967 2495 4

35 49 1968 108 39 94 2581 3

35.56 1981 107 402 2570 &

3569 1995 106 4051 25 10 a

35.88 2000 105 4082 252 80

3596 2024 104 au 2697 9

3610 20.39 103 a8 244 8

36.25 2055 102 a4 2793 m

36.99 2072 101 4221 23.46 76

2654 20.89 100 4260 2001 5

36.69 2107 39 4302 2959 4

3685 2126 38 265 30.20 13

3701 2145 ” 4302 2085 2

ami 2186 96 4440 3153 a

3734 2187 95 4491 70

8752 22.09 4 45.46 69 €

3770 7292 3 4603 @

3789 22.56 w 46.64 6

3308 2282 ° 4728 66

3928 2308 % 4196 9661 co

33.49 23.96 2 48.68 31.65 «4

3371 23.65 8 1944 3877 3

3899 23.95 7 5025 99.95 @

39.17 2427 6 ain 412 a

[Noms To convert pounds por equare inch (ps) t Kllopaceals (KPa), multiply by 6895.

“Br = 100 pal: Kp = 0 128; Ke = 0085

‘tear bette P mt a F

tabulated values, the smaller ? or should be used .

Table continued next page. @

‘THICKNESS DESIGN OF DUCTILEARON PIPE 35

e Table 11 Diameter-thickness ratios for laying condition Type 5° (continued)

‘Trench Load (Pp)—psi ‘Trench Load (P.)—psi

Bending Stress Bending Stress DDI

Design Deflection Design Design Deflection Design 2 ft

5202 4257 7588 3196 i

52.99 4401 7854 86 10 “4

5402 4556 8140 9129 8

55.12 4723 8450 9701 2

5628 4901 81.85 10931 “1

5753 50.93 % ou 027 40

58.86 58.00 54 95.40 u798 29

60.28 5.23 53 9907 12656 es

6179 ar64 82 10432 19611 a

+ Bat 6025 8 30040 14678 28

osu e307 50 n494 15875 35

67.00 6619 2 wai02 v2.21 %

68.90 e046 4“ 2169 18741 =

nw 7309 a 12503 204.88 2

1341 7104 4 314 20422 a1

‘Note: To convert pounds per square inch (psi) to kllopascals (kPa), multiply by 6 885

“B= 700 pal; Ky = 0128; Ky = 0.085

1 mPorPne ce tite a wheal Pawn he eet Ploy ben

tabulated van, he alr? or sd ewe

96 AWWA C150/A21 50.96

‘aod yxau ponuyjuco eqn,

@ ©

‘ssoxypnp you oy pappe aotns9po Soyiew puv souemoqre o1ares SopnppM] SEEING PORETATED TEL,

SIges xf UT uso osomp wey J9yBas8 49g09 JO sMAAOP 20} faEAD og Sour odd

oe oF 0m6 w

ose = oro 098 8

ose = oro ose %

oe = sro 088 0

ose = ato 098 or

om sto ose ¥

oe = ro ose ar

os to ose or

ose sto ose 6

oe =. aro ose 8

os = sto ose L

oe = aro 098 9

oe = sto ose 3

ose = aro one *

ose = sro ose &

oe = sro ose %

ose = oro ose ze

oe = sto ose 8%

ose sto ose ¥%

ose a0 oss oe

ose sto ose ot

ose = sro 098 wn

oe sro ose a

ose = sto ose or

ose sro ose 6

ose = #rO 098 8

oe = Fro ose L

oe = ¥rO ose 8

os = FrO ose ¢

ose 50 ose ¥

os = sto ose &

ose st 0 09 sro oe 10 09 10 036 sro 9 s

BHD) “ar 3585 "a Be a aH “ua Eon) “ur T "up

aunseold ,Sompmyg, sunewseg SSMU, ary SSOP, arteneeg SUTIN, AMET SHUM, Ae] oa

esq pow © ae eam es BED aa] een Perera) indo

Te Tren, TOL Te,

eck cs oom, ooanL Tomar

peo] yon shid peor WED 104 SSOUIUL Zh MEL

‘THICKNESS DESIGN OF DUCTILERON PIPE 37

‘aBiod peou ponurguos 29nL

‘soupy ae 0} poppe sounsar; Bunse> puw souAoyie souros sopnppurSEOEHETES POvUITES TAL,

orgs) omy Ut anon aacys URRY saesH santo Jo s~dop 30} o[qopEAP 09 KOU od

“Broe'0 Ard ( saxaut oy Cy) 295 sono 0 FAERIE ‘CaIUN sAROEILTUE oy (UP SBHDU HEATED a ALON

O88 oro ry 30 = oe al =e = = 7

ge sro ose eo = = = ee = on %

ose. 10 ose. Teo ose = = oa = %

ose 0 ose ozo ose ose 90 = — oz

098 a0 ge ero oss ose. ¥0 ose so or

ge sro ose. sro oss ose. eo, (Ose so w

ose sro ose aro ose ose. wo ose. ¥o ar

ose sro. ose 10 ose ose eo ose. a or

98 sro 098 40 oss ose ozo ose wo 6

ose 30 ose 10 ose ose. 00 ose. wo 8

ose. 30 ose 10 ose ose. ogo. ose. 10 L

ose a0 ose 160 oss oss. ero ose a 9

ose sv ose 200 oss 09g. ero ose 120 g

ose sro. ose 0 ose ose 0¢0. ose. wo ¥

oge sr. ose 400 ose ose. 170 ose a &

oss sro oss sto ose ose wo oe =. WO we 8

ose “0 ogg wo ose = = = = ee

ose 200 ose Teo ose ose so = = 8G

ose v0. ose ero ose ose wo o9e 970 cf

ose a oss 80 ose ose. wo ose. wo 07

ose a ose 100 ose ose. 1zo ose. 80 ot

ose 90 ose 40 oss ose ozo ose. wo wr

oss sro ose a0 ose ose. ogo ogg 10 ot

ose 0 ose, oro ose ose. ero ose. 10 or

ose sro. ose 9r0 ose ae. ero ose 00 6

oss st'0 oss sro ose. ose sto ge ozo 8

oss sro ose 910 ose, ose ato. 098: a L

ose sro ose. 9x0 ose ose sro. ose. ero 9

oss sv. ose oro ose ose sro. ose ero 8

o9e sro ose. 9c. oss o9e sro ose ozo ¥

ose 300 ose. 100 ge ose ero oss 120 e

ose. v0. ose. 10, ose ose wo at 0. ve 9

3510) ar BID aE 35019 BEI) "uF "Uy oT a

emag jssompriy, ameieg ssompmy, amaneld ,ssouym, omeesld jemDoRUL, emma jsreCNL, 10809 OTIS

een” enmereg een bevemone een” Bees een” Perma permeed JS mde

aL, ru, io TL,

geany Fea ma Zeca Tear

‘WoRTPUCD BuET

(panuguos) peo] yong snd peol yee 10j ssauMPYL ZI IqeL

e @ e

38 AWWA C150/A21 50-96

e @ e

“aBind you ponunzuoo 21qn1,

‘srouyen) 7 0} poppe souTINI} BURSTS pu aouEMO|E stAOs Soper SNE POTPA|E TAL,

axge aus Ua eBoy WoRp 49aud sasco yo syidop-oy ofgeTEae og ew od

‘By06'0 a Stara (x) sano oy Cy) 9 04D o 95g Aq ABOU CH SNORT o} CUD) eeEPUC AOD a, BLO

096 wo = = = = = = ae = e

ose. 10 ose 0 = = = a = = 8%

ose. ozo oge 920 = = i a ee aa %

ose ozo ose veo = = = = = = og

ose ero 098 wo ose 90 = = - = st

09 ero ge wo ose s@0 098. wo, = m

ose avo ose. 0 ose. ¥0 ose. 90 = = a

ose, sro ose. ozo ose 80 ose. a 098 a or

ose sro ose. oo. ose wo ose. wo ose 6

ose sro 038, oo ose. wo oss. eo ose 8

ose sro ose ero ose wo ose eo ose. 90 L

oss sro oss. ero ose 10 ose. eo ose 90 9

ose, sr ose ero ose zo ose evo ose 0 9

ose. ro ose. ero ose. wo ose. v0 ose. 0 %

oss sro ose 00 ose #20 ose seo ose. 90 8

ose, ero 088 wo ose. s@o ose. wo a5 > w% a

ose 10 = = a ma - = - = ze

ose oo ogg 9z'0 = = = = = = 8%

ose sro ose vo = = ee = = = %

ose. ero ose wo = = i = = = og

ose 80 098 0 ose wo = = = aa ot

ose sro ose ozo ogg. 80 ose 9x0 = = Ww

ose. sto 09g ozo ose wo 098 veo = = a

ose 400 ose ero ose. wo oss evo 98 wo or

098 10 ose ero. 09g wo ose 80 088 90 6

098 200 098 ero ose wo ogg wo ose 90 a

ose a 088 ero ose ozo ose wo ogg. ¥e0 L

ose. wo ose sro 09g, 0@'0 ose wo ose. veo 9

ose. 400 ge sro ose, 00 ose. wo ose. wo 8

oge 110 ose ero ose eo ose wo ose eo ¥

oge sto ose ero oss wo ose eo ose 9@0 8

ose 0 ose sea 098 eco ose 30 = ge or

ay

B58 “ut 388g see “ Bei a aD 7 a

amelg jssauypu, aimeesld erouNMLL, AMEN, SONI, eMaLZ {SUPT omaT SAP, e409 oa

sn pro an” Pemero sn emmy os Oa Power 38 doq

Tre, oo

aa ra aR eouky Tear

TORpuNg AAT

LS

(panuguos) peo; yong snjd peo] yee 40j ssowIYL Z] FIeL

39

‘THICKNESS DESIGN OF DUCTILE-IRON PIPE

‘aifod prou ponuaqu0d 219%, 1 ody, wor) rego eursspaoe Beecey 04 wou oq pmnogs woxyexapisuen‘za8z0f pur (aI 999) “UH FT edd 0g,

ose, yo 09%

ose. ca 09%

ose 120 09a

ose, 120 08@

ose, 1z0 09%

ose ozo 08%

ose. ozo 09g

086 0. 09%

088 a 0s

082 0@0 03g

092 ozo 09%

08¢ o@0 ose

4 0@0 ose

09% wo 09%

ed Leo =

08a so =

ose a og

08 0 08g

ose Teo ose 9

08 o@0 ose n

08% 0%'0 ose, fad

ose, ovo ose, or

08% oo ose 6

ose ero os 8

ose, ero ost L

ose, 600 ose. a

ose, ro ose g

088 ero 09% ¥

ose a 0s &

id oe. 096 80 4 seo oe. S60 i 2 ge wn

BEI it B80 ur Tri) Bei 35a) Tat wT ur

amoy sopra ametg somo, amuesid emNoTA, amolelg (SOOM, amas FMP, eo) eaS

ee) paremareD 0 PaO. =n Sees on Payee) =n Perma emdog

ven eo Ted,

Tay, oan, ra coun ra

WER PION BTAET

(panupuo>) peo] yon snjd peo} iva 403 SSaUyYL ZI PIAEL

40 AWWA .C150421 50-96

‘affod yxou ponuyyu09 29,

1 ody, wee saxo suoyspuce Bushey oy wane oq pmoys woxeaprsuoo'sa8r9] pur (um ggg) “ut pT odd sod,

ose, eso ose

ose 80 08

09 ¥e0 082

08% wo ose

09@ wo 092 ‘

09% wo 08g

ose, 120 ose i

ose. Teo osc veo ose. 80 ose 10 6

ose. Teo 093 wo 098 160 ose oro 8

ose, eo 09% eo ose. 0 ogg, ogo L

ose, oo. 09% eo ose. seo 08% a 9

ose. 0 ose, eo ose. 960 ogg, eo 8

ose 120 ose. 80 ose 160 ogg oe'o ¥

ose Iwo 092 wo ose. seo oss, 10 &

ose, 10 ose, so 09g eco ose. ero + cd 4

oe wo = ee a ae oe = ze

ose. eo ose 9e'0 = = = = 8%

ose, sco. 08 zo = = al = %

ose, so 09% eco = = = = 0%

ose, wo 09% a 08. eso = ea st

ose, zo 09% seo ose, 1e0 ose seo w

os, 0 gz wo ose, 60 008 eo a

ose 120 ose, Wo ose seo 09% Teo or

ose eo 4 eo. ose. wo 08% oso 6

ose. ozo ose, eo ose. 960 ose 0 8

ose co. 09% evo ose, 90 ogg, 80 L

ose, ozo ose, wo ose. seo ose, 80 9

09% 0@'0 08g wo 08% wo ose, seo g

09 ozo ose, eo 09g 90 ose, 80 ¥

096 0 ose 80 ose wo ose, oro 8

09% 120 08s, 50 08% sO. 008. zo £ 4 9% sr

Bay oa Seo "ar an) ut Seip) 7 1D 7 v "ar

amssoig ,SeuyPMYL, amssalg SOUP, amssarg ss, 3880] 07S

amssoig ssouxoray, omseoig seomsoTE,

paemoreg 36 ude

Tro,

een PeemeD = asp] «= we ee Pe] aa]

Tea, en TL, Te,

gear yea, Bou, eck, Teaky,

TWORTPUOD SURO

(panujuo>) pros yony snjd peo) yee Joj ssawrIYL ZI IGeL

‘THICKNESS DESIGN OF DUCTILEIRON PIPE 41

“28nd pxou ponanyuco 24904, 1 adc, ay soo suoppu Burky 0} wad og preys wopsipreuo> ‘fuel puw (Cu ef) wt YE dd xo,

ssouyory ow 0} PoppD Doussaen SERS Puw PoUEAOLTE soLAOS sop SENEAP|T Pove|TES TL,

“iqe) ay) Ut unoxs ogomy ety 2978 saH09 Jo sydop 40} ejgorean 99 feu adig

"BHOG'0 4 SSM ‘(4 Saou oC) ay HARROD oy Ae AU (HA) SaUFaSTTU o ' SOHRUT HOA gL BION,

ae #0 = a al a = = ae

008 wo — - = = = = &

oo 80 ose 8¥0 = = = = ve

ost 60 008 80 = = = = 4

ost so 002 io oe wo — ~ st