Abstract

Purpose

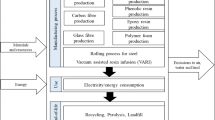

This study presents a life cycle assessment (LCA)-based sustainable and lightweight automotive engine hood design and compares the life cycle energy consumption and potential environmental impacts of a steel (baseline) automotive engine hood with three types of lightweight design: advanced high strength steel (AHSS), aluminum, and carbon fiber.

Methods

A “cradle-to-grave” LCA including the production, use, and end-of-life stages is conducted in accordance with the ISO 14040/14044 standards. Onsite data collected by Chinese automotive companies in 2015 are used in the assessment. The Cumulative Energy Demand v1.09 method is applied to evaluate cumulative energy demand (CED), and the International Panel on Climate Change 2013 100a method is used to estimate global warming potential (GWP 100a).

Results and discussion

Among the different lightweight designs for the engine hood, the aluminum design is the most sustainable and has the lowest CED and GWP (100a) from a life cycle perspective, which is based on a lifetime driving distance of approximately 150,000 km. In addition, the AHSS design is also sustainable and lightweight. The carbon fiber design results in higher CED and GWP (100a) values than the steel (baseline) design during the life cycle but results in the largest CED and GWP (100a) savings through waste material recycling. The AHSS design exhibits the best break-even distance based on CED and GWP (100a) within 150,000 km.

Conclusions

Sensitivity analysis results show that the lifetime driving distance and material recycling rate have the largest impacts on the overall CEDs and GWPs of the three lightweight designs.

Similar content being viewed by others

References

Ashnani MHM, Miremadi T, Johari A, Danekar A (2015) Environmental impact of alternative fuels and vehicle technologies: a life cycle assessment perspective. Por Environ Sci 30:205–210

CSA Group (2014) Guidelines for conducting LCA of auto parts incorporating weight changes due to material composition, manufacturing technology, or part geometry vol SPE-14040-14. Canadian Standards Association Group, Canada

Cui X, Zhang H, Wang S, Zhang L, Ko J (2011) Design of lightweight multi-material automotive bodies using new material performance indices of thin-walled beams for the material selection with crashworthiness consideration. Mater Design 32:815–821

Das S (2011) Life cycle assessment of carbon fiber-reinforced polymer composites. Int J Life Cycle Assess 16:268–282

Ding N, Gao F, Wang Z, Yang J (2015) Life cycle energy and greenhouse gas emissions of automobiles using aluminum in China. J Ind Ecol 20:818–827

Dubreuil A, Bushi I, Das S, Tharumarajah A, Gong X (2010) A Comparative Life Cycle Assessment of Magnesium Front End Autoparts. SAE Technical Papers 01 doi:10.4271/2010–01-0275

Dubreuil A, Bushi I, Das S, Tharumarajah A, Gong X (2012) A Comparative Life Cycle Assessment of Magnesium Front End Autoparts. SAE Technical Papers 01 doi:10.4271/2012–01-2325

EPA (2016) EPA’s FTP-75 and HWFET driving cycles. http://www.dieselnet.com/standards/cycles/hwfet.html. Accessed 2.24 2016

Frischknecht R, Jungbluth N et al (2003) Implementation of life cycle impact assessment methods. Final report ecoinvent 2000, Swiss Centre for LCI. Duebendorf, CH. www.ecoinvent.ch

Gao Z et al (2015) Drive cycle simulation of high efficiency combustions on fuel economy and exhaust properties in light-duty vehicles. Appl Energ 157:762–776

Hakamada M, Furuta T, Chino Y, Chen Y, Kusuda H, Mabuchi M (2007) Life cycle inventory study on magnesium alloy substitution in vehicles. Energy 32:1352–1360

Helms H, Lambrecht U (2007) The potential contribution of light-weighting to reduce transport energy consumption. Int J Life Cycle Assess 12:58–64

IPCC (2013) Climate change 2013: the physical science basis. Contribution of working group I to the fifth assessment report of the intergovernmental panel on climate change. Intergovernmental Panel on Climate Change, Cambridge, United Kingdom and New York, NY, USA

ISO (2006) ISO 14040: 2006 environmental management-life cycle assessment-principles and framework. International Organization for Standardization, Geneva

Kampe S (2001) Incorporating Green Engineering in Materials Selection and Design. In: 2001 Green Engineering Conference: Sustainable and Environmentally-Conscious Engineering, Roanoke, Virginia. Virginia Tech’s College of Engineering and the U.S. Environmental Protection Agency

Koffler C, Rohde-Brandenburger K (2010) On the calculation of fuel savings through lightweight design in automotive life cycle assessments. Int J Life Cycle Assess 15:128–135

Koffler C, Zahller M (2012a) Life cycle assessment of polymers in an automotive assist step, prepared for: American Chemistry Council. PE INTERNATIONAL, USA

Koffler C, Zahller M (2012b) Life cycle assessment of polymers in an automotive bolster, prepared for: American Chemistry Council. PE INTERNATIONAL, Inc., USA

Liu Q, Chen Q, Yang J (2011) The Impact of Tire Rolling Resistance on the Fuel Economy of Vehicle. AUTOMOB PARTS:77–80 doi:10.3969/j.issn.1674-1986.2011.08.029

Liu Z et al (2015) Targeted opportunities to address the climate-trade dilemma in China. Nature Clim Change advance online publication. doi:10.1038/nclimate2800

Liu ZF, Wang J, Zhang L, Bao H (2012) Life cycle assessment of automotive engine hoods made of aluminum alloy and glass mat reinforced thermoplastic. J Hefei Univ Tech 35:433–438

Mayyas AT, Qattawi A, Mayyas AR, Omar MA (2012) Life cycle assessment-based selection for a sustainable lightweight body-in-white design. Energy 39:412–425

Oliveux G, Dandy LO, Leeke GA (2015) Current status of recycling of fibre reinforced polymers: review of technologies, reuse and resulting properties. Prog Mater Sci 72:61–99

Pimenta S, Pinho ST (2011) Recycling carbon fibre reinforced polymers for structural applications: technology review and market outlook. Waste Manag 31:378–392

Saur K, Fava JA, Spatari S (2000) Life cycle engineering case study: automobile fender designs. Environ Prog 19:72–82

Sun X, Liu J, Yang D, Lv B (2014) The carbon footprint of household air-conditioners and its key influence factors. Acta Scien Circum 34:1054–1060

Vo Dong PA, Azzaro-Pantel C, Boix M, Jacquemin L, Domenech S (2015) Modelling of Environmental Impacts and Economic Benefits of Fibre Reinforced Polymers Composite Recycling Pathways. In: Krist V, Gernaey JKH, Rafiqul G (eds) Computer Aided Chemical Engineering, vol Volume 37. Elsevier, pp 2009–2014. doi:10.1016/B978–0–444-63576-1.50029-7

Wang H, Gao W, Pan L, Liu C (2006) Lightweight structure of engine hood. J Tongji Univ (Natrual Science) 34:1098–1103

Witik RA, Payet J, Michaud V, Ludwig C, Månson J-AE (2011) Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Cosmos Part A-Appl S 42:1694–1709

Witik RA, Teuscher R, Michaud V, Ludwig C, Månson J-AE (2013) Carbon fibre reinforced composite waste: an environmental assessment of recycling, energy recovery and landfilling. Compos Part A-Appl S 49:89–99

Yang D, Liu J, Yamg J, Ding N (2015) Life-cycle assessment of China’s multi-crystalline silicon photovoltaic modules considering international trade. J Clean Prod 94:35–45

Zhou J, Wang F, Wan X (2015) Optimal design and experimental investigations of Aluminium sheet for lightweight of car hood. Mater Today: Prog 2:5029–5036

Zhu P, Meng J, Yu M, Feng Q, Zhou QW (2011) Lightweight design and Formabil ity analysis of saloon car aluminum-alloy engine hood. CNN J Highway Transp 24:113–120

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Wulf-Peter Schmidt

Rights and permissions

About this article

Cite this article

Sun, X., Liu, J., Lu, B. et al. Life cycle assessment-based selection of a sustainable lightweight automotive engine hood design. Int J Life Cycle Assess 22, 1373–1383 (2017). https://doi.org/10.1007/s11367-016-1254-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-016-1254-y