Abstract

High-surface-area α-Al2O3 nanoparticles are used in high-strength ceramics and stable catalyst supports. The production of α-Al2O3 by phase transformation from γ-Al2O3 is hampered by a high activation energy barrier, which usually requires extended high-temperature annealing (~1500 K, > 10 h) and suffers from aggregation. Here, we report the synthesis of dehydrated α-Al2O3 nanoparticles (phase purity ~100%, particle size ~23 nm, surface area ~65 m2 g−1) by a pulsed direct current Joule heating of γ-Al2O3. The phase transformation is completed at a reduced bulk temperature and duration (~573 K, < 1 s) via an intermediate δʹ-Al2O3 phase. Numerical simulations reveal the resistive hotspot-induced local heating in the pulsed current process enables the rapid transformation. Theoretical calculations show the topotactic transition (from γ- to δʹ- to α-Al2O3) is driven by their surface energy differences. The α-Al2O3 nanoparticles are sintered to nanograined ceramics with hardness superior to commercial alumina and approaching that of sapphire.

Similar content being viewed by others

Introduction

High-surface-area corundum nanoparticles (α-Al2O3 NPs) have widespread applications. For examples, corundum is widely used in ceramics for biomedical implants1,2 and high-speed cutting tools3. α-Al2O3 NPs precursors provide access to nanometer-grained alumina ceramics with significantly improved fracture toughness4, wear resistance5, and high density under reduced sintering temperature6. Even though γ-Al2O3 NPs are primarily used as catalyst supports due to their high surface areas7, the α-Al2O3 with high surface area could be used as a catalytic support in auto-exhaust Pt-Mo-Co catalytic converters8 and enhance Ru catalyst activity for ammonia synthesis9. The high mechanical stability of α-Al2O3 enables a low sintering behavior, which is vital for its use in reforming reactions to obtain synthesis gas under harsh conditions10,11.

Much effort has been made toward improving the synthesis of α-Al2O3, yet very few of the processes afford high-surface-area NPs due to various intrinsic thermodynamic limits6,12,13. First, even though corundum is the thermodynamically stable phase of coarsely crystalized aluminum oxide (Al2O3), the synthesis of nanocrystalline Al2O3 usually leads to γ-Al2O3 because of its lower surface energy based on previous experimental observation and theoretical calculation12,14,15. The second reason is the high activation energy barrier of ~485 kJ mol–1 for the phase transformation from the cubic close-packed structure of the γ-phase to the hexagonal close-packed structure of the α-phase that involves intensive bond breaking and remaking16. Thirdly, the density of α-Al2O3 (3.99 g cm–3)17 is higher than that of the transition alumina phases (3.6–3.67 g cm–3 for γ-, η-, and δ-Al2O3)17, thus sufficient energy or high pressure18 is needed for the density uphill process from transition alumina to α-Al2O3. As a result, the thermal processes usually require temperatures >1470 K with prolonged annealing times of 10 to 20 h to facilitate the phase transformation16,17, which could also result in detrimental aggregation and sintering of alumina phases. The high-energy input and extended high-temperature annealing usually lead to surface area <10 m2 g–1 because of the substantial mass transfer13. Moreover, the polymorphism of Al2O3 during the phase transformation further increases the complexity and could lead to the mixed transition alumina with undesired δ- and θ-Al2O316,19,20.

The phase transformation and grain growth of alumina usually coexist in any thermal process. Previous kinetics studies show that the activation energies of the phase transformation from γ- to α-Al2O3 are around 200–500 kJ mol–1 depending on the sample conditions16,21,22; in contrast, the activation energies for the grain growth are around 500–900 kJ mol–1 depending on the grain-boundary orientations23,24,25,26. This implies that the kinetics of the phase transformation is possibly faster than the grain growth. Hence, based on these prior results, it is reasonable to presume that a rapid and lower-temperature thermal process would reduce the grain coarsening and maintain high surface area during the phase transformation process.

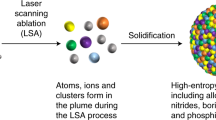

To meet these goals, here, we show a Joule heating process based on pulsed direct current (PDC) to complete the phase transformation from γ- to α-Al2O3 at a significantly reduced average bulk temperature and reaction duration (~573 K, < 1 s). The rapid transformation is enabled by the resistive hotspot-induced local heating in the PDC process when an appropriate volume fraction ratio of γ-Al2O3 precursors and carbon black conductive additives are used. The pulsed and local heating mitigates the aggregation, leading to the synthesis of α-Al2O3 NPs with an average particle size of ~23 nm and a surface area of ~65 m2 g–1. Ab initio calculations reveal that the topotactic phase transformation process (from γ- to δʹ- to α-Al2O3) is driven by the surface energy difference of the three phases. The calculations suggest that a particle size of ~17 nm is the thermodynamic limit for the synthesis of anhydrous α-Al2O3 NPs with the δʹ-Al2O3 as the intermediate phase by a thermal process, matching well with the experimental values. Also, based on the Joule heating technique, we develop an alternating current sintering (ACS) process and show the ultrafast and pressureless sintering of the α-Al2O3 NPs into alumina ceramics with nanoscale grain size. The ceramics from these α-Al2O3 NPs by two-step pressureless sintering process demonstrate hardness of ~15 GPa, superior to commercial standard alumina and comparable to single-crystal sapphire.

Results

Phase transformation synthesis of corundum nanoparticles by PDC

Since the γ-Al2O3 NPs precursors are electrically insulative, commercial carbon black (CB) was used as the conductive additive. In a typical experiment, the mixture of γ-Al2O3 NPs and CB were compressed inside a quartz tube between two graphite electrodes (Fig. 1a, Supplementary Fig. 1a and Supplementary Table 1). The CB also works as separators to avoid the aggregation of Al2O3 NPs during heating. The carbon black is composed of ultrafine amorphous carbon nanospheres and has a surface area of ~1600 m2 g–1, which permits the intimate mixing with γ-Al2O3 precursors, as confirmed by the energy dispersive X-ray spectroscopy (EDS) maps (Supplementary Fig. 2). The resistance was controlled by the compressive force on the two electrodes (Supplementary Table 1). The electrodes were connected to a capacitor bank with total capacitance of C = 0.624 F and charging voltage up to V0 = 500 V. The discharge circuit is a series resistor-inductor-capacitor circuit with the characteristic time of τ = 0.1 ms, which permits the PDC with frequency of f = 1000 Hz (Supplementary Fig. 1b). Joule heating affects the entire electric conductor; for a homogeneous conductor, the current density is uniform so the Ohmic dissipation enables the homogeneous temperature distribution throughout the sample27. However, when an electrical field is applied to an inhomogeneous medium, as in the composite of conductive CB and insulative Al2O3, the current and powder densities have strong spatial variation28. The power dissipation is substantially larger at some regions than the neighbor; these regions are termed resistive hotspots (Fig. 1a). Even though the average bulk temperature is low, the hotspots permit local heating and trigger the transformation that happens at a much higher temperature.

a Schematics of the PDC apparatus, and the resistive hotspots around and at the gaps of the insulative γ-Al2O3 NPs. The black arrows depict the electric current lines. b Representative methods for the phase transformation from γ- to α-Al2O3: flame spray pyrolysis, ref. 20 furnace annealing, ref. 16 high-energy ball milling, ref. 13 PDC, this work. c X-ray diffraction (XRD) patterns of γ-Al2O3 NPs after different PDC durations and the α-Al2O3 NPs product after calcination. The marks: γ-Al2O3 (square), δʹ-Al2O3 (triangle), α-Al2O3 (dot), and γ-Al(OH)3 (circle). The precursor is γ-Al2O3 with ~9 wt% γ-Al(OH)3 phase (gibbsite, crystal system: monoclinic; space group: P21/n; PDF No. 07-0324). The 0.8 s sample was calcined at 700 °C for 1 h. d Crystal structures of alumina phases: γ-Al2O3 (crystal system: cubic; space group: Fd-3m; PDF No. 10-0425), δʹ-Al2O3 (crystal system: orthorhombic; space group: P222; PDF No. 46−1215), and α-Al2O3 (crystal system: trigonal; space group: R-3c; PDF No. 46−1212). For γ-Al2O3, all the Al sites are depicted to show the crystal structure, while in the actual structure, not all the sites are 100% occupied. e Phase mass ratio of alumina polymorphs varied with PDC duration. f Raman spectra of as-synthesized α-Al2O3/carbon black mixture and the purified α-Al2O3 NPs by calcination at different temperatures.

By using this effect, we realized the phase transformation from γ-Al2O3 to α-Al2O3 accompanied by the intermediate phase of δʹ-Al2O3 at an average bulk temperature of ~573 K in <1 s (Fig. 1b, bottom). We compared our process to the representative phase transformation methods reported in the literatures (Fig. 1b)13,16,20. The liquid-feed flame spray pyrolysis produces α-Al2O3 at temperatures near 1873 K (Fig. 1b, top); however, the kinetically controlled process may render it difficult to access the pure phase (80–85% purity of α-phase)20. This phase purity is not an issue for ceramics since all other phases would transform to α-phase during the sintering process; nevertheless, the pure phase would be important for other applications such as in catalyst supports. Traditional heating methods that supply heat through the sample boundary, such as furnace annealing, require an extended period to permit uniform heating; hence 1473 K and 10 to 20 h are necessary to complete the phase conversion (Fig. 1b, middle)16. Other room-temperature nonequilibrium processes, such as high-energy ball milling, have been reported to form α-Al2O3 (Fig. 1b, middle)13 that shows hydrothermal stability29. Nevertheless, the Al2O3 can aggregate, which leads to loss of surface area during the extended time and high-energy collisions30,31.

We investigated the detailed phase transformation process of γ-Al2O3 by the PDC approach (Fig. 1c, d, e). Commercial γ-Al2O3 NPs with particle size of 5–10 nm and surface area of ~156 m2 g–1 were used as the precursors (Supplementary Figs. 3–5). X-ray diffraction (XRD) characterization and Rietveld refinement show that the starting materials are composed of ~91 wt% γ-Al2O3 with crystalline size of ~4 nm, and ~9 wt% γ-Al(OH)3 (Supplementary Fig. 6a). The γ-Al(OH)3 could be easily decomposed to γ-Al2O3 by mild calcination (Supplementary Fig. 6b). The mass ratio of γ-Al2O3 NPs and CB is 4 to 1, which gives a sample resistance of ~8 Ω (Supplementary Table 1). A discharging voltage of 60 V was applied with different discharging times controlled by a relay. The XRD patterns of the products with different PDC on-state time are shown in Fig. 1c. As the discharging time increased, the γ-Al(OH)3 first disappeared at 0.3 s; then, the γ-Al2O3 was transferred to the mixed δʹ- and α-Al2O3 at 0.4 to 0.5 s; last, the intermediate δʹ-Al2O3 was fully converted to α-Al2O3 after 0.8 s of discharge (Fig. 1e). The orthorhombic δʹ-Al2O3 is observed as the single intermediate phase (Fig. 1d), which is distinct from other thermal processes where δ- and θ-Al2O3 usually appear before the final α-Al2O3 phase (Fig. 1b)16,17,32.

Unlike our previous report33 on the synthesis of graphene by the high-voltage flash Joule heating at a high temperature of ~3000 K, the 60 V PDC does not provide enough energy to graphitize the CB (Supplementary Fig. 7). As a result, the residual CB (~20 wt%) could be easily removed by heating in air, according to thermal gravimetric analysis (TGA) (Supplementary Fig. 8a). Here, the as-synthesized mixture of α-Al2O3 NPs and CB was calcined in air at 700 °C for 1 h to purify the product. The X-ray photoemission spectrum (XPS) of the α-Al2O3 product after calcination showed very minor carbon signal, which could be caused by the carbon adsorption in air (Supplementary Fig. 8b). Raman spectra are sensitive to even a monolayer of carbon34; intriguingly, no characteristic Raman bands of carbon were detected after calcination at 700 °C (Fig. 1f), demonstrating the efficient removal of carbon. As a control, we show that the calcination process itself does not trigger the phase transformation and has negligible effect on the coarsening or aggregation of the γ-Al2O3 phase (Supplementary Fig. 9).

Characterization of the corundum nanoparticles

The α-Al2O3 NPs derived by PDC followed by mild calcination were further characterized in detail. Bright-field transmission electron microscopy (BF-TEM) images showed the well-dispersed particles (Fig. 2a). High-resolution TEM (HRTEM) showed the high degree of crystallinity of the α-Al2O3 NPs (Fig. 2b). The interplanar spacing values of ~2.57 Å and ~2.09 Å correspond to the d(\(10\bar{1}4\)) and d(\(11\bar{2}3\)) of α-Al2O3, respectively. The single set of lattice fringes in the NP and the nanobeam diffraction (NBD) show that the as-synthesized α-Al2O3 NPs are single-crystal particles (Supplementary Fig. 10). We observed some α-Al2O3 NPs with surface roughness features at a few nm (Supplementary Fig. 10), which are similar to the particle size of the γ-Al2O3 precursors (Supplementary Fig. 4). This demonstrates that the rapid PDC process triggers the phase transformation while no significant aggregation of the NPs occurs. The TEM images show that the particle size ranged from 14 to 36 nm, with an average particle size of 25.4 nm and standard derivation (σ) of 5.8 nm (Fig. 2c).

a Bright-field transmission electron microscopy (BF-TEM) image of the α-Al2O3 NPs. b High-resolution TEM (HRTEM) image of the α-Al2O3 NPs. The d spacing of 2.57 Å and 2.09 Å correspond to the d(\(10\bar{1}4\)) and d(\(11\bar{2}3\)) of α-Al2O3. c Histogram and distribution of the α-Al2O3 NPs particle size determined by TEM. d Pore width distribution determined by the application of density functional theory (DFT) model to the N2 isotherm. Inset, N2 adsorption–desorption isotherm of as-synthesized α-Al2O3 NPs at 77 K. e Fourier-transform infrared (FT-IR) spectra of the γ-Al2O3 NPs precursor and the α-Al2O3 NPs product. The black arrow points to the hydroxyl group absorbance. f X-ray photoelectron spectroscopy (XPS) fine spectra of Al and O of the α-Al2O3 NPs.

Brunauer–Emmett–Teller (BET) measurement showed that the surface area of the α-Al2O3 NPs is ~65 m2 g–1 (Fig. 2d, inset). The average particle size (D) is estimated to be ~23 nm by Eq. (1),

where ρ is the density of α-Al2O3 (3.96 g cm–3) and S is the specific surface area35. The pore size determined from the N2 adsorption–desorption isotherm using the density functional theory (DFT) model36 indicates the distribution with high probability at 3 to 10 nm (Fig. 2d and Supplementary Fig. 11). The observed surface area was mainly attributed to the nanoscale grain size or intraparticle pores, and minor interparticle voids and surface roughness features of the NPs (Supplementary Fig. 10). The crystalline size of the α-Al2O3 NPs was estimated to be ~22 nm based on the Halder-Wagner method (Supplementary Note 1 and Supplementary Fig. 12). The crystalline size (~22 nm) agrees well with the particle size measured from TEM statistics (~25 nm) and BET estimation (~23 nm), demonstrating the single-crystal feature of the NPs. The dynamic light scattering (DLS) measurement shows that the as-synthesized α-Al2O3 NPs are well-dispersible (Supplementary Fig. 13).

Unlike the starting γ-Al2O3 NPs that have hydrated surface states, the as-synthesized α-Al2O3 NPs surfaces are highly dehydrated because of the thermal process (Fig. 2e). The XPS fine spectra showed the dominate O2- peak at a binding energy of ~531.2 eV and single Al3+ peak at a binding energy of ~74.0 eV from the α-Al2O3 NPs (Fig. 2f). This demonstrated that the ultrafast PDC process does not result in obvious oxygen deficiencies or the carbothermic reduction of Al2O3 even with the existence of CB, presumably due to the high reduction potential of Al3+. No other peak was detected in the XPS full spectrum (Supplementary Fig. 8b), indicating the high-purity synthesis ability of the electric thermal process. This makes it superior to the solvent-based methods including ball milling13 or co-precipitation6, which inevitably suffer from lengthy purification processes and chemical contaminants.

Resistive hotspot effect revealed by current density simulation

As discussed before, the composition of an inhomogeneous media is critical for local power dissipation during the PDC process. To quantitatively investigate the effect of the composition on the phase transformation, a series of precursors with different mass ratio of γ-Al2O3 and CB were treated by PDC under the same voltage and time (Fig. 3a and Supplementary Table 1). According to the densities of γ-Al2O3 and CB, the volume fractions (f) of γ-Al2O3 are obtained (Supplementary Note 2 and Supplementary Table 2), and the phase mass ratios varied with f(γ-Al2O3) after the PDC process are calculated (Fig. 3b). The phase transformation degree is increased as the f(γ-Al2O3) increased from 0.41 to 0.73; the phase-pure α-Al2O3 is obtained at f(γ-Al2O3) ~0.73. Further increase in the f(γ-Al2O3) to ≥ 0.78 leads to no phase transformation.

a X-ray diffraction (XRD) patterns of γ-Al2O3/CB with different mass ratios after the same PDC process. The marks are γ-Al2O3 (square), δʹ-Al2O3 (triangle), and α-Al2O3 (dot). The numbers are the mass ratio of γ-Al2O3 to carbon black (CB). b Phase mass ratios of the product after PDC process varied with volume fraction of γ-Al2O3, f(γ-Al2O3). The blue region denotes the pure α-phase at f = 0.73. c Conductivities and temperatures varied with f(γ-Al2O3). The blue region denotes the pure α-phase at f = 0.73. d–f Simulated current density maps of the sample during PDC with different γ-Al2O3 volume fractions of d f = 0.41, e f = 0.73, and f f = 0.78. The separated balls are γ-Al2O3 NPs and the continuous phase is CB. The color bars show the current density values.

To explain the f(γ-Al2O3)-dependent phase transformation, the electrical conductivity and temperature were measured. The conductivities are calculated based on the measured resistance (R) and the feature size of the samples (Supplementary Table 1 and Fig. 3c). The conductivity is inversely proportional to f(γ-Al2O3), which is reasonable since γ-Al2O3 is electrically insulative. The real-time temperature was measured using an infrared (IR) thermometer (Supplementary Fig. 14). The average bulk temperature is decreased with the increase of f(γ-Al2O3) (Fig. 3c). This could be explained by the power (P) equation of Joule heating by Eq. (2),

where V is the voltage, and σ is the conductivity of the sample. Since the start voltages were fixed to V0 = 60 V, the power was proportional to the conductivity of the sample. Intriguingly, the phase-pure α-Al2O3 NPs were obtained at a low average bulk temperature of ~573 K with f(γ-Al2O3) ~0.73 (Fig. 3c).

Such a low temperature is not supposed to trigger the phase transformation from γ- to α-Al2O3 with a high activation energy of ~485 kJ mol–1 (ref. 16). The phase transformation temperatures from transition alumina to α-Al2O3 in other thermal processes are substantially higher (Fig. 1b), e.g., flame spray pyrolysis at 1873 K (ref. 20), furnace annealing at 1473 K (ref. 16), and the annealing process even with α-Fe2O3 seeds at 973 K (ref. 6). Moreover, the higher phase transformation degree at a lower temperature is counterintuitive (Fig. 3c). To explain the intriguing phenomenon, we conduct a numerical simulation based on the finite element method (FEM) on the current density distribution of the γ-Al2O3/CB composite during PDC process (see details in Supplementary Note 2, Supplementary Figs. 15–19, and Supplementary Tables 3–5). As shown in Fig. 3d–f, the current density is inhomogeneous in the composite of γ-Al2O3 and CB; the current densities at the regions of vertical gaps between γ-Al2O3 NPs are larger than the bulk regions. The gaps become narrower as the f(γ-Al2O3) increased, leading to substantially large current densities in those regions. Considering that the resistivity (R) of the conductive CB phase is constant, the heat (Q) per volume produced by PDC is proportional to the square of the current density (j) by Eq. (3),

The large thermal dissipation in the regions with high current densities leads to the hotspots near γ-Al2O3 NPs with much higher temperature than the bulk regions, which triggers the phase transformation.

Experimentally, f(γ-Al2O3) of ~0.73 is the optimized volume fraction for the rapid and thorough phase transformation. Since the phase transformation temperature from γ- to α-phase using a furnace annealing is reported to be ~1473 K (ref. 16), we here defined the region as the hotspot zone with temperature Thotspot ≥ 1473 K. Under such a definition, the hotspot zone is depicted (Supplementary Fig. 18), and it is estimated that ~30% of the particle surface area is heated to above the phase transformation temperature (see details in Supplementary Note 2, Estimation of the temperature and zone size of the hotspot). The quantitative analysis of the current densities suggests a decreased bulk temperature but an increased hotspot temperature as the f(γ-Al2O3) increases (Supplementary Fig. 19), which agrees well with the average bulk temperature measurement (Fig. 3c). Thus, the resistive hotspot-induced local heating during the PDC process well explains the observed phase transformation at a low bulk average temperature.

Topotactic transition pathway revealed by ab initio calculations

To provide deeper insight into the topotactic transition pathway, we conducted thermodynamic analysis of the three Al2O3 phases based on DFT (see details in Methods). Both the bulk energies and surface energies of the three Al2O3 phases were calculated (Fig. 4a and Supplementary Table 6). The bulk energy of α-Al2O3 is the lowest, followed by that of δʹ-Al2O3, and then γ-Al2O3, indicating that the α-Al2O3 is the most stable phase as a dense bulk crystal. The surface energies of (100), (110), and (111) facets of the cubic γ-Al2O3 and δʹ-Al2O3 were calculated, and the (0001), (\(1\bar{1}00\)), and \((11\bar{2}0)\) facets were calculated for hexagonal α-Al2O3 (Supplementary Fig. 20). The surface energy of Al2O3 is affected by the hydroxylated/anhydrous surface states13,37. The FT-IR spectra show that the intermediate δʹ-Al2O3 phase and the α-Al2O3 product are anhydrous (Fig. 2e and Supplementary Fig. 21a), while the γ-Al2O3 is hydroxylated. The TGA shows that the surface hydroxyl group density is ~2 OH nm–2 (Supplementary Fig. 21b); hence, the surfaces of γ-Al2O3 were modeled with this hydroxyl density (Supplementary Note 3 and Supplementary Figs. 22–23). It is found that the surface energy is opposite to the bulk energy, where γ-Al2O3 has the lowest surface energy, followed by δʹ-Al2O3, and then α-Al2O3 (Fig. 4a).

a The bulk energies (μ, eV per Al2O3) and the surface energies (є, eV Å–2) of representative crystal surfaces for the three Al2O3 phases. The δʹ-Al2O3 and α-Al2O3 phases are anhydrous and the γ-Al2O3 phase is hydroxylated with 2 OH nm–2. b The total energy (the sum of bulk energy and surface energy) of the Al2O3 nanocrystals of three phases as plotted against the specific surface area. c The contour plots of partial charge density at the highest bands (0.3 eV below the Fermi levels) of the anhydrous surface states of γ-Al2O3(100), δʹ-Al2O3(100), and α-Al2O3(0001) from top view (top) and lateral view (bottom).

The nanocrystal shapes of the three phases were optimized by the Wulff theorem38, and the specific surface area and total energy were calculated (Supplementary Note 4 and Supplementary Fig. 24). The surface energy difference regulates the thermodynamic stability of the three Al2O3 phases (Fig. 4b), driving the phase transformation from γ-Al2O3 to δʹ-Al2O3 and then to α-Al2O3 phase as the surface area decreases, consistent with the experimental observation (Fig. 1b). When smaller than a surface area of ~93 m2 g–1, or larger than a particle size of ~17 nm, the α-Al2O3 phase becomes more stable than the δʹ-phase. Hence, this particle size is suggested as the thermodynamic limit for the synthesis of anhydrous α-Al2O3 by a thermal process that involves an intermediate δʹ-phase. The particle size of α-Al2O3 (~23 nm) synthesized by PDC approaches the thermodynamically limited value, and smaller than those obtained by most other thermal processes (Supplementary Table 7). The ultrafast, pulsed, and low-temperature PDC process to a large extent avoids mass transfer and grain coarsening during the phase transformation process. After adding the entropic contribution, which is minor compared to enthalpy, the free energy vs. surface area is plotted which leads to the same conclusions (Supplementary Note 5 and Supplementary Fig. 25). We note that the energy diagram is merely dependent on the specific surface area and irrelevant to the pore features.

To gain insight into the structural origin of the phase-dependent bulk and surface energy, the partial charge density contour at the highest bands (0.3 eV below the Fermi levels) of the surface states of the three Al2O3 phases were plotted (Fig. 4c). All of the surface atoms on α-Al2O3(0001) are active, while the sites with missing Al atoms on the δʹ-Al2O3(100) and γ-Al2O3(100) surfaces are relatively active (Fig. 4c, top). Closer analysis indicates that the active states go deep into the bulk for the δʹ-Al2O3(100) and γ-Al2O3(100) but not for α-Al2O3(0001) (Fig. 4c, bottom). This explains the bulk as well as surface energy sequences of the three Al2O3 phases, and identifies the Al vacancies in γ- and δʹ-phases as the structural origin of their thermodynamic stability/instability vs. the α-phase. The calculation explicitly shows that the phase transformation is thermodynamically driven by the surface energy differences among the three Al2O3 phases.

To further verify this, we conducted ab initio dynamic simulations of phase transformation between γ- and α-phases (Supplementary Note 6 and Supplementary Table 8). Owing to the limitation of current calculation capability, we were unable to depict the full diagram of the phase transformation details. Nevertheless, we found that when the particle size is smaller, the high surface energy of α-phase drives its transformation to a structure with typical local order features of γ-phase (Supplementary Figs. 26 and 27). In contrast, based on the bulk crystal model, the high bulk energy of γ-phase drives its transformation to a structure with higher coordination numbers of Al and O, approaching those of the α-phase (Supplementary Fig. 28 and Supplementary Table 9). Thus, the phase transition from α- to γ-phase is a surface-initiated process while the transition from γ- to α-phase is a bulk defect-initiated process, consistent with the calculated energy landscape (Fig. 4a-b) and the electronic structure analysis (Fig. 4c).

Sintering of nanograined alumina ceramics

One prominent application of α-Al2O3 NPs is as the precursor for sintering high-strength nanograined alumina ceramics. The typical alumina ceramics sintering processes occur under high-pressure and high-temperature (HP-HT) conditions, such as hot isostatic pressing39, spark plasma sintering18, and pulse electric current sintering40. The high pressure, usually several GPa, retains the grain growth and advances densification41, which is critical for dense ceramic sintering using coarse grained precursors. The use of additives such as MgO can retard grain growth and advance densification42,43. However, the HP-HT process is not suitable for complex structures. The nanocrystalline precursors could undergo the pressureless sintering yet it would suffer from an elevated sintering temperature and prolonged time (>10 h)6,44,45. Spark plasma sintering that enables a heating rate up to 600 °C min–1 has been used for alumina sintering46. Very recently, an ultrafast high-temperature sinter method47 with heating rate up to 104 °C min–1 based on direct current heating is reported for the rapid screening of ceramics.

Here, also based on the Joule heating technique, we developed the alternative current sintering (ACS) process for pressureless, ultrafast sintering of alumina ceramics. The ACS system can provide stable and high-energy output with voltages up to 63 V and currents up to 100 A (Supplementary Fig. 29a), making it suitable for the sintering of structural ceramics. Two separated, highly graphitized carbon papers connected to electrodes were used as the heating elements (Supplementary Fig. 29b). The α-Al2O3 NPs, mixed with polyethylene glycol (PEG) binder48, were pressed at 500 MPa into green body (See details in Methods). Commercial α-Al2O3 nanopowders (APS ~300 nm) were used as a control. After removal of the binder (5 °C min–1 to 500 °C for 2 h hold; in air), the green body was put between the carbon papers and under the ACS process at ~15 V (Fig. 5a). The temperature was recorded by fitting the blackbody radiation (Supplementary Fig. 30). The temperature rapidly ramped up to ~2250 K with a heating rate of ~103 K s–1. After stable sintering for 5 s, the sample cooled also with a rapid cooling rate of ~103 K s–1 (Fig. 5b).

a Picture of the carbon papers during heating, sintering, and cooling. b Real-time temperature measurement during the alternating current sintering (ACS) process. c Grain size distribution of the alumina ceramic by ACS sintering using the α-Al2O3 NPs as precursor. Inset, scanning electron microscopy (SEM) image of the ceramic. d Grain size distribution of the alumina ceramic by two-step pressureless sintering (TS-PS) using the α-Al2O3 NPs as precursor. Inset, SEM image of the ceramic. e Grain size distribution of the alumina ceramic by TS-PS using the commercial α-Al2O3 nanopowders as precursor. Inset, SEM image of the ceramic. f Hardness distribution of the alumina ceramics by TS-PS process using the α-Al2O3 NPs (red) and commercial α-Al2O3 nanopowders (blue) as precursors. The dot within the box indicates the median, and the range indicates the 1.5IQR. The hardness of commercial standard alumina46 (10.5–12.7 GPa, lower band) and single-crystal sapphire50 (15.2–17.4 GPa, upper band) are labeled as reference.

Even after ACS sintering for only 1 min, the relative density of the ceramics from the α-Al2O3 NPs precursor reaches ~97%, higher than that from the commercial α-Al2O3 nanopowders at ~93% (Supplementary Fig. 31 and Supplementary Table 10). The microstructure of the alumina ceramics from α-Al2O3 NPs by scanning electron microscopy (SEM) showed the average grain size at ~0.12 μm (Fig. 5c); in comparison, the alumina ceramics sintered from the commercial α-Al2O3 nanopowders exhibited high residual porosity with grain size of ~1.15 μm (Supplementary Fig. 32), demonstrating that the sinter was in its initial stage. These results shows that the ultrafine particle size of the α-Al2O3 NPs facilitates the ultrafast sintering, presumably assisted by the grain growth at high temperature6. The mechanical properties were measured on the carefully polished ceramics (see details in Methods). Even with only 1 min ACS sintering, the Young’s modulus and hardness of the ceramics from the α-Al2O3 NPs reach ~86.0 GPa and ~6.2 GPa, respectively (Supplementary Fig. 33), higher than those from the commercial α-Al2O3 nanopowders (modulus ~40.6 GPa, hardness ~4.2 GPa).

To further improve the mechanical properties, the two-step pressureless sintering (TS-PS) using a high-temperature furnace was applied (see details in Method, Supplementary Fig. 34). Similar to the ACS process, the ceramics sintered by TS-PS from the α-Al2O3 NPs precursor have a higher density (~99%, Supplementary Fig. 31) and much finer grain size (~0.30 μm, Fig. 5d) than those from the commercial α-Al2O3 nanopowder precursors (density ~96% shown in Supplementary Fig. 31, and grain size ~1.21 μm shown in Fig. 5e and Supplementary Fig. 35). The mechanical properties of the ceramics were measured (Fig. 5f and Supplementary Fig. 35). The ceramics sintered from α-Al2O3 NPs precursor demonstrate an average Young’s modulus of ~179 GPa (Supplementary Fig. 36a), significantly higher than that from the commercial α-Al2O3 nanopowders (~106 GPa). The median hardness of the ceramics sintered from the α-Al2O3 NPs reaches ~15 GPa (Fig. 5f), which is better than the commercial standard alumina (10.5–12.7 GPa, ref. 49), and comparable to the single-crystal sapphire (15.2–17.4 GPa, ref. 50). We note that the mechanical properties of alumina ceramics are susceptible to various processing parameters51,52. For example, the hardness values of 15 – 20 GPa were achieved by Krell and coworkers50,52, who applied delicate specimens fabrication by hot isostatic pressing, pressure filtration, gel casting, etc. While we do not seek to systematically optimize the sintering process here, the density, grain size, and hardness obtained from the as-synthesized α-Al2O3 NPs are already superior to commercial products and comparable to most state-of-the-art reports (Supplementary Table 11).

Discussion

To conclude, an ultrafast PDC processing of γ-Al2O3 was developed for the synthesis of fully dehydrated α-Al2O3 NPs (~23 nm) at significantly reduced temperature and duration (~573 K, < 1 s) than previous thermal processes. Numerical simulations reveal that the phase transformation was enabled by the resistive hotspot effect that induces local heating in the PDC process. Being a highly efficient energy supplies technology, Joule heating has a coefficient of performance of 1.0. The localized heating by resistive hotspots in PDC makes the process more effective because most of the electrothermal energy is directly targeted to the phase transformation. The phase transformation synthesis of α-Al2O3 NPs is realized with a low-energy input of ~4.77 kJ g–1 or $0.027 kg–1 in electrical energy cost, which is at least 20× less energy consumptive than a normal furnace annealing process (Supplementary Note 7). Moreover, the PDC process could be scalable by adjusting sample cross-sectional area and the PDC voltage, as suggested by the theoretical analysis of the key parameters (Supplementary Note 8). We demonstrated the synthesis of α-Al2O3 NPs up to 1.4 g-scale per batch within a similar timescale by using a higher PDC voltage (Supplementary Fig. 37).

The PDC process combined with the resistive hotspot effect greatly reduces the required temperature for reactions that should be originally triggered at a high-energy input, serving as an alternative technique for cost-efficient synthesis. We envision that this would be a universal strategy in electrical heating processes whenever a composite (one conductive phase and one non-conductive phase, or two phases with different conductivities) is used. The ACS process with the ultrafast and energy-efficient features, as demonstrated by the sintering of the alumina ceramic within 1 min, could also be promising in the sintering of functional ceramics, porous ceramics, or for materials screening47.

Methods

Materials

Commercial γ-Al2O3 nanopowders (US Nano, 99.99%, hydrophilic, average particle size of 5 nm, made by high-temperature combustion method) were used as the precursors. Prior to use, the starting material is extensively characterized by XRD (Fig. 1c), Rietveld refinement (Supplementary Fig. 6a), FT-IR (Fig. 2e), SEM (Supplementary Fig. 3), TEM (Supplementary Fig. 4), and BET (Supplementary Fig. 5). The XRD refinement shows that the starting material is composed of ~91 wt% γ-Al2O3 and ~9 wt% γ-Al(OH)3 according to the quantitative analysis. The γ-Al(OH)3 could be easily decomposed to γ-Al2O3 by mild calcination (in air, 700 °C for 1 h; Supplementary Fig. 6b). CB (Carbot, BP-2000) was used as the conductive additive. Commercial α-Al2O3 nanopowders (US Nano, 99.9%, 300 nm) were used as comparison for alumina ceramics sintering.

PDC system and alumina phase transformation process

The electrical diagram of the PDC system is shown in Supplementary Fig. 1a. The γ-Al2O3 NPs precursor and CB with specific mass ratios were mixed by planetary ball milling (MSE Supplies, PMV1-0.4 L) for 2 h. The precursors (~150 mg per batch) were loaded into a quartz tube with an inner diameter (I.D.) of 8 mm and outside diameter (O.D.) of 12 mm. Graphite rods were used as the electrodes in both ends of the quartz tube. The use of graphite electrodes prevents the contamination of the product. The tube was then loaded on the reaction stage and connected to the PDC system. The resistance was controlled by the compressive force on the electrodes across the sample. The reaction stage was loaded into a plastic vacuum desiccator chamber under a mild vacuum (~10 mm Hg). A capacitor bank with a total capacitance of 0.624 F was charged by a DC supply that can reach voltages up to 500 V. A relay with programmable ms-level delay time was used to control the discharge time. A variable-frequency drive (VFD) was used to generate pulsed voltage with a frequency that ranges from 0 to 1000 Hz. In the synthesis, a voltage frequency of f = 1000 Hz was used. To prevent overheating, the discharge period (or ON state) was set to 20%, and the rest period (or OFF state) was set to 80% (Supplementary Fig. 1b). The heating time was calculated according to the discharge period. Detailed conditions are listed in Supplementary Table 1. After the PDC Joule heating, the apparatus was cooled to room temperature. CAUTION: There is a risk of electrical shock if improperly operated. Safety guidelines can be found in the Supplemental. After PDC Joule heating synthesis, the mixture of Al2O3 NPs and CB residues were calcined at 700 °C for 1 h in air using a Mafu furnace (NEY, MODELS 6-525) to remove the CB and purify the α-Al2O3 NPs product.

Alumina ceramics sintering

Green body preparation

PEG was used as the binder48. PEG (M.W. 10000) was dissolved into deionized (DI) water at a concentration of 1 wt%. The α-Al2O3 NPs (~20 mg) and PEG were mixed with the PEG ratio of 3 wt%. After drying at 80 °C for 3 h in air, the α-Al2O3 NPs were pressed into pellets (diameter of 5 mm, thickness of ~0.5 mm) using a hydraulic press (500 MPa, dwell time of 10 min, Strongway Benchtop 10-Ton Hydraulic Shop Press). The binder was removed by calcining at 500 °C for 3 h in air at a heating rate of 5 °C min–1 using a Mafu furnace (NEY, MODELS 6-525). The commercial α-Al2O3 nanopoweders (~300 nm) were used as control.

ACS system and ACS sintering process

The electric diagram of the ACS system is show in Supplementary Fig. 29a. The total capacitance of the capacitor bank is 1.5 F. The system was capable of charging to voltage of 0 to 63 V and the current of 0 to 100 A. Two carbon papers (Toray Carbon Paper 060, FuelCellStore) attached to a glass slide were used as the heating element and sample holder (Supplementary Fig. 29b). The resistance of the carbon paper was ~1 Ω. The α-Al2O3 green bodies were put in between the carbon papers, which were connected to the ACS system. The voltage was set to ~15 V and the sintering time was 1 min.

Two-step pressureless sintering process

The two-step pressureless sintering (TS-PS) of alumina ceramics was conducted using a Mafu furnace (Carbolite RHF 1500) with the maximum temperature of 1500 °C. In the first step, the sample temperature ramps to 1425 °C with the heating rate of 5 °C min–1 and is maintained at 1425 °C for 2 h. In the second step, the sample cools to 1350 °C and is maintained for 5 h. Then, the sample slowly cools to room temperature (Supplementary Fig. 34).

Density measurement

The densities of the samples, including the green bodies and the sintered ceramics, are measured by Archimedes’ method.

Ceramics surface polishing

Prior to the mechanical property measurement, the sintered ceramic samples were carefully ground and polished using a wafer polisher (MultiPrepTM Precision Polishing System). Diamond lapping film with grit of 15, 9, 6, 3, 1, and 0.1 μm were sequentially used. After the polishing process, mirror-like surfaces were obtained for the ceramics sintered from the α-Al2O3 NPs precursors. In contrast, we cannot obtain mirror-like surface for the ceramics sintered from commercial α-Al2O3 nanopowders precursors with the same polishing process.

Mechanical properties measurement

The Young’s modulus and Vickers hardness of ceramics were measured using a Hysitron TI 980 TriboIndenter. A diamond tip was used as the indenter. 25 curves were measured on each kind of ceramic sample surfaces to account for the deviation caused by residual porosity and heterogeneities. The reduced Young’s moduli were measured, and the Young’s moduli were calculated by Eq. (4),

where Er is the reduce Young’s modules of the sample, E is the Young’s modules of the sample, v is the Poisson’s ratio of the sample (v = 0.22), Ei is the Young’s modules of the indenter (Ei = 1220 GPa), and vi is the Poisson’s ratio of the indenter (vi = 0.2).

Microstructure characterization

For the ceramics sintered by the TS-PS process, the polished samples were thermally etching at 1400 °C using a furnace (Carbolite RHF 1500) for 30 min for SEM imaging20. For the ceramics sintered by the ultrafast ACS process, the thermal etching process is not suitable since it may change the original microstructures; hence, these samples were cracked and the fracture surfaces were characterized by SEM42. The grain size distribution is obtained by measuring 100 grains using ImageJ.

Characterization

SEM images were obtained using a FEI Helios NanoLab 660 DualBeam SEM system at voltage of 15 kV and beam current of 100 pA. The element maps by EDS were obtained on a FEI Quanta 400 ESEM FEG system with an EDS detector (Oxford Instrument). The Raman spectra were acquired using a Renishaw Raman microscope (laser wavelength of 532 nm, laser power of 5 mW, and lens of 50×). XRD was collected by using a Rigaku Smartlab II system configured with a Cu Kα radiation (λ = 1.5406 Å). The Rietveld refinement was conducted using the GSAS-II software53. Rwp values <5% were achieved to secure good convergence. XPS analyses were conducted using a PHI Quantera XPS system under a base pressure of 5 × 10-9 Torr. Elemental spectra were collected using a step size of 0.5 eV with the pass energy of 26 eV. All of the XPS spectra were calibrated by using the standard C 1 s peak at 284.8 eV. TEM images, selected area electron diffraction (SAED), and NBD patterns were taken on a JEOL 2100 field emission gun transmission electron microscope under the voltage of 200 kV. BET measurements were carried out on a Quantachrome Autosorb-iQ3-MP/Kr BET Surface Analyzer by using N2 as the adsorption/desorption gas at 77 K. FT-IR spectra were obtained using a Nicolet FT-IR Infrared Microscope. TGA measurement for carbon black removal was conducted in air at a heating rate of 10 °C min–1 by using a Q-600 Simultaneous TGA/DSC from TA instruments. TGA measurement of the surface hydroxyl coverage on γ-Al2O3 was conducted in N2 at a heating rate of 10 °C min–1 by using a Mettler Toledo TGA/DSC 3+ system from METTLER TOLEDO. The calcination in air (700 °C for 1 h) to remove the carbon black for purification of α-Al2O3 NPs was conducted using a Mafu furnace (NEY 6-160A). The DLS measurement was performed using a NanoSight NS300 system. Prior to measurement, the samples were dispersed in DI water and ultrasonicated using a cup horn sonicator for 0.5 h.

Temperature measurement

For the PDC induce phase transformation process, the temperature was measured using an IR thermometer (Micro-Epsilon) with temperature measurement range of 200 to 1500 °C. The thermometer is connected to LabView software by using a Multifunction I/O (NI USB-6009) for real-time temperature recording (Supplementary Fig. 14a). Prior to use, the temperature was calibrated on the thermometer.

For the ACS of alumina ceramics process, the temperature was measured by fitting the blackbody radiation of the sample using a homemade, time-resolved spectrometer (Supplementary Fig. 30). The light emitted from the sample during Joule heating was collected by a 16-channel photomultiplier tube (PMT) array, with the spectrum range of 640–1000 nm. The sampling rate was 10 kHz, allowing for the temporal resolution of ~100 μs. The emission spectra were then fitted to the blackbody radiation to obtain the temperature (T) using Eq. (5),

where λ is the wavelength, γ is a constant introduced for fitting, h is the Planck constant, c is the speed of light in vacuum, and kB is the Boltzmann constant.

DFT calculations

The DFT method54 was used as implemented in the Vienna ab initio Simulation Package (VASP)55. A plane wave expansion up to 500 eV is employed in combination with an all-electron-like projector augmented wave (PAW) potential56. Exchange-correlation is treated within the generalized gradient approximation (GGA) using the functional parameterized by Perdew, Burke, and Ernzerhof57.

Bulk energy calculation

We first calculated the three bulk crystals, α-Al2O3, δʹ-Al2O3, and γ-Al2O3. The α-Al2O3 is the ground-state structure with a hexagonal R-3c symmetry. Both δʹ-Al2O3 and γ-Al2O3 structures are derived from the spinel MgAl2O4 structure with the space group of Fd-3m and a cubic unit cell (a = 8.17Å) of 4-Al4O8 layers and 8 Mg atoms in between. The Al atoms are octahedrally coordinated and Mg atoms are tetrahedrally coordinated. By replacing Mg with Al atoms, the obtained spinel Al3O4 has 32 O atoms, 16 Al atoms at the octahedral sites, and 8 Al atoms at the tetrahedral sites. A 1 × 1 × 3 supercell (Al72O96) is constructed of 12-Al4O8 layers in z direction with 24-tetrahedral Al atoms between the layers. Removing 8 out of the total 72 Al atoms in the supercell yields the Al2O3 formula58. The δʹ-phase is formed by removing an octahedrally coordinated Al atom from each Al4O8 layers, with one out of every three layers being skipped. The γ-phase is formed by removing tetrahedrally coordinated Al atoms in such a way that every two of the three layers are skipped. Periodic boundary conditions are applied to the unit cell in all three dimensions, with the size of the unit cells or lattice constants being optimized. The Brillouin zone integrations are performed using Monkhorst-Pack type meshes59, with sufficient meshes of k-points chosen so that the energy and lattice constant are fully converged. All structures are fully relaxed when the maximum force on each atom is smaller than 0.01 eV Å–1. The results of calculated bulk properties of the three phases are summarized in Supplementary Table 6.

Surface energy calculation

We calculated the surface energies of both pristine and OH-adsorbed surfaces. For the OH-adsorbed surface, H-adsorption exists to balance the charge37. For the hexagonal α-Al2O3 phase, three surfaces of (0001), (\(1\bar{1}00\)), and \((11\bar{2}0)\) are studied and no surface reconstruction is found to further lower the surface energy (Supplementary Fig. 20a). For both δʹ-Al2O3 and γ-Al2O3 phases derived from the original cubic spinel structure, the (001), (110), and (111) surfaces are investigated (Supplementary Figs. 20b, c). These defect-rich surfaces are found to have lower-energy reconstructions with rearrangement of surface atoms. The surface slabs (15–23 Å thick) are constructed so that the two surfaces bounded by vacuum are in inversion symmetry. Low-energy structures of adsorption of OH─ (on the Al sites) and H+ (on O sites)37,60 are searched computationally based on the optimized symmetry and homogenous distribution. The optimized atomic structures of γ-Al2O3 surfaces with ~2 OH nm–2 are shown in Supplementary Fig. 23. The vacuum layers between the slabs are chosen to be 10 Å or thicker. The surface energy (є, in eV Å–2) is calculated by Eq. (6),

where \({E}_{{{{{{\rm{slab}}}}}}}\) is the total energy of the slab, N is the total number of Al2O3 units in the slab, μ is the bulk energy in eV per Al2O3, h is the number of water molecules adsorbed in the form of split OH─ and H+, \({E}_{{{{{{{\rm{H}}}}}}}_{2}{{{{{\rm{O}}}}}}}\) is the total energy of a water molecule, and S is the surface area of one side of the slab. The calculated surface energies of typical crystal surfaces for the three Al2O3 phases, both with and without surface OH group adsorption, are shown in Supplementary Table 6.

Nanocrystal shape optimization based on Wulff construction

Strict analysis of formation energy of nanocrystals is based on the generalized Wulff theorem that considers bulk energy, surface energy, edge energy, and vertex energy61. However, direct optimization of the Wulff energy is practically forbidden because in most cases it is not feasible to determine the detailed atomic structures of the reconstructed high-index surfaces, edges, vertices. Therefore, the more practical and typical method involves a limited rational search of hypothetical structures of nanocrystals that potentially have the lowest energy62. In this study, we optimize the polyhedral shape of nanoparticles based on the surfaces listed in Supplementary Table 6. Optimization of the shape of nanocrystals is based on the generalized Wulff theorem61,

where Etotal is the total energy, μ is the bulk energy per formular unit (or atom), N is the total number of formular unit in the particle, Si is the area of the ith facet of the nanocrystal, \({\epsilon }_{i}\) is the surface energy area of the ith facet of the nanocrystal, \({l}_{j}\) is the length of the jth edge, \({e}_{j}\) is the edge energy, and \({v}_{k}\) is the energy of the kth vertex. Then the Eq. (7) can be further simplified by considering only the most probable facets with relatively lower indexes because the higher-index facets normally have much higher energy or complicated reconstruction, which make them unlikely occur in nanocrystals. The detailed shape optimization processes of the three Al2O3 phases are shown in Supplementary Note 4.

Plotting total energy vs. specific surface area

The total energy (Etotal) of the nanocrystal is expressed as Eq. (8),

where N is the total number of Al2O3 units, μ is the bulk energy in eV per Al2O3, Si is the area of each facet of the nanocrystal, \({\epsilon }_{i}\) is the surface energy in eV Å–2, and N = V × n, where n is the density, and volume V and Si are the functions of the structural parameters of the polyhedrons. The specific surface area is calculated by Eq. (9),

where Si is the area of each facet of the nanocrystal, N is the total number of Al2O3 units, AAl is the atomic mass of Al (26.9815), AO is the atomic mass of O (15.9994), and u is the atomic mass (1.6605 × 10–24 g). The total energy and the specific surface area of the three Al2O3 phases are calculated based on the optimized nanocrystal shapes, and their detailed expressions are shown in Supplementary Note 4. The energy of the nanocrystals is thus plotted against surface area (Fig. 4b).

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information. The source data generated in this study have been deposited in the Zenodo database under https://doi.org/10.5281/zenodo.6850605. Other relevant data are available from the corresponding authors upon request. Source data are provided with this paper.

References

De Aza, A. H., Chevalier, J., Fantozzi, G., Schehl, M. & Torrecillas, R. Crack growth resistance of alumina, zirconia and zirconia toughened alumina ceramics for joint prostheses. Biomaterials 23, 937–945 (2002).

Piconi, C., Maccauro, G., Muratori, F. & Del Prever, E. B. Alumina and zirconia ceramics in joint replacements. J. Appl. Biomater. Biom. 1, 19–32 (2003).

Kumar, A. S., Durai, A. R. & Sornakumar, T. Machinability of hardened steel using alumina based ceramic cutting tools. Int. J. Refract. Met. H. 21, 109–117 (2003).

Ighodaro, O. L. & Okoli, O. I. Fracture toughness enhancement for alumina systems: A review. Int. J. Appl. Ceram. Tec. 5, 313–323 (2008).

Krell, A. & Klaffke, D. Effects of grain size and humidity on fretting wear in fine-grained alumina, Al2O3/TiC, and zirconia. J. Am. Ceram. Soc. 79, 1139–1146 (1996).

Guo, R. Y., Cao, W. B., Mao, X. & Li, J. G. Selective corrosion preparation and sintering of disperse α-Al2O3 nanoparticles. J. Am. Ceram. Soc. 99, 3556–3560 (2016).

Peterson, E. J. et al. Low-temperature carbon monoxide oxidation catalysed by regenerable atomically dispersed palladium on alumina. Nat. Commun. 5, 4885 (2014).

Frank, B., Emig, G. & Renken, A. Kinetics and mechanism of the reduction of nitric oxides by H2 under lean-burn conditions on a Pt-Mo-Co/α-Al2O3 catalyst. Appl. Catal. B: Environ. 19, 45–57 (1998).

Lin, B. Y. et al. Ammonia synthesis activity of alumina-supported ruthenium catalyst enhanced by alumina phase transformation. ACS Catal. 9, 1635–1644 (2019).

Marturano, M., Aglietti, E. F. & Ferretti, O. α-Al2O3 catalyst supports for synthesis gas production: Influence of different alumina bonding agents on support and catalyst properties. Mater. Chem. Phys. 47, 252–256 (1997).

Cui, Y., Zhang, H., Xu, H. & Li, W. Kinetic study of the catalytic reforming of CH4 with CO2 to syngas over Ni/α-Al2O3 catalyst: The effect of temperature on the reforming mechanism. Appl. Catal. A: Gen. 318, 79–88 (2007).

McHale, J. M., Auroux, A., Perrotta, A. J. & Navrotsky, A. Surface energies and thermodynamic phase stability in nanocrystalline aluminas. Science 277, 788–791 (1997).

Amrute, A. P., Lodziana, Z., Schreyer, H., Weidenthaler, C. & Schuth, F. High-surface-area corundum by mechanochemically induced phase transformation of boehmite. Science 366, 485–489 (2019).

Blonski, S. & Garofalini, S. H. Molecular dynamics simulations of α-alumina and γ-alumina surfaces. Surf. Sci. 295, 263–274 (1993).

Castro, R. H. R., Ushakov, S. V., Gengembre, L., Gouvêa, D. & Navrotsky, A. Surface energy and thermodynamic stability of γ-alumina: Effect of dopants and water. Chem. Mater. 18, 1867–1872 (2006).

Steiner, C. J. P., Hasselman & Spriggs, R. M. Kinetics of the gamma-to-alpha alumina phase transformation. J. Am. Ceram. Soc. 54, 412–413 (1971).

Levin, I. & Brandon, D. Metastable alumina polymorphs: crystal structures and transition sequences. J. Am. Ceram. Soc. 81, 1995–2012 (1998).

Balima, F. & Largeteau, A. Phase transformation of alumina induced by high pressure spark plasma sintering (HP-SPS). Scr. Mater. 158, 20–23 (2019).

Chang, P. L., Yen, F. S., Cheng, K. C. & Wen, H. L. Examinations on the critical and primary crystallite sizes during θ- to α-phase transformation of ultrafine alumina powders. Nano Lett. 1, 253–261 (2001).

Laine, R. M., Marchal, J. C., Sun, H. P. & Pan, X. Q. Nano-α-Al2O3 by liquid-feed flame spray pyrolysis. Nat. Mater. 5, 710–712 (2006).

Wilson, S. J. & Mc Connell, J. D. C. A kinetic study of the system γ-AlOOHAl2O3. J. Solid State Chem. 34, 315–322 (1980).

Macêdo, M. I. F., Bertran, C. A. & Osawa, C. C. Kinetics of the γ → α-alumina phase transformation by quantitative X-ray diffraction. J. Mater. Sci. 42, 2830–2836 (2007).

Prot, D., Le Gall, M., Lesage, B., Huntz, A. M. & Monty, C. Self-diffusion in α‒Al2O. IV. Oxygen grain-boundary self-diffusion in undoped and yttria-doped alumina polycrystals. Philos. Mag. A 73, 935–949 (1996).

Heuer, A. H. & Zahiri Azar, M. A disconnection mechanism of enhanced grain boundary diffusion in Al2O3. Scr. Mater. 102, 15–18 (2015).

Matsudaira, T., Wada, M., Saitoh, T. & Kitaoka, S. Oxygen permeability in cation-doped polycrystalline alumina under oxygen potential gradients at high temperatures. Acta Mater. 59, 5440–5450 (2011).

Nakagawa, T. et al. Grain boundary character dependence of oxygen grain boundary diffusion in α-Al2O3 bicrystals. Scr. Mater. 65, 544–547 (2011).

Johnson, W. L. et al. Beating crystallization in glass-forming metals by millisecond heating and processing. Science 332, 828–833 (2011).

Soderberg, M. Resistive breakdown of inhomogeneous-mdia. Phys. Rev. B 35, 352–357 (1987).

Amrute, A. P., Jeske, K., Łodziana, Z., Prieto, G. & Schüth, F. Hydrothermal stability of high-surface-area α-Al2O3 and its use as a support for hydrothermally stable fischer–tropsch synthesis catalysts. Chem. Mater. 32, 4369–4374 (2020).

Zielinski, P. A., Schulz, R., Kaliaguine, S. & Vanneste, A. Structural transformations of alumina by high-energy ball-milling. J. Mater. Res. 8, 2985–2992 (1993).

Chauruka, S. R. et al. Effect of mill type on the size reduction and phase transformation of gamma alumina. Chem. Eng. Sci. 134, 774–783 (2015).

Lamouri, S. et al. Control of the γ-alumina to α-alumina phase transformation for an optimized alumina densification. Bol. Soc. Esp. Ceram. V. 56, 47–54 (2017).

Luong, D. X. et al. Gram-scale bottom-up flash graphene synthesis. Nature 577, 647–651 (2020).

Wang, Y. Y. et al. Raman studies of monolayer graphene: the substrate effect. J. Phys. Chem. C. 112, 10637–10640 (2008).

Karagedov, G. R. & Lyakhov, N. Z. Preparation and sintering of nanosized α-Al2O3 powder. Nanostruct. Mater. 11, 559–572 (1999).

Landers, J., Gor, G. Y. & Neimark, A. V. Density functional theory methods for characterization of porous materials. Colloids Surf. A Physicochem. Eng. Asp. 437, 3–32 (2013).

Lagauche, M. et al. Thermodynamic characterization of the hydroxyl group on the γ-alumina surface by the energy distribution function. J. Phys. Chem. C. 121, 16770–16782 (2017).

Barmparis, G. D., Lodziana, Z., Lopez, N. & Remediakis, I. N. Nanoparticle shapes by using Wulff constructions and first-principles calculations. Beilstein J. Nanotechnol. 6, 361–368 (2015).

Mizuta, H. et al. Preparation of high-strength and translucent alumina by hot isostatic pressing. J. Am. Ceram. Soc. 75, 469–473 (1992).

Zhou, Y., Hirao, K., Yamauchi, Y. & Kanzaki, S. Densification and grain growth in pulse electric current sintering of alumina. J. Eur. Ceram. Soc. 24, 3465–3470 (2004).

Wang, S. F. et al. Transparent ceramics: processing, materials and applications. Prog. Solid State Chem. 41, 20–54 (2013).

Zhang, H. et al. Effects of heating rate on the microstructure and mechanical properties of rapid vacuum sintered translucent alumina. Ceram. Int. 41, 12499–12503 (2015).

Krell, A. & Klimke, J. Effects of the homogeneity of particle coordination on solid-state sintering of transparent alumina. J. Am. Ceram. Soc. 89, 1985–1992 (2006).

Cao, W. B. et al. Sintering of α-Al2O3 nanocrystalline ceramic from large α-Al2O3 polycrystalline nanoparticles. Ceram. Int. 43, 1378–1382 (2017).

Li, J. G. & Ye, Y. P. Densification and grain growth of Al2O3 nanoceramics during pressureless sintering. J. Am. Ceram. Soc. 89, 139–143 (2006).

Aman, Y., Garnier, V. & Djurado, E. Spark plasma sintering kinetics of pure α-alumina. J. Am. Ceram. Soc. 94, 2825–2833 (2011).

Wang, C. W. et al. A general method to synthesize and sinter bulk ceramics in seconds. Science 368, 521–526 (2020).

Taktak, R., Baklouti, S. & Bouaziz, J. Effect of binders on microstructural and mechanical properties of sintered alumina. Mater. Charact. 62, 912–916 (2011).

Superior Technical Ceramics Corp. https://www.ceramics.net/ceramic-materials-solutions/aluminas/std-alumina, accessed on 8th May (2022).

Krell, A. & Schädlich, S. Nanoindentation hardness of submicrometer alumina ceramics. Mater. Sci. Eng. A 307, 172–181 (2001).

Krell, A., Blank, P., Ma, H., Hutzler, T. & Nebelung, M. Processing of high-density submicrometer Al2O3 for new applications. J. Am. Ceram. Soc. 86, 546–553 (2003).

Krell, A. & Blank, P. The Influence of shaping method on the grain size dependence of strength in dense submicrometre alumina. J. Eur. Ceram. Soc. 16, 1189–1200 (1996).

Toby, B. H. & Von Dreele, R. B. GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J. Appl. Crystallogr. 46, 544–549 (2013).

Dudarev, S. L., Botton, G. A., Savrasov, S. Y., Humphreys, C. J. & Sutton, A. P. Electron-energy-loss spectra and the structural stability of nickel oxide: An LSDA+U study. Phys. Rev. B 57, 1505–1509 (1998).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Pinto, H. P., Nieminen, R. M. & Elliott, S. D. Ab initio study of γ-Al2O3 surfaces. Phys. Rev. B 70, 125402–125412 (2004).

Monkhorst, H. J. & Pack, J. D. Special points for brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Digne, M., Sautet, P., Raybaud, P., Euzen, P. & Toulhoat, H. Hydroxyl groups on γ-alumina surfaces: A DFT study. J. Catal. 211, 1–5 (2002).

Zhao, Y. F. & Yakobson, B. I. What is the ground-state structure of the thinnest Si nanowires? Phys. Rev. Lett. 91, 035501–035504 (2003).

Zhao, Y. F., Kim, Y. H., Du, M. H. & Zhang, S. B. First-principles prediction of icosahedral quantum dots for tetravalent semiconductors. Phys. Rev. Lett. 93, 015502–015505 (2004).

Acknowledgements

We thank Dr. Helge Gonnermann of Rice University for allowing us to use the FEM simulation software, and Dr. Bo Chen of Rice University for helpful discussion of the XPS results. The funding of the research is provided by Air Force Office of Scientific Research (FA9550-19-1-0296, J.M.T.), the Office of Naval Research (N00014-18-1-2182, B.I.Y.), and the U.S. Army Corps of Engineers, ERDC (W912HZ−21-2-0050, B.I.Y., Yufeng Z., and J.M.T.). The authors acknowledge the use of the Electron Microscopy Center (EMC) at Rice University. The characterization equipment used in this project is, in part, from the Shared Equipment Authority (SEA) at Rice University.

Author information

Authors and Affiliations

Contributions

B.D. and J.M.T. conceived the idea to use the PDC for alumina phase transformation. B.D. conducted the synthesis and characterizations with the help of E.A.M., Z.W., J.C., and R.A.C. B.D. conducted the numerical simulation. D.X.L. designed the PDC and ACS systems and the temperature measurement setups. B.D. conducted the ceramics sintering with the help of C.K. J.Z. and Yuji Z. helped with the ceramic polishing. P.A., B.Z., and J.L. conducted the mechanical measurement. Yufeng Z. and B.I.Y. conducted the DFT calculation. B.D., Yufeng Z., and J.M.T. wrote the manuscript. All aspects of the research were overseen by J.M.T. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

Rice University owns intellectual property on the PDC strategy for the phase transformation synthesis of corundum nanoparticles and ACS sintering process. The authors declare no other competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Deng, B., Advincula, P.A., Luong, D.X. et al. High-surface-area corundum nanoparticles by resistive hotspot-induced phase transformation. Nat Commun 13, 5027 (2022). https://doi.org/10.1038/s41467-022-32622-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-32622-4

This article is cited by

-

Heavy metal removal from coal fly ash for low carbon footprint cement

Communications Engineering (2023)

-

Studies of Thermo-electromagnetics Mechanisms Regulating a Direct/Hybrid Microwave Sintering of α and β-Aluminum Oxide: Kinetics of Densification and Influence of Magnetic Field

Metals and Materials International (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.