Valve and Valve Actuator Selection Guide - Staefa Control System

Valve and Valve Actuator Selection Guide - Staefa Control System

Valve and Valve Actuator Selection Guide - Staefa Control System

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

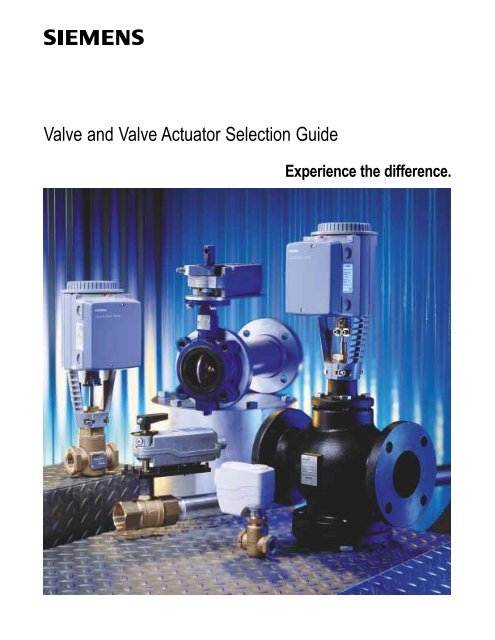

<strong>Valve</strong> <strong>and</strong> <strong>Valve</strong> <strong>Actuator</strong> <strong>Selection</strong> <strong>Guide</strong>Experience the difference.

Table of Contents<strong>Valve</strong>s <strong>and</strong><strong>Valve</strong> <strong>Actuator</strong>sExperience Counts............................................................................................... 4Siemens Delivers ................................................................................................. 5<strong>Valve</strong> <strong>and</strong> <strong>Valve</strong> <strong>Actuator</strong> <strong>Selection</strong> ChartsGlobe ........................................................................................................... 6–15Ball ................................................................................................................... 16Butterfly ..................................................................................................... 17–24Accessories .................................................................................................. 25–28Submittal SummariesQuick Reference .............................................................................................. 291/2 to 1-inch Powermite 599 Series MZ SeriesZone <strong>Control</strong> <strong>Valve</strong>s <strong>and</strong> <strong>Actuator</strong>s ........................................................... 30–331/2 to 1-1/2 inch Powermite 599 Series MT Series TerminalUnit <strong>Valve</strong>s <strong>and</strong> <strong>Actuator</strong>s .......................................................................... 34–451/2 to 2-inch Flowrite 599 Series <strong>Valve</strong>s <strong>and</strong> <strong>Actuator</strong>s ............................ 46–651/2 to 6-inch Flowrite 599 Series Flanged Iron Body,ANSI Class 125/250 <strong>Valve</strong>s <strong>and</strong> <strong>Actuator</strong>s ................................................ 48–651/2 to 2-inch Powermite 599 Series Ball <strong>Valve</strong>s ........................................ 66–692 to 20-inch Resilient Seat Butterfly <strong>Valve</strong>swith Electronic <strong>Actuator</strong>s ........................................................................... 70–752 to 20-inch Resilient Seat Butterfly <strong>Valve</strong>swith Pneumatic <strong>Actuator</strong>s .......................................................................... 76–79Features/Functions/BenefitsGlobe <strong>Valve</strong>sPowermite 599 Series .................................................................................. 80Flowrite 599 Series ...................................................................................... 81Flowrite 599 Series Flanged Iron ................................................................. 82Ball <strong>Valve</strong>sPowermite 599 Series .................................................................................. 83Butterfly <strong>Valve</strong>sSiemens ....................................................................................................... 84ReferenceGlossary .......................................................................................................... 85<strong>Selection</strong> <strong>and</strong> Sizing of <strong>Control</strong> <strong>Valve</strong>s ...................................................... 86–91<strong>Selection</strong> <strong>and</strong> Sizing of Butterfly <strong>Valve</strong>s .................................................... 92–94Tech Tips ................................................................................................... 95–97Terminal Designations ............................................................................... 98–99For More Information ..................................................................................... 1003

Experience Counts150 years of industry innovationsA leader in the Heating, Ventilation <strong>and</strong> AirConditioning (HVAC) industry, Siemens BuildingTechnology delivers the products <strong>and</strong> services thatyou depend on for outst<strong>and</strong>ing quality, reliability<strong>and</strong> performance.Need it fast? Same day shipping is no problem forrush orders. Helpful customer service representativescan input your order <strong>and</strong> ship st<strong>and</strong>ard delivery withinthree business days.Locate information fast online. Technicaldocumentation <strong>and</strong> installation instructions areat your fingertips as well as helpful tools <strong>and</strong>order tracking.Quality first. All Siemens valves <strong>and</strong> valve actuatorsare 100% factory-assembled <strong>and</strong> tested for quality<strong>and</strong> reliability in our state-of-the-art, ISO9002manufacturing facility.Delivered ready to install. Designed for flexibleconfigurations <strong>and</strong> fast installation, the Powermite<strong>and</strong> Flowrite Globe <strong>Valve</strong>s <strong>and</strong> <strong>Valve</strong> <strong>Actuator</strong>smeet most application needs. Ball <strong>and</strong> Butterfly<strong>Valve</strong>s address specific control challenges with thesame reliability <strong>and</strong> performance. <strong>Valve</strong>s areassembled <strong>and</strong> tagged for delivery direct to locationat job-site free of charge.Customer Care is a phone call away. For technicalsupport, ordering <strong>and</strong> pricing, call 1.888.593.7876.4

Siemens DeliversMeet your toughest control challenges head onGlobe Ball ButterflyBr<strong>and</strong> Powermite 599 Series Flowrite 599 Series Powermite 599 Series SiemensSize 1/2 to 1-1/2” 1/2 to 6” 1/2 to 2” 2 to 20”Applications • VAV Reheat • Air H<strong>and</strong>ling Units • Small Air H<strong>and</strong>ling Units • Tower Bypass• Small Terminal Units • Central Plant Equipment • Large Terminal Units • Isolation• Steam to 15 psi • High Temp. Steam • Central Plant Equipment • Central Plant EquipmentActuation Electronic Electronic Electronic ElectronicPneumatic Pneumatic Pneumatic5

globe2- <strong>and</strong> 3-way Assemblies 1/2 to 1”To build a complete assembly:1. Under <strong>Valve</strong> Body, work left-torightto select:• Action• Flow Rate (Cv)• Line Size2. For the <strong>Actuator</strong>, work from top-tobottomto select:• Fail-in-Place/Fail Safe• Signal3. At the intersection of the <strong>Valve</strong> row<strong>and</strong> the <strong>Actuator</strong> column locate thedesired close-off value <strong>and</strong> price.4. Create the assembly part numberby combining the <strong>Actuator</strong> PrefixCode (APC) in the <strong>Actuator</strong> columnwith the Part No. in the close-offrow.These selection tables only containFXF end connections with brass trim<strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.3-way 2-wayElectronicActionNormally ClosedNormally OpenMixing<strong>Valve</strong> Body<strong>Actuator</strong>Fail-in-Place3P0-10 VSSB81USSB61UPartNo.FlowRateLineSizeAPC254APC255Cv (Kvs) in. (mm)Close-off psi (kPa)0.4 (0.24) 1/2 (15) 70 (482) 70 (482) _ _ _ 011000.63 (0.54) 1/2 (15) 70 (482) 70 (482) _ _ _ 011021 (0.85) 1/2 (15) 70 (482) 70 (482) _ _ _ 011041.6 (1.37) 1/2 (15) 70 (482) 70 (482) _ _ _ 011062.5 (2.14) 1/2 (15) 40 (276) 40 (276) _ _ _ 011084 (3.42) 1/2 (15) 40 (276) 40 (276) _ _ _ 011106.3 (5.38) 3/4 (20) 30 (207) 30 (207) _ _ _ 0111210 (8.55) 1 (25) 30 (207) 30 (207) _ _ _ 011140.4 (0.24) 1/2 (15) 60 (414) 60 (414) _ _ _ 011150.63 (0.54) 1/2 (15) 60 (414) 60 (414) _ _ _ 011171 (0.85) 1/2 (15) 60 (414) 60 (414) _ _ _ 011191.6 (1.37) 1/2 (15) 60 (414) 60 (414) _ _ _ 011212.5 (2.14) 1/2 (15) 35 (241) 35 (241) _ _ _ 011234 (3.42) 1/2 (15) 35 (241) 35 (241) _ _ _ 011266.3 (5.38) 3/4 (20) 30 (207) 30 (207) _ _ _ 0112910 (8.55) 1 (25) 30 (207) 30 (207) _ _ _ 011310.4 (0.24) 1/2 (15) 70 (482) 70 (482) _ _ _ 011320.63 (0.54) 1/2 (15) 70 (482) 70 (482) _ _ _ 011331 (0.85) 1/2 (15) 70 (482) 70 (482) _ _ _ 011341.6 (1.37) 1/2 (15) 70 (482) 70 (482) _ _ _ 011352.5 (2.14) 1/2 (15) 40 (276) 40 (276) _ _ _ 011364 (3.42) 1/2 (15) 40 (276) 40 (276) _ _ _ 011376.3 (5.38) 3/4 (20) 30 (207) 30 (207) _ _ _ 0113810 (8.55) 1 (25) 30 (207) 30 (207) _ _ _ 01139Complete Assembly <strong>Valve</strong> Body OnlyAPC + Part No. 599 + Part No.Prices are subject to change without notice.6

globe2- <strong>and</strong> 3-way Assemblies 1/2 to 1”PneumaticFail-Safe3-8 psi (21-55 kPa) 8-13 psi (55-90 kPa) 10-15 psi (69-103 kPa)<strong>Actuator</strong>3-way 2-wayActionNormally ClosedNormally OpenMixing*<strong>Valve</strong> Body599-01088PartNo.Flow Line APC APC APCRate Size 257258256Cv (Kvs) in. (mm)Close-off psi (kPa)0.4 (0.34) 1/2 (15)0.63 (0.54) 1/2 (15)1 (0.85) 1/2 (15)1.6 (1.37) 1/2 (15)2.5 (2.14) 1/2 (15)4 (3.42) 1/2 (15)6.3 (5.38) 3/4 (20)10 (8.55) 1 (25)40 (276)40 (276)40 (276)40 (276)28 (193)28 (193)18 (124)18 (124)25702000B25702002B25702004B25702006B25702008B25702010B25702012B25702014B599-0108895 (655)95 (655)95 (655)95 (655)50 (345)50 (345)40 (276)40 (276)PartNo.25802000C25802002C25802004C25802006C25802008C25802010C25802012C25802014C599-01088120 (827)120 (827)120 (827)120 (827)65 (448)65 (448)50 (345)50 (345)PartNo.25602000256020022560200425602006256020082560201025602012256020140.4 (0.34) 1/2 (15) 95 (655) 25702030 45 (310) 25802030C 20 (138) 25602030A0.63 (0.54) 1/2 (15) 95 (655) 25702032 45 (310) 25802032C 20 (138) 25602032A1 (0.85) 1/2 (15) 95 (655) 25702034 45 (310) 25802034C 20 (138) 25602034A1.6 (1.37) 1/2 (15) 95 (655) 25702036 45 (310) 25802036C 20 (138) 25602036A2.5 (2.14) 1/2 (15) 45 (310) 25702038 25 (172) 25802038C 10 (69) 25602038A4 (3.42) 1/2 (15) 45 (310) 25702041 25 (172) 25802041C 10 (69) 25602041A6.3 (5.38) 3/4 (20) 35 (241) 25702044 10 (69) 25802044C — —10 (8.55) 1 (25) 35 (241) 25702046 10 (69) 25802046C — —0.4 (0.34) 1/2 (15) 40 (276) 25702064B 95 (655) 25802064 120 (827) 25602064A0.63 (0.54) 1/2 (15) 40 (276) 25702065B 95 (655) 25802065 120 (827) 25602065A1 (0.85) 1/2 (15) 40 (276) 25702066B 95 (655) 25802066 120 (827) 25602066A1.6 (1.37) 1/2 (15) 40 (276) 25702067B 95 (655) 25802067 120 (827) 25602067A2.5 (2.14) 1/2 (15) 28 (193) 25702068B 50 (345) 25802068 65 (448) 25602068A4 (3.42) 1/2 (15) 28 (193) 25702069B 50 (345) 25802069 65 (448) 25602069A6.3 (5.38) 3/4 (20) 18 (124) 25702070B 40 (276) 25802070 50 (345) 25602070A10 (8.55) 1 (25) 18 (124) 25702071B 40 (276) 25802071 50 (345) 25602071A*Values are for the upper port NC.Values in chart are for 15 psi supplied to the actuator.These selection tables only containFXF end connections with brass trim<strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.Prices are subject to change without notice.7

globe2- <strong>and</strong> 3-way Assemblies 1/2 to 1-1/2”ElectronicFail-in-PlaceFail-Safe3P 0-10 V 3P 0-10 V<strong>Actuator</strong>3-way 2-wayActionNormally Closed<strong>Valve</strong> BodyNormally OpenMixing*SSC81USSC61U SQS65U SSC81.5U SQS85.53U SSC61.5U SQS65.5UFlow Line APCAPC APC APC APCAPCAPCRate Size 259 261 264 260 266 262 265Cv (Kvs) in. (mm)Close-off psi (kPa)0.4 (0.24) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020000.63 (0.54) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020021 (0.85) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020041.6 (1.37) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020062.5 (2.14) 1/2 (15) 50 (345) 50 (345) 50 (345) 50 (345) 50 (345) 50 (345) 50 (345) _ _ _ 020084 (3.42) 1/2 (15) 50 (345) 50 (345) 50 (345) 50 (345) 50 (345) 50 (345) 50 (345) _ _ _ 020106.3 (5.38) 3/4 (20) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) _ _ _ 0201210 (8.55) 1 (25) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) _ _ _ 0201416 (13.8) 1-1/4 (32) 21 (145) 21 (145) 21 (145) 21 (145) 21 (145) 21 (145) 21 (145) _ _ _ 0208525 (21.5) 1-1/2 (40) — — 13 (90) — 13 (90) —13 (90) _ _ _ 020880.4 (0.34) 1/2 (15) 120 (828) 120 (828) 160 (1103) 120 (828) 160 (1103) 120 (828) 160 (1103) _ _ _ 020300.63 (0.54) 1/2 (15) 120 (828) 120 (828) 160 (1103) 120 (828) 160 (1103) 120 (828) 160 (1103) _ _ _ 020321 (0.85) 1/2 (15) 120 (828) 120 (828) 160 (1103) 120 (828) 160 (1103) 120 (828) 160 (1103) _ _ _ 020341.6 (1.37) 1/2 (15) 120 (828) 120 (828) 160 (1103) 120 (828) 160 (1103) 120 (828) 160 (1103) _ _ _ 020362.5 (2.14) 1/2 (15) 65 (448) 65 (448) 85 (586) 65 (448) 85 (586) 65 (448) 85 (586) _ _ _ 020384 (3.42) 1/2 (15) 65 (448) 65 (448) 85 (586) 65 (448) 85 (586) 65 (448) 85 (586) _ _ _ 020416.3 (5.38) 3/4 (20) 55 (379) 55 (379) 70 (482) 55 (379) 70 (482) 55 (379) 70 (482) _ _ _ 0204410 (8.55) 1 (25) 55 (379) 55 (379) 70 (482) 55 (379) 70 (482) 55 (379) 70 (482) _ _ _ 0204616 (13.8) 1-1/4 (30) 20 (138) 20 (138) 28 (193) 20 (138) 28 (193) 20 (138) 28 (193) _ _ _ 0208425 (21.5) 1-1/2 (40) 10 (68) 10 (68) 14 (96) 10 (68) 14 (96) 10 (68) 14 (96) _ _ _ 020870.4 (0.34) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020640.63 (0.54) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020651 (0.85) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020661.6 (1.37) 1/2 (15) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) 95 (655) _ _ _ 020672.5 (2.14) 1/2 (15) 50 (345) 50 (345) 50 (345) 55 (379) 50 (345) 50 (345) 50 (345) _ _ _ 020684 (3.42) 1/2 (15) 50 (345) 50 (345) 50 (345) 55 (379) 50 (345) 50 (345) 50 (345) _ _ _ 020696.3 (5.38) 3/4 (20) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) _ _ _ 0207010 (8.55) 1 (25) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) 40 (276) _ _ _ 0207116 (13.8) 1-1/4 (32) 10 (69) 10 (69) 10 (69) 10 (69) 10 (69) 10 (69) 10 (69) _ _ _ 0208625 (21.5) 1-1/2 (40) ——7(48) — 7 (48) —7(48) _ _ _ 02089PartNo.*Values are for the upper port NC.Values in chart are for 15 psi supplied to the actuator.For Fail-in-Place actuators at 0V valve is closed.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.These selection tables only containFXF end connections with brass trim<strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Prices are subject to change without notice.8

globe2- <strong>and</strong> 3-way Assemblies 1/2 to 2”Pneumatic<strong>Actuator</strong>4” 3-8 psi(21-55 kPa)4” 5-10 psi(34-69 kPa)4” 10-15 psi(69-103 kPa)Spring Return8”8”High Temp.8”with Positioner8” High Temp.with Positioner3-way 2-way<strong>Valve</strong> BodyPart599-01081 599-01082 599-01083 599-01050 599-01051 599-01050 599-01051 No.Flow Line APC APC APC APC APC APC APCRate Size 268 269 270 277 278 283 284Cv (Kvs) in. (mm)Close-off psi (kPa)1 (0.9) 1/2 (15) * * 236 (1627) 250 (1724) * 250 (1724) * _ _ _ 031801.6 (1.4) 1/2 (15) * * 236 (1627) 250 (1724) * 250 (1724) * _ _ _ 031812.5 (2.2) 1/2 (15) * * 236 (1627) 250 (1724) * 250 (1724) * _ _ _ 031824 (3.4) 1/2 (15) * * 236 (1627) 250 (1724) * 250 (1724) * _ _ _ 031836.3 (5.4) 3/4 (20) * * 155 (1069) 250 (1724) * 250 (1724) * _ _ _ 0318410 (8.6) 1 (25) * * 91 (627) 250 (1724) * 250 (1724) * _ _ _ 0318516 (14) 1-1/4 (32) * * 52 (359) 148 (1020) * 148 (1020) * _ _ _ 0318625 (22) 1-1/2 (40) * * 32 (331) 92 (634) * 92 (634) * _ _ _ 0318740 (34) 2 (50) * * 20 (138) 55 (379) * 55 (379) * _ _ _ 031881 (0.9) 1/2 (15) 142 (979) * * 250 (1724) — 250 (1724) — _ _ _ 031621.6 (1.4) 1/2 (15) 142 (979) * * 250 (1724) — 250 (1724) — _ _ _ 031632.5 (2.2) 1/2 (15) 142 (979) * * 250 (1724) — 250 (1724) — _ _ _ 031644 (3.4) 1/2 (15) 142 (979) * * 250 (1724) — 250 (1724) — _ _ _ 031656.3 (5.4) 3/4 (20) 80 (552) * * 231 (1593) — 231 (1593) — _ _ _ 0316610 (8.6) 1 (25) 52 (359) * * 150 (1034) — 150 (1034) — _ _ _ 0316716 (14) 1-1/4 (32) 32 (221) * * 93 (641) — 93 (641) — _ _ _ 0316825 (22) 1-1/2 (40) 20 (138) * * 60 (414) — 60 (414) — _ _ _ 0316940 (34) 2 (50) 12 (83) * * 37(255) — 37 (255) — _ _ _ 031701 (0.9) 1/2 (15) * 236 (1627) *250 (1724) — 250 (1724) — _ _ _ 031981.6 (1.4) 1/2 (15) * 236 (1627) *250 (1724) — 250 (1724) — _ _ _ 031992.5 (2.2) 1/2 (15) * 236 (1627) *250 (1724) — 250 (1724) — _ _ _ 032004 (3.4) 1/2 (15) * 236 (1627) *250 (1724) — 250 (1724) — _ _ _ 032016.3 (5.4) 3/4 (20) * 155 (1069) *250 (1724) — 250 (1724) — _ _ _ 0320210 (8.6) 1 (25) * 91 (627) *250 (1724) — 250 (1724) — _ _ _ 0320316 (14) 1-1/4 (32) * 52 (359) *148 (1020) — 148 (1020) — _ _ _ 0320425 (22) 1-1/2 (40) * 32 (331) *92 (634) — 92 (634) — _ _ _ 0320540 (34) 2 (50) * 20 (138) *55 (379) — 55 (379) — _ _ _ 03206ActionNormally ClosedNormally OpenMixing*Order valve <strong>and</strong> actuator separately.These selection tables only containFXF end connections with brass trim<strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.Prices are subject to change without notice.9

globe2- <strong>and</strong> 3-way Assemblies 1/2 to 2”ElectronicNon-Spring Return<strong>Actuator</strong>3P 30 sec.3P 120 sec.3P0-10 V/4-20 mA 0-10 V3-way 2-wayActionNormally Open Normally ClosedMixing<strong>Valve</strong> BodySQX82.03U SQX82.00U SKD82.50U SQX62U 599-10022Flow Line APC APC APC APC APCRate Size 273 272 275 271 295Cv (Kvs) in. (mm)Close-off psi (kPa)1 (0.9) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031801.6 (1.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031812.5 (2.2) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031824 (3.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031836.3 (5.4) 3/4 (20) 221 (1524) 221 (1524) 250 (1724) 221 (1524) 238 (1640) _ _ _ 0318410 (8.6) 1 (25) 130 (896) 130 (896) 203 (1400) 130 (896) 140 (965) _ _ _ 0318516 (14) 1-1/4 (32) 75 (517) 75 (517) 117 (807) 75 (517) 81 (558) _ _ _ 0318625 (22) 1-1/2 (40) 46 (317) 46 (317) 73 (503) 46 (317) 50 (345) _ _ _ 0318740 (34) 2 (50) 28 (193) 28 (193) 44 (303) 28 (193) 31 (214) _ _ _ 031881 (0.9) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031621.6 (1.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031632.5 (2.2) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031644 (3.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031656.3 (5.4) 3/4 (20) 173 (1193) 173 (1193) 250 (1724) 173 (1193) 186 (1282) _ _ _ 0316610 (8.6) 1 (25) 112 (772) 112 (772) 201 (1386) 112 (772) 121 (834) _ _ _ 0316716 (14) 1-1/4 (32) 69 (476) 69 (476) 124 (855) 69 (476) 75 (517) _ _ _ 0316825 (22) 1-1/2 (40) 44 (303) 44 (303) 80 (552) 44 (303) 48 (331) _ _ _ 0316940 (34) 2 (50) 27(186) 27(186) 49 (338) 27(186) 30 (207) _ _ _ 031701 (0.9) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031981.6 (1.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031992.5 (2.2) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 032004 (3.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 032016.3 (5.4) 3/4 (20) 221 (1524) 221 (1524) 250 (1724) 221 (1524) 238 (1640) _ _ _ 0320210 (8.6) 1 (25) 130 (896) 130 (896) 203 (1400) 130 (896) 140 (965) _ _ _ 0320316 (14) 1-1/4 (32) 75 (517) 75 (517) 117 (807) 75 (517) 81 (558) _ _ _ 0320425 (22) 1-1/2 (40) 46 (317) 46 (317) 73 (503) 46 (317) 50 (345) _ _ _ 0320540 (34) 2 (50) 28 (193) 28 (193) 44 (303) 28 (193) 31 (214) _ _ _ 03206PartNo.These selection tables only containFXF end connections with brass trim<strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.Prices are subject to change without notice.10

globe2- <strong>and</strong> 3-way Assemblies 1/2 to 2”ElectronicSpring Return2P3P0-10 V0-10 V/4-20 mA 0-10 V<strong>Actuator</strong>3-way 2-way<strong>Valve</strong> BodyActionNormally ClosedNormally OpenMixing599-03611 SKD82.51U 599-03609 SKD62U 599-10022Flow Line APC APC APC APC APCRate Size 299 276 298 274 296Cv (Kvs) in. (mm)Close-off psi (kPa)1 (0.9) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031801.6 (1.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031812.5 (2.2) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031824 (3.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031836.3 (5.4) 3/4 (20) 221 (1524) 221 (1524) 221 (1524) 221 (1524) 238 (1640) _ _ _ 0318410 (8.6) 1 (25) 130 (896) 130 (896) 130 (896) 130 (896) 140 (965) _ _ _ 0318516 (14) 1-1/4 (32) 75 (517) 75 (517) 75 (517) 75 (517) 81 (558) _ _ _ 0318625 (22) 1-1/2 (40) 46 (317) 46 (317) 46 (317) 46 (317) 50 (345) _ _ _ 0318740 (34) 2 (50) 28 (193) 28 (193) 28 (193) 28 (193) 31 (214) _ _ _ 031881 (0.9) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031621.6 (1.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031632.5 (2.2) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031644 (3.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031656.3 (5.4) 3/4 (20) 173 (1193) 250 (1724) 173 (1193) 250 (1724) 186 (1282) _ _ _ 0316610 (8.6) 1 (25) 112 (772) 201 (1386) 112 (772) 201 (1386) 121 (834) _ _ _ 0316716 (14) 1-1/4 (32) 69 (476) 124 (855) 69 (476) 124 (855) 75 (517) _ _ _ 0316825 (22) 1-1/2 (40) 44 (303) 80 (552) 44 (303) 80 (552) 48 (331) _ _ _ 0316940 (34) 2 (50) 27(186) 49 (338) 27(186) 49 (338) 30 (207) _ _ _ 031701 (0.9) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031981.6 (1.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 031992.5 (2.2) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 032004 (3.4) 1/2 (15) 250 (1724) 250 (1724) 250 (1724) 250 (1724) 250 (1724) _ _ _ 032016.3 (5.4) 3/4 (20) 221 (1524) 250 (1724) 221 (1524) 250 (1724) 238 (1640) _ _ _ 0320210 (8.6) 1 (25) 130 (896) 203 (1400) 130 (896) 203 (1400) 140 (965) _ _ _ 0320316 (14) 1-1/4 (32) 75 (517) 117 (807) 75 (517) 117 (807) 81 (558) _ _ _ 0320425 (22) 1-1/2 (40) 46 (317) 73 (503) 46 (317) 73 (503) 50 (345) _ _ _ 0320540 (34) 2 (50) 28 (193) 44 (303) 28 (193) 44 (303) 31 (214) _ _ _ 03206PartNo.These selection tables only containFXF end connections with brass trim<strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.Prices are subject to change without notice.11

globe2- <strong>and</strong> 3-way ANSI Class 125 2-1/2 to 6”3-way 2-wayPneumatic<strong>Valve</strong> Body<strong>Actuator</strong>Flow LineAction Rate SizeCv (Kvs) in. (mm)NormallyClosedNormallyOpenMixing8”8” Hi-Temp.Spring Return20 mm Stroke 40 mm Stroke599-01050 599-01051 599-01010APC APC APC277 278 279PartNo.63 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 05990100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 05991160 (140) 4 (100) — — — 46 (317) _ _ _ 05992250 (215) 5 (125) — — — 29 (199) _ _ _ 05993400 (340) 6 (150) — — — 20 (137) _ _ _ 0599463 (54) 2-1/2 (65) 31 (213) * 95 (655) — _ _ _ 05980100 (86) 3 (80) 20 (138) * 63 (434) — _ _ _ 05981160 (140) 4 (100) — — — 40 (275) _ _ _ 05982250 (215) 5 (125) — — — 26 (179) _ _ _ 05983400 (340) 6 (150) — — — 18 (124) _ _ _ 0598463 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 06160100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 06161160 (140) 4 (100) — — — 46 (317) _ _ _ 06162250 (215) 5 (125) — — — 29 (199) _ _ _ 06163400 (340) 6 (150) — — — 20 (137) _ _ _ 06164*Order valve <strong>and</strong> actuator separately.12”Close-off psi (kPa)12”599-01000APC281These selection tables only containflange end connections withst<strong>and</strong>ard trim <strong>and</strong> equalpercentage flow characterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.Pneumatic w/ Factory-Mounted Positioner<strong>Actuator</strong>8”with positionerSpring Return20 mm Stroke 40 mm Stroke8” Hi-Temp.with positioner12” withpositioner12” withpositioner<strong>Valve</strong> Body599-01050 599-01051 599-01010599-01000PartNo.3-way 2-wayFlow LineAction Rate SizeCv (Kvs) in. (mm)NormallyClosedNormallyOpenMixingAPC APC APC283 284 285Close-off psi (kPa)APC28763 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 05990100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 05991160 (140) 4 (100) — — — 46 (317) _ _ _ 05992250 (215) 5 (125) — — — 29 (199) _ _ _ 05993400 (340) 6 (150) — — — 20 (137) _ _ _ 0599463 (54) 2-1/2 (65) 31 (213) * 95 (655) — _ _ _ 05980100 (86) 3 (80) 20 (138) * 63 (434) — _ _ _ 05981160 (140) 4 (100) — — — 40 (275) _ _ _ 05982250 (215) 5 (125) — — — 26 (179) _ _ _ 05983400 (340) 6 (150) — — — 18 (124) _ _ _ 0598463 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 06160100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 06161160 (140) 4 (100) — — — 46 (317) _ _ _ 06162250 (215) 5 (125) — — — 29 (199) _ _ _ 06163400 (340) 6 (150) — — — 20 (137) _ _ _ 06164Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.*Order valve <strong>and</strong> actuator separately.Prices are subject to change without notice.12

globe2- <strong>and</strong> 3-way ANSI Class 125 2-1/2 to 6”3-way 2-wayElectronic<strong>Valve</strong> Body<strong>Actuator</strong>Flow LineAction Rate SizeCv (Kvs) in. (mm)NormallyClosedNormallyOpenMixing3PNon-Spring ReturnSKD82.50U SKB82.50U SKC82.60UAPC APC APC275 290 293Close-off psi (kPa)599-10021APC295599-1002363 (54) 2-1/2 (65) 34 (234) 97(668) — 50 (344) — _ _ _ 05990100 (86) 3 (80) 22 (152) 63 (434) — 32 (220) — _ _ _ 05991160 (140) 4 (100) — — 39 (268) — 20 (137) _ _ _ 05992250 (215) 5 (125) — — 25 (172) — — _ _ _ 05993400 (340) 6 (150) — — 17(117) — — _ _ _ 0599463 (54) 2-1/2 (65) 38 (262) 153 (518) — 48 (330) — _ _ _ 05980100 (86) 3 (80) 25 (172) 101 (342) — 32 (220) — _ _ _ 05981160 (140) 4 (100) — — 65 (448) — 21 (144) _ _ _ 05982250 (215) 5 (125) — — 42 (289) — — _ _ _ 05983400 (340) 6 (150) — — 29 (199) — — _ _ _ 0598463 (54) 2-1/2 (65) 34 (234) 34 (234) — 50 (344) — _ _ _ 06160100 (86) 3 (80) 22 (152) 22 (152) — 32 (220) — _ _ _ 06161160 (140) 4 (100) — — 39 (268) — 20 (137) _ _ _ 06162250 (215) 5 (125) — — 25 (172) — — _ _ _ 06163400 (340) 6 (150) — — 17(117) — — _ _ _ 06164Lo0-10 VHiAPC297PartNo.These selection tablesonly contain flangeend connections withst<strong>and</strong>ard trim <strong>and</strong>equal percentage flowcharacterics.For completeselection, refer to thecurrent edition ofMaster HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.ElectronicSpring Return<strong>Actuator</strong>3P0-10 V/4-20 mA 0-10 V 0-10 V/4-20 mA<strong>Valve</strong> BodySKD82.51U SKB82.51U SKC82.61USKD62USKB62U 599-10022 SKC62UPartNo.3-way 2-wayFlow LineAction Rate SizeCv (Kvs) in. (mm)NormallyClosedNormallyOpenMixingAPC APC APC276 289 29263 (54) 2-1/2 (65) 34 (234) 97(668) — 34 (234) 97(668) 24 (165) — _ _ _ 05990100 (86) 3 (80) 22 (152) 63 (434) — 22 (152) 63 (434) 15 (103) — _ _ _ 05991160 (140) 4 (100) — — 39 (268) — — — 39 (268) _ _ _ 05992250 (215) 5 (125) — — 25 (172) — — — 25 (172) _ _ _ 05993400 (340) 6 (150) — — 17 (117) — — — 17 (117) _ _ _ 0599463 (54) 2-1/2 (65) 38 (262) 153 (518) — 38 (262) 153 (518) 23 (158) — _ _ _ 05980100 (86) 3 (80) 25 (172) 101 (342) — 25 (172) 101 (342) 16 (110) — _ _ _ 05981160 (140) 4 (100) — — 65 (448) — — — 65 (448) _ _ _ 05982250 (215) 5 (125) — — 42 (289) — — — 42 (289) _ _ _ 05983400 (340) 6 (150) — — 29 (199) — — — 29 (199) _ _ _ 0598463 (54) 2-1/2 (65) 34 (234) 97(668) — 34 (234) 97(668) 24 (165) — _ _ _ 06160100 (86) 3 (80) 22 (152) 63 (434) — 22 (152) 63 (434) 15 (103) — _ _ _ 06161160 (140) 4 (100) — — 39 (268) — — — 39 (268) _ _ _ 06162250 (215) 5 (125) — — 25 (172) — — — 25 (172) _ _ _ 06163400 (340) 6 (150) — — 17 (117) — — — 17 (117) _ _ _ 06164APC274Close-off psi (kPa)APC291APC296APC294Prices are subject to change without notice.13

globe2- <strong>and</strong> 3-way ANSI Class 250 2-1/2 to 6”3-way 2-wayPneumatic<strong>Valve</strong> Body<strong>Actuator</strong>Flow LineAction Rate SizeCv (Kvs) in. (mm)NormallyClosedNormallyOpenMixing8”8” Hi-Temp.Spring Return20 mm Stroke 40 mm Stroke599-01050 599-01051 599-01010APC APC APC277 278 279PartNo.63 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 05950100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 05951160 (140) 4 (100) — — — 46 (317) _ _ _ 05952250 (215) 5 (125) — — — 29 (199) _ _ _ 05953400 (340) 6 (150) — — — 20 (137) _ _ _ 0595463 (54) 2-1/2 (65) 31 (213) * 95 (655) — _ _ _ 05940100 (86) 3 (80) 20 (138) * 63 (434) — _ _ _ 05941160 (140) 4 (100) — — — 40 (275) _ _ _ 05942250 (215) 5 (125) — — — 26 (179) _ _ _ 05943400 (340) 6 (150) — — — 18 (124) _ _ _ 0594463 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 06170100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 06171160 (140) 4 (100) — — — 46 (317) _ _ _ 06172250 (215) 5 (125) — — — 29 (199) _ _ _ 06173400 (340) 6 (150) — — — 20 (137) _ _ _ 06174*Order valve <strong>and</strong> actuator separately.Pneumatic w/ FactoryMounted Positioner<strong>Actuator</strong>8”with positioner12”Close-off psi (kPa)12”599-01000APC281Spring Return20 mm Stroke 40 mm Stroke8” Hi-Temp.with positioner12” withpositioner12” withpositionerThese selection tables only containflange end connections with st<strong>and</strong>ardtrim <strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.<strong>Valve</strong> Body599-01050 599-01051 599-01010599-01000PartNo.3-way 2-wayActionNormallyClosedNormallyOpenMixingAPC APC APCAPCFlow LineRate Size283 284 285 287Cv (Kvs) in. (mm)Close-off psi (kPa)63 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 05950100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 05951160 (140) 4 (100) — — — 46 (317) _ _ _ 05952250 (215) 5 (125) — — — 29 (199) _ _ _ 05953400 (340) 6 (150) — — — 20 (137) _ _ _ 0595463 (54) 2-1/2 (65) 31 (213) * 95 (655) — _ _ _ 05940100 (86) 3 (80) 20 (138) * 63 (434) — _ _ _ 05941160 (140) 4 (100) — — — 40 (275) _ _ _ 05942250 (215) 5 (125) — — — 26 (179) _ _ _ 05943400 (340) 6 (150) — — — 18 (124) _ _ _ 0594463 (54) 2-1/2 (65) 36 (248) * 114 (786) — _ _ _ 06170100 (86) 3 (80) 23 (158) * 74 (610) — _ _ _ 06171160 (140) 4 (100) — — — 46 (317) _ _ _ 06172250 (215) 5 (125) — — — 29 (199) _ _ _ 06173400 (340) 6 (150) — — — 20 (137) _ _ _ 06174*Order valve <strong>and</strong> actuator separately.Prices are subject to change without notice.14

globe2- <strong>and</strong> 3-way ANSI Class 250 2-1/2 to 6”3-way 2-wayElectronic<strong>Valve</strong> Body<strong>Actuator</strong>Flow LineAction Rate SizeCv (Kvs) in. (mm)NormallyClosedNormallyOpenMixing3PNon-Spring ReturnSKD82.50U SKB82.50U SKC82.60UAPC APC APC275 290 293Close-off psi (kPa)599-10021APC295599-1002363 (54) 2-1/2 (65) 34 (234) 97(668) — 50 (344) — _ _ _ 05950100 (86) 3 (80) 22 (152) 63 (434) — 32 (220) — _ _ _ 05951160 (140) 4 (100) — — 39 (268) — 20 (137) _ _ _ 05952250 (215) 5 (125) — — 25 (172) — — _ _ _ 05953400 (340) 6 (150) — — 17(117) — — _ _ _ 0595463 (54) 2-1/2 (65) 38 (262 153 (518) — 48 (330) — _ _ _ 05940100 (86) 3 (80) 25 (172) 101 (342) — 32 (220) — _ _ _ 05941160 (140) 4 (100) — — 65 (448) — 21 (144) _ _ _ 05942250 (215) 5 (125) — — 42 (289) — — _ _ _ 05943400 (340) 6 (150) — — 29 (199) — — _ _ _ 0594463 (54) 2-1/2 (65) 34 (234) 97(688) — 50 (344) — _ _ _ 06170100 (86) 3 (80) 22 (152) 63 (434) — 32 (220) — _ _ _ 06171160 (140) 4 (100) — — 39 (268) — 20 (137) _ _ _ 06172250 (215) 5 (125) — — 25 (172) — — _ _ _ 06173400 (340) 6 (150) — — 17(117) — — _ _ _ 06174Lo0-10 VHiAPC297PartNo.These selection tablesonly contain flange endconnections withst<strong>and</strong>ard trim <strong>and</strong> equalpercentage flowcharacterics.For complete selection,refer to the currentedition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.ElectronicSpring Return<strong>Actuator</strong>3P0-10 V/4-20 mA0-10 V0-10 V/4-20 mA<strong>Valve</strong> BodySKD82.51U SKB82.51U SKC82.61USKD62USKB62U599-10022 SKC62UPartNo.3-way 2-wayFlow LineAction Rate SizeCv (Kvs) in. (mm)NormallyClosedNormallyOpenMixingAPC APC APC276 289 29263 (54) 2-1/2 (65) 34 (234) 97(668) — 34 (234) 97(668) 24 (165) — _ _ _ 05950100 (86) 3 (80) 22 (152) 63 (434) — 22 (152) 63 (434) 15 (103) — _ _ _ 05951160 (140) 4 (100) — — 39 (268) — — — 39 (268) _ _ _ 05952250 (215) 5 (125) — — 25 (172) — — — 25 (172) _ _ _ 05953400 (340) 6 (150) — — 17 (117) — — — 17 (117) _ _ _ 0595463 (54) 2-1/2 (65) 38 (262) 153 (518) — 38 (262) 153 (518) 23 (158) — _ _ _ 05940100 (86) 3 (80) 25 (172) 101 (342) — 25 (172) 101 (342) 16 (110) — _ _ _ 05941160 (140) 4 (100) — — 65 (448) — — — 65 (448) _ _ _ 05942250 (215) 5 (125) — — 42 (289) — — — 42 (289) _ _ _ 05943400 (340) 6 (150) — — 29 (199) — — — 29 (199) _ _ _ 0594463 (54) 2-1/2 (65) 34 (234) 97(668) — 34 (234) 97(668) 24 (165) — _ _ _ 06170100 (86) 3 (80) 22 (152) 63 (434) — 22 (152) 63 (434) 15 (103) — _ _ _ 06171160 (140) 4 (100) — — 39 (268) — — — 39 (268) _ _ _ 06172250 (215) 5 (125) — — 25 (172) — — — 25 (172) _ _ _ 06173400 (340) 6 (150) — — 17 (117) — — — 17 (117) _ _ _ 06174APC274Close-off psi (kPa)APC291APC296APC294Prices are subject to change without notice.15

2-way Assemblies 1/2 to 2”ballElectronic<strong>Actuator</strong>Fail-in-PlaceFail-Safe3P 0-10 Vdc 2P 3P0-10 Vdc<strong>Valve</strong> BodyActionNormallyOpenGDE131.1P GLB131.1P GDE161.1P GLB161.1P GMA121.1P GMA131.1U GMA161.1PLine Flow APC APC APC APC APC APC APCSize Rate 171A 171B 171C 171D 171E 171F 171Gin. (mm) Cv (Kvs)Close-off psi (kPa)1/2 (15) 0.4 (0.34) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102031/2 (15) 0.63 (0.54) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102041/2 (15) 1.6 (1.4) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102051/2 (15) 2.5 (2.2) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102061/2 (15) 4 (3.5) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102071/2 * (15) 10 (8.6) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102083/4 (20) 10 (8.6) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102093/4 * (20) 25 (22) 130 (869) — 130 (869) — 130 (869) 130 (869) 130 (869) _ _ _ _ 102101 (25) 10 (8.6) 100 (689) — 100 (689) — 100 (689) 100 (689) 100 (689) _ _ _ _ 102111 (25) 25 (22) 100 (689) — 100 (689) — 100 (689) 100 (689) 100 (689) _ _ _ _ 102121 (25) 16 (14) 100 (689) — 100 (689) — 100 (689) 100 (689) 100 (689) _ _ _ _ 102131 * (25) 63 (54) 100 (689) — 100 (689) — 100 (689) 100 (689) 100 (689) _ _ _ _ 102141-1/4 (30) 16 (14) 100 (689) — 100 (689) — 100 (689) 100 (689) 100 (689) _ _ _ _ 102151-1/4 (30) 40 (35) 100 (689) — 100 (689) — 100 (689) 100 (689) 100 (689) _ _ _ _ 102161-1/4 * (30) 100 (86) 100 (689) — 100 (689) — 100 (689) 100 (689) 100 (689) _ _ _ _ 102171-1/2 (40) 25 (22) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 102181-1/2 * (40) 63 (54) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 102191-1/2 (40) 40 (35) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 102201-1/2 * (40) 160 (138) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 102212 (50) 40 (35) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 102222 * (50) 100 (86) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 102232 (50) 63 (54) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 102242 * (50) 250 (214) — 70 (482) — 70 (482) 70 (482) 70 (482) 70 (482) _ _ _ _ 10225PartNo.* Denotes a full-port valve with no flow optimizer insert.These selection tables only containFXF end connections with st<strong>and</strong>ardtrim <strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Complete AssemblyAPC + Part No.<strong>Valve</strong> Body Only599 + Part No.Prices are subject to change without notice.16

utterfly2-way Assemblies 2 to 12”Base Model Positioner120 V E/P <strong>Valve</strong>24 V E/P <strong>Valve</strong>Pneumatic Spring ReturnNormally Closed (Fail Closed)Normally Open (Fail Open)150 psi Close-off 100 psi Close-off - 4-6 150 psi Close-off 100 psi Close-off - 4-6Cv 50 psi Close-off - 8-12 50 psi Close-off - 8-12Size Part No. Part No. Part No. Part No.60 2" BV2W02FS2LCXXXX —BV2W02FS2LOXXXX—151 2-1/2" BV2W25FS2LCXXXX —BV2W25FS2LOXXXX—262 3" BV2W03FS2LCXXXX —BV2W03FS2LOXXXX—6474" BV2W04FS2LCXXXX BV2W04US2LCXXXX BV2W04FS2LOXXXX BV2W04US2LOXXXX1141 5" BV2W05FS2LCXXXX BV2W05US2LCXXXX BV2W05FS2LOXXXX BV2W05US2LOXXXX1160*/1580 6" BV2W06FS2LCXXXX BV2W06US2LCXXXX BV2W06FS2LOXXXX BV2W06US2LOXXXX1754* 8" —BV2W08US2LCXXXX —BV2W08US2LOXXXX2524* 10" —BV2W10US2LCXXXX —BV2W10US2LOXXXX3470* 12" —BV2W12US2LCXXXX —BV2W12US2LOXXXX60 2" BV2W02FS2LCPXXX —BV2W02FS2LOPXXX—151 2-1/2" BV2W25FS2LCPXXX —BV2W25FS2LOPXXX—262 3" BV2W03FS2LCPXXX —BV2W03FS2LOPXXX—6474" BV2W04FS2LCPXXX BV2W04US2LCPXXX BV2W04FS2LOPXXX BV2W04US2LOPXXX1141 5" BV2W05FS2LCPXXX BV2W05US2LCPXXX BV2W05FS2LOPXXX BV2W05US2LOPXXX1160*/1580 6" BV2W06FS2LCPXXX BV2W06US2LCPXXX BV2W06FS2LOPXXX BV2W06US2LOPXXX1754* 8" —BV2W08US2LCPXXX —BV2W08US2LOPXXX2524* 10" —BV2W10US2LCPXXX —BV2W10US2LOPXXX3470* 12" —BV2W12US2LCPXXX —BV2W12US2LOPXXX60 2" BV2W02FS2LCTXXX —BV2W02FS2LOTXXX—151 2-1/2" BV2W25FS2LCTXXX —BV2W25FS2LOTXXX—262 3" BV2W03FS2LCTXXX —BV2W03FS2LOTXXX—6474" BV2W04FS2LCTXXX BV2W04US2LCTXXX BV2W04FS2LOTXXX BV2W04US2LOTXXX1141 5" BV2W05FS2LCTXXX BV2W05US2LCTXXX BV2W05FS2LOTXXX BV2W05US2LOTXXX1160*/1580 6" BV2W06FS2LCTXXX BV2W06US2LCTXXX BV2W06FS2LOTXXX BV2W06US2LOTXXX1754* 8" —BV2W08US2LCTXXX —BV2W08US2LOTXXX2524* 10" —BV2W10US2LCTXXX —BV2W10US2LOTXXX3470* 12" —BV2W12US2LCTXXX —BV2W12US2LOTXXX60 2" BV2W02FS2LCUXXX —BV2W02FS2LOUXXX—151 2-1/2" BV2W25FS2LCUXXX —BV2W25FS2LOUXXX—262 3" BV2W03FS2LCUXXX —BV2W03FS2LOUXXX—6474" BV2W04FS2LCUXXX BV2W04US2LCUXXX BV2W04FS2LOUXXX BV2W04US2LOUXXX1141 5" BV2W05FS2LCUXXX BV2W05US2LCUXXX BV2W05FS2LOUXXX BV2W05US2LOUXXX1580 6" BV2W06FS2LCUXXX BV2W06US2LCUXXX BV2W06FS2LOUXXX BV2W06US2LOUXXX1754 8" —BV2W08US2LCUXXX —BV2W08US2LOUXXX2524 10" —BV2W10US2LCUXXX —BV2W10US2LOUXXX3470 12" —BV2W12US2LCUXXX —BV2W12US2LOUXXX*6-inch 150 psi <strong>and</strong> 8-, 10- <strong>and</strong> 12-inch only rotate to 70° max.These selection tables only contain lugend connections with st<strong>and</strong>ard trim.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Prices are subject to change without notice.17

utterfly3-way Assemblies 2 to 12”Base ModelPositionerPneumatic Spring ReturnCvRun Branch58 54135 114165 148*419 348*740 600*1051 867*1661 1424*2439 2132*3401 3019*58 54135 114165 148*419 348*740 600*1051 867*1661 1424*2439 2132*3401 3019*58 54135 114165 148*419 348*740 600*1051 867*1661 1424*2439 2132*3401 3019*58 54135 114165 148*419 348*740 600*1051 867*1661 1424*2439 2132*3401 3019*Assembly A Assembly A Assembly B Assembly B150 psi Close-off 100 psi Close-off - 4-6 150 psi Close-off 100 psi Close-off - 4-650 psi Close-off - 8-12 50 psi Close-off - 8-12Size Part No. Part No. Part No. Part No.2" BV3W02FS2LAXXXX —BV3W02FS2LBXXXX—2-1/2" BV3W25FS2LAXXXX —BV3W25FS2LBXXXX—3" BV3W03FS2LAXXXX —BV3W03FS2LBXXXX—4" BV3W04FS2LAXXXX BV3W04US2LAXXXX BV3W04FS2LBXXXX BV3W04US2LBXXXX5" BV3W05FS2LAXXXX BV3W05US2LAXXXX BV3W05FS2LBXXXX BV3W05US2LBXXXX6" BV3W06FS2LAXXXX BV3W06US2LAXXXX BV3W06FS2LBXXXX BV3W06US2LBXXXX8" —BV3W08US2LAXXXX —BV3W08US2LBXXXX10" —BV3W10US2LAXXXX —BV3W10US2LBXXXX12" —BV3W12US2LAXXXX —BV3W12US2LBXXXXAssembly C Assembly C Assembly D Assembly D2" BV3W02FS2LCXXXX —BV3W02FS2LDXXXX—2-1/2” BV3W25FS2LCXXXX —BV3W25FS2LDXXXX—3” BV3W03FS2LCXXXX —BV3W03FS2LDXXXX—4” BV3W04FS2LCXXXX BV3W04US2LCXXXX BV3W04FS2LDXXXX BV3W04US2LDXXXX5” BV3W05FS2LCXXXX BV3W05US2LCXXXX BV3W05FS2LDXXXX BV3W05US2LDXXXX6” BV3W06FS2LCXXXX BV3W06US2LCXXXX BV3W06FS2LDXXXX BV3W06US2LDXXXX8” —BV3W08US2LCXXXX —BV3W08US2LDXXXX10” —BV3W10US2LCXXXX —BV3W10US2LDXXXX12” —BV3W12US2LCXXXX —BV3W12US2LDXXXXAssembly A Assembly A Assembly B Assembly B2" BV3W02FS2LAPXXX —BV3W02FS2LBPXXX—2-1/2" BV3W25FS2LAPXXX —BV3W25FS2LBPXXX—3" BV3W03FS2LAPXXX —BV3W03FS2LBPXXX—4" BV3W04FS2LAPXXX BV3W04US2LAPXXX BV3W04FS2LBPXXX BV3W04US2LBPXXX5" BV3W05FS2LAPXXX BV3W05US2LAPXXX BV3W05FS2LBPXXX BV3W05US2LBPXXX6" BV3W06FS2LAPXXX BV3W06US2LAPXXX BV3W06FS2LBPXXX BV3W06US2LBPXXX8" —BV3W08US2LAPXXX —BV3W08US2LBPXXX10" —BV3W10US2LAPXXX —BV3W10US2LBPXXX12" —BV3W12US2LAPXXX —BV3W12US2LBPXXXAssembly C Assembly C Assembly D Assembly D2" BV3W02FS2LCPXXX —BV3W02FS2LDPXXX—2-1/2” BV3W25FS2LCPXXX —BV3W25FS2LDPXXX—3” BV3W03FS2LCPXXX —BV3W03FS2LDPXXX—4” BV3W04FS2LCPXXX BV3W04US2LCPXXX BV3W04FS2LDPXXX BV3W04US2LDPXXX5” BV3W05FS2LCPXXX BV3W05US2LCPXXX BV3W05FS2LDPXXX BV3W05US2LDPXXX6” BV3W06FS2LCPXXX BV3W06US2LCPXXX BV3W06FS2LDPXXX BV3W06US2LDPXXX8” —BV3W08US2LCPXXX —BV3W08US2LDPXXX10” —BV3W10US2LCPXXX —BV3W10US2LDPXXX12” —BV3W12US2LCPXXX —BV3W12US2LDPXXX*3- through 12-inch valves only rotate 70° max.3-way Assembly ConfigurationsKeyF.C.F.O.ACTFail ClosedFail Open<strong>Actuator</strong> Location18

120 V EP <strong>Valve</strong>24 V EP <strong>Valve</strong>butterfly3-way Assemblies 2 to 12”Pneumatic Spring ReturnCvRun Branch58 54135 114165 148*419 348*740 600*1051 867*1661 1424*2439 2132*3401 3019*Assembly A Assembly A Assembly B Assembly B150 psi Close-off 100 psi Close-off - 4-6 150 psi Close-off 100 psi Close-off - 4-650 psi Close-off - 8-12 50 psi Close-off - 8-12Size Part No. Part No. Part No. Part No.2" BV3W02FS2LATXXX —BV3W02FS2LBTXXX—2-1/2" BV3W25FS2LATXXX —BV3W25FS2LBTXXX—3" BV3W03FS2LATXXX —BV3W03FS2LBTXXX—4" BV3W04FS2LATXXX BV3W04US2LATXXX BV3W04FS2LBTXXX BV3W04US2LBTXXX5" BV3W05FS2LATXXX BV3W05US2LATXXX BV3W05FS2LBTXXX BV3W05US2LBTXXX6" BV3W06FS2LATXXX BV3W06US2LATXXX BV3W06FS2LBTXXX BV3W06US2LBTXXX8" —BV3W08US2LATXXX —BV3W08US2LBTXXX10" —BV3W10US2LATXXX —BV3W10US2LBTXXX12" —BV3W12US2LATXXX —BV3W12US2LBTXXX58 54135 114165 148*419 348*740 6001051 867*1661 1424*2439 2132*3401 3019*58 54135 114165 148*419 348*740 600*1051 867*1661 1424*2439 2132*3401 3019*58 54135 114165 148*419 348*740 6001051 867*1661 1424*2439 2132*3401 3019*Assembly C Assembly C Assembly D Assembly D2" BV3W02FS2LCTXXX —BV3W02FS2LDTXXX—2-1/2" BV3W25FS2LCTXXX —BV3W25FS2LDTXXX—3” BV3W03FS2LCTXXX —BV3W03FS2LDTXXX—4” BV3W04FS2LCTXXX BV3W04US2LCTXXX BV3W04FS2LDTXXX BV3W04US2LDTXXX5” BV3W05FS2LCTXXX BV3W05US2LCTXXX BV3W05FS2LDTXXX BV3W05US2LDTXXX6” BV3W06FS2LCTXXX BV3W06US2LCTXXX BV3W06FS2LDTXXX BV3W06US2LDTXXX8” —BV3W08US2LCTXXX —BV3W08US2LDTXXX10” —BV3W10US2LCTXXX —BV3W10US2LDTXXX12” —BV3W12US2LCTXXX —BV3W12US2LDTXXXAssembly A Assembly A Assembly B Assembly B2" BV3W02FS2LAUXXX —BV3W02FS2LBUXXX—2-1/2" BV3W25FS2LAUXXX —BV3W25FS2LBUXXX—3" BV3W03FS2LAUXXX —BV3W03FS2LBUXXX—4" BV3W04FS2LAUXXX BV3W04US2LAUXXX BV3W04FS2LBUXXX BV3W04US2LBUXXX5" BV3W05FS2LAUXXX BV3W05US2LAUXXX BV3W05FS2LBUXXX BV3W05US2LBUXXX6" BV3W06FS2LAUXXX BV3W06US2LAUXXX BV3W06FS2LBUXXX BV3W06US2LBUXXX8" —BV3W08US2LAUXXX —BV3W08US2LBUXXX10" —BV3W10US2LAUXXX —BV3W10US2LBUXXX12" —BV3W12US2LAUXXX —BV3W12US2LBUXXXAssembly C Assembly C Assembly D Assembly D2" BV3W02FS2LCUXXX —BV3W02FS2LDUXXX—2-1/2" BV3W25FS2LCUXXX —BV3W25FS2LDUXXX—3” BV3W03FS2LCUXXX —BV3W03FS2LDUXXX—4” BV3W04FS2LCUXXX BV3W04US2LCUXXX BV3W04FS2LDUXXX BV3W04US2LDUXXX5” BV3W05FS2LCUXXX BV3W05US2LCUXXX BV3W05FS2LDUXXX BV3W05US2LDUXXX6” BV3W06FS2LCUXXX BV3W06US2LCUXXX BV3W06FS2LDUXXX BV3W06US2LDUXXX8” —BV3W08US2LCUXXX —BV3W08US2LDUXXX10” —BV3W10US2LCUXXX —BV3W10US2LDUXXX12” —BV3W12US2LCUXXX —BV3W12US2LDUXXX*3- through 12-inch valves only rotate 70° max.These selection tables only contain lug end connections withst<strong>and</strong>ard trim.For complete selection, refer to the current edition of MasterHVAC Products Catalog.Prices are subject to change without notice.19

utterfly2-way Assemblies 2 to 12”24 VacFloating24 VacMod. 0-10 V24 VacOn/Off120 VacOn/Off24 VacMod. 4-20 mAElectric Spring ReturnNormally ClosedNormally Open(Fail Closed)(Fail Open)100 psi Close-off 100 psi Close-offCv Size Part No. Part No.60 2" BV2W02UG1LCXXXX BV2W02UG1LOXXXX151 2-1/2" BV2W25UG1LCXXXX BV2W25UG1LOXXXX262 3" BV2W03UG1LCXXXX BV2W03UG1LOXXXX6474" BV2W04UG1LCXXXX BV2W04UG1LOXXXX60 2" BV2W02UG2LCXXXX BV2W02UG2LOXXXX151 2-1/2" BV2W25UG2LCXXXX BV2W25UG2LOXXXX262 3" BV2W03UG2LCXXXX BV2W03UG2LOXXXX6474" BV2W04UG2LCXXXX BV2W04UG2LOXXXX60 2" BV2W02UG3LCXXXX BV2W02UG3LOXXXX151 2-1/2" BV2W25UG3LCXXXX BV2W25UG3LOXXXX262 3" BV2W03UG3LCXXXX BV2W03UG3LOXXXX6474" BV2W04UG3LCXXXX BV2W04UG3LOXXXX60 2" BV2W02UG4LCXXXX BV2W02UG4LOXXXX151 2-1/2" BV2W25UG4LCXXXX BV2W25UG4LOXXXX262 3" BV2W03UG4LCXXXX BV2W03UG4LOXXXX6474" BV2W04UG4LCXXXX BV2W04UG4LOXXXX60 2" BV2W02UG5LCXXXX BV2W02UG5LOXXXX151 2-1/2" BV2W25UG5LCXXXX BV2W25UG5LOXXXX262 3" BV2W03UG5LCXXXX BV2W03UG5LOXXXX6474" BV2W04UG5LCXXXX BV2W04UG5LOXXXXThese selection tables only contain lugend connections with st<strong>and</strong>ard trim.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Prices are subject to change without notice.20

utterfly3-way Assemblies 2 to 12”24 VacOn/Off24 VacMod. 0-10 V120 VacOn/Off24 VacFloating24 VacMod. 4-20 mAElectric Spring ReturnAssembly A Assembly B Assembly C Assembly DCv 100 psi Close-off 100 psi Close-off 100 psi Close-off 100 psi Close-offRun Branch Size Part No. Part No. Part No. Part No.58 54 2" BV3W02UG1LAXXXX BV3W02UG1LBXXXX BV3W02UG1LCXXXX BV3W02UG1LDXXXX135 114 2-1/2" BV3W25UG1LAXXXX BV3W25UG1LBXXXX BV3W25UG1LCXXXX BV3W25UG1LDXXXX229 188 3" BV3W03UG1LAXXXX BV3W03UG1LBXXXX BV3W03UG1LCXXXX BV3W03UG1LDXXXX511 385 4" BV3W04UG1LAXXXX BV3W04UG1LBXXXX BV3W04UG1LCXXXX BV3W04UG1LDXXXX58 54 2" BV3W02UG2LAXXXX BV3W02UG2LBXXXX BV3W02UG2LCXXXX BV3W02UG2LDXXXX135 114 2-1/2" BV3W25UG2LAXXXX BV3W25UG2LBXXXX BV3W25UG2LCXXXX BV3W25UG2LDXXXX229 188 3" BV3W03UG2LAXXXX BV3W03UG2LBXXXX BV3W03UG2LCXXXX BV3W03UG2LDXXXX511 385 4" BV3W04UG2LAXXXX BV3W04UG2LBXXXX BV3W04UG2LCXXXX BV3W04UG2LDXXXX58 54 2" BV3W02UG3LAXXXX BV3W02UG3LBXXXX BV3W02UG3LCXXXX BV3W02UG3LDXXXX135 114 2-1/2" BV3W25UG3LAXXXX BV3W25UG3LBXXXX BV3W25UG3LCXXXX BV3W25UG3LDXXXX229 188 3" BV3W03UG3LAXXXX BV3W03UG3LBXXXX BV3W03UG3LCXXXX BV3W03UG3LDXXXX511 385 4" BV3W04UG3LAXXXX BV3W04UG3LBXXXX BV3W04UG3LCXXXX BV3W04UG3LDXXXX58 54 2" BV3W02UG4LAXXXX BV3W02UG4LBXXXX BV3W02UG4LCXXXX BV3W02UG4LDXXXX135 114 2-1/2" BV3W25UG4LAXXXX BV3W25UG4LBXXXX BV3W25UG4LCXXXX BV3W25UG4LDXXXX229 188 3" BV3W03UG4LAXXXX BV3W03UG4LBXXXX BV3W03UG4LCXXXX BV3W03UG4LDXXXX511 385 4" BV3W04UG4LAXXXX BV3W04UG4LBXXXX BV3W04UG4LCXXXX BV3W04UG4LDXXXX58 54 2" BV3W02UG5LAXXXX BV3W02UG5LBXXXX BV3W02UG5LCXXXX BV3W02UG5LDXXXX135 114 2-1/2" BV3W25UG5LAXXXX BV3W25UG5LBXXXX BV3W25UG5LCXXXX BV3W25UG5LDXXXX229 188 3" BV3W03UG5LAXXXX BV3W03UG5LBXXXX BV3W03UG5LCXXXX BV3W03UG5LDXXXX511 385 4" BV3W04UG5LAXXXX BV3W04UG5LBXXXX BV3W04UG5LCXXXX BV3W04UG5LDXXXX3-way Assembly ConfigurationsKeyF.C.F.O.ACTFail ClosedFail Open<strong>Actuator</strong> LocationThese selection tables only contain lugend connections with st<strong>and</strong>ard trim.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Prices are subject to change without notice.21

utterfly2-way Assemblies 2 to 12”Modulating 0-10 VElectric Non-Spring ReturnNon-Fail SafeNon-Fail Safe150 psi Close-off, 2-6 100 psi Close-off, 24 Vac120 Vac 8-12 50 psi Close-off, 120 VacCv Size Part No. Part No.60 2" BV2W02FE2LNXXXX BV2W02UG6LNXXXX151 2-1/2" BV2W25FE2LNXXXX BV2W25UG6LNXXXX262 3" BV2W03FE2LNXXXX BV2W03UG6LNXXXX6474" BV2W04FE2LNXXXX BV2W04UG6LNXXXX1141 5" BV2W05FE2LNXXXX BV2W05UG6LNXXXX1580 6" BV2W06FE2LNXXXX BV2W06UG6LNXXXX2892 8" BV2W08FE2LNXXXX BV2W08UE2LNXXXX4593 10" BV2W10FE2LNXXXX BV2W10UE2LNXXXX6682 12" BV2W12FE2LNXXXX BV2W12UE2LNXXXX60 2" BV2W02FEMLNXXHX BV2W02UG7LNXXXX151 2-1/2" BV2W25FEMLNXXHX BV2W25UG7LNXXXX262 3" BV2W03FEMLNXXHX BV2W03UG7LNXXXX6474" BV2W04FEMLNXXHX BV2W04UG7LNXXXX1141 5" BV2W05FEMLNXXHX BV2W05UG7LNXXXX1580 6" BV2W06FEMLNXXHX BV2W06UG7LNXXXX2892 8" BV2W08FEMLNXXHX BV2W08UEMLNXXHX4593 10" BV2W10FEMLNXXHX BV2W10UEMLNXXHX6682 12" BV2W12FEMLNXXHX BV2W12UEMLNXXHX60 2" BV2W02FEPLNXXHX BV2W02UG8LNXXXX151 2-1/2" BV2W25FEPLNXXHX BV2W25UG8LNXXXX262 3" BV2W03FEPLNXXHX BV2W03UG8LNXXXX6474" BV2W04FEPLNXXHX BV2W04UG8LNXXXX1141 5" BV2W05FEPLNXXHX BV2W05UG8LNXXXX1580 6" BV2W06FEPLNXXHX BV2W06UG8LNXXXX2892 8" BV2W08FEPLNXXHX BV2W08UEPLNXXHX4593 10" BV2W10FEPLNXXHX BV2W10UEPLNXXHX6682 12" BV2W12FEPLNXXHX BV2W12UEPLNXXHXFloating/2-position Modulating 4-20 mAThese selection tables only contain lugend connections with st<strong>and</strong>ard trim.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Prices are subject to change without notice.22

utterfly3-way Assemblies 2 to 12”Floating 2-positionElectric Non-Spring ReturnAssembly A Assembly A Assembly B Assembly B150 psi Close-off, 100 psi Close-off, 24 Vac 150 psi Close-off, 120 Vac 100 psi Close-off, 24 VacCv120 Vac 50 psi Close-off, 120 Vac 50 psi Close-off, 120 VacRun Branch Size Part No. Part No. Part No. Part No.58 54 2" BV3W02FE2LAXXXX BV3W02UG6LAXXXX BV3W02FE2LBXXXX BV3W02UG6LBXXXX135 114 2-1/2" BV3W25FE2LAXXXX BV3W25UG6LAXXXX BV3W25FE2LBXXXX BV3W25UG6LBXXXX229 188 3" BV3W03FE2LAXXXX BV3W03UG6LAXXXX BV3W03FE2LBXXXX BV3W03UG6LBXXXX511 385 4" BV3W04FE2LAXXXX BV3W04UG6LAXXXX BV3W04FE2LBXXXX BV3W04UG6LBXXXX870 642 5" BV3W05FE2LAXXXX BV3W05UG6LAXXXX BV3W05FE2LBXXXX BV3W05UG6LBXXXX1242 935 6" BV3W06FE2LAXXXX BV3W06UG6LAXXXX BV3W06FE2LBXXXX BV3W06UG6LBXXXX2254 1688 8" BV3W08FE2LAXXXX BV3W08UE2LAXXXX BV3W08FE2LBXXXX BV3W08UE2LBXXXX3570 2667 10" BV3W10FE2LAXXXX BV3W10UE2LAXXXX BV3W10FE2LBXXXX BV3W10UE2LBXXXX5240 3938 12" BV3W12FE2LAXXXX BV3W12UE2LAXXXX BV3W12FE2LBXXXX BV3W12UE2LBXXXXAssembly C Assembly C Assembly D Assembly D58 54 2" BV3W02FE2LCXXXX BV3W02UG6LCXXXX BV3W02FE2LDXXXX BV3W02UG6LDXXXX135 114 2-1/2" BV3W25FE2LCXXXX BV3W25UG6LCXXXX BV3W25FE2LDXXXX BV3W25UG6LDXXXX229 188 3” BV3W03FE2LCXXXX BV3W03UG6LCXXXX BV3W03FE2LDXXXX BV3W03UG6LDXXXX511 385 4” BV3W04FE2LCXXXX BV3W04UG6LCXXXX BV3W04FE2LDXXXX BV3W04UG6LDXXXX870 642 5” BV3W05FE2LCXXXX BV3W05UG6LCXXXX BV3W05FE2LDXXXX BV3W05UG6LDXXXX1242 935 6” BV3W06FE2LCXXXX BV3W06UG6LCXXXX BV3W06FE2LDXXXX BV3W06UG6LDXXXX2254 1688 8” BV3W08FE2LCXXXX BV3W08UE2LCXXXX BV3W08FE2LDXXXX BV3W08UE2LDXXXX3570 2667 10” BV3W10FE2LCXXXX BV3W10UE2LCXXXX BV3W10FE2LDXXXX BV3W10UE2LDXXXX5240 3938 12” BV3W12FE2LCXXXX BV3W12UE2LCXXXX BV3W12FE2LDXXXX BV3W12UE2LDXXXX3-way Assembly ConfigurationsKeyF.C.F.O.ACTFail ClosedFail Open<strong>Actuator</strong> LocationThese selection tables only contain lugend connections with st<strong>and</strong>ard trim.For complete selection, refer to thecurrent edition of Master HVACProducts Catalog.Prices are subject to change without notice.23

utterfly3-way Assemblies 2 to 12”Modulating 4-20 mAModulating 0-10 VElectric Non-Spring ReturnAssembly A Assembly A Assembly B Assembly B150 psi Close-off, 120 Vac 100 psi Close-off, 24 Vac 150 psi Close-off, 120 Vac 100 psi Close-off, 24 VacCv50 psi Close-off, 120 Vac 50 psi Close-off, 120 VacRun Branch Size Part No. Part No. Part No. Part No.58 54 2" BV3W02FEMLAXXHX BV3W02UG7LAXXXX BV3W02FEMLBXXHX BV3W02UG7LBXXXX135 114 2-1/2" BV3W25FEMLAXXHX BV3W25UG7LAXXXX BV3W25FEMLBXXHX BV3W25UG7LBXXXX229 188 3" BV3W03FEMLAXXHX BV3W03UG7LAXXXX BV3W03FEMLBXXHX BV3W03UG7LBXXXX511 385 4" BV3W04FEMLAXXHX BV3W04UG7LAXXXX BV3W04FEMLBXXHX BV3W04UG7LBXXXX870 642 5" BV3W05FEMLAXXHX BV3W05UG7LAXXXX BV3W05FEMLBXXHX BV3W05UG7LBXXXX1242 935 6" BV3W06FEMLAXXHX BV3W06UG7LAXXXX BV3W06FEMLBXXHX BV3W06UG7LBXXXX2254 1688 8" BV3W08FEMLAXXHX BV3W08UEMLAXXHX BV3W08FEMLBXXHX BV3W08UEMLBXXHX3570 2667 10" BV3W10FEMLAXXHX BV3W10UEMLAXXHX BV3W10FEMLBXXHX BV3W10UEMLBXXHX5240 3938 12" BV3W12FEMLAXXHX BV3W12UEMLAXXHX BV3W12FEMLBXXHX BV3W12UEMLBXXHXAssembly C Assembly C Assembly D Assembly D58 54 2" BV3W02FEMLCXXHX BV3W02UG7LCXXXX BV3W02FEMLDXXHX BV3W02UG7LDXXXX135 114 2-1/2" BV3W25FEMLCXXHX BV3W25UG7LCXXXX BV3W25FEMLDXXHX BV3W25UG7LDXXXX229 188 3” BV3W03FEMLCXXHX BV3W03UG7LCXXXX BV3W03FEMLDXXHX BV3W03UG7LDXXXX511 385 4” BV3W04FEMLCXXHX BV3W04UG7LCXXXX BV3W04FEMLDXXHX BV3W04UG7LDXXXX870 642 5” BV3W05FEMLCXXHX BV3W05UG7LCXXXX BV3W05FEMLDXXHX BV3W05UG7LDXXXX1242 935 6” BV3W06FEMLCXXHX BV3W06UG7LCXXXX BV3W06FEMLDXXHX BV3W06UG7LDXXXX2254 1688 8” BV3W08FEMLCXXHX BV3W08UEMLCXXHX BV3W08FEMLDXXHX BV3W08UEMLDXXHX3570 2667 10” BV3W10FEMLCXXHX BV3W10UEMLCXXHX BV3W10FEMLDXXHX BV3W10UEMLDXXHX5240 3938 12” BV3W12FEMLCXXHX BV3W12UEMLCXXHX BV3W12FEMLDXXHX BV3W12UEMLDXXHXAssembly A Assembly A Assembly B Assembly B58 54 2" BV3W02FEPLAXXHX BV3W02UG8LAXXXX BV3W02FEPLBXXHX BV3W02UG8LBXXXX135 114 2-1/2" BV3W25FEPLAXXHX BV3W25UG8LAXXXX BV3W25FEPLBXXHX BV3W25UG8LBXXXX229 188 3" BV3W03FEPLAXXHX BV3W03UG8LAXXXX BV3W03FEPLBXXHX BV3W03UG8LBXXXX511 385 4" BV3W04FEPLAXXHX BV3W04UG8LAXXXX BV3W04FEPLBXXHX BV3W04UG8LBXXXX870 642 5" BV3W05FEPLAXXHX BV3W05UG8LAXXXX BV3W05FEPLBXXHX BV3W05UG8LBXXXX1242 935 6" BV3W06FEPLAXXHX BV3W06UG8LAXXXX BV3W06FEPLBXXHX BV3W06UG8LBXXXX2254 1688 8" BV3W08FEPLAXXHX BV3W08UEPLAXXHX BV3W08FEPLBXXHX BV3W08UEPLBXXHX3570 2667 10" BV3W10FEPLAXXHX BV3W10UEPLAXXHX BV3W10FEPLBXXHX BV3W10UEPLBXXHX5240 3938 12" BV3W12FEPLAXXHX BV3W12UEPLAXXHX BV3W12FEPLBXXHX BV3W12UEPLBXXHXAssembly C Assembly C Assembly D Assembly D58 54 2" BV3W02FEPLCXXHX BV3W02UG8LCXXXX BV3W02FEPLDXXHX BV3W02UG8LDXXXX135 114 2-1/2" BV3W25FEPLCXXHX BV3W25UG8LCXXXX BV3W25FEPLDXXHX BV3W25UG8LDXXXX229 188 3” BV3W03FEPLCXXHX BV3W03UG8LCXXXX BV3W03FEPLDXXHX BV3W03UG8LDXXXX511 385 4” BV3W04FEPLCXXHX BV3W04UG8LCXXXX BV3W04FEPLDXXHX BV3W04UG8LDXXXX870 642 5” BV3W05FEPLCXXHX BV3W05UG8LCXXXX BV3W05FEPLDXXHX BV3W05UG8LDXXXX1242 935 6” BV3W06FEPLCXXHX BV3W06UG8LCXXXX BV3W06FEPLDXXHX BV3W06UG8LDXXXX2254 1688 8” BV3W08FEPLCXXHX BV3W08UEPLCXXHX BV3W08FEPLDXXHX BV3W08UEPLDXXHX3570 2667 10” BV3W10FEPLCXXHX BV3W10UEPLCXXHX BV3W10FEPLDXXHX BV3W10UEPLDXXHX5240 3938 12” BV3W12FEPLCXXHX BV3W12UEPLCXXHX BV3W12FEPLDXXHX BV3W12UEPLDXXHXThese selection tables only contain lug endconnections with st<strong>and</strong>ard trim.3-way Assembly ConfigurationsFor complete selection, refer to the currentedition of Master HVAC Products Catalog.Prices are subject to change without notice.KeyF.C.F.O.ACTFail ClosedFail Open<strong>Actuator</strong> Location24

AccessoriesDescription Product Group Quantity Part No.1/2” Conduit Adaptor Powermite 599 Series 1 544-023For use when a plenum-rated SQS, SQX, SKDconnection is required.& SKB/CConduit Connectors Powermite 599 Series 1 ASY97For use when a plenum-ratedSSB61U/81Uconnection is required.Terminal Plug Powermite 599 Series 1 ASY99Labeled Y1-G-Y2.SSB81UTerminal Plug Powermite 599 Series 1 ASY100Labeled G-G0-Y.SSB61UReplacement Screws Powermite 599 Series 1 ASY98For use with conduitSSB61U/81Uor terminal connectors.Protective Black Knob. Powermite 599 Series MT 1 4 268 8895 0Protects bonnet <strong>and</strong> threads.Allows manual operation prior toactuator mounting.Diaphragm Kit Powermite 599 Series MT Package of 5 656-736Contains five diaphragms <strong>and</strong>mounting screws.Auxiliary Switch Flowrite 599 Series SKD, 1 ASC1.6Sends a signal to indicate that SKB/C62the valve is in the 0% strokeposition; switching point is fixedat the 0% stroke position.These accessories are for new installations. For complete selection, refer to the current edition of the Master HVAC Products Catalog.Prices are subject to change without notice.25

Accessories (continued)Description Product Group Quantity Part No.Double Auxiliary Switch Flowrite 599 Series 1Adjustable cams can be set toprovide a signal at a desiredstroke position.• SKB/C62• SKDASC9.3BCUASC9.3DUDouble Auxiliary Switch Flowrite 599 Series SQX 1 ASC9.4UAdjustable cams can be set toprovide a signal at a desiredstroke position.Manual High Signal Flowrite 599 Series SQX 1 FZA61.11<strong>Selection</strong> Unit.Used for manual control or remotesetting of minimum positions ofcontrolled devices; for flush panelmounting only/0 to 10 Vdc.Remote Setting Unit. Flowrite 599 Series 1 FZA21.11<strong>Control</strong> Input-R; 0 to 1,000 Ohms. SKD & SKB/CAuxiliary Potentiometer Flowrite 599 Series 1 ASZ7.3Used for remote indication of SKD & SKB/Cvalve stem position.Positioning Relay <strong>and</strong> Flowrite 599 Series 1Mounting Kit.• 8-inch 599-00426• 12-inch 599-00423These accessories are for new installations. For complete selection, refer to the current edition of the Master HVAC Products Catalog.Prices are subject to change without notice.26

Description Product Group Quantity Part No.Positioning Relay Pneumatic <strong>Valve</strong> <strong>Actuator</strong>s 1 147-2000Provides positive positioning of apneumatic valve actuator.Rack <strong>and</strong> Pinion Bracket Flowrite 599 Series 1 599-03610for OpenAir ActuationWeathershield Flowrite 599 Series SKB/C 1 599-10065Weathershield Flowrite 599 Series 1 599-10071SKD, SQXPacking Heating Element Flowrite 599 Series SKB/C 1 599-00418Packing Heating Element Flowrite 599 Series 1 599-00417SKD/SQXThese accessories are for new installations. For complete selection, refer to the current edition of the Master HVAC Products Catalog.Prices are subject to change without notice.27

Accessories (continued)Description Product Group Quantity Part No.3-way <strong>Valve</strong> Service Flange Flowrite 599 Series 1 See tableAllows easy access to the stem 2-1/2 to 6” <strong>Valve</strong> Bodies below.<strong>and</strong> plug assembly withoutremoving the valve.ANSI Class 125ANSI Class 2502-1/2” 599-05011 599-050163” 599-05012 599-050174” 599-05013 599-050185” 599-05014 599-050196” 599-05015 599-05020Flange GasketsANSI Class 125ANSI Class 2502-1/2” 599-09100 599-091053” 599-09101 599-091064” 599-09102 599-091075” 599-09103 599-091086” 599-09104 599-09109Flange Bolts Description Part No.Refer to page 91 for2-1/2” 5/8” -11 x 1-1/2” cap screw 035-175Kbolt quantities <strong>and</strong>3” 5/8” -11 x 1-3/4” cap screw 035-177Kbolt hole specifications.4” 5/8” -11 x 2” cap screw 035-176K5 & 6” 3/4” -10 x 2” cap screw 035-182K2-1/2” 3/4” -10 x 2” cap screw 035-182K3 & 4” 3/4” -10 x 2-1/2” cap screw 035-183K5 & 6” 3/4” -10 x 2-3/4” cap screw 035-184KANSI Class 125ANSI Class 250These accessories are for new installations. For complete selection, refer to the current edition of the Master HVAC Products Catalog.Prices are subject to change without notice.28

29 MBUROJA.net“Allahu nuk ju ndalon të silleni mirë dhe të jeni të drejtë ndaj atyre që nuk luftojnëkundër jush për shkak të fesë dhe që nuk ju dëbojnë prej shtëpive tuaja.” (El-Mumtehine, 8)Përgjigjja ndaj këtij gabimi të madh, në të cilën doktor Kardavi ka rënë, është se ky ajetnuk është argument për atë që pretendon Kardavi në aspektin e dashurisë ndaj dikujtprej jobesimtarëve, mirëpo këtu ka lehtësim për t'i mbajtur marrëdhëniet e mira ndaj njëlloji të jobesimtarëve dhe t'i trajtosh me mirësi dhe bamirësi, si shpërblim për veprimin etyre. Kjo nuk obligon që ata të jenë të dashur në zemër.Hafidh Ibn Haxheri ka thënë në Fet'hul Bari [5/233]: “Mirësia dhe mbajtja e lidhjeve nuke kërkojnë dashurinë e ndërsjellë, e cila është e ndaluar me fjalët e të Lartësuarit:“Nuk gjen njerëz, që besojnë në Allahun dhe në Ditën e Fundit, që të ushqejnë dashurindaj atyre, të cilët kundërshtojnë Allahun dhe të Dërguarin e tij, edhe në qofshin ataetërit e tyre ose bijtë e tyre, ose vëllezërit e tyre, ose farefisi i tyre.” (El-Muxhadele, 22)Ky ajet është i përgjithshëm për të gjithë, luftoi ai apo nuk luftoi. Allahu e di më së miri”(Ibn Haxher, Fet'hul-Bari, 5/233)Kardavi i respekton fetë e tyre të devijuaraNga lëshimet e Kardavit me ta është edhe fjala e tij: “Ne biem dakord me ta – dmth mesekularistët - në prosperitetin e domosdoshëm të atdheut tonë dhe ne përputhemi rrethkrenarisë së Islamit, pasi kjo fe është e shumicës dhe respektuese e feve qiellore tëjomuslimanët. Islami për qytetarët e tyre është kulturë dhe civilizim, edhe nëse nukështë feja dhe besim i tyre.” (El-Islamu vel-ilmanijje,101)Kemi thënë më parë se nuk ekziston diçka që quhet Islam sipas kulturës dhe civilizimit,se Islam është feja e Allahut që ne e manifestojmë, kurse gjithçka tjetër jashtë saj ështëpabesim e mashtrim dhe nuk quhet Islam.Ai thotë këtu se ne i respektojmë fetë qiellore te jomuslimanëve, dhe ne e dimë se në tëgjitha këto fetë janë futur shumë shtrembërime. Atëherë, si t'i respektojnështrembërimet/devijimet e ithtarëve të Librit, të cilët ata shpikën gënjeshtra ndajAllahut?!Ne besojnë në të gjitha librat e Allahut dhe të Dërguarit i respektojnë, mirëpo jemi tëbindur se Islami i anuloi/abrogoi të gjitha. Për këtë shkak, nuk i është lejuar njeriut tëqëndrojë në to dhe ta lërë Islamin, ose të besojë në to dhe të veprojë sipas tyre kundrejtbesimit dhe praktikimit të islamit, pasi ato janë të anuluara.

Submittal Summary1/2 to 1-inch Zone <strong>Control</strong>Two- <strong>and</strong> Three-wayGlobe <strong>Valve</strong>sThe Powermite 599 Series ANSI Class 250 MZ Series <strong>Valve</strong>bodies work with any MZ Series electronic actuator with a7/32-inch (5.5 mm) stroke. Typical applications includecontrol of hot or chilled water, glycol solutions up to 50%,or steam up to 15 psi (103 kPa). Compatible actuatorsdeliver a minimum of 45 lbs. (200 N) of force.Features• Direct-coupled universal bonnet• Female NPT connections <strong>and</strong> brass trim• ANSI Class IV Leakage (0.01% of Cv)• Steam to 15 psiSpecificationsLine Size ......................................................... 1/2 to 1-inch (15 to 25 mm)Body ........................... Globe style, UNS CA 844 bronze, ANSI Class 250Trim ................................................................................................... BrassStem .............................................. Stainless steel ASTM A582 Type 303,7/32-inch (5.5-mm) strokeSeat ..................................................................................... Metal-to-metalPacking ............................................................ Ethylene propylene O-ringMounting Location ................................................... NEMA 1 (interior only)Flow CharacteristicsTwo-way ...................................................... Modified Equal PercentageThree-way ................................................... Modified Equal PercentageClose-off Ratings ........................................... According to ANSI/FCI 70-2<strong>Control</strong>led MediumTwo-way ..................................... Water, steam, glycol solutions to 50%Three-way .............................................. Water, glycol solutions to 50%Medium Temperature .......................................... 35 to 250°F (2 to 120°C)Max. Differential Pressure for Modulating ServiceLiquid 2w <strong>and</strong> 3w ......................................................... 25 psi (173 kPa)Steam 2w only ............................................................. 15 psi (103 kPa)Rangeability .............................................. Cv 50:1, Cv >1 = >100:1Leakage Rate ......................................................... Class IV (0.01% of Cv)30

Electro-MechanicalBCAABC2-way3-waySizeDimensions in. (mm)Weightin. (mm) A B C lb. (kg)1/2 (15) 1-3/8 (35) 2-1/4 (57) 1-5/16 (33) 1.3 (0.6)3/4 (20) 1-5/8 (41) 2-3/8 (59) 1-5/16 (33) 1.8 (0.8)1 (25) 1-15/16 (49) 2-3/4 (69) 1-9/16 (39) 2.6 (1.2)1/2 (15) 2-3/4 (69) 2-1/4 (74) 1-5/16 (33) 1.5 (0.7)3/4 (20) 3-1/4 (83) 3-9/16 (90) 1-5/16 (33) 2.3 (1.05)1 (25) 3-7/8 (98) 3-15/16 (99) 1-9/16 (39) 3.3 (1.5)A2-way3-wayMZ Series <strong>Valve</strong> BodiesMZ Series <strong>Valve</strong> <strong>Actuator</strong>s2-way3-wayAction/TrimWater Mix Normally Open (NO) Normally Closed (NO)Flow RateCv (Kvs)Line Sizein. (mm)PartNo.0.4 (0.34) 1/2 (15) 599-011000.63 (0.54) 1/2 (15) 599-011021 (0.85) 1/2 (15) 599-011041.6 (1.37) 1/2 (15) 599-011062.5 (2.14) 1/2 (15) 599-011084 (3.42) 1/2 (15) 599-011106.3 (5.38) 3/4 (20) 599-0111210(8.55) 1 (25) 599-011140.4 (0.34) 1/2 (15) 599-011150.63 (0.54) 1/2 (15) 599-011171 (0.85) 1/2 (15) 599-011191.6 (1.37) 1/2 (15) 599-011212.5 (2.14) 1/2 (15) 599-011234 (3.42) 1/2 (15) 599-011266.3 (5.38) 3/4 (20) 599-0112910(8.55) 1 (25) 599-011310.4 (0.34) 1/2 (15) 599-011320.63 (0.54) 1/2 (15) 599-011331 (0.85) 1/2 (15) 599-011341.6 (1.37) 1/2 (15) 599-011352.5 (2.14) 1/2 (15) 599-011364 (3.42) 1/2 (15) 599-011376.3 (5.38) 3/4 (20) 599-0113810(8.55) 1 (25) 599-01139<strong>Actuator</strong>PrefixDescription Part No. CodeThere are no repair parts for thisproduct. Replace the entire valvebody if inoperative.24 V, 3P NSR SSB81U 25424 V, 0-10V NSR SSB61U 255Complete AssemblyAPC + Part No.These selection tables only contain FXF endconnections with brass trim <strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to the current edition ofMaster HVAC Products Catalog.spage6<strong>Valve</strong> Body Only599 + Part No.e31

Submittal SummarySSB <strong>Valve</strong> <strong>Actuator</strong>,24 Vac Proportional <strong>Control</strong>The Powermite SSB61U Electronic <strong>Valve</strong> <strong>Actuator</strong> requiresa 24 Vac supply <strong>and</strong> receives a 0 to 10 Vdc control signalto proportionally control a valve. This actuator is designedto work with Powermite 599 MZ Series <strong>Valve</strong>s with a7/32-inch (5.5 mm) stroke <strong>and</strong> a threaded valve bonnetthat fits the actuator.Wiring Diagram+-YG0Neut24VacGEarth GroundIsolating Class 2Transformer for24 Vac PowerPart No.<strong>Actuator</strong>PrefixDescription Part No. Code0 to 10 V SSB61U 255A0-V Board120 VacSpecificationsOperating Voltage .................................... 24 Vac ± 20% or 24 Vdc ± 25%Frequency .................................................................................... 50/60 HzPower Consumption ........................................................................ 2.0 VAFunctionRunning Time ............................................................................. 75 sec.Nominal Stroke .............................................................. 7/32” (5.5 mm)Nominal Force ................................................................. 45 lb. (200 N)Agency Approvals ............................................................................ UL873CSA C22.2 No. 24-93Ambient TemperatureOperation .......................................................... 34 to 122°F (1 to 50°C)Transport <strong>and</strong> Storage ............................. -13 to +158°F (-25 to +70°C)Medium Temperature .......................................... 34 to 230°F (1 to 110°C)Mounting Location ................................................... NEMA 1 (interior only)Dimensions<strong>Valve</strong> Center LineLine to Top of Service Actual ServiceSize <strong>Actuator</strong> Height Width WidthH 1 H W 1 W1/2” 4-1/2” 12” 3-1/4” 11”(15 mm) (115 mm) (300 mm) (83 mm) (275 mm)3/4” 4-1/2” 12” 3-1/4” 11”(20 mm) (115 mm) (300 mm) (83 mm) (275 mm)1” 4-3/4” 12” 3-1/4” 11”(25 mm) (121 mm) (300 mm) (83 mm) (275 mm)32

Submittal SummarySSB <strong>Valve</strong> <strong>Actuator</strong>,24 Vac 3-position(floating) <strong>Control</strong>The Powermite SSB81U Electronic <strong>Valve</strong> <strong>Actuator</strong> requires a24 Vac supply floating control signal to provide three-positioncontrol. This actuator is designed to work with Powermite599 MZ Series <strong>Valve</strong>s with a 7/32-inch (5.5 mm) stroke <strong>and</strong>a threaded valve bonnet that fits the actuator.Wiring Diagram0 Y21Y1G<strong>Actuator</strong>PrefixDescription Part No. Code24VacNeutEarth GroundIsolating Class 2Transformer for24 Vac PowerPart No.3-position SSB81U 254Specifications120 VacOperating Voltage ................................................................. 24 Vac ±20%Frequency .................................................................................... 50/60 HzPower Consumption ........................................................................ 0.8 VAFunctionRunning Time ........................................................................... 150 sec.Nominal Stroke .............................................................. 7/32” (5.5 mm)Nominal Force ................................................................. 45 lb. (200 N)Agency Approvals ............................................................................ UL873CSA C22.2 No. 24-93Ambient TemperatureOperation .......................................................... 34 to 122°F (1 to 50°C)Transport <strong>and</strong> Storage ............................. -13 to +158°F (-25 to +70°C)Medium Temperature .......................................... 34 to 230°F (1 to 110°C)Mounting Location ................................................... NEMA 1 (interior only)Dimensions<strong>Valve</strong> Center LineLine to Top of Service Actual ServiceSize <strong>Actuator</strong> Height Width WidthH 1 H W 1 W1/2” 4-1/2” 12” 3-1/4” 11”(15 mm) (115 mm) (300 mm) (83 mm) (275 mm)3/4” 4-1/2” 12” 3-1/4” 11”(20 mm) (115 mm) (300 mm) (83 mm) (275 mm)1” 4-3/4” 12” 3-1/4” 11”(25 mm) (121 mm) (300 mm) (83 mm) (275 mm)33

Submittal Summary1/2 to 1-1/2 inchTerminal Unit Two- <strong>and</strong>Three-way Globe <strong>Valve</strong>sThe Powermite 599 Series ANSI Class 250 MT SeriesTwo- <strong>and</strong> Three-way <strong>Valve</strong> bodies work with any MT Seriespneumatic or electronic actuator with a 7/32-inch (5.5-mm)stroke. They are suitable for normally open or normallyclosed control. Typical applications include control of hot orchilled water, glycol solutions up to 50%, or steam up to15 psi (103 kPa). Compatible actuators deliver a minimumof 67 lbs. (300 N) of force.Features• Higher close-offs than MZ Series• Direct-coupled universal bonnet• Female NPT end connections <strong>and</strong> brass trim• ANSI Class IV Leakage (0.01% of Cv)SpecificationsLine Size ................................................... 1/2 to 1-1/2-inch (15 to 25 mm)Body .......................... Globe style, UNS CA 844 bronze, ANSI Class 250Trim ................................................................................................. BrassStem .............................................. Stainless steel ASTM A582 Type 303,7/32-inch (5.5-mm) strokeSeat ................................................................................... Metal-to-metalPacking ............................................................ Ethylene propylene O-ringClose-off Ratings ........................................... According to ANSI/FCI 70-2<strong>Control</strong>led Medium ......................... Water, steam, glycol solutions to 50%Medium Temperature .......................................... 35 to 250°F (2 to 120°C)Max. Differential Pressure for Modulating ServiceLiquid ........................................................................... 25 psi (173 kPa)Steam .......................................................................... 15 psi (103 kPa)Rangeability .............................................. Cv 50:1, Cv >1 = >100:1Leakage Rate ......................................................... Class IV (0.01% of Cv)Flow Characteristics ......................................... Modified equal percentageMounting Location ................................................... NEMA 1 (interior only)These selection tables only contain FXF endconnections with brass trim <strong>and</strong> equal percentage flowcharacterics.For complete selection, refer to the current edition ofMaster HVAC Products Catalog.spage7e34

Electro-MechanicalPneumaticBMT Series <strong>Valve</strong> Bodies2-way3-wayCActionNormally Closed (NC)Normally Open (NO)MixingA2-wayFlow RateCv (Kvs)ALine Sizein. (mm)PartNo.0.4 (0.34) 1/2 (15) 599-020000.63 (0.54) 1/2 (15) 599-020021 (0.85) 1/2 (15) 599-020041.6 (1.37) 1/2 (15) 599-020062.5 (2.14) 1/2 (15) 599-020084 (3.42) 1/2 (15) 599-020106.3 (5.38) 3/4 (20) 599-0201210 (8.55) 1 (25) 599-0201416 (13.8) 1-1/4 (32) 599-02085*25 (21.5) 1-1/2 (40) 599-02088*0.4 (0.34) 1/2 (15) 599-020300.63 (0.54) 1/2 (15) 599-020321 (0.85) 1/2 (15) 599-020341.6 (1.37) 1/2 (15) 599-020362.5 (2.14) 1/2 (15) 599-020384 (3.42) 1/2 (15) 599-020416.3 (5.38) 3/4 (20) 599-0204410 (8.55) 1 (25) 599-0204616 (13.8) 1-1/4 (32) 599-02084*25 (21.5) 1-1/2 (40) 599-02087*0.4 (0.34) 1/2 (15) 599-020640.63 (0.54) 1/2 (15) 599-020651 (0.85) 1/2 (15) 599-020661.6 (1.37) 1/2 (15) 599-020672.5 (2.14) 1/2 (15) 599-020684 (3.42) 1/2 (15) 599-020696.3 (5.38) 3/4 (20) 599-0207010 (8.55) 1 (25) 599-0207116 (13.8) 1-1/4 (32) 599-02086*25 (21.5) 1-1/2 (40) 599-02089**Can only be assembled withelectro-mechanical actuators.BCA3-wayThere are norepair parts forthis product.Replace theentire valve bodyif inoperative.2-way (NC)2-way (NO)3-waySizeDimensions in. (mm)Weightin. (mm) A B C lb. (kg)1/2 (15) 1-3/8 (35) 2-1/4 (57) 1-5/16 (33) 1.3 (0.6)3/4 (20) 1-5/8 (41) 2-3/8 (59) 1-5/16 (33) 1.8 (0.8)1 (25) 1-15/16 (49) 2-3/4 (69) 1-9/16 (39) 2.6 (1.2)1-1/4 (32) 2-1/2 (64) 3-7/8 (98) 1-11/16 (43) 4 (1.8)1-1/2 (40) 2-9/16 (65) 3-7/8 (98) 1-5/8 (41) 5 (2.3)1/2 (15) 1-3/8 (35) 2-1/4 (57) 1-5/16 (33) 1.3 (0.6)3/4 (20) 1-5/8 (41) 2-3/8 (59) 1-5/16 (33) 1.8 (0.8)1 (25) 1-15/16 (49) 2-3/4 (69) 1-9/16 (39) 2.6 (1.2)1-1/4 (32) 2-1/2 (64) 4-1/4 (108) 2-3/16 (56) 4 (1.8)1-1/2 (40) 2-9/16 (65) 4-1/4 (108) 2-1/4 (57) 5 (2.3)1/2 (15) 2-3/4 (70) 2-15/16 (74) 1-5/16 (33) 1.5 (0.7)3/4 (20) 3-1/4 (83) 3-9/16 (90) 1-5/16 (33) 2.3 (1.05)1 (25) 3-7/8 (98) 3-15/16 (99) 1-9/16 (39) 3.3 (1.5)1-1/4 (32) 4-15/16 (125) 4-1/4 (109) 1-11/16 (43) 4.0 (1.8)1-1/2 (40) 5-1/8 (130) 4-1/2 (114) 1-5/8 (41) 5.0 (2.3)MT Series <strong>Valve</strong> <strong>Actuator</strong>s2”<strong>Actuator</strong>Part PrefixDescription No. Code10-15 psi 599-01088 256(69-103 kPa)3-8 psi 599-01088 257(21-55 kPa)8-13 psi 599-01088 258(55-90 kPa)24 V SSC61U 261SSC61.5U 26224 V SSC81U 259SSC81.5U 26024 V 0-10 V SQS65U 264NSR24 V 0-10 V SQS65.5U 265SR24 V 3P SQS85.53U 266SR35

Submittal Summary2-inch Pneumatic<strong>Valve</strong> <strong>Actuator</strong>The Powermite Two-inch Pneumatic <strong>Valve</strong> <strong>Actuator</strong> isdesigned for use with the 1/2 to 1-inch Powermite 599 MTSeries Terminal Unit <strong>Valve</strong>s with a 7/32-inch (5.5 mm) stroke.SpecificationsEffective Diaphragm Area ................................................. 3.4 in. 2 (22 cm 2 )Diaphragm Material ....................................................................... SiliconeNominal Spring Range .................................................... <strong>Valve</strong> dependentSpan ................................................................................... 5 psi (34 kPa)Nominal Stroke .................................................................. 7/32” (5.5 mm)Max. Diaphragm Pressure ............................................... 35 psi (241 kPa)Air Connection ................................................................... 1/8” NPT fittingfor 1/4” (6 mm) OD polyethylene tubingAmbient TemperatureTransportation .......................................... -40 to +180°F (-40 to +82°C)Mounting Location ................................................... NEMA 1 (interior only)Shipping Weight ................................................................ 0.43 lb. (0.2 kg)Part Nos.<strong>Actuator</strong>PrefixDescription Part No. Code8-13 psi (55-90 kPa) SR 599-01088 25810-15 psi (69-103 kPa) SR 599-01088 2563-8 psi (21-55 kPa) SR 599-01088 257Ordering NoteSpring is inside bonnet assembly of valve body. Use the<strong>Valve</strong> <strong>Selection</strong> Charts in the Powermite ReferenceSection to determine spring range.Dimensions<strong>Valve</strong> Center Line ActualLine to Top of Service Width of ServiceSize <strong>Actuator</strong> Height <strong>Actuator</strong> WidthH 1 H W 1 W1/2” 3-1/16” 11” 4” 10”(15 mm) (78 mm) (280 mm) (100 mm) (250 mm)3/4” 3-1/16” 11” 4” 10”(20 mm) (78 mm) (280 mm) (100 mm) (250 mm)1” 3-5/16” 11-1/4” 4” 10”(25 mm) (84 mm) (285 mm) (100 mm) (250 mm)36

Capabilities CornerSmart-engineered for better solutionsSiemens HVAC products are designed to provide installerswith timesaving features such as quick-connect valves <strong>and</strong>actuators <strong>and</strong> convenient services such as free assembly<strong>and</strong> tagging of valve assemblies for direct shipping to job sitelocation. The result is improved efficiency, labor savings <strong>and</strong>lower installation costs.Support systemsFor assistance in sizing <strong>and</strong> selection for any of our HVACproducts or for technical support assistance, call CustomerCare for fast, helpful answers to your questions at:1.888.593.7876.Need to place an order? Our Customer Service Group isavailable from 7 a.m. to 6 p.m., Central St<strong>and</strong>ard Time byphone <strong>and</strong> 24/7 by via fax or email. St<strong>and</strong>ard orders shipwithin three business days <strong>and</strong> rush orders can beprocessed <strong>and</strong> shipped on the same day.Tools that make your job easierFrom the in-depth Master HVAC Products Catalog to onlineaccess to sizing tools <strong>and</strong> technical documentation onwww.valves-actuators.com, find the information you needquickly <strong>and</strong> easily.Other tools include: Target CD-ROM, product selectionguides <strong>and</strong> online Order Tracker. For more information,contact your Siemens representative.37