Abstract

Since packaging contributes to severe environmental impacts in food production, alternatives of packaging materials that satisfy customer needs while minimizing environmental impacts in a cost-effective manner should be preferred for food product sustainability. This paper compares two different packaging materials (aluminum cans and retort pouches) with a life cycle approach to assess the environmental impacts of ready-to-eat bean packaging. The life cycle assessment (LCA) was used to define and compare the environmental performance of ready-to-eat beans in aluminum cans and retort pouches. The gate-to-gate approach was used in the LCA, with a functional unit of 1 kg of packaged ready-to-eat bean product. Inventory for packaging in retort pouch was created in collaboration with Duru Bulgur Company (Karaman, Turkey) and the data for ready-to-eat beans in the aluminum can were gathered from the literature. The findings show that ready-to-eat beans in retort pouches have lower environmental impacts than ready-to-eat beans in aluminum cans. The packaging and washing processes for both ready-to-eat beans packaged in aluminum cans and retort pouches had the greatest environmental impact. In ready-to-eat beans production, retort pouch provides 87% better environmental performance than aluminum can in terms of global warming (GW). Overall, the results demonstrated that replacing aluminum cans with retort pouches in ready-to-eat bean production can significantly reduce environmental effects in all impact categories.

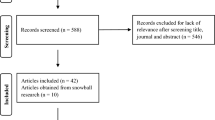

Graphical abstract

Similar content being viewed by others

References

Coles R, McDowell D, Kirwan MJ (2003) Food packaging technology. Blackwell, CRC Press, Boca Raton

Marsh K, Bugusu B (2007) Food packaging—roles, materials, and environmental issues. J Food Sci 72:R39–R55. https://doi.org/10.1111/J.1750-3841.2007.00301.X

Bindu J, Ravishankar CN, Gopal TKS (2012) Packaging of retort-processed seafood, meat and poultry. Adv Meat Poult Seaf Packag. https://doi.org/10.1533/9780857095718.3.331

Accorsi R, Cholette S, Manzini R, Tufano A (2018) A hierarchical data architecture for sustainable food supply chain management and planning. J Clean Prod 203:1039–1054. https://doi.org/10.1016/J.JCLEPRO.2018.08.275

Robertson GL (2005) Food Packaging: principles and Practice, 2nd edn. CRC Press, Boca Raton

Walsh H, Kerry JP (2012) Packaging of ready-to-serve and retail-ready meat, poultry and seafood products. In: Advances in meat, poultry and seafood packaging, pp 406–436. https://doi.org/10.1533/9780857095718.3.406

Bindu J, Mallick A, Gopal TK (2014) Thermal processing of fishery products in flexible and rigid containers. Fish Technol 51:137–148

Agency UEP (2002) Solid waste management: a local challenge with global impacts. Washington DC, USA

Deshwal GK, Panjagari NR (2020) Review on metal packaging: materials, forms, food applications, safety and recyclability. J Food Sci Technol 57(7):2377–2392

Demetrious A, Crossin E (2019) Life cycle assessment of paper and plastic packaging waste in landfill, incineration, and gasification-pyrolysis. J Mater Cycles Waste Manag 21(4):850–860. https://doi.org/10.1007/s10163-019-00842-4

Ferreira S, Cabral M, De Jaeger S, Da Cruz NF, Simões P, Marques RC (2017) Life cycle assessment and valuation of the packaging waste recycling system in Belgium. J Mater Cycles Waste Manag 19(1):144–154. https://doi.org/10.1007/s10163-015-0383-x

Notarnicola B, Tassielli G, Renzulli PA, Castellani V, Sala S (2017) Environmental impacts of food consumption in Europe. J Clean Prod 140:753–765. https://doi.org/10.1016/J.JCLEPRO.2016.06.080

Chiellini E (2008) Environmentally compatible food packaging. Elsevier, Amsterdam

Dilkes-Hoffman LS, Lane JL, Grant T, Pratt S, Lant PA, Laycock B (2018) Environmental impact of biodegradable food packaging when considering food waste. J Clean Prod 180:325–334. https://doi.org/10.1016/J.JCLEPRO.2018.01.169

Geueke B, Groh K, Muncke J (2018) Food packaging in the circular economy: overview of chemical safety aspects for commonly used materials. J Clean Prod 193:491–505. https://doi.org/10.1016/J.JCLEPRO.2018.05.005

Kan M, Miller SA (2022) Environmental impacts of plastic packaging of food products. Resour Conserv Recycl 180:106156. https://doi.org/10.1016/J.RESCONREC.2022.106156

Mattsson B, Sonesson U (2003) Environmentally-friendly food processing. Woodhead Publishing, Sawston

Perez-Martinez MM, Noguerol R, Casales BI et al (2018) Evaluation of environmental impact of two ready-to-eat canned meat products using life cycle assessment. J Food Eng 237:118–127. https://doi.org/10.1016/J.JFOODENG.2018.05.031

Cabral CFS, Elabras Veiga LB, Araújo MG, de Souza SLQ (2020) Environmental life cycle assessment of goat cheese production in Brazil: a path towards sustainability. LWT 129:109550. https://doi.org/10.1016/J.LWT.2020.109550

Ghamkhar R, Hartleb C, Wu F, Hicks A (2020) Life cycle assessment of a cold weather aquaponic food production system. J Clean Prod 244:118767. https://doi.org/10.1016/J.JCLEPRO.2019.118767

Costa MP, Chadwick D, Saget S, Rees RM, Williams M, Styles D (2020) Representing crop rotations in life cycle assessment: a review of legume LCA studies. Int J Life Cycle Assess 25:1942–1956. https://doi.org/10.1007/S11367-020-01812-X

Fadare OO, Wan B, Guo LH, Zhao L (2020) Microplastics from consumer plastic food containers: are we consuming it? Chemosphere 253:126787. https://doi.org/10.1016/j.chemosphere.2020.126787

Simon B, Ben AM, Földényi R (2016) Life cycle impact assessment of beverage packaging systems: focus on the collection of post-consumer bottles. J Clean Prod 112:238–248. https://doi.org/10.1016/J.JCLEPRO.2015.06.008

Siracusa V, Ingrao C, Lo Giudice A, Mbohwa C, Rosa MD (2014) Environmental assessment of a multilayer polymer bag for food packaging and preservation: an LCA approach. Food Res Int 62:151–161. https://doi.org/10.1016/J.FOODRES.2014.02.010

Abejón R, Bala A, Vázquez-Rowe I, Aldaco R, Fullana-i Palmer P (2020) When plastic packaging should be preferred: life cycle analysis of packages for fruit and vegetable distribution in the Spanish peninsular market. Resour Conserv Recycl 155:104666. https://doi.org/10.1016/J.RESCONREC.2019.104666

Leadley C, Tucker G, Fryer P (2008) A comparative study of high pressure sterilisation and conventional thermal sterilisation: quality effects in green beans. Innov Food Sci Emerg Technol 9:70–79. https://doi.org/10.1016/J.IFSET.2007.06.005

Rodríguez JJ, Olivas GI, Sepúlveda DR, Warner H, Clark S, Barbosa-Canovas GV (2003) Shelf-life study of retort pouch black bean and rice burrito combat rations packaged at selected residual gas levels. J Food Qual 26:409–424. https://doi.org/10.1111/J.1745-4557.2003.TB00256.X

Humbert S, Rossi V, Margni M, Jolliet O, Loerincik Y (2009) Life cycle assessment of two baby food packaging alternatives: glass jars vs. plastic pots. Int J Life Cycle Assess 14:95–106. https://doi.org/10.1007/s11367-008-0052-6

Poovarodom N, Ponnak C, Manatphrom N (2012) Comparative carbon footprint of packaging systems for tuna products. Packag Technol Sci 25:249–257. https://doi.org/10.1002/PTS.975

Del Borghi A, Strazza C, Magrassi F, Taramasso AC, Gallo M (2018) Life cycle assessment for eco-design of product–package systems in the food industry—the case of legumes. Sustain Prod Consum 13:24–36. https://doi.org/10.1016/J.SPC.2017.11.001

Walters KJ, Hosfield GL, Uebersax MA, Kelly JD (1997) Navy bean canning quality: correlations, heritability estimates, and randomly amplified polymorphic DNA markers associated with component traits. J Am Soc Hortic Sci 122:338–343. https://doi.org/10.21273/JASHS.122.3.338

Schoeninger V, Coelho SRM, Bassinello PZ (2017) Industrial processing of canned beans. Ciência Rural 47:5. https://doi.org/10.1590/0103-8478CR20160672

Wang CCR, Chang SKC (2002) Effect of selected canning methods on trypsin inhibitor activity, sterilization value, and firmness of canned navy beans. J Agric Food Chem 36:1015–1018. https://doi.org/10.1021/JF00083A028

White BL, Howard LR (2012) Canned whole dry beans and bean products. Dry Beans Pulses Prod Process Nutr. https://doi.org/10.1002/9781118448298.CH7

ISO (2006) ISO 14040: environmental management, life cycle assessment, principles and framework. Geneva, Switzerland

ISO (2006) ISO 14044: environmental management, life cycle assessment, requirements and guidelines. Geneva, Switzerland

Ahmad S, Wong KY, Ahmad R (2019) Life cycle assessment for food production and manufacturing: recent trends, global applications and future prospects. Procedia Manuf 34:49–57. https://doi.org/10.1016/J.PROMFG.2019.06.113

Ecoinvent Database (2013) https://ecoinvent.org/. Accessed 13 Apr 2022

Jolliet O, Margni M, Charles R et al (2003) IMPACT 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assess 8:324–330. https://doi.org/10.1007/BF02978505

Peng T, Ou X, Yan X, Wang G (2019) Life-cycle analysis of energy consumption and GHG emissions of aluminium production in China. Energy Procedia 158:3937–3943. https://doi.org/10.1016/J.EGYPRO.2019.01.849

Yang Y, Guo YQ, Zhu WS, Huang JB (2019) Environmental impact assessment of China’s primary aluminum based on life cycle assessment. Trans Nonferrous Met Soc China 29:1784–1792. https://doi.org/10.1016/S1003-6326(19)65086-7

Del Borghi A, Gallo M, Strazza C, Del Borghi M (2014) An evaluation of environmental sustainability in the food industry through life cycle assessment: the case study of tomato products supply chain. J Clean Prod 78:121–130. https://doi.org/10.1016/j.jclepro.2014.04.083

Matthews C, Moran F, Jaiswal AK (2021) A review on European Union’s strategy for plastics in a circular economy and its impact on food safety. J Clean Prod 283:125263. https://doi.org/10.1016/J.JCLEPRO.2020.125263

Farjana SH, Huda N, Mahmud MAP (2019) Impacts of aluminum production: a cradle to gate investigation using life-cycle assessment. Sci Total Environ 663:958–970. https://doi.org/10.1016/J.SCITOTENV.2019.01.400

Biswas WK, Naude G (2016) A life cycle assessment of processed meat products supplied to Barrow Island: a Western Australian case study. J Food Eng 180:48–59. https://doi.org/10.1016/J.JFOODENG.2016.02.008

Calderón LA, Iglesias L, Laca A, Herrero M, Diaz M (2010) The utility of life cycle assessment in the ready meal food industry. Resour Conserv Recycl 54:1196–1207. https://doi.org/10.1016/J.RESCONREC.2010.03.015

Hanssen OJ, Vold M, Schakenda V, Tufte PA, Moller H, Olsen NV, Skaret J (2017) Environmental profile, packaging intensity and food waste generation for three types of dinner meals. J Clean Prod 142:395–402. https://doi.org/10.1016/J.JCLEPRO.2015.12.012

Hospido A, Vazquez ME, Cuevas A et al (2006) Environmental assessment of canned tuna manufacture with a life-cycle perspective. Resour Conserv Recycl 47:56–72. https://doi.org/10.1016/J.RESCONREC.2005.10.003

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gulcimen, S., Ozcan, O., Çevik, S.B. et al. Comparative life cycle assessment of retort pouch and aluminum can for ready-to-eat bean packaging. J Mater Cycles Waste Manag 25, 3723–3733 (2023). https://doi.org/10.1007/s10163-023-01791-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01791-9