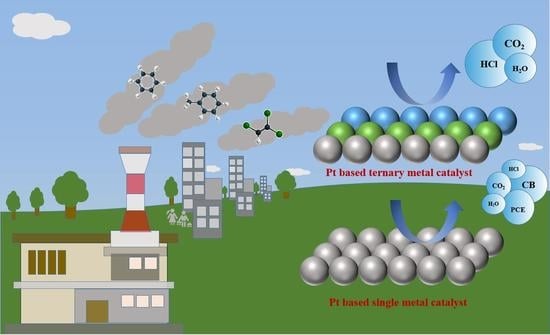

Enhanced Performance of Supported Ternary Metal Catalysts for the Oxidation of Toluene in the Presence of Trichloroethylene

Abstract

:1. Introduction

2. Results and Discussion

2.1. Catalytic Performance

2.2. Crystal Structure, Morphology, and Surface Area

2.3. Redox Ability and Oxygen Mobility

2.4. Surface Elemental Composition

2.5. NH3-TPD, Toluene&TCE-TPD, and Toluene&TCE-TPSR

2.6. GC-MS and In Situ DRIFTS

3. Materials and Methods

3.1. Preparation of the Catalysts

3.2. Catalyst Characterization

3.3. Catalytic Activity Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, J.M.; Lee, C.Y.; Jerng, D.W.; Ahn, H.S. Toluene and acetaldehyde removal from air on to graphene-based adsorbents with microsized pores. J. Hazard. Mater. 2018, 344, 458–465. [Google Scholar] [CrossRef] [PubMed]

- Li, W.B.; Wang, J.X.; Gong, H. Catalytic conbustion of VOCs on non-noble metal catalyst. Catal. Today 2009, 148, 81–87. [Google Scholar] [CrossRef]

- Lu, C.-Y.; Wey, M.-Y. Simultaneous removal of VOC and NO by activated carbon impregnated with transition metal catalysts in combustion flue gas. Fuel Process. Technol. 2007, 88, 557–567. [Google Scholar] [CrossRef]

- Drago, R.S.; Jurczyk, K.; Singh, D.J.; Young, V. Low-temperature deep oxidation of hydrocarbons by metal oxides supported on carbonaceous materials. Appl. Catal. B Environ. 1995, 6, 155–168. [Google Scholar] [CrossRef]

- Sun, P.F.; Wang, W.L.; Weng, X.L.; Dai, X.X.; Wu, Z.B. Alkali Potassium Induced HCl/CO2 selectivity enhancement and chlo-rination reaction inhibition for catalytic oxidation of chloroaromatics. Environ. Sci. Technol. 2018, 52, 6438–6447. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Dai, L.; Liu, Y.; Deng, J.; Jing, L.; Yu, X.; Han, Z.; Zhang, K.; Dai, H. 3DOM CeO2-supported RuyM (M = Au, Pd, Pt) alloy nanoparticles with improved catalytic activity and chlorine-tolerance in trichloroethylene oxidation. Catal. Sci. Technol. 2020, 10, 3755–3770. [Google Scholar] [CrossRef]

- Yang, P.; Fan, S.; Chen, Z.; Bao, G.; Zuo, S.; Qi, C. Synthesis of Nb2O5 based solid superacid materials for catalytic combustion of chlorinated VOCs. Appl. Catal. B Environ. 2018, 239, 114–124. [Google Scholar] [CrossRef]

- Weon, S.; Kim, J.; Choi, W. Dual-components modified TiO2 with Pt and fluoride as deactivation-resistant photocatalyst for the degradation of volatile organic compound. Appl. Catal. B Environ. 2018, 220, 1–8. [Google Scholar] [CrossRef]

- Avgouropoulos, G.; Oikonomopoulos, E.; Kanistras, D.; Ioannides, T. Complete oxidation of ethanol over alkali-promoted Pt/Al2O3 catalysts. Appl. Catal. B Environ. 2006, 65, 62–69. [Google Scholar] [CrossRef]

- Hosseini, M.; Siffert, S.; Cousin, R.; Aboukaïs, A.; Hadj-Sadok, Z.; Su, B.L. Total oxidation of VOCs on Pd and/or Au supported on TiO2/ZrO2 followed by “operando” DRIFT. C. R. Chim. 2009, 12, 654–659. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, Y.; Fu, G.; Duchesne, P.N.; Gu, L.; Zheng, Y.; Weng, X.; Chen, M.; Zhang, P.; Pao, C.-W.; et al. Interfacial Effects in Iron-Nickel Hydroxide–Platinum Nanoparticles Enhance Catalytic Oxidation. Science 2014, 344, 495–499. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Priya, M.; Kiruthika, S.; Muthukumaran, B. Synthesis and characterization of Pt-Sn-Ce/MC ternary catalysts for ethanol oxi-dation in membraneless fuel cells. Ionics 2017, 23, 1209–1218. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Y.X.; Deng, J.G.; Zhao, X.T.; Zhang, K.F.; Han, Z.; Dai, H.X. AgAuPd/meso-Co3O4: High-performance catalysts for methanol oxidation. Chin. J. Catal. 2019, 40, 837–848. [Google Scholar] [CrossRef]

- García, T.; Solsona, B.; Taylor, S.H. The Oxidative Destruction of Hydrocarbon Volatile Organic Compounds Using Palladium–Vanadia–Titania Catalysts. Catal. Lett. 2004, 97, 99–103. [Google Scholar] [CrossRef]

- Huang, H.B.; Leung, D.Y.C. Complete oxidation of formaldehyde at room temperature using TiO2 supported metallic Pd na-noparticles. ACS Catal. 2011, 1, 348–354. [Google Scholar] [CrossRef]

- Brink, R.V.D.; Krzan, M.; Feijen-Jeurissen, M.; Louw, R.; Mulder, P. The role of the support and dispersion in the catalytic combustion of chlorobenzene on noble metal based catalysts. Appl. Catal. B Environ. 2000, 24, 255–264. [Google Scholar] [CrossRef]

- Zhang, K.Y.; Dai, L.Y.; Liu, Y.X.; Deng, J.G.; Jing, L.; Zhang, K.F.; Hou, Z.Q.; Zhang, X.; Wang, J.; Feng, Y.; et al. Insights into the active sites of chlorine-resistant Pt-basedbimetallic catalysts for the oxidative removal of benzene. Appl. Catal. B 2020, 279, 119372. [Google Scholar] [CrossRef]

- Dai, Q.; Wang, W.; Wang, X.; Lu, G. Sandwich-structured CeO2@ZSM-5 hybrid composites for catalytic oxidation of 1, 2-dichloroethane: An integrated solution to coking and chlorine poisoning deactivation. Appl. Catal. B Environ. 2017, 203, 31–42. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Xia, H.Q.; Dai, Q.G.; Gu, Y.F.; Lao, Y.J.; Wang, X.Y. Chlorinated volatile organic compound oxidation over SO42−/Fe2O3 catalysts. J. Catal. 2018, 360, 277–289. [Google Scholar] [CrossRef]

- Weng, X.; Meng, Q.; Liu, J.; Jiang, W.; Pattisson, S.; Wu, Z. Catalytic Oxidation of Chlorinated Organics over Lanthanide Perovskites: Effects of Phosphoric Acid Etching and Water Vapor on Chlorine Desorption Behavior. Environ. Sci. Technol. 2018, 53, 884–893. [Google Scholar] [CrossRef]

- Fang, C.; Jiang, X.; Hu, J.; Song, J.; Sun, N.; Zhang, D.; Kuai, L. Ru Nanoworms Loaded TiO2 for Their Catalytic Performances toward CO Oxidation. ACS Appl. Mater. Interfaces 2021, 13, 5079–5087. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Wang, F.; Li, Y.; Lv, H.; Sun, M.; Zhai, Y.; Lv, G.; Zhang, X. Enhanced catalytic performance of oxidized Ru supported on N-doped mesoporous carbon for acetylene hydrochlorination. Appl. Catal. A Gen. 2021, 623, 118236. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, Y.; Deng, J.; Zhang, K.; Hou, Z.; Zhao, X.; Zhang, X.; Zhang, K.; Wei, R.; Dai, H. Coupled Palladium–Tungsten Bimetallic Nanosheets/TiO2 Hybrids with Enhanced Catalytic Activity and Stability for the Oxidative Removal of Benzene. Environ. Sci. Technol. 2019, 53, 5926–5935. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Q.; Wang, Y.; Zhao, Z.-J.; Pei, C.; Chen, S.; Gao, L.; Mu, R.; Fu, Q.; Gong, J. Defect-mediated reactivity of Pt/TiO2 catalysts: The different role of titanium and oxygen vacancies. Sci. China Ser. B Chem. 2020, 63, 1323–1330. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, X.; Shan, Y.; Liu, J.; Xu, G.; Du, J.; Yan, Z.; Yu, Y.; He, H. Promotion effect of cerium doping on iron–titanium composite oxide catalysts for selective catalytic reduction of NOx with NH3. Catal. Sci. Technol. 2020, 10, 648–657. [Google Scholar] [CrossRef]

- Ettireddy, P.R.; Ettireddy, N.; Mamedov, S.; Boolchand, P.; Smirniotis, P.G. Surface characterization studies of TiO2 supported manganese oxide catalysts for low temperature SCR of NO with NH3. Appl. Catal. B Environ. 2007, 76, 123–134. [Google Scholar] [CrossRef]

- Sun, M.M.; Liu, J.Y.; Song, C.; Ogata, Y.; Rao, H.B.; Zhao, X.Q.; Xu, H.D.; Chen, Y.Q. Different reaction mechanisms of am-monia oxidation reaction on Pt/Al2O3 and Pt/CeZrO2 with various Pt states. ACS Appl. Mater. Interfaces 2019, 11, 23102–23111. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Z.; Zhou, M.; Ma, Z.; Chen, J.; Tang, X. Single Silver Adatoms on Nanostructured Manganese Oxide Surfaces: Boosting Oxygen Activation for Benzene Abatement. Environ. Sci. Technol. 2017, 51, 2304–2311. [Google Scholar] [CrossRef]

- Yang, Y.; Li, H.; Zhao, H.; Qu, R.; Zhang, S.; Hu, W.; Yu, X.; Zhu, X.; Liu, S.; Zheng, C.; et al. Structure and crystal phase transition effect of Sn doping on anatase TiO2 for dichloromethane decomposition. J. Hazard. Mater. 2019, 371, 156–164. [Google Scholar] [CrossRef]

- Miao, S.; Liu, Z.; Han, B.; Huang, J.; Sun, Z.; Zhang, J.; Jiang, T. Ru Nanoparticles Immobilized on Montmorillonite by Ionic Liquids: A Highly Efficient Heterogeneous Catalyst for the Hydrogenation of Benzene. Angew. Chem. Int. Ed. 2006, 45, 266–269. [Google Scholar] [CrossRef]

- Zeng, L.; Wan, B.; Huang, R.; Yan, Y.; Wang, X.; Tan, W.; Liu, F.; Feng, X. Catalytic oxidation of arsenite and reaction pathways on the surface of CuO nanoparticles at a wide range of pHs. Geochem. Trans. 2018, 19, 12. [Google Scholar] [CrossRef] [PubMed]

- Lin, F.W.; Wang, Z.; Zhang, Z.M.; Xiang, L.; Yuan, D.K.; Yan, B.B.; Wang, Z.H.; Chen, G.Y. Comparative investigation on chlorobenzene oxidation by oxygen and ozone over a MnOx/Al2O3 catalyst in the presence of SO2. Environ. Sci. Technol. 2021, 55, 3341–3351. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Ma, J.Z.; Li, X.T.; Zhang, C.B.; He, H. Enhancing oxygen vacancies of Ce-OMS-2 via optimized hydrothermal con-ditions to improve catalytic ozone decomposition. Ind. Eng. Chem. Res. 2019, 59, 118–128. [Google Scholar] [CrossRef]

- Dai, Q.; Zhu, Q.; Lou, Y.; Wang, X. Role of Brønsted acid site during catalytic combustion of methane over PdO/ZSM-5: Dominant or negligible? J. Catal. 2018, 357, 29–40. [Google Scholar] [CrossRef]

- Ardagh, M.A.; Bo, Z.; Nauert, S.L.; Notestein, J.M. Depositing SiO2 on Al2O3: A Route to Tunable Brønsted Acid Catalysts. ACS Catal. 2016, 6, 6156–6164. [Google Scholar] [CrossRef]

- Sun, W.; Gong, B.W.; Pan, J.; Wang, Y.Y.; Xia, H.Q.; Zhang, H. Catalytic combustion of CVOCs over CrxTi1−x oxide catalysts. J. Catal. 2020, 391, 132–144. [Google Scholar] [CrossRef]

- Gu, Y.; Jiang, X.; Sun, W.; Bai, S.; Dai, Q.; Wang, X. 1,2-Dichloroethane Deep Oxidation over Bifunctional Ru/CexAly Catalysts. ACS Omega 2018, 3, 8460–8470. [Google Scholar] [CrossRef] [Green Version]

- Iwasaki, M.; Iglesia, E. Mechanistic assessments of NO oxidation turnover rates and active site densities on WO3-promoted CeO2 catalysts. J. Catal. 2016, 342, 84–97. [Google Scholar] [CrossRef]

- Hetrick, C.E.; Lichtenberger, J.; Amiridis, M.D. Catalytic oxidation of chlorophenol over V2O5/TiO2 Catalysts. Appl. Catal. B 2008, 77, 255–263. [Google Scholar] [CrossRef]

- Chen, J.; Xu, W.; Jiang, M.; Jia, H. Polyoxometallate functionalizing CeO2 via redox-etching precipitation to synergistically catalyze oxidation of gaseous chlorinated pollutants: From lab to practice. Appl. Catal. B Environ. 2020, 278, 119263. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, X.; Peng, R.; Zhao, M.; Ye, D. Catalytic properties of manganese oxide polyhedra with hollow and solid morphologies in toluene removal. Appl. Surf. Sci. 2017, 405, 20–28. [Google Scholar] [CrossRef]

- Besselmann, S.; Löffler, E.; Muhler, M. On the role of monomeric vanadyl species in toluene adsorption and oxidation on V2O5/TiO2 catalysts: A Raman and in situ DRIFTS study. J. Mol. Catal. A 2000, 162, 401–411. [Google Scholar] [CrossRef]

- Rainone, F.; Bulushev, D.A.; Kiwi-Minsker, L.; Renken, A. DRIFTS and transient-response study of vanadia/titania catalysts during toluene partial oxidation. Phys. Chem. Chem. Phys. 2003, 5, 4445–4449. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Na, H.; Zeng, X.; Zhu, T.; Liu, Z. In situ DRIFTS investigation for the oxidation of toluene by ozone over Mn/HZSM-5, Ag/HZSM-5 and Mn–Ag/HZSM-5 catalysts. Appl. Surf. Sci. 2014, 311, 690–696. [Google Scholar] [CrossRef]

- Wu, W.-C.; Liao, L.-F.; Lien, C.-F.; Lin, J.-L. FTIR study of adsorption, thermal reactions and photochemistry of benzene on powdered TiO2. Phys. Chem. Chem. Phys. 2001, 3, 4456–4461. [Google Scholar] [CrossRef]

- Fu, X.H.; Liu, Y.X.; Deng, J.G.; Jing, L.; Zhang, X.; Zhang, K.F.; Han, Z.; Jiang, X.Y.; Dai, H.X. Intermetallic compound PtMny-derived Pt-MnOx supported on mesoporous CeO2: Highly efficient catalysts for the combustion of toluene. Appl. Catal. A 2020, 595, 117509. [Google Scholar] [CrossRef]

| Sample | Toluene Conversion | TCE Conversion | Specific Reaction Rates (×10−6 mol/(gPt s)) | TOFPt (×10−5 s−1) | Metal Dispersion (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| T50% (°C) | T90% (°C) | T50% (°C) | T90% (°C) | Toluene | TCE | Toluene | TCE | ||

| Pt/TiO2 | 260 | 310 | 340 | >500 | 17.3 | 4.9 | 9.4 | 2.6 | 36 |

| PtW/TiO2 | 250 | 296 | 300 | 378 | 20.5 | 6.3 | 13.3 | 4.1 | 30 |

| PtWRu/TiO2 | 240 | 275 | 272 | 305 | 25.0 | 9.0 | 20.3 | 7.3 | 24 |

| PtWCr/TiO2 | 225 | 258 | 276 | 300 | 44.9 | 8.4 | 26.2 | 6.1 | 27 |

| PtWMn/TiO2 | 216 | 255 | 272 | 318 | 36.2 | 8.0 | 25.7 | 5.1 | 34 |

| Sample | Particle Size a (nm) | Actual Pt Loading b (wt%) | Actual W Loading b (wt%) | Actual Ru Loading b (wt%) | Actual Cr Loading b (wt%) | Actual Mn Loading b (wt%) | BET Surface Area (m2/g) | Surface Elemental Composition c (mol/mol) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pt0/Pt2+ c | Olatt/Oads | W6+/W5+ | Ru4+/Ru0 | Cr6+/Cr3+ | Mn4+/Mn3+/Mn2+ | ||||||||

| Pt/TiO2 | 3.0 | 0.43 | 8.2 | 2.1 | 4.3 | ||||||||

| PtW/TiO2 | 9.1 | 0.45 | 4.86 | 9.1 | 1.8 | 4.9 | 1.9 | ||||||

| PtWRu/TiO2 | 6.2 | 0.42 | 4.85 | 1.89 | 7.7 | 1.5 | 5.5 | 3.1 | 0.4 | ||||

| PtWCr/TiO2 | 7.3 | 0.45 | 4.90 | 0.96 | 13.2 | 1.5 | 5.1 | 10.3 | 0.6 | ||||

| PtWMn/TiO2 | 8.2 | 0.43 | 4.88 | 0.94 | 12.0 | 5.1 | 4.5 | 9.5 | 1.4:1.5:1 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, T.; Liu, K.; Gao, R.; Chen, H.; Yu, X.; Hou, Z.; Jing, L.; Deng, J.; Liu, Y.; Dai, H. Enhanced Performance of Supported Ternary Metal Catalysts for the Oxidation of Toluene in the Presence of Trichloroethylene. Catalysts 2022, 12, 541. https://doi.org/10.3390/catal12050541

Dong T, Liu K, Gao R, Chen H, Yu X, Hou Z, Jing L, Deng J, Liu Y, Dai H. Enhanced Performance of Supported Ternary Metal Catalysts for the Oxidation of Toluene in the Presence of Trichloroethylene. Catalysts. 2022; 12(5):541. https://doi.org/10.3390/catal12050541

Chicago/Turabian StyleDong, Tiantian, Kun Liu, Ruyi Gao, Hualian Chen, Xiaohui Yu, Zhiquan Hou, Lin Jing, Jiguang Deng, Yuxi Liu, and Hongxing Dai. 2022. "Enhanced Performance of Supported Ternary Metal Catalysts for the Oxidation of Toluene in the Presence of Trichloroethylene" Catalysts 12, no. 5: 541. https://doi.org/10.3390/catal12050541