Heat Shrinkable Moulded Shapes Brochure - RB Racing

Heat Shrinkable Moulded Shapes Brochure - RB Racing

Heat Shrinkable Moulded Shapes Brochure - RB Racing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

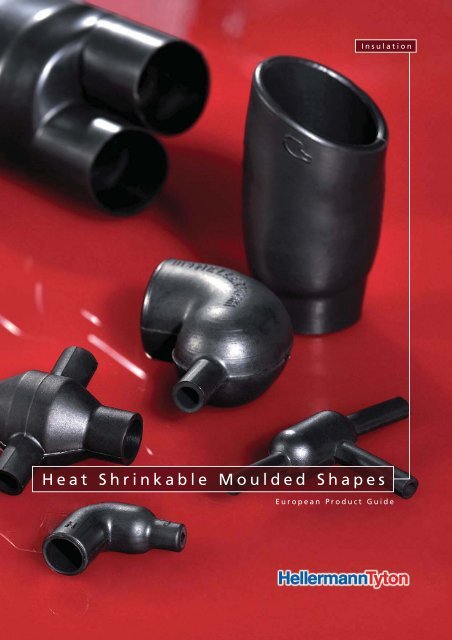

<strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong><br />

Insulation<br />

European Product Guide

Our Corporate Philosophy 4<br />

Our partners, local and global Contacts 6<br />

<strong>Moulded</strong> <strong>Shapes</strong> Expertise 8<br />

1 Technical Introduction<br />

Selection Guide 10<br />

Selection Guide Overview<br />

• Low Profile Boots and Transitions 12<br />

• Bulbous Boots and Transitions 12<br />

• Bulbous Boots and Transitions 13<br />

Technical Information<br />

• Materials for <strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong> 14<br />

• Adhesives for <strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong> 15<br />

Material & Adhesive combinations search 16<br />

2.1 Low Profile Boots and Transitions<br />

Low Profile Convolute Boots<br />

• Helashrink 313C Series, with adapter lip 22<br />

Low Profile Shim Boots<br />

• Helashrink 313E Series, without adapter lip 23<br />

Low Profile Straight Boots<br />

• Helashrink 313F Series, with adapter lip 24<br />

Low Profile Right Angle Boots<br />

• Helashrink 333F Series, with adapter lip, 90° angle 25<br />

Low Profile Transition Boots<br />

• Helashrink 412H Series, side breakout 26<br />

• Helashrink 492H Series, 1 to 2 cables 27<br />

• Helashrink 573H Series, 1 to 3 cables 28<br />

2.2 Bulbous Boots and Transitions<br />

Bottle <strong>Shapes</strong>, VG style<br />

• Helashrink 150 Series, with rib 29<br />

Bottle <strong>Shapes</strong>, MIL style<br />

• Helashrink 100 Series, with rib 31<br />

Bottle <strong>Shapes</strong><br />

• Helashrink 100 Series, without rib 32<br />

• Helashrink 120 Series, with and without rib 34<br />

Page Page<br />

Long Outlet Shape, VG style<br />

• Helashrink 130 Series, with rib, low profile 35<br />

Long Outlet <strong>Shapes</strong><br />

• Helashrink 140 Series, without rib 37<br />

Bottle <strong>Shapes</strong><br />

• Helashrink 160 Series, without rib 38<br />

Bottle <strong>Shapes</strong>, VG style<br />

• Helashrink 170 Series, with rib 39<br />

• Helashrink 190 Series, with external ribs 40<br />

2-Way Outlet <strong>Shapes</strong><br />

• Helashrink 200 Series, low profile 41<br />

2-Way Outlet <strong>Shapes</strong>, VG style<br />

• Helashrink 200 Series 42<br />

2-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 200 Series, in line, low voltage 43<br />

3-Way Outlet <strong>Shapes</strong>, VG style<br />

• Helashrink 300 Series 44<br />

3-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 300 Series, in line, low voltage 45<br />

4-Way Outlet <strong>Shapes</strong>, VG style<br />

• Helashrink 400 Series 46<br />

4-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 400 Series, in line, low voltage 47<br />

5-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 500 Series, in line, low voltage 48<br />

6-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 600 Series, in line, low voltage 49<br />

Right Angle <strong>Shapes</strong>, VG style<br />

• Helashrink 1100 Series, with rib 50<br />

• Helashrink 1100 Series, without rib, thick wall 51<br />

Right Angle <strong>Shapes</strong>, MIL style<br />

• Helashrink 1100 Series, with rib 52<br />

Right Angle <strong>Shapes</strong><br />

• Helashrink 1100 Series, without rib 53<br />

Right Angle <strong>Shapes</strong>, VG style/MIL style<br />

• Helashrink 1100 Series, with rib, low profile 54

Right Angle <strong>Shapes</strong>, VG style<br />

• Helashrink 1100 Series, with rib, low profile, high ratio 56<br />

T-<strong>Shapes</strong>, VG style<br />

• Helashrink 1200 Series 57<br />

T-<strong>Shapes</strong><br />

• Helashrink 1200 Series, Offset 58<br />

T-<strong>Shapes</strong>, VG style<br />

• Helashrink 1200 Series, Offset 59<br />

Angled T-<strong>Shapes</strong>, VG style<br />

• Helashrink 1300 Series, 30° & 45° angle 60<br />

Double T-<strong>Shapes</strong><br />

• Helashrink 1310 Series, 30° angle 61<br />

Angle Elbow <strong>Shapes</strong><br />

• Helashrink 1400 Series, 90° angle 62<br />

Connector Cover for Min-D Series<br />

• Helashrink 1500 Series, with top entry 63<br />

GSR Graduated Strain Relief<br />

• Helashrink 1750 Series with rib 64<br />

Angle <strong>Shapes</strong><br />

• Helashrink 1800 Series, with rib, 30°, 45°, 60° angle 65<br />

Right-Angle Cross <strong>Shapes</strong><br />

• Helashrink 2000 Series - T-Joint 66<br />

Locating Bushes<br />

• Helashrink 1760, 1790, 1820 Series 67<br />

Connector Cover for Min-D Series<br />

• Helashrink 2100 Series, with 90° entry 68<br />

3.1 Breakout Boots and End Caps<br />

2-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 200 Series, in line, low voltage 70<br />

3-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 300 Series, in line, low voltage 71<br />

4-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 400 Series, in line, low voltage 72<br />

End Caps<br />

• Helashrink 1600 Series, low voltage 73<br />

Content<br />

Page Page<br />

Pinched End Caps<br />

• Helashrink PEC Series, low voltage 74<br />

3.2 <strong>Heat</strong> <strong>Shrinkable</strong> Tubing<br />

<strong>Heat</strong> <strong>Shrinkable</strong> Tubing 2:1 - Fluororubber<br />

• Viton®-E 75<br />

<strong>Heat</strong> <strong>Shrinkable</strong> Tubing 2:1 - Elastomer<br />

• SE28 76<br />

• TE28 - light weight 77<br />

<strong>Heat</strong> <strong>Shrinkable</strong> Tubing up to 4:1 - 1 m lengths<br />

• MU47 - medium wall unlined 78<br />

• MA47 - medium wall adhesive lined<br />

3.3 Adaptor Springs<br />

Constant Force Spring Adaptor<br />

• Zetalok 79<br />

3.4 Adhesives<br />

Two-component Adhesive for <strong>Heat</strong> <strong>Shrinkable</strong> Tubing and <strong>Shapes</strong><br />

• V9500 Dosing Gun 80<br />

Hot Melt Tape for <strong>Heat</strong> <strong>Shrinkable</strong> Tubing and <strong>Shapes</strong><br />

• HMT200A 81<br />

High Temperature Hot Melt Adhesive Tape for Low Profile Products<br />

• TSA 200 82<br />

4.1 HellermannTyton Product Standards<br />

Standards for HellermannTyton <strong>Heat</strong> <strong>Shrinkable</strong> Tubing and<br />

<strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong> according to VG Norm 84<br />

Standards for HellermannTyton <strong>Heat</strong> <strong>Shrinkable</strong> Tubing 85<br />

VG/MIL Specification Cross Reference 86<br />

HellermannTyton <strong>Shapes</strong> for use with MIL Connectors 87<br />

MIL Specification Slash Sheet Cross Reference 88<br />

4.2 Terms and Conditions 95

4<br />

Moving the market takes more than good ideas.<br />

Developing the product solutions for the future, requires visionary<br />

thinking and the passion to turn ideas into reality.<br />

When visions become functional products, innovations are<br />

generated that benefit our customers.<br />

We create the conditions for this by employing motivated people<br />

who are committed to working as a team. When only the best<br />

solutions will do, you need dedicated professionals with expert<br />

knowledge.<br />

The result is product solutions that not only reshape the market<br />

but re-develope it.<br />

We are able to offer product solutions before our customers<br />

know they need them.<br />

We maintain good relationships with our customers and also keep<br />

a close eye on the latest market developments. This allows us to<br />

recognise trends affecting trade and industry at an early stage. And<br />

enables us to remain a step ahead of customer requirements at all<br />

times.<br />

Meeting high expectations calls for ongoing development.<br />

As well as paying particular attention to communicating with<br />

our customers and knowledge of the market, we invest heavily in<br />

research and development. To ensure that we can support our<br />

customers into the future by offering custom product solutions,<br />

we continually optimise our technical and logistical processes.

At your service wherever – and whenever – you need us.<br />

What use are the best product solutions if they are not available to<br />

local markets in a timely way? HellermannTyton’s motto is therefore<br />

“Think global, act local”. For us, this not only means responding to<br />

the needs of local markets – we also have a presence there for the<br />

benefit of our customers.<br />

Employees on the ground allow us to cater for cultural, market-<br />

specific and linguistic factors effectively. In addition, our customers<br />

have access to a worldwide distribution network. This adds value<br />

that makes us one of the leading providers for trade and industry.<br />

To truly excel, you need to<br />

keep improving all the time.<br />

Our Corporate Philosophy<br />

Certified processes and quality, for your security.<br />

HellermannTyton always aim for the highest quality.<br />

To live up to this claim we have implemented a quality<br />

and environmental management systems.<br />

Our quality management is certified to DIN EN ISO 9001:2008<br />

and DIN EN ISO/TS 16949:2002.<br />

In addition, our environmental management complies with the<br />

requirements of DIN EN ISO 14001:2005.<br />

DIN EN ISO<br />

9001:2000<br />

DIN EN ISO/TS<br />

16949:2002<br />

DIN EN ISO<br />

14001:2004<br />

5

6<br />

... you will find your local contact here:<br />

Europe<br />

HellermannTyton GmbH – Austria<br />

Obachgasse 6<br />

1221 Vienna<br />

Tel: +43 (0) 1 259 99 55 - 0<br />

Fax: +43 (0)1 259 99 11<br />

E-Mail: office@HellermannTyton.at<br />

www.HellermannTyton.at<br />

HellermannTyton B.V. – Belgium<br />

E-Mail: info@HellermannTyton.be<br />

www.HellermannTyton.be<br />

HellermannTyton – Czech Republic<br />

E-Mail: office.cz@HellermannTyton.at<br />

www.HellermannTyton.cz<br />

HellermannTyton Denmark<br />

Baldersbuen 15D 1. TV<br />

2640 Hedehusene<br />

Tel: +45 702 371 20<br />

Fax: +45 702 371 21<br />

E-Mail: htdk@HellermannTyton.dk<br />

www.HellermannTyton.dk<br />

HellermannTyton Oy – Finland<br />

Sähkötie 8<br />

01510 Vantaa<br />

Tel: +358 9 8700 450<br />

Fax: +358 9 8700 4520<br />

E-Mail: myynti@HellermannTyton.fi<br />

www.HellermannTyton.fi<br />

HellermannTyton S.A.S. – France<br />

2 rue des Hêtres, B.P. 130<br />

78196 Trappes Cedex<br />

Tel: +33 1 30 13 80 00<br />

Fax: +33 1 30 13 80 60<br />

E-Mail: info@HellermannTyton.fr<br />

www.HellermannTyton.fr<br />

HellermannTyton GmbH – Germany<br />

Großer Moorweg 45<br />

25436 Tornesch<br />

Tel: +49 4122 701-0<br />

Fax: +49 4122 701-400<br />

E-Mail: info@HellermannTyton.de<br />

www.HellermannTyton.de<br />

HellermannTyton KFT – Hungary<br />

Kisfaludy u. 13<br />

1044 Budapest<br />

Tel: +36 1 369 4151<br />

Fax: +36 1 369 4151<br />

E-Mail: office@HellermannTyton.hu<br />

www.HellermannTyton.hu<br />

HellermannTyton S.r.l. – Italy<br />

Via Praimbole 9 Bis<br />

35010 Limena (PD)<br />

Tel: +39 049 767 870<br />

Fax: +39 049 767 985<br />

E-Mail: info@HellermannTyton.it<br />

www.HellermannTyton.it<br />

HellermannTyton Ltd – Ireland<br />

Unit 77 Cherry Orchard<br />

Industrial Estate<br />

Ballyfermot, Dublin 10<br />

Tel: +353 1 626 8267<br />

Fax: +353 1 626 8022<br />

E-Mail: sales@HellermannTyton.ie<br />

www.HellermannTyton.co.uk<br />

HellermannTyton B.V. – Netherlands<br />

Vanadiumweg 11-C<br />

3812 PX Amersfoort<br />

Tel: +31 33 460 06 90<br />

Fax: +31 33 460 06 99<br />

E-Mail: info@HellermannTyton.nl<br />

www.HellermannTyton.nl<br />

HellermannTyton AS – Norway<br />

PO Box 240 Alnabru<br />

0614 Oslo<br />

Tel: +47 23 17 47 00<br />

Fax: +47 22 97 09 70<br />

E-Mail: firmapost@HellermannTyton.no<br />

www.HellermannTyton.no<br />

HellermannTyton – Poland<br />

E-Mail: info@HellermannTyton.pl<br />

www.HellermannTyton.pl<br />

OOO HellermannTyton – Russia<br />

St. Petersburg<br />

E-Mail: info@HellermannTyton.ru<br />

www.HellermannTyton.ru<br />

HellermannTyton – Slovenia<br />

Branch Office Ljubljana<br />

Trubarjeva 79<br />

1101 Ljubljana<br />

Tel: +386 1 433 70 56<br />

Fax: +386 1 433 63 21<br />

E-Mail: sales@HellermannTyton.si<br />

www.HellermannTyton.si<br />

HellermannTyton España s.l. –<br />

Spain/Portugal<br />

Avda. de la Industria nº 37, 2º 2ª<br />

28.108 Alcobendas, Madrid<br />

Tel: +34 91 661 2835<br />

Fax: +34 91 661 2368<br />

E-Mail: HellermannTyton@HellermannTyton.es<br />

www.HellermannTyton.es<br />

HellermannTyton AB – Sweden<br />

Datavägen 5, PO Box 569<br />

17526 Järfälla<br />

Tel: +46 8 580 890 00<br />

Fax: +46 8 580 890 01<br />

E-Mail: support@HellermannTyton.se<br />

www.HellermannTyton.se<br />

HellermannTyton Ltd – UK<br />

Manufacturing Site<br />

William Prance Road<br />

Plymouth International Technology Park<br />

Plymouth PL6 5WR<br />

United Kingdom<br />

Tel: +44 (0) 1752 761211<br />

Fax: +44 (0) 1752 761210<br />

E-Mail: info@HellermannTyton.co.uk<br />

www.HellermannTyton.co.uk<br />

Whenever you need us ...<br />

HellermannTyton Ltd – UK<br />

Manufacturing Site<br />

Sharston Green Business Park<br />

1 Robeson Way<br />

Altrincham Road, Wythenshawe<br />

Manchester M22 4TY<br />

Tel: +44 161 945 4181<br />

Fax: +44 161 947 2220<br />

E-Mail: info@HellermannTyton.co.uk<br />

www.HellermannTyton.co.uk<br />

HellermannTyton Ltd – UK<br />

Main Contact for Customer Service<br />

Wharf Approach<br />

Aldridge, Walsall, West Midlands<br />

WS9 8BX<br />

Tel: +44 1922 458 151<br />

Fax: +44 1922 743 237<br />

E-Mail: info@HellermannTyton.co.uk<br />

www.HellermannTyton.co.uk<br />

HellermannTyton Data Ltd – UK<br />

43-45 Salthouse Road<br />

Cornwell Business Park Brackmills<br />

Northampton NN4 7EX<br />

Tel: +44 1604 707 420<br />

Fax: +44 1604 705 454<br />

E-Mail: hns@htdata.co.uk<br />

www.htdata.co.uk<br />

North America<br />

HellermannTyton – Canada<br />

Tel: +1 905 726 1221<br />

Fax: +1 905 726 8538<br />

E-Mail: sales@HellermannTyton.ca<br />

www.HellermannTyton.ca<br />

HellermannTyton – Mexico<br />

Tel: +52 333 133 9880<br />

Fax: +52 333 133 9861<br />

E-Mail: info@HellermannTyton.com.mx<br />

www.HellermannTyton.com<br />

HellermannTyton – USA<br />

Tel: +1 414 355 1130<br />

Fax: +1 414 355 7341<br />

E-Mail: corp@htamericas.com<br />

www.HellermannTyton.com<br />

South America<br />

HellermannTyton – Argentina<br />

Tel: +54 11 4754 5400<br />

Fax: +54 11 4752 0374<br />

E-Mail: ventas@HellermannTyton.com.ar<br />

www.HellermannTyton.com.ar<br />

HellermannTyton – Brazil<br />

Tel: +55 11 4815 9000<br />

Fax: +55 11 4815 9030<br />

E-Mail: vendas@HellermannTyton.com.br<br />

www.HellermannTyton.com.br<br />

www.HellermannTyton.com<br />

Asia-Pacific<br />

HellermannTyton – Australia<br />

Tel: +61 2 9525 2133<br />

Fax: +61 2 9526 2495<br />

E-Mail: cservice@HellermannTyton.com.au<br />

www.HellermannTyton.com.au<br />

HellermannTyton – China<br />

Tel: +86 510 528 2536<br />

Fax: +86 510 528 0112<br />

E-Mail: cservice@HellermannTyton.com.cn<br />

www.HellermannTyton.com.cn<br />

HellermannTyton – Hong Kong<br />

Tel: +852 2832 9090<br />

Fax: +852 2832 9381<br />

E-Mail: cservice@HellermannTyton.com.hk<br />

www.HellermannTyton.com.sg<br />

HellermannTyton – India<br />

Tel: +91 11-2620 9230/6661 9230<br />

Fax: +91 11-2620 9330/6661 9330<br />

E-Mail: cservice@HellermannTyton.co.in<br />

www.HellermannTyton.co.in<br />

HellermannTyton – Japan<br />

Tel: +81 3 5790 3111<br />

Fax: +81 3 5790 3112<br />

E-Mail: cservice@HellermannTyton.co.jp<br />

www.HellermannTyton.co.jp<br />

HellermannTyton – Korea<br />

Tel: +82 2 2614 0157<br />

Fax: +82 2 2614 0284<br />

E-Mail: cservice@HellermannTyton.co.kr<br />

www.HellermannTyton.co.kr<br />

HellermannTyton – Philippines<br />

Tel: +63 2 752 6551<br />

Fax: +63 2 752 6553<br />

E-Mail: cservice@HellermannTyton.com.ph<br />

www.HellermannTyton.com.ph<br />

HellermannTyton – Singapore<br />

Tel: +65 6 852 8585<br />

Fax: +65 6 756 6798<br />

E-Mail: cservice@HellermannTyton.sg<br />

www.HellermannTyton.com.sg<br />

HellermannTyton – Thailand<br />

Tel: +66 2 237 6702<br />

Fax: +66 2 266 8664<br />

E-Mail: cservice@HellermannTyton.com.th<br />

www.HellermannTyton.com.sg<br />

Africa<br />

HellermannTyton – South Africa<br />

Tel: +27 11 879 6680<br />

Fax: +27 11 879 6601<br />

E-Mail: sales.jhb@Hellermann.co.za<br />

www.HellermannTyton.co.za

Contact<br />

If you have a particular problem that you would like us to help you with then please contact us.<br />

With our vast experience and practically unlimited technical capabilities we are confident of being able to help you find a solution.<br />

Remember, we are a service provider and not just a supplier.<br />

Give us a call! Here are your contacts for enquiries and orders<br />

For all product information please visit our Website www.HellermannTyton.co.uk<br />

<strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong><br />

Plymouth<br />

Telephone 00 44 1752 701 261<br />

Facsimile 00 44 1752 790 058<br />

e-mail heatshrinkshapes@HellermannTyton.co.uk<br />

Aldridge<br />

Telephone 00 44 1922 458 151<br />

Facsimile 00 44 1922 743 237<br />

e-mail heatshrinkshapes@HellermannTyton.co.uk<br />

General Contacts<br />

UK Head Office<br />

Telephone 00 44 161 945 4181<br />

Facsimile 00 44 161 947 2233<br />

e-mail ukho@HellermannTyton.co.uk<br />

OEM Sales - Fixings & Fastenings<br />

Telephone 00 44 161 947 2200<br />

Facsimile 00 44 161 945 3708<br />

e-mail sales@HellermannTyton.co.uk<br />

OEM Sales - Insulation & Protection<br />

Telephone 00 44 1752 701 261<br />

Facsimile 00 44 1752 790 058<br />

e-mail insulation&protection@HellermannTyton.co.uk<br />

OEM Sales - Identification<br />

Telephone 00 44 1752 701 261<br />

Facsimile 00 44 1752 790 058<br />

e-mail identification@HellermannTyton.co.uk<br />

OEM Sales - Automated Systems<br />

Telephone 00 44 161 947 2200<br />

Facsimilie 00 44 161 945 3708<br />

e-mail automatedsystems@HellermannTyton.co.uk<br />

7

8<br />

<strong>Heat</strong> <strong>Shrinkable</strong><br />

<strong>Moulded</strong> <strong>Shapes</strong> Expertise<br />

<strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong> Expertise<br />

HellermannTyton heat shrinkable moulded shapes combine the advantages<br />

of quick, easy installation with high electric strength, mechanical toughness<br />

and superior chemical and environmental resistance. Our products offer<br />

important functional and cost saving benefits for electrical and electronic<br />

applications ranging from insulation and protection of individual components<br />

to fabrication of complete inter-connecting cable harness assemblies.<br />

Strain-relieving boots, transitions and connector backshell covers, as well as<br />

other specialised shapes, are available in a wide range of sizes and options.<br />

HellermannTyton's extensive product line includes low profile, bulbous and<br />

lipped types for use on circular and D-type connectors as well as complex<br />

multiway transitions. Only a minimum number of shapes are needed to<br />

cover a full range of applications as the products have high shrink ratios of<br />

up to 5:1.<br />

Applications<br />

The use of our heat shrinkable moulded shapes in conjunction with our<br />

specialist heat shrinkable tubings makes it easy to fabricate complete jacketed<br />

wire and cable harnessing and interconnection systems of the highest quality.<br />

<strong>Heat</strong> shrinkable shapes are available for the complete range of electrical<br />

and electronic harnessing applications. They can be sealed with our special<br />

adhesives and encapsulants to ensure the proper degree of mechanical<br />

support, strain relief and environmental protection. Encapsulating the complete<br />

harnessing and interconnection system to the desired configuration is easily<br />

and neatly accomplished, with minimum weight and bulk.<br />

Choice of Materials<br />

A range of specially formulated materials is available to meet a variety of<br />

performance requirements. Material selection can be made according to<br />

individual applications. We also have the ability to make customized<br />

materials to suit special requirements.<br />

Technical Capabilities<br />

Our materials are formulated in our own laboratory and produced in the<br />

HellermannTyton factory. We have experience and knowledge of all major<br />

applications and offer full technical support from design through to<br />

prototyping, to service.<br />

NOTE:<br />

Copyright to all drawings in this brochure is reserved by HellermannTyton.<br />

They are issued on condition that they are not copied, reproduced or<br />

disclosed to any third party either wholly or in part, without the written<br />

consent of HellermannTyton.

1<br />

Technical Introduction<br />

1 Technical Information<br />

Selection Guide 10<br />

Selection Guide Overview<br />

• Low Profile Boots and Transitions 12<br />

• Bulbous Boots and Transitions 12<br />

• Bulbous Boots and Transitions 13<br />

Technical Information<br />

• Materials for <strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong> 14<br />

• Adhesives for <strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong> 15<br />

Material & Adhesive combinations search 16<br />

Page

1<br />

10<br />

Insulation<br />

XXX Selection Guide<br />

This selection guide will help you to find the correct moulded shape for your application:<br />

Step 1. Product Style<br />

Use the Selection Guide Overview on page 12 to quickly select a suitable product profile.<br />

Step 2. Product Size<br />

Choose the correct dimensions to meet your application from our sizes and types table<br />

which appears on the relevant product profile page. An example of these tables is shown<br />

below:<br />

Step 3. Material/ Adhesive<br />

Choose a material and adhesive to meet your application requirements from the tables<br />

on page 14/15.<br />

Further combinations are available.<br />

Here is an example:<br />

3.1 Material<br />

These symbols denote the material or<br />

adhesive availability for each profile type.<br />

In this example the adhesive W21 is not<br />

available with the material B7,G, and B8<br />

because of the ″-″.<br />

But it is available with<br />

the material H because<br />

of the ″√″.<br />

Parts can be supplied in a choice of materials. The ″combinations″ table on each product<br />

page provides a quick and easy material recognition guide for the product profiled.<br />

The standard colour is black but other colours are available on request, please contact us<br />

for further information.<br />

On page 14 you will find detailed information on our range of materials.

3.2 Adhesive<br />

To maximise environmental protection and strain relief we recommend the use<br />

of an adhesive from our range below.<br />

Pre-lined hot melt adhesive:<br />

• WM250<br />

• W<br />

• W2<br />

• W8<br />

• W21<br />

Step 4. Standard combinations<br />

5. Special Modifications<br />

6. Ordering Procedure<br />

When ordering heat shrinkable shapes, it is necessary to give a complete part number to<br />

enable efficient processing of your order. Part numbers can be made up of the following<br />

typical components:<br />

Example:<br />

154 - 42 - G - P - W8<br />

Component adhesive:<br />

• HMT200A<br />

• W24<br />

• V9500<br />

• TSA-200<br />

For further information on adhesives please refer to page 15.<br />

To help you with your decision we offer standard<br />

combinations for each product type.<br />

In this example we offer the Type 223-2 in B8<br />

material and with the adhesive W.<br />

Filler ports and drain holes are also available where the injection of potting epoxy is required.<br />

P = Filler ports for potting – 3mm Ø vent and 4.5mm Ø filler.<br />

D = Drain holes 4 offset – 3mm Ø at H end equally spaced 90° apart.<br />

Presence and type of adhesive<br />

Filler ports add suffix ″P″; Drain holes add suffix ″D″<br />

Material reference<br />

Expansion and special details<br />

Exact shape<br />

Insulation<br />

Selection Guide XXX<br />

11<br />

1

1<br />

12<br />

Insulation<br />

Selection Guide Overview<br />

Low Profile Boots and Transitions<br />

Low Profile<br />

Convolute Boots<br />

Helashrink 313C Series,<br />

with adapter lip<br />

Low Profile<br />

Straight Boots<br />

Helashrink 313F Series,<br />

with adapter lip<br />

Low Profile<br />

Transition Boots<br />

Helashrink 412H Series,<br />

side breakout<br />

Low Profile<br />

Transition Boots<br />

Helashrink 573H Series,<br />

1 to 3 cables<br />

Bulbous Boots and Transitions<br />

Bottle <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 150 Series,<br />

with rib<br />

Bottle <strong>Shapes</strong><br />

Helashrink 100 Series,<br />

without rib<br />

Long Outlet Shape,<br />

VG style<br />

Helashrink 130 Series,<br />

with rib, low profile<br />

Bottle <strong>Shapes</strong><br />

Helashrink 160 Series,<br />

without rib<br />

Bottle <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 190 Series,<br />

with external ribs<br />

2-Way Outlet <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 200 Series<br />

3-Way Outlet <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 300 Series<br />

Page 22<br />

Low Profile<br />

Shim Boots<br />

Helashrink 313E Series,<br />

without adapter lip<br />

Page 23<br />

Page 24<br />

Page 26<br />

Page 28<br />

Page 29<br />

Bottle <strong>Shapes</strong>,<br />

MIL style<br />

Helashrink 100 Series,<br />

with rib<br />

Page 31<br />

Page 32<br />

Page 35<br />

Page 38<br />

Page 40<br />

Page 42<br />

Page 44<br />

Low Profile<br />

Right Angle Boots<br />

Helashrink 333F Series,<br />

with adapter lip, 90° angle<br />

Low Profile<br />

Transition Boots<br />

Helashrink 492H Series,<br />

1 to 2 cables<br />

Bottle <strong>Shapes</strong><br />

Helashrink 120 Series,<br />

with and without rib<br />

Long Outlet <strong>Shapes</strong><br />

Helashrink 140 Series,<br />

without rib<br />

Bottle <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 170 Series,<br />

with rib<br />

2-Way Outlet <strong>Shapes</strong><br />

Helashrink 200 Series,<br />

low profile<br />

2-Way Outlet <strong>Shapes</strong>,<br />

Breakout Boots<br />

Helashrink 200 Series,<br />

in line, low voltage<br />

3-Way Outlet <strong>Shapes</strong>,<br />

Breakout Boots<br />

Helashrink 300 Series,<br />

in line, low voltage<br />

Page 25<br />

Page 27<br />

Page 34<br />

Page 37<br />

Page 39<br />

Page 41<br />

Page 43<br />

Page 45

Bulbous Boots and Transitions<br />

4-Way Outlet <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 400 Series<br />

5-Way Outlet <strong>Shapes</strong>,<br />

Breakout Boots<br />

Helashrink 500 Series,<br />

in line, low voltage<br />

Right Angle <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 1100 Series,<br />

with rib<br />

Right Angle <strong>Shapes</strong>,<br />

MIL style<br />

Helashrink 1100 Series,<br />

with rib<br />

Right Angle <strong>Shapes</strong>,<br />

VG style/MIL style<br />

Helashrink 1100 Series,<br />

with rib, low profile<br />

T-<strong>Shapes</strong>, VG style<br />

Helashrink 1200 Series<br />

T-<strong>Shapes</strong>, VG style<br />

Helashrink 1200 Series,<br />

Offset<br />

Double T-<strong>Shapes</strong><br />

Helashrink 1310 Series,<br />

30° angle<br />

Connector Cover<br />

for Min-D Series<br />

Helashrink 1500 Series,<br />

with top entry<br />

Angle <strong>Shapes</strong><br />

Helashrink 1800 Series,<br />

with rib, 30°, 45°, 60° angle<br />

Locating Bushes<br />

Helashrink 1760, 1790,<br />

1820 Series<br />

Insulation<br />

Selection Guide Overview<br />

Page 46<br />

4-Way Outlet <strong>Shapes</strong>,<br />

Breakout Boots<br />

Helashrink 400 Series,<br />

in line, low voltage<br />

Page 47<br />

Page 48<br />

Page 50<br />

Page 52<br />

Page 54<br />

Page 57<br />

Page 59<br />

Page 61<br />

Page 63<br />

Page 65<br />

Page 67<br />

6-Way Outlet <strong>Shapes</strong>,<br />

Breakout Boots<br />

Helashrink 600 Series,<br />

in line, low voltage<br />

Right Angle <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 1100 Series,<br />

without rib, thick wall<br />

Right Angle <strong>Shapes</strong><br />

Helashrink 1100 Series,<br />

without rib<br />

Right Angle <strong>Shapes</strong>,<br />

VG style<br />

Helashrink 1100 Series,<br />

with rib, low profile,<br />

high ratio<br />

T-<strong>Shapes</strong><br />

Helashrink 1200 Series,<br />

Offset<br />

Angled T-<strong>Shapes</strong>,<br />

VG style<br />

Helashrink 1300 Series,<br />

30° & 45° angle<br />

Angle Elbow <strong>Shapes</strong><br />

Helashrink 1400 Series,<br />

90° angle<br />

GSR Graduated<br />

Strain Relief<br />

Helashrink 1750 Series,<br />

with rib<br />

Right Angle<br />

Cross <strong>Shapes</strong><br />

Helashrink 2000 Series,<br />

T-Joint<br />

Connector Cover<br />

for Min-D Series<br />

Helashrink 2100 Series,<br />

with 90° entry<br />

Page 49<br />

Page 51<br />

Page 53<br />

Page 56<br />

Page 58<br />

Page 60<br />

Page 62<br />

Page 64<br />

Page 66<br />

Page 68<br />

13<br />

1

1<br />

14<br />

Insulation<br />

Technical Information<br />

Materials for <strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong><br />

Material Specifications<br />

Description B7 G J<br />

Material Semi-rigid flame retarded<br />

polyolefin<br />

Material Specifications<br />

Fluid resistant elastomer Flexible polyolefin<br />

Continuous Operating<br />

Temperature °C<br />

-55 to +135 -75 to +150 -55 to +135<br />

Minimum Shrink Temperature °C +135 +135 +135<br />

Specifications MIL-I-81765/1 TYPE I<br />

DEF 59-97<br />

BSG198 Part 5<br />

VG 95343 Pt6 & Pt18<br />

DEF 59-97<br />

BSG198 Part 5<br />

Tensile Strength (MPa) 13 15 14<br />

Ultimate Elongation (%) 500 580 610<br />

Dielectric Strength kV/mm 14 14 12<br />

Flammability<br />

(Self extinguishing)<br />

Excellent Excellent Excellent<br />

Characteristics Good physical and<br />

Excellent resistance<br />

Flexible<br />

chemical resistance<br />

to fuels<br />

Typical applications Military and general high performance harnessing<br />

Material Specifications<br />

Description H B8 L<br />

Material Flexible limited fire hazard material Semi-rigid flame retarded<br />

polyolefin<br />

Description -9 -8 -6<br />

MIL-1-81765/1 TYPE II<br />

DEF 59-97<br />

BSG198 Part 5<br />

Flexible flame retarded<br />

fluoroelastomer<br />

Continuous Operating<br />

Temperature °C<br />

-55 to +105 -55 to +100 -55 to +200<br />

Minimum Shrink Temperature °C +135 +135 +175<br />

Specifications NAVSEA 5617649<br />

DEF 59-97<br />

VG 95343 Pt29<br />

BSG198 Part 5<br />

EA-TS 09-11 MIL-81765/4<br />

DEF Stan 59-97<br />

BSG198 Part 5<br />

Tensile Strength (MPa) 10 15 12<br />

Ultimate Elongation (%) 450 500 300<br />

Dielectric Strength kV/mm 15 15 8<br />

Flammability<br />

(Self extinguishing)<br />

Excellent Good Excellent<br />

Characteristics Low smoke<br />

Good physical and reasonable High temperature excellent chem.<br />

Halogen free<br />

chemical resistance<br />

resistance<br />

Typical applications Ships, submarines & railways Power/utility shapes Military and high performance<br />

harnessing<br />

Material Modified elastomer blend Modified fluoroelastomer Flexible flame retarded polyolefin<br />

Continuous Operating<br />

Temperature °C<br />

-55 to +120 -55 to +150 -55 to +120<br />

Minimum Shrink Temperature °C +135 +135 +135<br />

Specifications SCX15112 SCX15111 MIL-1-81765/1 Type I + II<br />

Tensile Strength (MPa) 12 15 12<br />

Ultimate Elongation (%) 500 450 500<br />

Dielectric Strength kV/mm 20 20 20<br />

Flammability<br />

(Self extinguishing)<br />

Excellent

Adhesives for <strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong><br />

Adhesive Specifications<br />

Description W / W2 WM250 W8<br />

Adhesive General purpose<br />

hot melt adhesive<br />

General purpose<br />

hot melt adhesive<br />

Insulation<br />

Technical Information<br />

EVA, high performance,<br />

hot melt adhesive<br />

Operating Temperature Range °C -55 to +80 -55 to +80 -55 to +105<br />

Softening Point °C +95 +95 +110<br />

Supplied Form pre-applied pre-applied pre-applied<br />

Shelf Life 5 years 5 years 5 years<br />

Solvent Resistance<br />

Fair under splash conditions<br />

Adhesive Specifications<br />

Description W21 W24 TSA-200<br />

Adhesive Modified polyamide<br />

High performance, pre-coat, Thermoset +125° C<br />

hot melt adhesive<br />

1 part epoxy<br />

Operating Temperature Range °C -55 to +120 -75 to +200 -55 to +125<br />

Softening Point °C +120 - -<br />

Supplied Form pre-applied pre-applied Tape<br />

Shelf Life 5 years 5 years 5 years<br />

Solvent Resistance Saline: Very good<br />

De-icing fluid: Excellent<br />

Fair under splash conditions<br />

De-icing fluid: Good<br />

Petrol: Excellent<br />

Diesel: Excellent<br />

Lubricating Oil: Excellent<br />

Lubricating Oil: Good<br />

Hydraulic Oil: Good<br />

Aviation Fuel: Good<br />

Automotive Fuel: Good<br />

Hydraulic Oil: Excellent<br />

Adhesive Specifications<br />

Description V9500 HMT200A<br />

Adhesive Two part, black, epoxy adhesive Hot melt adhesive tape<br />

Operating Temperature Range °C -75 to +150 -55 to +105<br />

Softening Point °C - +110<br />

Supplied Form Cartridge Tape<br />

Shelf Life 18 months 5 years<br />

Solvent Resistance De-icing fluid: Excellent<br />

Petrol: Excellent<br />

Lubricating Oil: Excellent<br />

Hydraulic Oil: Excellent<br />

Fair under splash conditions<br />

15<br />

1

1<br />

16<br />

Insulation<br />

Material & Adhesive Combinations Search<br />

Use this table to find the adhesive compatibility for your preferred material.<br />

Material<br />

Material Combinations G B7 B8 H<br />

Semi -rigid flame<br />

Semi -rigid flame<br />

Flexible limited fire<br />

Material Description<br />

Shape<br />

Fluid resistant elastomer retarded polyolefin retarded polyolefin hazard polyolefin<br />

Minimum Shrink Temperature °C +135 +135 +135 +135<br />

Operating Temperature Range °C -75 to +150 -55 to +135 -55 to +100 -55 to +105<br />

Shelf Life 5 years 5 years 5 years 5 years<br />

Helashrink 100 Series yes yes no yes<br />

Helashrink 1100 Series yes yes no yes<br />

Helashrink 200 Series yes yes no yes<br />

Helashrink 300 Series yes yes no yes<br />

Helashrink 400 Series yes yes no yes<br />

Helashrink 1200 Series yes yes no yes<br />

Helashrink 1300 Series yes yes no yes<br />

Low Profile <strong>Shapes</strong> (Series 313, 412, 492, 573) no no no no<br />

Helashrink 1600 Series no no yes no<br />

Helashrink In Line Series, low voltage no no yes no<br />

Adhesive Compatibility WM250 WM250 WM250 WM250<br />

W8 W8 W8 W8<br />

W24 W24 W24<br />

V9500 V9500 W21<br />

HMT200A HMT200A

Insulation<br />

Material & Adhesive Combinations Search<br />

Material<br />

Material Combinations L -9 -6 -8<br />

Material Description<br />

Flexible flame retarded<br />

fluoroelastomer<br />

Modified elastomer<br />

blend<br />

Flexible flame retarded<br />

polyolefin<br />

Fluoro-elastomer<br />

polymer blend<br />

Shape low profile low profile low profile<br />

Minimum Shrink Temperature °C +175 +135 +135 +135<br />

Operating Temperature Range °C -55 to +200 -55 to +120 -55 to +120 -55 to +150<br />

Shelf Life 5 years<br />

Helashrink 100 Series yes no no no<br />

Helashrink 1100 Series yes no no no<br />

Helashrink 200 Series yes no no no<br />

Helashrink 300 Series yes no no no<br />

Helashrink 400 Series yes no no no<br />

Helashrink 1200 Series yes no no no<br />

Helashrink 1300 Series yes no no no<br />

Low Profile <strong>Shapes</strong> (Series 313, 412, 492, 573) no yes yes yes<br />

Helashrink 1600 Series no no no no<br />

Helashrink In Line Series, low voltage no no no no<br />

Adhesive Compatibility W24 WM250 WM250 WM250<br />

W8 W8 W8<br />

W24 W24 W24<br />

V9500 V9500 V9500<br />

HMT200A HMT200A HMT200A<br />

TSA200 TSA200 TSA200<br />

17<br />

1

1<br />

18<br />

Insulation<br />

Material & Adhesive Combinations Search<br />

Use this table to find the material compatibility for your preferred adhesive.<br />

Adhesive<br />

Adhesive Combinations W / W2 WM250 W8 W21<br />

Adhesive Description<br />

General purpose<br />

hot melt adhesive<br />

General purpose<br />

hot melt adhesive<br />

EVA, high performance,<br />

hot melt adhesive<br />

Modified polyamide<br />

hot melt adhesive<br />

Operating Temperature Range °C -55 to +80 -55 to +80 -55 to +105 -55 to +120<br />

Softening Point °C +95 +95 +110 -<br />

Supplied Form pre-applied pre-applied pre-applied pre-applied<br />

Shelf Life 5 years 5 years 5 years 5 years<br />

Solvent Resistance<br />

Fair under<br />

splash conditions<br />

Fair under<br />

splash conditions<br />

Fair under<br />

splash conditions<br />

Helashrink 100 Series no yes yes yes<br />

Helashrink 1100 Series no yes yes yes<br />

Helashrink 200 Series no yes yes yes<br />

Helashrink 300 Series no yes yes yes<br />

Helashrink 400 Series no yes yes yes<br />

Helashrink 1200 Series no yes yes yes<br />

Helashrink 1300 Series no yes yes yes<br />

Low Profile <strong>Shapes</strong> (Series 313, 412, 492, 573) no yes yes yes<br />

Helashrink 1600 Series yes yes no no<br />

Helashrink In Line Series, low voltage yes yes no no<br />

Material Compatibility B8 G G G<br />

B7 B7 B7<br />

B8 H B8<br />

H -6 H<br />

-6 -9<br />

-9<br />

-8<br />

-8<br />

Saline: Very good<br />

De-icing fluid: Good<br />

Diesel: Excellent<br />

Lubricating Oil: Good<br />

Hydraulic Oil: Good<br />

Aviation Fuel: Good<br />

Automotive Fuel: Good

Insulation<br />

Material & Adhesive Combinations Search<br />

Adhesive<br />

Adhesive Combinations W24 TSA-200 V9500 HMT200A<br />

Adhesive Description<br />

High performance,<br />

pre-coat, 1 part epoxy Thermoset +125°C<br />

Two part, black,<br />

epoxy adhesive Hot melt adhesive tape<br />

Operating Temperature Range °C -75 to +200 -55 to +125 -75 to +150 -55 to +105<br />

Softening Point °C - - - + 110<br />

Supplied Form pre-applied Tape Cartridge Tape<br />

Shelf Life 5 years 5 years 18 months 5 years<br />

Solvent Resistance<br />

De-icing fluid: Excellent<br />

Petrol: Excellent<br />

Lubricating Oil: Excellent Fair under splash<br />

Hydraulic Oil: Excellent conditions<br />

De-icing fluid: Excellent<br />

Petrol: Excellent<br />

Lubricating Oil: Excellent Fair under splash<br />

Hydraulic Oil: Excellent conditions<br />

Helashrink 100 Series yes no yes yes<br />

Helashrink 1100 Series yes no yes yes<br />

Helashrink 200 Series yes no yes yes<br />

Helashrink 300 Series yes no yes yes<br />

Helashrink 400 Series yes no yes yes<br />

Helashrink 1200 Series yes no yes yes<br />

Helashrink 1300 Series yes no yes yes<br />

Low Profile <strong>Shapes</strong> (Series 313, 412, 492, 573) yes yes yes yes<br />

Helashrink 1600 Series no no no yes<br />

Helashrink In Line Series, low voltage no no no yes<br />

Material Compatibility G -6 G G<br />

B7 -9 B7 B7<br />

H -8 H B8<br />

L H<br />

-6 -6<br />

-9 -9<br />

-8 -8<br />

19<br />

1

2.1 Low Profile Boots and Transitions<br />

Low Profile Convolute Boots<br />

• Helashrink 313C Series, with adapter lip 22<br />

Low Profile Shim Boots<br />

• Helashrink 313E Series, without adapter lip 23<br />

Low Profile Straight Boots<br />

• Helashrink 313F Series, with adapter lip 24<br />

Low Profile Right Angle Boots<br />

• Helashrink 333F Series, with adapter lip, 90° angle 25<br />

Low Profile Transition Boots<br />

• Helashrink 412H Series, side breakout 26<br />

• Helashrink 492H Series, 1 to 2 cables 27<br />

• Helashrink 573H Series, 1 to 3 cables 28<br />

2.2 Bulbous Boots and Transitions<br />

Bottle <strong>Shapes</strong>, VG style<br />

• Helashrink 150 Series, with rib 29<br />

Bottle <strong>Shapes</strong>, MIL style<br />

• Helashrink 100 Series, with rib 31<br />

Bottle <strong>Shapes</strong><br />

• Helashrink 100 Series, without rib 32<br />

• Helashrink 120 Series, with and without rib 34<br />

Page Page<br />

Long Outlet Shape, VG style<br />

• Helashrink 130 Series, with rib, low profile 35<br />

Long Outlet <strong>Shapes</strong><br />

• Helashrink 140 Series, without rib 37<br />

Bottle <strong>Shapes</strong><br />

• Helashrink 160 Series, without rib 38<br />

Bottle <strong>Shapes</strong>, VG style<br />

• Helashrink 170 Series, with rib 39<br />

• Helashrink 190 Series, with external ribs 40<br />

2-Way Outlet <strong>Shapes</strong><br />

• Helashrink 200 Series, low profile 41<br />

2-Way Outlet <strong>Shapes</strong>, VG style<br />

• Helashrink 200 Series 42<br />

2-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 200 Series, in line, low voltage 43<br />

3-Way Outlet <strong>Shapes</strong>, VG style<br />

• Helashrink 300 Series 44<br />

3-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 300 Series, in line, low voltage 45<br />

4-Way Outlet <strong>Shapes</strong>, VG style<br />

• Helashrink 400 Series 46

<strong>Heat</strong> <strong>Shrinkable</strong> <strong>Moulded</strong> <strong>Shapes</strong><br />

4-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 400 Series, in line, low voltage 47<br />

5-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 500 Series, in line, low voltage 48<br />

6-Way Outlet <strong>Shapes</strong>, Breakout Boots<br />

• Helashrink 600 Series, in line, low voltage 49<br />

Right-Angle <strong>Shapes</strong>, VG style<br />

• Helashrink 1100 Series, with rib 50<br />

• Helashrink 1100 Series, without rib, thick wall 51<br />

Right-Angle <strong>Shapes</strong>, MIL style<br />

• Helashrink 1100 Series, with rib 52<br />

Right-Angle <strong>Shapes</strong><br />

• Helashrink 1100 Series, without rib 53<br />

Right-Angle <strong>Shapes</strong>, VG style/MIL style<br />

• Helashrink 1100 Series, with rib, low profile 54<br />

Right-Angle <strong>Shapes</strong>, VG style/MIL style<br />

• Helashrink 1100 Series, with rib, low profile 55<br />

Right-Angle <strong>Shapes</strong>, VG style<br />

• Helashrink 1100 Series, with rib, low profile, high ratio 56<br />

T-<strong>Shapes</strong>, VG style<br />

• Helashrink 1200 Series 57<br />

2<br />

Page Page<br />

T-<strong>Shapes</strong><br />

• Helashrink 1200 Series, Offset 58<br />

T-<strong>Shapes</strong>, VG style<br />

• Helashrink 1200 Series, Offset 59<br />

Angled T <strong>Shapes</strong>, VG Style<br />

• Helashrink 1300 Series, 30° & 45° angle 60<br />

Double T <strong>Shapes</strong><br />

• Helashrink 1310 Series, 30° angle 61<br />

Angle Elbow <strong>Shapes</strong><br />

• Helashrink 1400 Series, 90° angle 62<br />

Connector Cover for Min-D Series<br />

• Helashrink 1500 Series, with top entry 63<br />

GSR Graduated Strain Relief<br />

• Helashrink 1750 Series, with rib 64<br />

Angle <strong>Shapes</strong><br />

• Helashrink 1800 Series, with rib, 30°, 45°, 60° angle 65<br />

Right-Angle Cross <strong>Shapes</strong><br />

• Helashrink 2000 Series - T-Joint 66<br />

Locating Bushes<br />

• Helashrink 1760, 1790, 1820 Series 67<br />

Connector Cover for Min-D Series<br />

• Helashrink 2100 Series, with 90° entry 68

Insulation<br />

2.1 Low Profile Boots and Transitions<br />

Transition<br />

22<br />

Low Profile Convolute Boots<br />

• Helashrink 313C Series, with adapter lip<br />

This style is used with a circular grooved<br />

adapter to provide strain relief and, if<br />

adhesive is used, excellent environmental<br />

sealing can be achieved.<br />

The convoluted design provides the flexibility<br />

to accommodate different cable outlet angles.<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

ØJ<br />

min. a<br />

313C722-774 Series supplied / fully recovered.<br />

ØJ<br />

max. b<br />

ØH<br />

Adhesive Material<br />

9 8 6<br />

TSA-200 √ √ √<br />

WM250 √ √ √<br />

W8 √ √ √<br />

W24 √ √ √<br />

V9500 √ √ √<br />

HMT200A √ √ √<br />

Without<br />

Adhesive<br />

√ √ √<br />

R<br />

Sizes and Type Table<br />

P<br />

± 10%<br />

Combinations ″On request″<br />

S<br />

T<br />

b: Fully recovered form (after heating)<br />

R<br />

max.<br />

JO<br />

± 10%<br />

B<br />

W<br />

min<br />

P<br />

B<br />

nom.<br />

313C722 14.2 6.9 11.1 4.8 120.6 21.1 17.3 1.5 62.4 1.3 1.5<br />

313C732 22.4 11.7 17.7 8.1 133.3 26.5 19.8 1.5 67.8 1.3 1.5<br />

313C743 34.0 17.5 26.9 12.7 146.0 32.7 22.3 1.5 73.4 1.3 1.8<br />

313C753 44.2 22.3 36.5 17.5 158.7 37.8 25.4 1.5 78.2 1.3 1.8<br />

313C764 53.8 27.9 45.7 22.3 171.4 42.9 28.4 1.5 82.8 2.0 1.8<br />

313C774 77.2 40.6 54.6 22.8 236.2 62.2 25.4 1.5 138.4 2.0 2.0<br />

All dimensions in mm. Subject to technical changes.<br />

JO-<br />

T<br />

± 0.5<br />

W<br />

Standard combinations<br />

Article-No. Type<br />

422-00001 313C722-9<br />

422-00101 313C732-9<br />

422-00201 313C743-9<br />

422-00302 313C753-9<br />

422-00400 313C764-9<br />

422-00501 313C774-9<br />

ØJ<br />

S<br />

± 0.5

Low Profile Shim Boots<br />

• Helashrink 313E Series,<br />

without adapter lip<br />

This part is normally used to build up or<br />

shim a cable diameter to facilitate a better<br />

fit for components in a cable harness.<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

!<br />

For Material / Adhesive<br />

selection and other<br />

information please<br />

refer to page 10.<br />

ØJ<br />

min. a<br />

Adhesive Material<br />

9 8 6<br />

TSA-200 √ √ √<br />

WM250 √ √ √<br />

W8 √ √ √<br />

W24 √ √ √<br />

V9500 √ √ √<br />

HMT200A √ √ √<br />

Without<br />

Adhesive<br />

√ √ √<br />

Insulation<br />

Low Profile Boots and Transitions<br />

Transition<br />

313E445-457 Series supplied / fully recovered.<br />

Sizes and Type Table<br />

ØJ<br />

max. b<br />

P<br />

±10%<br />

b: Fully recovered form (after heating)<br />

HO<br />

± 10%<br />

HW<br />

± 25%<br />

JW<br />

± 25%<br />

JO<br />

± 10%<br />

313E445 12.7 12.7 11.1 3.3 63.5 41.1 1.5 1.5 15.7<br />

313E455 22.1 22.1 11.2 3.3 53.3 27.9 2.3 1.5 15.7<br />

313E447 20.8 14.7 20.6 9.9 63.5 41.1 1.5 1.5 16.5<br />

313E457 22.1 22.1 20.6 9.9 53.3 27.9 2.3 1.5 14.0<br />

All dimensions in mm. Subject to technical changes.<br />

Combinations ″On request″ Standard combinations<br />

Article-No. Type<br />

422-10000 313E445-9<br />

422-10200 313E455-9<br />

422-10100 313E447-9<br />

422-10300 313E457-9<br />

2.1<br />

23

Insulation<br />

2.1 Low Profile Boots and Transitions<br />

24<br />

Low Profile Straight Boots<br />

• Helashrink 313F Series, with adapter lip<br />

This boot provides strain relief in applications<br />

with partially loaded connectors, resulting in<br />

small cable diameters requiring a high<br />

shrink ratio.<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

ØJ<br />

min. a<br />

313F322-396 Series supplied / fully recovered.<br />

ØJ<br />

max. b<br />

Sizes and Type Table<br />

P<br />

±10%<br />

Adhesive Material<br />

9 8 6<br />

TSA-200 √ √ √<br />

WM250 √ √ √<br />

W8 √ √ √<br />

W24 √ √ √<br />

V9500 √ √ √<br />

HMT200A √ √ √<br />

Without<br />

Adhesive<br />

√ √ √<br />

b: Fully recovered form (after heating)<br />

R<br />

± 15%<br />

T<br />

± 0.8<br />

JO<br />

± 10%<br />

313F322 23.8 9.9 17.2 6.6 105.9 11.6 1.3 86.3 1.5 1.5 1.5<br />

313F332 27.1 13.2 20.8 7.6 121.1 12.1 1.3 98.5 1.5 1.5 1.5<br />

313F343 30.9 18.5 24.3 8.9 138.6 12.1 1.3 112.7 1.7 1.5 1.7<br />

313F353 35.6 22.1 28.7 10.1 159.5 12.1 1.3 130.8 1.7 1.5 1.7<br />

313F364 38.8 28.2 31.4 10.9 177.8 13.9 1.8 142.2 1.7 1.5 1.7<br />

313F374 42.2 32.2 38.3 12.7 203.2 15.2 1.8 163.0 1.7 1.5 1.7<br />

313F385 51.5 45.4 45.4 14.9 203.2 15.2 1.8 157.7 1.7 1.7 1.7<br />

313F396 62.7 45.4 53.3 16.7 228.6 16.0 1.8 153.1 1.7 1.7 1.7<br />

All dimensions in mm. Subject to technical changes.<br />

Combinations ″On request″<br />

HW<br />

± 1.5<br />

JW<br />

± 0.8<br />

Standard combinations<br />

Article-No. Type<br />

422-20000 313F322-9<br />

422-20100 313F332-9<br />

422-20200 313F343-9<br />

422-20300 313F353-9<br />

422-20400 313F364-9<br />

422-20500 313F374-9<br />

422-20600 313F385-9<br />

422-20700 313F396-9<br />

S<br />

± 1.5

Low Profile Right Angle Boots<br />

• Helashrink 333F Series, with adapter<br />

lip, 90° angle<br />

The boot provides connector strain relief in<br />

applications with partially loaded connectors,<br />

resulting in small cable diameters requiring a<br />

high shrink ratio.<br />

ØH ØJ<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

ØJ<br />

min. a<br />

333F322-385 Series supplied / fully recovered.<br />

Sizes and Type Table<br />

ØJ<br />

max. b<br />

P<br />

±10%<br />

Combinations ″On request″<br />

Adhesive Material<br />

9 8 6<br />

TSA-200 √ √ √<br />

WM250 √ √ √<br />

W8 √ √ √<br />

W24 √ √ √<br />

V9500 √ √ √<br />

HMT200A √ √ √<br />

Without<br />

Adhesive<br />

√ √ √<br />

Insulation<br />

Low Profile Boots and Transitions<br />

b: Fully recovered form (after heating)<br />

R<br />

± 15%<br />

T<br />

± 0.8<br />

JO<br />

± 10%<br />

333F322 23.8 9.9 17.2 6.6 105.1 18.5 1.3 87.6 1.5 1.5 1.5<br />

333F332 27.1 13.2 20.8 7.6 115.8 19.8 1.3 99.0 1.5 1.5 1.5<br />

333F343 30.9 18.5 24.3 8.9 146.3 20.8 1.3 114.3 1.7 1.5 1.7<br />

333F353 35.3 21.6 28.7 10.1 172.2 21.8 1.3 132.5 1.7 1.5 1.7<br />

333F364 38.8 27.9 31.4 10.9 185.1 24.1 1.8 143.7 1.7 1.5 1.7<br />

333F374 45.2 34.0 38.3 12.1 213.6 27.4 1.8 169.0 1.7 1.5 1.7<br />

333F385 51.5 41.1 44.4 15.0 224.5 29.4 1.7 173.2 1.7 1.7 1.7<br />

All dimensions in mm. Subject to technical changes.<br />

!For Material / Adhesive<br />

selection and other<br />

information please<br />

refer to page 10.<br />

HW<br />

± 1.5<br />

JW<br />

± 0.8<br />

Standard combinations<br />

Article-No. Type<br />

422-30000 333F322-9<br />

422-30004 333F332-9<br />

422-30100 333F343-9<br />

422-30200 333F353-9<br />

422-30301 333F364-9<br />

422-30400 333F374-9<br />

422-30500 333F385-9<br />

S<br />

± 1.5<br />

2.1<br />

25

Insulation<br />

2.1 Low Profile Boots and Transitions<br />

26<br />

Low Profile Transition Boots<br />

• Helashrink 412H Series, side breakout<br />

This style provides connector cable strain<br />

relief and is used in conjunction with a<br />

circular grooved adapter.<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

ØJ/K<br />

min. a<br />

412H622-625 Series supplied / fully recovered.<br />

Sizes and Type Table<br />

ØJ/K<br />

max. b<br />

Combinations ″On request″<br />

b: Fully recovered form (after heating)<br />

HO/JO/KO<br />

± 10%<br />

412H622 19.8 6.6 13.2 6.6 25.4 80.7 1.0 40.3<br />

412H623 34.2 11.4 22.8 6.6 41.1 120.3 1.3 60.1<br />

412H624 60.1 20.0 40.1 20.0 63.5 175.7 1.5 87.8<br />

412H625 83.3 33.2 54.8 33.2 88.9 242.3 1.7 121.1<br />

All dimensions in mm. Subject to technical changes.<br />

Adhesive Material<br />

9 8 6<br />

TSA-200 √ √ √<br />

WM250 √ √ √<br />

W8 √ √ √<br />

W24 √ √ √<br />

V9500 √ √ √<br />

HMT200A √ √ √<br />

Without<br />

Adhesive<br />

√ √ √<br />

P<br />

nom<br />

W<br />

nom<br />

R/S<br />

nom<br />

Standard combinations<br />

Article-No. Type<br />

422-40000 412H622-9<br />

422-40100 412H623-9<br />

422-40200 412H624-9<br />

422-40300 412H625-9

Low Profile Transition Boots<br />

• Helashrink 492H Series, 1 to 2 cables<br />

This style provides strain relief, sealing and<br />

mechanical protection on cable harness<br />

breakouts or transitions.<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

492H412-415 Series supplied / fully recovered.<br />

Sizes and Type Table<br />

ØJ/K<br />

min. a<br />

Combinations ″On request″<br />

Adhesive Material<br />

9 8 6<br />

TSA-200 √ √ √<br />

WM250 √ √ √<br />

W8 √ √ √<br />

W24 √ √ √<br />

V9500 √ √ √<br />

HMT200A √ √ √<br />

Without<br />

Adhesive<br />

√ √ √<br />

Insulation<br />

Low Profile Boots and Transitions<br />

ØJ/K<br />

max. b<br />

b: Fully recovered form (after heating)<br />

HO/JO/KO<br />

+/- 15%<br />

492H412 19.8 6.6 13.2 6.6 25.4 1.0 40.6<br />

492H413 34.2 11.4 22.8 11.4 41.1 1.3 62.9<br />

492H414 60.1 20.0 40.1 20.0 63.5 1.5 94.7<br />

492H415 83.3 33.2 54.8 33.2 49.7 1.7 133.8<br />

All dimensions in mm. Subject to technical changes.<br />

!For Material / Adhesive<br />

selection and other<br />

information please<br />

refer to page 10.<br />

W<br />

nom<br />

P/R/S<br />

nom<br />

Standard combinations<br />

Article-No. Type<br />

422-50000 492H412-9<br />

422-50101 492H413-9<br />

422-50202 492H414-9<br />

422-50302 492H415-9<br />

2.1<br />

27

Insulation<br />

2.1 Low Profile Boots and Transitions<br />

28<br />

Low Profile Transition Boots<br />

• Helashrink 573H Series, 1 to 3 cables<br />

This style provides strain relief, sealing and<br />

mechanical protection on cable harness<br />

breakouts or transitions.<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

573H532-535 Series supplied / fully recovered.<br />

ØJ/K/L<br />

min. a<br />

Sizes and Type Table<br />

ØJ/K/L<br />

max. b<br />

Adhesive Material<br />

9 8 6<br />

TSA-200 √ √ √<br />

WM250 √ √ √<br />

W8 √ √ √<br />

V9500 √ √ √<br />

HMT200A √ √ √<br />

Without<br />

Adhesive<br />

√ √ √<br />

b: Fully recovered form (after heating)<br />

P<br />

nom<br />

R/S/T<br />

nom<br />

W<br />

nom<br />

HO/JO/KO/LO<br />

± 15%<br />

573H532 19.8 6.6 13.2 6.6 85.8 42.9 1.0 25.4<br />

573H533 34.2 11.4 20.5 11.4 135.6 67.8 1.3 41.1<br />

573H534 60.1 20.0 36.0 20.0 207.2 103.6 1.5 63.5<br />

573H535 99.8 33.2 54.8 33.2 294.6 147.3 1.7 88.9<br />

All dimensions in mm. Subject to technical changes.<br />

Combinations ″On request″ Standard combinations<br />

Article-No. Type<br />

422-60000 573H532-9<br />

422-60100 573H533-9<br />

422-60202 573H534-9<br />

422-60302 573H535-9

Bottle <strong>Shapes</strong>, VG style<br />

• Helashrink 150 Series, with rib<br />

This style is used in conjunction with a circular<br />

grooved adaptor, providing strain relief and<br />

enviromental sealing. For VG shapes with<br />

port holes ″P″ please refer to product<br />

standards tables in the appendix.<br />

Type<br />

Designation as per<br />

VG-Norm<br />

ØH<br />

min. a<br />

150 Series supplied.<br />

ØH ØJ<br />

a: Expanded form (supplied)<br />

!For Material / Adhesive<br />

selection and other<br />

information please<br />

refer to page 10.<br />

ØH<br />

max. b<br />

Sizes and Type Table<br />

ØJ<br />

min. a<br />

ØJ<br />

max. b<br />

P<br />

± 10%<br />

b: Fully recovered form (after heating)<br />

R<br />

± 10%<br />

150 Series boot recovered onto a connector.<br />

JO<br />

± 10%<br />

HW<br />

± 20%<br />

JW<br />

± 20%<br />

Insulation<br />

Bulbous Boots and Transitions<br />

V<br />

± 10%<br />

152-42 VG 95343 T06 B 001 A 24.0 10.5 24.0 6.0 38.0 21.0 10.0 1.6 0.5 3.0 1.0<br />

153-42 VG 95343 T06 B 002 A 25.0 14.0 9.0 3.5 55.0 28.0 16.0 1.8 0.5 3.0 1.0<br />

154-42 VG 95343 T06 B 003 A 30.0 14.0 30.0 6.0 55.0 32.0 13.0 1.8 1.0 3.0 1.0<br />

155-42 VG 95343 T06 B 004 A 31.0 18.0 31.0 7.0 67.0 35.0 18.0 1.8 1.0 3.0 1.0<br />

156-42 VG 95343 T06 B 005 A 36.0 22.5 36.0 8.5 80.0 42.0 20.0 2.0 1.0 3.0 1.0<br />

157-43 VG 95343 T06 C 001 A 43.0 28.0 43.0 10.0 99.0 61.0 20.0 2.2 1.0 3.0 1.7<br />

158-43 VG 95343 T06 C 002 A 60.0 35.0 60.0 16.0 130.0 72.0 38.0 3.2 1.5 3.0 1.7<br />

159-43 VG 95343 T06 C 003 A 66.0 45.0 66.0 17.0 171.0 90.0 50.0 3.8 2.0 3.0 2.0<br />

160-43 VG 95343 T06 C 004 A 82.0 58.0 82.0 27.0 213.0 113.0 62.0 3.8 3.8 3.0 2.0<br />

152-41 VG 95343 T06 A 001 A 24.0 10.5 24.0 6.0 26.0 9.0 10.0 1.6 0.5 3.0 1.0<br />

153-41 VG 95343 T06 A 002 A 25.0 14.0 9.0 3.5 40.0 13.0 16.0 1.8 0.5 3.0 1.0<br />

154-41 VG 95343 T06 A 003 A 30.0 14.0 30.0 6.0 43.0 20.0 13.0 1.8 1.0 3.0 1.0<br />

155-41 VG 95343 T06 A 004 A 31.0 18.0 31.0 7.0 47.0 15.0 18.0 1.8 1.0 3.0 1.0<br />

156-41 VG 95343 T06 A 005 A 36.0 22.5 36.0 8.5 60.0 22.0 20.0 2.0 1.0 3.0 1.0<br />

159-41 VG 95343 T06 A 008 A 66.0 45.0 66.0 17.0 130.0 50.0 50.0 3.8 2.0 3.0 2.0<br />

157-42 VG 95343 T06 B 006 A 43.0 28.0 43.0 10.0 79.0 41.0 20.0 2.2 1.0 3.0 1.7<br />

158-41 VG 95343 T06 A 007 A 60.0 35.0 60.0 16.0 90.0 32.0 38.0 3.2 1.5 3.0 1.7<br />

159-41 VG 95343 T06 A 008 A 66.0 45.0 66.0 17.0 130.0 50.0 50.0 3.8 2.0 3.0 2.0<br />

159-42 VG 95343 T06 B 008 A 66.0 45.0 66.0 17.0 150.0 70.0 50.0 3.8 2.0 3.0 2.0<br />

160-41 VG 95343 T06 A 009 A 82.0 58.0 82.0 27.0 137.0 37.0 62.0 3.8 3.8 3.0 2.0<br />

160-42 VG 95343 T06 B 009 A 82.0 58.0 82.0 27.0 158.0 58.0 62.0 3.8 3.8 3.0 2.0<br />

All dimensions in mm. Subject to technical changes.<br />

T<br />

± 20%<br />

2.2<br />

29

2.2<br />

30<br />

Insulation<br />

Bulbous Boots and Transitions<br />

Bottle <strong>Shapes</strong>, VG style<br />

• Helashrink 150 Series, with rib<br />

150 Series supplied. 150 Series boot recovered onto a connector.<br />

Combinations ″On request″<br />

Adhesive Material<br />

B7 G J H L<br />

WM250 √ √ √ √ -<br />

W8 √ √ √ √ -<br />

W24 √ √ √ √ √<br />

W21 √ √ √ √ -<br />

V9500 √ √ √ √ -<br />

HMT200A √ √ √ √ -<br />

Without<br />

Adhesive<br />

√ √ √ √ √<br />

Standard combinations<br />

Article-No. Type<br />

401-52880 152-42-G<br />

401-53880 153-42-G<br />

401-54880 154-42-G<br />

401-55880 155-42-G<br />

401-56880 156-42-G<br />

401-57980 157-43-G<br />

401-58980 158-43-G<br />

401-59980 159-43-G<br />

401-60980 160-43-G<br />

401-52780 152-41-G<br />

401-53780 153-41-G<br />

401-54780 154-41-G<br />

401-55780 155-41-G<br />

401-56780 156-41-G<br />

401-59780 159-41-G<br />

401-57880 157-42-G<br />

401-58780 158-41-G<br />

401-59780 159-41-G<br />

401-59880 159-42-G<br />

401-60780 160-41-G<br />

401-60880 160-42-G

Bottle <strong>Shapes</strong>, MIL style<br />

• Helashrink 100 Series, with rib<br />

This style is used in conjunction with a<br />

circular grooved adaptor providing strain<br />

relief and environmental sealing when<br />

used in conjunction with one of our<br />

complementary adhesives.<br />

ØH<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

ØJ<br />

min. a<br />

ØJ<br />

max. b<br />

ØJ<br />

Sizes and Type Table<br />

P<br />

± 10%<br />

R<br />

± 10%<br />

Insulation<br />

Bulbous Boots and Transitions<br />

HW<br />

± 20%<br />

JW<br />

± 20%<br />

V<br />

± 10%<br />

T<br />

± 20%<br />

1030-4 12.0 9.8 6.0 2.0 19.0 8.0 1.0 0.5 1.5 0.5 4.6<br />

1031-4 12.0 9.8 6.0 2.0 15.0 4.0 1.0 0.5 1.5 0.5 4.6<br />

1037-4 9.0 5.6 9.0 2.0 19.0 9.0 1.0 0.6 1.5 0.6 4.5<br />

1009-1 9.0 5.6 4.0 3.2 27.0 14.0 1.0 0.5 1.6 0.9 7.5<br />

113-4 10.7 7.9 4.6 2.0 25.4 14.5 1.3 1.0 3.0 1.0 4.6<br />

104-4 16.5 7.9 16.5 3.8 25.4 14.2 1.3 1.3 3.0 1.0 6.9<br />

105-4 23.4 10.4 23.4 5.6 38.1 14.2 1.5 1.5 3.0 1.0 10.2<br />

106-4 31.0 14.2 31.0 6.6 55.4 22.9 1.8 1.8 3.0 1.0 10.2<br />

101-4 31.0 17.8 31.0 7.1 67.0 38.1 2.0 2.0 3.0 1.0 17.8<br />

102-4 36.1 22.4 36.1 8.4 73.7 43.2 1.8 1.8 3.0 1.0 21.0<br />

103-4 42.7 28.2 42.7 9.9 99.1 54.0 2.0 2.0 3.0 1.7 24.0<br />

107-4 51.9 35.1 51.9 15.8 124.5 66.0 3.1 3.1 3.0 1.7 40.6<br />

118-4 66.0 44.4 66.0 20.3 160.5 91.4 3.8 3.8 3.0 2.0 48.3<br />

All dimensions in mm. Subject to technical changes.<br />

!For Material / Adhesive<br />

selection and other<br />

information please<br />

refer to page 10.<br />

104-4 supplied / fully recovered.<br />

Combinations ″On request″<br />

Adhesive Material<br />

B7 G J H L<br />

WM250 √ √ √ √ -<br />

W8 √ √ √ √ -<br />

W24 √ √ √ √ √<br />

W21 √ √ √ √ -<br />

HMT200A √ √ √ √ -<br />

V9500 √ √ √ √ -<br />

Without<br />

Adhesive<br />

√ √ √ √ √<br />

b: Fully recovered form (after heating)<br />

S<br />

nom<br />

Standard combinations<br />

Article-No. Type<br />

410-30480 1030-4-G<br />

410-31001 1031-4-G<br />

410-37001 1037-4-G<br />

410-09001 1009-1-G<br />

401-13480 113-4-G<br />

401-04024 104-4-G<br />

401-05034 105-4-G<br />

401-06036 106-4-G<br />

401-01037 101-4-G<br />

401-02031 102-4-G<br />

401-03041 103-4-G<br />

401-07030 107-4-G<br />

401-18018 118-4-B7<br />

2.2<br />

31

2.2<br />

32<br />

Insulation<br />

Bulbous Boots and Transitions<br />

Bottle <strong>Shapes</strong><br />

• Helashrink 100 Series, without rib<br />

This style provides connector cable strain<br />

relief. Can be installed on the connector<br />

rear thread or plain shaft and allows easy<br />

re-entry for repair when combined with a<br />

hot melt adhesive.<br />

ØH<br />

a: Expanded form (supplied)<br />

109-1-G supplied / fully recovered.<br />

Type<br />

ØJ<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

ØJ<br />

min. a<br />

b: Fully recovered form (after heating)<br />

Sizes and Type Table<br />

ØJ<br />

max. b<br />

P<br />

± 10%<br />

R<br />

max.<br />

HW<br />

± 20%<br />

JW<br />

± 30%<br />

S<br />

nom<br />

104-1 16.5 7.9 16.5 3.8 25.4 14.2 1.3 1.3 6.9<br />

104-2 10.7 7.9 8.4 3.8 25.4 14.2 1.3 1.3 6.9<br />

105-1 23.4 10.4 23.4 5.6 38.1 22.9 1.5 1.5 10.2<br />

106-1 31.0 14.2 31.0 6.6 55.4 26.5 1.8 1.8 16.5<br />

106-2 19.3 14.2 14.2 6.6 55.4 26.5 1.8 1.8 16.5<br />

101-1 31.0 17.8 31.0 7.1 66.0 38.1 2.0 2.0 17.8<br />

101-2 23.9 17.8 15.5 7.1 66.0 38.1 2.0 2.0 17.8<br />

102-1 36.1 22.4 36.1 8.4 73.7 43.2 1.8 1.8 17.8<br />

102-2 30.0 22.4 18.0 8.4 73.7 43.2 1.8 1.8 17.8<br />

1006-1 40.0 20.0 20.0 6.0 78.8 30.0 1.5 1.0 20.0<br />

103-1 42.7 28.2 42.7 9.9 95.5 54.0 2.0 2.0 24.0<br />

103-2 37.8 28.2 21.3 9.9 95.5 54.0 2.0 2.0 24.0<br />

107-1 51.9 35.1 51.9 15.8 124.5 66.0 3.1 3.1 40.6<br />

107-2 46.9 35.1 35.6 15.8 124.5 66.0 3.1 3.1 40.6<br />

118-1 66.0 44.4 66.0 20.3 150.0 80.0 3.8 3.8 48.3<br />

119-1 86.4 57.2 86.4 26.6 209.6 118.1 4.6 4.6 61.0<br />

113-1 10.7 7.9 4.6 2.0 25.4 14.5 1.3 1.0 4.6<br />

113-2 21.6 7.9 5.8 2.0 25.4 14.5 1.3 1.3 4.6<br />

108-1 13.7 10.4 6.6 3.1 38.1 22.9 1.5 1.0 7.6<br />

108-2 27.9 10.4 7.9 3.1 38.1 22.9 1.5 1.0 7.6<br />

109-1 19.3 14.2 8.1 4.1 53.3 35.6 2.0 1.3 7.6<br />

109-2 38.1 14.2 11.7 4.1 53.3 35.6 2.0 1.3 7.6<br />

110-1 23.9 17.8 11.7 5.6 63.5 38.1 2.5 1.5 12.7<br />

110-2 50.8 17.8 17.0 5.6 63.5 38.1 2.5 1.5 12.7<br />

111-1 30.0 22.4 14.7 7.1 76.2 43.2 3.1 1.8 15.2<br />

111-2 63.5 22.4 21.3 7.1 76.2 43.2 3.1 1.8 15.2<br />

116-1 59.4 44.5 43.7 20.8 158.8 91.4 5.6 4.6 41.9<br />

All dimensions in mm. Subject to technical changes.

Bottle <strong>Shapes</strong><br />

• Helashrink 100 Series, without rib<br />

109-1-G supplied / fully recovered.<br />

Combinations ″On request″<br />

Adhesive Material<br />

B7 G J H L<br />

WM250 √ √ √ √ -<br />

W8 √ √ √ √ -<br />

W24 √ √ √ √ √<br />

V9500 √ √ √ √ -<br />

HMT200A √ √ √ √ -<br />

W21 - - - √ -<br />

Without<br />

Adhesive<br />

√ √ √ √ -<br />

!For Material / Adhesive<br />

selection and other<br />

information please<br />

refer to page 10.<br />

Insulation<br />

Bulbous Boots and Transitions<br />

Standard combinations<br />

Article-No. Type<br />

401-04006 104-1-G<br />

401-04017 104-2-G<br />

401-05005 105-1-G<br />

401-06005 106-1-G<br />

401-06023 106-2-G<br />

401-01006 101-1-G<br />

401-01026 101-2-G<br />

401-02005 102-1-G<br />

401-02020 102-2-G<br />

410-06006 1006-1-B7<br />

401-03006 103-1-G<br />

401-03024 103-2-B7<br />

401-07006 107-1-G<br />

401-07016 107-2-B7<br />

401-18005 118-1-G<br />

401-19001 119-1-B7<br />

401-13180 113-1-G<br />

401-13011 113-2-G<br />

401-08001 108-1-B7<br />

401-08016 108-2-G<br />

401-09002 109-1-B7<br />

401-09011 109-2-G<br />

401-10005 110-1-G<br />

401-10011 110-2-G<br />

401-11003 111-1-J<br />

401-11011 111-2-G<br />

401-16007 116-1-B7.<br />

2.2<br />

33

2.2<br />

34<br />

Insulation<br />

Bulbous Boots and Transitions<br />

Bottle <strong>Shapes</strong><br />

• Helashrink 120 Series,<br />

with and without rib<br />

This style has a long tail providing extended<br />

strain relief for small diameter wires and<br />

can be supplied with or without rib and in<br />

various material / adhesive combinations<br />

to meet your requirement.<br />

a: Expanded form (supplied)<br />

Type<br />

ØH<br />

min. a<br />

ØH<br />

max. b<br />

*Note: 120-41 & 42 are with end ribs.<br />

ØJ<br />

min. a<br />

120-42-G supplied / fully recovered.<br />

ØJ<br />

max. b<br />

R<br />

± 10%<br />

Sizes and Type Table<br />

W<br />

± 20%<br />

P<br />

± 10%<br />

b: Fully recovered form (after heating)<br />

HW<br />

± 20%<br />

JW<br />

± 20%<br />

V<br />

± 10%<br />

T<br />

± 10%<br />

120-1 16.5 7.0 10.2 3.0 24.0 1.3 60.9 1.3 1.3 – – 32.0<br />

120-2 20.3 7.0 10.2 3.0 24.0 1.3 60.9 1.3 1.3 – – 32.0<br />

120-3 16.5 7.0 10.7 3.0 24.0 1.3 38.0 1.3 1.3 – – 9.1<br />

120-41* 16.5 7.0 10.7 3.0 24.0 1.3 38.0 1.3 1.3 3.0 1.0 32.0<br />

120-42* 16.5 7.0 10.2 3.0 24.0 1.3 60.9 1.3 1.3 3.0 1.0 –<br />

All dimensions in mm. Subject to technical changes.<br />

Combinations ″On request″<br />

Adhesive Material<br />

B7 G J H L<br />

WM250 √ √ √ √ -<br />

W8 √ √ √ √ -<br />

W24 √ √ √ √ √<br />

V9500 - √ √ √ -<br />

HMT200A √ √ √ √ -<br />

W21 - - - √ -<br />

Without<br />

Adhesive<br />

√ √ √ √ √<br />

Standard combinations<br />

Article-No. Type<br />

401-20003 120-1-G<br />

401-20014 120-2-G<br />

401-20020 120-3-G<br />

401-20022 120-41-G<br />

401-20026 120-42-G<br />

S<br />

nom

Long Outlet Shape, VG style<br />

• Helashrink 130 Series,<br />

with rib, low profile<br />

This style is low profile and lightweight.<br />

Typically used on airborne harnesses.<br />

Rib locates on circular backshell. For<br />

VG shapes with port holes ″P″ please refer to<br />

product standards tables in the appendix.<br />

!For Material / Adhesive<br />

selection and other<br />

information please<br />

refer to page 10.<br />

ØH ØJ<br />

a: Expanded form (supplied)<br />

Type<br />

Designation as per<br />

VG-Norm<br />

ØH<br />

min. a<br />

135-1 supplied / fully recovered.<br />

ØH<br />

max. b<br />

Sizes and Type Table<br />

ØJ<br />

min. a<br />

ØJ<br />

max. b<br />

Insulation<br />

Bulbous Boots and Transitions<br />

b: Fully recovered form (after heating)<br />

P<br />

± 10%<br />

R<br />

± 10%<br />

HW<br />

± 20%<br />

JW<br />

± 20%<br />

V<br />

± 10%<br />

129-1 VG95343T06D001A 22.0 12.0 22.0 6.5 76.0 12.0 1.5 1.1 3.0 1.0<br />

130-1 VG95343T06D002A 25.5 15.0 25.5 7.5 83.0 12.0 1.5 1.1 3.0 1.0<br />