Barrel Heaters - Hasmak.com.tr

Barrel Heaters - Hasmak.com.tr

Barrel Heaters - Hasmak.com.tr

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

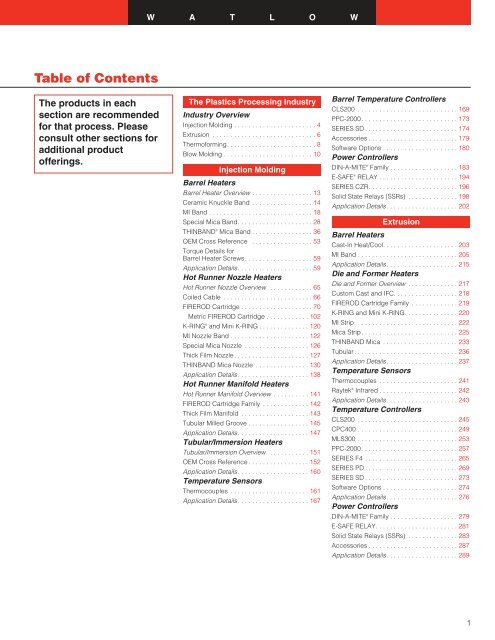

W A T L O WTable of ContentsThe products in eachsection are re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mendedfor that process. Pleaseconsult other sections foradditional productofferings.The Plastics Processing Indus<strong>tr</strong>yIndus<strong>tr</strong>y OverviewInjection Molding . . . . . . . . . . . . . . . . . . . . . . . 4Ex<strong>tr</strong>usion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Thermoforming. . . . . . . . . . . . . . . . . . . . . . . . . 8Blow Molding . . . . . . . . . . . . . . . . . . . . . . . . . 10Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong><s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Heater Overview . . . . . . . . . . . . . . . . . 13Ceramic Knuckle Band . . . . . . . . . . . . . . . . . 14MI Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Special Mica Band. . . . . . . . . . . . . . . . . . . . . 28THINBAND ® Mica Band . . . . . . . . . . . . . . . . . 36OEM Cross Reference . . . . . . . . . . . . . . . . . 53Torque Details for<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Heater Screws. . . . . . . . . . . . . . . . . . . 59Application Details. . . . . . . . . . . . . . . . . . . . . 59Hot Runner Nozzle <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Hot Runner Nozzle Overview . . . . . . . . . . . . 65Coiled Cable . . . . . . . . . . . . . . . . . . . . . . . . . 66FIREROD Car<strong>tr</strong>idge . . . . . . . . . . . . . . . . . . . . 70Me<strong>tr</strong>ic FIREROD Car<strong>tr</strong>idge . . . . . . . . . . . . 102K-RING ® and Mini K-RING . . . . . . . . . . . . . . 120MI Nozzle Band . . . . . . . . . . . . . . . . . . . . . . 122Special Mica Nozzle . . . . . . . . . . . . . . . . . . 126Thick Film Nozzle. . . . . . . . . . . . . . . . . . . . . 127THINBAND Mica Nozzle . . . . . . . . . . . . . . . 130Application Details. . . . . . . . . . . . . . . . . . . . 138Hot Runner Manifold <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Hot Runner Manifold Overview . . . . . . . . . . 141FIREROD Car<strong>tr</strong>idge Family . . . . . . . . . . . . . 142Thick Film Manifold . . . . . . . . . . . . . . . . . . . 143Tubular Milled Groove . . . . . . . . . . . . . . . . . 145Application Details. . . . . . . . . . . . . . . . . . . . 147Tubular/Immersion <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Tubular/Immersion Overview . . . . . . . . . . . 151OEM Cross Reference . . . . . . . . . . . . . . . . . 152Application Details. . . . . . . . . . . . . . . . . . . . 160Temperature SensorsThermocouples . . . . . . . . . . . . . . . . . . . . . . 161Application Details. . . . . . . . . . . . . . . . . . . . 167<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Temperature Con<strong>tr</strong>ollersCLS200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169PPC-2000. . . . . . . . . . . . . . . . . . . . . . . . . . . 173SERIES SD . . . . . . . . . . . . . . . . . . . . . . . . . . 174Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 179Software Options . . . . . . . . . . . . . . . . . . . . . 180Power Con<strong>tr</strong>ollersDIN-A-MITE ® Family . . . . . . . . . . . . . . . . . . . 183E-SAFE ® RELAY . . . . . . . . . . . . . . . . . . . . . . 194SERIES CZR. . . . . . . . . . . . . . . . . . . . . . . . . 196Solid State Relays (SSRs) . . . . . . . . . . . . . . 198Application Details. . . . . . . . . . . . . . . . . . . . 202Ex<strong>tr</strong>usion<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Cast-In Heat/Cool. . . . . . . . . . . . . . . . . . . . . 203MI Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205Application Details. . . . . . . . . . . . . . . . . . . . 215Die and Former <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Die and Former Overview . . . . . . . . . . . . . . 217Custom Cast and IFC. . . . . . . . . . . . . . . . . . 218FIREROD Car<strong>tr</strong>idge Family . . . . . . . . . . . . . 219K-RING and Mini K-RING. . . . . . . . . . . . . . . 220MI S<strong>tr</strong>ip . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222Mica S<strong>tr</strong>ip. . . . . . . . . . . . . . . . . . . . . . . . . . . 225THINBAND Mica . . . . . . . . . . . . . . . . . . . . . 233Tubular. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236Application Details. . . . . . . . . . . . . . . . . . . . 237Temperature SensorsThermocouples . . . . . . . . . . . . . . . . . . . . . . 241Raytek ® Infrared . . . . . . . . . . . . . . . . . . . . . . 242Application Details. . . . . . . . . . . . . . . . . . . . 243Temperature Con<strong>tr</strong>ollersCLS200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245CPC400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249MLS300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253PPC-2000. . . . . . . . . . . . . . . . . . . . . . . . . . . 257SERIES F4 . . . . . . . . . . . . . . . . . . . . . . . . . . 265SERIES PD . . . . . . . . . . . . . . . . . . . . . . . . . . 269SERIES SD . . . . . . . . . . . . . . . . . . . . . . . . . . 273Software Options . . . . . . . . . . . . . . . . . . . . . 274Application Details. . . . . . . . . . . . . . . . . . . . 276Power Con<strong>tr</strong>ollersDIN-A-MITE ® Family . . . . . . . . . . . . . . . . . . . 279E-SAFE RELAY. . . . . . . . . . . . . . . . . . . . . . . 281Solid State Relays (SSRs) . . . . . . . . . . . . . . 283Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 287Application Details. . . . . . . . . . . . . . . . . . . . 2891

Table of ContentsThe products in eachsection are re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mendedfor that process. Pleaseconsult other sections foradditional productofferings.Thermoforming<s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Radiant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291S<strong>tr</strong>ip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314Radiant Band and S<strong>tr</strong>ip Emitters . . . . . . . . . 325Application Details. . . . . . . . . . . . . . . . . . . . 326Temperature Con<strong>tr</strong>ollersCLS200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329CPC400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330MLS300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331PPC-2000. . . . . . . . . . . . . . . . . . . . . . . . . . . 332SERIES D8 . . . . . . . . . . . . . . . . . . . . . . . . . . 333SERIES PD . . . . . . . . . . . . . . . . . . . . . . . . . . 337SERIES SD . . . . . . . . . . . . . . . . . . . . . . . . . . 341Application Details. . . . . . . . . . . . . . . . . . . . 342Temperature SensorsThermocouples . . . . . . . . . . . . . . . . . . . . . . 343RAYTEK Infrared . . . . . . . . . . . . . . . . . . . . . 344Application Details. . . . . . . . . . . . . . . . . . . . 349Power Con<strong>tr</strong>ollersDIN-A-MITE Family. . . . . . . . . . . . . . . . . . . . 351E-SAFE RELAY. . . . . . . . . . . . . . . . . . . . . . . 353SERIES CZR . . . . . . . . . . . . . . . . . . . . . . . . 355Solid State Relays (SSRs) . . . . . . . . . . . . . . 357Application Details. . . . . . . . . . . . . . . . . . . . 361Blow Molding<s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>FIREROD Car<strong>tr</strong>idge Family . . . . . . . . . . . . . 363MI Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364Radiant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368Application Details. . . . . . . . . . . . . . . . . . . . 372Con<strong>tr</strong>ol SystemsCapabilities . . . . . . . . . . . . . . . . . . . . . . . . . 373Packaging<s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377Custom Cast and IFC. . . . . . . . . . . . . . . . . . 378FIREROD Car<strong>tr</strong>idge Family . . . . . . . . . . . . . 379Thick Film . . . . . . . . . . . . . . . . . . . . . . . . . . 380Tubular . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381Application Details. . . . . . . . . . . . . . . . . . . . 383Temperature and Power Con<strong>tr</strong>ollersTemperature and Power Con<strong>tr</strong>oller Overview . 387Resources and InformationConversion Charts . . . . . . . . . . . . . . . . . . . . 389Ohms Law, Application Guide Details. . . . . 395Power Con<strong>tr</strong>ollers. . . . . . . . . . . . . . . . . . . . . 404Con<strong>tr</strong>oller Replacement Guide . . . . . . . . . . 408Wiring Practices. . . . . . . . . . . . . . . . . . . . . . 409Thermocouple and Extension WireColor Codes . . . . . . . . . . . . . . . . . . Back Cover2

W A T L O WIndus<strong>tr</strong>y SegmentOverviewsPlastics ProcessingSelecting the right auxiliary equipmentcan assist the plastics processor'sgoal of higher productivity andgreater yields. It is more than justthe cost of heaters, sensors or con<strong>tr</strong>ollers;it's performance that counts.With Watlow's thermal <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ponentsprocessors can count on less downtimedue to increased heater reliability;and a reduction in operatingcosts due to energy conservation -both of which help achieve greateroutput. Watlow has provided plasticprocessors with product innovationsfor injection molding, thermoformingand ex<strong>tr</strong>usion operations and blowmolding for more than 50 years.Quality, innovation and reliability arethe hallmarks of our family ofheaters, sensors and con<strong>tr</strong>ollers.Watlow provides not only <strong>tr</strong>aditionalthermal solutions, but also innovative,high-performance technologiesto meet the specific processingdemands of indus<strong>tr</strong>ies such as automotive,medical and packaging,requiring highly-engineered resinsand tight tolerances.Whether OEM, custom or captiveprocessor - Watlow has your thermalsolution with our <strong>tr</strong>aditional products,new technologies, engineeringservices and global manufacturingcapabilities.Plastics Processing Indus<strong>tr</strong>yIndus<strong>tr</strong>y Segment Overviews3

Indus<strong>tr</strong>y SegmentOverviewsInjection MoldingInjection molding is the most versatileof all plastics processing methodsand is used to make a wide variety ofproducts. Watlow provides a broadrange of heaters, sensors and con<strong>tr</strong>ollersfor various applications.Applications include:• Automotive• Consumer products• Medical, dental equipment• Small appliances, hand tools• Agricultural, lawn equipment• Containers and closures• Aircraft, aerospace• Personal care products• Computer, business and officeequipment• Elec<strong>tr</strong>ical, elec<strong>tr</strong>onics• Furniture, fixtures• Recreation, toys and sportinggoods• Communications equipment• Food service, institutional products• Packaging• Transportation• Building, cons<strong>tr</strong>uctionProducts like our barrel heaters areideal for highly engineered or filledresins that require higher temperaturesand tighter tolerances.Regardless of your machine tonnage,Watlow has the product to fityour need, such as:• Multiple barrel heaters• Sprue heaters• Temperature con<strong>tr</strong>ollers• Mercury-free power switchingdevices• Temperature sensors4

W A T L O WIndus<strong>tr</strong>y SegmentOverviewsInjection MoldingPlastics Processing Indus<strong>tr</strong>yIndus<strong>tr</strong>y Segment OverviewsHot Runner Nozzle <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• Coiled Cable• FIREROD ® Car<strong>tr</strong>idge• K-RING ®• MI Nozzle Bands• Thick Film Nozzle• THINBAND Mica NozzleHot Runner Manifold <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• FIREROD ® Car<strong>tr</strong>idge• Thick Film Manifold• Tubular Milled GrooveTemperature Sensors• ThermocouplesPower Con<strong>tr</strong>ollers• DIN-A-MITE ® s• E-SAFE ® RELAY• SERIES CZR• Solid State RelaysTemperature Con<strong>tr</strong>ollers• CLS200• PPC-2000• SERIES SD<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• Ceramic Knuckle Bands• MI Bands• THINBAND ® Mica Bands5

Indus<strong>tr</strong>y SegmentOverviewsEx<strong>tr</strong>usionProduct quality begins ups<strong>tr</strong>eam.Regardless of your ex<strong>tr</strong>usion system,Watlow's family of thermal solutionsprovides the high-performance, reliabilityand accuracy needed to optimizeyour process.Whether OEM or end-user, many oftoday's applications require processcon<strong>tr</strong>ol data as well as history documentationto <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ply with variouspolicies and regulations. Manyprocessors proactively seekproducts that offer both <strong>tr</strong>aceabilityand product repeatability. Watlow'sproduct solutions bridge the gap byproviding evidence of overall productquality, assuring processrepeatability and shortening overallstartup time.Watlow has the heaters, sensors andcon<strong>tr</strong>ollers for your ex<strong>tr</strong>usionprocess:• Blown film and cast film• Profile, shapes and rods• Flat sheet and web ex<strong>tr</strong>usion• Wire and cable coating• Pipe tubing and conduit ex<strong>tr</strong>usionApplications include:• Larger diameter band heaters forsingle- or multi-layer blown filmdies• PPC-2000 for advanced ex<strong>tr</strong>usioncon<strong>tr</strong>ol and system rebuilds• High- and low-watt densitycar<strong>tr</strong>idge heaters for a varietyprofile and shape dies• SERIES SD con<strong>tr</strong>ollers withPalm PDA for a low-cost dataacquisition interface• Cast-in and a variety of bandheaters for <strong>tr</strong>aditional barrelheating• S<strong>tr</strong>ip heaters for versatile surfacedie and former heating• A <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>prehensive offering ofmercury-free power con<strong>tr</strong>ollers• Traditional and hand-heldtemperature sensors6

W A T L O WIndus<strong>tr</strong>y SegmentOverviewsEx<strong>tr</strong>usionTemperatureCon<strong>tr</strong>ollers• CLS200• CPC400• MLS300• PPC-2000• SERIES F4• SERIES PD• SERIES SDPower Con<strong>tr</strong>ollers• DIN-A-MITE ® s• E-SAFE ® RELAY• Solid State RelaysPlastics Processing Indus<strong>tr</strong>yIndus<strong>tr</strong>y Segment OverviewsDie and Former <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• Custom Cast and IFC• FIREROD ® Car<strong>tr</strong>idge• K-RING ®• MI S<strong>tr</strong>ip• Mica S<strong>tr</strong>ip• THINBAND ® Mica• TubularTemperature Sensors• Thermocouples• RAYTEK ® Infrared<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• Cast-In Heat/Cool• MI Bands7

Indus<strong>tr</strong>y SegmentOverviewsThermoformingIn recent years, thermoforming partdesign has developed rapidly andbe<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>e more multifaceted. Becausethe thermoforming process offersadvantages such as superior finishedpart quality and the ability to formlarge parts, processors are:• investing in larger and fastermachines• expanding both ups<strong>tr</strong>eam anddowns<strong>tr</strong>eam servicesAlthough thermoforming consists of abroad range of materials, materialthicknesses and processing levels,Watlow can help optimize yourprocess. Whether you require a'sealed face' heater to keep sheet/rollcontaminants away from the elementwhile offering ease-of-cleaning andlonger life, or overall precise processcon<strong>tr</strong>ol, Watlow's family of heater,temperature sensor and con<strong>tr</strong>ollersolutions can meet your needs.Regardless of the application, Watlowhas the solution to meet your need:• <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>- Radiant, S<strong>tr</strong>ip andTubular• Con<strong>tr</strong>ol System Con<strong>tr</strong>ollers-CLS200, CPC400, MLS300,PPC-2000 and SERIES SD/PD• Power Con<strong>tr</strong>ollers- DIN-A-MITE ® ,E-SAFE ® , SERIES CZR andSolid State Relays• Sensors- Infrared non-contact andother Richmond productsApplications include:• Vacuum forming• High definition thermoforming• Pressure assisted thermoforming• Drape forming• Press forming• Line bending8

W A T L O WIndus<strong>tr</strong>y SegmentOverviewsThermoformingTemperature Con<strong>tr</strong>ollers• CLS200 • SERIES D8• CPC400 • SERIES PD• MLS300 • SERIES SD• PPC-2000Power Con<strong>tr</strong>ollers• DIN-A-MITE ® s• E-SAFE ® RELAY• SERIES CZR• Solid State RelayPlastics Processing Indus<strong>tr</strong>yIndus<strong>tr</strong>y Segment Overviews<s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• Radiant• S<strong>tr</strong>ip• Radiant Bandand S<strong>tr</strong>ip EmittersTemperature Sensors• Raytek ® Infrared• Thermocouples9

Indus<strong>tr</strong>y SegmentOverviewsBlow MoldingBlow molding is the art and scienceof making the hollow plastic containersthat are indispensable parts ofeveryday life. Common processingtechniques such as ex<strong>tr</strong>usion, s<strong>tr</strong>etchblow, injection and co-ex<strong>tr</strong>usion areall utilized in forming these parts.Whether it is a diverse and <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>plexpart that requires high performancesuch as an elastically functionalautomotive <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ponent; or ahigh-volume hollow piece such asa single-serve PET water bottle, thefront-end blow molding process stillrequires an exacting thermal solution.Regardless of your resin choice orfinal part shape, Watlow has anextensive offering of heaters, sensorsand con<strong>tr</strong>ollers to meet the applicationrequirements.Applications include:• Automotive <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ponents• Double-walled cases and tonercar<strong>tr</strong>idges• Food and beverage packaging• Medical feeding containers• Specialty consumer containers for:• Personal care products• Household products• Aggressive chemicals• Sporting goods• Toys10

W A T L O WIndus<strong>tr</strong>y SegmentOverviewsBlow MoldingPlastics Processing Indus<strong>tr</strong>yIndus<strong>tr</strong>y Segment OverviewsBand <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• FIREROD ® Car<strong>tr</strong>idge<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>• MI Bands• Mica Bands• Radiant• THINBAND ®Temperature Con<strong>tr</strong>ollers• CLS200• CPC400• MLS300• PPC-2000• SERIES D8• SERIES PD• SERIES SDPower Con<strong>tr</strong>ollers• DIN-A-MITE ® s• E-SAFE RELAY• SERIES CZRCommunications• Ethernet• DeviceNetTemperature Sensors• Thermocouples• Heat/Cool Cast-Ins• MI Bands• Mica Bands• Radiant• THINBAND ® Mica Bands11

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Watlow’s Familyof <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> HeaterSolutionsWatlow offers a full line of barrelheaters for the plastics indus<strong>tr</strong>y.While every Watlow heater has aunique set of qualities, each Watlowbarrel heater is designed with theneeds of plastics processors in mind.Whether you require high performance,high temperature, high wattdensity, or all of these, Watlow hasthe heater to best fit your application.Watlow’s family of barrel heatersinclude:• Ceramic knuckle heaters• MI band heaters• THINBAND ® mica heatersThese barrel heaters are ideallysuited to meet the demands oftoday’s new resins and provide awide range of benefits including:• High performance materials suchas Watlow’s exclusive mineralinsulation and high temperatureceramics which con<strong>tr</strong>ibute toexcellent insulation and longheater life• Aluminized and stainless steelsheaths resulting in corrosionresistance• Flexible designs ensuring easyinstallation and removalApplications• Injection molding machines• Ex<strong>tr</strong>usion equipment• Blown film dies<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Heater Termination andClamping OptionsTermination OptionsWatlow offers a large selection oftermination styles providing theopportunity to customize the heaterto a particular application forimproved performance. Some terminationchoices include, but are notlimited to, Post Terminals, StainlessSteel Braids, Flexible Lead Wire,Flexible Stainless Steel Hose andEuropean Style Plugs (Horizontaland Vertical).Clamping OptionsIn addition to Watlow’s offering ofvarious termination styles, we alsooffer a variety of clamping options.Some of these clamping options are,but are not limited to, Tig Welded<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Nuts, Low Profile Clamp Bars,Clamping Pads and HV Wedge-Lok.For more information on Watlow’sline of barrel heaters, contact yourlocal Watlow representative.Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>13

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Ceramic KnuckleBandCeramic knuckle band heaters aredesigned to provide high-performancebarrel heating at temperaturesup to 760°C (1400°F). This level ofperformance is achieved from theceramic knuckles that provide excellentinsulation and long heater life.The cons<strong>tr</strong>uction of the ceramicknuckle heater includes interlockingceramic blocks with resistance wiresthreaded through holes within theceramic. This method providessuperior heat dis<strong>tr</strong>ibution across theband, resulting in a uniformly heatedsurface. Ceramic knuckle heatersare specifically engineered andmanufactured with three layers:• Aluminized steel sheath layerimproves mechanical protectionto heater and resists corrosion.• Ceramic fiber layer providesthermal insulation, energy conservationand minimizes heat loss.• Ceramic knuckle layer providesmechanical protectionand elec<strong>tr</strong>ical insulation to theresistance element, whichincreases heater life and conductsor radiates the heat tothe surface.Performance Capabilities• 760°C (1400°F) maximumoperational temperatures• Watt densities up to 45 W/in 2Features and BenefitsCeramic insulator• Allows for high temperatureoperation• Provides longer heater life• Accurate heatingAluminized steel cover• Provides excellent protection fromabrasionRadiation or conduction heat<strong>tr</strong>ansfer• Ensures dependable heat <strong>tr</strong>ansfermethodStandard Cons<strong>tr</strong>uction• Aluminized sheath• Clamp tabs• Post terminalsApplications• Injection molding barrels• Ex<strong>tr</strong>uder barrels• Blown film dies14

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Ceramic KnuckleBandSpecificationsElec<strong>tr</strong>icalResistance tolerance: -10 percent (+5 percent)Wattage tolerance: +10 percent (-5 percent)Maximum watt density: 114 W/cm 2 (45 W/in 2 )Maximum operating temperature: 760°C (1400°F)Termination OptionsMechanicalOverall thickness: 12.7 mm (0.5 in.)Minimum width: 38.1 mm (1.5 in.)Maximum width: 246 mm (9.69 in.)Minimum I.D.: 50.8 mm (2 in.)Maximum I.D.: 381 mm (15 in.)*Width tolerance: ±3.175 mm (0.125 in.)Standard gap: 6.35 mm (0.25 in.)*One piece cons<strong>tr</strong>uctionInjection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Post Terminals are the standard termination, providingquick connection with ring or fork connectors or busss<strong>tr</strong>ips, 1 ⁄4 -20 inch thread and includes double nuts andwashers. Standard terminal location is 180° from gap.Stainless Steel Braid method includes a loose metalbraid that is welded to the terminal box with a coupler.This provides excellent abrasion protection and flexibility.Leads are attached to posts with ring connectors.Flexible Lead Wire exits tangential to heater and includesleads connected to the post terminals with ring connectors.This termination method requires a terminal box.Note: These are all standard termination options, for special cons<strong>tr</strong>uctionsplease consult factory.Flexible Stainless Steel Hose is welded to the terminalbox with a coupler. This terminal option provides superiormechanical protection where lead abrasion is a problem.Leads are attached to posts with ring connectors.15

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Ceramic KnuckleBandClamping OptionsEuropean Style Plugs provide a simple and safe way toapply power. The <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>bination of high temperature maleand female quick disconnect plug assemblies eliminateall live exposed terminals and elec<strong>tr</strong>ical wiring. Whenordering, specify vertical or horizontal European Plug.Vertical<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Clamps are used in applicationswhere access for ins<strong>tr</strong>umentationis required. Includes an oversized gap.HorizontalSpring Loaded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Clamps helpto <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>pensate for the thermalexpansion of metals.Clamp Tabs are a standard clampingoption that offer a uniform clampingforce across the heater width.Latch And Trunion Clamps providea quick clamp option. Clamping forceis similar to barrel clamps and aspring is included to allow for thermalexpansion of metals.16Physical LimitationsOptions I.D. Width Terminals ClampMin. Max. Min. Max.mm (in.) mm (in.) mm (in.) mm (in.)One piece 64 (2.5) 381 (15) 38 (1.5) 254 (10) — —Partial 178 (7) — — 38 (1.5) 248 (9.75) — Exceptcoverageclamp tabsClamp tabs 64 (2.5) 381 (15) 38 (1.5) 254 (10) — —<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> nuts 102 (4) — — 38 (1.5) 254 (10) — —Spring loaded 102 (4) — — 38 (1.5) 254 (10) — —barrel nutsLatch and 76 (3) — — 38 (1.5) 254 (10) — —<strong>tr</strong>union clampsStud terminals — — — — — — 254 (10) — —Flexible leads 64 (2.5) — — 64 (2.5) 254 (10) — —SS hose leads 64 (2.5) — — 64 (2.5) 254 (10) — —SS braided 64 (2.5) — — 64 (2.5) 254 (10) — —leadsTerminal box 64 (2.5) — — 64 (2.5) 254 (10) — —Holes and 64 (2.5) — — 64 (2.5) 254 (10) — —notchesCeramic cover 51 (2) — — 38 (1.5) 254 (10) Post —Terminal 76 (3) — — 64 (2.5) 248 (9.75) Post with —clampterminal boxEuropean Plug 64 (2.5) — — 51 (2) 254 (10) — —both verticaland horizontal— No res<strong>tr</strong>ictions.Note: These are all standard clamping options, for special cons<strong>tr</strong>uctionsplease consult factory.

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Ceramic KnuckleBandOptions:Terminal box provides protection forelec<strong>tr</strong>ical connections in hazardousenvironments.Partial coverage helps heating oflarge pipes and covers large diameterswith two or more sections.Dimensional drawings are requiredwhen ordering.T/C bracket 3 ⁄8 NPT necessary forins<strong>tr</strong>umentation. A dimensionaldrawing is required when ordering.Holes and notches necessary forins<strong>tr</strong>ument access, etc. Heater mustbe 63.5 mm (2.5 in.) minimum widthand 63.5 mm (2.5 in.) minimum I.D.;dimensional drawing required whenordering.Ceramic terminal covers provideeasy installation and protect elec<strong>tr</strong>icalconnections on each individualterminal.Other Options:• Dual voltage (factory approvalrequired)• Stainless steel sheath• Ground stud• Ground lead• Three-phase voltage (factoryapproval required)Ceramic Band Heater Check List:• The surface where a heater willbe mounted must be clean andthe heater maintained free of allcontaminants that might causea short circuit in the heater(typically conductive liquids).• To prevent overheating, Watlowre<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mends installing an appropriatetemperature con<strong>tr</strong>oller andchecking the correct performanceof the thermocouple.• Do not use in environmentscontaining <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>bustible gasesor vapors.• Keep all elec<strong>tr</strong>ical connectionsproperly protected to avoidelec<strong>tr</strong>ical hazards to machineoperators.• Do not over tighten clamps to thepoint where serrated side foldsbegin to collapse. Ceramic bandheaters utilize radiation heatingand excessive force may breakceramic insulators.Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>17

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI BandApplications andTechnical Data• Review Watt Density chart onpage 20 to ensure that theapplication does not exceed themaximum watt density atoperating temperature afterapplying derating factors.• Locate clamping guideline for unitdiameter, width and watt density.• Description of guideline lettersare below.• Note: Upward arrows are up toand not including specified wattdensity. Downward arrows aregreater than or equal to specifiedwatt density.MI <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Clamping Ma<strong>tr</strong>ix Application GuideDia.8 > 10 10 > 12 12 > 14 14 > 16 16 > 18 18 > 20 20 > 22 22 > 24 24 > 26 26 > 28Watt Density–W/in 28075706560555045403530252015100Width1 1 2 in. 4 1 2 in.to 4in.BAto 7in.BA1 1 2 in.to 4in.BA4 1 2 in.to 7in.BA1 1 2 in.to 4in.BA4 1 2 in.to 7in.BA1 1 2 in.to 4in.DC4 1 2 in.to 7in.DC1 1 2 in. 4 11 2 in. 1 1 2 in. 4 1 2 in.to 4in.DCto 7in.to 4in.to 7in.1 1 2 in.to 4in.4 1 2 in.to 7in.1 1 2 in.to 4in.4 1 2 in.to 7in.Above Re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mended Watt DensitiesConsult EngineeringA = Standard clamping, expandable or one piece cons<strong>tr</strong>uction Width Clamp Points at Each GapB = Spring clamps, expandable or one piece cons<strong>tr</strong>uction ≥ 127 mm (5 in.) 3C = Spring clamps, at one gap, welded barrel nuts at other gap ≥ 76.2 mm (3 in.) 2D = Spring clamps, spring clamps at both gaps < 76.2 mm (3 in.) 1DCDCDCDCDCDCDC1 1 2 in.to 4in.DC4 1 2 in.to 7in.DC1 1 2 in.to 4in.DC4 1 2 in.to 7in.DCInjection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI Installation Procedures - For Standard Product1.Install heaters over a cleansurface.2.After installing the unit, begin totighten the clamp screw. Thestandard clamping screw is6.35 mm-508 x 31.75 mm(0.25 in.-20 x 1.25 in.), nickelplated allen head cap screw.Begin tightening the clamp bars.If the clamp bars appear not tohave seated, tap the clamp barswith a small hammer to insure thebars are well seated in the angleformed by the 60 degree bent taband the heater.3.If the bar has multiple screws,alternately tighten the screws at10 lb-in. as you would the lug nutson a car wheel to insure evenloading.4.Torque all screws toapproximately 80 lb-in. (9-N-M).5.When installing terminal lugs,torque the top nuts to 15-20 lb-in.or 2.26 N meters.21

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI BandTermination VariationsLeads Type B, Type B—90 degreeRotation,Type B—180 degreeRotation or Type C: Two fiberglassinsulatedlead wires exit in a singlemetal braid for good abrasionprotection, lead flexibility and wiringconvenience. Leads are 51 mm(2 in.) longer than braid. Shippedwith 305 mm (12 in.) leads, unlesslonger length is specified. To order,specify type and length.Type BStock17 mm(0.67 in.)9 mm(0.36 in.)I.D.32 mm(1.250 in.)305 mm(12 in.)4 mm(0.16 in.)21 mm(0.812 in.)Width ± . 1.6 mm(0.0625 in.)Type B—90 Degree RotationNon-Stock9 mm(0.36 in.)16 mm(0.625 in.)Nom.Type B—180 Degree RotationStock17 mm(0.67 in.)Type CStock4.90 mm(0.191 in.)9 mm(0.36 in.)I.D.32 mm(1.250 in.)16.70 mm Dia.(0.656 in.)14.10 mm(0.557 in.)4 mm(0.16 in.)21 mm(0.812 in.)Width ± 1.6 mm(0.0625 in.)305 mm(12 in.)19.05 mm Nom.(0.75 in.)I.D.Post TerminalsStockType EStockType FStock19 mm(0.75 in.)I.D.4 mm(0.16 in.)16 mm (0.625 in.)Nom.4.90 mm(0.191 in.)16.70 mm Dia.(0.656 in.)16.10 mm(0.635 in. )19.05 mm Nom.(0.75 in. )4.90 mm(0.191 in.)16.70 mm Dia.(0.656 in.)16.10 mm(0.635 in.)19.05 mm Dia.(0.75 in.)17 mm(0.67 in.)I.D.I.D.2232 mm(1.250 in.)Width ± 1.6 mm(0.0625 in.)Post terminals provide optimumconnections. Screw thread is 10-24.To order, specify post terminals.Type KStock4.90 mm(0.191 in.)I.D.16.70 mm Dia.(0.656 in.)14.10 mm(0.557 in.)19.05 mm Nom.(0.75 in.)Type K: Flexible lead wires exit verticallyfrom the heater. These leadscan be bent adjacent to the heaterfor a quick and easy connection. Toorder, specify Type K and length.Type E: Loose metal braid enclosestwo fiberglass leads for goodabrasion protection, lead flexibilityand wiring convenience. Leads are51 mm (2 in.) longer than braid.Shipped with 305 mm (12 in.) leads,unless longer length is specified. Toorder, specify Type E and length.Type HStock4.90 mm(0.191 in.)I.D.16.70 mm Dia.(0.656 in.)16.10 mm(0.635 in.)19.05 mm Nom.(0.75 in.)Type F: Loose fiberglass sleevingencloses two fiberglass leads foradditional insulation protectionwhere high temperature or minorabrasion is present. Leads are51 mm (2 in.) longer than thesleeving. To order, specify Type Fand length.Type H: A flexible steel hoseencloses the leads for maximumabrasion protection. Leads are51 mm (2 in.) longer than hose.Shipped with 305 mm (12 in.) leads,unless longer length is specified. Toorder, specify Type H and length.

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI BandVariationsLead Wire<s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> rated at less than250VÅ(ac) use UL ® approved leadinsulation for operations to 250°C(480°F) as standard. Lead insulationUL ® rated for operation to 450°C(840°F) is available for hightemperature applications where theleads are shrouded or enclosed withthe heater. These leads are availablein any of the Type B with loose braidas well as Types E, F and H leadconfigurations. All heaters rated atmore than 250VÅ(ac) use this wire.When ordering, specify 450˚C(850°F) wire.ThermocoupleASTM Type J or K internal thermocouplesare available on lead Type Bwith loose braid. The thermocouplejunction, which is welded inside thelead cap or spot-welded to heatersheath, provides a signal for measuringrelative heater temperature.Spot welded toheater sheathInjection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Expandable <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> With and Without Leads38 mm (1.5 in.) wideand greaterExpandable heaters are two-pieceunits with a <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mon top metal thatallows the heater to expand open tothe full diameter of the barrel. Onexpandable bands, each half will beone half of the total wattage. Plus,on both expandable and two-piecebands, each half will be rated at fulloperating voltage, unless otherwisespecified.MI Band heaters 38 mm (1.5 in.)wide or greater will have postterminals located next to theexpansion joint. Leads may belocated anywhere along thecircumference except near the gapand at the expansion joint. Two setsof leads are required.On 25 mm (1 in.) wide MI Bandheaters, post terminals will belocated 90 degrees from theexpansion joint. Leads may belocated anywhere along thecircumference except near the gapand at the expansion joint. Two setsof leads are required. To order,specify expandable.11 mm(0.4375 in.)S<strong>tr</strong>ain ReliefType SLETwo fiberglass lead wires exit asingle tightly woven metal braid a<strong>tr</strong>ight angle on the expandablecons<strong>tr</strong>uction verses two sets ofleads. Minimum diametercapabilities is 100 mm (4 in.).Minimum width capabilities is38 mm (1.5 in.). To order, specifyType SLE and length.UL ® is a registered <strong>tr</strong>ademark ofUnderwriter's Laboratories, Inc.23

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI BandVariationsContinued57 mm(2.25 in.)41 mm(1.625 in.)46 mm(1.8125 in.)33 mm(1.3125 in.)102 mm(4 in.)51 mm(2 in.)High Temperature “Quick Disconnect” European Style PlugsThese plugs provide the simplestand safest way to apply power tobarrel heaters. The <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>bination ofhigh temperature male and femalequick disconnect plug assemblieseliminates all live exposed terminalsand elec<strong>tr</strong>ical wiring that can be apotential hazard to employees ormachine. Maximum 15 amps at240VÅ(ac), maximum volts 240. Toorder, specify vertical or horizontalEuropean Plug.VerticalHorizontalHigh Temperature “Quick Disconnect” European Style Female AdaptersAvailable as an accessory item thatmust be used in conjunction withhigh temperature “quick disconnect”European Style Plugs. To order,specify code number N2027AF049or N6027ZZ028 and quantity.Right AngleCode# N6027AF049S<strong>tr</strong>aightCode# N6027ZZ0286.4 mm(0.250 in.)Heavy Duty S<strong>tr</strong>ain ReliefHeavy duty s<strong>tr</strong>ain relief isre<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mended for applicationswhere there is great s<strong>tr</strong>ess orcontinued flexing of the leads.The s<strong>tr</strong>ain relief is available onType B, Type B—90 degree andType B—180 degree leads only. Toorder, specify heavy duty s<strong>tr</strong>ainrelief.Ceramic Terminal CoverCeramic covers, with openingsfor leads, are screwed on to postterminals, providing a convenient,economical insulator. To order,specify code number Z-4918 andquantity.46 mm(1.8125 in.)3.5 in. for 3.5-5.9375 in. I.D.4 in. for 6-28 in. I.D.37 mm(1.4375 in.)Metallic Terminal BoxMetallic terminal boxes are availablefrom stock on 89 mm x 38 mm(3.5 in. inside diameter x 1.5 in. wide)or larger heaters. Terminal boxes,which attach directly to the heater, actas a safety feature by covering theterminals. Conduit may be attachedto the box through 22 mm (0.875 in.)diameter holes in the ends of the box.Two piece heaters require two boxes.To order, specify terminal box.Oversized terminal boxes areavailable on heaters 51 mm (2 in.)and wider. Consult a Watlowrepresentative.24

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI BandVariationsContinuedMI Band Heater With HolesMI Band heaters with holes areavailable on all widths except25.4 mm (1 in.) wide. Consult theWatlow factory in St. Louis, Missourifor hole sizes and location res<strong>tr</strong>aints.To order, specify hole size andlocation. 76.2 mm (3 in.) insidediameter minimum.11 mm(0.420 in.)22 mm(0.875 in.)Clamping VariationsOutside Diameter HeaterTwo fiberglass insulated lead wiresrated to 450°C (840°F) exit a metalbraid 180 degrees opposite fromgap, Type B outside diameterdesigned and cons<strong>tr</strong>ucted to mateTig Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Nuts With Spring Loaded Clampingwith inside diameter of cylinders.To order, specify outside diameterheater. Note that 76.2 mm (3 in.) isthe minimum cylinder I.D.Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>147 mm (5.8 in.)19 mm(0.75 in.)Welded barrel nuts with springloaded clamping are used duringstart-up to maintain a tight heater fiton large barrels. This clampingvariation is standard for all MI <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong>heaters that are greater than355 mm (14 in.) in diameter and38 mm (1.5 in.) or greater in width.Refer to MI <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Clamping Ma<strong>tr</strong>ixApplication Guide, page 21. Forsmaller diameter heaters, this isan option and must be orderedseparately. To order, specify springloaded clamping.Tig Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> NutsTig Welded14 mm(0.563 in.)An ideal way to provide accessfor ins<strong>tr</strong>umentation is to specify anoversized gap between the heaterends. If the clamp bar screwinterferes with the positioning ofthe ins<strong>tr</strong>umentation device, weldedbarrel nuts are re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mended. Toorder, specify tig welded barrelnuts and gap dimension whenordering.Low Profile Tig Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> NutsLow profile barrel nuts are availableon all widths. Low profile barrel nutshave a clearance of 10 mm(0.406 in.). To order, specify lowprofile tig welded barrel nuts.Low Profile Clamp Bars11 mm(0.45 in.)I.D.Low profile clamp bars are availableon both one 25 mm (1 in.) and38 mm (1.5 in.) wide heaters, forwider widths consult factory. Thebars are 6 mm (0.25 in.) diameterwith an 8-32 screw. To order, specifylow profile clamp bars.25

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI BandMI Stock ProductWattApprox.I.D. Width Cons<strong>tr</strong>uction Volts Watts Density Termination Net. Wt. Avail. Code No.mm (in.) mm (in.) W/cm 2 (W/in 2 ) kg (lbs)25.4 (1) 25.4 (1) 1pc 120 100 9.4 (61) Type B,C,E or H 0.05 (0.1) Stock MB1A1AN225.4 (1) 1pc 120 150 14.2 (92) Type B,C,E or H 0.05 (0.1) Stock MB1A1AN125.4 (1) 1pc 120 200 18.9 (122) Type B,C,E or H 0.05 (0.1) Stock MB1A1AN325.4 (1) 1pc 240 200 18.9 (122) Type B,C,E or H 0.05 (0.1) Stock MB1A1AN438.1 (1 1 ⁄2) 1pc 120 200 10.8 (70) Type B,C,E or H 0.05 (0.1) Stock MB1A1JN438.1 (1 1 ⁄2) 1pc 240 200 10.8 (70) Type B,C,E or H 0.05 (0.1) Stock MB1A1JN338.1 (1 1 ⁄2) 1pc 120 300 16.4 (106) Type B,C,E or H 0.05 (0.1) Stock MB1A1JN238.1 (1 1 ⁄2) 1pc 240 300 16.4 (106) Type B,C,E or H 0.05 (0.1) Stock MB1A1JN138.1 (1 1 ⁄2) 1pc 240 400 21.8 (141) Type B,C,E or H 0.05 (0.1) Stock MB1A1JN531.8 (1 1 ⁄4) 25.4 (1) 1pc 120 250 16.1 (104) Type B,C,E or H 0.05 (0.1) Stock MB1E1AN225.4 (1) 1pc 240 250 16.1 (104) Type B,C,E or H 0.05 (0.1) Stock MB1E1AN125.4 (1) 1pc 240 300 19.2 (124) Type B,C,E or H 0.05 (0.1) Stock MB1E1AN338.1 (1 1 ⁄2) 1pc 120 350 13.5 (87) Type B,C,E or H 0.09 (0.2) Stock MB1E1JN238.1 (1 1 ⁄2) 1pc 240 350 13.5 (87) Type B,C,E or H 0.09 (0.2) Stock MB1E1JN138.1 (1 1 ⁄2) 1pc 240 450 17.3 (112) Type B,C,E or H 0.09 (0.2) Stock MB1E1JN331.8 (1 1 ⁄4) 25.4 (1) 1pc 120 200 9.6 (62) Type B,C,E or H 0.05 (0.1) Stock MB1J1AN425.4 (1) 1pc 240 200 9.6 (62) Type B,C,E or H 0.05 (0.1) Stock MB1J1AN325.4 (1) 1pc 120 300 14.4 (93) Type B,C,E or H 0.05 (0.1) Stock MB1J1AN225.4 (1) 1pc 240 300 14.4 (93) Type B,C,E or H 0.05 (0.1) Stock MB1J1AN125.4 (1) 1pc 240 400 19.3 (125) Type B,C,E or H 0.05 (0.1) Stock MB1J1AN538.1 (1 1 ⁄2) 1pc 120 300 9.0 (58) Type B,C,E or H 0.09 (0.2) Stock MB1J1JN138.1 (1 1 ⁄2) 1pc 240 300 9.0 (58) Type B,C,E or H 0.09 (0.2) Stock MB1J1JN338.1 (1 1 ⁄2) 1pc 240 300 10.0 (64) Post 0.09 (0.2) Stock MB1J1JP438.1 (1 1 ⁄2) 1pc 240 450 13.5 (87) Type B,C,E or H 0.09 (0.2) Stock MB1J1JN238.1 (1 1 ⁄2) 1pc 240 450 14.8 (96) Post 0.09 (0.2) Stock MB1J1JP638.1 (1 1 ⁄2) 1pc 240 600 17.9 (116) Type B,C,E or H 0.09 (0.2) Stock MB1J1JN450.8 (2) 1pc 240 300 6.5 (42) Type B,C,E or H 0.14 (0.3) Stock MB1J2AN250.8 (2) 1pc 240 450 8.8 (57) Type B,C,E or H 0.14 (0.3) Stock MB1J2AN150.8 (2) 1pc 240 900 19.3 (125) Type B,C,E or H 0.14 (0.3) Stock MB1J2AN376.2 (3) 1pc 240 350 4.8 (31) Type B,C,E or H 0.18 (0.4) Stock MB1J3AN276.2 (3) 1pc 240 500 7.0 (45) Type B,C,E or H 0.18 (0.4) Stock MB1J3AN176.2 (3) 1pc 240 1000 16.1 (104) Type B,C,E or H 0.18 (0.4) Stock MB1J3AN3CONTINUED26

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>MI BandWattApprox.I.D. Width Cons<strong>tr</strong>uction Volts Watts Density Termination Net. Wt. Avail. Code No.mm (in.) mm (in.) W/cm 2 (W/in 2 ) kg (lbs)44.5 (1 3 ⁄4) 38.1 (1 1 ⁄2) 1pc 120 300 7.7 (50) Type B,C,E or H 0.09 (0.2) Stock MB1N1JN238.1 (1 1 ⁄2) 1pc 240 300 7.3 (47) Type B,C,E or H 0.09 (0.2) Stock MB1N1JN138.1 (1 1 ⁄2) 1pc 240 700 17.0 (110) Type B,C,E or H 0.09 (0.2) Stock MB1N1JN350.8 (2) 1pc 240 750 13.3 (86) Type B,C,E or H 0.14 (0.3) Stock MB1N2AN150.8 (2) 25.4 (1 1 ⁄2) 1pc 120 350 11.3 (73) Type B,C,E or H 0.09 (0.2) Stock MB2A1AN225.4 (1 1 ⁄2) 1pc 240 350 11.3 (73) Type B,C,E or H 0.09 (0.2) Stock MB2A1AN125.4 (1 1 ⁄2) 1pc 240 450 14.5 (94) Type B,C,E or H 0.09 (0.2) Stock MB2A1AN338.1 (1 1 ⁄2) 1pc 240 400 8.2 (53) Type B,C,E or H 0.14 (0.3) Stock MB2A1JN138.1 (1 1 ⁄2) 1pc 240 1000 20.4 (132) Type B,C,E or H 0.14 (0.3) Stock MB2A1JN250.8 (2) 1pc 240 750 11.3 (73) Type B,C,E or H 0.18 (0.4) Stock MB2A2AN150.8 (2) 1pc 240 1200 19.3 (125) Type B,C,E or H 0.18 (0.4) Stock MB2A2AN257.2 (2 1 ⁄4) 63.5 (2 1 ⁄2) 1pc 240 1000 11.2 (72) Type B,C,E or H 0.23 (0.5) Stock MB2E2JN163.5 (2 1 ⁄2) 25.4 (1) 1pc 240 400 9.7 (63) Type B,C,E or H 0.09 (0.2) Stock MB2J1AN138.1 (1 1 ⁄2) 1pc 240 500 7.7 (50) Type B,C,E or H 0.18 (0.4) Stock MB2J1JN176.2 (3) 25.4 (1) 1pc 240 400 8.4 (54) Post 0.14 (0.3) Stock MB3A1AP138.1 (1 1 ⁄2) 1pc 240 500 6.2 (40) Post 0.18 (0.4) Stock MB3A1JP138.1 ( 1 ⁄2) 2pc exp 230/460 525 8.2 (53) Post 0.18 (0.4) Stock ME3A1JP1088.9 (3 1 ⁄2) 50.8 (2) 1pc 240 800 6.5 (42) Post 0.32 (0.7) Stock MB3J2AP292.1 (3 5 ⁄8) 38.1 (1 1 ⁄2) 2pc exp 230/460 650 7.9 (51) Post 0.23 (0.5) Stock ME3L1JP5101.6 (4) 38.1 (1 1 ⁄2) 2pc exp 230/460 625 6.7 (43) Post 0.27 (0.6) Stock ME4A1JP1138.1 (1 1 ⁄2) 2pc exp 230/460 725 7.8 (50) Post 0.27 (0.6) Stock ME4A1JP1238.1 (1 1 ⁄2) 1pc 240 800 7.4 (48) Post 0.27 (0.6) Stock MB4A1JP2114.3 (4 1 ⁄2) 63.5 (2 1 ⁄2) 1pc 240 1250 6.2 (40) Post 0.45 (1.0) Stock MB4J2JP1127.0 (5) 38.1 (1 1 ⁄2) 2pc exp 240/480 1000 8.1 (52) Post 0.36 (0.8) Stock ME5A1JP8133.4 (5 1 ⁄4) 38.1 (1 1 ⁄2) 2pc exp 230/460 600 4.5 (29) Post 0.32 (0.7) Stock ME5E1JP938.1 (1 1 ⁄2) 2pc exp 240/480 1000 7.4 (48) Post 0.36 (0.8) Stock ME5E1JP176.2 (3) 2pc exp 230/460 1700 6.2 (40) Post 0.68 (1.5) Stock ME5E3AP5139.7 (5 1 ⁄2) 38.1 (1 1 ⁄2) 2pc exp 240/480 1000 7.1 (46) Post 0.40 (0.9) Stock ME5J1JP1152.4 (6) 38.1 (1 1 ⁄2) 2pc exp 240/480 1000 6.4 (41) Post 0.40 (0.9) Stock ME6A1JP2165.1 (6 1 ⁄2) 38.1 (1 1 ⁄2) 2pc exp 240/480 1250 7.3 (47) Post 0.45 (1.0) Stock ME6J1JP5171.5 (6 3 ⁄4) 38.1 (1 1 ⁄2) 2pc exp 230/460 815 4.5 (29) Post 0.40 (0.9) Stock ME6N1JP638.1 (1 1 ⁄2) 2pc exp 230/460 1000 5.6 (36) Post 0.40 (0.9) Stock ME6N1JP7101.6 (4) 2pc exp 230/460 2600 5.4 (35) Post 1.1 (2.5) Stock ME6N4AP2127.0 (5) 2pc exp 230/460 3700 6.2 (40) Post 1.5 (3.2) Stock ME6N5AP3152.4 (6) 2pc exp 230/460 3750 5.1 (33) Post 1.7 (3.8) Stock ME6N6AP5177.8 (7) 38.1 (1 1 ⁄2) 2pc exp 240/480 1250 6.6 (43) Post 0.50 (1.1) Stock ME7A1JP4190.5 (7 1 ⁄2) 38.1 (1 1 ⁄2) 2pc exp 240/480 1500 7.3 (47) Post 0.50 (1.1) Stock ME7J1JP4193.7 (7 5 ⁄8) 76.2 (3) 2pc exp 230/460 1800 4.3 (28) Post 1.0 (2.2) Stock ME7L3AP1203.2 (8) 38.1 (1 1 ⁄2) 2pc exp 240/480 1250 5.7 (37) Post 0.54 (1.2) Stock ME8A1JP4228.6 (9) 38.1 (1 1 ⁄2) 2pc exp 240/480 1500 6.0 (39) Post 0.64 (1.4) Stock ME9A1JP1241.3 (9 1 ⁄2) 76.2 (3) 2pc exp 230/460 3000 5.7 (37) Post 1.2 (2.6) Stock ME9J3AP2285.8 (11 1 ⁄4) 76.2 (3) 2pc exp 230/460 2400 3.7 (24) Post 1.5 (3.2) Stock ME11E3AP2127.0 (5) 2pc exp 230/460 5100 4.8 (31) Post 2.4 (5.2) Stock ME11E5AP1Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>How to OrderTo order your stock MI Bandheater, specify:• Quantity• Watlow code number• Options• Lead type and length, orterminal type configuration(If code number has an “N” asthe last letter in the code, youmust specify termination typeand lead length. 305 mm (12 in.)leads will be supplied unlessotherwise specified).AvailabilityStock: Same day shipment onMI Band heaters with post terminalsor 305 mm (12 in.)Type B leads. Longer lead lengthsor other terminations will ship nextday.Made-to-order: If stock units do notmeet application needs, Watlowcan manufacture MI Band heatersto special requirements. Pleaseconsult a Watlow sales engineer orauthorized dis<strong>tr</strong>ibutor.27

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandFor over 80 years, Watlow has beensolving <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>plex and unique applicationproblems with standard micaband heaters. Watlow is continuouslyimproving design and applicationknowledge through engineeringexpertise and experience withnumerous OEM and end-userapplications.This has resulted in the developmentof many specialty variations incons<strong>tr</strong>uction resulting in the bestheat solutions. This catalog containsa sampling of what can be done.Please contact a local Watlow salesengineer or dis<strong>tr</strong>ibutor for customapplications.Performance Capabilities• Sheath temperatures to 480°C(900°F)• Watt densities to 7.0 W/cm 2(4.5 W/in 2 )Features and Benefits• UL ® <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ponent recognitionavailable for applications up to480°C (900°F) sheath temperature.• Patented clamping s<strong>tr</strong>ap assuresefficient heat <strong>tr</strong>ansfer.• Low mass design allows fastheat-up and quick response.• Design variations provide userconvenience and heaterprotection.Applications• Injection molding barrels• Ex<strong>tr</strong>udersSS S<strong>tr</strong>apResistance RibbonMica InsulationZinc SteelPost Terminals28

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandApplications andTechnical DataOperating FactorsUse as a low watt density rating as theapplication permits. A close match ofthe heat supplied to the actual requirementswill reduce temperature overshoot,reduce cycling and increase thelife of any band heater used.Calculate the safe maximum wattagefor the heater using:Heated Area x MaximumWatt DensityCalculate the heated area of the bandheater by sub<strong>tr</strong>acting the no-heat areafrom the total area in contact with thecylinder (3.14 x I.D. x width). Sub<strong>tr</strong>actthe no-heat area at the terminals(from table) and any additionalno-heat area caused by holes, slotsor oversize gaps.Determine the maximum watt densityof the heater from the graph on thispage. The curves are based onnarrow heaters mounted on a smooth,steel cylinder. Apply the necessarycorrection factors:• For heaters 57 mm (2.25 in.) to127 mm (5 in.) wide, multiply wattdensity by 0.8.• For high expansion cylinders(aluminum or brass), reduce thewatt density by 0.46 W/cm 2 (3 W/in 2 ).• For heaters 63.5 to 127 mm (2.25 in.to 5 in.) wide installed on a highexpansion cylinder, reduce wattdensity by a total of 0.46 W/cm 2(3 W/in 2 ) only.• For regular cylinder surfaces otherthan smooth, machined finish,reduce watt density by 0.46 W/cm 2(3 W/in 2 ).• For heaters that will be insulatedor enclosed, contact Watlow forspecific watt densities.No-Heat Area for Special Mica Band (Post Terminals)Heater SizeNo-Heat AreaHeater Diameter Width at TerminalsType mm (in.) mm (in.) mm (in.)One PieceTwo PieceCylinder Temperature—°F1100100090080070060050040030050.8 (Less than 2) 152.4 (Up to 6) 25.4 (1 x width)50.8 (2 or more)76.2 (3 or more)76.2 (Up to 3) 38.1 (1.5 x width)76.2 (More than 3) 25.4 (1 x width)76.2 (Up to 3) 76.2 (3 x width)76.2 (More than 3) 50.8 (2 x width)Maximum Allowable Watt DensityWatt Density—W/cm 22 4 6 8254 mm (10 in.) Dia.10020010 20 30 40 50 60Watt Density—W/in 276.2 mm (3 in.) Dia.500400300200Cylinder Temperature—°CInjection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>29

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandPhysical Limitations ofVariationsCheck the table to be certain thevariations and lead arrangementsbeing ordered are available on theheater size required. If you need toexceed any limitations please contacta Watlow representative.Physical Limitations of VariationsDiameterWidthHeater Type Min. Max. Min. Max.mm (in.) mm (in.) mm (in.) mm (in.)1 pc. 33.3 (1 5 ⁄16) 559 (22) 15.8 ( 5 ⁄8) 381 (15)2 pc. 76.2 (3) 1117 (44) 15.8 ( 5 ⁄8) 381 (15)Expandable:Narrow 44.4 (1 3 ⁄4) — — 25.4 (1) 76.2 (3)Wide 44.4 (1 3 ⁄4) — — 50.8 (2) 152.4 (6)O.D. heater:1 pc. 76.2 (3) 559 (22) 25.4 (1) 76.2 (6)2 pc. 76.2 (3) 1117 (44) 25.4 (1) 76.2 (6)Type K leads 19.05 ( 3 ⁄4) — — 15.8 ( 5 ⁄8) 381 (15)Type L leads 19.05 ( 3 ⁄4) — — 19.05 ( 5 ⁄8) 381 (15)Type E leads 38.1 (1 1 ⁄2) 559 (22) 19.05 ( 5 ⁄8) 381 (15)Type F leads 38.1 (1 1 ⁄2) 559 (22) 19.05 ( 5 ⁄8) 381 (15)Type H leads 38.1 (1 1 ⁄2) 559 (22) 19.05 ( 5 ⁄8) 381 (15)Type B leads 38.1 (1 1 ⁄2) 559 (22) 19.05 ( 5 ⁄8) 381 (15)Post terminal: 33.3 (1 5 ⁄16) — — 25.4 (1) 381 (15)Type A leads 19 ( 3 ⁄4) — — 19 ( 3 ⁄4) 381 (15)Type C leads 33.3 (1 5 ⁄16) — — 25.4 (1) 381 (15)Terminal box 88.9 (3 1 ⁄2) — — 34.9 (1 3 ⁄8) 381 (15)Plug w/bracket 76.2 (3) — — 88.9 (3 1 ⁄2) 381 (15)3-phase — — — — 76.2 (3) 381 (15)European Plug:1 pc. vertical 33.3 (1 5 ⁄16) 559 (22) 25.4 (1) 381 (15)1 pc. horizontal 76.2 (3) 559 (22) 50.8 (2) 381 (15)2 pc. vertical 76.2 (3) 1117 (44) 25.4 (1) 381 (15)2 pc. horizontal 76.2 (3) 1117 (44) 50.8 (2) 381 (15)HV Wedge-Lok 2.5.4 (1) 76.2 (3) 25.4 (1) 76.2 (6)Clamping tabs 50.8 (2) — — 25.4 (1) 381 (15)Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Nuts1 pc. 50.8 (2) 559 (22) 25.4 (1) 381 (15)2 pc. 101.6 (4) 1117 (44) 25.4 (1) 381 (15)Note: Some <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>binations of maximum and minimums cannotoccur on the same heater.Standard gap is 6.35 mm (0.25 in.)VariationsDifferent WidthsThe 38 mm (1.5 in.) wide heater isthe most efficient due to maximumclamping action. <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> areavailable in widths from 16 mm(0.625 in.) to 381 mm (15 in.).Multiple clamping s<strong>tr</strong>aps areprovided for heaters more than76 mm (3 in.) wide.Expandable <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong><s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> 76 mm (3 in.) wide or lessare cons<strong>tr</strong>ucted with a notchedsheath. <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> wider than threeinches are cons<strong>tr</strong>ucted with anexpansion seam. These heatersare shipped open and should notbe closed and reopened more thantwice. To order, specify expandable.30

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandVariationsContinued;;;;;;;;;;;;;;;;Holes and NotchesAn economical way to provideaccess for ins<strong>tr</strong>umentation is tospecify an oversize gap betweenthe heater ends. Holes and notchesin the sheath should be specifiedonly when all the cylinder surfacesadjacent to the hole or notch mustbe heated. When required, holesmay be provided in nearly anylocation as long as there is at least25 mm (1 in.) between the hole andone side of the heater. Standardhole sizes up to 51 mm (2 in.)diameter. For proper hole and/ornotch location, a dimensionaldrawing is required.Two Piece Band <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Two-piece cons<strong>tr</strong>uction is availableon heaters 76 mm (3 in.) or greater indiameter. <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> three inches wideor less with post terminals have oneterminal on each end. <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> overthree inches wide with post terminalshave the two terminals side by sideon one end. On two-piece units withleads, also specify the power supplyvoltage. The power supply voltage isthe voltage to which the heater will bewired. For example, a two-piece bandthat is 240VÅ(ac) per half may bewired in series to a 480VÅ(ac) powersupply. In this case the band heaterlead wire insulation must be rated for480VÅ(ac). To order, specify twopiece band heater, with volts andwatts per half and power supplyvoltage.Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Outside Diameter16 mm(0.625 in.)This variation is specially designedand cons<strong>tr</strong>ucted to heat the insidediameter of cylinders, i.e., largediameter blown film dies. All theterminations and mounting hardwareare located on the I.D. of the heater.Consult Watlow for available sizesand terminations. Option availableas standard mica cons<strong>tr</strong>uction only.To order, specify outside diameterheater.3.5 in. for 3.5-5.9375 in. I.D.4 in. for 6-39.9375 in. I.D. 37 mm(1.4375 in.)46 mm(1.8125 in.)Metallic Terminal BoxTerminal boxes are attached to theheater to cover the terminals for anadded safety feature. Conduit maybe attached to the box through22 mm (0.875 in.) diameter holes inthe ends of the box. Terminal box isavailable on two piece heaters. Whenordering, specify terminal box.See page 30 forminimum/maximumdimensional requirements.31

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandVariationsContinued57 mm(2.25 in.)44 mm46 mm (1.75 in.)(1.8125 in.)59 mm 52 mm(2.3125 in.) (2.0625 in.)High Temperature “Quick Disconnect” European Style PlugsThese plugs provide the simplestand safest way to apply power toband heaters. The <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>bination ofhigh temperature male and femalequick disconnect plug assemblieseliminates all live exposed terminalsand elec<strong>tr</strong>ical wiring that can be apotential hazard to employees ormachine. Maximum amps 15 at240VÅ(ac), maximum volts 240.To order, specify vertical orhorizontal European Plug.33 mm(1.3125 in.)VerticalHorizontalHigh Temperature “Quick Disconnect” European Style Female AdaptersAvailable as an accessory item thatmust be used in conjunction withhigh temperature “quickdisconnect” European Style Plugs.Specify code number N6027AF049or N6027ZZ028 and quantity.Right AngleCode # N6027AF049S<strong>tr</strong>aightCode # N6027ZZ028Ceramic Terminal CoversStock OptionA convenient and economic way toinsulate post terminals. Sized forstandard length posts. 10-24 screwthread size. These are supplied asan accessory item and shippedseparately. Specify Z-4918 andquantity.Code # Z-4918Special Cons<strong>tr</strong>uctionVariationsSquare, Rectangular and Hex BandsSquare and rectangular heaters aremade in either one or two-piececons<strong>tr</strong>uction. These units are idealfor heating dies on plasticex<strong>tr</strong>uders, or the barrels of twinscrew ex<strong>tr</strong>uders. Hex-shapedheaters are <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>monly used on thehex shaped portion of the nozzleinjection molding machines. Hexshapedheaters are made to exactcustomer specifications. To order,specify square or rectangularheaters. A dimensional drawing isrequired.See page 30 forminimum/maximumdimensional requirements.32

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandSpecial Cons<strong>tr</strong>uctionVariationsContinuedSquare, Rectangular and Hex Bands (continued)Clamping StylesThe preferred clamping style isillus<strong>tr</strong>ated in Figure 1 showing bentupflange clamping. This clampingstyle applies a uniform clampingforce at the corners.Figure 2 shows bent-up flanges orbuilt-in s<strong>tr</strong>apping bracket at the side.The least preferred clamping style isshown in Figure 3. The one-pieceheater does not apply a uniformclamping force."B""B""B""A""A""A"Figure 1 Figure 2 Figure 3Hinged Two-Piece BandThe hinged, two-piece band heateris connected with a reinforcedhinge. It can be opened and closedas often as necessary resulting ineasy installation and removal.To order, specify hinged two-pieceband and watts and volts per eachhalf.Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Thermocouple CouplingThe thermocouple couplingsimplifies the installation of anexternal thermocouple with athreaded fitting. The standardlocation for the coupling is90 degrees from the gap.Standard bushing sizes available are:NPT Size Depth Heightin. in. in.0.5 - 27 9⁄160.25 - 20 3⁄45⁄811⁄160.375 - 18 7⁄85⁄8To order, specify thermocouplecoupling.Bayonet AdapterThe bayonet adapter simplifies theinstallation of an externalthermocouple with a bayonetadapter. The standard location forthe adapter is 90 degrees from thegap. To order, specify bayonetadapter.33

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandClamping Variations14 mm(0.563 in.)Standard and Low-ProfileClamping S<strong>tr</strong>apThe standard clamping s<strong>tr</strong>aprequires 14 mm (0.563 in.)clearance above the heated surface,at the barrel nuts. When clearance islimited, smaller barrel nuts can beused which require only 9 mm(0.375 in.) clearance. The clearancerequired by the clamping screwdepends on the screw length andthe diameter of the heater. The lowprofileclamping s<strong>tr</strong>ap is standard onunits less than 45 mm (1.375 in.)wide and utilizes a 13 mm (0.5 in.)wide s<strong>tr</strong>ap. Consult Watlow for moreinformation. To order, specifylow-profile clamping s<strong>tr</strong>ap.Spot Welded14 mm(0.563 in.)Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> NutsAn ideal way to provide accessfor ins<strong>tr</strong>umentation is to specify anoversized gap between the heaterends. If the clamp s<strong>tr</strong>ap interfereswith the positioning of theins<strong>tr</strong>umentation device,welded barrel nuts are re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mended.Maximum gap is 25 mm (1 in.)Specify welded barrel nuts andgap dimension when ordering.See page 30 forminimum/maximumdimensional requirements.34

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Special Mica BandClamping VariationsContinuedNon-Stock OptionClamping TabsTabs—or lock-up flanges—areavailable. However, the special micaband heater and s<strong>tr</strong>ap designprovides superior clamping andimproved heat <strong>tr</strong>ansfer and shouldbe used whenever possible. Toorder, specify clamping tabs.Clamping PadsClamping pads have a hole to alloweasy fastening to machine barrel.Clamping pads are used when anobs<strong>tr</strong>uction hinders a standardclamping s<strong>tr</strong>ap from fitting <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>pletelyaround the machine barrel.To order, specify clamping padsand degrees coverage.As requiredClamping PadInjection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Termination VariationsPost Terminal OptionsStandard post terminals have athreaded length of 11 mm(0.4375 in.) and require 19 mm(0.75 in.) clearance from the cylinder.Terminals with 17 mm (0.6875 in.)threaded lengths are available tha<strong>tr</strong>equire one inch of clearance.Button terminals require only 11 mm(0.4375 in.) clearance. Maximumamperage for post terminals is35 amps. To order, specify standard,long or button terminals.11 mm (0.4375 in.)27 mm (0.6875 in.)19 mm (0.75 in.)Standard25 mm (1 in.)Long11 mm (0.4375 in.)ButtonThree Terminal Cons<strong>tr</strong>uctionA third terminal can be added toprovide dual voltage or three-heatoperation. Or, it can be connectedto the sheath for easy grounding.Standard terminal location on heaters76 mm (3 in.) wide or less is oneterminal at each end of the heatercentered on the width. On heatersthree inches wide or wider, the terminalsare located side-by-side onone end. Special terminal locationsare available. To order, specify dualvoltage or three-heat operation.35

• Same day shipment on more than 1000 variationsof THINBAND heaters.<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>THINBAND ® MicaThe THINBAND ® heater is Watlow’spatented redesign of the mica band.THINBAND heaters deliver fast andinstall easily, keeping costs downand machines running.Performance Capabilities• Sheath temperatures to480°C (900°F)• Watt densities to 8.5 W/cm 2(55 W/in 2 )Features and Benefits• New flexible, one-piece designmakes installation faster on plasticprocessing equipment becausethe heater can be opened to thefull diameter of the barrel withoutinternal damage. The THINBANDheater can be installed on abarrel without removing otherband heaters already in place.• Same day shipment onmore than 1000 variations ofTHINBAND lead attachments isdue to Watlow’s exclusive LeadAdapter—or LA—manufacturingmethod. Customers can reduceinventories and costly downtime.• Only one set of leads orterminals is needed on theTHINBAND heater, unlike the twosets required on the cumbersometwo-piece replacement barrelheaters with s<strong>tr</strong>aps.Clamping Bars• QUICK CLAMP opens to fit overbarrels and snaps in place withone easy flip of its latching lever.No need to remove other heaters.• Permanently attachedclamping bars.• Contamination resistance.No folds on outside of heater.Zinc SteelInner SheathSide Foldsto the InsideDiameterPost TerminalsMica InsulationResistanceRibbonAluminizedSteel OutsideDiameterSheathApplications• Injection molding machines• Ex<strong>tr</strong>uders• Blown film dies36

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>THINBAND MicaApplications andTechnical DataOperating FactorsUse as low a watt density rating as yourapplication permits. A close match ofthe heat supplied to the actual requirementswill reduce temperatureovershoot, reduce cycling and increasethe life of any band heater you use.Calculate the safe maximum wattagefor your heater using:Heated Area x Maximum Watt DensityCalculate the heated area of your barrelheater by sub<strong>tr</strong>acting the no-heat areafrom the total area in contact with thecylinder (3.14 x I.D. x width). Sub<strong>tr</strong>actthe no-heat area at the terminals (fromtable) and any additional no-heat areacaused by holes, slots or oversize gaps.Determine the maximum watt density ofyour heater from the graph on this page.The curves are based on narrow heatersmounted on a smooth, steel cylinder.Apply the necessary correction factors:• For heaters 57 mm (2.25 in.) to127 mm (5 in.) wide, multiply wattdensity by 0.8.• For high expansion cylinders(aluminum or brass), reduce the wattdensity by 0.46 W/cm 2 (3 W/in 2 ).• For heaters 57 mm to 127 mm wide(2.25 in. to 5 in.) installed on a highexpansion cylinder, reduce wattdensity by a total of 0.46 W/cm 2(3 W/in 2 ) only.• For regular cylinder surfaces otherthan smooth, machined finish, reducewatt density by 0.46 W/cm 2 (3 W/in 2 ).• For heaters that will be insulatedor enclosed, contact Watlow forspecific watt densities.• For units greater than 355 mm (14 in.)diameter, consult re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mendedclamping graph on page 39.• For units used in verticalapplications, consult factory forapplication assistance.No-Heat Area for THINBAND (All Terminations)Heater SizeNo-Heat AreaHeater Diameter Width at TerminalsType mm (in.) mm (in.) mm (in.)One Piece 63.5 (Less than 2.5) 177.8 (Up to 7) 25.4 (1) x widthTwo Piece 127 (5 or more) 76.2 (More than 3) 50.8 (2) x widthCylinder Temperature—°F11001000900800700600500400300Maximum Allowable Watt DensityWatt Density—W/cm 22 4 6 810020010 20 30 40 50 60Watt Density—W/in 238.1 mm (1.5 in.) Dia.76.2 mm (3 in.) Dia.500400300200Cylinder Temperature—°CInjection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>37

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>THINBAND MicaPhysical Limitations ofLead VariationsCheck the table to be certain thevariations and lead arrangementsyou order are available on theheater size you require. If you needto exceed any limitations pleasecontact a Watlow representative.32 mm(1.25 in.)Minimum63 mm (2.5 in.)Maximum368 mm (14.5 in.) 1pc.736 mm (29 in.) 2pc.THINBAND <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong>10-24thread2.8 mm(0.110 in.)Physical Limitations of Lead VariationsDiameterWidthHeater Type Min. Max. Min. Max.mm (in.) mm (in.) mm (in.) mm (in.)1 pc. const. 25.4 (1) 368.3 (14 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)2 pc. const. 127.0 (5) 736.6 (29) 38.1 (1 1 ⁄2) 177.8 (7)NozzleType A 25.4 (1) 101.6 (4) 25.4 (1) 152.4 (6)Type L 25.4 (1) 101.6 (4) 25.4 (1) 152.4 (6)<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong>Type T 63.5 (2 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Type H 63.5 (2 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Type F, FR 63.5 (2 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Type E 63.5 (2 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Type C, BR 63.5 (2 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Type K, KR 63.5 (2 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Terminal Box 88.9 (3 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)European Plug1 pc. vertical 63.5 (2 1 ⁄2) 368.3 (14 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)1 pc. horizontal 63.5 (2 1 ⁄2) 368.3 (14 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Nuts1 pc. 63.5 (2 1 ⁄2) 368.3 (14 1 ⁄2) 38.1 (1 1 ⁄2) 177.8 (7)Note: Some <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>binations of maximums and minimums cannot occur on thesame heater. Check the table to be certain the variations and lead arrangementsyou order are available on the heater size you require. If you need to exceedany limitations, please contact your Watlow representative.Standard gap is 9.53 mm (0.375 in.) between clamp bars.14 mm(0.5625 in.)Minimum 38 mm (1.5 in.)Maximum 177 mm (7 in.)38

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>THINBAND Mica<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> HeaterQUICK CLAMP OptionQUICK CLAMP eliminates tools, loose parts and hassle• THINBAND opens up to fit overbarrel. There is no need to removeother heaters.• One easy flip of the latching leverand QUICK CLAMP shuts,<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>pleting installation.With QUICK CLAMP, the THINBANDheater can be secured tightly inplace in a matter of seconds. Thespring-loaded clamp secures theheater tightly around the barrel withan easy flip of the lever.Features and Benefits• THINBAND with QUICK CLAMPfits over barrels and snaps in placewith easy flip of its latching lever.• Hot change-outs are <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>pleted inseconds.• Spring tensioned clamp keepsthe THINBAND heater tightagainst barrel—won’t loosen overtime.• Ideal for vertical applications.• Available on selected stockand made-to-order THINBANDbarrel heaters—minimum100 mm (4 in.) diameter,38 mm (1.5 in.) width.• Standard gap is 12.7 mm (0.5 in.).Clearance DimensionsWidth Range Number of Distance Between Clampsmm (in.) Quick Clamps mm (in.)38.1 to 69.3 (1 1 ⁄2) to (2 11 ⁄16) 1 NA69.9 to 94.8 (2 D⁄4) to (3 11 ⁄16) 2 12.7 ( 1 ⁄2)69.9 to 120.1 (3 3 ⁄4) to (4 11 ⁄16) 2 25.4 (1)120.6 to 145.5 (4 3 ⁄4) to (5 11 ⁄16) 3 12.7 ( 1 ⁄2)146.1 to 145.5 11 (5 3 ⁄4) to (7) 3 25.4 (1)1.27 mm(0.5 in.)54 mm(2.125 in.)Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mendedClamping OptionsTHINBAND <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> ProductsClamp BarsClamp BarsOr QUICK CLAMPabove 101.6 mm (4 in.) diameterQUICK CLAMPFor 2 piece:Clamp bar at other gapCoil SpringFor 2 piece only:Clamp bar at other gapNotes: Widths 101.6 mm (4 in.) and over add50.8 mm (2 in.) to diameter then referencechart clamp selection.Watt Density (W/in 2 )50403020Diameter (millimeters)76 127 178 229 279 330 381 432 483 533 584 635 686 7371 Piece2 PieceAbove Re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mended Watt DensityConsult Engineering10 2 4 6 8 10 12 14 16 18 20 22 24 26 28Diameter (inches)765432Watt Density (W/cm 2 )39

<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>THINBAND Mica<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> HeaterClamping VariationsTig Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Nuts With Spring Loaded Clamping147 mm (5.8 in.)19 mm(0.75 in.)Tig welded barrel nuts with springloaded clamping are used duringstart-up to maintain a tight heaterfit on large barrels. Stainless steeltop metal is required.Refer to the THINBAND re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mendedclamping graph on page 39.This option is mandatory on verticalapplications. To order, specifyspring loaded clamping.Tig Welded <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> NutsTig Welded14 mm(0.563 in.)An ideal way to provide accessfor ins<strong>tr</strong>umentation is to specify anoversized gap between the heaterends. If the THINBAND clamp barscrew interferes with the positioningof the ins<strong>tr</strong>umentation device,tig welded barrel nuts are re<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>mended.Stainless steel top metal isrequired. Maximum gap is 25 mm(1 in.). Specify tig welded barrelnuts and gap dimension whenordering.Non-Stock OptionClamping PadsClamping pads are used when anobs<strong>tr</strong>uction would prevent astandard full circumferential heaterfrom fitting <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>pletely around amachine barrel. The clamping padshave a hole to allow easy fasteningto the machine barrel. Dimensionaldrawing required when ordering.VariationsNon-Stock OptionHolesAn economical way to provideaccess for ins<strong>tr</strong>umentation is tospecify an oversized gap betweenthe heater ends. A hole in the sheathshould be specified only when all thecylinder surface adjacent to the holemust be heated. When required,one hole may be provided innearly any location as long asthere is at least 25 mm (1 in.)between the hole and one side ofthe heater. Standard hole sizes upto 51 mm (2 in.) diameter. Consultfactory for limitations. For properhole location, a dimensional drawingis required.40

W A T L O W<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>THINBAND Mica<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> Heater VariationsContinued35 mm(1.375 in.)Stock LA OptionStock Option45 mm(1.75 in.)Non-Stock OptionStock Option48 mm(1.875 in.)73 mm(2.875 in.)60 mm(2.375 in.)Two-Piece <s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>Two-piece cons<strong>tr</strong>uction is availableon heaters 127 mm (5 in.) or greaterin diameter. <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong> 38 mm (1.5 in.)wide and greater with post terminalshave the two terminals side-by-side.Note: When ordering two-piecebarrel heaters, specify the volts andwatts per half. On two-piece unitswith leads, you must also specify thepower supply voltage. Example:a two-piece barrel that is 240VÅ(ac)per half may be wired in series to aHigh Temperature “Quick Disconnect” European Style PlugsThey provide the simplest and safestway to apply power to barrelheaters.The <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>bination of hightemperature male and female quickdisconnect plug assemblieseliminates all live exposed terminalsand elec<strong>tr</strong>ical wiring that can be a480VÅ(ac) power supply. In thiscase the barrel heater lead wireinsulation must be rated for480VÅ(ac). Available from stock by<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>bining two one-piece heaters tocreate a large diameter. Terminationswill be 90 degrees from each gap.QUICK CLAMP must be supplied atone gap when ordering.potential hazard to employees ormachine. Maximum 15 amps at240VÅ(ac), maximum volts 240.When ordering, specify vertical orhorizontal European Plug.Injection Molding<s<strong>tr</strong>ong>Barrel</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Heaters</s<strong>tr</strong>ong>VerticalHorizontalStock OptionRight AngleCode # N6027AF049Stock OptionS<strong>tr</strong>aightCode # N6027ZZ028High Temperature “Quick Disconnect” European Style Female AdaptersAvailable as an accessory item thatmust be used in conjunction withhigh temperature “quick disconnect”European Style Plugs. Specify codenumber N6027AF049 or N6027ZZ028and quantity.See page 38 forminimum/maximumdimensional requirements.41