The UA80E first showed up in 2017. It was used from 2017 through 2022 in the Toyota Highlander with 2.5L and 3.5L engines. From 2018 through 2022, it came in the Toyota Camry 3.5L and Rav 4 with a 2.5L all-wheel-drive model. From 2019 through 2022, it came in the Toyota Avalon 3.5L and the Lexus ES300. And finally, you’ll find it in the 2020 Toyota Sienna with the 3.5L engine.

So, these vehicles have been on the road for almost six years and will begin showing up in your shops. Knowing where to start and what to check in diagnostics will be a great help.

Like everything today, you’ll want to start by checking for codes. Depending on what codes you have (if any), you will need to follow the diagnostic procedure for that code. Next, let’s check the fluid level.

To accurately check the fluid level, the factory recommends that fluid temperatures be at least 20°C (68° F), With the engine running in park. Now remove the bottom plug; fluid should just drip out of the hole (figure 1). If the fluid is low, add fluid slowly into the transmission fill hole (figure 2) until the fluid drips from the bottom plug. Depending on the complaint, you may want to check line pressure.

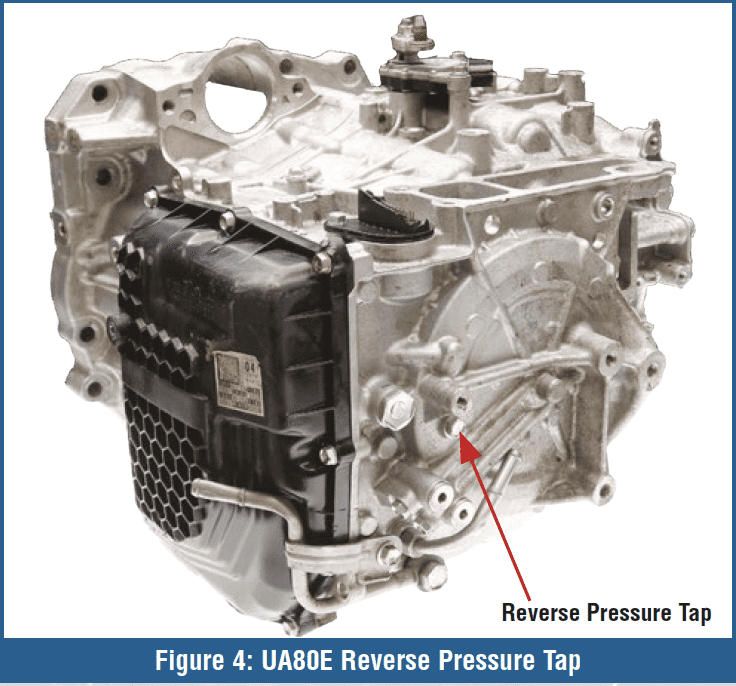

The UA80E has two pressure check locations, one for forward ranges and one for the reverse (figures 3 & 4). Forward pressure (with the engine idling) should be 73 to 102 PSI. The pressure should be 189 to 232 PSI during a stall test. In reverse (and the engine idling), you should have 73 to 102 PSI. The pressure should be 247 to 305 PSI during a stall test.

After checking the pressure, we can evaluate what the conditions are. If the pressure reads high in all positions, then possible causes can be the SLT solenoid valve is defective or the pressure regulator valve is sticking.

If line pressure is low when the shift lever is in reverse only, then you may have a leak in the number 3 clutch (C3) or number two brake (B2).

One thing I like about this unit is that it has no sprags or bands. It utilizes four clutch packs and two brakes. It shifts from clutch to clutch, as seen in the clutch apply chart (figure 5). Each gear has two components on (and four off). This makes it simple as to what clutch or brake is at fault.

The UA80E transmission uses two Ravigneaux-type planetary gear sets to produce eight gears.

The UA80E uses a centrifugal fluid pressure canceling piston in the C1, C2, C3, and C4 clutches. A more general term used for these are balance pistons. They aid in releasing the clutch and ensuring that oil trapped on the apply-side does not partially apply the clutch while it is commanded off. It also helps control the apply rate of the clutch relative to powertrain demand.

Another fuel-economy feature is that the torque converter will apply in any gear (including first) based on the driving conditions.

Lock-up is controlled by the SL and SLU soleonids. The SL solenoid is an on-off type that directs oil to a relay valve to enable the lock-up hydraulic circuit. The SLU is responsible for the rate of apply and release of the torque converter clutch.

VALVE BODY REMOVAL AND SOLENOID IDENTIFICATION

The valve body must be removed to service the solenoids. Remove the nine bolts marked with an X, then remove the valve body.

There’s lots more to come on this unit. Wait until you see the valve body breakdown in the next issue of Gears Magazine.

And that’s not just smart. That’s street smart.