Abstract

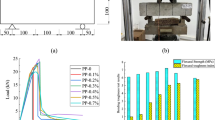

The continuous growth of industrialization causes major challenges in the disposal of extensive amounts of industrial by-products. The utilization of industrial by-products in concrete is a sustainable substitute for natural river sand and reduces the scarcity of global resources. In this intent, current research aims to utilize copper slag as an alternative to natural fine aggregate in the reinforced concrete beam. The incorporation of copper slag as a partial substitute for fine aggregate influences the mechanical characteristics of concrete. The reinforced concrete beam with the optimum percentage of copper slag is prepared and tested to evaluate the flexural parameters. The results exhibit that the addition of copper slag results in a denser concrete structure due to its fine particles and pozzolanic reactivity. Incorporating 40% copper slag results in a 21.4% increase in ultimate load-carrying capacity and a 20.23% increase in stiffness of the RC beam. Furthermore, finite element analysis is conducted for the reinforced concrete beam to validate the experimental results. ANSYS model simulates the failure mode and responses of reinforced concrete beams with high accuracy. The numerical results show that the replacement of copper slag has a significant effect on the flexural characteristics of reinforced concrete beams. The outcomes of this numerical investigation show that the load–deflection relationship, crack pattern, and failure modes are in close agreement with their experimental observation. The numerical analysis results show a maximum deviation percentage of 7.218 in comparison to the results obtained from the experimental investigation.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article [and/or] its supplementary materials.

Code availability

ANSYS.

References

P Gorai RK Jana Premchand 2003 Characteristics and utilisation of copper slag—a review Resour Conserv Recycl 39 299 313 https://doi.org/10.1016/S0921-3449(02)00171-4

C Shi C Meyer A Behnood 2008 Utilization of copper slag in cement and concrete Resour Conserv Recycl 52 1115 1120 https://doi.org/10.1016/j.resconrec.2008.06.008

RKD Obe J Brito De R Mangabhai CQ Lye 2016 Sustainable construction materials, copper slag Woodhead Publishing Sawston

W Moura A Masuero D Molin Dal A Vilela 1999 Concrete performance with admixtures of electrical steel slag and copper concerning mechanical properties Spec Publ 186 81 100

Wu Wei W Zhang G Ma 2010 Optimum content of copper slag as a fine aggregate in high strength concrete Mater Des 31 6 2878 2883 https://doi.org/10.1016/j.matdes.2009.12.037

KS Al-Jabri M Hisada SK Al-Oraimi AH Al-Saidy 2009 Copper slag as sand replacement for high performance concrete Cement Concrete Comp 31 483 488 https://doi.org/10.1016/j.cemconcomp.2009.04.007

Al-Jabri KS (2006) Copper slag as fine aggregate in high-performance concrete, highperformance structures and materials III. In: WIT transactions on the built environment, vol 85. WIT Press, pp 381–389

RA Taha AS Al-Nuaimi KS Al-Jabri AS Al-Harthy 2007 Evaluation of controlled low strength materials containing industrial by-products Build Environ 42 3366 3372

VM Malhotra 1993 Fly ash, slag, silica fume, and rice-husk ash in concrete: a review Concr Int 15 4 23 28

R Tixier R Devaguptapu B Mobasher 1997 Effect of copper slag on the hydration and mechanical properties of cementitious mixtures Cem Concr Res 27 10 1569 1580

AM Arino B Mobasher 1999 Effect of copper slag on the strength, and toughness of cementitious mixtures ACI Mater J 96 1 68 75

E Douglas PR Mainwaring 1986 Pozzolanic properties of Canadian non-ferrous slag, SP91-75 American Concrete Institute Farmington Hills 1525 1550

Deja J, Malolepszy J (1989) Resistance of alkali activated slag mortars to chloride solution. In: Proceedings of the third international conference on the use of fly ash, silica fume, slag, and natural pozzolans in concrete, SP-114, vol 2, pp 1677–1695

CL Hwang JC Laiw 1989 Properties of concrete using copper slag as a substitute for fine aggregate Spec Publ 114 1677 1696

CMA Resende 2009 Study of copper slag incorporation viability as fine aggregate for construction products Universidade do Porto Porto

Caliskan S, Behnood A (2004) Recycling copper slag as coarse aggregate: hardened properties of concrete. In: Proceedings of seventh international conference on concrete technology in developing countries, pp 91–98

Hwang CL, Laiw JC (1989) Properties of concrete using copper slag as a substitute for fine aggregate. In: Proceedings of the 3rd international conference on fly ash, silica fume, slag, and natural pozzolans in concrete, SP-114-82, pp 1677–1695

Ayano T, Sakata K (2000) Durability of concrete with copper slag fine aggregate. In: Proceedings of the fifth CANMET/ACI international conference on durability of concrete, SP-192, pp 141–58

I Afshoon Y Sharifi 2014 Ground copper slag as a supplementary cementing material and its influence on the fresh properties of self-consolidating concrete IES J Part A Civ Struct Eng 7 4 229 242

S Chithra SRR Senthil Kumar K Chinnaraju 2016 The effect of Colloidal Nanosilica on workability, mechanical and durability properties of High-Performance Concrete with Copper slag as partial fine aggregate Constr Build Mater 113 794 804 https://doi.org/10.1016/j.conbuildmat.2016.03.119

KS Al-Jabri AH Al-Saidy R Taha 2011 Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete Constr Build Mater 25 933 938

M Selvaradjou R Baskar 2019 Research on the effect of copper slag as a fine aggregate on the properties of concrete Int J Recent Technol Eng 8 619 623

S Mirnezami A Hassani A Bayat 2023 Evaluation of the effect of metallurgical aggregates (steel and copper slag) on the thermal conductivity and mechanical properties of concrete in jointed plain concrete pavements (JPCP) Constr Build Mater 367 129532

AM Sayed 2019 Numerical study using FE simulation on rectangular RC beams with vertical circular web openings in the shear zones Eng Struct 198 109471

E Hognestad NW Hanson D McHenry 1955 Concrete stress distribution in ultimate strength design J Am Concrete Inst 52 455

Willam KJ, Warnke EP (1974) Constitutive model for the triaxial behavior of concrete. In: International association of bridge and structural engineering seminar on concrete structures subjected triaxial stresses. Bergamo, Italy

ASTM C469 (2002) Standard test method for static modulus of elasticity and Poisson’s ratio of concrete in compression. American Society of Testing and Material International.

P Manibalan G Abirami S Kesavan 2022 Flexural response of RC beam strengthened with BFRP plate Innov Infrastruct Solut 7 142 1 13 https://doi.org/10.1007/s41062-022-00743-w

P Manibalan S Kesavan G Abirami R Baskar 2022 Fatigue response of RC beam strengthened by BFRP plate Case Stud Constr Mater 18 2023 e01707

Funding

Non-funding project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethics approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national researchcommittee.

Consent to participate

Not applicable.

Consent to publication

Not applicable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Manibalan, P., Selvaradjou, M., Baskar, R. et al. Flexural behavior of RC beam using industrial copper slag as a sustainable substitute for fine aggregate. Innov. Infrastruct. Solut. 9, 64 (2024). https://doi.org/10.1007/s41062-024-01373-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-024-01373-0