Abstract

Rheo-diecasting with high solid fraction is a new die casting process developed in recent years. In order to promote the application of this process in magnesium alloys, taking the test bar castings as the research object in the experiment, the commercial simulation software, FLOW-3D, was used to simulate the effects of the semisolid rheo-diecasting process parameters on the test bar air entrainment and oxide inclusion of Mg-6Al-1Ca-0.5Sb magnesium alloy with solid fraction range from 0.42 to 0.64, and the optimal process parameters were finally determined through orthogonal simulation experiments. The magnesium alloy slurry was fabricated by the swirled enthalpy equilibration device (SEED), and the die casting test bar was verified using the optimal process parameters that slurry temperature of 580 °C, injection speed of 1.75 m/s and mold temperature of 225 °C. The experimental results show that the die castings have complete mold filling, smooth surface and no surface defects. The microstructure of the test bar was composed of rounded grains with an average grain size of 34.42μm and an average shapes factor of 0.79. The tensile strength of the test bar after T6 treatment was 250 MPa and elongation was 18.9%, which were increased by 33% and 84% compared with that of semisolid rheo-diecasting test bar, respectively.

Similar content being viewed by others

References

S.E. Kleiner et al., Semi-solid metal processing of aluminum alloy A356 and magnesium alloy AZ91: comparison based on metallurgical consideration. Adv. Eng. Mater. 5, 653–658 (2003). https://doi.org/10.1002/adem.200300358

J. Tao, J. Jiang, C. Hong et al., Application of cyclic upsetting-extrusion to semi-solid processing of AZ91D magnesium alloy. Trans. Nonferrous Metals Soc. China. 23(4), 909–915 (2013). https://doi.org/10.1016/S1003-6326(13)62547-9

H.A. Patel, D.L. Chen, S.D. Bhole et al., Cyclic deformation and twinning in a semi-solid processed AZ91D magnesium alloy. Mater. Sci. Eng. A 528(1), 208–219 (2010). https://doi.org/10.1016/j.msea.2010.09.016

W. Shan, S. Luo, Mechanical behavior and microstructure during compression of semi-solid ZK60-RE magnesium alloy at high solid content. Mater. Sci. Eng. A 465(1–2), 247–254 (2007). https://doi.org/10.1016/j.msea.2007.02.030

J. Qzhu, Semi-solid moulding: competition to cast and machine from forging in making automotive complex components. Trans. Nonferrous Metals Soc. China 3, 335–340 (2010). https://doi.org/10.1016/S1003-6326(10)60628-0

G. Eisaabadi, A. Nouri, Effect of Sr on the microstructure of electromagnetically stirred semi-solid hypoeutectic Al-Si alloys. Int. J. Metalcast. 12, 292–297 (2018). https://doi.org/10.1007/s40962-017-0161-8

C. Xghab, D. Qza, E. Spma et al., Blistering in semi-solid die casting of aluminium alloys and its avoidance. Acta Materialia 124, 446–455 (2017). https://doi.org/10.1016/j.actamat.2016.11.032

S. Ren, F. Wang, J. Sun et al., Gating system design based on numerical simulation and production experiment verification of aluminum alloy bracket fabricated by semi-solid Rheo-Die casting process. Int. J. Metalcast. 16, 878–893 (2022). https://doi.org/10.1007/s40962-021-00648-x

C. Lin, H.U. Jian, W. Zhang, Numerical simulation of flow field under electromagnetic stirring of semi-solid slurry of aluminum alloy. Hot Working Technol. 38(1), 73–76 (2009)

H. Liu, Y. Mei, G. Chen et al., Numerical simulation and experimental investigation of thixoforming for semi-solid magnesium alloy. Hot Working Technol. 5, 21 (2008)

Y.F. Zhang, Y.B. Liu, Z.Y. Cao et al., Numerical simulation and parameters optimization of thixomolded process for semisolid AZ91D magnesium alloy. Chin. J. Nonferrous Metals 18(4), 703–709 (2008)

Y. Zhang, Q. Ma, Y. Chen et al., LBM simulation of magnesium alloy rheological cast-rolling with porous medium model. Mater. Sci. Technol. 22(2), 117–122 (2014)

L. Wei, D.Y. Dou, F.Q. Gao et al., Microstructure evolution of semisolid Mg-2Zn-0.5Y alloy during isothermal heat treatment. Rare Metal Mater. Eng. 45(8), 1967–1972 (2016). https://doi.org/10.1016/S1875-5372(16)30155-2

L. Rogal, G. Garzel, Semi-solid state mixing of Mg-Zn-RE alloys microstructure and mechanical properties. J. Mater. Process. Technol. 264, 352–365 (2018). https://doi.org/10.1016/j.jmatprotec.2018.09.012

Z. Ji, M. Hu, S. Sugiyama et al., Formation process of AZ31B semi-solid microstructures through strain-induced melt activation method. Mater. Charact. 59(7), 905–911 (2008). https://doi.org/10.1016/j.matchar.2007.07.015

B. Nami, H. Razavi, S.M. Miresmaeili et al., Impression creep properties of a semi-solid processed magnesium-aluminum alloy containing calcium and rare earth elements. Scripta Mater. 65(3), 221–224 (2011). https://doi.org/10.1016/j.scriptamat.2011.04.011

F. Czerwinski, A. Zielinska-Lipiec, P.J. Pinet et al., Correlating the microstructure and tensile properties of a thixomolded AZ91D magnesium alloy. Acta Mater. 49(7), 1225–1235 (2001). https://doi.org/10.1016/S1359-6454(01)00015-5

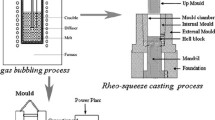

J. Mao, W. Liu, G. Wu et al., Semi-solid slurry preparation, rheo-die casting and rheo-squeeze casting of an AZ91-2Ca-1.5Ce ignition-proof magnesium alloy by gas-bubbling process. J. Mater. Res. 32(3), 677–686 (2017). https://doi.org/10.1557/jmr.2016.517

H.W. Liu, F. Feng, J.M. Liu. Finite Element Analysis of Semi-Solid Die-Casting Technology of Magnesium Alloy Hook Based on AnyCasting. Atlantis Press, pp. 601–605 (2012).

C.W. Hirt, B.D. Nichols, Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 39(1), 201–225 (1981)

C.G. Kang, S.M. Lee, B.M. Kim, A study of die design of semi-solid die casting according to gate shape and solid fraction. J. Mater. Process. Technol. 204(1–3), 8–21 (2008). https://doi.org/10.1016/j.jmatprotec.2008.01.038

M.D. Ibrahim, G.L. Tan, L. Roslan et al., Numerical and experimental analysis on runner and gate positioning for magnesium alloy Die-casted test piece. Mater. Sci. Forum 975, 242–247 (2020). https://doi.org/10.4028/www.scientific.net/MSF.975.242

M.C. Flemings, Behavior of metal alloys in the semisolid state. Metall. and Mater. Trans. A. 22(5), 957–981 (1991). https://doi.org/10.1007/BF02661090

M. Sakamoto, S. Akiyama, K. Ogi, Suppression of ignition and burning of molten Mg alloys by Ca bearing stable oxide film. J. Mater. Sci. Lett. 16(12), 1048–1050 (1997). https://doi.org/10.1023/A:1018526708423

X.D. Du, F. Wang, Z. Wang et al., Effect of addition of minor amounts of Sb and Gd on hot tearing susceptibility of Mg-5Al-3Ca alloy. J. Magnes. Alloys. (2021). https://doi.org/10.1016/j.jma.2021.05.015

Z.T. Li, X.D. Zhang, M.Y. Zheng et al., Effect of Ca/Al ratio on microstructure and mechanical properties of Mg-Al-Ca-Mn alloys. Mater. Sci. Eng.,A 682, 423–432 (2017). https://doi.org/10.1016/j.msea.2016.11.026

A. Boby, A. Srinivasan, U.T.S. Pillai et al., Mechanical and wear properties of Sb-and Y-added Mg-9Al-1Zn (AZ91) alloy. Metall. Mater. Trans. A. 46(9), 4234–4246 (2015). https://doi.org/10.1007/s11661-015-3013-2

F. Wang, S.J. Sun, S.J. An et al., Effects of heat treatment on microstructure and mechanical properties of Mg-7Al-2Sn alloy prepared by vacuum die-casting. Trans. Mater. Heat Treat. 36(S1), 72–77 (2015)

Funding

This work was supported by General Project of Liaoning Provincial Department of Education (No. LJKMZ20220462); High level innovation team of Liaoning Province (No. XLYC1908006); and Innovative Talents Support Program of Higher Education of Liaoning Province (No. 2020-389).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gu, Y., Wang, F., Jiao, J. et al. Study on Semisolid Rheo-Diecasting Process, Microstructure and Mechanical Properties of Mg-6Al-1Ca-0.5Sb Alloy with High Solid Fraction. Inter Metalcast 18, 123–137 (2024). https://doi.org/10.1007/s40962-023-01001-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01001-0