Grounding Products and Systems - Elec.ru

Grounding Products and Systems - Elec.ru

Grounding Products and Systems - Elec.ru

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

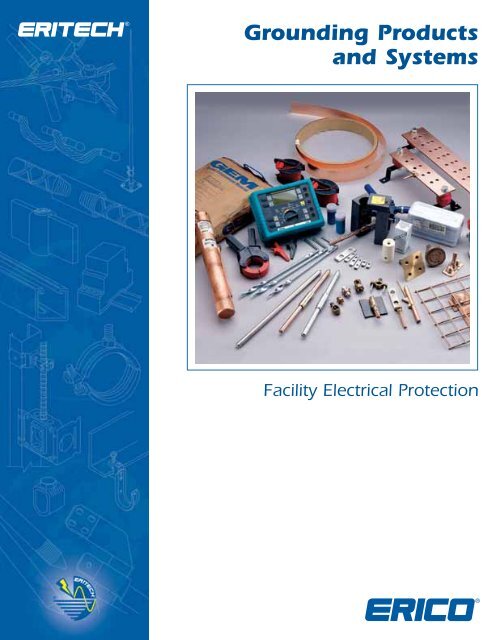

<strong>Grounding</strong> <strong>Products</strong><strong>and</strong> <strong>Systems</strong>Facility <strong>Elec</strong>trical Protection

Founded in 1903 as the <strong>Elec</strong>tric Railway Improvement Company, ERICO developed theCADWELD ® exothermic welding process in 1938. CADWELD connections have foundindustry-wide acceptance as the ultimate electrical connection. During the 1970s, ERICO pioneeredthe development <strong>and</strong> st<strong>and</strong>ardization of the copperbonded steel groundingelectrode. Since that time, ERICO’s dominance as the world’s leading supplier of grounding productshas seen its expansion into many related industries.Facility <strong>Elec</strong>trical ProtectionDivisionLightning protection, grounding, equipotential bonding <strong>and</strong>surge protection are all interdependent disciplines, <strong>and</strong> the focusof our Facility <strong>Elec</strong>trical Protection division. Reliable protection ofst<strong>ru</strong>ctures, industrial <strong>and</strong> commercial operations <strong>and</strong> personnel,dem<strong>and</strong>s a systematic <strong>and</strong> comprehensive approach tominimizing threats caused by transients.For instance, no air terminal can safely capture <strong>and</strong> arrest thelightning energy without adependable route to ground.Equally, even the most expensiveSurge Protection Device (SPD) willnot provide optimum protection ifa low impedance electricalconnection to the ground is notprovided. The solution does notstop here - a low impedanceground system may create hazardsto equipment <strong>and</strong> personnel alike ifequipotential bonding practices arenot followed. Theseinterdependent disciplines are bestapplied when looking at a totalfacility rather than an individualpiece of equipment or portion ofthe facility. Our team of qualifiedapplications engineers is here tohelp you with such challenges.Noting that there is no singletechnology that can eliminate theharmful effects of lightning or induced surge transients, ERICOInc. has developed the Six Point Protection Plan. The conceptbehind this plan is to prompt the user to consider a holistic <strong>and</strong>coordinated approach to lightning protection, one embracing allaspects of potential damage. This ranges from the more obviousdirect strike to the more subtle mechanisms of differential earthpotential rises <strong>and</strong> voltage induction at service entry points. Thesix interdependent disciplines that form the protection plan are:1. Capture the lightning strike to a known <strong>and</strong> preferredattachment point2. Safely convey this energy to the ground3. Dissipate energy into the grounding system4. Bond all ground points together5. Protect incoming AC power feeders6. Protect low voltage data/telecommunications circuitsAt ERICO, we offer more than just the best range ofgrounding <strong>and</strong> bonding products available. We offer engineeringexperience <strong>and</strong> technical supportthat is second to none in theindustry.With this experience, ERICOis a world leading authority inthe design <strong>and</strong> const<strong>ru</strong>ction ofpermanent, low impedance,grounding systems.ERICO’s quality assuranceprogram, ensures that detailedprocedures required for every stepof operation, including design,materials procurement,manufacturing, installation <strong>and</strong>testing, produce the best possiblesystem for our clients.Our research <strong>and</strong> developmentcapabilities provide continuousdesign improvement with new<strong>and</strong> improved products that preemptthe challengingrequirements of ever evolving industry applications. Engineeringexpertise is shared among the other ERICO operations worldwide,to provide the most comprehensive knowledge pool in the field.Our commitment to providing cost-effective, permanentsolutions for our customers is enhanced by on-site services, suchas providing advice in choosing the right product for the job <strong>and</strong>comprehensive site surveys.

Table of Contents<strong>Grounding</strong> Principles....................................................................................................................2Introduction..............................................................................................................................3<strong>Grounding</strong> Principles..........................................................................................................4 - 7Ground System ComponentsGround Conductors....................................................................................................................8<strong>Grounding</strong> Clamps <strong>and</strong> Connectors.....................................................................................9 – 11Ground <strong>Elec</strong>trodes............................................................................................................ 12 – 17Ground <strong>Elec</strong>trodes <strong>and</strong> Accessories...................................................................................18 – 30Equipotential BondingIntroduction..............................................................................................................................31Equipment Ground Bars................................................................................................... 32 – 37Perimeter Bus System................................................................................................................38Equipment Ground Plates................................................................................................. 39 – 40Aircraft Receptacles.................................................................................................................. 41Transient Earth Clamp/Joint Protector....................................................................................... 42Signal Reference Grid (SRG)..............................................................................................43 – 46Signal Reference Grids & <strong>Grounding</strong>.........................................................................................47Equipotential Mesh / Mats................................................................................................48 – 52Temporary Protective <strong>Grounding</strong> Jumpers................................................................................. 53Bonding Devices............................................................................................................... 54 – 55Temporary Protective <strong>Grounding</strong> Jumpers................................................................................. 56Fence Post & Gate <strong>Grounding</strong>.......................................................................................... 57 – 59Static <strong>Grounding</strong> <strong>and</strong> BondingStatic <strong>Grounding</strong> & Bonding Components................................................................................ 60Static <strong>Grounding</strong> Conductors....................................................................................................61Static <strong>Grounding</strong> Conductors & Clamps....................................................................................62Static <strong>Grounding</strong> Clamps..................................................................................................63 – 64Static <strong>Grounding</strong> Components..........................................................................................65 – 66Ground TestingGround Test Equipment.................................................................................................... 67 – 68<strong>Grounding</strong> <strong>Products</strong> <strong>and</strong> <strong>Systems</strong>Technical Section.............................................................................................................. 69 – 80Ph: 1-800-677-9089www.erico.com1

<strong>Grounding</strong> PrinciplesIntroduction<strong>Grounding</strong> <strong>and</strong> bonding are an integral part of any modernelectrical protection system design.An effective, low-impedance ground system is a keyelement of this system. It is c<strong>ru</strong>cial in ensuring personnelsafety, as well as providing reliable protection for vitalequipment <strong>and</strong> to minimize inter<strong>ru</strong>ptions of service <strong>and</strong>costly downtime.With almost a century of experience in the design <strong>and</strong>manufacture of bonding <strong>and</strong> grounding products, ERICO ® ,a single source provider, offers what we believe is the bestrange of long lasting <strong>and</strong> cost-effective grounding productsavailable.The following pages of this catalog detail these products<strong>and</strong> their respective applications.DefinitionsGround: A conducting connection, whetherintentional or accidental, between an electrical circuit orequipment <strong>and</strong> the earth, or to some conducting bodythat serves in place of the earth.The need to ground!There are important reasons why a grounding system should be installed.1 The most important reason is to protect people!2 Protection of st<strong>ru</strong>ctures <strong>and</strong> equipment from unintentional contact with liveconductors.3 Ensure maximum safety from electrical system faults <strong>and</strong> lightning.Figure 1.Earth: The conductive mass of the earth, whoseelectric potential at any point is conventionally taken asequal to zero. (In some countries the term "ground" isused instead of "earth.")Figure 2.Bonding: The permanent joining of metallic parts toform an electrically conductive path that will ensureelectrical continuity <strong>and</strong> the capacity to conduct safelyany current likely to be imposed.It is a fundamental fact that electricity ALWAYS flows to the point of lowest potential.The task is to ensure that electricity, including faults, lightning <strong>and</strong> electronic noise,flows to this point with maximum safety to people, while maintaining the reliabilityof equipment. Therefore we must ensure the safe, controlled flow of electricity withminimum voltage drop to earth in all cases.<strong>Grounding</strong> Codes <strong>and</strong> St<strong>and</strong>ards<strong>Grounding</strong> needs vary according to function. The grounding requirements of a powersystem will vary from those of electrical equipment, lightning protection or for theproper function of electronic equipment.Proper installation of appropriate grounding systems requires knowledge of the needs<strong>and</strong> layout of the facility. Soil characteristics, grounding conductor materials groundingconnections <strong>and</strong> terminations, are significant factors determining the design of agrounding system. Applicable st<strong>and</strong>ards <strong>and</strong> codes must be applied.While many codes <strong>and</strong> st<strong>and</strong>ards contain minimum grounding <strong>and</strong> bondingrequirements, the design <strong>and</strong> installation of electrical grounding systems is one ofthe most important aspects of any electrical distribution system. However, codes <strong>and</strong>st<strong>and</strong>ards are often misunderstood <strong>and</strong> grounding systems subsequently installedimproperly.Figure 3.2 Ph: 1-800-677-9089www.erico.com

IntroductionThe facility electrical ground system must:• Efficiently dissipate lightning surge energy that may arrive via downconductorsof the lightning protection system;• Efficiently dissipate electrical surges <strong>and</strong> faults to minimize the chancesof injury from either “step potentials” or “touch potentials”;• Provide a stable reference for electrical <strong>and</strong> RF circuits at the facility tominimize noise during normal operation;• Be properly bonded to provide an equipotential plane under faultconditions;• Be electrically <strong>and</strong> mechanically robust to assure performance over the“life” of the facility (nominally 40 years from const<strong>ru</strong>ction date).Applicable Codes <strong>and</strong> St<strong>and</strong>ardsEuropean American AustralianIEC 10234-1 IEEE Std 80 AS3000--AS2307IEC 61364-5 NFPA 70 (NEC) AS 1768-ENV 61024-1UL 96ABS 1400CSA C22.1-94BS 7430 NFPA 780BS6651 IEEE 837IEEE 1100IEEE 142IEEE 81The primary functions of grounding can be defined as follows:1. Personnel Safety2. Equipment <strong>and</strong> Building Protection 3. <strong>Elec</strong>trical Noise ReductionAvoid hazardous Step <strong>and</strong>Touch Potentials (shock) or evendeath by low impedance grounding <strong>and</strong>bonding between metallic equipment,chassis, piping, <strong>and</strong> other conductiveobjects so that currents, due to faults orlightning, do not result in hazardousvoltage rise.A direct, low impedancepath to ground <strong>and</strong> bondingbetween electrical services, protectivedevices, equipment <strong>and</strong> other conductiveobjects so that faults or lightning currents arequickly dissipated <strong>and</strong> do not result inhazardous voltages within the building.Proper grounding also facilitates theoperation of over-currentprotective devices.Propergrounding aids in electricalnoise reduction <strong>and</strong> ensures:1. Minimal impedance between the signalground points throughout the building.2. Minimal voltage potential betweeninterconnected equipment.3. Minimal effect of electrical <strong>and</strong>magnetic field coupling.STEP POTENTIALStep Potential is the voltage difference between aperson’s feet caused by the dissipation gradient of afault entering the earth.STEP POTENTIALTOUCH POTENTIALTOUCH POTENTIALTouch Potential is similar to "Step Potential" exceptthat the fault current passes through the person’s arm<strong>and</strong> torso on the way to the ground.Another function of the grounding system is to providea reference for circuit conductors to stabilize theirvoltage to ground during normal operation. The earthitself is not essential to provide a reference function;another suitable inductive body may be used instead.The function of a grounding electrode system <strong>and</strong> aground terminal is to provide a system of conductors,which ensures electrical contact with the earth.Figure 4. Typically, one meter from a fault entry point, voltage will bereduced by 50%. (e.g. A 1,000 Amp fault in a 5 Ohm grounding systemwill enter the earth at 5,000 volts. At a distance of less than one meteraway, a fatal potential of 2,500 volts will exist).Ph: 1-800-677-9089www.erico.com3

<strong>Grounding</strong> PrinciplesGround ResistanceWhen current flows from a ground electrode intothe surrounding soil, it is often described asflowing through a series of concentric shells ofincreasing diameter.Each successive shell has a greater area forcurrent flow <strong>and</strong> consequently, lower resistance.At some point distant from the earth conductorthe current dissipation becomes so large <strong>and</strong>current density so small, that the resistance isnegligible.In theory, the ground resistance may be derivedfrom the general formula:R = P L Resistance = Resistivity x LengthAAreaThis formula illustrates why the shells ofconcentric earth decrease in resistance the fartherthey are from the ground rod:R = Resistivity of Soil xThickness of ShellAreaIn the case of ground resistance, uniform earth(or soil) resistivity throughout the volume isassumed, although this is seldom the case innature. The equations for systems of electrodesare very complex <strong>and</strong> often expressed only asFigure 5. Sphere of Influence - electrical current flows from the ground rod into surrounding soil <strong>and</strong> progressively dissipates inwaves of increasing diameter.approximations. The most commonly usedformula for single ground electrode systems,developed by Professor H. R. Dwight of theMassachusetts Institute of Technology, is thefollowing:R = __ ρ {(ln 4L) - 1}2πL rR = resistance in ohms of the ground rodto the earth (or soil)L = grounding electrode lengthr = grounding electrode radiusρ = average resistivity in ohms-cm.Conditions Influencing Soil ResistivityThe resistance of the earth itself (soil resistivity)can significantly impact the overall impedanceof the grounding system. Several factors, suchas soil composition, moisture content, mineralcontent, contaminants, etc., determine theoverall resistivity of the earth (refer Table 1).SOIL TYPEResistivity ohm-cmAverage Min. Max.Fills – ashes, cinders, brine wastes 2,370 590 7,000Clay, shale, gumbo, loam 4,060 340 16,300Clay, shale, gumbo, loam with varyingproportions of s<strong>and</strong> <strong>and</strong> gravel15,800 1,020 135,000Gravel, s<strong>and</strong>, stones, with little clay or loam 94,000 59,000 458,000Soil CompositionSoil types vary in content <strong>and</strong> consistency. Blackdirt or soils with high organic content, areusually good conductors because they retainhigher moisture levels <strong>and</strong> have a higherelectrolyte level. S<strong>and</strong>y soils, which drain faster,have a much lower moisture content <strong>and</strong>electrolyte level. Therefore they have higherimpedance. Solid rock <strong>and</strong> volcanic ash containvirtually no moisture or electrolytes <strong>and</strong> hencehigh levels of resistivity.Soils have generally been deposited in layers orstrata. These strata can have different values ofsoil resistivity. By measuring the resistivity of thesoil at varying depths, it is possible to develop aprofile, which can be used to identify the mostappropriate ground electrode design.U.S. Bureau of St<strong>and</strong>ards Technical Report 108Moisture ContentMoisture content has the largest influenceon soil resistivity because it helps chemicalsin the soil that surround ground conductorscarry the electric current. In general, thehigher the moisture content the lower thesoil’s resistivity.Moisture retention can be influenced bylocal climate conditions <strong>and</strong> electrolyticmechanisms such as mineral content, soilionization, consistent grain size, evendistribution <strong>and</strong> packing density.<strong>Systems</strong> designed for areas which typicallyhave very dry soil <strong>and</strong> arid climates mayneed to use enhancement materials orother means to achieve lower soil resistivity.TemperatureTable 1. Soil Resistivity.High temperatures <strong>and</strong> drought, ortemperatures below freezing <strong>and</strong> deepfrosts, can cause high resistivity in soils thathave much lower values in the precedingmonths. When moisture turns to ice,resistivity increases sharply. Areas withregular rainfall <strong>and</strong> no ground frost aremore likely to have low soil resistivity, incomparison to those regions that are aridor have permafrost.In areas subject to freezing winters drivingthe ground rod below the frost line isnecessary to maintain a low resistivity.4 Ph: 1-800-677-9089www.erico.com

<strong>Grounding</strong> PrinciplesSoil Resistivity TestingTo properly design a grounding system, it is essential to testsoil resistivity. Several methods can he used to measure earthresistivity: the four-point method, the variation in-depthmethod (three-point method) <strong>and</strong> the two-point method.The most accurate method <strong>and</strong> the one that ERICO ®recommends is the four-point method.The Four-Point Method1. Four test stakes are positioned in a straight line an equaldistance apart <strong>and</strong> are hammered into the ground to besurveyed to a depth of not more than 1/20 the distancebetween the adjacent stakes.2. An earth resistance tester is connected to these fourstakes as shown in Figure 6.A Line Traverse Soil Resistivity SurveySoil resistivity levels can vary significantly both with depth, <strong>and</strong>from one point to another on a site, <strong>and</strong> as such, a single soilresistivity measurement is usually not sufficient. To obtain abetter picture of soil resistivity variations, it is advisable toconduct a detailed survey.The Line Traverse technique is a commonly used method forperforming soil resistivity surveys. In this method imaginaryparallel lines are drawn across the area to be surveyed. Takinga number of measurements along each ‘line’ using differentstake separations provide an indication of how the soilresistivity varies with depth, while measurements taken alongdifferent lines provide an indication of how the resistivitychanges across the site.3. The DC test option on the tester is then selected <strong>and</strong>performed, <strong>and</strong> the resistance figure "R" recorded.4. The soil resistivity level "r" (in ohms/cm) is then calculatedusing the formula: r=2paR where:R = the resistance figure, in ohmsa = the separation of the test stakes, in meters.p =4πAR1 + 2A - 2A√ (A 2 + 4B 2 ) √ (A 2 + 4B 2 )Where:A = distance between the electrodes in centimetersB = electrode depth in centimetersIf A > 20 B, the formula becomes:p = 2π AR (with A in cm)p = 191.5 AR (with A in feet)p = Soil resistivity (ohm-cm)This value is average resistivity of the ground at a depthequivalent to the distance “A” between two electrodes.Figure 7. Performing a Line Traverse survey. A commonly used method for soil resistivitysurvey work.≤Figure 6.Measuring Soil Resistivity using the “Four-Point” Method.Ph: 1-800-677-9089www.erico.com5

<strong>Grounding</strong> PrinciplesTypes of <strong>Grounding</strong> <strong>Systems</strong>The basic philosophy of any ground electrode installation should be anattempt to maximize the surface area contact with the surroundingsoil. Not only does this help to lower the resistance of the groundingsystem, but it also greatly improves the surge impedance of thegrounding system due to the large capacitive coupling which isachieved.The actual layout of the grounding system, <strong>and</strong> the number, length<strong>and</strong> depth of ground rods will vary with the usages, type of soil <strong>and</strong>space availability. Some common designs include:Single Ground RodOne single ground electrode may be sufficient for anelectrical installation in a built up area where the localsupply authority utilizes a multiple or common multipleearth neutral (MEN or CMEN) system. However, it maynot provide an adequately low impedance for lightningcurrent injection.Single Strip End ConnectedThis is a common option for installations where, becauseof rock, driving an electrode is impractical. It is notrecommended for lightning protection systems as thereis only one path. Very high ground voltages will beexperienced at the injection point.Single Strip Center ConnectedSince the connection to the strip is at the center, anyfault/injection current travels in two directions. This layouthas lower impedance, but it is generally not adequate forlightning protection systems.Radial <strong>Grounding</strong>, Single RadialsA design that is well suited to lightning protection inareas of medium resistivity. The radials can <strong>ru</strong>n to 100feet in length.Radial <strong>Grounding</strong>, Multiple RadialsCrows foot design. Well suited to lightning as it allowsenergy to diverge as each conductor takes a share of thecurrent, offering a lower impedance. Voltage gradientsleading away from the injection point will be lower, reducingdanger from step potentials.Equipotential Mesh <strong>Elec</strong>trodesMinimize the risk of step <strong>and</strong> touch potential hazard bypositioning a mat <strong>and</strong> bonding it to the st<strong>ru</strong>cture oroperating h<strong>and</strong>le at locations where personnel may berequired to operate switchgear or st<strong>and</strong> in the course oftheir duties. Low ground impedance.Grid <strong>Elec</strong>trodes<strong>Grounding</strong> for installations where there is concentrationof electrical equipment, such as electrical substations,are often designed to meet a specific value of resistance(typically 1 ohm). Under fault conditions, a grid c<strong>and</strong>issipate currents over a large area.Grid with Ground RodsIt may be advantageous to add ground rods to the grid.In doing so, it may be possible to access a low resistivitysoil layer. Care must be taken to ensure each ground rodis spaced at least twice the installation depth.Ring <strong>Elec</strong>trodeInstallations, including communications huts, pad mounttransformers <strong>and</strong> fences surrounding high voltageinstallations, are generally surrounded by a ground ring.This practice also reduces the hazard of step <strong>and</strong> touchpotential.Figure 8.6 Ph: 1-800-677-9089www.erico.com

<strong>Grounding</strong> PrinciplesGround / Earthing System Design<strong>Grounding</strong> systems are important. It is not expensive to build anappropriate ground system during initial const<strong>ru</strong>ction of a facility, butit can be very expensive to add to it, enhance it, or replace it after thefacility is complete. Care should be taken to design a system that isappropriate both for clearing ground faults <strong>and</strong> dissipating lightningenergy. The system must have a long performance life, meet applicablecodes / st<strong>and</strong>ards for safety, <strong>and</strong> have sufficient bonding points tomake it easy to add new equipment / facility grounding to it easily.Design considerations include:• Purpose of facility• Design life of facility• Soil resistivity at 3 depths• Corrosive nature of soil• Shape <strong>and</strong> available area of facility site• Existing st<strong>ru</strong>ctures <strong>and</strong> their grounding systems• Seasonal variations in moisture <strong>and</strong> temperature for facility site• Public access & personnel use• Adjacent facilities <strong>and</strong> electrical systems• Future uses, additions, equipment for facilityFor proper operation of overcurrent devices, it is important to have alow DC ohmic resistance to remote earth. In many instances, this isbest achieved by installing a deep ground electrode on site. It shouldbe driven deep enough to reach the permanent water table.For dissipation of direct or indirect lightning currents, it is better tohave many horizontal ground conductors in the soil, preferably in aradial array. This provides a low impedance path of dissipation to thehigh frequency component of the lightning energy.For safety of personnel, particularly where people congregate orwhere equipment operators will be located, it is important to have agrid system or other equipotential plane to reduce "step potential"<strong>and</strong> have equipment <strong>and</strong> metal st<strong>ru</strong>ctures bonded to the groundsystem to reduce "touch potential".A proper facility grounding system incorporates these necessities inthe most cost-effective manner that will last for the design life of thefacility.ERICO ® is a manufacturer <strong>and</strong> marketer of grounding, bonding,lightning protection <strong>and</strong> surge protection products <strong>and</strong> systems.ERICO has many knowledgeable <strong>and</strong> experienced engineers on staffwith the training <strong>and</strong> the tools (including some of the latest designsoftware) to design appropriate grounding systems. These engineerscan assist facility owners, engineers <strong>and</strong> contractors in designing themost appropriate system for the facility in question.<strong>Grounding</strong> Chain• <strong>Grounding</strong> <strong>Elec</strong>trode Conductor• <strong>Grounding</strong> Connections• <strong>Grounding</strong> <strong>Elec</strong>trode• <strong>Elec</strong>trode to Soil Resistance• SoilThe <strong>Grounding</strong> ChainThe performance of the grounding system is determined by the qualityof the following five components all of which are of equal importance.1. The <strong>Grounding</strong> <strong>Elec</strong>trode Conductor. Typically made from copperor copper-clad steel, the grounding electrode conductor must belarge enough to withst<strong>and</strong> the maximum available fault currentover the maximum clearing time.2. The <strong>Grounding</strong> Connections. Often overlooked, the groundingconnections are used to tie the elements of the electrode systemtogether. Exothermically welded connections provide a molecularbond that will never loosen or corrode. Mechanical connectors,such as crimp, bolted, <strong>and</strong> wedge type, rely on physical point-topointsurface contact to maintain the integrity of the electricalconnection. IEEE St<strong>and</strong>ard 837 provides detailed information onthe application <strong>and</strong> testing of permanent grounding connections.ERICO can provide an independent, third-party test reportevaluating the performance of these connectors in accordancewith the testing procedures set forth in IEEE 837 St<strong>and</strong>ard forQualifying Permanent Substation <strong>Grounding</strong> Connections.3. The <strong>Grounding</strong> <strong>Elec</strong>trode. The grounding electrode provides thephysical connection to the earth <strong>and</strong> is the inst<strong>ru</strong>ment used todissipate current into it. There are two main types of electrodes."Natural" electrodes are intrinsic to the facility <strong>and</strong> include metalunderground water pipe, the metal frame of the building (ifeffectively grounded), <strong>and</strong> reinforcing bar in concrete foundations."Made" electrodes are installed specifically to improve theperformance of the ground system <strong>and</strong> include wire meshes,metallic plates, buried copper conductor <strong>and</strong> rods or pipes driveninto the ground. The ground rod is the most widely usedelectrode.4. <strong>Elec</strong>trode to Soil Resistance. Amount of rod surface <strong>and</strong> rodreplacement are the controlling factors. Doubling diameter reducesresistance by only 10% <strong>and</strong> is not cost effective. Doubling rodlength, however, theoretically reduces resistance by 40%. Themost common solution is proper placement of multiple rods thatare driven to the required depths.5. The Soil. The soil resistivity, measured in ohm-centimeters or ohmmeters,plays a significant role in determining the overallperformance of the grounding system <strong>and</strong> must be known beforea proper grounding system can be engineered. Measuring soilresistivity allows the design engineer to locate an area with themost conductive soil <strong>and</strong> to determine the depth of theconductive soil so that electrodes can be placed accordingly.The grounding system will carry little or no current for long periods oftime until a fault occurs or a lightning strike or other transient requiresdissipation. At that point, the grounding system components will beexpected to perform like new while conducting large amounts ofcurrent. Most of the grounding system is concealed below grade,making inspection of the grounding components difficult orimpossible. The underground environment is a harsh one. The initialselection of the components used in the grounding system is of criticalimportance to its long-term effectiveness.Ph: 1-800-677-9089www.erico.com7

Ground System ComponentsGround ConductorsConductorsThere are two basic criteria for groundingconductor selection:1. The physical characteristics of the conductormust be of a robust nature, sufficient forthe environment.2. The cross sectional area of the conductormust be of sufficient size, so that it shallsuccessfully conduct the maximum fault(surge) current for a period, which allowsthe operation of protection equipment (orthe dissipation of this energy).Physical CharacteristicsThe most common ground conductor is a soft drawn, str<strong>and</strong>ed copper conductor.Flat copper strip / tape is also popular because it offers a large surface area. When siteconditions are corrosive towards copper (eg. sulphurous soil), a tinned copper conductoris often the first choice.In some circumstances, the maximum fault current for the installation is small. While aconductor of correspondingly small size could be used, a minimum cross section, oftenset by the governing authority or applicable St<strong>and</strong>ards body (to minimize potentialdamage likely to occur from any future excavation on the site), is applied.Maximum Fault CurrentWhere higher fault conditions exist, the conductor size is determined by considering thecircumstances required to avoid fusing (melting) the conductor. The accepted industrySt<strong>and</strong>ard is IEEE 80, Guide for Safety in Substation <strong>Grounding</strong>.ERITECH ® Flat Strip Ground Conductor• Pure electrolytic copper• Low impedance• Lower impedance than equivalent sized round conductorPart Description DimensionsNo. H (in.) W (in.) L (ft.)A811A26F20 Copper Strip, roll .0159 2 20A811A26F50 Copper Strip, roll .0159 2 50A811A26F500 Copper Strip, roll .0159 2 500A811C20F100 Copper Strip, roll .032 3 100A811K26F100 Copper Strip, roll .0159 6 100A811K20F100 Copper Strip, roll .032 6 100Also available tin platedERITECH Ground Conductor• Pure electrolytic copperPart No. Part Number Wire Size Type Description(100 Ft. Reel) (250 Ft. Reel)A809A07F100 A809A07F250 #2 Solid BareA809A06F100 A809A06F250 #4 Solid BareA809A04F100 A809A04F250 #6 Solid BareA809A07TF100 A809A07TF250 #2 Solid Bare TinnedA809A02F100 A809A02F250 #2 7 Str<strong>and</strong> BareA809A01F100 A809A01F250 #4 7 Str<strong>and</strong> BareA809A024F100 A809A024F250 #6 7 Str<strong>and</strong> BareA819A02F100 A819A02F250 #2 7 Str<strong>and</strong> THW insulationA819A03F100 A819A03F250 #4 7 Str<strong>and</strong> THW insulationA819A04F100 A819A04F250 #6 7 Str<strong>and</strong> THW insulation8 Ph: 1-800-677-9089www.erico.com

Ground System Components<strong>Grounding</strong> Clamps <strong>and</strong> ConnectorsERITECH ® Ground Clamps• For use with copperbonded ground rods.• Suitable for direct burial.Bronze St<strong>and</strong>ard DutyPart Conductor RodNo. Range SizeERITECH Split Bolts - Silicon BronzePart No.Wire RangeCP38 10 Sol.- 4 Str. 3/8CP12 8 Sol.- 2 Str. 1/2CP58 8 Sol.- 2 Str. 5/8CP34 8 Sol.- 2 Str. 3/4Bronze Heavy DutyPart Conductor RodNo. Range SizeESB8ESB6ESB4ESB3ESB2ESB1/0ESB2/0ESB4/0ESB250ESB350ESB50010 sol - 8 str.8 sol - 6 sol.8 sol - 4 sol.6 sol - 3 str.6 sol - 2 str.4 sol - 1/0 str.2 sol - 2/0 str.2 sol - 4/0 str.#1 str - 250 KCM250 KCM - 350 KCM400 KCM - 500 KCMHDC12* 10 Sol.- 2 Str. 1/2HDC58R* 8 Sol.- 1/0 Str. 5/8HDC58* 8 Sol.- 1/0 Str. 5/8HDC34* 8 Sol.- 1/0 Str. 3/4HDC34SP 8 Sol.- 3/0 Str. 3/4HDC1 1 Sol.- 4/0 Str. 1*UL ListedERITECH Split Bolts -Tin Plated Silicon BronzePart No.Wire RangeGalvanized Steel ClampsPartRodNo.SizeS58 1/2” rod #8 - 3/0 wire5/8” rod #14 -1/0 wireS68 5/8” rod #14 -16 wire3/4” rod - 4/0 wireESBP8ESBP6ESBP4ESBP2ESBP1/0ESBP2/0ESBP4/0ESBP350ESBP50012 sol - 8 str.10 sol - 6 sol.10 sol - 4 sol.6 sol - 1 sol.2 sol - 1/0 str.2 sol - 2/0 str.2 sol - 4/0 str.250 KCM - 350 KCM400 KCM - 500 KCMPh: 1-800-677-9089www.erico.com9

Ground System Components<strong>Grounding</strong> Clamps <strong>and</strong> ConnectorsERITECH ® Bronze Water Pipe Clamps• High-strength silicone bronze clamps can be utilized for connectingcopper conductors to metallic water pipe or ground rods.PartNo.WaterPipe SizeConductor RangeMin. Max.CWP1J** 1/2-1 10 Sol. 2 Str.CWP1JJ 1/2-1 10 Sol. 4 Str.CWP2J** 1-1/4-2 10 Sol. 2 Str.CWP4J** 2-1/2-4 10 Sol. 4 Str.CWP6J 4-1/4-6 10 Sol. 4 Str.CWP1JU* 1/2-1 10 Sol. 2 Str.CWP2JU* 1-1/4-2 10 Sol. 2 Str.*With copper screw for use in direct burial applications.**UL ListedERITECH Bronze Water Pipe Clamps• For use in grounding rigid conduit systems to metallic water pipe.PartNo.WaterPipe SizeConduitSizeConductor RangeMin. Max.CWP1JH12 1/2 - 1 1/2 10 Sol. 6 Sol.CWP2JH12 1-1/4 - 2 1/2 10 Sol. 6 Sol.CWP4JH12 2-1/2 - 4 1/2 10 Sol. 6 Sol.CWP1JH34 1/2-1 3/4 10 Sol. 2/0 Str.CWP2JH34 1-1/4 - 2 3/4 10 Sol. 2/0 Str.CWP4JH34 2-1/2 - 4 3/4 10 Sol. 2/0 Str.CWP1JH44 1/2 - 1 1 10 Sol. 3/0 Str.CWP2JH44 1-1/4 - 2 1 10 Sol. 3/0 Str.CWP4JH44 2-1/2 - 4 1 10 Sol. 3/0 Str.ERITECH Bronze Water Pipe Clamps• For use in grounding armored cable to metallic pipePart Water Conductor RangeNo. Pipe Size Min. Max.CWP1JA 1/2-1 10 Sol 6 Sol.CWP2JA 1-1/4 - 2 10 Sol 6 Sol.CWP4JA 2-1/2 - 4 10 Sol 6 Sol.ERITECH Bronze Water Pipe ClampsWith Copper Strap - Heavy-Duty HubPartNo.WaterPipe SizeConduitSizeConductor RangeMin. Max.ERITECH Zinc Water Pipe ClampPart Water Conductor RangeNo. Pipe Size Min. Max.ZWP1J 1/2-1 10 Sol 6 Sol.CWP12SH 1/2 - 1 1/2 10 Sol. 6 Sol.CWP34SH 1/2 - 1 3/4 10 Sol. 2/0 Str.CWP44SH 1/2 - 1 1 10 Sol. 3/0 Str.With Copper Strap - St<strong>and</strong>ard-Duty HubPartNo.WaterPipe SizeConduitSizeConductor RangeMin. Max.ERITECH Dual Rated AluminumWater Pipe Clamps• For use with copper or aluminum conductors.CWP12SH-E 1/2 - 1 1/2 10 Sol. 6 Sol.CWP34SH-E 1/2 - 1 3/4 10 Sol. 2/0 Str.CWP44SH-E 1/2 - 1 1 10 Sol. 3/0 Str.PartNo.Conductor RangeMin. Max.PipeRangeEGC1 14 Sol 10 Sol. 1/2 - 110 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsERITECH ® Pipe Clamp• 2” wide tinned copper strap draws tightly around pipe(all hardware is included)• Conductor stub is easily spliced to ground conductor• Adjusts to fit pipes from 3” NPS to 12” NPS• CADWELD ® connection of conductor to strap eliminatesa mechanical interfaceOrdering Information:Part No. B852A12C_ _ _ConductorCodeExample: 4/0 Bare, 12 Inches Long;Part No. B852A12C2Q12<strong>Grounding</strong> Clamps <strong>and</strong> ConnectorsConductor Length,inches “L”Conductor3” to 12”PipeAllHardwareIncluded“L”CADWELD ®ConnectionFigure 9. ERITECH Pipe clamp fitted to metalpipe with conductor stub CADWELDexothermically welded to copper conductor.CONDUCTOR CONDUCTORSIZECODE1/0 2C2/0 2G4/0 2Q250 2V500 3Q750 4LERITECH Transformer Tank Ground Connectors• Cast of high conductivity bronze <strong>and</strong> 1/2”-13 stud. Fits all st<strong>and</strong>ard EEI-NEMA distribution transformers.• Eyebolt rotates to accommodate cable in either vertical or horizontal direction <strong>and</strong> no special tools are required - use regular lineman’s wrench.• RUS Listed.ERITECH AluminumMechanical ConnectorsPart No.4AT2AT10AT320AT300AT350AT10AT3220AT2300AT2350AT2Wire Range14 sol - 4 str.14 sol - 2 str.14 sol - 1/0 sol.14 sol - 2/0 str.6 sol - 300 KCM6 sol - 350 KCM14 sol - 1/0 str.14 sol - 2/0 str.6 sol - 300 KCM6 sol - 350 KCMERITECH Copper Mechanical ConnectorsPart No.ECM25ECM35ECM70ECM125ECM175PartNo.Wire Range14 str - 10 str.14 str - 6 str.8 str - 2 str.8 str - 1/0 str.4 str - 3/0 str.Conductor RangeMax. Min.StudThread SizeTGC2/0 2/0 Str. 8 Sol. 1/2” - 13Ph: 1-800-677-9089www.erico.com11

Ground System ComponentsGround <strong>Elec</strong>trodesGround <strong>Elec</strong>trodesThe ground electrode is a critical component of the grounding system.Many different types of electrodes are available, some "natural" <strong>and</strong>some "made". The natural types include metal underground water pipe,the metal frame of a building (if effectively grounded), a copper wire orreinforcing bar in a concrete foundation or underground st<strong>ru</strong>ctures orsystems. Consideration should be given to bonding of natural earths toensure electrical continuity with a facilities’ other "earths"."Made" electrodes are specifically installed to improve the systemgrounding or earthing. These earth electrodes must ideally penetrate intothe moisture level below the ground level to reduce resistance. Theymust also consist of metal conductors (or a combination of metalconductor types), which do not corrode excessively for the period of timethey are expected to serve. Made electrodes include rods or pipes driveninto the earth, metallic plates buried in the earth or a copper wire ringencircling the st<strong>ru</strong>cture. Underground gas piping or aluminium electrodesare NOT permitted for use as ground electrodes.Ground RodsWhich ground rod should be used?Ground rods are often selected on the basis of their resistance to corrosion. Theother major factor is cost. All too often, the cost of a product is seen as theinitial, up front price, but the real cost is determined by the serviceable life of theground rod.Galvanized steel rods are one of the cheapest electrodes available. However,they are not the most cost effective since they have a relatively short service life.Solid copper <strong>and</strong> stainless steel rods have a long service life. However, they areconsiderably more expensive than galvanized steel rods. In addition to this, solidcopper rods are not suited to deep driving or even driving shortlengths into hard ground, without bending.As a compromise, steel cored ground rods, swaged in acopper or stainless steel sheath were developed. Theseground rods are much less expensive than their solidcounterparts. They are capable of being deep driven.However, the sheath of this rod type has been knownto slip or tear, particularly the copper version. Once thissheath has been damaged, the integrity of the entireelectrode is at risk.Ask for the ERICO ® White Paper on Ground Rods –Copperbonded vs. Galvanized.Figure 10.Copperbonded ground rodversus Galvanized ground rod.COPPERBONDEDGROUND RODGALVANIZEDGROUND ROD12 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround <strong>Elec</strong>trodesThe copperbonded ground rod has anelectrolytic coating of copper depositedover a layer of nickel. This processensures a long lasting, molecular bondbetween the copper layer <strong>and</strong> the steelcore. ERICO ® recommendscopperbonded ground rods becausethe copper coating will not slip or tearwhen driven nor will it crack if the rodis bent . The tough, carbon steel corehas good characteristics for deepdriving. Copperbonded ground rodshave a high resistance to corrosion <strong>and</strong>provide a low resistance path toground.The Stainless Steel OptionIt is important to note that certain soils <strong>and</strong> l<strong>and</strong> fillareas may not be compatible with copper. In thesesituations, stainless steel is a better proposition.Stainless steel may also be an alternative, wherest<strong>ru</strong>ctures or components, such as steel towers,poles or lead sheathed cables are in close proximityto an array of ground electrodes. In thesecircumstances, consideration must be given to theconsequence of galvanic corrosion. The high costof stainless steel rods prohibits their widespreaduse.Figure 11.Photo shows two ground rods subjected to the same pressureload test. The ERITECH ® copperbonded ground rod, shown onthe left, will bend without tears, cracks or folds, to the outersheath. The inferior copperclad rod shown on right, hasdeveloped cracks <strong>and</strong> creases to the outer sheath, which willsignificantly reduce its servicable life <strong>and</strong> put the integrity of theentire electrode at risk.GROUND ROD LIFE EXPECTANCYGROUND ROD ANNUAL COSTFigure 12. Figure 13.Ph: 1-800-677-9089www.erico.com13

Ground System ComponentsGround <strong>Elec</strong>trodesGround Rod Accessories<strong>and</strong> ApplicationERICO ® is the world’s largest manufacturer of ULlisted ground rods <strong>and</strong> accessories <strong>and</strong> offers acomplete range of rods, driving heads, rod couplingmethods <strong>and</strong> connections for reliable grounding innearly any application.Driving SleevesThe driving head fits over the ground rod to protectthe rod end from "mushrooming" as the groundrod is driven into earth.CouplingCouplings enable ground rods to be driven deepquickly <strong>and</strong> easily without the risk of rod separation.They are generally tapered so when the rod is driveninto the coupling, the two parts compress to form aconductive connection.Ground RodGround Rod Diameter & LengthGround rod diameter must also be considered.Although larger diameter rods are more rigid <strong>and</strong>less prone to whip or bending, they may have agreater drag than smaller diameter rods when beingdriven. It must also be noted that increasing theground rod diameter has little impact on groundingsystem resistance. St<strong>and</strong>ards nominate a minimumdiameter or periphery <strong>and</strong> thickness if not cylindrical.In general, lightning protection st<strong>and</strong>ardsrecommend copper bonded electrodes of specifieddiameter. St<strong>and</strong>ard UL 467 requires a minimum rodlength of 8’ with a minimum diameter of 0.50” <strong>and</strong>10 mils of copper.Other St<strong>and</strong>ards may nominate a specific resistancefor the installation. If space is limited, the contractormay be required to install electrodes to a depth thatachieves the required value.14 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround Rod InstallationGround <strong>Elec</strong>trodesThere are two main methods of installing ground rods.• It is common for the ground rod to be driven into the earth using ah<strong>and</strong> held ground rod driver or mechanically operated driver.• Where driving the rod is not possible due to ground conditions,a hole may be drilled to take the ground rod.ERITECH ® Ground Rod DriverThe ERITECH Ground Rod Driver from ERICO ® is a safe, simple <strong>and</strong>effective way to install longer ground rods. This one tool enables drivingof rods to ground level, without heavy sledge-hammers or ladders. Thissaves time <strong>and</strong> money <strong>and</strong> dramatically reduces risk of employee injury.Figure 14. The ERITECH Ground Rod Driver from ERICO,provides a safe, simple<strong>and</strong> affordable way to install ground rods.Features• Suitable for use on all types of cylindrical ground rods: copperbonded,galvanized, stainless steel.• 5/8" <strong>and</strong> 3/4"inserts are interchangeable with st<strong>and</strong>ard driver bodyto enable easy driving of st<strong>and</strong>ard rods.• Integral insert prevents driver from slipping off the rod nearground level.• The driver will not deform the end of the rod – making theconnection of the ground conductor quick <strong>and</strong> easy.• Convenient retaining collar holds the insert in tool when not in use.• Self-contained <strong>and</strong> easy to store.• Heavy-duty steel const<strong>ru</strong>ction provides robustness <strong>and</strong> excellentdriving force.• Soft <strong>ru</strong>bber ergonomic grip provides user comfort.Ph: 1-800-677-9089www.erico.com15

Ground System ComponentsInstallation of Ground RodsUsing the ERITECH ® Ground Rod DriverGround <strong>Elec</strong>trodesStep OneRemove the insert <strong>and</strong> slide driver bodyover ground rod.Figure 15. Figure 16. Figure 17.Step TwoPosition rod in vertical position <strong>and</strong> driverod by sliding driver body in an up-<strong>and</strong>downmotion over the ground rod.Step ThreeWhen the end of the rod reaches approximately900mm (30") above ground, slidethe body off the rod <strong>and</strong> place insert onground rod. Slide the driver body over theinsert <strong>and</strong> drive rod to installed depth.ERITECH Ground Rod Drivers• Heavy-duty steel const<strong>ru</strong>ction provides maximum driving forces,while the soft <strong>ru</strong>bber ergonomic grip provides user comfort.• 5/8” <strong>and</strong> 3/4” inserts are interchangeable with st<strong>and</strong>ard driverbody.• Use on all types of ground rods without deforming ends.• No heavy tools or ladders required.Part No.DescriptionEGRD58 5’ Driver body with insert for up to 5/8” ground rodsEGRD58I* Replacement insert for 5/8” ground rodsEGRD34 5’ Driver body with insert for up to 3/4” ground rodsEGRD34I* Replacement insert for 3/4” ground rods* Both 5/8” <strong>and</strong> 3/4” inserts fit st<strong>and</strong>ard body of EGRD58 or EGRD34.The Mechanical HammerFor adverse soil conditions where it is not suitable to h<strong>and</strong> driverods or where a greater depth must be achieved, it may benecessary to use power operated aids. For normal applications werecommend the use of medium tools in the 15 to 25 lb. range,with a stroke of approximately 2" to 4" delivering 2200 blows perminute.Drilling OptionsWhere driving is difficult or progress is inhibited, it is necessary touse purpose-designed drilling equipment, such as electric,pneumatic <strong>and</strong> petrol driven machinery capable of penetratingrock. Once the hole is drilled, you can use one of two methods toinstall the ground rod:■ Backfill the hole with Ground Enhancement Material, <strong>and</strong>add water to the hole as rod is driven to the required depth.■ Insert the rod into the drilled hole, then add GroundEnhancement Material which has been mixed with water toform a slurry. For more details, see page 30 (GEM installation).16 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround <strong>Elec</strong>trodesERITECH ® Copperbonded Pointed Ground Rods• Copper is molecularly bonded to nickel-sealed high-strength steel cores.• ERITECH ground rods provide the company name, length, diameter,part number, roll-stamped within 12” of chamfered end <strong>and</strong> theUL logo <strong>and</strong> control number where applicable on each rod for easyinspection after installation.• See specifications on page 69.Part Plating Dia. LgthNo. Thickness (in.) (ft.)(ml.)613852 5 3/8 5613862 5 3/8 6613880 10 3/8 8611255 5 Nom. 1/2 5611265 5 Nom. 1/2 6611285 5 Nom. 1/2 8611380* 10 1/2 8611205 5 Nom. 1/2 10611300* 10 1/2 10615850 10 5/8 5615860 10 5/8 6615880* 10 5/8 8615883* 13 - RUS 5/8 8615800* 10 5/8 10615803* 13 - RUS 5/8 10615812* 10 5/8 12615815* 10 5/8 15613460 10 3/4 6613480* 10 3/4 8613483* 13 - RUS 3/4 8613400* 10 3/4 10613412* 10 3/4 12613415* 10 3/4 15614400* 10 1 10*UL Listed rodsPh: 1-800-677-9089www.erico.com17

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesERITECH ® Threadless Couplings forCopperbonded Pointed Rods• Made of high-strength silicon bronze.• Tapered so when the rod is driven into the coupling,the two parts compress to form a conductive connection.PartNo.NominalDiameterCC12 1/2” NominalCC12F 1/2” FullCC58 5/8”CC34 3/4”A Compression Coupling – Full ViewB Compression Coupling – Cut AwayABERITECH Ground Rod Driving Sleeves*• Slides on top of ground rod to prevent mushrooming while drivinginto ground.Part No.Ground Rod SizeB137-14 1/2” Copperbonded or Steel RodB137-16 5/8” Copperbonded (.563” dia.)B137-31 5/8” Steel (.625” dia.)B137-18 3/4” Copperbonded (.682” dia.)B137-33 3/4” Steel (.750” dia.)B137-22 1” Copperbonded (.914” dia.)B137-37 1” Steel (1.00” dia.)* For plain (unthreaded) ground rods only.• Sleeves for use in power assisted ground rod drivers.Part No.Ground Rod Size (Unthreaded)4.00"7.00"DH58DH345/8” Copperbonded (.563” dia.)3/4” Copperbonded (.682” dia.).850"18 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesERITECH ® Copperbonded Sectional GroundRods, Couplings <strong>and</strong> Driving Studs• The cold-rolled threads with their continuous unbroken grain flowsare stronger than cut-threads.• High-strength couplings are threaded bronze <strong>and</strong> chamfered at bothends for easy driving.• High strength, corrosion-resistant couplings ensure permanent,low resistance copper-to-copper connections.Drive StudCouplingPart Plating Dia. LengthNo. Thickness (in.) (ft.)(ml)631380* 10 1/2 8631300* 10 1/2 10635830 10 5/8 3635840 10 5/8 4635850 10 5/8 5635860 10 5/8 6635880* 10 5/8 8635883* 13 - RUS 5/8 8635800* 10 5/8 10633480* 10 3/4 8633400* 10 3/4 10634400* 10 1 10*UL Listed rodsGround RodGround RodERITECH Couplings for Sectional RodsPartNo.CR-12CR-12SCR-58CR-34CR-100RodSize1/2” Nominal1/2” Full Size5/8” Nominal3/4” Nominal1” NominalCouplingERITECH Driving Studs for Sectional RodsPartNo.DS12FDS12DS58DS34DS1RodSize1/2” Nominal1/2” Full Size5/8” Nominal3/4” Nominal1” NominalGround RodPh: 1-800-677-9089www.erico.com19

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesERITECH ® Copperbonded Pigtail Ground Rods• Pigtails are either Copperweld ® or copper wire securely mig-welded to rod.• Contact ERICO for specific requirement.Part Nominal Dia Cu WireNo. X Length Thickness (Mil.)6138529 3/8” x 5’ 5 Mil #10CW x 18” Lg6138629 3/8” x 6’ 5 Mil #10CW x 18” Lg615889 5/8” x 8’ 10 Mil #6 AWG Cu x 48” Lg615809 5/8” x 10’ 10 Mil #6 AWG Cu x 48” Lg6158839 5/8” x 8’ 13 Mil #6 AWG Cu x 48” Lg6158039 5/8” x 10’ 13 Mil #6 AWG Cu x 48” Lg® Copperweld is a registered trademark of The LTV Corporation.20 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesERITECH ® Solid Stainless Steel Ground Rods• Sectional rods utilize a cut thread for highly corrosive soil.• Contact ERICO ® for other available sizes.Part Description Dia. LengthNo. (in.) (ft.)681300 304 Pointed FS 1/2 10683400 304 Pointed 3/4 10683400S 304 Sectional 3/4 10685880 304 Pointed 5/8 8685800 304 Pointed 5/8 10685880S 304 Sectional 5/8 8681300S 304 Sectional 1/2 10ERITECH Threaded Stainless Steel CouplingPartNo.DescriptionCR13SS 1/2” Full SizeCR58SS 5/8”CR34SS 3/4”ERITECH Galvanized Pointed Ground Rods• Meets NEMA, GR1 <strong>and</strong> is RUS Approved.• Zinc-coated exteriors are hot-dip galvanized for solid protection againstcorrosion in accordance with ASTM specification A153-78.• Surfaces are rigidly inspected to eliminate seams, slivers <strong>and</strong> other defects.PartRodNo.Size811250 1/2” x 5’811260 1/2” x 6’811280 1/2” x 8’815860 5/8” x 6’815880* 5/8” x 8’815800 5/8” x 10’813480* 3/4” x 8’813400 3/4” x 10’814400 1” x 10’*RUS ApprovedERITECH Galvanized Steel CouplingPart Rod RodNo. Type SizeGCC58 Threadless 5/8”Ph: 1-800-677-9089www.erico.com21

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesERITECH ® Copper Ground Plate <strong>Elec</strong>trode withTerminated 2 Foot Welded Pigtail ConnectionPart No.GPECEAH24 "xx" 24GPECEAJ18 "xx" 24GPECEAJ24 "xx" 24GPECEAJ36 "xx" 24GPECEAK24 "xx" 24GPECEAM36 "xx" 24GPECEBH12 "xx" 24GPECEBH24 "xx" 24Dimensions12"x24"x20 Ga Cu18"x18"x20 Ga Cu18"x24"x20 Ga Cu18"x36"x20 Ga Cu24"x24"x20 Ga Cu36"x36"x20 Ga Cu12"x12"x1/16" Cu12"x24"x1/16" CuERITECH Copper Ground Plate <strong>Elec</strong>trode with2 Foot Welded Through Pigtail ConnectionPart No.DimensionsGPECCAH24 "xx" 2412"x24"x20 Ga CuGPECCAJ18 "xx" 2418"x18"x20 Ga CuGPECCAJ24 "xx" 2418"x24"x20 Ga CuGPECCAJ36 "xx" 2418"x36"x20 Ga CuGPECCAK24 "xx" 2424"x24"x20 Ga CuGPECCAM36 "xx" 2436"x36"x20 Ga CuGPECCBH12 "xx" 2412"x12"x1/16" CuGPECCBH24 "xx" 2412"x24"x1/16" Cu"xx" - Cable code for required conductor type <strong>and</strong> sizeERITECH Copper Ground Plates• Made from 20 gauge thick, high conductivity copper sheet.• Two cable attachments LPC535L securely fastened to plate.Part No.LPC750LPC751LPC752Dimensions12” wide by 24” long18” wide by 18” long36” wide by 36” long• Cable attachments LPC532L securely fastened to plate.Part No.LPC753LPC754LPC755Description12” wide by 24” long18” wide by 18” long36” wide by 36” long22 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesERITECH ® Copper Utility Pole Butt PlatePart Conductor PlateNo. Range DiameterEGP100 #14-#4 AWG 7.5”ERITECH Copper Utility Pole Ground PlatePart No. Description DimensionsGPECEHX1 Copper w/#6 solid ground wire 10' 1/16"x17"x17"long exothermically welded to plateERITECH Steel Ground Plate <strong>Elec</strong>trodePart No. Description DimensionsEGGP* Galvanized steel grounding plate 1/4”x10”x16” w/o connectorEGGPC* Galvanized steel grounding plate 1/4”x10”x16” w/HDC58 connectorEBGP Bare steel grounding plate 1/4”x10”x16” w/o connectorEBGPC Bare steel grounding plate 1/4”x10”x16” w/HDC58 connector*CSA ListedPh: 1-800-677-9089www.erico.com23

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesChemical Ground RodERITECH ® chemical ground electrodes provide a low impedance ground in locations of high soil resistivity.Used in conjunction with a bentonite backfill <strong>and</strong> ERICO’s unique GEM material, the ERITECH chemicalground electrode system, provides a method to improve soil resistivity directly surrounding the electrode.It maintains a low ground resistance, maintenance-free installation that dissipates lightning energy <strong>and</strong>other dangerous electrical fault currents, even in s<strong>and</strong>y or rocky soil conditions. The Chemical Ground<strong>Elec</strong>trode is useful for providing an effective earth in poor soil conditions wherespacing for electrodes is limited.Benefits <strong>and</strong> FeaturesUL <strong>and</strong> CSA Listed• Contains natural electrolytic salts, which permeate into thesurrounding soil to condition the soil <strong>and</strong> increase its conductivity.• Low impedance to effectively dissipate lightning <strong>and</strong> electrical fault currents.• Over 70 configurations available, other assemblies made to order.• Easy connection to ground electrode conductor using the factory provided pigtail(up or down orientation)• Provides decades of reliable services due to <strong>ru</strong>gged const<strong>ru</strong>ction, <strong>and</strong> high qualitymetals with a 30 year minimum service life• 2-1/8" OD Type K copper pipe, 0.083" wall contains natural electrolytic salts thatpermeate into the surrounding soil, improving electrode to soil connection.• Available up to 20 feet in length. Longer rods can be field assembled using10 foot sections.• Optional factory attached radial stripsare available to reduce impedance tohigh-frequency lightning energy <strong>and</strong> tocontrol the direction of the dissipation• L-shaped rods are available for horizontal installation applications where it is impracticalto auger deep vertical holes.See specification on page 70.The Chemical Ground <strong>Elec</strong>trode issuitable for high soil resistivity, dry soilconditions, as it can replace multipleconventional ground rods, making thesystem ideal where space limitationsapply. Where seasonal variations causefluctuations in soil resistivity ,theChemical Ground <strong>Elec</strong>trode ensures aconstant <strong>and</strong> reliable low impedanceground.Market Applications• Telecommunications• Power Generation & Distribution• Commercial & Industrial• Manufacturing• Transport – Rail, Aviation• Lightning Protection• Recreational Facilities• Defense24 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesChemical Ground RodChemical Ground <strong>Elec</strong>trode SystemERICO ® Chemical Ground <strong>Elec</strong>trodes are most effectivewhen installed as part of a total system that includeshigh conductivity backfill materials, access/inspectionwells, <strong>and</strong> permanent, reliable CADWELD ®connections. They may be installed either vertically orhorizontally, as shown below in figure 18. ERICOrecommends installing the complete system.LightningDownconductor -Conducts the lightningenergy safely to ground.ERICO Inspection Well -Protects Chemical <strong>Elec</strong>trodewhile allowing necessary air<strong>and</strong> moisture to enter.Provides access formaintenance.VERTICALINSTALLATIONHORIZONTALINSTALLATIONCADWELDConnections -Permanently bonds allelements of thegrounding system.Pigtails -Factory attached conductorconnection. Upward ordownward orientationavailable.Chemical Ground<strong>Elec</strong>trode -Provides continualconditioning of highresistivity soils.Figure 18. Chemical Ground <strong>Elec</strong>trode can be installed either verticallyor horizontally. Chemical electrodes are available in a range of st<strong>and</strong>ard<strong>and</strong> custom configurations <strong>and</strong> are available individually or as part of acomplete kit.How to OrderGround Enhancementmaterial GEM - Lowresistance, non corrosivematerial, fills void betweenelectrode <strong>and</strong> earth.Figure 19. Typical vertical installation showing major components required to form an effective ground electrode.Chemical ground rods can be ordered as individualcomponents or as a complete kit. Kits include the chemicalelectrode (pre-filled with electrolytic salts), bentonite, GEMbackfill <strong>and</strong> an access well. To order the chemical electrodeonly, add "B" to the end of the part number.COPPER CONDUCTOR CODES - Pigtail ConductorConductor Size Conductor SizeCode Description Code Description1T #2 Solid Tinned 2Q 4/0 Conc.2C 1/0 Conc. 2V 250 Kcmil Conc.2G 2/0 Conc. 3Q 500 Kcmil Conc.INDIVIDUAL COMPONENTSPart No.DescriptionERICO Ground<strong>Elec</strong>trode System(V) Vertical Style(H) Horizontal Style(E) Extended vertical<strong>Elec</strong>trode Length (Ft)Pigtail Cable CodeAdd (B) for(Rod Assy. only)Pigtail Orientation(D) Down or(U) UpPigtail Length (Ft)(see above)GEM25ABENTFILL(see catalog #A1A)T416BHT416DChemical ground rod electrode only25 lg. (11.4 kg) bag of GEM Ground Enhancement Material50 lb. (22.7 kg) bag of bentoniteCADWELD ® material for cable-to-cable connectionsHigh-density polyethylene access pit for no traffic areas (type supplied with kits)Concrete access well for traffic areasPh: 1-800-677-9089www.erico.com25

Ground System ComponentsGround Enhancement Material(Part# GEM25A)Only rarely do grounding systemdesigners <strong>and</strong> contractors get to work ona site with good grounding conditions.Even under ideal circumstances, soilst<strong>ru</strong>cture can vary <strong>and</strong> make it difficult toachieve uniform, low levels of resistivityacross a wide area. Under almost all soilconditions, the use of a groundenhancement material will improvegrounding effectiveness. Some arepermanent <strong>and</strong> require no maintenance.When selecting a ground enhancementmaterial be sure it is compatible with theground rod, conductor <strong>and</strong> connectionmaterial.To improve the conductivity of agrounding system, ERICO ®recommends using GroundEnhancement Material (GEM).Ground <strong>Elec</strong>trodes <strong>and</strong> AccessoriesResistivity ComparisonFigure 20. As the graph clearly shows, GEM has a resistivityfactor more than 20 times lower than bentonite clay.GEM is a low-resistance, non-corrosive, carbon dust based material that improves grounding effectiveness,especially in areas of poor conductivity. GEM contains cement, which hardens when set to providea permanent, maintenance-free, low-resistant grounding system that never leaches or washes away.Benefits <strong>and</strong> FeaturesNo other material matches GEM for reducingearthing resistance <strong>and</strong> maintaining lowresistance permanently. No other materialequals GEM in providing conductivity for thelife of the grounding system.GEM is effective• GEM can dramatically lower earthresistance <strong>and</strong> impedance measures• GEM maintains constant resistances forthe life of the system once in set form• GEM performs in soil conditions evenduring dry spells• Because it is chemically stable <strong>and</strong> verylow in sulfate <strong>and</strong> chloride, it protectsground conductors from corrosion insteadof attacking them like salts do.GEM is Permanent• Does not dissolve, decompose nor leach out with time• Does not require periodic charging treatments nor replacement• Does not require maintenance• Does not require continuous presence of water to maintain effectiveness• Freezing will increase resistivity by only 10-15 percentGEM is Environmentally Friendly• Does not adversely affect the soil• Does not leach ions or contaminate ground water• Meets (USA) Environmental Protection Authority requirements for l<strong>and</strong>fillApplicationGEM improves grounding effectiveness regardless of soil conditions <strong>and</strong> providesexcellent permanent conductivity:• For areas with high resistance, such as rocky ground, mountain tops, <strong>and</strong> s<strong>and</strong>y soil• As a backfill when you have to drill because the ground is too hard to drive, orwhere ground rods cannot be driven, or• Where limited space makes adequate grounding difficult by conventional methods26 Ph: 1-800-677-9089www.erico.com

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesGEM INSTALLATIONGEM is supplied in easy-to-h<strong>and</strong>le 25 lb.bags for one-man installation. GEM can beinstalled dry or wet (recommended). GEMquickly absorbs moisture from the soilwhen used dry, to reach its maximumconductivity in days. To accelerate curingtime, water can be added after GEM isinstalled, or it can be pre-mixed withwater.Ask ERICO fora complimentarySix Point Plan CD that includes theGEM calculator to determine theamount of GEM required for yourgrounding application.1. Dig a trench at least 4 incheswide x 30 inches deep orbelow the frost line,whichever is deeper. Spreadout enough GEM to uniformlycover bottom of trench-about1 inch deep.2. Place conductor on top ofGEM.3. Spread more GEM on top ofconductor to completelycover conductor about 1 inchdeep.4. Carefully cover the GEMwith soil to a depth of about4 inches, making sure not toexpose the conductor. Tampdown the soil, then fill in thetrench. For various trenchwidths <strong>and</strong> GEM thicknesses,see the table on page 28.TRENCH INSTALLATIONGROUND ROD BACKFILL INSTALLATION1. Auger a 3 inch or larger diameterhole to a depth of 6 inches lessthan the length of the ground rod.2. Place ground rod into augered hole<strong>and</strong> drive one foot (if possible) intobottom of the hole. The top of theground rod will be approximately6 inches below grade. At this time,make any connections to groundrod using CADWELD connections.3. Pour the appropriate amount ofGEM around the ground rod. Toensure the GEM material completelyfills the hole, tamp around theground rod with a pole.4. Fill remainder of augered hole withsoil removed during augering. Forvarious augered-hole diameters <strong>and</strong>depths, see the table on page 28.Figure 21.Note: If premixing GEM into a slurry form,use a st<strong>and</strong>ard cement mixer or hard-mix ina mixing box, wheelbarrow, etc. Use 1-1/2 to Note: ExcessFigure 22.2 gallons of clean water per bag of GEM. st<strong>and</strong>ing watermust be removed from thehole.Ph: 1-800-677-9089www.erico.com27

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesTrench WidthTRENCH INSTALLATIONEstimated linear feet of ground conductorcovering with each bag of GEMTotal Thickness of GEM1" 2" 3" 4"(2.5cm) (5.1cm) (7.6cm) (10.2cm)4" (10.2cm) 14.0 (4.3m) 7.0 (2.1m) 4.7 (1.4m) 3.5 (1.1m)6" (15.2cm) 9.3 (2.8m) 4.7 (1.4m) 3.1 (0.9m) 2.3 (0.7m)8" (20.3cm) 7.0 (2.1m) 3.5 (1.1m) 2.3 (0.7m) 1.8 (0.5m)10" (25.4cm) 5.6 (1.7m) 2.8 (0.9m) 1.9 (0.6m) 1.4 (0.4m)12" (30.5cm) 4.7 (1.4m) 2.3 (0.7m) 1.6 (0.5m) 1.2 (0.4m)A 25-pound bag of GEM will cover 7 linear feet (2.1m) of conductor length for a4-inch-wide (10.2cm), 2-inch-thick (5.1cm) covering [1 inch (2.5cm) below<strong>and</strong> 1 inch (2.1cm) above conductor], based on 63.5 Ib/cu ft (1017 kg /m 3 ).GROUND ROD BACKFILL INSTALLATIONEstimated bags of GEM for backfilling around groundrods to a density of 90 lb/cu ft (1442kg/m3)Dia. of holeDepth of hole (feet)*6' 7' 8' 9' 17' 19' 20'(1.8m) (2.1m) (2.4m) (2.7m) (5.2m) (5.8m) (6.1m)3" (7.6cm) 2 2 2 2 4 4 44" (10.2cm) 2 3 3 3 6 7 75" (12.7cm) 3 4 4 5 9 10 106" (15.2cm) 5 5 6 7 13 14 157" (17.8cm) 6 7 8 9 17 19 208" (20.3cm) 8 9 11 12 22 25 269" (22.9cm) 10 12 13 15 28 31 3210" (25.4cm) 12 14 16 18 34 38 40*8-foot (2.44m) minimum rod length required to be in contact with the soil (or GEM). Per NEC 250-52.How to Specify GEM• Ground enhancement material must be permanent <strong>and</strong>maintenance-free (no recharging with salts or chemicals whichmay be corrosive) <strong>and</strong> maintain its earth resistance with time.• It must set up firmly <strong>and</strong> not dissolve or decompose orotherwise pollute the soil or the local water table.• The ground enhancement material shall be suitable forinstallation in dry form, or in slurry form.• The ground enhancement material shall not depend on thecontinuous presence of water to maintain its conductivity.• Ground enhancement material in its set form shall have aresistivity of not more than 20 ohm-cm.Figure 23. GEM permanent ground enhancement material, isideal in areas of poor conductivity <strong>and</strong> is suitable for bothbackfilling around ground rods <strong>and</strong> trench installations.28 Ph: 1-800-677-9089www.erico.com

23-1/4"Ground System ComponentsGround Inspection WellsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesFor periodically measuring the electrical resistance of a buried groundsystem, inspection wells are used as a means of access to the groundconductor. To make electrical resistance measurements, remove thecover <strong>and</strong> attach a lead from a resistance measuring inst<strong>ru</strong>ment to theground conductor.Inspection wells are available in various sizes <strong>and</strong> materials. Light-dutyunits are generally used. For areas of high vehicular traffic, you shoulduse heavy-duty inspection wells.Figure 24.Conducting ResistanceTesting®Figure 25. Resistance testing using a ground resistance meter, with access to the groundconductor provided by the ground inspection well.ERITECH ® Polymer Concrete WellsPart Material Color Dimensions Cover Box Base with FeaturesNo. Weight Inserts WeightT416A Polymer Concrete* Concrete Gray 14" x 23" x 18" deep 25 lbs. 50 lbs. Bolt down cover; skid resistant surfaceT416D Polymer Concrete* Concrete Gray 13" x 13" x 12" deep 25 lbs. 50 lbs. Bolt down cover; skid resistant surfaceT416E Polymer Concrete* Concrete Gray 13" x 13" x 18" deep 25 lbs. 50 lbs. Bolt down cover; skid resistant surfaceT416F Polymer Concrete* Concrete Gray 13" x 13" x 26" deep 25 lbs. 50 lbs. Bolt down cover; skid resistant surface*Polymer Concrete reinforced with heavy weave fiberglass resulting in high strength <strong>and</strong> minimal weight.Enclosures <strong>and</strong> covers rated for 10,000 lbs. maximum load.13-3/4"12-7/8"12-7/8"12-7/8"12-7/8"12-7/8"12-7/8"18"12"18"26"T416APh: 1-800-677-9089www.erico.comT416D T416E T416F29

Ground System ComponentsGround <strong>Elec</strong>trodes <strong>and</strong> AccessoriesERITECH ® High Density Polyethylene WellsPart Material Color Dimensions Cover Box Base with FeaturesNo. Weight Inserts WeightT416B High Density Green 10" round x 10" deep 1-1/2 lbs. 3 lbs. Stainless steel lock bolt (3/8”-16 x 1-3/4");Polyethylenevery resistant to acids <strong>and</strong> chemicals;boxes <strong>and</strong> covers nest in 3-1/4" increments;2 knockouts per box (3-1/2" x 1-1/2")T416C High Density Black 14" round x 18" deep 4-1/4 lbs. 13.4 lbs. Resistant to acids <strong>and</strong> chemicals;Polyethylenepipe slot (2 places)ERICOGROUND14-1/2" Dia.10" Dia.18"10-1/4"13" O.D.24-1/2" O.D.T416BT416C30 Ph: 1-800-677-9089www.erico.com

Equipotential BondingEquipotential BondingIntroductionAlthough closely related to grounding, bonding is a distinctdiscipline that is essential to the overall facility electricalprotection scheme. <strong>Grounding</strong> provides the actual physicalconnection to earth used for establishing <strong>and</strong> maintaining itspotential, theoretically 0 volts. Bonding is the practice ofestablishing an equipotential plane by permanently joiningtogether metal parts of the wiring system as well as tyingtogether all of the electrical service grounds. Proper bondingestablishes a low impedance fault return path that allows for theproper operation of over-current devices. Additionally, bondingof all ground electrode systems (main power, telecommunications,<strong>and</strong> lightning protection) eliminates dangerous potential differencesthat can arise during fault <strong>and</strong> transient voltage conditionsjeopardizing people <strong>and</strong> equipment. Bonding of separate groundelectrode systems is required by the NFPA (The NEC ® ) as well asother international electric codes.The Importance of a Correctly Bonded Ground SystemFigure 26. Figure 27.Figure 26 shows an example of a well-designed grounding systemwith a "single point" connection of equipment power, lightningprotection, <strong>and</strong> communication ground wires to the ground-ring.If lightning hits the air terminal on the facility, the lightning protectionearth would rise equipotentially with all other ground points as theyare closely bonded together. Bonding provides little opportunity forpotential differences between ground points creating ground loops orcausing sparking or sideflashing.A non-ideal system can include multiple connection points to theground-ring <strong>and</strong> / or poor bonding connections. Figure 27 shows acase where an incoming power feed was effected by lightning.Adequate protection equipment on both power <strong>and</strong> communicationsinterface was provided, however the separate electrical <strong>and</strong>communications earths are located some distance apart.Figure 27. A non-ideal grounding system uses multiple connectionpoints.Regardless of how good each individual ground is, for a very shortperiod of time the potential of the electrical ground will be higherthan the communications ground. As a result the excess energy hastwo paths to follow to reach the lower potential communicationsground, thus creating a dangerous ground loop that will damage thesensitive electronic equipment in the equipment room. ERICO ®provides a number of technologies to assist in the const<strong>ru</strong>ction ofeffective "best practice" equipotential grounding systems includingthe Transient Earth Clamp <strong>and</strong> the Insulated Joint Protector.Ph: 1-800-677-9089www.erico.com31

Equipotential BondingEquipment Ground BarsProper bonding is essential to create an equipotential plane between servicegrounds <strong>and</strong> equipment during fault <strong>and</strong> transient conditions. Thisequipotential plane provides a near zero voltage differential <strong>and</strong> serves toprotect people <strong>and</strong> equipment during these events. The most popularbonding product in use today is the ground bar or bonding bar. Ground barsprovide a convenient, single-point grounding <strong>and</strong> bonding location.Conductors are welded to the bar using the CADWELD ® process or aremechanically fastened by using lugs.ERICO ® can design <strong>and</strong> manufacture custom bars. In addition, the breadth ofthe product offering includes TMGB bars, which meet the requirements ofTIA/EIA 607 <strong>and</strong> conform to BICSI recommendations. Our perimeter bussystem allows for fast <strong>and</strong> easy field installation of halo <strong>and</strong> other perimetergrounding schemes.ERITECH ® EGB SeriesMaterialsBusbars– 1/4” thick copper– ASTM B187-C11000– <strong>Elec</strong>tro-tin plated (if required)Insulators:– Material: flame resistant fiberglass reinforcedthermoset polyester– Color: red– Indoor rating: 600 volts– 1-1/2” heightBrackets:– Type 304 stainless steel– 1/8” thickFasteners:– 3/8” Type 304 stainless steel fasteners <strong>and</strong>stainless steel bracketsFigure 28.ERITECH TGB & TMGBMaterialsBusbars:– 1/4” thick copper– ASTM B187-C11000– <strong>Elec</strong>tro-tin platedInsulators:– Manufactured of <strong>ru</strong>gged polyamide, anenvironmentally friendly, halogen-free nylonmaterial which is reinforced with glass fiber– 2” st<strong>and</strong>off height– Meets the requirements of UL94 VO for selfextinguishingmaterialsBrackets:– Type 304 stainless steel– 1/8” thickFasteners:– Type 304 stainless steelFigure 29.32 Ph: 1-800-677-9089www.erico.com

Equipotential BondingEquipment Ground BarsERITECH ® EGB SeriesPART NUMBERING SYSTEME G BERITECHGROUND BARDESIGNATIONCONFIGURATIONA = INSUL & BRKTB = BRKT ONLYC = NONE (BAR ONLY)D = INSUL ONLYTHICKNESS18 = 1/8"14 = 1/4"38 = 3/8"12 = 1/2"58 = 5/8"34 = 3/4"WIDTH1 = 1"2 = 2"3 = 3"4 = 4"5 = 5"6 = 6"7 = 7"8 = 8"9 = 9"LENGTH(ROUNDED TO THE NEARESTINCH, UP TO 96 INCH MAX.)TIN PLATING(EMPTY IF NONE)T = TINNEDHOLE PATTERNPIG TAIL LENGTH FT. (EMPTY IF NONE)A = 1 E = 5 J = 9 N = 16 S = 24 W = 32B = 2 F = 6 K = 10 P = 18 T = 26 X = 34C = 3 G = 7 L = 12 Q = 20 U = 28 Y = 36D = 4 H = 8 M = 14 R = 22 V = 30 Z = 38ERICO ® CABLE CODE(EMPTY IF NONE)1K = #4 SOL TIN 2Q = 4/01T = #2 SOL TIN 2V = 250 KCM2C = 1/03D = 350 KCM2G = 2/03Q = 500 KCM2L = 3/04L = 750 KCMPATTERN: "AA" PATTERN: "BB" PATTERN: "CC" PATTERN: "DD"PATTERN: "EE" PATTERN: "FF" PATTERN: "GG" PATTERN: "HH"PATTERN: "JJ" PATTERN: "LL" PATTERN: "MM" PATTERN: "NN"Figure 30.Ph: 1-800-677-9089www.erico.com33

Equipotential BondingERITECH ® EGB SeriesEquipment Ground Bars5/16"7/16"1"3/4"7/16" 2"7/16" 1"EGBA14212TES (1/4 x 2 x 12)EGBA14212EE (1/4 x 2 x 12)EGBA14212HH (1/4 x 2 x 12)7/16" 2"7/16"1"3/4"5/16"7/16"1"3/4"EGBA14112EE (1/4 x 1 x 12)EGBA14215JJ (1/4 x 2 x 15)EGBA14215TES (1/4 x 2 x 15)7/16"2" 7/16"3/4"2"3/4"7/16"2"3/4"1"1"1"EGBA14412CC (1/4 x 4 x 12)EGBA14412CCT (1/4 x 4 x 12 tinned)EGBA1442OCC (1/4 x 4 x 12)EGBA14412OCCT (1/4 x 4 x 12 tinned)EGBA14424CC (1/4 x 4 x 12)EGBA144124CCT (1/4 x 4 x 12 tinned)7/16"2"3/4"7/16"2"3/4"1"1"EGBA14428CC (1/4 x 4 x 28)EGBA144128CCT (1/4 x 4 x 28 tinned)EGBA14436CC (1/4 x 4 x 36)EGBA144136CCT (1/4 x 4 x 36 tinned)7/16"2"7/16"2"7/16"2"2"2"1"EGBA14412AAEGBA14412BB (1/4 x 4 x 12)EGBA14412AA1TT (1/4 x 4 x 12 tinned)(#2 tinned sol pigtail 25ft lg)1/8"Typ.9/32"5/32"3/4"7/16" 5/16" 1"5/16"7/16"2"3/4"1"1"1"2"1"EGBA14410FF (1/4 x 4 x 10)EGBA14412MM (1/4 x 4 x 12)EGBA144120CCSKY (1/4 x 4 x 20)Figure 31.34 Ph: 1-800-677-9089www.erico.com

Equipotential BondingEquipment Ground BarsERITECH ® EGB Series (cont.)EGBA1442OHIG (1/4 x 4 x 20)EGBA1442OHIGT (1/4 x 4 x 20 tinned)EGBA14424CIGBE (1/4 x 4 x 24)EGBA14424CIGBET (1/4 x 4 x 24 tinned)EGBA14424MM (1/4 x 4 x 24)EGBA14412NN (1/4 x 4 x 12) EGBA14420NN (1/4 x 4 x 20)Figure 32.ERITECH B540 SeriesB544A028 (1/4 x 4 x 16”)B544A028 (1/4 x 4 x 16”)B543A010 (1/4 x 3 x 20”)B543A010 (1/4 x 3 x 20”)B542A004 (1/4 x 2 x 18”)Figure 33.Ph: 1-800-677-9089www.erico.com35

Equipotential BondingERITECH ® TGB & TMGB SeriesEquipment Ground BarsPART NUMBERING SYSTEMT G BERICO ®TELECOMMUNICATIONGROUND BARDESIGNATIONT M G BLPPIG TAIL LENGTH FT. (BLANK IF NONE)ERICOTELECOMMUNICATIONMAIN GROUND BARDESIGNATIONA = 1 E = 5 J = 9 N = 16 S = 24 W = 32B = 2 F = 6 K = 10 P = 18 T = 26 X = 34C = 3 G = 7 L = 12 Q = 20 U = 28 Y = 36D = 4 H = 8 M = 14 R = 22 V = 30 Z = 38SPECIFICATIONSCONFIGURATIONA = INSULATOR & BRACKETC = NONE (BAR ONLY)LENGTH(ROUND UP TONEAREST INCH)NUMBEROF PAIRS OF5/16" HOLEST = TINNED(BLANK IF NONE)ERICO CABLE CODE (BLANK IF NONE)1K = #4 SOL2Q = 4/0 CONC1T = #2 SOL TIN 2V = 250 KCM CONC2C = 1/0 CONC 3D = 350 KCM CONC2G = 2/0 CONC 3Q = 500 KCM CONC2L = 3/0 CONC4L = 750 KCM CONCTGB-A29L18PTTMGB-A29L41PTTGB-A25L14PTTMGB-A25L33PTTGB-A20L12PTTMGB-A20L27PTTGB-A18L10PTTMGB-A18L23PTTGB-A16L08PTTMGB-A16L19PTTGB-A14L06PTTMGB-A14L15PTFigure 34.36 Ph: 1-800-677-9089www.erico.com