CAN BOARD POSITIONER INPUT/OUTPUT PRINTED WIRE ASSEMBLY

Replaces GE Healthcare 2293142CAN BOARD POSITIONER INPUT/OUTPUT PRINTED WIRE ASSEMBLY

Goods sold on an “Exchange” basis require that Buyer return a like, repairable item within 15 days (or the seller's specified time frame) in order to receive the price quoted. For full details, see Terms and Conditions.

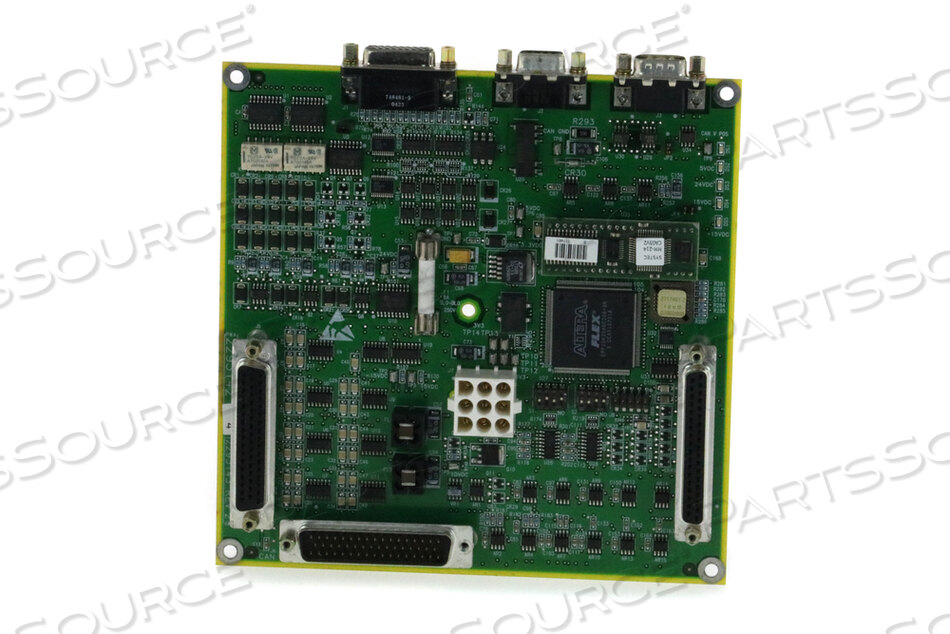

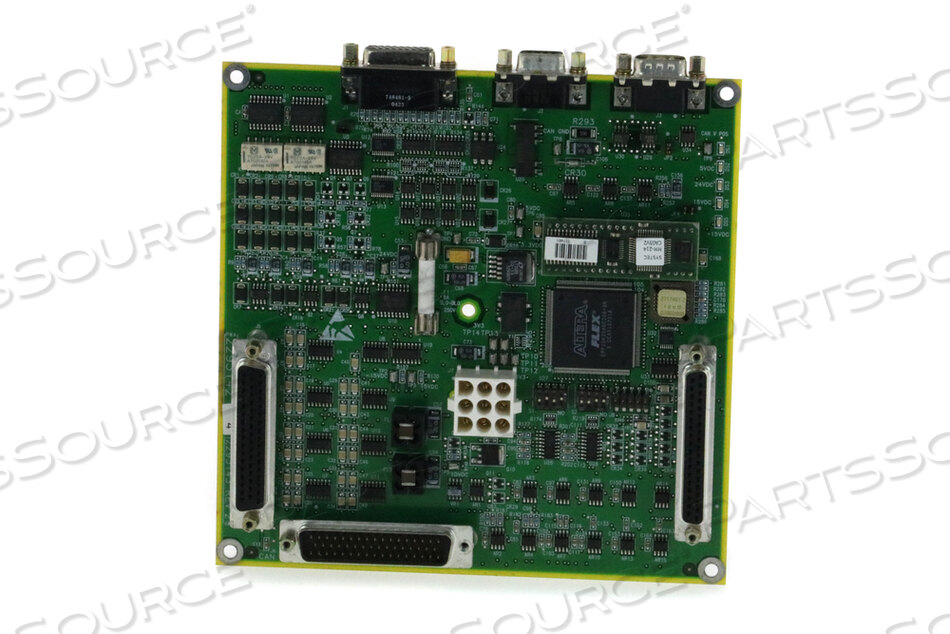

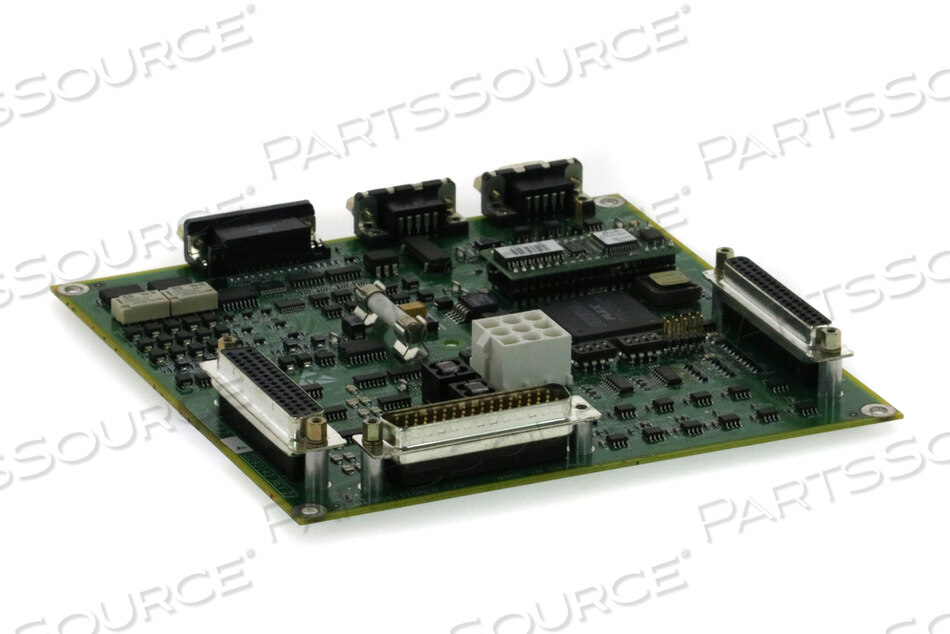

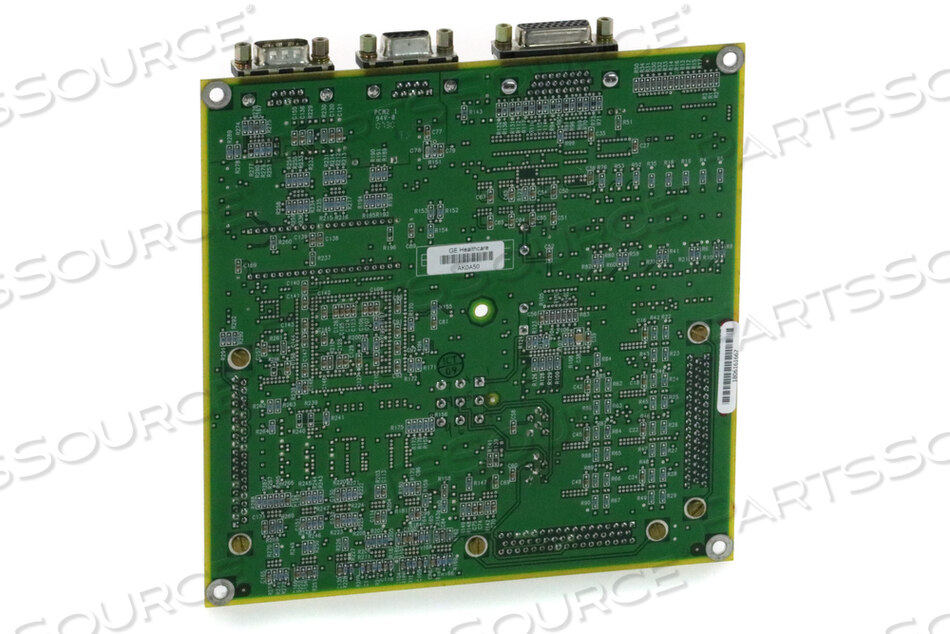

The CAN board positioner input/output printed wire assembly (PWA) is a custom designed circuit board that is used in the Aretha positioner cabinet and other X-ray systems as applicable. The primary function of the CAN positioner I/O board is to provide a signal and CAN communication interface between the positioner cabinet and other peripheral components. The CAN positioner I/O board assembly is comprised of various components including resistor, capacitor, fuse, logic interface, micro peripheral CAN open chip, Field Programmable Gate Array (FPGA), connectors, relays, voltage regulator, surface mount transient voltage suppressor, mounting screws and barcode label. The main functions of the CAN positioner I/O board is to provide communications link between the positioner cabinet and table to the CAN open standard bus Interface with the analog positioner, signal interface for the power assist CAN motion control amplifiers, interface with the legacy table and Spot Film Device (SFD) IDD sensors and switches. The board is mounted vertically against the back wall, inside the positioner cabinet. The maximum permissible board weight is 10 lb or 4.5 kg. The board must be braced to its grounded mounting plate by means of 4 screws or metallic fasteners positioned along the corners of the board and other pressure points. The CAN Positioner I/O board to meet the test, acceptance criteria for the vibration test, classical shock test, and shipping drop test as described in the mechanical environmental test guidelines.

- Seller: PartsSource

- Condition: Tested

- Purchase Type: Exchange

- Warranty: 6 Month

- Returnable: No

- GE Healthcare

- PRECISION 500D

- PRECISION 500

P/N: 2293142 Key Specs

The CAN board positioner input/output printed wire assembly (PWA) is a custom designed circuit board that is used in the Aretha positioner cabinet and other X-ray systems as applicable. The primary function of the CAN positioner I/O board is to provide a signal and CAN communication interface between the positioner cabinet and other peripheral components. The CAN positioner I/O board assembly is comprised of various components including resistor, capacitor, fuse, logic interface, micro peripheral CAN open chip, Field Programmable Gate Array (FPGA), connectors, relays, voltage regulator, surface mount transient voltage suppressor, mounting screws and barcode label. The main functions of the CAN positioner I/O board is to provide communications link between the positioner cabinet and table to the CAN open standard bus Interface with the analog positioner, signal interface for the power assist CAN motion control amplifiers, interface with the legacy table and Spot Film Device (SFD) IDD sensors and switches. The board is mounted vertically against the back wall, inside the positioner cabinet. The maximum permissible board weight is 10 lb or 4.5 kg. The board must be braced to its grounded mounting plate by means of 4 screws or metallic fasteners positioned along the corners of the board and other pressure points. The CAN Positioner I/O board to meet the test, acceptance criteria for the vibration test, classical shock test, and shipping drop test as described in the mechanical environmental test guidelines.

- GE Healthcare

- PRECISION 500D

- PRECISION 500

The CAN board positioner input/output printed wire assembly (PWA) is a custom designed circuit board that is used in the Aretha positioner cabinet and other X-ray systems as applicable. The primary function of the CAN positioner I/O board is to provide a signal and CAN communication interface between the positioner cabinet and other peripheral components. The CAN positioner I/O board assembly is comprised of various components including resistor, capacitor, fuse, logic interface, micro peripheral CAN open chip, Field Programmable Gate Array (FPGA), connectors, relays, voltage regulator, surface mount transient voltage suppressor, mounting screws and barcode label. The main functions of the CAN positioner I/O board is to provide communications link between the positioner cabinet and table to the CAN open standard bus Interface with the analog positioner, signal interface for the power assist CAN motion control amplifiers, interface with the legacy table and Spot Film Device (SFD) IDD sensors and switches. The board is mounted vertically against the back wall, inside the positioner cabinet. The maximum permissible board weight is 10 lb or 4.5 kg. The board must be braced to its grounded mounting plate by means of 4 screws or metallic fasteners positioned along the corners of the board and other pressure points. The CAN Positioner I/O board to meet the test, acceptance criteria for the vibration test, classical shock test, and shipping drop test as described in the mechanical environmental test guidelines.

- Seller: PartsSource

- Condition: Tested

- Purchase Type: Exchange

- Warranty: 6 Month

- Returnable: No

- GE Healthcare

- PRECISION 500D

- PRECISION 500

P/N: 2293142 Key Specs

The CAN board positioner input/output printed wire assembly (PWA) is a custom designed circuit board that is used in the Aretha positioner cabinet and other X-ray systems as applicable. The primary function of the CAN positioner I/O board is to provide a signal and CAN communication interface between the positioner cabinet and other peripheral components. The CAN positioner I/O board assembly is comprised of various components including resistor, capacitor, fuse, logic interface, micro peripheral CAN open chip, Field Programmable Gate Array (FPGA), connectors, relays, voltage regulator, surface mount transient voltage suppressor, mounting screws and barcode label. The main functions of the CAN positioner I/O board is to provide communications link between the positioner cabinet and table to the CAN open standard bus Interface with the analog positioner, signal interface for the power assist CAN motion control amplifiers, interface with the legacy table and Spot Film Device (SFD) IDD sensors and switches. The board is mounted vertically against the back wall, inside the positioner cabinet. The maximum permissible board weight is 10 lb or 4.5 kg. The board must be braced to its grounded mounting plate by means of 4 screws or metallic fasteners positioned along the corners of the board and other pressure points. The CAN Positioner I/O board to meet the test, acceptance criteria for the vibration test, classical shock test, and shipping drop test as described in the mechanical environmental test guidelines.

- GE Healthcare

- PRECISION 500D

- PRECISION 500

The CAN board positioner input/output printed wire assembly (PWA) is a custom designed circuit board that is used in the Aretha positioner cabinet and other X-ray systems as applicable. The primary function of the CAN positioner I/O board is to provide a signal and CAN communication interface between the positioner cabinet and other peripheral components. The CAN positioner I/O board assembly is comprised of various components including resistor, capacitor, fuse, logic interface, micro peripheral CAN open chip, Field Programmable Gate Array (FPGA), connectors, relays, voltage regulator, surface mount transient voltage suppressor, mounting screws and barcode label. The main functions of the CAN positioner I/O board is to provide communications link between the positioner cabinet and table to the CAN open standard bus Interface with the analog positioner, signal interface for the power assist CAN motion control amplifiers, interface with the legacy table and Spot Film Device (SFD) IDD sensors and switches. The board is mounted vertically against the back wall, inside the positioner cabinet. The maximum permissible board weight is 10 lb or 4.5 kg. The board must be braced to its grounded mounting plate by means of 4 screws or metallic fasteners positioned along the corners of the board and other pressure points. The CAN Positioner I/O board to meet the test, acceptance criteria for the vibration test, classical shock test, and shipping drop test as described in the mechanical environmental test guidelines.

- Seller: PartsSource

- Condition: Tested

- Purchase Type: Exchange

- Warranty: 6 Month

- Returnable: No

- GE Healthcare

- PRECISION 500D

- PRECISION 500

P/N: 2293142 Key Specs

The CAN board positioner input/output printed wire assembly (PWA) is a custom designed circuit board that is used in the Aretha positioner cabinet and other X-ray systems as applicable. The primary function of the CAN positioner I/O board is to provide a signal and CAN communication interface between the positioner cabinet and other peripheral components. The CAN positioner I/O board assembly is comprised of various components including resistor, capacitor, fuse, logic interface, micro peripheral CAN open chip, Field Programmable Gate Array (FPGA), connectors, relays, voltage regulator, surface mount transient voltage suppressor, mounting screws and barcode label. The main functions of the CAN positioner I/O board is to provide communications link between the positioner cabinet and table to the CAN open standard bus Interface with the analog positioner, signal interface for the power assist CAN motion control amplifiers, interface with the legacy table and Spot Film Device (SFD) IDD sensors and switches. The board is mounted vertically against the back wall, inside the positioner cabinet. The maximum permissible board weight is 10 lb or 4.5 kg. The board must be braced to its grounded mounting plate by means of 4 screws or metallic fasteners positioned along the corners of the board and other pressure points. The CAN Positioner I/O board to meet the test, acceptance criteria for the vibration test, classical shock test, and shipping drop test as described in the mechanical environmental test guidelines.

- GE Healthcare

- PRECISION 500D

- PRECISION 500