4.1. Building a SEnviro Node

The main objective of the current work is to propose an example of IoT node which follows the architecture made using open-hardware components, as detailed in the previous section. In this way, the development below is composed intimately of these types of elements.

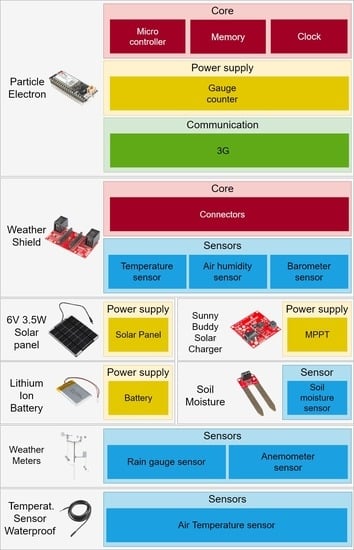

Following the physical components defined in

Section 3, the IoT node is composed as shown in

Figure 4. We now detail how each defined group (

Core,

Sensing/Acting,

Power Supply and

Communication) is developed. The same categorization is used to describe each component in

Table 2. The total price per

SEnviro node is €256.45. In what follows, each component is detailed and classified in each fixed group.

Particle (

Figure 5): This component has been chosen to be part of the core of the IoT node. As introduced in

Section 2, the Particle Electron microcontroller follows an open-source design. As shown in

Figure 5, this microcontroller is present in different blocks defined in

Figure 1, such as

Core,

Power Supply and

Communication. In the first group,

Core, the Electron acts as a microcontroller and is responsible for bringing the node to life and implementing all business models so that the node functions correctly. Unlike a conventional PC, Electron can only run one program, which will be detailed in the next subsection. It incorporates a STM32F205RGT6 ARM Cortex M3 chip which works at a frequency of 120 MHz. It can be updated using OTA updates. This functionality adds a considerable expansion regarding keeping each node updated and supporting new functionalities or behaviors in the future without the need to physically go to where the IoT node is deployed. The Electron will also be responsible for storing all the variables to support a normal operation by using RAM (128 KB RAM) and ROM (1 MB Flash). Within the Core group, it will also function to keep the current time; this is possible because Electron offers a Real-Time Operating System (RTOS) module.

The second group in which the Electron microcontroller is present is the Power supply. The Electron provides a chip called MAX17043, which can measure the energy consumed by the microcontroller (and all IoT node components). This microchip has an ultra-compact design, and its cost is meagre.

Finally, in the last group,

Communication, the announced microcontroller provides 2G and 3G (or any new technology such as 5–6 G) connectivity. The cellular module, U-blox SARA-U270, allows an Internet connection. To do this, it has a cellular antenna, which is essential for the microcontroller to establish a connection to a cellular tower. One difference from the version presented in [

7] can be found in the communication group. This new version provides 2G and 3G connectivity instead of Wi-Fi. This feature increases the possibility of installing a node anywhere with mobile data coverage.

Weather shield: This component is an easy-to-use circuit compatible with the Particle microcontrollers (Photon and Electron). The Electron can interact with the world through pins (30 Mixed-Signal GPIO), which will be used to connect this shield. The weather shield has built-in barometric pressure sensors (MPL3115A2), relative humidity and temperature (Si7021). Besides, the shield contains some RJ11 connectors to plug external sensors such as an anemometer and a rain gauge.

Table 3 describes all the features of the sensors. The weather shield is present in the

Core (Connectors) and

Sensors groups.

Solar panel: This component is waterproof, scratch resistant, and UV resistant. It uses a high-efficiency monocrystalline cell. The output is 6 V at 530 mA via 3.5 mm × 1.1 mm DC jack connector. The solar panel will be used to charge the battery and offers an uninterrupted IoT node operation. The solar panel is included in the Power supply.

Lithium ion battery: This component has a 2000 mA capacity and has been used to offer an energetically autonomous platform. It supplies an output voltage of 3.7 V and is charged using the power generated by the solar panel. The battery is included in the Power supply.

Sunny Buddy solar charger: This component is a MPPT solar charger and is included in the Power supply. It is responsible for monitoring current flow and is limited to a specific value to prevent damage to the battery. It is also an open-hardware component.

Soil Moisture: This component also has an open-hardware design, and through a simple breakout it can measure the humidity of the soil. The two pads act as a variable resistor; the more water there is in the soil, the better the conductivity between them. This results in less resistance and higher output. It is considered to be a part of the Sensor group.

Weather meters provide the three components of weather measurement: wind speed, wind direction, and rainfall. It offers RJ11 connectors, which facilitates installation with the above-mentioned weather shield. The weather meters are included in the Sensor group.

An enclosure has been designed to house all the components and to protect the electronic components. The box has been purposely designed to meet this end (

Figure 6), it has been printed using a 3D printer, and is valid for printing using polylactic acid (PLA) filament. Each node is identified by a QR code. This code is used to claim a device and start to collect data from the node.

Table 3 summarizes all the information about the

Sensors used in this proposal. All the

Sensors that have been chosen are open hardware and low cost. Despite their low price, most of the sensors used in industrial environments obtain reliable measurements.

4.2. Details of the Behavior

As indicated above, the microcontroller will be in charge of orchestrating the general operation of the node. That will be possible through a program, or sketch, that is responsible for giving functionality to each of the hardware components that make up the node. In this way, following the logic modules and state machine defined in the previous section, a sketch is developed. The

Figure 7 shows at a global level how each module has been used. We will now go on to detail each of them and how they work.

The first module is

Logic control, which does not have a specific functionality. It is responsible for joining the different modules in a coherent way. As in [

7], two modes are defined, initial (INIT in states machine) and loop modes. The initial mode is executed as an initializer when the node boots. When the initial mode is complete, the loop method is executed repeatedly while the node is on.

The Basic config module is responsible for storing and managing the basic configuration/settings. Part of its configuration is defined in the initial mode and updated during the loop mode. The basic configuration is responsible for defining aspects such as which sensors will be consulted, the list of actions to be performed on the actuators, the observation frequency, the configuration to establish an M2M communication and checking whether the IoT node has a new update.

Within the loop mode, which is executed depending on the frequency of the Basic config module, the first module is the Energy savings. This module determines the energetic strategy depending on the battery charge. Three different modes are defined, each of which are detailed below.

Normal mode: the most usual operating mode. The node works with the defined observation frequency (10 min).

Recovery mode: the observation frequency is maintained, but the observations will not be sent to the server, instead they are stored in the microcontroller EEPROM memory. The stored observations are sent when the IoT node has better battery conditions.

Critical mode: the IoT node does not collect new observations and goes into the most in-depth sleep mode.

The second module, Observe, consults from among the available sensors those that are indicated in the configuration. Among them, it includes the temperature, soil and air humidity, atmospheric pressure, rain, and wind speed/direction sensors. This module is responsible for transforming the signals from the sensors to obtain the correct values and adapt the values to the correct units for each phenomenon. For example, it treats the electric pluviometer pulsations and transforms them into the corresponding milliliters.

The next module is Act, which carries out actions on the available actuators. Although the current IoT node does not have an actuator due to the use case in which it has been applied, it is considered to define a general solution which is transferable to other scenarios with different requirements.

The next module is the Communication module. It has two differentiated functionalities: sending and receiving. To achieve this, the module establishes a connection using the 3G module included in the Electron microcontroller. Each node uses the MQTT protocol to set up M2M communication. They define an MQTT client that can send and receiving data. To do so, the node takes on the role of publisher to send sensor observations. Each observation is published on a different topic. In this way, a hierarchical organization is defined; that is, the sensor ID plus the phenomenon type name, for example /current/4e0022000251353337353037/Temperature or /current/4e0022000251353337353037/Humidity. The first hierarchical level (current) determines that the topic is in real-time. Another topic at the same level, called lost, is defined to send lost observations (due to in connection issues or the energy mode).

Moreover, MQTT is used to establish a dual communication between nodes. Each node is subscribed in different topics to trigger updates (OTA), or note which sensors should be consulted. The JSON format is established to code both incoming and outgoing data.

The last two modules are in parallel; this implies that they cannot be executed at the same time in the same iteration. The first one, the Update module, is responsible for enabling the deployment of a new update. Through the Communication module, when a new update message arrives in the update topic for a particular node, the update mode is activated and, to receive the update, the sleep state is not applied.

Finally, the last module, and one of the most important regarding energy consumption, is the sleep module. On the one hand, the Electron microcontroller offers different sleep modes, depending on which functionalities are active. The microcontroller provides a sleep operation, which is characterized by various parameters to determine which features are restricted to reduce power consumption. The sleep operation can be accompanied by seconds, which is used to define the sleep period. Also, the Electron supports the possibility to awaken using some external interruption in one of its pins.

In addition to the possibility of awakening the microcontroller, the sleep mode is also required. All the available modes are detailed below:

Without any argument. This option does not stop the execution of the sketch. The node continues running normally, while the 3G module remains in standby mode. The energy consumption is from 30 mA to 38 mA.

SLEEP_MODE_DEEP: this mode turns off the network module and puts the microcontroller in standby mode. When the device wakes up from the deep suspension, it restarts and executes all the user code from the beginning without maintaining the memory values. Its consumption is about 0.0032 mA.

SLEEP_MODE_SOFT_POWER_OFF: this mode is like SLEEP_MODE_DEEP with the added benefit that the fuel gauge chip also sleeps.

SLEEP_NETWORK_STANDBY: this mode is like SLEEP_MODE_DEEP but it does not turn off the 3G module. It reduces the amount of energy needed to reconnect with the operator when the Electron reboots from SLEEP_MODE_DEEP.

The

Figure 8 shows at a generalization of how the node works at the energy level and how it applies the sleep operations previously listed. In this way, three different modes are defined depending on the battery level at any given time. These modes are listed below.

Normal mode. When the battery is higher than 25% the node performs shipments depending on the observed frequency. The basic sleep mode is applied as detailed in the definition above. In addition to using the seconds to wake up, it can also use the rain gauge pin to wake up, and in this way accumulate the quantity of rainwater during the period in which the microcontroller is sleeping. The connectivity module is running while the cellular module is in standby mode.

Recovery Mode. When the battery is at less than 25%, the recovery mode is activated, and no new deliveries are made until the battery exceeds 35%. The observations are saved in the EEPROM memory and are labelled with a timestamp at the moment of capture.

Critical Mode. If the battery is at less than 15%, the critical mode is activated. In this mode, new observations are not produced or stored in EEPROM memory. The node goes into deep sleep and wakes up every 60 min to monitor the battery level. The critical mode is stopped when the remaining battery level is greater than 20%, and the node continues in recovery mode until it exceeds the threshold of 35%.

All the values defined above to categorize each mode have been fixed empirically. Depending on the different energy modes, we have tried to balance the behavior of the normal mode without compromising the total loss of battery, which this last would produce the loss of autonomy.

4.3. Autonomous Power Supply

This section details some aspects regarding energy consumption. The first subsection shows the theoretical energy consumption. The second subsection offers the energy consumption tests in a unit of the SEnviro node.

4.3.1. Theoretical Energy Consumption

Table 4 shows the energy consumption of the Electron microcontroller in the different modes (normal, sleep and deep sleep).

Consumption can vary considerably depending on the peripherals connected to the board. The different components along with their energy consumption are shown in

Table 5.

To obtain the theoretical consumption, we consider the IoT node operating in the normal energy mode defined in the previous section. The other modes have a secondary role, and the normal mode is executed throughout the majority of its life assuming a proper operation.

In what follows, the

Table 6 shows the seconds of each hour in which the node is applying energy-saving techniques, sending data or in the normal mode. The microcontroller consumes 19.3 mA every hour.

The consumptions of all sensors included in the

SEnviro node version are shown below. We consider that all sensors are active for 60 seconds during each iteration, which corresponds to the period in which the microcontroller is active.

Table 7 shows the consumptions of the components per hour, in total it needs 2.1625 mA.

Regarding the MPPT, it has a consumption of 3.5 mA every hour when it is active (when it charges the solar panel) and 0.085 mA in standby. The number of solar hours in Spain has been taken into consideration, considering an average of 12 solar hours (minimum 9.5 solar hours and maximum 14.9 solar hours). The consumption of the rain gauge and anemometer is negligible since they are passive circuits.

In this way, the total consumption of the node (microcontroller, sensors, and components) is 21.4625 mA in the normal energy mode. Thus, with the indicated battery (2000 mA), the node can work continuously for 93.19 h, which corresponds to 3 days, 21 h and 11 min until the battery is exhausted.

As detailed above, two modes have been added (Recovery and Critical) to prolong the life of the node, with which it is expected to extend the life of the node to so that it can function in long cloudy periods with little presence of the sun.

The recovery mode starts up when the battery is at less than 25%, that is when it reaches approximately a battery load of 500 mA.

Table 8 shows the energy consumption of the different states within the recovery mode. Unlike the normal mode, the recovery does not realize deliveries; otherwise, the node saves the observations in EPROM, to be sent later, when it goes into normal mode.

The energy consumption of the microcontroller in Recovery mode is around 6.80 mA per hour, to which should be added the consumption of the components (2.1625 mA) shown in

Table 7. In total on consumption of 8.9625 mA, and with the remaining battery of 500 mA, the node could extend its life to 55.788 h (2 days, 7 h, 18 min) until the entire battery was discharged.

The last and most severe mode is the critical mode, which is activated when the battery is at less than 15%, that is when it reaches approximately a load of 300 mA.

Table 9 shows the consumption of the different states within the critical mode. Unlike the other modes, the critical mode keeps the node in a deep sleep and only wakes up to check the battery status, it does not consult the sensors, so any observations are lost.

In this case, the sensors are not being consulted, despite this a consumption of 0.02916 mA is generated during the period in which the battery level would be consulted, since the sensors are in a standby mode. To this the consumption of the microcontroller of 0.1998 mA per hour should be added, so that the total energy consumption of the critical mode would be 0.22896 mA per hour. With this consumption and with the remaining 300 mAh, the node could extend its life to 1310.27 h (54 days, 14 h and 16 min).

Figure 9 shows the theoretical energy consumption of the node. The chart indicates when changes in energy modes occur. These changes would occur: from the normal mode to the recovery on the 3rd day; from the recovery mode to the critical the 5th day; and through the critical mode, the node would be without a battery after 37 days (864 h).

4.3.2. Real Energy Consumption

The first test without a solar panel and using only the normal mode with a 2000 mAh battery reveals 73.5 h of autonomy. Nonetheless, the real test suggests that under such conditions the energy consumption is 27.25 mA per hour, instead of the 19.3 mA defined in the theoretical consumption. If we compare the results obtained with the solution presented in the previous version of SEnviro, we obtain a substantial improvement, tripling the energy autonomy.

This result seems satisfactory in terms of being able to deploy the nodes and keep them permanently active. The developed IoT node could keep the sensor alive for three days, one hour and 30 minutes without any charge through the solar panel. The first energy problems could appear after three cloudy days without any sun. However, even on a cloudy day, according to the tests made, the solar panel can charge with a low frequency or maintain the battery. Besides, the solar panel presents very satisfactory results; it can charge the battery with an approximate rate of 200 mA per hour.

As will be shown in the next section, five SEnviro nodes were deployed for 140 days, and none of them presented energy problems. During this period there were several consecutive cloudy days, which did not affect node operation. The solar panel also managed to charge during some of those days, although at a lower rate.

The chart below (

Figure 10) shows the time series of the battery level of one of the nodes. It shows the recharge capacity of the solar panel, which manages to reach the highest battery charge possible in a few hours. The maximum level has been 87.4% of battery. We can assert that, on sunny days, at the end of the night, the battery never drops below 60.77% and manages to recover its charge in 3 h of sunshine. On cloudy days (like the 2nd of November) the battery can maintain the level and increase with a low rate. During the period indicated period no node entered into recovery mode.