Abstract

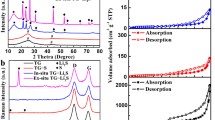

Combining nanoparticles in well-designed architecture with complementary properties is an attractive strategy used for developing multi-functional, high-performance materials. Herein, to explore the mechanism of Li-ions uptake and storage potential of layered ternary carbides (MAX phases), we report on the Ti2SC and Ti3SiC2 with two-dimensional (2D)-reduced graphene oxide (rGO) that electrically connects MAX phase particles. The heterostructure formation was achieved through in-situ wet chemical processing. The method efficiently prevented restacking of rGO nanosheets, aggregation of MAX particles, and generated a porous heterostructure permeable for electrolyte. This facilitated the electrolyte transport and the access of ions to the electrode. In addition, there was a strong coupling effect between MAX phase compound and rGO in these hybrids. When tested as anodes for Li-ion batteries, the hybrids displayed high reversible capacity, very good rate performance, and excellent cycling stability. Specifically, the capacity of in-situ synthesized Ti2SC/rGO hybrid showed an increasing trend during cycling. After a few initial cycles, 576 mAh·g−1 was achieved after 500 charge/discharge cycles with a current of 400 mA·g−1. This work further demonstrates the Li-ion storage potential of MAX phases and suggests the need for further exploration of this large family of layered materials.

Graphical abstract

Similar content being viewed by others

Change history

04 June 2022

A Correction to this paper has been published: https://doi.org/10.1007/s41127-022-00050-2

References

Liang B, Liu Y, Xu Y (2014) Silicon-based materials as high capacity anodes for next generation lithium ion batteries. J Power Sources 267:469–490. https://doi.org/10.1016/j.jpowsour.2014.05.096

Yue L, Zhang W, Yang J, Zhang L (2014) Designing Si/porous-C composite with buffering voids as high capacity anode for lithium-ion batteries. Electrochim Acta 125:206–217

Son Y, Sim S, Ma H, Choi M, Son Y, Park N, Cho J, Park M (2018) Exploring critical factors affecting strain distribution in 1D Silicon-Based nanostructures for Lithium-Ion battery anodes. Adv Mater 30:1705430. https://doi.org/10.1002/adma.201705430

Park S, Zhao H, Ai G, Wang C, Song X, Yuca N, Battaglia VS, Yang W, Liu G (2015) Side-chain conducting and phase-separated polymeric binders for high-performance silicon anodes in Lithium-Ion batteries. J Am Chem Soc 137:2565–2571. https://doi.org/10.1021/ja511181p

Devic T, Lestriez B, Roué L (2019) Silicon electrodes for Li-Ion batteries. Addressing the challenges through coordination chemistry. ACS Energy Lett 4(2):550–557. https://doi.org/10.1021/acsenergylett.8b02433

Li P, Hwang J, Sun Y (2019) Nano/Microstructured Silicon-Graphite composite anode for high-energy-density Li-Ion battery. ACS Nano 13:2624–2633. https://doi.org/10.1021/acsnano.9b00169

Choi S, Cho Y, Kim J, Choi N, Song H, Wang G, Park S (2017) Mesoporous germanium anode materials for Lithium-Ion battery with exceptional cycling stability in wide temperature range. Small 13:1603045. https://doi.org/10.1002/smll.201603045

Liu X, Liu Y, Harris MM, Li J, Wang K, Chen J (2018) Germanium nanoparticles supported by 3D ordered macroporous nickel frameworks as high-performance free-standing anodes for Li-ion batteries. Chem Eng J 354:616–622. https://doi.org/10.1016/j.cej.2018.08.056

Mo R, Lei Z, Rooney D, Sun K (2019) Three-Dimensional Double-Walled ultrathin graphite tube conductive scaffold with encapsulated germanium nanoparticles as a High-Areal-Capacity and Cycle-Stable anode for Lithium-Ion batteries. ACS Nano 13:7536–7544. https://doi.org/10.1021/acsnano.8b09027

Kim C, Song G, Luo L, Cheong JY, Cho S, Kwon D, Choi S, Jung J, Wang C, Kim I, Park S (2018) Stress-Tolerant nanoporous germanium nanofibers for long cycle life lithium storage with high structural stability. ACS Nano 12:8169–8176. https://doi.org/10.1021/acsnano.8b03278

Jiang Y, Li Y, Zhou P, Lan Z, Lu Y, Wu C, Yan M (2017) Ultrafast, highly reversible, and Cycle-Stable lithium storage boosted by pseudocapacitance in Sn-Based alloying anodes. Adv Mater 29:1606499. https://doi.org/10.1002/adma.201606499

Chen P, Wu F, Wang Y (2014) Four-Layer Tin-Carbon nanotube Yolk-Shell materials for High-Performance Lithium-Ion batteries. Chemsuschem 7:1407–1414. https://doi.org/10.1002/cssc.201301198

Poizot P, Laruelle S, Grugeon S, Dupont L, Tarascon JM (2000) Nano-sized transition-metaloxides as negative-electrode materials for lithium-ion batteries. Nature 407:496–499

Xu J, Zhao M, Wang Y, Yao W, Chen C, Anasori B, Sarycheva A, Ren CE, Mathis T, Gomes L, Liang Z, Gogotsi Y (2016) Demonstration of Li-Ion capacity of MAX phases. ACS Energy Lett 1:1094–1099. https://doi.org/10.1021/acsenergylett.6b00488

Sun Z, Yuan M, Lin L, Yang H, Nan C, Li H, Sun G, Yang X (2019) Selective lithiation–expansion–microexplosion synthesis of two-dimensional fluoride-free MXene. ACS Materials Letters 1:628–632. https://doi.org/10.1021/acsmaterialslett.9b00390

Zhao S, Dall Agnese Y, Chu X, Zhao X, Gogotsi Y, Gao Y (2019) Electrochemical interaction of Sn-Containing MAX phase (Nb2SnC) with Li-Ions. ACS Energy Lett 4:2452–2457. https://doi.org/10.1021/acsenergylett.9b01580

Wu H, Zhu J, Liu L, Cao K, Yang D, Gong C, Lei H, Hang H, Yao W, Xu J (2021) Intercalation and delamination of Ti2SnC with high lithium ion storage capacity. Nanoscale 13:7355–7361. https://doi.org/10.1039/D0NR06260J

Luan S, Zhou J, Xi Y, Han M, Wang D, Gao J, Hou L, Gao F (2019) High lithium-ion storage performance of Ti3SiC2 MAX by oxygen doping. ChemistrySelect 4:5319–5321. https://doi.org/10.1002/slct.201900328

Zhu J, Chroneos A, Wang L, Rao F, Schwingenschlögl U (2017) Stress-enhanced lithiation in MAX compounds for battery applications. Appl Mater Today 9:192–195. https://doi.org/10.1016/j.apmt.2017.07.002

Eklund P, Beckers M, Jansson U, Högberg H, Hultman L (2010) The Mn+1AXn phases: Materials science and thin-film processing. Thin Solid Films 518:1851–1878. https://doi.org/10.1016/j.tsf.2009.07.184

Barsoum MW (2013) MAX phases: Properties of machinable ternary carbides and nitrides. Wiley, Germany

Wang XH, Zhou YC (2010) Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: a review. J Mater Sci Technol 26:385–416. https://doi.org/10.1016/S1005-0302(10)60064-3

Barsoum MW, Radovic M (2011) Elastic and mechanical properties of the MAX phases. Annu Rev Mater Res 41:195–227. https://doi.org/10.1146/annurev-matsci-062910-100448

Ahuja R, Eriksson O, Wills JM, Johansson B (2000) Electronic structure of Ti3SiC2. Appl Phys Lett 76:2226–2228. https://doi.org/10.1063/1.126304

Islam MM, Aboutalebi SH, Cardillo D, Liu HK, Konstantinov K, Dou SX (2015) Self-Assembled multifunctional hybrids: toward developing High-Performance Graphene-Based architectures for energy storage devices. ACS Cent Sci 1:206–216. https://doi.org/10.1021/acscentsci.5b00189

Lukatskaya MR, Dunn B, Gogotsi Y (2016) Multidimensional materials and device architectures for future hybrid energy storage. Nat Commun 7:12647. https://doi.org/10.1038/ncomms12647

Naguib M, Mochalin VN, Barsoum MW, Gogotsi Y (2014) 25Th Anniversary Article: MXenes: a new family of two-dimensional materials. Adv Mater 26:992–1005. https://doi.org/10.1002/adma.201304138

Naguib M, Gogotsi Y (2014) Synthesis of two-dimensional materials by selective extraction. Accounts Chem Res 48:128–135. https://doi.org/10.1021/ar500346b

Naguib M, Mashtalir O, Carle J, Presser V, Lu J, Hultman L, Gogotsi Y, Barsoum MW (2012) Two-Dimensional transition metal carbides. ACS Nano 6:1322–1331. https://doi.org/10.1021/nn204153h

Barsoum MW (2000) The M(N+1)AX(N) phases: a new class of solids; Thermodynamically stable nanolaminates. Prog Solid State Ch 28:201–281. https://doi.org/10.1016/S0079-6786(00)00006-6

Xie X, Wang S, Kretschmer K, Wang G (2017) Two-dimensional layered compound based anode materials for lithium-ion batteries and sodium-ion batteries. J Colloid Interf Sci 499:17–32. https://doi.org/10.1016/j.jcis.2017.03.077

Byeon A, Glushenkov AM, Anasori B, Urbankowski P, Li J, Byles BW, Blake B, Van Aken KL, Kota S, Pomerantseva E, Lee JW, Chen Y, Gogotsi Y (2016) Lithium-ion capacitors with 2D Nb2CTx (MXene) - carbon nanotube electrodes. J Power Sources 326:686–694. https://doi.org/10.1016/j.jpowsour.2016.03.066

Liu Y, Wang W, Ying Y, Wang Y, Peng X (2015) Binder-free layered Ti3C2/CNTs nanocomposite anodes with enhanced capacity and long-cycle life for lithium-ion batteries. Dalton Trans 44:7123–7126. https://doi.org/10.1039/C4DT02058H

Ren CE, Zhao M, Makaryan T, Halim J, Boota M, Kota S, Anasori B, Barsoum MW, Gogotsi Y (2016) Porous two-dimensional transition metal carbide (MXene) flakes for High-Performance Li-Ion storage. ChemElectroChem 3:689–693. https://doi.org/10.1002/celc.201600059

Xu B, Wang H, Zhu Q, Sun N, Anasori B, Hu L, Wang F, Guan Y, Gogotsi Y (2018) Reduced graphene oxide as a multi-functional conductive binder for supercapacitor electrodes. Energy Storage Mater 12:128–136. https://doi.org/10.1016/j.ensm.2017.12.006

Xu S, Wei G, Li J, Han W, Gogotsi Y (2017) Flexible MXene-graphene electrodes with high volumetric capacitance for integrated co-cathode energy conversion/storage devices. J Mater Chem A 5:17442–17451. https://doi.org/10.1039/C7TA05721K

Lin Z, Sun D, Huang Q, Yang J, Barsoum MW, Yan X (2015) Carbon nanofiber bridged two-dimensional titanium carbide as a superior anode for lithium-ion batteries. J Mater Chem A 3:14096–14100. https://doi.org/10.1039/C5TA01855B

Luo J, Zhang W, Yuan H, Jin C, Zhang L, Huang H, Liang C, Xia Y, Zhang J, Gan Y, Tao X (2017) Pillared structure design of MXene with ultralarge interlayer spacing for High-Performance Lithium-Ion capacitors. ACS Nano 11:2459–2469. https://doi.org/10.1021/acsnano.6b07668

Han Y, Wang T, Gao X, Li T, Zhang Q (2016) Preparation of thermally reduced graphene oxide and the influence of its reduction temperature on the thermal, mechanical, flame retardant performances of PS nanocomposites. Composit Part A: Appl Sci Manufact 84:336–343. https://doi.org/10.1016/j.compositesa.2016.02.007

Liu B, Huo L, Zhang G, Zhang J (2016) Ternary hollow mesoporous TiN/N-Graphene/Pt hybrid results in enhanced electrocatalytic performance for methanol oxidation and oxygen reduction reaction. Electrochim Acta 213:771–782. https://doi.org/10.1016/j.electacta.2016.07.098

Wang WL, Oh B, Park J, Ki H, Jang J, Lee G, Gu H, Ham M (2015) Solid-state synthesis of Ti2Nb10O29/reduced graphene oxide composites with enhanced lithium storage capability. J Power Sources 300:272–278. https://doi.org/10.1016/j.jpowsour.2015.09.078

Jiang S, Wang R, Pang M, Wang H, Zeng S, Yue X, Ni L, Qiu S, Zhang Z (2015) Hierarchical composites of ultrathin carbon self-coated TiO2 nanosheets on reduced graphene oxide with enhanced lithium storage capability. Chem Eng J 280:614–622. https://doi.org/10.1016/j.cej.2015.06.054

Shiraishi Y, Shiota S, Hirakawa H, Tanaka S, Ichikawa S, Hirai T (2017) Titanium Dioxide/Reduced graphene oxide hybrid photocatalysts for efficient and selective partial oxidation of cyclohexane. ACS Catal 7:293–300. https://doi.org/10.1021/acscatal.6b02611

Hui-Ling MA, Long Z, You-Wei Z, Di L, Chao S, Xin-Miao Z, Mao-Lin Z (2015) Γ-Ray induced reduction of graphene oxide in aqueous solution. Acta Phys-Chim Sin 31:2016–2022. https://doi.org/10.3866/PKU.WHXB201508102

Zhang CJ, Pinilla S, McEvoy N, Cullen CP, Anasori B, Long E, Park S, Seral-Ascaso A, Shmeliov A, Krishnan D, Morant C, Liu X, Duesberg GS, Gogotsi Y, Nicolosi V (2017) Oxidation stability of colloidal Two-Dimensional titanium carbides (MXenes). Chem Mater 29:4848–4856. https://doi.org/10.1021/acs.chemmater.7b00745

Li Y, Ma G, Shao H, Xiao P, Lu J, Xu J, Hou J, Chen K, Zhang X, Li M, Persson POÅ, Hultman L, Eklund P, Du S, Chai Z, Huang Z, Jin N, Ma J, Liu Y, Lin Z, Huang Q (2021) Electrochemical lithium storage performance of molten salt derived V2SnC MAX phase. Nano-Micro Letters 13:158. https://doi.org/10.1007/s40820-021-00684-6

Ha JU, Lee J, Abbas MA, Lee MD, Lee J, Bang JH (2019) Designing hierarchical assembly of Carbon-Coated TiO2 nanocrystals and unraveling the role of TiO2/Carbon interface in Lithium-Ion storage in TiO2. ACS Appl Mater Interfaces 11:11391–11402. https://doi.org/10.1021/acsami.8b21705

Yu Y (2016) Prediction of mobility, enhanced storage capacity, and volume change during sodiation on Interlayer-Expanded functionalized Ti3C2 MXene anode materials for Sodium-Ion batteries. J Phys Chem C 120:5288–5296. https://doi.org/10.1021/acs.jpcc.5b10366

Li Y, Liang Y, Robles Hernandez FC, Deog Yoo H, An Q, Yao Y (2015) Enhancing sodium-ion battery performance with interlayer-expanded MoS2-PEO nanocomposites. Nano Energy 15:453–461. https://doi.org/10.1016/j.nanoen.2015.05.012

Xie X, Zhao M, Anasori B, Maleski K, Ren CE, Li J, Byles BW, Pomerantseva E, Wang G, Gogotsi Y (2016) Porous heterostructured MXene/carbon nanotube composite paper with high volumetric capacity for sodium-based energy storage devices. Nano Energy 26:513–523. https://doi.org/10.1016/j.nanoen.2016.06.005

Zhao M, Torelli M, Ren CE, Ghidiu M, Ling Z, Anasori B, Barsoum MW, Gogotsi Y (2016) 2D titanium carbide and transition metal oxides hybrid electrodes for Li-ion storage. Nano Energy 30:603–613. https://doi.org/10.1016/j.nanoen.2016.10.062

Le Z, Liu F, Nie P, Li X, Liu X, Bian Z, Chen G, Wu HB, Lu Y (2017) Pseudocapacitive sodium storage in mesoporous Single-Crystal-like TiO2–graphene nanocomposite enables High-Performance Sodium-Ion capacitors. ACS Nano 11:2952–2960. https://doi.org/10.1021/acsnano.6b08332

Yao W, Zhao M, Dai Y, Tang J, Xu J (2017) Micro-/Mesoporous Zinc-Manganese Oxide/Graphene hybrids with high specific surface area: A High-Capacity, Superior-Rate, and Ultralong-Life anode for lithium storage. ChemElectroChem 4:230–235. https://doi.org/10.1002/celc.201600564

Cui S, Feng W, Hu H, Feng Z, Liu H (2009) Hexagonal Ti2SC with high hardness and brittleness: a first-principles study. Scripta Mater 61:576–579. https://doi.org/10.1016/j.scriptamat.2009.05.026

Sarycheva A, Gogotsi Y (2020) Raman spectroscopy analysis of the structure and surface chemistry of Ti3C2Tx MXene. Chem Mater 32:3480–3488. https://doi.org/10.1021/acs.chemmater.0c00359

Chen J, Hu Q, Zhou A, Sun D (2015) Theoretical studies of lithium storage properties of novel Two-Dimensional carbides. Acta Phys-Chim Sin 31:2278–2284. https://doi.org/10.3866/PKU.WHXB201510136

Xie Y, Naguib M, Mochalin VN, Barsoum MW, Gogotsi Y, Yu X, Nam K, Yang X, Kolesnikov AI, Kent PRC (2014) Role of surface structure on Li-Ion energy storage capacity of two-dimensional transition-Metal carbides. J Am Chem Soc 136:6385–6394. https://doi.org/10.1021/ja501520b

Kim J, Lee KE, Kim KH, Wi S, Lee S, Nam S, Kim C, Kim SO, Park B (2017) Single-layer graphene-wrapped Li4Ti5O12 anode with superior lithium storage capability. Carbon 114:275–283. https://doi.org/10.1016/j.carbon.2016.12.022

Li X, Li M, Yang Q, Liang G, Huang Z, Ma L, Wang D, Mo F, Dong B, Huang Q, Zhi C (2020) In situ electrochemical synthesis of MXenes without Acid/Alkali usage in/for an aqueous zinc ion battery. Adv Energy Mater 10:2001791. https://doi.org/10.1002/aenm.202001791

Sun ZM (2013) Progress in research and development on MAX phases: a family of layered ternary compounds. Int Mater Rev 56:143–166. https://doi.org/10.1179/1743280410Y.0000000001

Gupta S, Barsoum MW (2011) On the tribology of the MAX phases and their composites during dry sliding: a review. Wear 271:1878–1894. https://doi.org/10.1016/j.wear.2011.01.043

Hu C, Zhang H, Li F, Huang Q, Bao Y (2013) New phases’ discovery in MAX family. Int J Refract Metal Hard Mater 36:300–312. https://doi.org/10.1016/j.ijrmhm.2012.10.011

Acknowledgements

J. Xu thanks the National Natural Science Foundation of China (No. 21671167), Starting fund for returned overseas Chinese scholars of Ministry of Education of China and the Joint Open Fund of Jiangsu Collaborative Innovation Center for Ecological Building Material and Environmental Protection Equipments and Key Laboratory for Advanced Technology in Environmental Protection of Jiangsu Province (No. JH201847). W. Yao thanks the National Natural Science Foundation of China (No. 51602277), the Natural Science Foundation of Jiangsu Province (No. BK20140473).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article corrected to make changes in acknowledgements section and to the affiliation of a co-author.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xu, J., Yao, X., Sun, G. et al. Lithium-ions uptake by MAX/graphene hybrid. Graphene and 2D mater 7, 59–71 (2022). https://doi.org/10.1007/s41127-022-00048-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41127-022-00048-w