General Products - ALP Industries Inc.

General Products - ALP Industries Inc.

General Products - ALP Industries Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Corporate HistoryIn 1981 Reitzel Swaim and Ron Space formed American Lifting <strong>Products</strong>, <strong>Inc</strong>. (the forerunner of <strong>ALP</strong> <strong>Industries</strong>, <strong>Inc</strong>.) inParkesburg, PA. The company was relocated to Coatesville, PA in 1993.The first major expansion occurred in 1983 when the acquisition of Pennsylvania Sling Company and Cobb Wire Rope andSling Company added locations in Harrisburg and Pittsburgh, PA, and Atlanta, GA.During the 1980’s and 90’s, Carolina Chain and Cable Company, The Harding Company, Wayland <strong>Inc</strong>orporated, FloridaWire Rope & Supply, and others were purchased. During this time <strong>ALP</strong> started new businesses in Aberdeen, NC, Parkesburg,PA, and Duncan, SC. Acquisitions were made in Tampa, FL (2000) and Tacoma, WA (2001). Another start-up location wasopened in Las Vegas, NV in 2006.<strong>ALP</strong>’s registered trademarks include Penco®, Saf-T-Grip®, Grip-Tite®, Redi-Grip®, Mulox®, and Tufskin®. PMSBlue is the trademarked color of <strong>ALP</strong>’s ratchet and lever type load binders. In addition, the combination of “orange andwhite” colored strands in wire rope is a registered trademark of <strong>ALP</strong> <strong>Industries</strong>, <strong>Inc</strong>.2011 marks <strong>ALP</strong> <strong>Industries</strong> 30th Anniversary. Our 140+ Employees and 15 Sales/Warehouse locations are dedicated to“LIFTING AMERICA: Yesterday - Today - Tomorrow”MISSION STATEMENT<strong>ALP</strong> <strong>Industries</strong>, <strong>Inc</strong>. is dedicated to its growth, customers, employees, and the concept of linked prosperity. Our mission consistsof three interrelated parts:Product Mission:To distribute and sell the finest quality industrial lifting products in the indusry.To ensure both safety and customer satisfaction.Growth Mission:To take a proactive growth strategy which include an internal growth rate of sales and an external growth strategy to addadditional locations in the Americas to better serve our customers and diversify our product line and customer base.Economic Mission:To operate the company on a sound financial basis of profitable growth and create career opportunities and financial rewardsfor our employees.Underlying the mission of <strong>ALP</strong> <strong>Industries</strong> is the determination to seek new and creative ways of addressing all three parts,while holding a deep respect for individuals, inside and outside the company, and for the communities of which they are a part.

This catalog has been assembled to assist you in finding the products you need. It is impossible toillustrate all the products available through <strong>ALP</strong> <strong>Industries</strong> and the manufacturers we represent. Wehave listed the more common items. If the item you require is not in the catalog, contact your sales representativefor more information.In addition, it is difficult to present all the instructions and conditions for safe use of these products.We have included many statements regarding safety and useful information. Consult the applicablefederal, state, industry, and manufacturer’s standards and recommendations before using theseproducts. In many instances we have enclosed important information in a rectangular box - Blue forsafety/warning or Black for additional notes.We have applied for copyright protection for the cover and contents of this publication. Any reproductionof this catalog, in whole or in part, without the expressed written consent of the management of<strong>ALP</strong> <strong>Industries</strong>, <strong>Inc</strong>. is strictly prohibited.

TABLE OF CONTENTSWIRE ROPE<strong>General</strong> InformationTerminology & Properties . . . . . . . . . . . . . . .1Wire Rope Inspection . . . . . . . . . . . . . . . . . .4Troubleshooting Checklist . . . . . . . . . . . . . . .7Suggested Wire Rope Construction . . . . . . . .9Wire Rope Definitions . . . . . . . . . . . . . . . . .11<strong>General</strong> Purpose Wire RopesSix Strand Ropes . . . . . . . . . . . . . . . . . . 13Rotation Resistant Ropes . . . . . . . . . . . . . 15Galvanized & Stainless . . . . . . . . . . . . . . . . 17Specialty RopesBethlehem . . . . . . . . . . . . . . . . . . . . . . . 18 - 20Bridon . . . . . . . . . . . . . . . . . . . . . . . 21 - 23Wireco . . . . . . . . . . . . . . . . . . . . . . . . .24 - 25Wire Rope Slings<strong>General</strong> Information . . . . . . . . . . . . . . . . . . . 26Sling Capacities- 6x19 & 6x37 Class . . . . . ..27Sling Capacities - Special Slings . . . . . . . . . 29Common Terminations . .. . . . . . . . . . . . . . . . .30Pendant Socket Arrangements . . . . . . . . . .30Terminal Efficiencies . . . . . . . . . . . . . . . . . . 31ELEVATOR PRODUCTSBethlehem Elevator Wire RopeWire Rope Specification . . . . . . . . . . . . . . . 32Short Service Life . . . . . . . . . . . . . . . . . . . . . 32Technical Bulletins . . . . . . . . . . . . . . . . . . . .32Related MRO <strong>Products</strong>: . . . . . . . . . . . . . . . .32Bethlehem 8&6 Strand Elevator Ropes . . . . . 33Bethlehem Liftpac Elevator Rope . . . . . . . .34Bethlehem 8&9 Strand IWRC ElevatorRopes35Usha Martin Elevator Wire RopeRelated Elevator <strong>Products</strong>Reeving Splices . . . . . . . . . . . . . . . . . . . . . . .37Elevator Shackles . . . . . . . . . . . . . . . . . . . . . 38Elevator Rope Tools . . . . . . . . . . . . . . . . . . .40CHAINAlloy Chain SlingsTypes of Chain Slings . . . . . . . . . . . . . . . . . 43Alloy Chain Sling Working Load Limits . . 44Alloy Chain Attachments . . . . . . . . . . . . . . 48Magnet Chains . . . . . . . . . . . . . . . . . . . . . . . 58Recommended Chain Sling Use . . . . . . . . . 59Chain Sling Inspection . . . . . . . . . . . . . . . . .60Carbon ChainGrade 30 Proof Coil Chain . . . . . . . . . . . . . .62Grade 43 High Test Chain . .. . . . . . . . . . . . 62Grade 70 Transport Chain . . . . . . . . . . . . . .63Machine Chain . . . . . . . . . . . . . . . . . . . . . . .63Jack Chain . . . . . . . . . . . . . . . . . . . . . . . . . . .64Double Lock Link Chain . . . . . . . . . . . . . . 64Binders & Chains . . . . . . . . . . . . . . . . . . . . 65MESH SLINGSCambridge Gripper ® Slings . . . . . . . . . . . . .66Alloy Chain Mesh Sling . . . . . . . . . . . . . . . .67SYNTHETIC SLINGSSynthetic Web SlingsStandard Web Sling Types . . . . . . . . . . . . . 68Considerations When Ordering . . . . . . . . . 69Saf-T-Grip ® Light Duty Nylon Slings . . . . 71Mulox ® Heavy Duty Nylon Slings . . . . . . .72Penco Tufskin ® Abrasion Resistant Slings. . .74Web Sling Hardware . . . . . . . . . . . . . . . . . . 75Web Sling Inspection . . . . . . . . . . . . . . . . . 81Polyester RoundslingsPenco ® Polyester Roundslings . . . . . . . . . 82Braided Roundup Roundslings . . . . . . . . . .83Roundsling Inspection . . . . . . . . . . . . . . . . .84CARGO CONTROLStrap AssembliesLogistic & Utility Strap Assemblies . . . . . . 85Safety Considerations . . . . . . . . . . . . . . . . . 87Part Number Identification . . . . . . . . . . . . . 88Buckle & Ratchet Specifications . . . . . . . . 89Winches & Bars . . . . . . . . . . . . . . . . . . . . . . 91End Fitting Hardware . . . . . . . . . . . . . . . . . . 92Interior Bars . . . . . . . . . . . . . . . . . . . . . . . . . .94FITTINGSClips, Links, Shackles, Hooks & LatchesForged Wire Rope Clips . . . . . . . . . . . . . . . .96Links & Rings . . . . . . . . . . . . . . . . . . . . . . . 100Shackles . . . . . . . . . . . . . . . . . . . . . . . . . . . 102Hoist Hooks . . . . . . . . . . . . . . . . . . . . . . . . 108Specialty Hooks . . . . . . . . . . . . . . . . . . . . . 119Thimbles & TerminationsThimbles . . . . . . . . . . . . . . . . . . . . . . . . . . . 121Spelter Sockets . . . . . . . . . . . . . . . . . . . . . .126Swage Sockets . . . . . . . . . . . . . . . . . . . . . . 128Sling Saddle . . . . . . . . . . . . . . . . . . . . . . . . 130Turnbuckles, Swivels, & Hoist RingsTurnbuckles . . . . . . . . . . . . . . . . . . . . . . . . .131Hoist Rings . . . . . . . . . . . . . . . . . . . . . . . . . 139Electroline Fittings . . . . . . . . . . . . . . . . . . . 145Stainless Steel Fittings & Specialty Chain

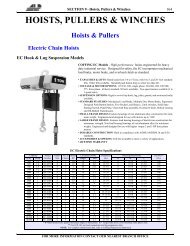

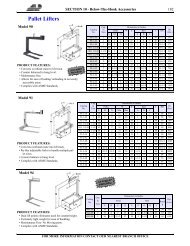

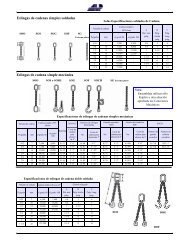

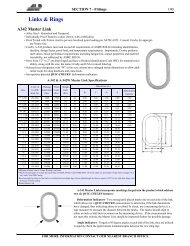

BLOCKSWire Rope BlocksSnatch Block . . . . . . . . . . . . . . . . . . . . . . . . 155Diamond & Oval Wire Rope Block . . . . . .157Manila Rope Blocks . . . . . . . . . . . . . . . . . . 158Crane Blocks . . . . . . . . . . . . . . . . . . . . . . . .159Overhaul BallsUB500 Top Swiveling Overhaul Ball . . . . 161UB500 Non Swiveling Overhaul Ball . . . .162Split Overhaul Ball . . . . . . . . . . . . . . . . . . . 162Tackle Block ReevingHOISTS, PULLERS & WINCHESHoists & PullersElectric Chain Hoists . . . . . . . . . . . . . . . . . 164Rail Power- Light Rail Systems . . . . . . . . .167Manual Hoists . . . . . . . . . . . . . . . . . . . . . . .168Economy Hoists . . . . . . . . . . . . . . . . . . . . . 171Trolleys & Other Accessories . . . . . . . . . . 172WinchesHand Winches . . . . . . . . . . . . . . . . . . . . . . .175Power Winches . . . . . . . . . . . . . . . . . . . . . . 176Special Purpose Winches . . . . . . . . . . . . . 177BELOW-THE-HOOKLiftingLifting Beams . . . . . . . . . . . . . . . . . . . . . . . 178Pallet Lifters . . . . . . . . . . . . . . . . . . . . . . . . 182Coil Lifters . . . . . . . . . . . . . . . . . . . . . . . . . .183Sheet Lifters . . . . . . . . . . . . . . . . . . . . . . . . 184Pipe & Manhole Lifters . . . . . . . . . . . . . . .186Grabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189Magnetic Lift Devices . . . . . . . . . . . . . . . .194Concrete Bucket . . . . . . . . . . . . . . . . . . . . .197Load Positioner . . . . . . . . . . . . . . . . . . . . . 198Lifting Clamps & Beam GrabsLifting Clamps . . . . . . . . . . . . . . . . . . . . . . 201MARINE PRODUCTSAnchor SelectionStockless Type Anchors . . . . . . . . . . . . . . .216Lightweight Type Anchors . . . . . . . . . . . 217Anchor Chain & AttachmentsStud Link Chain . . . . . . . . . . . . . . . . . . . . . 218Anchor Chain Attachments . . . . . . . . . . . . .220U.S.C.G. Approved LaddersDJM Series . . . . . . . . . . . . . . . . . . . . . . . . 223Pilot Ladders . . . . . . . . . . . . . . . . . . . . . . . .223Erik Series . . . . . . . . . . . . . . . . . . . . . . . . . . 223Debarkation Ladders . . . . . . . . . . . . . . . . .223Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223Mooring BuoysCleats-Chocks-Bollards . . . . . . . . . . . . . . . 225Snap Hooks . . . . . . . . . . . . . . . . . . . . . . . . 226Patterson TensorsTM . . . . . . . . . . . . . . . . 227Ratchet Turnbuckles . . . . . . . . . . . . . . . . . 227AnodesHull Zinc Anodes . . . . . . . . . . . . . . . . . . . 228TOOLS & MISCELLANEOUSCable CuttersImpact Type . . . . . . . . . . . . . . . . . . . . . . . . 229Hydraulic Cutters . . . . . . . . . . . . . . . . . . . .230Manual Cutters . . . . . . . . . . . . . . . . . . . . . 231Corrosion Protective Coating . . . . . . . . . . 232Wire Rope GripsWire Mesh Grips . . . . . . . . . . . . . . . . . . . . 233Haven Grips . . . . . . . . . . . . . . . . . . . . . . . . 234Klein Hand ToolsLineman Tools . . . . . . . . . . . . . . . . . . . . . . 234Conversion TablesCORDAGETwisted Ropes . . . . . . . . . . . . . . . . . . . . . . 206Braided Ropes . . . . . . . . . . . . . . . . . . . . . . 208Rope Use Reference . . . . . . . . . . . . . . . . .209FALL RESTRAINTBeamer Fall Arrester . . . . . . . . . . . . . . . . . .210Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . 210Retractables Lifelines . . . . . . . . . . . . . . . . .211Lanyards . . . . . . . . . . . . . . . . . . . . . . . . . . . 212Carabineers & Hooks . . . . . . . . . . . . . . . . . . 212Suspended Personnel Platform . . . . . . . . . . .213

1 SECTION 1 - Wire RopeWIRE ROPE<strong>General</strong> InformationTerminology & PropertiesTerminologyWith precise, moving parts, designed and manufactured tobear definite relationship toone another, Wire Rope canbe a complex mechanism.Wire rope is generally composedof wires, strands andthe core (See Fig.). Thewires are helically laidtogether in a precise geometricpattern to form the strand.The strands helically laidabout the core to form thewire rope. The process ofpositioning the strands aboutthe core is called “closing”.The process of positioningthe wires within the strand iscalled “stranding”.the extreme outer dimensions of the strands. (See Fig.). Newwire rope is manufactured to an oversized diameter ofapproximately 2-1/2%. This allows for the normal reductionof diameter experienced when a new rope is placed underload because of constructional stretch.Wire rope varies:• By Diameter• The grade of steel utilized• The direction of stranding and closing• The finish on the wire (Bright, Galvanized, etc.)• The core materialEach variation changes the performance characteristics ofthe wire rope.The first differentiation of wire rope is by diameter. Thediameter is measured at the diameter of the circle formed byThe RIGHT WayThe WRONG WayCAUTION: At NO time should the measured diameterbe less than the nominal diameter of the wire rope.The grade of steel (or other material) utilized in the constructionof the wire rope has a major influence upon theultimate break strength. <strong>General</strong>ly most steel wire ropetoday is at Improved Plow Steel Grade or IPS. In recentyears Extra Improved Plow Steel (EIPS) wire rope hasgained in popularity and is approximately 10% stronger thanIPS. Manufacturers have begun producing limited constructionsof Extra Extra Improved Plow Steel (EEIPS), which is10% higher than EIPS grade. Some special constructionsexceed EEIPS grade.The “Lay” of the wire rope (the direction of stranding andclosing) directly affects the operating properties. In RegularLay wire rope, the direction of the wires are twisted in anopposite direction than the direction of the strands. RegularLay may be Right Regular Lay or Left Regular Laydepending upon the direction of the strands. (See Fig.).FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 2In Lang Lay wire ropes the direction of the wires aretwisted in the same direction as the strands. Lang Lay maybe Right Lang Lay or Left Lang Lay depending upon thedirection of the strands. The wires of a regular wire ropeseem to travel parallel and along the length of the rope whilethose of a lang lay rope appear to travel around the rope.In addition, the Lay Length, the length of the rope necessaryfor one strand to travel completely around the rope (SeeFig.) may be varied slightly by manufacturer.Most wire rope has a Bright, self-colored finish and acoating of lubricant. However, many wire ropes are galvanized,stainless steel, or plastic/vinyl/urethane coated.Most wire ropes are supplied with either a fiber or steelcore. The core’s primary function is to support the wirestrands of the rope, maintaining the corrective relative positionsduring the operating life. Fiber Cores are composed ofnatural Vegetable Fiber Core (VFC - sisal, etc.) or SyntheticFiber Core (PFC- polypropylene, etc.) which havebeen formed into yarns and twisted into strands. Steel coresmay be Independent WireRope Core (IWRC) or WireStrand Core (WSC). Thesesteel cores provide more supportthan fiber cores to theouter strands during the rope’soperating life. Steel coresresist crushing, are more resistantto heat, reduce the amountof stretch, and increase thestrength of the rope. The Right WayUnreeling & UncoilingThe Right Way to Unreel. To unreel wire rope from aheavy reel, place a shaft through the center and jack up thereel far enough to clear the floor and revolve easily. Oneperson holds the end of the rope and walks a straight lineaway from the reel, taking the wire rope off the top of thereel. A second person regulates the speed of the turning reelby holding a wood block against the flange as a brake, takingcare to keep slack from developing on the reel, as this caneasily cause a kink in the rope. Lightweight reels can beproperly unreeled using a vertical shaft; the same careshould be taken to keep the rope taut.The Wrong Way to Unreel. If a reel of wire rope is laidon its flange with it’s axis vertical to the floor and the ropeunreeled by throwing off the turns, spirals will occur andkinks are likely to form in the rope. Wire rope alwaysshould be handled in a way that neither twists nor unlays it.If handled in a careless manner, reverse bends and kinks caneasily occur.The Right WayThe Right Way to Uncoil.There is only one way to uncoilwire rope. One person musthold the end of the rope while asecond person rolls the coilalong the floor, backing away.The rope is allowed to uncoilnaturally with the lay, withoutspiraling or twisting. Alwaysuncoil wire rope as shown.The Wrong Way to Uncoil. If a coil of wire rope is laid flaton the floor and uncoiled by pulling it straight off, spiralswill occur and kinking is likely. Torsions are put into therope by every loop that is pulled off, and the rope becomestwisted and unmanageable. Also, wire rope cannot beuncoiled like hemp rope. Pulling one end through the middleof the coil will only result in kinking.KinksGreat stress has been placed on the care that should betaken to avoid kinks in wire rope. Kinks are places wherethe rope has been unintentionally bent to a permanent set.This happens where loops are pulled through by tension onthe rope until the diameter of the loop is only a few inches.They are also caused by bending a rope around a sheave havingtoo severe a radius. Wires in the strands at the kink arepermanently damaged and will not give normal service,even after apparent “restraightening.”Drum Winding. When wire rope is wound onto a sheaveor drum, it should bend in the manner in which it was originallywound. This will avoid causing a reverse bend in therope. Always wind wire rope from the top of the one reelonto the top of the other. Also acceptable, but less so, is rereelingfrom the bottom of one reel to the bottom of another.Re-reeling may also be done with reels having their shaftsvertical, but extreme care must be taken to ensure that therope always remains taut. It should never be allowed to dropbelow the lower flange on the reel. A reel resting on thefloor with its axis horizontal may also be rolled along thefloor to unreel the rope.Wire rope should be attached at the correct location on aflat or smooth-faced drum, so that the rope will spool evenly,with the turns lying snugly against each other in even layers.If wire rope is wound on a smooth-face drum in the wrongdirection, the turns in the first layer of rope will tend tospread apart on the drum. This results in the second layer ofrope wedging between the open coils, crushing and flatteningthe rope as successive layers are spooled.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

3 SECTION 1 - Wire Ropebeen applied. Twist the two ends of the wire together, andby alternately pulling and twisting, draw the seizing tight.Method No. 2: Twist the two ends of the seizing wiretogether, alternately twisting and pulling until the propertightness is achieved.A simple method of determining how a wire rope should bestarted on a drum is shown in the above diagram. Theobserver stands behind the drum, with the rope comingtowards him. Using the right hand for right-lay wire rope,and the left hand for left lay wire rope, the clenched fistdenotes the drum, the extended index finger the oncomingrope.Seizing Wire RopeProper seizing and cutting operations are not difficult toperform, and they ensure that the wire rope will meet theuser’s performance expectations. Proper seizings must beapplied on both sides of the place where the cut is to bemade. In a wire rope, carelessly or inadequately seized endsmay become distorted and flattened, and the strands mayloosen. Subsequently, when the rope is operated, there maybe an uneven distribution of loads to the strands; a conditionthat will significantly shorten the life of the rope.Either of the following seizing methods is acceptable.Method No. 1 is usually used on wire ropes over one inch indiameter. Method No. 2 applies to ropes one inch and under.Method No. 1Method No. 2Method No. 1: Place one end of the seizing wire in thevalley between two strands. Then turn its long end at rightangles to the rope and closely and tightly wind the wire backover itself and the rope until the proper length of seizing hasThe Seizing Wire. The seizing wire should be soft orannealed wire or strand. Seizing wire diameter and thelength of the seize will depend on the diameter of the wirerope. The length of the seizing should never be less than thediameter of the rope being seized.Proper end seizing while cutting and installing, particularlyon rotation- resistant ropes, is critical. Failure toadhere to simple precautionary measures may cause coreslippage and loose strands, resulting in serious rope damage.Refer to the table for established guidelines. If core protrusionoccurs beyond the outer strands, or core retractionwithin the outer strands, cut the rope flush to allow forproper seizing of both the core and outer strands.In the absence of proper seizing wire or tools, the use ofsufficiently- sized hose clamps is acceptable.Rope DesignEnd PreparationAll standard preformed wire rope6x26 Reverse LaySingle Seizing6-Pac, 6-Pac RV, Flex-X, Endurance Dyform ® 6 & 8/8PIAll standard non-preformed wire ropeDouble Seizing19x7 & 8x19 Class Rotation ResistantSFP19, Endurance Dyform ® 18/18PI, Endurance Constructex ® , (Fused EndsTriple-PAC, Endurance 35x7 ® , Endurance 34LR/PI/MAX ® Recommended)Double SeizingSFP 35AND FusedEndsInstallationThe majority of wire rope problems occurring during operationactually begin during installation, when the rope is atgreatest risk of being damaged. Proper installation proceduresare vital in the protection and performance of wirerope products.• Provide Proper Storage- Avoid damage and moisture• Check the Rope Diameter Prior to Installation• Use Proper Unreeling/Uncoiling Procedures• Keep the Wraps Tight• Treat Rotation-Resistant Ropes with Extra Care• Secure the Ends Before Cutting• Use a Wire Mesh Grip or Chinese Finger (to PreventTorque from the old rope transferring to the new rope)• Always Perform a Break-In Procedure to Maximize ServiceLife• Avoid Slack in the Rope• Slowly Lift or Release the Load• Use the Wire Rope ONLY for the Job it was Intended.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 4Wire Rope InspectionThe most widely used wire rope replacement, inspectionand maintenance standard for mobile-type cranes is ASMEB30.5, section 5-2.4. The following is an excerpt from thatstandard.All running ropes in service should be visually inspectedonce each working day. A visual inspection shall consist ofobservation of all rope which can reasonably be expected tobe in use during the day’s operations. These visual observationsshould be concerned with discovering gross damage,such as listed below which may be an immediate hazard:[A] Distortion of the rope such as kinking, crushing,unstranding, birdcaging, main strand displacement, or coreprotrusion. Loss of rope diameter in a short rope length orunevenness of outer strands should provide evidence that therope must be replaced.[B] <strong>General</strong> Corrosion[C] Broken or Cut strands[D] Number, distribution, and type of visible broken wires[E] Core failure in rotation resistant ropes: when suchdamage is discovered, the rope shall be either removed fromservice or given an inspection (further detail per S-2.4.2).The frequency of detailed and thorough inspections shouldbe determined by a qualified person, who takes into accountthe following factors:• Expected rope life as determined by [a] maintenancerecords, and [b] experience on the particular installationor similar installations• Severity of environment• Percentage of capacity lifts• Frequency rates of operation, and exposure to shock loadsInspect the entire length of the rope. Some areas of thewire rope such as around the core are more difficult toinspect. To inspect the core, examine the rope as it passesover the sheaves. The strands have a tendency to open upslightly which will afford the inspector a better view of thecore. Also regularly inspect for any reduction in diameterand lengthening of rope lay as both conditions indicate coredamage.Basic GuidelinesAbrasion Abrasion damage may occur when the rope contactsan abrasive medium or simply when it passes over thedrum and sheaves. Therefore it is vital that all componentsbe in proper working order and of the appropriate diameterof the rope. A badly corrugated or worn sheave or drum willseriously damage a new rope, resulting in premature ropereplacement.Corrosion Corrosion is very difficult to evaluate but is amore serious cause of degradation than abrasion. Usuallysignifying a lack of lubrication, corrosion will often occurinternally before there is any visible external evidence on therope’s surface. A slight discoloration caused by rusting usuallyindicates a need for lubrication which should be tendedto immediately. If this condition persists, it will lead tosevere corrosion which promotes premature fatigue failuresin the wires and strands, necessitating the rope’s immediateremoval from service.Wire Breaks The table below shows the number of allowablewire breaks per crane type. The inspector must knowthe ASME standard for the equipment being inspected. Thenumber of broken wires on the outside of the wire rope is anindication of its general condition and whether or not it mustbe considered for replacement. The inspector may use a typeof spike to gently probe the strands for any wire breaks thatdo not protrude. Check as the rope runs at a slow speed overthe sheaves, where crown (surface) wire breaks may be easierto see. Also examine the rope near the end connections.Keeping a detailed inspection record of the wire breaks andother types of damage will help the inspector determine theelapsed time between breaks. Note the area of the breaksand carefully inspect these areas in the future. Replace therope when the wire breaks reach the total number allowableby ASME or other applicable specifications.ASMENo.EquipmentNo. BrokenWries in RunningRopes inOne RopeLayOneStrandNo. BrokenWries in StandingRopes inOneRopeLayOneStrandB30.2 Overhead and Gantry Cranes 12* 4 N/A N/AB30.4 Portal, Tower and Pillar Cranes 6* 3 3* 2B30.5 Crawler, Locomotive & Truck Cranes 6* 3 3* 2B30.6 Derricks 6* 3 3* 2B30.7 Base-Mounted drum Hoists 6* 3 3* 2B30.8 Floating Cranes & Derricks 6* 3 3* 2A10.4 Personnel Hoists 6* 3 2* 2A10.5 Material Hoists 6* N/A N/A N/A* Also remove for ONE valley break. OSHA require monthly record keeping of wirerope conditions. NOTE: current industry recommendations and OSHA standards arebased upon steel sheaves. The manufacturer of plastic and synthetic sheaves or linersshould be consulted for its recommendation on the safe application of the product andinspection criteria.Valley breaks, or breaks in between strands, must be takenvery seriously at all times! When two or more valleybreaks are found in one lay-length, immediately replacethe rope. Valley breaks are difficult to see; however, if yousee one you can be assured that there are a few more hiddenin the same area. Crown breaks are signs of normal deterioration,but valley breaks indicate an abnormal condition suchas fatigue or breakage of other wires such as those in thecore.Once crown and valley breaks appear, their number willsteadily and quickly increase as time goes on. The brokenwires should be removed as soon as possible by bending thebroken wire back and forth with a pair of pliers. In this waythe wire is more likely to break inside the rope where theFOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

5 SECTION 1 - Wire Ropeends will be tucked away. If the broken wires are notremoved they may cause further damage.The inspector must obey the broken wire standard; pushingthe rope for more life will create a dangerous situation.Diameter Reduction. Diameter reduction is critical deteriorationfactor and can be caused by:• Excessive abrasion of the outside wires• Loss of core diameter/support• Internal or external corrosion damage• Inner wire failure• A lengthening of rope layIt is important to check and record a new rope’s actualdiameter when under normal load conditions. During the lifeof the rope the inspector should periodically measure theactual diameter of the rope at the same location under equivalentloading conditions. This procedure if followed carefullyreveals a common rope characteristic--after an initialreduction, the overall diameter will stabilize and slowlydecrease in diameter during the course of the rope’s life.This condition is normal. However, if diameter reduction isisolated to one area or happens quickly, the inspector mustimmediately determine (and correct, if necessary) the causeof the diameter loss, and schedule the rope for replacement.Crushing. Crushing or flattening of the strands can becaused by a number of different factors. These problemsusually occur on multilayer spooling conditions but canoccur by simply using the wrong wire rope construction.Most premature crushing and/or flattening conditions occurbecause of improper installation of the wire rope. In manycases failure to obtain a very tight first layer (the foundation)will cause loose or “gappy” conditions in the wire ropewhich will cause rapid deterioration. Failure to properlybreak- in the new rope, or worse, to have no break-in procedureat all, will cause similar poor spooling conditions.Therefore, it is imperative that the inspector knows how toinspect the wire rope as well as how that rope was installed.Shock loading. Shock loading (birdcaging) of the rope isanother reason for replacement of the rope. Shock loading iscaused by the sudden release of tension on the wire rope andits resultant rebound from being overloaded. The damagethat occurs can never be corrected and the rope must bereplaced.High Stranding. High stranding may occur for a numberof reasons such as failure to properly seize the rope prior toinstallation or maintain seizing during wedge socket installation.Sometimes wavy rope occurs due to kinks or a verytight grooving problem. Another possibility is simply introducingtorque or twist into a new rope during poor installationprocedures. This condition requires the inspector toevaluate the continued use of the rope or increase the frequencyof inspection.Inspection Guidelines - Specialty RopesPlastic-Infused Rope. Plastic-infused rope was developedto provide better fatigue, abrasion and crushing resistancederived from the cushioning and dampening effect of theplastic. However great the benefits, the plastic becomes atthe very least an inconvenience when trying to inspect thewire rope. Because of the plastic coating, some operatorschoose to forego inspection and run the ropes to failure.Other operators may just visually inspect the plastic coating.Both practices are wrong and carry equally the potential fordisaster.Abrasion and Crushing. In inspecting plastic-infusedropes, the basic inspection guidelines still apply and shouldbe followed. Abrasion and crushing damage may still occur,so it is imperative to inspect flanges, sheaves, bearings, rollersand fairleads. Look for unusual wear patterns in the plastic--a key indicator that damage to the wire rope isoccurring.Wire Breaks. Wire breaks will still occur in a plasticinfusedrope, but are sometimes extremely difficult to detect,though occasionally a broken wire will protrude through theplastic. Every effort must be made to determine the overallcondition of the rope. The plastic covering the crown (surface)wires is generally applied in a thin coat and tends towear quickly in areas which pass over sheaves and drums.As the rope runs at a slow speed, inspect the rope in theseareas. As the rope and plastic open up the inspector will beafforded a look at not only the surface area but also the interstrandcontact points. If a valley break is detected, immediatelypull the ropes from service. Also inspect areas whereplastic has peeled, regardless of the location of the “window.”Remove as much plastic from these areas as possibleto allow for efficient and effective inspection techniques.Remember, due to the nature of plastic-infused ropes, thereis no way to clearly determine the number of valley breaks.Corrosion. Plastic-infused ropes provide only improvedcorrosion resistance. Regardless of manufacturers’ claims, aplastic-infused rope can corrode, and rope failure due to corrosionis still possible. Moisture is sometimes trapped in therope and as with all machines, the lubricant may becomeineffective over time. The inspector must visually check forany signs of corrosion damage as evidenced by rope bleedingor rouging. In addition, the diameter must be frequentlymeasured. If there is any damage to the core, it will bedetected by a reduction in diameter. Also inspect the lay ofthe rope. As the plastic is thinner over the crown wires, athorough inspection may be able to determine a lengtheningof lay, also a sign of rope deterioration. Especially when tryingto determine lengthening of lay, watch for and inspectareas where the plastic pulls away from the rope. Whilepeeling in and of itself is not an indication of rope deteriorationand is a factor of normal wear, peeling in areas where noabrasion exists may signify a problem.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 6Maintenance Records. Equally important in inspectingplastic-infused ropes is maintaining accurate service records.The service records of previous ropes will provide a guidelineas to the expected life of the rope. However, they shouldnot be used alone or only in conjunction with visual inspectionsdue to the number of variables which exist, includinginstallation, spooling and manufacturinng practices. Maintenancerecords must be used in combination with both visualand physical inspection techniques to be truly of value indetermining the remaining life of the rope.Overall, perhaps the most important inspection techniqueis recognizing the limits of wire rope. While it’s true thatcompacted and plastic infused ropes are more durable,neglect and abuse will still quickly end the rope’s life. Thereis no substitute for proper installation, handling and inspectiontechniques in combination with a preventative maintenanceprogram.Compacted Rope. Die drawn and swaged ropes fall intothe compacted category. Compacting serves several purposes.By flattening the outer wires, metallic area increasesallowing for a higher breaking strength as well as improvedcrushing and abrasion resistance. In addition, the compactionminimizes interstrand nicking and thereby improvesfatigue resistance.In the inspection of compacted rope designs, again it isimperative to follow the basic inspection guidelines and useboth visual and actual measuring techniques to determine theremaining life of the rope. In fact, actual measuring techniquesare very important when inspecting these ropes.While corrosion is relatively easy to visually determine,diameter reduction may not be due to the compacted rope’sappearance. Therefore the inspector must regularly measurefor diameter reduction and closely examine the rope for laylengthening. Measurements must be recorded and the ropemonitored for sudden variations.By and large the most difficult retirement criteria to determinein compacted ropes is wire breaks. These breaks maynot protrude from the rope due to the compaction and can beeasily overlooked. Because of this, the inspector mustslowly and carefully examine the rope, especially in thoseareas passing over drums and sheaves or in areas whereproblems existed in previous ropes.A wire break may appear as nothing more than a crack inthe wire, and again can be easily overlooked. If the inspectornotes a “flaw” in a wire, it should be carefully checked. Theinspector should carry some type of magnifying device todetermine if a flaw is actually a break. If a break hasoccurred, thoroughly check the area for additional breaks,both on the crown and in the valleys. Remember, valleybreaks in round strand ropes are difficult to determine; compactiononly increases the difficulty. The inspector must beslow and methodical in inspecting compacted ropes; a quickcheck will reveal nothing.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

7 SECTION 1 - Wire RopeTroubleshooting ChecklistTension (Cone) Tension (Cup) Tension & WearTension BreakWire break shows one end of broken wire coned, theother cupped. Necking down of the broken ends is typicalof this type break. Where tension breaks are found,the rope has been subjected to overloading, either for itsoriginal strength (new rope) or for its remaining strength inthe case of a used rope. Tension breaks frequently arecaused by the sudden application of a load to a slack rope,thereby setting up incalcuable impact stress.AbrasionFatigue Fatigue Fatigue & Wear Fatigue & NickingAbrasion BreakWire break shows broken ends worn to a knife-edgethinness. Abrasive wear obviously is concentrated atpoints, where the rope contacts an abrasive medium, suchas the grooves of sheaves and drums, or other objects withwhich the rope comes into contact. Unwarranted abrasivewear indicates improperly grooved sheaves and drums,incorrect fleet angle, or other localized abrasive conditions.Fatigue BreakWire breaks are usually transverse or square showinggranular structure. Often these breaks will develop ashattered or jagged fracture, depending on the type ofoperation. Where fatigue breaks occur, the rope hasrepeatedly been bent around too small a radius. Whipping,vibration, slapping and torsional stresses will also causefatique. Fatigue breaks are accelerated by abrasion andnicking.Corrosion BreakEasily noted by the wire’s pitted surface, wire breaksusually show evidence of tension, abrasion and/orfatigue. Corrosion usually indicates improper lubrication.The extent of the damage to the interior of the rope isextremely difficult to determine; consequently corrosion isone of the most dangerous causes of rope deterioration.CorrosionCut or ShearWire will be pinched down and cut at broken ends, orwill show evidence of shear-like cut.This condition is evidence of mechanical abuse caused byagents outside the installation, or by something abnormalon the installation itself, such as a broken flange.Cut or ShearFOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 8ABRASIONCORE PROTRUSIONAND SLIPPAGECORROSIONFrozen sheaves or rollersTight groovesExcessive fleet angleOversized or undersized ropeCorrugated sheave or drumSheave overspinRope jumping the sheavePoor spoolingMisaligned sheavesShockloadingPoor seizing techniquesPoor installation techniquesLack of lubricationEnvironmental damage, e.g. acidicFume exposureAbrasionCore Protrusion (Shockloading)CRUSHINGDIAMETERREDUCTIONPoor installation techniquesCrosswindingPoor Spooling<strong>Inc</strong>orrect wire rope constructionPoor break-in procedureExcessive fleet angleLack of lubrication (fiber core)Excessive abrasionCorrosion, internal and/or externalCorrosionFATIGUEHIGH STRANDINGJUMPING THESHEAVEKINKINGLAY LENGTHENING& TIGHTENINGOut of round sheavesTight groovesMisaligned sheavesUndersized sheavesWorn bearingsVibrationSlappingWhippingPoor seizing techniquesTight groovesUndersized sheavesPoor spoolingExcessive rope lengthPoor unreeling proceduresPoor installation techniquesUndersized sheavesPoor installation techniquesPoor unreeling proceduresCorrosionCrushingFatigue (Reverse Bend)Fatigue (Undersized Sheave)LOOPED WIRESUNBALANCEDROPEPoor installation techniquesOversized sheavesFOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

9 SECTION 1 - Wire RopeSuggested Wire Rope ConstructionAPPLICATIONS GENERAL CONDITIONS SEVERE CONDITIONSCRANESDROP BALLSLoad Lines 6x25 RR IWRC 6-PACGANTRY CRANESMain Hoist 6x25 RR IWRC;6x36 Class RR IWRC 6-PAC;8-PAC;SFP19Auxiliary Hoist 6x25 RR IWRC 6-PAC;8-PAC;SFP19Gantry crane types include: P& H. Demag, Kone and KrancoCONTAINER CRANESHoist Lines 6x36 RR IWRC 8-PACTrolley Lines 6x36 RR IWRC 8-PACLOCOMOTIVE CRANESMain Hoists 6x25 RR IWRC 6-PAC; TRIPLE PACAuxiliary Hoist 6x25 RR IWRC 6-PAC; TRIPLE PACBoom Hoist 6x25 RR IWRC 6-PAC; TRIPLE PACTag Lines 6x33 Warrington Seale RR FC n/aOFFSHORE PEDESTAL CRANES (DRILLING RIGS, PLATFORMS AND BARGES)Boom Hoist 6x25 RR IWRC 6-PAC;6-PAC RV; SUPER-PACHoist Lines 8x19 RR IWRC;19X7 SFP 19Auxiliary Lines 8x19 RR IWRC;19X7 SFP 19Offshore pedestal crane types include: Applied Hydraulics, Titan, Offshore crane, Unit Mariner, Link-Belt, National, Weatherford, Manitowac, Manitex,Bucyrus-Errie, SeaKing, FAVCO, Liebherr, Le Toureau, Nautilus, Clyde, American, Baker Marine and Skagit.OVERHEAD TRAVELING CRANESHoist Lines 6x19 Class RR IWRC;6X36 Class RR IWRC 6-PAC;8-PAC;SFP 19ROUGH TERRAIN, ALL TERAIN, TELESCOPIC AND LATTICE BOOM TRUCK CRANES,LATTICE BOOM HYDRAULIC CRAWLERS AND LATTICE BOOM FRICTION CRAWLERSBoom Hoist 6x25 RR IWRC;6X36 Class RR IWRC 6-PAC;6-PAC RV; SUPER-PACHoist Lines 6x25 RR IWRC;6X36 Class RR IWRC 6-PAC;8-PAC;TRIPLE-PAC;SFP19Auxiliary Lines 8x19 RR IWRC;19x7 SFP 19Boom Pendants 6x25 RR IWRC 6-PAC;TRIPLE-PACRough terrain et al crane types include: Galion, Grove, Link-Belt, Lorain, Koehring, P&H, PPM, Tadano, Liebherr, Demag, American, Manitowac,Manitex, National, and ClarkSIDE BOOM TRACTORSHoist Lines 6x25 RR IWRC 6-PAC; TRIPLE-PACBoom Lines 6x25 RR IWRC 6-PAC; TRIPLE-PACSTILL LEG DERRICKS AND REVOLVING DERRICK CRANESHoist Lines 6x25 RR IWRC 6-PAC;TRIPLE-PACAuxiliary Lines 6x25 RR IWRC 6-PAC; TRIPLE-PAC;SFP 19Boom Lines 6x25 RR IWRC 6-PAC; TRIPLE PAC;SFP 19Derrick crane types include: AMCLYDE, American, Clyde and ManitowacTOWER CRANESLoad Lines SFP 19;SFP 35 SFP 35Trolley Lines 6x25 RR IWRC n/aWHIRLEY CRANESMain Hoist 6x25 RR IWRC 6-PAC;SFP 19Auxiliary Hoist 6x25 RR IWRC 6-PAC;SFP 19Boom Hoist 6x25 RR IWRC 6-PAC;SUPER-PACWhirley crane types include: AMCLYDE, American, FAVCO and ClydeDREDGINGDIPPER DREDGESHoist Lines 6x19 Class RR IWRC;6X36 Class RR IWRC 6-PAC;6-PAC RVSwinging and Backing Lines 6x19 Class RR IWRC;6X36 Class RR IWRC 6-PACSpud Lines 6x19 Class RR IWRC; 6X36 Class RR IWRC 6-PACCLAMSHELL DREDGESHolding and Closing Lines 6x19 Class RR IWRC 6-PACSwing Lines 6x19 Class RR IWRC;6X36 Class RR IWRC 6-PACBoom Hoist Lines 6x19 Class RR IWRC 6-PAC;6-PAC RV;SUPER-PACStern or Anchor Lines 6x19 Class RR IWRC 6-PACSpud Lines 6x19 Class RG IWRC;6X36 Class RR IWRC 6-PACLADDER OR CHAIN BUCKET DREDGESLadder Lines 6x19 Class RR or RG IWRC 6-PACBow and Stern Lines 6x19 Class RR IWRC;6X36 Class RR IWRC 6-PACSpud Lines 6x19 Class RG IWRC;6X36 Class RR IWRC 6-PACSUCTION DREDGESLadder Lines 6x19 Class RR or RG IWRC 6-PACSwing Lines 6x19 Class RR IWRC 6-PACSpud Lines 6x19 Class RR IWRC; 6X36 Class RR IWRC 6-PACPontoon Lines 6x19 Class RR IWRC 6-PACFOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 10APPLICATION GENERAL CONDITIONS SEVERE CONDITIONSEXCAVATINGPOWER SHOVELSHoist Lines 6x25 RR or RG IWRC;6X36 Class RG IWRC 6-PACCrowd and Retract Lines 6x25 RR or RG IWRC;6X36 Class RG IWRC 6-PAC;6-PAC RVBoom Lines 6x25 RR or RG IWRC; 6x36 Class RG IWRC 6-PAC;6-PAC RVTrip Lines 6x19 Warrington RR FC;6x33 Warrington Seale RR FC n/aDRAGLINE EXCAVATORSDraglines 6x19 Class RG IWRC 6-PACHoist Lines 6x19 Class RR or RG IWRC 6-PAC;6-PAC RVBoom Lines 6x19 Class RR or RG IWRC;6X36 Class RG IWRC 6-PAC;6-PAC RVDump Lines 6x25 RR or RG IWRC 6-PAC;6-PAC RVCLAMSHELLSHoist Lines 6x19 Class RR IWRC;19x7 6-PAC;TRIPLE-PAC;SFP19Holding and Closing Lines 6x19 Class RR or RG IWRC;6x37 Class RR IWRC or FC 6-PAC;6-PAC RVBoom Lines 6x25 RR IWRC;6x26 RV IWRC 6-PAC;6-PAC RV;SUPER-PACTag Lines 6x33 Warrington Seale RR FC n/aCARRY-ALL SCRAPERS AND WAGONSHoist and Dump Lines 6x25 RR or RG IWRC;6x36 Class RR or RG IWRC 6-PACTRENCH HOES, DITCHERS AND PULL SHOVELSDigging Lines 6x19 Class RG IWRC 6-PACHoist Lines 6x25 RR IWRC;6x26 Warrington Seale RR IWRC 6-PACBoom Lines or Shear-Leg Lines 6x26 RR IWRC 6-PACSLACKLINE EXCAVATORSTrack Lines 6x19 Class RG FC; flattened strand RG FC 6-PAC;6-PAC RVLoad or Unhaul Lines 6x19 Class RR IWRC 6-PACTension or Track Adjusting Lines 6x25 RR IWRC 6-PACHOISTS AND WINCHESConstruction Hoists 6x19 Class RR IWRC;6x36 Class RR IWRC 6-PACElectric and Air Hoists 6x19 Warrington RR FC;6x36 Class RR FC;19x7;SFP 19 N/AWinches 6x19 Class RR IWRC;6x36 Class RR IWRC 6-PACLOGGINGEASTERNWinch Lines 6x26 Warrington Seale RR IWRC SUPER-BChokers 6x26 Warrington Seale RR IWRC n/aWESTERNArchlines 6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACBoom Loaders 6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACChokers 6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACHaulbacks 6x19 Seale RR IWRC;6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACHelicopter Chokers SKYBRITE n/aMainlines 6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACSawmill Carriage 6x25 RR IWRC SUPER-B, SUPER-PACSkylines 6x19 Seale RR IWRC;6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACStrawlines 6x19 Seale RR IWRC SUPER-B, SUPER-PACTriple Drum Lines 6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACWinch Lines 6x26 Warrington Seale RR IWRC SUPER-B, SUPER-PACOILFIELD AND MARINEAnchor Lines 6x19 Class RR IWRC; 6x36 Class RR IWRC Galvanized, Bethpac, Z-nodesCoring, Sand& Swabbing Lines 6x7 FC GalvanizedDiving Bells 19x7;SFP 19 SFP 35Marcellus Shale Drill Lines6x21 LR FCMooring Lines 6x19 and 6x36 Classes RR IWRC; Galvanized Strand Galvanized Rope, Bethpac, Z-nodesRiser Tensioner Lines 6x36 Class RR IWRC BethpacRotary Drill Lines 6x19 Seale RR IWRC;6x26 Warrington Seale RR IWRC BethpacTow Lines 6x36 Class RR IWRC GalvanizedTubing Lines 6x26 Warrington Seale RR IWRC SUPER-BWork Wire, Chain Chasers 6x19 Class RR IWRC;6x36 Class RR IWRC GalvanizedSTEEL MILLBell Ropes 6x25 RR IWRC 6-PACCar Puller, Spotter, Retarder Rope 6x19 Class RR IWRC or FC 6-PACLadle Cranes 6x36 Class RR IWRC 6-PAC;TRIPLE-PACOre Bridges and Unloaders 6x19 Class RR IWRC 6-PACSkip Hoists 6x19 Class RR or RG FC, flattened strand RG FC TRIPLE-PACStripper and Soaking Pit Cranes 6x36 Class RR IWRC 6-PAC;TRIPLE-PACRR= Right regular lay LR= Left Regular Lay RG= Right Lang lay LG= Left Lang LayRV=Right reverse lay FC= Fiber Core IWRC= Independent wire rope coreBXL, or plastic-infusion, may be added to many standard and specialty wire rope constructions, and is therefore not listed as a recommendation under Severe Conditions. Refer toSpecialty Applications: BXL for further information.In some instances, WWW specifies class and not a specific construction. This is due to multiple diameters used on a particular application, and /or multiple constructions suitablefor the application. For more information, please contact WWW’s sales or engineering department.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

11 SECTION 1 - Wire RopeRopesWire Rope DefinitionsSpiral Rope: An assembly of two or more layers of shapedand/or round wires laid helically over a center, usually asingle round wire. There are three categories of spiral rope,i.e. spiral strand, half locked coil and full-locked coil.Spiral Strand: An assembly of two or more layers of roundwires laid helically over a center, usually a single roundwire.Half-locked coil Rope: A spiral rope type having an outerlayer of wires containing alternate half lock and round wires.Full-locked Coil Rope: A spiral rope having an outer layerof full lock wires.Stranded Rope: An assembly of several strands laid helicallyin one or more layers around a core or center. Thereare three categories of stranded rope, i.e. single layer,multi-layer and parallel-closed.Single Layer Rope: Stranded rope consisting of one layer ofstrands laid helically over a core.Note: Stranded ropes consisting of three of four outer strandsmay, or may not, have a core. Some three and four strand singlelayer ropes are designed to generate torque levels equivalentto those generated by Rotation-Resistant ropes.Rotation-Resistant rope: Stranded rope designed to generatereduced levels of torque and rotation when loaded andcomprising an assembly of two or more layers of strands laidhelically around the center, the direction of lay of the outersstrands being opposite to that of the underlying layer.Rotation-Resistant rope: category 1:Stranded rope constructed in such a manner that it displayslittle or no tendency to rotate, or, if guided, transmitslittle or no torque, has at least fifteen outer strands and comprisingan assembly of at least three layers of strands laidhelically over a center in two or three operations, the directionof lay of the outer strands being opposite to that of theunderlying layer.Rotation-Resistant rope: category 2:Stranded rope constructed in such a manner that it has significantresistance to rotation, has at least ten out strands andcomprising an assembly of two or more layers of strandslaid helically over a centre in two or three operations, thedirection of lay of the outer strands being opposite to that ofthe underlying layer.Rotation-Resistant rope: category 3:Stranded rope constructed in such a manner that it has limitedresistance to rotation, has no more than nine outerstrands and comprising an assembly of two layers of strandslaid helically over a center in two operations, the direction oflay of the outer strands being opposite to that of the underlyinglayer.Compacted Strand Rope: Rope in which the outer strands,prior to closing of the rope, are subjected to a compactingprocess such as drawing, rolling or swaging.Compacted Swaged Rope: Rope which is subjected to acompacting process after closing, thus reducing its diameter.Plastic (Solid Polymer) Filled Rope: Rope in which the freeinternal spaces are filled with a solid polymer. The polymerextends to, or slightly beyond, the outer circumference of therope.Cushioned Rope: Stranded rope in which the inner layers,inner strands or core strands are covered with solid polymersor fibers to form a cushion between adjacent strands orlayers of strands.Cushion Core Rope: Stranded rope in which the core iscovered (coated) or filled and covered (coated) with a solidpolymer.Solid Polymer Covered Rope: Rope which is covered(coated) with a solid polymer.Solid Polymer Covered and Filled Rope: Rope which iscovered (coated) and filled with a solid polymer.Rope Grade (Rr): A number corresponding to a wire tensilestrength grade on which the minimum breaking force of arope is calculated.Note: It does not imply that the actual tensile strength grades ofthe wires in a rope are necessarily the same as the rope grade.Preformed Rope: Stranded rope in which the wires in thestrands and the strands in the rope have their internal stressesreduced resulting in a rope in which, after removal of anyserving, the wires and the strands will not spring out of therope formation.Note: Rotation Resistant stranded ropes should be regarded asnon-performed rope even though the strands may have beenpartially (lightly) preformed during the closing process.Rope Class: A grouping of rope constructions where thenumber of outer strands and the number of wires and howthey are laid up are within defined limits, resulting in ropeswithin the class having similar strength and rotationalproperties.Rope Construction: System which denotes the arrangementof the strands and wires within a rope, e.g. 6x19S; 6x36WS;18x7; 34x7.Cable-laid Rope: An assembly of several (usually six) singlelayer stranded ropes (referred to as unit ropes) laid helicallyover a core (usually a seventh single layer stranded rope).Braided Rope: An assembly of several round strands braidedin pairs.Electro-mechanical Rope: A stranded or spiral containingelectrical conductors.Strand and Rope LaysLay direction of strand: The direction right (z) or left (s)corresponding to the direction of lay of the outer layer ofwires in relation to the longitudinal axis of the strand.Lay direction of rope: The direction right (Z) or left (S)corresponding to the direction of lay of the outer strands inrelation to the longitudinal axis of a stranded rope or thedirection of lay of the outer wires in relation to thelongitudinal axis of a spiral rope.Regular Lay: Stranded rope in which the direction of lay ofthe wires in the outer strands is in the opposite direction toFOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 12the lay of the outer strands in the rope. Right Regular Lay isdesignated zZ and Left Regular Lay is designated zS.Note: This type of lay is sometimes referred to as 'ordinary' lay.Lang Lay: Stranded rope in which the direction of lay of thewires in the outer strands is the same as that of the outerstrands in the rope. Right Lang Lay is designated zZ andLeft Lang lay is designated sS.Alternate Lay: Stranded rope in which the lay of the outerstrands is alternatively Lang's lay and regular lay. Righthand alternate lay is designated AZ and left hand alternatelay is designated AS.Contra-Lay: Rope in which at least one layer of wires in aspiral rope or one layer of strands in a stranded rope is laid inthe opposite direction to the other layer(s) of wire or strandsrespectively.Note: Contra-lay is only possible in spiral ropes havingmore than one layer of wires in, multi-layer stranded ropes.Rope Lay Length (Stranded Rope): That distance parallel tothe axis of the rope in which the outer strands make onecomplete turn (or helix) about the axis of the rope.to the amount of rotation when one end of the rope is free torotate and the rope is subjected to tensile loading.Initial extension: Amount of extension which is attributed tothe initial bedding down of the wires within the strands andthe strands within the rope due to tensile loading.Note: This is sometimes referred to as constructional stretch.Elastic extension: Amount of extension which followsHooke's Law within certain limits due to application of atensile load.Permanent rope extension: Non-elastic extension.CoresCore: Central element, usually of fiber or steel, of a singlelayer stranded rope, around which are laid helically the outerstrands of a stranded rope or the outer unit ropes of acable-laid rope.Fiber core: Core made from either natural (e.g. hemp, sisal)or synthetic fibers (e.g. polypropylene) and designated by itsdiameter and runnage.Steel Core: Core produced either as an independent wirerope (e.g. 7x7) or wire strand (e.g. 1x7).Solid polymer core: Core produced as a single element ofsolid polymer having a round or grooved shaped. It mayalso contain internal elements of wire or fiber.Insert: Element of fiber or solid polymer so positioned as toseparate adjacent strands or wires in the same or overlyinglayers and fill, or partly fill, some of the interstices in therope.Rope Characteristics and PropertiesFill factor: The ratio between the sum of the nominalcross-sectional areas of all the load bearing wires in the ropeand the circumscribed area of the rope based on its nominaldiameter.Spinning loss factor: The ratio between the calculatedminimum breaking force of the rope and the calculatedminimum aggregate breaking force of the rope.Minimum breaking force (T min): Specified value, in tonsor kN, below which the measured breaking force is notallowed to fall in a prescribed test.Rope torque: Value, usually expressed in ft pounds or N.m,resulting from either test or calculation, relating to the torquegenerated when both ends of the rope are fixed and the ropeis subjected to tensile loading.Rope turn: Value, usually expressed in degrees perfoot/meter, resulting from either test or calculation, relatingFOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

13 SECTION 1 - Wire RopeSix Strand Ropes<strong>General</strong> Purpose Wire Ropes6 x 19 ClassStrands: 6Wires per strand: 19 to 26Core: IWRC or fiber coreStandard Grade: EIPSLay: Regular or LangFinish: Bright or galvanizedThe 6x19 Classification of wire ropeis the most widely used. With its goodcombination of flexibility and wear resistance,rope in this class can be suited tothe specific needs of diverse kinds ofmachinery and equipment.The 6 x 19 Seale construction, with itslarge outer wires, provides great ruggednessand resistance to abrasion and crushing.However, its resistance to fatigue issomewhat less than that offered by a 6x25construction. The 6x25 possesses the bestcombination of flexibility and wear resistancein the 6x19 Class due to the fillerwires providing support and imparting stabilityto the strand. The 6x26 WarringtonSeale construction has high resistance tocrushing. This construction is a goodchoice where the end user needs the wearresistance of a 6x19 Class Rope and theflexibility midway between a 6x19 Classand 6x37 Class rope.6 x 36 ClassStrands: 6Wires per strand: 27 to 49Core: IWRC or fiber coreStandard Grade: EIPSLay: Regular or LangFinish: Bright or galvanizedThe 6x36 Class of wire rope ischaracterized by the relatively largenumber of wires used in each strand.Ropes of this class are among the mostflexible available due to the greaternumber of wires per strand, howevertheir resistance to abrasion is less thanropes in the 6x19 Class.The designation 6x36 is onlynominal, as in the case with the 6x19Class. The ropes may not actually have36 wires per strand. Improvements inwire rope design, as well as changingmachine designs, have resulted in theuse of strands with widely varyingnumbers of wires and a smaller numberof available constructions. Typical6x36 Class constructions include 6x33for diameters under 1/2”, 6x36 WarringtonSeale (the most common 6x37Class construction) offered in diameters1/2” through 1-5/8”, and 6x49Filler Wire Seale over 1-3/4” diameter.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 146x19 And 6x36 ClassesTechnical Data6x19 Class6x19 Seale6x19 Warrington6x21 Filler Wire6x21 Seale6x25 Filler Wire6x25 Seale6x26 Warrington SealeRope DiameterApproximateWeightNominal Strength - tons*(Bright or Drawn Galvanized**)(lbs./ft.)EIPSEEIPSinches mm. Fiber Core IWRC Fiber Core IWRC IWRC1/4 6.5 0.105 0.116 3.02 3.40 3.745/16 8.0 0.164 0.18 4.69 5.27 5.803/8 9.5 0.236 0.26 6.71 7.55 8.317/16 11.0 0.32 0.35 9.09 10.2 11.21/2 13.0 0.42 0.46 11.8 13.3 14.69/16 14.5 0.53 0.59 14.9 16.8 18.55/8 16.0 0.66 0.72 18.3 20.6 22.73/4 19.0 0.95 1.04 26.2 29.4 32.37/8 22.0 1.29 1.42 35.4 39.8 43.81 26.0 1.68 1.85 46.0 51.7 56.91-1/8 29.0 2.13 2.34 57.9 65.0 71.51-1/4 32.0 2.63 2.89 71.0 79.9 87.91-3/8 35.0 3.18 3.50 85.4 96.0 106.01-1/2 38.0 3.78 4.16 101.0 114.0 125.01-5/8 42.0 4.44 4.88 118.0 132.0 146.01-3/4 45.0 5.15 5.67 136.0 153.0 169.01-7/8 48.0 5.91 6.50 155.0 174.0 192.02 52.0 6.72 7.39 176.0 198.0 217.02-1/8 54.0 7.59 8.35 197.0 221.0 243.02-1/4 58.0 8.51 9.36 220.0 247.0 272.02-3/8 60.0 9.48 10.4 244.0 274.0 301.02-1/2 64.0 10.5 11.6 269.0 302.0 332.02-3/4 70.0 12.7 14.0 321.0 361.0 397.0*tons of 2,000 lbs.** Reduced values for coated galvanizing. For Class A coatingdeduct 10% from EIP Grade. For other coating thicknesses consultthe manufacturer.Technical data for the above listedconstructions are the same anddetailed in the table.6x36 Class6x31 Warrington Seale6x336x36 Warrington Seale6x41 Warrington Seale6x43 Filler Wire Seale6x49 Filler Wire SealeFor further information on additionalconstructions and diameters, contactyour <strong>ALP</strong> Sales Representative.Note: The picture at the top depicts a Right LangLay IWRC wire rope. The picture at the bottomdepicts a Right Regular Lay IWRC wire rope.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

15 SECTION 1 - Wire RopeRotation Resistant RopesIn certain instances the use of rotation-resistant wire rope is necessary to provide rotational stability to thelifted load. In general, the use of these wire ropes is limited to those situations where it is impractical to:1. Use a tag line2. Relocate rope dead end.3. <strong>Inc</strong>rease sheave sizes.4. Eliminate “odd-part” reeving.5. Significantly reduce rope loading and rope fall length.Rotation-resistant wire ropes have less of a tendency to unlay when loaded than do conventional wire ropes.This results in improved rotational stability to the lifted load. Rotation-resistant wire ropes are designed in sucha way that the rotational force of the outer strands is partially counteracted by the rotational force of the innerstrands or core when the rope is subjected to a load.The chart compares the rotational properties of rotation-resistant ropes with a standard 6x25 wire rope. Therotation-resistant ropes far surpass the rotational stability of a conventional 6x25 IWRC wire rope on both shortand long falls.SAFETY DESIGN FACTORSASME B30.5 specifies that rotation-resistant ropes have a safety design factor of five or greater. The required strengthdesign factor of rotation-resistant rope becomes very important from the standpoint of maintaining the inherent low rotationof the rope and eliminating any tendency to overload the inner core, thereby causing a reduction in rope strength.HANDLING & INSTALLATIONPrecautions should be followed when using rotation-resistant wire rope. The rope ends must be properly seized andsecured (refer to Handling and Installation: Seizing Wire Rope) and cut with a saw or impact hammer to prevent unlaying ofthe strands.Attachment of end fittings must be done with care to prevent kinking or unlaying of rope, which harms the rotationalbalance of the rope.Operation of rotation-resistant wire ropes (excluding SFP 35 ) with a swivel is generally not recommended. Theuse of a swivel allows the inner core to twist tighter, resulting in a significant reduction in rope strength, possibly leading topremature rope failure. A swivel may be used as a temporary device only during the initial installation period to help eliminateany installation-induced twisting or cabling.The swivel must be removed from the reeving after the rope installation is completed and before the crane beginsoperation.Due to the opposite lay direction of the inner core and outer strand layers in rotation-resistant ropes, care should betaken to avoid shock loading. Shock loading will result in distortion of the rope structure, causing birdcaging, core protrusion,etc. Due to the potential for complete rope failure, shockloaded wire ropes must be immediately removed from service.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 16CAUTIONThe rated strengths of the 19 x7 class and 8 x19 class wire ropes are less than wire ropes in the 6x19 and 6x36 Classes.Larger sheaves are required in order to achieve comparable fatigue life. Refer to Technical Information: Effect of SheaveSize for further information on proper sheave sizes.19x7 Rotation-Resistant8x19 Rotation-ResistantStrands: 19Wires per strand:7Core: WSCStandard grade(s):EIPSLay: RegularFinish: BrightStrands: 8Wires per strand: 19Core: IWRCStandard grade(s):EIPSLay: RegularFinish: Bright19x7 is recommended for hoistingunguided loads with a single-part line.The rotation-resistant properties of thisrope are secured by two layers of strands. Theinner strands are left lay, while the 12 outerstrands are right lay, which enables one layer tocounteract the other layer’s rotation.The rotation-resistant characteristics ofthe 19x7 wire ropes are superior to those of the8x19 Class wire ropes.The 8x19 Classification rotation-resistantropes are recommended for hoisting unguidedloads with a single-part or multi-part line.The eight outer strands are manufactured inright lay, with the inner strands being left lay.These ropes are slightly stronger and significantlymore rugged than the 19x7 construction.However, the rotation-resistant properties of the8x19 rotation- resistant ropes are much less thanthose of the 19x7 construction.These ropes are manufactured in right regularlay in the 8x19 Seale and 8x25 Filler Wireconstructions.Rope Diameter Approx. Weight(lb./ft.)NominalStrength(tons*)inches mm. EIPS3/16 4.8 0.064 1.571/4 6.5 0.113 2.775/16 8.0 0.177 4.303/8 9.5 0.250 6.157/16 11.0 0.350 8.331/2 13.0 0.450 10.809/16 14.5 0.580 13.605/8 16.0 0.710 16.803/4 19.0 1.020 24.007/8 22.0 1.390 32.501 26.0 1.820 42.201-1/8 29.0 2.300 53.101-1/4 32.0 2.840 65.101-3/8 35.0 3.430 78.401-1/2 38.0 4.080 92.80Rope DiameterApprox.Weight (lb./NominalStrength(tons*)inches mm. ft.) EIPS1/2 13.0 0.47 11.79/16 14.5 0.60 14.75/8 16.0 0.73 18.13/4 19.0 1.06 25.97/8 22.0 1.44 35.01 26.0 1.88 45.51-1/8 29.0 2.39 57.31-1/4 32.0 2.94 70.51-3/8 35.0 3.56 84.91-1/2 38.0 4.24 100.0FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

17 SECTION 1 - Wire RopeGalvanized & StainlessGalvanized GalvanizedSmall diameter galvanized wirerope, sometimes called GalvanizedAircord, has many applications. Theseinclude small winches & hoists, overheaddoors, yacht rigging and clothesline. This rope may also be coatedwith vinyl, plastic, or urethane. Whenused as an operating rope they shouldbe lubricated. <strong>ALP</strong> has both domesticand imported sources for these products.In some applications, these ropes arerequired to conform to MIL-W-83420.Diam<strong>Inc</strong>hes7x7 GalvanizedNominal StrengthLbs.Approx. Wt.Lbs/ 100 FtNominalStrengthLbs.7x19 GalvanizedApprox. Wt.Lbs/ 100 Ft3/64 270 0.42 - -1/16 480 0.75 480 0.753/32 920 1.6 1,000 1.741/8 1,700 2.8 2,000 2.905/32 2,600 4.3 2,800 4.503/16 3,700 6.2 4,200 6.507/32 4,800 8.3 5,600 8.601/4 6,100 10.6 7,000 11.05/16 9,200 16.7 9,800 17.33/8 13,100 23.6 14,400 24.3Made to commercial practice. Available in other diameters.Stainless(Corrosion Resistant)Stainless ropes are used in enviromentswhich would quickly degradebright or galvanized ropes. The term“Corrosion Resistant” is technicallypreferable to “Stainless” because theseproducts are not stainless in all atmospheres.Types 302/304 are offered in allcommon sizes. Types 305/316 are availableon special order. All operatingropes should be lubricated.In some applications, these ropes arerequired to conform to MIL-W-83420.These items will require special order.Diam<strong>Inc</strong>hes7x7 StainlessNominal StrengthLbs.StainlessApprox. Wt.Lbs/ 100 Ft7x19 StainlessNominal StrengthLbs.Approx. Wt.Lbs/ 100 Ft3/64 270 0.42 270* 0.361/16 480 0.75 480 0.753/32 920 1.6 920 1.741/8 1,700 2.8 1,760 2.905/32 2,400 4.3 2,400 4.503/16 3,700 6.2 3,700 6.507/32 4,800 8.3 5,000 8.601/4 6,100 10.6 6,400 11.009/32 7,600 13.4 7,800 13.905/16 9,000 16.7 9,000 17.303/8 12,000 23.6 12,000 24.30* Commercial practice- no published standard. Available in other diameters.1/16 and 3/16 strengths are from MIL-W-83420B.Strand <strong>Products</strong><strong>ALP</strong> stocks many common diametersof small strand products. Strandproducts generally have constructionslike 1x7, 1x19, etc.Both galvanized and stainless strandproducts are available. Various gradesof strand are available including aircraftquality, common grade, utility gradeand EHS. In addition, larger diameterproducts are available for pendants andsupport lines.Consult the nearest <strong>ALP</strong> branch formore information.Diam (in.)6x19 IWRC & 6x37 IWRC - StainlessNominalB/S lbs.Approx. lbs./100 ft.Diam. (in)Nominal B/Slbs.Approx.lbs./100 ft.1/4 5,400 11.6 3/4 49,600 1045/16 8,300 18.0 7/8 66,500 1423/8 11,700 26.0 1 85,400 1857/16 16,300 35.0 1-1/8 106,400 2341/2 22,800 46.0 1-1/4 129,400 2899/16 28,500 59.0 1-3/8 153,600 3505/8 35,000 72.0 1-1/2 180,500 416Manufactured to RRW-410D where applicable.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 18Specialty RopesBethlehemSuper Flex Pac 19 Rotation- ResistantStrands: 19Wires per strand: 19Core: WSCStandard grade(s):EEIPSLay: Right RegularFinish: BrightSFP 19 is recommended for both multipart loadand single-part fast line applications where rotationalstability of the lifted load is needed, such as for use aslong fall on offshore pedestal cranes, rough and all terraincranes, and crawler cranes.SFP 19 provides:Fatigue Resistance. Improved fatigue properties arederived through the combination of the flexible 19x19construction and die drawn strands. The drawn strandsurfaces minimize the interstrand and interlayer nickingthat take place in round rotation-resistant ropes.Abrasion Resistance. Die drawn ropes provide improvedabrasion resistance as compared with round wire ropesbecause of the greater wire and strand bearing surfacescontacting sheaves and drum.Resistance to Drum Crushing. SFP 19 wire ropes areresistant to the effects of drum crushing due to the compactedstrands and smoothness of the rope surface.Flexibility. With 19 strands of 19 wires in all diameters,SFP 19 remains extremely flexible and easy to handleduring both the installation process and under theextremely harsh conditions from fast line speeds duringspooling.Rope DiameterApproximateNominal Strength(tons)*inches mm Weight(lb./ft.)Royal Purple(EEIPS)7/16 11.0 0.42 11.21/2 13.0 0.54 14.69/16 14.5 0.69 18.55/8 16.0 0.83 22.73/4 19.0 1.19 32.37/8 22.0 1.62 43.81 26.0 2.12 56.91-1/8 29.0 2.68 71.51-1/4 32.0 3.31 87.91-3/8 35.0 4.01 106.01-1/2 38.0 4.77 125.06-PAC Strands: 6Wires per strand: 19 to 36Core: IWRCStandard grade(s): EEIPSLay: Right RegularFinish: Bright6-PAC is recommended for use where the rope issubjected to heavy use or where conditions areextremely abusive, such as offshore pedestal, crawlerand lattice boom equipped truck crane boom hoistapplications. 6-PAC is also recommended for winchlines, overhead cranes, multipart hoist lines where rotation-resistantropes are not required, and other applicationswhere flexibility, high strength and resistance tocrushing are important, and a cost-effective 6-strandrope is desired.6-PAC provides:Fatigue Resistance. Improved fatigue properties arederived from the combination of 6-PAC’s flexible constructionsand the compacted strand surface minimizesthe interstrand and interlayer nicking that take place instandard 6-strand ropes.Abrasion Resistance. 6-PAC’s compacted strand designprovides improved abrasion resistance as compared tostandard 6-strand ropes because of the increased wireand strand surfaces contacting sheaves and drums.Flexibility. 6-PAC’s design provides increased flexibility,making it easy to install, and 6-PAC also offers betterspooling at high line speeds.Resistance To Multilayer Drum Crushing. 6-PAC dramaticallyincreases the amount of wire contact with thedrums and sheaves, reducing the wire rope, sheave anddrum wear normally associated with standard wirerope. Damage at the crossover points is also reduced.Rope Diameter StandardApprox.WeightNominal Strength(tons*)inches mm. Constructions (lb./ft.) Royal Purple(EEIPS)3/8 9.5 6x19 Seale 0.285 8.317/16 11.0 6x19 Seale 0.388 11.201/2 13.0 6x26 0.503 15.509/16 14.5 6x26 0.642 18.505/8 16.0 6x26 0.795 22.703/4 19.0 6x31 1.143 32.207/8 22.0 6x31 1.547 43.801 26.0 6x31 2.075 56.901-1/8 29.0 6x31 2.575 71.501-1/4 32.0 6x36 3.169 87.901-3/8 35.0 6x36 3.758 106.001-1/2 38.0 6x36 4.564 125.001-5/8 41.3 6x36 5.356 146.001-3/4 45.5 6x36 6.212 169.00FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

19 SECTION 1 - Wire RopeBethlehem8-PACSuper Flex Pac 35Strands: 35Wires per Strand: 7Core: WSCStandard Grade: 2160 N/mm 2Lay: Right RegularFinish: BrightSFP 35 is a rotation-resistant rope of high strength thatcan resist block twist in long falls.SFP 35 provides: Superior Rotation Resistance - theSFP 35 rope is the most rotation resistant rope manufacturedby WW. Due to its rotation-resistant properties, SFP 35may be used with a swivel in both single part and multiplepart reeving.SFP 35 provides: High Strength -WW’s compactionprocess provides a high strength rope which exceeds EEIPnominal break strength.Application: SFP 35 excels in crawler and truck-typecrane load lines, and tower crane ropes.Flexibility: SFP 35’s multiple strand construction providesincreased flexibility which improves service life andhigh speed spooling. The compacted multiple strand constructionalso reduces sheave and drum abrasion and providesexcellent resistance to drum crushing.Super Flex Pac 35 (SFP 35)Rope Diameter Approx. Wt. Nominal Strengthmm inches (kg/m) (lbs/ft) (kN) (tons)19 1.79 3443/4 1.21 38.7022 2.4 4667/8 1.65 53.001 2.15 70.0026 3.36 66028 3.90 7581-1/8 2.73 86.90Strands: 8Wires per Strand: 19 to 36Core: Plastic Filled (BXL)Standard Grade: Royal PurpleLay: RightFinish: Bright8-PAC is recommended for hoist ropes for steel mill ladlecranes and hoist and trolley ropes for container cranes, orother hoisting applications with heavy duty cycles or whereversevere bending occurs.Superior Performance: 8-PAC has higher breakingstrength and gives superior performance in difficult hoistingapplications compared to 6-strand and 6-strand compactedropes.Abrasion Resistance: 8-Pac’s compacted strand designprovides improved abrasion resistance as compared to standard6-strand and 8-strand ropes because of the increasedwire and strand surfaces contacting the sheaves and drums.Superior Flexibility: 8-Pac is significantly more flexiblethan standard 6-strand and compacted 6-strand ropes withbetter spooling and longer service life.Resistance to Multilayer Drum Crushing: 8-PAC’splastic filled (BXL) core offers increased resistance to crushingthrough better support of the outer strands.8-PACRope Diameter Standard Approx. Wt. Minimum Breakinginches Construction (lb/ft) Strength (net tons)5/8 8x26 WS 0.80 25.03/4 8x26 WS 1.17 36.07/8 8x26 WS 1.60 48.31 8x26 WS 2.10 62.81-1/8 8x26 WS 2.63 79.01-1/4 8x31 WS 3.26 98.0Other Sizes are AvailableFOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE

SECTION 1 - Wire Rope 20BethlehemBXL Triple-PAC TRIPLE-PAC was developed for the most demandinghoist applications. TRIPLE- PAC offers the extra highstrength and crushing resistance needed for applicationssuch as boom hoist ropes, boom pendants and multipartload lines.TRIPLE-PAC provides:Superior abrasion and fatigue resistance as comparedwith most compacted ropes due to WWW’s uniquedesign of compacting the IWRC, individual strands andthe rope itself. Other benefits include:High strength. TRIPLE-PAC is designed to provide a nominalstrength of 35% above EIP. WWW achieves thisstrength through selected grades of steel and TRIPLE-PAC’s unique design and manufacturing processes.Superior Resistance to Multilayer Drum Crushing.TRIPLE-PAC provides superior resistance to crushingthrough its design. Its triple compaction provides adenser cross section, enabling the rope to withstand therigors of multilayer spooling. Damage at the cross overpoints is also significantly reduced. In addition, TRI-PLE-PAC’s design increases the amount of wire contactwith sheaves and drums, reducing wire rope, drum andsheave wear.Triple-PACStrands: 6Wires per strand:31 to 36Core: IWRCStandard grade(s):EEIPSLay: Right RegularFinish: BrightRope Diameter Approx. WeightNominalStrength (tons)*inches mm (lbs./ft.) Royal PurplePlus (EEIPS)7/16 11.0 0.412 13.81/2 13.0 0.543 18.09/16 14.5 0.680 22.75/8 16.0 0.840 27.83/4 19.0 1.297 39.77/8 22.0 1.646 53.71 26.0 2.147 69.81-1/8 29.0 2.722 87.81-1/4 32.0 3.297 107.91-3/8 35.0 3.997 129.61-1/2 38.0 4.839 153.9BXL is infused with a special polymer, creating a wellbalancedmatrix. BXL is recommended for numerous hoist,marine, and logging rope applications.BXL provides:• Fatigue Resistance - Improved fatigue resistance is derivedfrom the cushioning and dampening effect of the polymer onthe wires and strands. BXL also evenly distributes stresseswhich may lead to fatigue breaks.• Abrasion Resistance - The polymer acts as a barrier betweenthe individual strands, preventing penetration of any adversematerial. BXL distributes and reduces contact stressesbetween the rope and sheave, reducing wire rope wear.• Resistance To Multilayer Drum Crushing - BXL’ssmooth profile evenly distributes crushing pressures from theoverlying layers of rope in multilayer drum winding applications.• Extended Sheave and Drum Service Life - BXL minimizescorrugation and wear normally associated with standardrope usage by restricting water and dirt penetration and eliminatingpickup of abrasive materials.• Clean Handling - The exterior rope surface is free from theBXLRope Diameter Approx. Wt. Nominal Strength*inches mm (lb/ft) Tons (2000 Lbs)3/8 9.5 0.27 7.57/16 11.0 0.37 10.21/2 13.0 0.49 13.39/16 14.5 0.61 16.85/8 16.0 0.76 20.63/4 19.0 1.09 29.47/8 22.0 1.49 39.81 26.0 1.94 51.71-1/8 29.0 2.46 65.01-1/4 32.0 3.03 79.91-3/8 35.0 3.67 96.01-1/2 38.0 4.37 114.0Strands: 6Wires per Strand: 19 to 36Core: IWRCStandard Grade(s): Purple Plus (EIPS)Lay: Regular or LangFinish: Plastic-InfusedNote: The strengths listed in the table reflect only the 6x19 and6x36 classes. BXL, or plastic-infused, may be added to manyproducts, excluding rope designs in which the rope itself is compacted.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE