An ROV-operated oil recovery system could cut pollution from sunken tankers by at least 70%, says its inventor, Jean-Luc Dabi. The JLMD system, which has been in development for the past four years, has had its basic principles verified by Institut Francais du Petrole, Bureau Veritas and the French Navy. It was also due to be presented to the International Maritime Organization last month, with support from France's Ministry of Transport, as part of a campaign to better regulate the shipping and oil transport sector.

The shipping sector has reacted favorably. Two companies in Qatar and a French company registered in Greece have commissioned systems for 14 tankers. And Dabi's company JLMD Ecologic Group, based near Nice, has also formed a cooperation agreement with Dutch maritime contractor Smit Salvage for worldwide clean-up response operations.

null

Dabi's "inspiration" for his invention was the break-up and subsequent sinking of the Total-owned tanker Erika off the coast of western Brittany in 1999. A hastily convened team of leading offshore engineering contractors took 10 months to recover what was left of its cargo of crude. Remedial work on the Prestige tanker, which went aground off northwest Spain in November 2002, took even longer. Dabi claims that the contents of a tanker pre-installed with his system's connection points could mostly be recovered within one week.

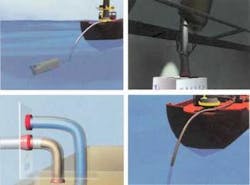

The JLMD system can be installed or retrofitted to new or existing, single or double-hulled tankers. "Boxes" with outlet points for ROV connections are fitted to all four corners of the vessel's lateral compartment, at port and starboard. These boxes provide access to two 20-cm-diameter rigid tubes inside the tanks. Irrespective of the tanker's final position on sinking to the seabed, the boxes and tubes can be accessed by the ROV. Unlike other salvage operations, there is no need to breach the hull first, usually the most dangerous part of the procedure.

Once the ROV has located the wreck, and has connected its tanks to those of the surface vessel, it begins the operation by opening the system's pre-installed valves. Seawater is drawn in under hydrostatic pressure via orifices located at the bottom of the tanks. Based on the Archimedes principle of fluid displacement, the pressurized water flows to the bottom of the tanks, in turn pushing the crude out and up through the ROV-attached flexible hose to the surface vessel.

The system was validated in Paris initially by separator specialist Bertin and by IFP, and was later tested successfully in the ACRI wave basin near Nice. This trial achieved drainage rates of up to 10,000 cu m/d.

In its basic version, the system is designed for a maximum external pressure of 100 bar. Fluid analysis studies have shown that even under low temperature deepwater conditions, which have a negative impact on crude viscosity, the system is still efficient, provided intervention can be achieved within one week.

Smit's worldwide salvage fleet should guarantee on-site assistance within 48 hours for any stricken tanker anywhere equipped with the JLMD system. Oil recovery operations would only be detained by a prolonged bout of severe weather, Dabi says. Whatever the size of the tanker and its storage capacity, the system should not cost more than Eu150,000, he adds. It has also been designed for installation by most standard shipyards.