Abstract

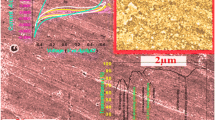

Metal self-anodization for the generation of hydroxides represents a versatile innovation. In the preparation of Ru-doped copper hydroxide thin films, copper plates were subjected to self-anodization in a 1 M ethanolic NaOH bath, maintaining a constant deposition potential of 0.8 V. The resulting thin films of Cu(OH)2 were then used directly for the doping of Ru, employing a cathodization technique. This cathodization process was conducted separately using RuCl3 electrolytes prepared in methanol, ethanol, and propanol. Furthermore, to assess the impact of different doping deposition potentials ranging from 0.7 to 0.9 V on the structural and electrochemical properties of the Ru-doped Cu(OH)2 material, optimized electrodes were prepared. The phase and crystal structure of the deposited material were confirmed through XRD analysis. Scanning electron microscope images revealed a spongy, granular, and rough surface, a characteristic further confirmed by atomic force microscopy analysis. Transmission electron microscope images displayed the formation of nano granules. To evaluate the electrochemical performance of the samples, cyclic voltammetry (CV), chronopotentiometry (CP) tests, and impedance spectroscopy (EIS) were conducted in a 1 M NaOH solution. Notably, the optimized sample exhibited a maximum specific capacitance (SC) of 4133.3 F/g, with a measured diffusion coefficient of 2.21 × 10−16 cm2/s.

Similar content being viewed by others

Data availability

Research data is original and it made available on request.

References

R.S. Kate, S.A. Khalate, R.J. Deokate, J. Alloys Comp. (2018). https://doi.org/10.1016/j.jallcom.2017.10.262

R.K. Sharma, H.S. Oh, Y.G. Shul, H. kim, J. Power Sources 173, 1024 (2007). https://doi.org/10.1016/J.JPOWSOUR.2007.08.076

J.S. Shaikh, R.C. Pawar, R.S. Devan, Y.R. Ma, P.P. Salvi, S.S. Kolekar, P.S. Patil, Electrochimica Acta 56, 2127 (2011). https://doi.org/10.1016/J.ELECTACTA.2010.11.046

S. Chuhadiya, D. Himanshu, S.L. Suthar, M.S. Patel, Coord. Chem. Rev. 446, 214115 (2021). https://doi.org/10.1016/j.ccr.2021.214115

T.S. Ghadge, A.L. Jadhav, B.J. Lokhande, J. Alloys Comp. (2020). https://doi.org/10.1016/j.jallcom.2020.153860

S.V. Khavale, R.C. Ambare, B.J. Lokhande, J. Mater. Sci. Mater. Electron. 31, 7315 (2020). https://doi.org/10.1007/s10854-019-02420-8

T. Li, H. Yu, L. Zhi, W. Zhang, L. Dang, Z. Liu, Z. Lei, J. Phys. Chem. C 121(35), 18982 (2017). https://doi.org/10.1021/acs.jpcc.7b04330

R.C. Ambare, S.R. Bharadwaj, B.J. Lokhande, Curr. Appl. Phys. 11(14), 1582 (2014). https://doi.org/10.1016/j.cap.2014.08.001

B.Y. Fugare, B.J. Lokhande, Mater. Sci. Semicond. Process. 71, 121 (2017). https://doi.org/10.1016/j.mssp.2017.07.016

R.C. Ambare, S.R. Bharadwaj, B.J. Lokhande, Measurement. 88, 66 (2016). https://doi.org/10.1016/j.measurement.2016.02.063

M. Huang, F. Li, F. Dong, Y.X. Zhang, L. Zhang, J. Mater. Chem. A 3, 21380 (2015). https://doi.org/10.1039/C5TA05523G

T.S. Ghadge, A.L. Jadhav, Y.M. Uplane, A.V. Thakur, S.V. Kamble, B.J. Lokhande, J. Mater. Sci. Mater. Electron. 32(7), 9018 (2021). https://doi.org/10.1007/s10854-021-05572-8

R.C. Ambare, P.S. Shinde, U.T. Nakate, B.J. Lokhande, R.S. Mane, Appl. Surf. Sci. 453, 214 (2018). https://doi.org/10.1016/J.APSUSC.2018.05.090

A.V. Kadam, S.B. Patil, Mater. Res. Express 5(8), 085036 (2018). https://doi.org/10.1088/2053-1591/aad406

S.V. Kambale, A.L. Jadhav, R.M. Kore, A.V. Thakur, Macromol. Symp. (2019). https://doi.org/10.1002/masy.201800213

S. Sonia, S. Poongodi, P. Suresh Kumar, D. Mangalaraj, N. Ponpandian, C. Viswanathan, Mater. Sci. Semicond. Process 30, 585 (2015). https://doi.org/10.1016/j.mssp.2014.10.012

A.V. Kadam, J. Appl. Electrochem. 47, 335 (2017). https://doi.org/10.1007/s10800-016-1011-8

J. Sultana, S. Paul, A. Karmakar, R. Yi, G.K. Dalapati, S. Chattopadhyay, Appl. Surf. Sci. 418, 380 (2016). https://doi.org/10.1016/j.apsusc.2016.12.139

O. Gençyılmaz, T. Taşköprü, J. Alloys Compd. 695, 1205 (2017). https://doi.org/10.1016/j.jallcom.2016.10.247

B. Vidyadharan, I. Misnon, J. Ismail, M.M. Yusoff, R. Jose, J. Alloys Compd. 633, 22 (2015). https://doi.org/10.1016/j.jallcom.2015.01.278

P. Revathi, V. Manikandan, P. Ezhilmathi, V.U. Shankar, P. Suganya, K. Krishnasamy, Asi J. Chem. 32(11), 2763 (2020). https://doi.org/10.14233/ajchem.2020.22845

M.R. Pallavolu, A.N. Banergee, S.W. Joo, Coatings. 13, 1337 (2023). https://doi.org/10.3390/coatings13081337

R.N. Bulakhe, V.Q. Nguyen, D. Tuma, Y.R. Lee, H. Zhang, S. Zhang, J.-J. Shim, J. Ind. Eng. Chem. 66, 288 (2018). https://doi.org/10.1016/j.jiec.2018.05.043

S.K. Shinde, D.P. Dubal, B.S. Ghodake, Y. Kimc, V.J. Fulari, J. Electroanal. Chem. 732, 80 (2014). https://doi.org/10.1016/j.jelechem.2014.09.004

F. Basile, G. Fornasari, M. Gazzano, A. Vaccari, Appl. Clay Sci. 16, 185 (2000). https://doi.org/10.1016/S0169-1317(99)00053-8

T. Liu, K. Wang, Y. Chen, S. Zhao, Y. Han, Green Energy Environ. 4(2), 171 (2019). https://doi.org/10.1016/j.gee.2019.01.010

I. Misumi, K. Naoi, K. Sugawara, S. Gonda, Measurement. 73, 295 (2015). https://doi.org/10.1016/j.measurement.2015.05.026

Y. Dessie, S. Tadesse, R. Eswaramoorthy, J. Nanomater. (2021). https://doi.org/10.1155/2021/7475902

S.K. Kim, I.J. Park, D.Y. Lee, J.G. Kim, J. Appl. Electrochem. 43, 507 (2013). https://doi.org/10.1007/s10800-013-0534-5

Q. Chen, X. Li, X. Zang, Y. Cao, Y. He, P. Li, K. Wang, J. Wei, D. Wu, H. Zhu, RSC Adv. 4, 36253 (2014). https://doi.org/10.1039/C4RA05553E

T.S. Ghadge, B.J. Lokhande, J. Mater. Sci. 51(21), 9879 (2016). https://doi.org/10.1007/s10853-016-0221-0

J.E. Baur, S. Wang, M.C. Brandt, Anal. Chem. 68(21), 3815 (1996). https://doi.org/10.1021/ac960603m

Funding

Authors are grateful to thank Bhabha Atomic Research Centre (BARC), Mumbai, for their monetary endorsement of the venture Policy 2010/34/46/BRNS/2228 and Department of Science and Technology, New Delhi for providing financial supports through the project scheme DST-SERB sanction no.SB/EMEQ-331/2013.

Author information

Authors and Affiliations

Contributions

TSG: Conceptualization, Investigation, Methodology, Writing—review & editing. SVK: Investigation, Formal analysis, Writing—review & editing. BYF: Writing—original draft, Writing—review & editing. RCA: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, BJL: Funding acquisition, Investigation, Supervision, Writing—original draft, review & editing.

Corresponding authors

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Indicate that our research manuscript has been conducted ethically, keeping in mind privacy, consent and appropriate reporting of those involved in the study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghadage, T.S., Kambale, S.V., Fugare, B.Y. et al. Ru-doped nano grain hydrophilic copper hydroxide electrodes for supercapacitor application. J Mater Sci: Mater Electron 34, 2309 (2023). https://doi.org/10.1007/s10854-023-11708-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11708-9