Abstract

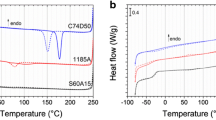

Solid-state cooling based on caloric effects is an alternative to traditional vapor-compression refrigeration systems. This technique and the solid-state materials have received great attention in recent decades. For example, the elastomers are promising because they have high values of adiabatic temperature change (ΔTS) and isothermal entropy change (ΔST). However, their thermal conductivity is limited, which is a fundamental property for heat transfer. Hence, in this work, we characterized the mechanocaloric effect in natural graphite/thermoplastic polyurethane (NG/TPU) composites. The pure TPU and its NG/TPU composites were characterized by their thermal and mechanical properties. The NG/TPU composites presented ΔTS = 8.6 K and ΔST = 35 J kg−1 K−1, which correspond to a maximum reduction of 28 and 45% in the ΔTS and ΔST, respectively, when compared to pure TPU, but with an increase of 500% in thermal conductivity. We reported no significant reduction in the ΔTS for the composites after 105 compression cycles. Our findings combine a large mechanocaloric effect with the unique characteristics of TPUs and the enhanced thermal conductivity of its NG/TPU composites.

Graphical Abstract

Similar content being viewed by others

Data availability

Not applicable.

References

Takeuchi I, Sandeman K (2015) Solid-state cooling with caloric materials. Phys Today 68:48–54. https://doi.org/10.1063/PT.3.3022

Cazorla C (2019) Novel mechanocaloric materials for solid-state cooling applications. Appl Phys Rev 6:041316–041416. https://doi.org/10.1063/1.5113620

Greco A, Aprea C, Maiorino A, Masselli C (2019) A review of the state of the art of solid-state caloric cooling processes at room-temperature before 2019. Int J Refrig 106:66–88. https://doi.org/10.1016/j.ijrefrig.2019.06.034

Cirillo L, Greco A, Masselli C (2022) Cooling through barocaloric effect: a review of the state of the art up to 2022. Therm Sci Eng Prog 33:101380–101414. https://doi.org/10.1016/j.tsep.2022.101380

Imamura W, Paixão LS, Usuda ÉO et al (2018) I-Caloric effects: a proposal for normalization. In: Proceedings of the 8th international conference on caloric cooling (Thermag VIII), Darmstadt, Germany, 16–20 September, pp 179–184. https://doi.org/10.18462/iir.thermag.2018.0029

Xie Z, Sebald G, Guyomar D (2017) Comparison of elastocaloric effect of natural rubber with other caloric effects on different-scale cooling application cases. Appl Therm Eng 111:914–926. https://doi.org/10.1016/j.applthermaleng.2016.09.164

Coativy G, Haissoune H, Seveyrat L et al (2020) Elastocaloric properties of thermoplastic polyurethane. Appl Phys Lett 117:193903–193905. https://doi.org/10.1063/5.0023520

Yoshida Y, Yuse K, Guyomar D et al (2016) Elastocaloric effect in poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) terpolymer. Appl Phys Lett 108:242904–242914. https://doi.org/10.1063/1.4953770

Usuda EO, Bom NM, Carvalho AMG (2017) Large barocaloric effects at low pressures in natural rubber. Eur Polym J 92:287–293. https://doi.org/10.1016/j.eurpolymj.2017.05.017

Carvalho AMG, Imamura W, Usuda EO, Bom NM (2018) Giant room-temperature barocaloric effects in PDMS rubber at low pressures. Eur Polym J 99:212–221. https://doi.org/10.1016/j.eurpolymj.2017.12.007

Usuda EO, Imamura W, Bom NM et al (2019) Giant reversible barocaloric effects in nitrile butadiene rubber around room temperature. ACS Appl Polym Mater 1:1991–1997. https://doi.org/10.1021/acsapm.9b00235

Imamura W, Usuda ÉO, Paixão LS et al (2020) Supergiant barocaloric effects in acetoxy silicone rubber over a wide temperature range: great potential for solid-state cooling. Chin J Polym Sci 38:999–1005. https://doi.org/10.1007/s10118-020-2423-9

Patel S, Chauhan A, Vaish R, Thomas P (2016) Elastocaloric and barocaloric effects in polyvinylidene di-fluoride-based polymers. Appl Phys Lett 108:072903–072905. https://doi.org/10.1063/1.4942000

Wang R, Fang S, Xiao Y et al (2019) Torsional refrigeration by twisted, coiled, and supercoiled fibers. Science 366:216–221. https://doi.org/10.1126/science.aax6182

Wang R, Zhou X, Wang W, Liu Z (2021) Twist-based cooling of polyvinylidene difluoride for mechanothermochromic fibers. Chem Eng J 417:128060–128069. https://doi.org/10.1016/j.cej.2020.128060

Lloveras P, Tamarit J-L (2021) Advances and obstacles in pressure-driven solid-state cooling: a review of barocaloric materials. MRS Energy Sustain 8:3–15. https://doi.org/10.1557/s43581-020-00002-4

Xie Z, Sebald G, Guyomar D (2017) Temperature dependence of the elastocaloric effect in natural rubber. Phys Lett A 381:2112–2116. https://doi.org/10.1016/j.physleta.2017.02.014

Xie Z, Sebald G, Guyomar D (2015) Elastocaloric effect dependence on pre-elongation in natural rubber. Appl Phys Lett 107:081905–081914. https://doi.org/10.1063/1.4929395

Sebald G, Xie Z, Guyomar D (2016) Fatigue effect of elastocaloric properties in natural rubber. Philos Trans R Soc A Math Phys Eng Sci 374:20150302–20150313. https://doi.org/10.1098/rsta.2015.0302

Guyomar D, Li Y, Sebald G et al (2013) Elastocaloric modeling of natural rubber. Appl Therm Eng 57:33–38. https://doi.org/10.1016/j.applthermaleng.2013.03.032

Xie Z, Wei C, Guyomar D, Sebald G (2016) Validity of Flory’s model for describing equilibrium strain-induced crystallization (SIC) and thermal behavior in natural rubber. Polymer (Guildf) 103:41–45. https://doi.org/10.1016/j.polymer.2016.09.038

Zhang S, Yang Q, Li C et al (2022) Solid-state cooling by elastocaloric polymer with uniform chain-lengths. Nat Commun 13:1–7. https://doi.org/10.1038/s41467-021-27746-y

Zhang S, Fu Y, Li C et al (2022) Polymer elastomer near plastic-to-rubber critical transition produces enhanced elastocaloric effects. Cell Rep Phys Sci 3:101147–101212. https://doi.org/10.1016/j.xcrp.2022.101147

Bom NM, Imamura W, Usuda EO et al (2018) Giant barocaloric effects in natural rubber: a relevant step toward solid-state cooling. ACS Macro Lett 7:31–36. https://doi.org/10.1021/acsmacrolett.7b00744

Bocca JR, Favaro SL, Alves CS et al (2021) Giant barocaloric effect in commercial polyurethane. Polym Test 100:107251–107256. https://doi.org/10.1016/j.polymertesting.2021.107251

Weerasekera N, Ajjarapu KPK, Sudan K et al (2022) Barocaloric properties of thermoplastic elastomers. Front Energy Res 10:887006–887010. https://doi.org/10.3389/fenrg.2022.887006

Zhang C, Wang D, Qian S et al (2022) Giant barocaloric effects with a wide refrigeration temperature range in ethylene vinyl acetate copolymers. Mater Horiz 9:1293–1298. https://doi.org/10.1039/D1MH01920A

Imamura W, Usuda EO, Lopes ÉSN, Carvalho AMG (2022) Giant barocaloric effects in natural graphite/polydimethylsiloxane rubber composites. J Mater Sci 57:311–323. https://doi.org/10.1007/s10853-021-06649-9

Bera M, Prabhakar A, Maji PK (2020) Nanotailoring of thermoplastic polyurethane by amine functionalized graphene oxide: Effect of different amine modifier on final properties. Compos B Eng 195:108075–108115. https://doi.org/10.1016/j.compositesb.2020.108075

Voda A, Beck K, Schauber T et al (2006) Investigation of soft segments of thermoplastic polyurethane by NMR, differential scanning calorimetry and rebound resilience. Polym Test 25:203–213. https://doi.org/10.1016/j.polymertesting.2005.10.007

Ryu S, Oh H, Kim J (2019) A study on the mechanical properties and thermal conductivity enhancement through TPU/BN composites by hybrid surface treatment (mechanically and chemically) of boron nitride. Mater Chem Phys 223:607–612. https://doi.org/10.1016/j.matchemphys.2018.11.052

More AS, Lebarbé T, Maisonneuve L et al (2013) Novel fatty acid based di-isocyanates towards the synthesis of thermoplastic polyurethanes. Eur Polym J 49:823–833. https://doi.org/10.1016/j.eurpolymj.2012.12.013

Kwiecińska B, Petersen HI (2004) Graphite, semi-graphite, natural coke, and natural char classification—ICCP system. Int J Coal Geol 57:99–116. https://doi.org/10.1016/j.coal.2003.09.003

Bom NM, Usuda EO, Guimarães GM et al (2017) Note: experimental setup for measuring the barocaloric effect in polymers: application to natural rubber. Rev Sci Instrum 88:046103–046113. https://doi.org/10.1063/1.4979464

Xu Y-X, Juang J-Y (2021) Measurement of nonlinear Poisson’s ratio of thermoplastic polyurethanes under cyclic softening using 2D digital image correlation. Polymers (Basel) 13:1498–1511. https://doi.org/10.3390/polym13091498

Diani J, Fayolle B, Gilormini P (2009) A review on the Mullins effect. Eur Polym J 45:601–612. https://doi.org/10.1016/j.eurpolymj.2008.11.017

Marckmann G, Verron E, Gornet L et al (2002) A theory of network alteration for the Mullins effect. J Mech Phys Solids 50:2011–2028. https://doi.org/10.1016/S0022-5096(01)00136-3

Samaca Martinez JR, Le Cam J-B, Balandraud X et al (2014) New elements concerning the Mullins effect: a thermomechanical analysis. Eur Polym J 55:98–107. https://doi.org/10.1016/j.eurpolymj.2014.03.014

Zhang M-G, Xu W, Wu T et al (2021) Investigation on Mullins effect of rubber materials by spherical indentation method. Forces Mech 4:100037–100047. https://doi.org/10.1016/j.finmec.2021.100037

Ain QT, Haq SH, Alshammari A et al (2019) The systemic effect of PEG-nGO-induced oxidative stress in vivo in a rodent model. Beilstein J Nanotechnol 10:901–911. https://doi.org/10.3762/bjnano.10.91

Bera M, Chandravati GP, Maji PK (2018) Facile one-pot synthesis of graphene oxide by sonication assisted mechanochemical approach and its surface chemistry. J Nanosci Nanotechnol 18:902–912. https://doi.org/10.1166/jnn.2018.14306

Lavakusa B, Mohan BS, Prasad PD et al (2017) Facile synthesize of graphene oxide by modified hummer’s method and degradation of methylene blue dye under visible light irradiation. Int J Adv Res (Indore) 5:405–412. https://doi.org/10.21474/IJAR01/3526

Venkatesan N, Archana KS, Suresh S et al (2019) Boron-doped graphene as efficient electrocatalyst for zinc-bromine redox flow batteries. ChemElectroChem 6:1107–1114. https://doi.org/10.1002/celc.201801465

Yang Y, Wang Z, Zheng S (2021) Secondary exfoliation of electrolytic graphene oxide by ultrasound assisted microwave technique. Nanomaterials 12:68. https://doi.org/10.3390/nano12010068

Bandi S, Ravuri S, Peshwe DR, Srivastav AK (2019) Graphene from discharged dry cell battery electrodes. J Hazard Mater 366:358–369. https://doi.org/10.1016/j.jhazmat.2018.12.005

Wu B, Wang H, Chen Y et al (2021) Preparation and properties of thermoplastic polyurethane foams with bimodal structure based on TPU/PDMS blends. J Supercrit Fluids 177:105324–105410. https://doi.org/10.1016/j.supflu.2021.105324

Wang X, Xue R, Li M et al (2022) Strain and stress sensing properties of the MWCNT/TPU nanofiber film. Surf Interfaces 32:102132–102139. https://doi.org/10.1016/j.surfin.2022.102132

Yahiaoui M, Denape J, Paris J-Y et al (2014) Wear dynamics of a TPU/steel contact under reciprocal sliding. Wear 315:103–114. https://doi.org/10.1016/j.wear.2014.04.005

Pandey S, Jana KK, Aswal VK et al (2017) Effect of nanoparticle on the mechanical and gas barrier properties of thermoplastic polyurethane. Appl Clay Sci 146:468–474. https://doi.org/10.1016/j.clay.2017.07.001

Menes O, Cano M, Benedito A et al (2012) The effect of ultra-thin graphite on the morphology and physical properties of thermoplastic polyurethane elastomer composites. Compos Sci Technol 72:1595–1601. https://doi.org/10.1016/j.compscitech.2012.06.016

Mi H-Y, Salick MR, Jing X et al (2013) Characterization of thermoplastic polyurethane/polylactic acid (TPU/PLA) tissue engineering scaffolds fabricated by microcellular injection molding. Mater Sci Eng C 33:4767–4776. https://doi.org/10.1016/j.msec.2013.07.037

Mistry P, Chhabra R, Muke S et al (2021) Fabrication and characterization of starch-TPU based nanofibers for wound healing applications. Mater Sci Eng C 119:111316–111411. https://doi.org/10.1016/j.msec.2020.111316

Mochane MJ, Luyt AS (2015) The effect of expanded graphite on the flammability and thermal conductivity properties of phase change material based on PP/wax blends. Polym Bull 72:2263–2283. https://doi.org/10.1007/S00289-015-1401-9

Mochane MJ, Luyt AS (2015) The effect of expanded graphite on the thermal stability, latent heat, and flammability properties of EVA/wax phase change blends. Polym Eng Sci 55:1255–1262. https://doi.org/10.1002/PEN.24063

Che J, Wu K, Lin Y et al (2017) Largely improved thermal conductivity of HDPE/expanded graphite/carbon nanotubes ternary composites via filler network-network synergy. Compos Part A Appl Sci Manuf 99:32–40. https://doi.org/10.1016/j.compositesa.2017.04.001

Fu YX, He ZX, Mo DC, Lu SS (2014) Thermal conductivity enhancement with different fillers for epoxy resin adhesives. Appl Therm Eng 66:493–498. https://doi.org/10.1016/j.applthermaleng.2014.02.044

Vitorino N, Abrantes JCC, Frade JR (2014) Highly conducting core–shell phase change materials for thermal regulation. Appl Therm Eng 66:131–139. https://doi.org/10.1016/j.applthermaleng.2014.02.001

Tu H, Ye L (2009) Thermal conductive PS/graphite composites. Polym Adv Technol 20:21–27. https://doi.org/10.1002/pat.1236

Kultys A, Rogulska M, Głuchowska H (2011) The effect of soft-segment structure on the properties of novel thermoplastic polyurethane elastomers based on an unconventional chain extender. Polym Int 60:652–659. https://doi.org/10.1002/PI.2998

Piana F, Pionteck J (2013) Effect of the melt processing conditions on the conductive paths formation in thermoplastic polyurethane/expanded graphite (TPU/EG) composites. Compos Sci Technol 80:39–46. https://doi.org/10.1016/j.compscitech.2013.03.002

Rittigstein P, Torkelson JM (2006) Polymer–nanoparticle interfacial interactions in polymer nanocomposites: confinement effects on glass transition temperature and suppression of physical aging. J Polym Sci B Polym Phys 44:2935–2943. https://doi.org/10.1002/polb.20925

Li B, Kawakita Y, Ohira-Kawamura S et al (2019) Colossal barocaloric effects in plastic crystals. Nature 567:506–510. https://doi.org/10.1038/s41586-019-1042-5

Aznar A, Lloveras P, Barrio M et al (2020) Reversible and irreversible colossal barocaloric effects in plastic crystals. J Mater Chem A Mater 8:639–647. https://doi.org/10.1039/C9TA10947A

Lloveras P, Aznar A, Barrio M et al (2019) Colossal barocaloric effects near room temperature in plastic crystals of neopentylglycol. Nat Commun 10:1803–1807. https://doi.org/10.1038/s41467-019-09730-9

Lu B, Liu J (2015) Mechanocaloric materials for solid-state cooling. Sci Bull (Beijing) 60:1638–1643. https://doi.org/10.1007/s11434-015-0898-5

Sakata A, Suzuki N, Higashiura Y et al (2013) Measurement of the mechanocaloric effect in rubber. J Therm Anal Calorim 113:1555–1563. https://doi.org/10.1007/s10973-013-3066-7

Tishin AM (1997) Magnetocaloric effect in lanthanide materials. J Alloys Compd 250:635–641. https://doi.org/10.1016/S0925-8388(96)02521-2

Miliante CM, Christmann AM, Usuda EO et al (2020) Unveiling the origin of the giant barocaloric effect in natural rubber. Macromolecules 53:2606–2615. https://doi.org/10.1021/acs.macromol.0c00051

Dong M, Li Q, Liu H et al (2018) Thermoplastic polyurethane-carbon black nanocomposite coating: fabrication and solid particle erosion resistance. Polymer 158:381–390. https://doi.org/10.1016/j.polymer.2018.11.003

Fathy A, Shaker A, Hamid MA, Megahed AA (2016) The effects of nano-silica/nano-alumina on fatigue behavior of glass fiber-reinforced epoxy composites. J Compos Mater 51:1667–1679. https://doi.org/10.1177/0021998316661870

Tate JS, Akinola AT, Espinoza S et al (2018) Tension–tension fatigue performance and stiffness degradation of nanosilica-modified glass fiber-reinforced composites. J Compos Mater 52:823–834. https://doi.org/10.1177/0021998317714855

Dani MSH, Venkateshwaran N (2021) Role of surface functionalized crystalline nano-silica on mechanical, fatigue and drop load impact damage behaviour of effective stacking sequenced E-glass fibre-reinforced epoxy resin composite. SILICON 13:757–766. https://doi.org/10.1007/S12633-020-00486-2

Velmurugan N, Manimaran G, Ravi S, Jayabalakrishnan D (2021) Effect of silanised reinforcements on thermal, wear, visco-elastic and fatigue behaviour of stitched E-glass fibre-reinforced epoxy hybrid composite. J Rubber Res 24:41–50. https://doi.org/10.1007/S42464-020-00070-8

Acknowledgements

This work was funded by the Conselho Nacional de Desenvolvimento Científico e Tecnológico (Grant No. 406233/2021-7).

Author information

Authors and Affiliations

Contributions

Flávio Clareth Colman, Jean Rodrigo Bocca, and Eduardo Radovanovic conceived the study. The measurements were performed by Flávio Clareth Colman. Flávio Clareth Colman, William Imamura, Nicholas Dicati Pereira da Silva, Cleber Santiago Alves and Erik Oda Usuda contributed to the writing-original draft. Flávio Clareth Colman contributed to data curation and formal analysis. Nicholas Dicati P. da Silva, William Imamura, Erik Oda Usuda, Jean Rodrigo Bocca, Fernando Rodrigo Moro, Alexandre Magnus Gomes Carvalho, Paulo Vinicius Trevizoli, Cleber Santiago Alves, and Júlio César Dainezi de Oliveira contributed to the formal analysis. Rita de Cássia Colman Simões contributed to formal analysis and resources. Silvia Luciana Favaro contributed to project administration, supervision, formal analysis, and resources. Eduardo Radovanovic contributed to project administration, supervision, methodology, formal analysis, and resources. All authors contributed to the writing review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Additional information

Handling Editor: Jaime Grunlan.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

See supplementary material for additional data on Scanning Electron Microscopy for pure TPU and NG/TPU composites, FTIR of NG/TPU composites, and Differential Scanning Calorimetry for pure TPU and NG/TPU composites. We show adiabatic temperature change vs. temperature and Isothermal entropy change vs. temperature for 10 wt% NG/TPU, 20 wt% NG/TPU, and 30 wt% NG/TPU. We assess the normalized temperature change |ΔTS Δσ−1| as a function of ΔTS around room temperature (292–334 K) for pure TPU, NG/TPU composites (this work), and elastomers presented on literature. We present the temperature versus time curves for 10x cycles, with x varying from 0 to 5 for pure TPU, 20 wt% NG/TPU composite, and 40 wt% NG/TPU composite (this data were used to develop Fig. 8). Finally, we report a briefly description of the device for measuring the thermal conductivity of the samples.

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Colman, F.C., da Silva, N.D.P., Imamura, W. et al. On the mechanocaloric effect of natural graphite/thermoplastic polyurethane composites. J Mater Sci 58, 11029–11043 (2023). https://doi.org/10.1007/s10853-023-08700-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08700-3