Abstract

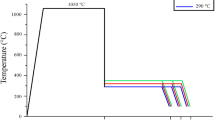

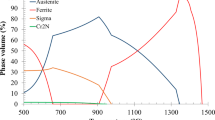

Austempered ductile iron (ADI) has complex microstructure containing a multiphase matrix (called ‘ausferrite’), graphite spheres and oxide inclusions. The corrosion resistance of ADI is related to its microstructure which is determined by heat treatment parameters (like austempering temperature, austempering time, austenitising temperature and austenitising time). In the present paper, the electrochemical behaviour and corrosion resistance of ADI have been investigated by means of the electrochemical microcell technique and classical electrochemical measurements in sodium chloride solution. Particular attention has been paid to the influence of austempering temperature on the microstructure and pitting corrosion. It has been shown that ADI austempered at 430 °C has upper ausferritic microstructure and reveals a better corrosion resistance in sodium chloride solution than ADI austempered at 280 °C. Moreover, the corrosion resistance increases as the volume fracture of ferrite increases and the carbon content of austenite decreases. The good corrosion behaviour of ADI austempered at 430 °C was also related to the good coarsening of the austenite grains and broad ferrite needles (less ferrite/austenite interfaces). It has been demonstrated that silicon is the alloying element hindering the anodic dissolution of the alloy.

Similar content being viewed by others

References

Labrecque C, Gagne M (1998) Can Metall Q 37:343, doi:10.1016/S0008-4433(98)00031-7

Hsu C-H, Jung-Kai R-JT (2005) Mater Sci Eng A 398:282, doi:10.1016/j.msea.2005.03.092

Ghaderi AR, Nili Ahmadabadi M, Ghsemi HM (2003) Wear 255:410, doi:10.1016/S0043-1648(03)00156-X

Prasad Rao P, Putatunda SK (2003) Mater Sci Eng A 349:136, doi:10.1016/S0921-5093(02)00633-0

Yang J, Putatunda SK (2005) Mater Sci Eng A 406:217, doi:10.1016/j.msea.2005.06.036

Janowak JF, Norton PA (1985) AFS Trans 88:123

Eric O, Jovanovic M, Sidanin L, Rajnovic D, Zec S (2006) Mater Des 27:617, doi:10.1016/j.matdes.2004.11.028

Zimba J, Simbi DJ, Navara E (2003) Cement Concr Compos 25:643, doi:10.1016/S0958-9465(02)00078-1

Darwish N, Elliot R (1993) Mater Sci Technol 9:882

Heydarzadeh Sohi M, Nili Ahmadabadi M, Bahrami Vahdat A (2004) J Mater Process Technol 153-154:203, doi:10.1016/j.jmatprotec.2004.04.308

Hemanth J (2000) J Mater Process Technol 101:159, doi:10.1016/S0924-0136(00)00424-6

Pepe A, Galliano P, Cere S, Aparicio M, Duran A (2005) Mater Lett 59:2219, doi:10.1016/j.matlet.2005.03.001

Krawiec H, Stypuła B, Stoch J, Mikołajczyk M (2006) Corros Sci 48:595, doi:10.1016/j.corsci.2005.02.019

Krawiec H, Vignal V, Banas J (2006) J Electrochem Soc 153:B231, doi:10.1149/1.2197635

Bohni H, Suter T, Assi F (2000) Technol Surf Coat 130:80, doi:10.1016/S0257-8972(00)00681-2

Putatunda SK (2001) Mater Sci Eng A 297:31

Roberts CS, Aime T (1953) J Met 197:203

Pourbaix M (1974) Atlas of electrochemical equilibria in aqueous solution, 2nd English edition, Chapter IV. National Association of Corrosion Engineers, Houston, Texas, USA, pp 452–455

Monchoux JP, Verdu C, Tougeres G, Reynaud A (2001) Acta Mater 49:4355, doi:10.1016/S1359-6454(01)00230-0

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krawiec, H., Lelito, J., Tyrała, E. et al. Relationships between microstructure and pitting corrosion of ADI in sodium chloride solution. J Solid State Electrochem 13, 935–942 (2009). https://doi.org/10.1007/s10008-008-0636-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-008-0636-x