View the Enertrols Main Catalog featuring industrial shock ...

View the Enertrols Main Catalog featuring industrial shock ...

View the Enertrols Main Catalog featuring industrial shock ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

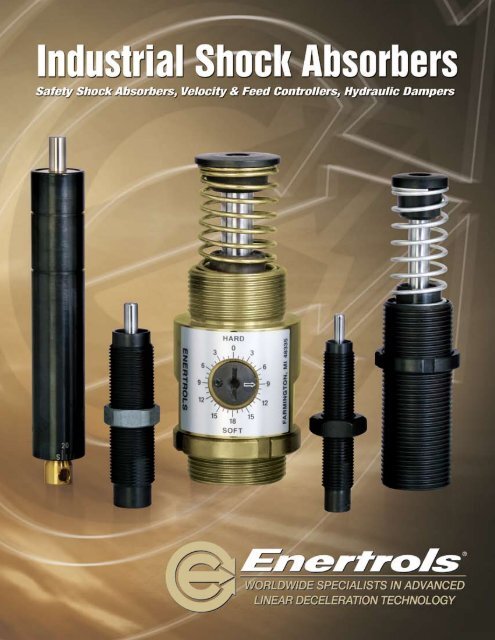

Any mechanism that moves and that must be stopped is a potential application for controlled lineardeceleration. There is no more effective way to achieve that control than through <strong>the</strong> use of <strong>Enertrols</strong><strong>shock</strong> absorbers. With <strong>the</strong>m, you can quickly and safely stop any type of motion including: straight-line,rotary, free-falling, sliding, rolling, etc. It makes no difference if <strong>the</strong> motion is driven electrically, mechanically,hydraulically, or pneumatically. Listed below are a few areas where <strong>Enertrols</strong> <strong>shock</strong> absorbershave replaced solid stops, deceleration valves, flow control valves, cylinder cushions, springs, rubberbumpers, dash-pots, feed controls, hydraulic checks, complicated and costly circuits and conventional<strong>industrial</strong> <strong>shock</strong> absorbers.Automotive: press welders, extractors, blankloaders, transfer shuttles, roll overs, pivoting pillars,K.D. fixtures, drop-away clamps, end stops, overheadcranes, destackers, iron hands, conveyors,lift and carry units, walking beams, welding guns,flying shears, press weld trans. and more.Foundry: core machines, flask stops, patternshuttles, rammer carriage stops, roll overs, cope& drag pick off, overhead cranes, turntables,cooling lines, disappearing stops, cope & dragpunch out, cope mold closer, drag mold set on,drag mold lift off, sand shields, push off cylinder,elevator stop, conveyor stopPackaging: drop packer, tunnel packer, traffic cop,index stations, turn tables, conveyor stops, filling,palletizers, baggingRubber: tire curing press - loading arm, post tireinflator, vertical load head; tire building machinebeadset, collapsing drum, servicer tray; biascutter, guillotine cutter, skivers, tread cutter, forcevariation machine, wig-wag, conveyors, calendarsSteel: up enders, down enders, strip support arms,coil buggies, ingot buggies, transfer cars, bloomstops, entry table stops, fly shears, manipulators,run-out tables, c-car at coilers, overhead cranes,banding & strapping, bar turners, furnace stops,tube stops, draw benchesLumber/Paper/Textile/O<strong>the</strong>r: roll stops, weighingstations, saw cut-off, drop chutes, vernier calipers,saw carriages, log turners, stops, picker arms,loom shuttles, fabric rolls, carpet presses, injectionmolding doors, die-cast machine transfers,pick-off arms

Table of ContentsGeneral InformationQuality, Why <strong>Enertrols</strong>? ......................................................................... 1<strong>Enertrols</strong> Product Line .......................................................................... 2Controlled Linear Deceleration ................................................................... 2Construction & Design Features .................................................................. 3Standard Shock Absorbers .....................................................................4-5Standard Shock Absorbers for Special Applications ................................................. 6Accessories & Special Application Shock Absorbers ................................................. 7PSS Positive Stop Systems ...................................................................... 8Selecting <strong>the</strong> Correct Type of Shock Absorber ...................................................... 9Selecting <strong>the</strong> Correct Model Shock Absorber ...................................................... 10Selecting <strong>the</strong> Correct Size Shock Absorber. ....................................................... 11Calculating Effective Weight and Examples .....................................................12-19<strong>Enertrols</strong>Size and 3D Solid Model CAD Files ....................................................... 19Model Rating Charts. ........................................................................20-23Construction and Parts Descriptions for Gold Line & SILVERLINE Series ........................... 24Air/Oil Tank Dimensions ........................................................................ 25Installation Recommendations and Tips ........................................................26-27Additional <strong>Enertrols</strong> Products ................................................................... 28Stocking Distributor Locations .................................................................. 94Industrial Shock AbsorbersSub Miniature Shock Absorbers - SM9 to SM75 ..................................................29-30Miniature Shock Absorbers - SNALD 150 to 600 ..................................................31-32Miniature Shock Absorbers - SNALD 1/2 x 1,2 ...................................................33-34Miniature Shock Absorbers - SA 30 to 150 & 1/4 Bore .............................................35-36Miniature Shock Absorbers - SALD 3/8 x 1 ......................................................37-38Miniature Shock Absorbers - SALD 1/2 x 1,2. ....................................................39-40Miniature Series Accessories. ................................................................... 41Weartec Plus ................................................................................. 42Mid Size Shock Absorbers - SNALD 33, 45 & 64 Series ............................................43-50SNALD 33, 45 & 64 Series Accessories. .........................................................51-52Side Load Adapters. ........................................................................... 52Gold Line Series. ..........................................................................53-62SILVERLINE Series. ........................................................................63-65High Precision Metric (HPM) Series. ............................................................ 66Heavy Industrial Shock Absorbers - ECA 2 to ECA 4 ................................................ 67Heavy Industrial Shock Absorbers - EA 2 to EA 3. .................................................. 68Heavy Industrial Shock Absorbers - ECA & EA 2,3 ................................................69-72Heavy Industrial Shock Absorbers - ECA 4 ......................................................73-74Stacker Crane & Crane Bumper ShocksStacker Crane Shock Absorbers ESCS-38-63 ....................................................75-78Crane Bumper Shocks ECB-63 to 160 ..........................................................79-82EHB Hydraulic Dampers<strong>Enertrols</strong> Hydraulic Dampers EHB15-EHB40. ....................................................83-87Mounting Brackets ............................................................................ 88EDVC/EVC Velocity and Feed ControllersEDVC Velocity & Feed Controllers. .............................................................89-90EVC Velocity & Feed Controllers with Fine Adjustment ............................................91-93

Construction & Design FeaturesMiniature Adjustable & Self-Compensating (Shown)(Typical for SNALD 150 to 600 Models)Versatile full threaded-body canbe mounted in any position usingfurnished lock nut. Screw-onthreaded flanges also available.Hardened steel metering tube hasmetering holes with knife edgesfor high flow efficiencyReturn oilflow passagesClosed-cell accumulator sponge is compressed by oil forcedthrough metering holes. It expands to help force oil back intobore as spring returns piston to its original positionExtra-long rod bearing for maximum lifeand side load capacityRod seal and wiper assemblyHeavy-duty, high-cyclereturn springBuilt-in Positive Stopfor work positioning.Protects <strong>shock</strong> frombottoming out at endof stroke.Floating, heat-treated piston headwith built-in check valve controlsflow of oil as <strong>shock</strong> absorberoperatesPrecision machined surfaces forclose-tolerance fitsAvailable with UNF andmetric threadsHardened stainless steel piston rodfor maximum strength.Standard Primary Mount & Fixed Flange ModelsPrecision machined shoulders provide exact positioning. This permitsrotation of <strong>the</strong> body for easy access to <strong>the</strong> side-located adjustor,without changing set-down dimension of <strong>the</strong> installationExtra-large diamter, solid one-piecepiston and rod for maximum strength.Rod is heat treated, ground and chromeplatedfor excellent corrosion and wearresistanceStandard or Vitonseals availableAdjuster turns through a full 360 degrees,from 'Hard' to 'Soft' and back to 'Hard' in onerevolution. More precise adjustment thancompetitive limited-range designsCast iron high-pressurepiston ring sealVersatile Primary-Mount Series can befront or rear mounted, using threads atei<strong>the</strong>r end of <strong>the</strong> heavy-duty steel bodyEasily disassembledfor fast field repairs.All component partsand seals are readilyavailableCorrosion-resistantreturn springs standardClosed-cellaccumulator spongeHardened button standardon all models. Poly pads forquiet-mar-free operation areavailableExtra-long rod bearingsfor maximum life andside load capacityHardened ball-typecheck valve forpositive sealingStrong, heat-treated steel, high pressure internalmetering tubes have knife-edge orifices for high flowefficiency. <strong>Enertrols</strong> patented metering system requiresNO adjustment when fluid temperatures changeWrench flats on bodyfor easy installationPlated zinc-chromate finish forgood appearance and superiorcorrosion resistancePrecision-machined surfaces andextremely close tolerance fits323435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Standard Shock AbsorbersSub-Miniature, Self-Compensating Series<strong>Enertrols</strong> sub-miniature, self-compensating <strong>industrial</strong> <strong>shock</strong> absorbers offer energy per cyclecapacities from 9 to 75 inch-lbs. A variety of effective weight ranges are available forhandling a wide range of applications.These fully threaded versatile models are easily mounted in confinedspaces. Select models such as <strong>the</strong> SM 25 and SM 75 includeWeartec Plus on <strong>the</strong> outer tubes for outstandingcorrosion protection.Applications include: small linear slides, materialhandling and packaging equipment, office andmedical equipment, instrumentation and more.Miniature, Self-Compensating Series<strong>Enertrols</strong> versatile, high-capacity, miniature, self-compensating <strong>industrial</strong> <strong>shock</strong> absorbers offertrue linear deceleration to protect relatively small, high-speed moving machinesand equipment. These dependable models are available in a number ofeffective weight ranges to help eliminate equipment impact damage.A built-in positive stop prevents bottoming out damage andprovides a positive work-positioning point.Applications include: small, high-speed movingmachines and equipment, material handlingequipment, robotics, packaging equipment, pickand place systems and more.Miniature, Adjustable SeriesMiniature, adjustable series <strong>industrial</strong> <strong>shock</strong> absorbers from <strong>Enertrols</strong> feature fullythreadedouter tubes for unlimited mounting versatility. Models such as <strong>the</strong> SA 35,SA 50 and SA 150 include Weartec Plus on <strong>the</strong> outer tubes for outstanding protectionagainst corrosion, erosion and <strong>the</strong> ravages of time.These dependable models can be easily adjusted to obtain optimum lineardeceleration.Applications include: linear slides, material handling and packagingequipment, robotics, pick and place systems, office and medicalequipment and much more.General InformationMid-Size, Self-Compensating 33, 45 & 64 Series<strong>Enertrols</strong> larger Mid-Size self-compensating <strong>shock</strong> absorbers are designed for higher energycapacities to a maximum effective weight capacity of 140,400 lbs. Four effective weightranges are offered for handling a wide range of applications. Threaded outertubes of <strong>the</strong>se durable models include, as standard, Weartec Plusfor outstanding corrosion protection.Applications include: automotive manufacturing and productionequipment, material handling and packaging equipment, lumberindustry equipment, <strong>the</strong>me park rides, robotics and more.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com4

Standard Shock AbsorbersGold Line ® SeriesGold Line ® adjustable <strong>shock</strong> absorbers are recommended for most deceleration applications, especially whereit is desirable to use <strong>the</strong> same model on a number of different installations. They perform well under a very widerange of conditions. For example, <strong>the</strong> weight range of <strong>the</strong>se units is approximately 250:1, meaning maximumweight capacity can be as much as 250 times greater than minimum weight capacity. Theadjustable fine-tuning feature provides maximum performance on virtually any applicationwith a velocity ranging from 1-15 fps. By keeping impact forces to a minimum,<strong>the</strong>y provide <strong>the</strong> softest stop, especially when critical and precisework-positioning is required.Primary Mounting Type ½, ¾ & 1 1/8 " Bore SizesThis larger series also features versatility of mounting through use of optional accessories that are threaded onei<strong>the</strong>r end of <strong>the</strong> <strong>shock</strong> absorber body and securely locked against a machined shoulder. Primary series units areheavily used in environments that require a number of different style mountings of <strong>the</strong> same basic bore size andstroke length <strong>shock</strong> absorbers.Fixed Flange Mounting Type ¾"to 2¼" Bore SizesConventional Fixed Flange <strong>Enertrols</strong> <strong>shock</strong> absorbers have permanentlyattached front or rear flanges plus foot and clevis mount options. Theyare ideally suited for use by cost-conscious OEM's using <strong>the</strong> same basic<strong>shock</strong> absorber in large volume. Positive set-down positioning when changingunits is a major feature of this type.Heavy-Duty 2, 3 & 4" Bore Self-Compensating& Adjustable Shock AbsorbersThese high-capacity <strong>Enertrols</strong> models were designed to handle extremelyheavy-duty applications. Rugged 2, 3 & 4" bore models offer strokelengths from 2 to 16 inches. Energy per cycle capacities range from32,000 in-lbs (3,616 Nm) to 1,120,000 in-lbs (126,500 Nm).Applications for <strong>the</strong>se rugged performers include: foundry, steel mill,marine, lumber, heavy equipment industries and more.523435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Standard Shock Absorbers for Special Applications¾" & 1 1/8" , 1½" & 2¼" Bore SILVERLINE ® Seriesfor Low-Velocity High Effective Weight Applications<strong>Enertrols</strong> SILVERLINE ® Fixed Flange and Primary Mount Series adjustable <strong>shock</strong> absorbers are designed for compact,high-energy automated equipment that operates at low velocities from 0.25 to 2.0 feet/second coupled with high effectiveweight conditions. Most robotic installations involve rotary motion and <strong>shock</strong> absorbers are typically positioned nearpivot points for increased clearance and more room in <strong>the</strong> work area.Rotary motion installations are almost always subjected to higheffective weight conditions caused by low velocity. As a result, most of <strong>the</strong> energy comes from<strong>the</strong> propelling force instead of inertia. These conditions usually meant ordering special<strong>shock</strong>s with larger bore sizes, stop tubes and heavier oils, resulting in longer leadtimes and higher prices. With SILVERLINE ® <strong>shock</strong> absorbers, it is no longernecessary to order special models. <strong>Enertrols</strong> solves <strong>the</strong>se problemswith lower-cost, standard, off-<strong>the</strong>-shelf products.Any application position (rotary, vertical, horizontal and incline)where low velocity and high effective weight exists, is an excellentapplication for <strong>Enertrols</strong> SILVERLINE ® <strong>shock</strong> absorbers. Theyare designed to operate in a velocity range of 0.25 to 2.0 fps and inan effective weight range of 300 lbs to 3,175,000 lbs maximum. Allmodels use standard weight hydraulic oil for fast rod return on high cycling applications.19mm & 28mm Bore High-Precision Metric (HPM) Fixed Flange SeriesThis series of fixed-flange adjustable <strong>shock</strong> absorbers israpidly becoming an international automotive standard. Theyprovide an exceptional high-positioning accuracy - positiveset-down positioning repeatable within +/- .05mm - wi<strong>the</strong>asy "bolt-in place" installation. They are interchangeable withall <strong>Enertrols</strong> Gold Line ® Primary Mount <strong>shock</strong> absorbers withscrew-on flanges and all standard <strong>Enertrols</strong> Gold Line ® weldedflange models, as well as o<strong>the</strong>r manufacturers models of <strong>the</strong>same bore size.Welded front flange models are equipped with positive stopbars. Welded rear flange models are equipped with <strong>Enertrols</strong>positive stop collars. There are 14 models available in twoconfigurations, two bore sizes and three stroke lengths.Four models are available for Low-Velocity applications(0.25 to 2.0 fps).General Information1 1/8" Bore Quick-Change Mount Shock Absorber<strong>Enertrols</strong> patented QCM (Quick-Change Mount)adjustable hydraulic <strong>shock</strong> absorber is designed todirectly replace existing <strong>shock</strong> absorbers onhorizontal extractors, shuttles, loaders andunloaders. Easy, fast removal and reinstallationof <strong>the</strong> QCM <strong>shock</strong> is its major feature.Since it is a true linear decelerator, <strong>the</strong> QCM unitreduces deceleration time and increases cycle rates.It also reduces impact forces at <strong>the</strong> end-of-stroke,even with today's high shuttle speeds. There are nothreads to nick or trap weld flash and o<strong>the</strong>rcontaminants.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com6

Accessories & Special Application Shock AbsorbersPoly Pads<strong>Enertrols</strong> Poly Pads (shown installed on a ¾"- bore GoldLine Primary Mount <strong>shock</strong> absorber) are available infive sizes to fit securely over <strong>the</strong> piston rod button ofall 3/8", 1/2", 3/4", 1 1/8" and 1 1/2" bore-size models.They are made of tough, long-wearing polyurethane toreduce noise and/or marring of <strong>the</strong> object impacting on<strong>the</strong> steel button.Standard Air-Over-Oil Tanks<strong>Enertrols</strong> Air-over-Oil Tanks (AOT) are available in <strong>the</strong> fourstock sizes shown for use with all ALD and ALDS models,½" through 4"-bore sizes. The three largest tanks are madeof high-strength steel, use no soft seals and have easy-toreadsight gauges.Tow Bar Snubbers<strong>Enertrols</strong> tow bar snubbers are ideal for use on highspeedmaterial handling systems. The higher speedsutilized today on power and free handling systems greatlyincrease <strong>the</strong> potential for both product and/or systemdamage due to <strong>the</strong> rapid acceleration/deceleration speedsgenerated.The tow bar snubber is designed to absorb and smoothrapid acceleration/deceleration when starting and stopping.This prevents stretching and compressing load conditions,reduces maintenance and increases <strong>the</strong> up-time of <strong>the</strong>material handling system.723435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

PSS Positive Stop Systemsfor Gold Line ® & SILVERLINE ® Shock AbsorbersMounting Stop Collars<strong>Enertrols</strong> Mounting Stop Collar (MSC), shown installed on a GoldLine ® Primary-Mount Series <strong>shock</strong> absorber. The MSC provides asecure front mounting with an integral, tamper proof positive stop.The FSC Flanged Stop Collar (not shown) provides a front flangetype mount with an integral positive stop. Available to fit all GoldLine ® and SILVERLINE ® Primary-Mount Models.Positive Stop Collars<strong>Enertrols</strong> Positive Stop Collar (PSC) shown, installed on aGold Line ® Primary-Mount Series (also for SILVERLINE ®Primary-Mount Models.) It is not used to mount <strong>the</strong> unit,but only to establish a fixed, tamper proof work-positioningpoint that also provides a positive stop to protect <strong>the</strong> <strong>shock</strong>absorber from bottoming out. You do not need to calculateclearance to prevent bottoming out. It's automatic!Positive Stop Bars and Collars<strong>Enertrols</strong> Positive Stop Collars and Bars establish a fixed work-positioningpoint with no need to calculate clearance to prevent bottoming out of GoldLine ® Fixed Flange and SILVERLINE ® Fixed Flange <strong>shock</strong> absorbers. Theyare not used to mount <strong>the</strong> <strong>shock</strong> absorber. The precision-machinedand hardened steel bars are securely bolted to <strong>the</strong> flange.Positive Stop Collars for Fixed Rear Flange models fit snugly over<strong>the</strong> front of <strong>the</strong> <strong>shock</strong> absorber body. Set screws secure <strong>the</strong> collarafter a recessed shoulder is located against <strong>the</strong> <strong>shock</strong> absorber.This collar also aids in protecting <strong>the</strong> return spring, rod and sealsfrom weld spatter, metal chips and o<strong>the</strong>r contaminants.General Information23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com8

Selecting <strong>the</strong> Correct Type of Shock AbsorberBefore beginning <strong>the</strong> manual ma<strong>the</strong>matical calculations to determine <strong>the</strong> correct size <strong>shock</strong> absorber you need, <strong>Enertrols</strong>suggests first considering <strong>the</strong> type, style and options that will be best suited to your application.<strong>Enertrols</strong> also offers and recommends using <strong>the</strong> <strong>Enertrols</strong>Size software program available on CD-ROM or fordownloading from <strong>the</strong> <strong>Enertrols</strong> website at www.enertrols.comIf you prefer, <strong>Enertrols</strong> will size your application for you. There is no charge for this service. Simply contact<strong>Enertrols</strong> Applications Department at 734-595-4500.Full Threaded-Body TypeThese <strong>shock</strong> absorbers offer real mounting versatility. Stud mounting,in or through a threaded hole; universal mounting brackets,threaded on and locked anywhere on <strong>the</strong> body allow you toinstall <strong>the</strong>se miniature units almost anywhere. Available in bothadjustable and self-compensating models.Primary Mounting TypeThis larger series also features versatility of mounting throughuse of optional accessories that are threaded on ei<strong>the</strong>r endof <strong>the</strong> <strong>shock</strong> absorber body and securely locked against amachine shoulder. Primary series units are heavily used inenvironments that require a number of different stylemountings of <strong>the</strong> same basic bore size and stroke length<strong>shock</strong> absorbers.Fixed Flange Mounting TypeConventional fixed flange <strong>Enertrols</strong> <strong>shock</strong> absorbers havepermanently attached flanges. They are ideally suited for useby cost-conscious OEM's using <strong>the</strong> same basic <strong>shock</strong>absorber in large volume. Positive set-down positioningwhen changing units is a major feature of this type.Type of Mounting<strong>Enertrols</strong> <strong>shock</strong> absorbers are available in a number ofmounting configurations to meet most any need. For fixed flange series you must specify front or rear mount flanges,which are available in square, rectangular, lug or clevis-type choices. Primary series do not require choice of front or rearmounting since you may thread flanges on ei<strong>the</strong>r end.Type of AccumulatorInternal accumulators are <strong>the</strong> most widely used and permit immediate installation and use with no piping or fittingrequired. High cycle rates and/or extremely high energy requirements may require an external accumulator for cooling<strong>the</strong> oil by recirculating it outside <strong>the</strong> <strong>shock</strong> absorber body.Type of Rod ReturnSpring return piston rods, used with internal accumulators, are <strong>the</strong> most common type. Air (or mechanical) returns,used with external accumulators, permit delayed rod return type installations where required.Type of OptionsCertain types of options should also be selected at this time: positive stop collars, mounting stop collars and positivestop bars have been among <strong>Enertrols</strong> fastest growing options items. They provide a unique, tamper proof positive stopthat establishes an accurate work-positioning point. These attachments also prevent impact damage that might becaused by bottoming <strong>the</strong> <strong>shock</strong> absorber piston. As standard, stock items, <strong>the</strong>y also eliminate <strong>the</strong> cost to design andfabricate external positive stops into your system.Poly pads, molded polyurethane pads that snap over <strong>the</strong> hardened steel impact button of our <strong>shock</strong> absorbers, preventmarring of <strong>the</strong> object being stopped and help reduce noise.On-board proximity sensors are available for most of <strong>the</strong> <strong>shock</strong> absorbers in <strong>the</strong> <strong>Enertrols</strong> line. They electronically signal<strong>the</strong> end-of-stroke, or home position of <strong>the</strong> piston rod to control interlocking motions, devices, etc.923435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Selecting <strong>the</strong> Correct Model Shock AbsorberThe model type of an <strong>Enertrols</strong> <strong>shock</strong> absorber is determined by:• Type of accumulator–self-contained or external air/oil tank (AOT)• Method of piston rod return–spring, air or mechanicalModel and mounting selection are usually determined by <strong>the</strong> application. Self-contained models are generallypreferred over <strong>the</strong> external accumulator-equipped models. They are pre-filled at <strong>the</strong> factory and ready to use whenreceived. No external piping or o<strong>the</strong>r system components are required.Because <strong>Enertrols</strong> <strong>shock</strong>s stop a moving object in less time than non-linear decelerating devices, you shouldselect a unit with <strong>the</strong> longest possible stroke that can be accommodated without exceeding side-loading limits.This will minimize impact forces on <strong>the</strong> mounting structure and <strong>the</strong> moving object being stopped.AccumulatorsWith internal accumulator models, <strong>the</strong> fluiddisplaced by <strong>the</strong> piston rod under impact isforced against a nitrogen-filled, closed cellsponge in <strong>the</strong> body of <strong>the</strong> <strong>shock</strong> absorber. As <strong>the</strong>piston rod is returned, <strong>the</strong> sponge expands tohelp force fluid back into <strong>the</strong> high-pressure tube.Where conditions permit, internal accumulatormodels are preferred.Where more energy per hour (E 4), or heatdissipation is needed, as found in high duty-cycleapplications, or high-temperature environments,external accumulator models should be used.The external accumulator is a tank or reservoir,ei<strong>the</strong>r open or closed to atmosphere, that isconnected to <strong>the</strong> <strong>shock</strong> absorber with appropriatesize piping. The oil flows back and forthbetween it and <strong>the</strong> <strong>shock</strong> absorber, helping tocool <strong>the</strong> oil as <strong>the</strong> unit is cycled. The air/oil tank(AOT) of external accumulator-equipped modelsmust be above <strong>the</strong> <strong>shock</strong> absorber and shouldbe located as close to <strong>the</strong> <strong>shock</strong> absorber aspossible. A 10-micron filter, installed between <strong>the</strong>exit of <strong>the</strong> air/oil tank and <strong>the</strong> <strong>shock</strong> absorber, isrecommended.Type ofAccumulatorMethod ofPiston Rod ReturnInternal Spring SAModelInternal Spring SALDExternal Air (or Mechanical) ALDInternal Mechanical ALDAExternal Spring ALDSInternal Spring (self-compensating) SMInternal Spring (self-compensating) SNALDExternal Air or Mech. (self-compensating) NALDInternal Spring (SILVERLINE) SASLExternal Air (SILVERLINE) ASLExternal Spring (SILVERLINE) ASLSInternal Mechanical (SILVERLINE) ASLAGeneral InformationIf <strong>the</strong> AOT must be located at a substantial distance from <strong>the</strong> <strong>shock</strong> use a positive oil recirculation circuit (Fig 2B).O<strong>the</strong>rwise, oil may simply move back and forth in <strong>the</strong> lines and never reach <strong>the</strong> tank to be cooled.Piston Rod ReturnThe return of <strong>the</strong> piston rod is accomplished in one of three ways (spring, air/oil, or mechanically). Mechanicalreturns usually make use of clevis-mounting designs and may be operated by a lever arm actuated by some o<strong>the</strong>rmoving part of <strong>the</strong> equipment. On self-contained models, or air/oil models with a spring, an externally mountedspring returns <strong>the</strong> rod when <strong>the</strong> load is removed.FIGURE 2A B CIn external accumulator models, an air/oil system, or some o<strong>the</strong>rmechanical means, must be used to return <strong>the</strong> piston rod. ALD modelspermit a variable rate of rod return, time delay and/or lower rod returnforces. This is accomplished by adding a pressure regulator (Fig. 2B)to <strong>the</strong> air/oil system, or by adding a 3-way valve and pressure regulator(Fig. 2C) to <strong>the</strong> system.ALDS models are shipped with a rod return spring installed. Thus, even when an external accumulator is used toimprove heat dissipation, it need not be pressurized. The spring will provide <strong>the</strong> necessary rod return force. Forbest results, <strong>the</strong> accumulator should be vented to <strong>the</strong> atmosphere with a filter/brea<strong>the</strong>r unit. Recommended airpressure for air oil tanks is 70-100 psi depending on <strong>the</strong> application.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com10

Selecting <strong>the</strong> Correct Size Shock AbsorberThere are a number of factors that must be considered when selecting a hydraulic <strong>shock</strong> absorber. First, determine howmuch energy must be dissipated during each deceleration stroke (cycle). Second, find <strong>the</strong> total amount of energy thatmust be dissipated during one hour of operation. Third, be sure to consider <strong>the</strong>effective weight of your application.The formulas used to determine <strong>the</strong> amount of kinetic energy per cycle are derived from <strong>the</strong> equationKE=½MV². When used in <strong>the</strong> form KE=0.2WV², <strong>the</strong> equation yields an answer in inch-lbs thatcan be correlated directly to <strong>the</strong> <strong>shock</strong> absorber energy rating charts. A movingobject's energy will always consist of ei<strong>the</strong>r pure inertia, or a combination of thatinertia and a propelling force.Sub-Miniature and Miniature full threaded-body adjustable <strong>shock</strong> absorbers are ideal for small, motor-driven, linearapplications such as business machines (copiers, scanners & printers).<strong>Enertrols</strong> Primary Mounting Series <strong>shock</strong>s are most widely used models because of <strong>the</strong>ir versatility and energy capacityratings. You can install <strong>the</strong>m almost anywhere and handle impact loads from 10 to 150,000 lbs of Effective Weight.You might think slow-moving loads (less than 2 ft./second) wouldn'tpresent much of a <strong>shock</strong> problem. Not so! In fact <strong>the</strong>yare one of <strong>the</strong> toughest to handle. Most applicationsinvolving rotary motions are slow movers.<strong>Enertrols</strong> developed its SILVERLINE ®Series especially for <strong>the</strong>se applications.When you need heavy-duty, <strong>Enertrols</strong>Gold Line ® Fixed Flange <strong>shock</strong>s and 2,3 & 4" bore models are your answer. Energy per cycle ratings range from3,000 in-lbs (339 Nm) to 1,120,000 in-lbs (126,500 Nm). You'll find a lot of <strong>the</strong>m on vertical, horizontal and inclined planefree-falling applications.Basic FormulasE 1= 0.2WV² (or W x H for free falling objects) in. -lbs.E 2= F x S (or W x S for free-falling objects) in. -lbs.E 3= E 1+ E 2in.-lbs.E 4= E 3x C (cycles/hour) in.-lbs./hr.V = √5.36 x Hg = .2 x V²SV = Dis in feettV = 2 x Dis in feettF = D² x .78 x PSIF = 1375 x HPVt = S6Vdetermines velocity of free-fallingobject-ft./sec.to determine G force, or stroke (S)to determine impact velocity whenweight is moving at a constant speedover a distance-ft./sec.to determine impact velocity whenweight is accelerating over a distancefrom a stopped position-ft/sec.to determine cylinder force in poundsto determine Propelling Force inpounds when using an Electric Motorstopping time through strokeEnergy Calculation Symbolst = Time in secondsS = Shock absorber stroke in inchesRs = Radius to <strong>shock</strong> absorber in inchesRc = Radius to cylinder in inchesK = Radius to center of gravity (c.g.)V = Impact velocity in feet/secondg = Deceleration in G'sD = Diameter in inchesDis = Distance in feetW = Weight in pounds (lbs.)WE = Effective Weight (lbs.)H = Height in inches (in.)F = Propelling Force (lbs.)C = Cycles per hourE 1= Inertial energy (in.-lbs./cycle)E 2= Propelling Force energy (in.-lbs./cycle)E 3= Total energy per cycleE 4= Total energy to be dissipated per hourPSI = Pressure (pounds per square inch)HP = HorsepowerT = Torque (in.-lbs.)L = Distance (in.)1123435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Example 4Moving Load No Propelling Force(W) WEIGHT(V) VELOCITYModel Selection: SALD 1-1/8 x 4STROKE(INCHES)W = 1,950 lbs.V = 5 ft./sec.F = 0C = 200/hr.E 1= .2WV² = .2 x 1,950 x 5² = 9,750 in-lbs.E 2= 0E 3= E 1+ E 2= 9,750 in.-lbsE 4= E 3x C = 9,750 x 200 = 1,950,000 in.-lbs./hr.WE = E 3/ [.2V²] = 1,950Example 5Moving Load With Propelling ForceCYLINDER: BORE DIA.PRESSURE(W) WEIGHT(V) VELOCITYModel Selection: SALD 1-1/8 x 2STROKE(INCHES)W = 1,950 lbs.V = 5 ft./sec.Cyl. Dia = 2 in.PSI = 80S = 2 in. *C = 100/hr.E 1= .2WV² = .2 x 1,950 x 5² = 9,750 in-lbs.F = Cyl. Force = .78 x D² x PSI = .78 x (2)² x 80 = 250 lbs.E 2= F x S = 250 x 2 = 500 in.-lbs.E 3= E 1+ E 2= 9,750 + 500 = 10,250 in.-lbs.E 4= E 3x C = 10,250 x 100 = 1,025,000 in.-lbs./hr.WE = E 3/ [.2V] = 10,250 / [.2(5)²] = 2,050 lbs.Example 6Moving Load Motor Driven(V) VELOCITY(W) WEIGHTModel Selection: SALD 1-1/8 x 2MOTOR RATING HPSTROKEW = 1,950 lbs.V = 5 ft./sec.HP= 1 HorsepowerS = 2 in. *C = 100/hr.E 1= .2WV² = .2 x 1,950 x 5² = 9,750 in-lbs.F = 1,375 x HP / [V] = 1,375 x 1 / [5] = 275 lbs.E 2= F x S = 550 in.-lbs.E 3= E 1+ E 2= 9,750 + 550 = 10,300 in.-lbsE 4= E 3x C = 10,300 x 100 = 1,030,000 in.-lbs./hr.WE = 10,300 / [.2V²] = 2,060 lbs.Example 7Moving Load Propelled by Drive Rollers (Chain/Belt Drive Conveyor)(W) WEIGHT(V) VELOCITYCOEFFICIENT OF FRICTIONSTROKEModel Selection: SALD 1-1/8 x 2*Note: These items will vary with individual applicationsand were selected for illustration purposes only.W = 1,950 lbs.V = 5 ft./sec.F = Coefficient of friction x WCoefficient of friction in thisexample = .18S = 2 in. *C = 100/hr.E 1= .2WV² = .2 x 1,950 x 5² = 9,750 in-lbs.E 2= F x S = (.18 x W) x 2 = 702 in.-lbs.E 3= E 1+ E 2= 9,750 + 702 = 10,452 in.-lbs.E 4= E 3x C = 10,452 x 100 = 1,045,200 in.-lbs./hr.WE = E 3/ [.2V] = 10,452 / [.2(5)²] = 2,090 lbs.Example 8Moving Load Down an Inclined Plane13(W) WEIGHTDISTANCE(INCHES)Model Selection: SALD 1½ x 2AºSTROKEW = 1,950 lbs.Angle of Incline = 15ºL = Distancetraveled= 30 in.S = 2 in. *C = 100/hr.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.comE 1= W x Sin A x L = 1,950 x .26 x 30 = 15,210 in-lbs.E 2= W x Sin A x S = 1,950 x .26 x 2 = 1,014 in-lbs.E 3= E 1+ E 2= 15,210 + 1,014 = 16,224 in.-lbsE 4= E 3x C = 16,224 x 100 = 1,622,400 in.-lbs./hr.VS = √ 5.36 x (SinA) x L = √ 5.36 x .26 x 30 = 6.4 ft./sec.WE = E 3/ [.2VS²] = 16,224 / [.2(6.4)²] = 1980 lbs.

Example 9Horizontal-Moving Load-RotaryDISTANCE FROMPIVOTTO CENTEROF GRAVITY(INCHES)WEIGHTModel Selection: SALD ½ x 1SHOCK ABSORBERMOUNTING RADIUS(INCHES)K = Distance to C.G.from Pivot = 30 in.cW = 900 lbs.A = Rotation angle = 90ºt = Time thru angle = 3 secRs = Shock absorber mtg.radius = 29 in.F = 0S = 1 in. *C = 100/hr.Vs = Vel. @ Rs (ft./sec.)Velocity of Load =(A x K) / [688t] = 90 x 30 / [688 x 3] = 1.31 ft./sec.E 1= .2WV² = .2 x 900 x (1.31)² = 309 in-lbs.E 2= 0E 3= E 1+ E 2= 309 in.-lbs.E 4= E 3x C = 309 x 100 = 30,900 in.-lbs./hr.VS = (A x RS) / [688t] = 90 x 29 / [688 x 3] = 1.26 ft./sec.WE = E 3/ [.2VS²] = 309 in.-lbs. / [.2(1.26)²] = 973 lbs.Example 10Horizontal-Propelled Moving Load-RotaryMOTOR DRIVEW = 900 lbs.E 1= .2WV² = .2 x 900 x 4² = 2,880 in.-lbs.TORQUEK = Distance to C.G.VS = V x Rs / [K] = 4 x 29 / [30] = 3.87 ft./sec.from Pivot = 30 in.(V) VELOCITYF = 1,375 x HP / [ Vs ] = 1,375 x 1 / [3.87] = 355 lbs.V = Linear VelocityDISTANCE FROME 2= F x S = 355 x 2 = 710 in.-lbs.PIVOT TO CENTERSHOCK ABSORBER at C.G. = 4 ft./sec.OF GRAVITYMOUNTING RADIUS(INCHES) Rs = 29 in.E 3= E 1+ E 2= 2,880 + 710 = 3,590 in.-lbsS = 2 in. *E 4= E 3x C = 3,590 x 100 = 359,000 in.-lbs./hr.WEIGHTC = 100/hr.WE = E 3/ [.2VS²] = 3,590 / [.2(3.87)²] = 1,199 lbs.HP = 1 HorsepowerVs = Vel. @ Rs (ft./sec.)Model Selection: SALD ¾ x 2*Note: These items will vary with individual applications and were selected for illustration purposes only.Example 11Horizontal-Rotary Index TableANGULAR VELOCITY(RADIANS/SEC.)(W) TABLEWEIGHTROTARY TABLE DIA.STROKESHOCK ABSORBERMOUNTINGRADIUS (INCHES)W = 900 lbs.V T= 4 ft./sec. at 36 in.from PivotC = 100/hr.F = 0Rs = 30 in.DT = Table Dia. = 72 in.RT = 36 in.Vs = Vel. @ Rs (ft./sec.)E 1= .1WVT² = .1 x 900 x 4² = 1,440 in-lbs.E 2= 0E 3= E 1+ E 2= 1,440 in.-lbs.E 4= E 3x C = 1,440 x 100 = 144,000 in.-lbs./hr.VS = (VT x RS) / [RT] = (4 x 30) / [36] = 3.3 ft./sec.WE = E 3/ [.2VS] = 1,440 / [.2(3.3)²] = 661 lbs.General InformationModel Selection: SALD ½ x 2Example 12Horizontal-Rotary Index Table PropelledMOTOR DRIVETORQUEωANGULAR VELOCITYROTARY TABLE DIA.(W) TABLE WEIGHTRTRSSHOCK STROKE(INCHES)SHOCK ABSORBERMOUNTINGRADIUS (INCHES)W = 900 lbs.w = 2 Radians/sec.T = 1,500 in.-lbs. at tableS = 2 in. *C = 100/hr.Rs = 30 in.RT = Radius of table = 36 in.Vs = Vel. @ Rs (ft./sec.)VT = (w x RT) / [12] = (2 x 36) / [12] = 6 ft./sec.E 1= .1WVT² = .1 x 900 x 6² = 3,240 in-lbs.F = T / RS = 1,500 / 30 = 50 lbs.E 2= F x S = 50 x 2 = 100 in.-lbs.E 3= E 1+ E 2= 3,240 + 100 = 3,340 in.-lbs.E 4= E 3x C = 3,340 x 100 = 334,000 in.-lbs./hr.VS = (w x RS) / [12] = 2 x 30 / [12] = 5 ft./sec.WE = E 3/ [.2VS²] = 3,340 / [.2(5)²] = 668 lbs.Model Selection: SALD ¾ x 2*Note: These items will vary with individual applications and were selected for illustration purposes only.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com14

Example 13Vertical-RotaryWEIGHTDISTANCE FROMPIVOT TO CENTEROF GRAVITY(INCHES)SHOCK ABSORBERMOUNTINGRADIUS (INCHES)W = 500 lbs.K = Distance to C.G. = 34 in.V = 4 ft./sec. @ 34 in.Rs = Shock absorber mtg.radius = 32 in.S = 2 in. *C = 100/hr.Vs = Vel. @ Rs (ft./sec.)E 1= .2WVT² = .2 x 500 x 4² = 1,600 in-lbs.F = (W x K) / RS = 500 x 34 / 32 = 531 lbs.E 2= F x S = 531 x 2 = 1,062 in.-lbs.E 3= E 1+ E 2= 1,600 + 1,062 = 2,662 in.-lbs.E 4= E 3x C = 2,662 x 100 = 266,200 in.-lbs./hr.VS = V x RS / [K] = 4 x 32 / [34] = 3.76 ft./sec.WE = E 3/ [.2VS ] = 2,662 / [.2(3.76)²] = 941 lbs.STROKE(INCHES)Model Selection: SALD ¾ x 2Example 14Vertical-Rollover-Turn OverROTATIONROLLOVERPARTVELOCITYW = 1,500 lbs.A = 180º Angle of RotationRs = 62 in.T = 12,000 in.-lbs.S = 2 in. *C = 100/hr.RR = 60 in. Radius of RolloverVR = Vel. @ RR (ft./sec.)Vs = Vel. @ Rs (ft./sec.)t = 3 sec. Time of RotationVR = RR x A / [688t] = 60 x 180 / [688 x 3] = 5.24 ft./sec.E 1= .1WVR² = .1 x 1,500 x 5.24² = 4,119 in-lbs.F = T / [RS] = 12,000 / [62] = 194 lbs.E 2= F x S = 194 x 2 = 388 in.-lbs.E 3= E 1+ E 2= 4,119 + 388 = 4,507 in.-lbs.E 4= E 3x C = 4,507 x 100 = 450,700 in.-lbs./hr.VS = RS x A / [688t] = 62 x 180 / [688 x 3] = 5.4 ft./sec.WE = E 3/ [.2VS] = 4,507 / [.2(5.4)²] = 722 lbs.Model Selection: SALD 1½ x 2*Note: These items will vary with individual applications and were selected for illustration purposes only.Example 15Horizontal Application Moving Load- Rotary Table Motor Driven with Additional Load InstalledDRIVETORQUE(T)(W)WEIGHTANGULARVELOCITYRLRTSHOCKSTROKEWLRSW = 440 lbs.WL= Additional weight = 100 lbs.RL= Radius to load C.G.from pivot – 8 in. *S = 1 in. *C = 1/hr.w = 1 radian/sec.Rs = 8.86 in.T = 2,200 in.-lbs.RT = 20 in.VT = Vel. @ RT (ft./sec.)VL = Vel. @ RL (ft./sec.)VS = Vel. @ RS (ft./sec.)VT = w x RT / [12] = 1 x 20 / [12] = 1.67 ft./sec.E 1 (TABLE)=.1WVT² = .1 x 440 x 1.67² = 123 in.-lbs.VL = w x RL / [12] = 1 x 8 / [12] = .67² = 9 ft./sec.E 1 (ADD 'L LOAD)= .2WLVL² = .2 x 100 x .67² = 9 in.-lbs.E 1 (TOTAL)= E 1 (TABLE)+ E 1 (ADD'L LOAD)= 123 + 9 = 132 in.-lbs.F = T / RS = 2,200 / 8.86 = 248 in.-lbs.E 2= F x S = 248 x 1 = 248 in.-lbs.E 3= E 1+ E 2= 132 + 248 = 380 in.-lbs.E 4= E 3+ C = 380 x 1 = 380 in.-lbs./hr.VS = w x (RS / 12) = 1 x 8.86 / [12] = .74 ft./sec.WE = E 3/ [.2VS²] = 380 / [.2(.74)²] = 3,470 lbs.15Model Selection: SALD ¾ x1 (Due to effective weight)23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Example 16Vertical-Rotating Beam Driven by Air CylinderωSRCKRSCyl Dia. = 3 in.PSI = 70w = 3 rad./sec.W = 1,900 lbs. at C.G.K = 20 in. to beam C.G.S = 2 in. *C = 100/hr.RS = 32 in.Vs = Vel. @ Rs (ft./sec.)Rc = 18 in.I = W x K² / [386] = 1,900 x 20² / [386] = 1,969 in.-lbs./sec.²F = .78 x D² x PSI x RC / [ RS ]= .78 x 3² x 70 x 18 / [32] = 276 lbs.E 1= I x w² / [2] = 1,969 / [2] x 3² = 8,861 in-lbs.E 2= F x S = 276 x 2 = 552 in.-lbs.E 3= E 1+ E 2= 8,861 + 552 = 9,413 in.-lbs.E 4= E 3x C = 9,413 x 100 = 941,300 in.-lbs./hr.VS = 0.83 x RS x w = 0.83 x 32 x 3 = 8.00 ft./sec.WE = E 3/ [.2VS²] = 9,413 / [.2(8)²] = 735 lbs.Model Selection: SALD 1-1/8 x 2*Note: These items will vary with individual applications and were selected for illustration purposes only.Example 17Vertical-Motor Driven Rotating Arm with Attached Load Opposing GravityαRSModel Selection: SALD ¾ x 2S(T) DRIVETORQUEKωW = 150 lbs.K = 36 in.Rs = 27 in.w = 3 rad./sec.a = 30ºT = 3,000 in.-lbs.S = 2 in. *C = 175/hr.Vs = Vel. @ Rs (ft./sec.)I = W / [386] x K² = 150 / [386] x 36² = 504 in.-lbs./sec.²F = T - W x K x Sin a / [RS] = 3,000 - (150 x 36 x 0.5) / 27 = 11 lbs.E 1= I x w² / [2] = 504 x 3² / [2] = 2,268 in-lbs.E 2= F x S = 11 x 2 = 22 in.-lbs.E 3= E 1+ E 2= 2,268 + 22 = 2,290 in.-lbs.E 4= E 3x C = 2,290 x 175 = 400,750 in.-lbs./hr.VS = .083 x RS x w = .083 x 27 x 3 = 6.72 ft./sec.WE = E 3/ [.2VS²] = 2,290 / [.2(6.72)²] = 254 lbs.General InformationExample 18Vertical-Motor Driven Rotating Arm with Attached Load Aided by Gravity(W)WEIGHTαSRSωK(T) DRIVE TORQUEW = 350 lbs.K = 36 in.Rs = 27 in.w = 3 rad./sec.a = 40ºT = 2,500 in.-lbs.S = 2 in. *C = 175/hr.Vs = Vel. @ Rs (ft./sec.)I = W x K² / [386] = 350 / [386] x 36² = 1,175 in.-lbs./sec.²F = T + W x K x Sin a / [RS]= 2,500 + (350 x 36 x .643) / [27] = 393 lbs.E 1= I x w² / [2] = 1,175 x 3² / [2] = 5,288 in-lbs.E 2= F x S = 393 x 2 = 786 in.-lbs.E 3= E 1+ E 2= 5,288 + 786 = 6,074 in.-lbs.E 4= E 3x C = 6,074 x 175 = 1,062,950 in.-lbs./hr.VS = 0.83 x RS x w = 0.83 x 27 x 3 = 6.72 ft./sec.WE= E 3/ [.2VS²] = 6,074 / [.2(6.72)²] = 673 lbs.Model Selection: SALD 1-1/8 x 2*Note: These items will vary with individual applications and were selected for illustration purposes only.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com16

Example 19Vertical Rotating Arm – Cylinder Driven (Push Type) with Attached Load Aided by GravityD (Cyl. Dia.) = 2.5 in.PSI = 80Rc = 15 in.W = 250 lbs. At C.G.K = 30 in.Rs = 25 in.w = 3 rad./sec.a = 45ºS = 2 in. *C = 100/hr.I = W / [386] x K² = 250 / [386] x 30² = 583 in.-lbs./sec.²T = .78 x D² x PSI x RC = .78 x 2.5² x 80 x 15 = 5,850 in. -lbs.F = T + W x K x Sin a / [RS]= 5,850 + (250 x 30 x 7.07) / [25] = 446 lbs.E 1= I x w² / [2] = 583 x 3² / [2] = 2,623 in-lbs.E 2= F x S = 446 x 2 = 892 in.-lbs.E 3= E 1+ E 2= 2,623 + 892 = 3515 in.-lbs.E 4= E 3x C = 3515 x 100 = 351,500 in.-lbs./hr.VS = 0.83 x RS x w = 0.83 x 25 x 3 = 6.23 ft./sec.WE = E 3/ [.2VS²] = 3515 / [.2(6.23)²] = 453 lbs.Model Selection: SALD ¾ x 2Example 20Vertical Rotating Arm – Cylinder Driven (Pull Type) with Attached Load Aided by GravityD (Cyl. Dia.) = 2.5 in.D1 (Cyl. Rod Dia.) = 1 in.PSI = 80Rc = 15 in.W = 250 lbs. At C.G.K = 30 in.Rs = 25 in.w = 3 rad./sec.a = 45ºS = 2 in. *C = 100/hr.Model Selection: SALD ¾ x 2*Note: These items will vary with individual applications and were selected for illustration purposes only.I = W / [386] x K² = 250 / [386] x 30² = 583 in.-lbs./sec.²T = ((.78 x D²) - (.78 x D 1²)) x PSI x RC =((.78 x 2.5²) - (.78 x 1²)) x 80 x 15 = 4,914 in.-lbs.F = T + (W x K x Sin a) / [RS] =4,914 + (250 x 30 x 7.07) / [25] = 409 lbs.E 1= I x w² / [2] = 583 x 3² / [2] = 2,623 in-lbs.E 2E 3E 4VSWE == F x S = 409 x 2 = 818 in.-lbs.= E 1+ E 2= 2623 + 818 = 3,441 in.-lbs.= E 3x C = 3.441 x 100 = 344,100 in.-lbs./hr.= .083 x RS x w = .083 x 25 x 3 = 6.23 ft./sec.E 3/ [.2VS²] = 3,441 / [.2(6.23)²] = 443 lbs.Example 21Vertical Rotating Arm – Cylinder Driven (Push Type) with Attached Load Opposing GravityD (Cyl. Dia.) = 2.5 in.PSI = 80Rc = 15 in.W = 150 lbs. At C.G.K = 30 in.Rs = 25 in.w = 3 rad./sec.a = 30ºS = 2 in. *C = 100/hr.I = W / [386] x K² = 150 / [386] x 30² = 350 in.-lbs./sec.²T = .78 x D² x PSI x RC = .78 x 2.5² x 80 x 15 = 5,850 in. -lbs.F = T - (W x K x Sin a) / [RS] = 5,850 - (150 x 30 x .5) / [25] = 144 lbs.E 1= I x w² / [2] = 350 x 3² / [2] = 1575 in-lbs.E 2= F x S = 144 x 2 = 288 in.-lbs.E 3= E 1+ E 2= 1,575 + 288 = 1,863 in.-lbs.E 4= E 3x C = 1,863 x 100 = 186,300 in.-lbs./hr.VS = .083 x RS x w = .083 x 25 x 3 = 6.23 ft./sec.WE = E 3/ [.2VS²] = 1,863 / [.2(6.23)²] = 240 lbs.Model Selection: SALD ½ x 21723435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Example 22Vertical Rotating Arm – Cylinder Driven (Pull Type) with Attached Load Opposing GravityD (Cyl. Dia.) = 2.5 in.D1 (Cyl. Rod Dia.) = 1 in.PSI = 80Rc = 15 in.W = 150 lbs. At C.G.K = 30 in.Rs = 25 in.w = 3 rad./sec.a = 30ºS = 2 in. *C = 100/hr.I = W x K² / [386] = 150 x 30² / [386] = 350 in.-lbs./sec.²T = ((.78 x D²) - (.78 x D 1²)) x PSI x RC =((.78 x 2.5²) - (.78 x 1²)) x 80 x 15 = 4,914 in.-lbs.F = T - (W x K x Sin a) / [RS]= 4,914 - (150 x 30 x .5) / [25] = 107 lbs.E 1= I x w² / [2] = 350 x 3² / [2] = 1,575 in-lbs.E 2= F x S = 107 x 2 = 214 in.-lbs.E 3= E 1+ E 2= 1,575 + 214 = 1,789 in.-lbs.E 4= E 3x C = 1,789 x 100 = 178,900 in.-lbs./hr.VS = .083 x RS x w = .083 x 25 x 3 = 6.23 ft./sec.WE = E 3/ [.2VS²] = 1,789 / [.2(6.23)²] = 231 lbs.Model Selection: SALD ½ x 2*Note: These items will vary with individual applications and were selected for illustration purposes only.Example 23Horizontal Rotary Load – Propelled by a CylinderD (Cyl. Dia.) = 2.5 in.PSI = 80Rc = 15 in.W = 900 lbs. At C.G.K = 30 in.Rs = 20 in.A = Rotation angle = 90ºt = 3 sec.S = 1 in. *C = 100/hr.Model Selection: SASL ¾ x 1 (Due to velocity and effective weight)V = A x K / [688t] = 90 x 30 [688 x 3] = 1.3 ft./secE 1= .2WV² = .2 x 900 x (1.3)² = 304 in.-lbs.F = .78 x D² x PSI x Rc / [RS] =.78 x 2.5² x 80 x 15 / [20] = 293 in.-lbs.E 2= F x S = 293 x 1 = 293 in.-lbs.E 3= E 1+ E 2= 304 + 293 = 597 in.-lbs.E 4= E 3x C = 597 x 100 = 59,700 in.-lbs./hr.VS = A x RS / [688t] = 90 x 20 / [688 x 3] = 0.87 ft./secWE = E 3/ [.2VS²] = 597 / [.2(.87)²] = 3,944 lbs.General InformationExample 24Horizontal Rotary Table – Propelled by a Cylinder, with or without additional loadD (Cyl. Dia.) = 2.5 in.PSI = 80Rc = 10 in.W = 440 lbs.RT = 20 in.RL = 8 in.WL= 100 lbs.Rs = 8.86 in.A = Rotation angle = 90ºt = 1 sec.S = 1 in. *C = 10/ hr.VT = A x RT / [688t] = 90 x 20 / [688 x 1] = 2.6 ft./secE 1(TABLE) = .1WVT² = .1 x 440 x (2.6)² = 297 in.-lbs.VL = A x RL / [688t] = 90 x 8 / [688 x 1] = 1.04 ft./secE 1(ADD'L LOAD) = .2 x 100 (1.04)² = 22 in.-lbs.E 1(TOTAL) = E (TABLE) + E (ADD'L LOAD) = 297 + 22 = 319 in.-lbs.1 1F = .78 x D² x PSI x Rc / [Rs]= .78 x 2.5² x 80 x 10 / [8.86] = 440 lbs.E 2= F x S = 440 x 1 = 440 in.-lbs.E 3= E 1+ E 2= 319 + 440 = 759 in.-lbsE 4= E 3+ C = 759 x 10 = 7,590 in.-lbsVS = A x Rs / [688t] = 90 x 8.86 / [688 x 1] = 1.16 ft./secWE = E 3/ [.2VS²] = 759 / [.2(1.16)²] = 2,820 lbs.Model Selection: SALD ¾ x 1*Note: These items will vary with individual applications and were selected for illustration purposes only.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com18

Example 25Inclined Plane – Moving Load Propelled Down by a CylinderD (Cyl. Dia.) = 2.5 in.PSI = 80V = 5 ft./sec.W = 500 lbs.A = Angle of incline = 15ºS = 2 in. *C = 100 / hr.E 1= .2WV² = .2 x 500 x (5)² = 2,500 in.-lbs.F = .78 x D² x PSI = 390 lbs.E 2= (F +(W x SinA)) x S =(390 + (500 x .26)) x 2 = 1,040 in.-lbs.E 3= E 1+ E 2= 2,500 + 1,040 = 3,540 in.-lbs.E 4= E 3x C = 3,540 x 100 = 354,000 in.-lbs./hr.WE = E 3/ [.2VS²] = 3,540 / [.2(5)²] = 708 lbs.Model Selection: SALD ¾ x 2Example 26Inclined Plane – Moving Load Propelled Up by a CylinderD (Cyl. Dia.) = 2.5 in.PSI = 80V = 5 ft./sec.W = 300 lbs.A = Angle of incline = 15ºS = 1 in. *C = 100 / hr.E 1= .2WV² = .2 x 300 x (5)² = 1,500 in.-lbs.F = .78 x D² x PSI = 390 lbs.E 2= (F - (W x SinA)) x S = (390 - (300 x .26)) x 1 = 312 in.-lbs.E 3= E 1+ E 2= 1,500 + 312 = 1,812 in.-lbs.E 4= E 3x C = 1,812 x 100 = 181,200 in.-lbs./hr.WE = E 3/ [.2VS²] = 1,812 / [.2(5)²] = 362 lbs.Model Selection: SALD ¾ x 1*Note: These items will vary with individual applications and were selected for illustration purposes only.<strong>Enertrols</strong>Size and 3D Solid Model CAD Files<strong>Enertrols</strong> sizing program, <strong>Enertrols</strong>Size, patterned in<strong>the</strong> spreadsheet format, enables you to select <strong>the</strong> proper<strong>industrial</strong> <strong>shock</strong> absorber or elastomeric bumper for yourapplication.The program is available on CD-ROM and soon willbe available for downloading from <strong>the</strong> <strong>Enertrols</strong> website.To receive a CD-ROM simply email <strong>Enertrols</strong> direct atcustomerservice@enertrols.com.If you prefer, <strong>Enertrols</strong> will size your application for you.There is no charge for this service. Contact <strong>Enertrols</strong>Applications Department at 734-595-4500.3D solid model CAD file drawings are availablefor downloading by visiting <strong>the</strong> <strong>Enertrols</strong> website atwww.enertrols.com.1923435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Model Rating ChartsShock Absorber Selection Suggestions...After determining <strong>the</strong> energy requirements of your applicationusing <strong>the</strong> formulas an examples on <strong>the</strong> previous pages, select <strong>the</strong> required model and stroke size from <strong>the</strong> charts below.<strong>Enertrols</strong> recommends that you select a model with 20% more capacity than your calculations indicate necessary.This extra capacity allows for changes if <strong>the</strong> weight, velocity or cycle rates increase in <strong>the</strong> future.<strong>Enertrols</strong> also recommends using <strong>the</strong> longest stroke possible when calculating. This will provide maximum decelerationperformance with <strong>the</strong> lowest impact forces. If you prefer, an <strong>Enertrols</strong> application engineer will size your applicationfor you and recommend <strong>the</strong> correct <strong>shock</strong> absorber for your linear deceleration requirement. There is no cost forthis service.Self-Compensating Sub-Miniature ModelsModel NumberSM 9M-1SM 9M-2SM 10ELSM 10EHSM 10MLSM 10MHSM 25LSM 25SM 25HSM 30M1SM 30M2SM 30M3SM 75-1SM 75-2SM 75-3Stroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 Nm0.20 9.00.200.2011.011.04.07.00.26 200.32 310.40 75WE (lbs.)Effective Weightlbs, 1 lb = .45 kg1.35 - 7.01.75 - 9.00.75 - 6.01.5-110.75 - 6.01.5 -111.5 - 5.04 -1210 -301.0 - 4.303.97 - 11.9011.02 - 33.070.5 - 2.52 - 146 - 80Self-Compensating Miniature ModelsModel NumberSNALD 150SNALD 150HSNALD 150H2SNALD 225SNALD 225HSNALD 225H2SNALD 450SNALD 450HSNALD 450H2SNALD 600SNALD 600HSNALD 600H2SNALD 1/2x1-S-1SNALD 1/2x1-S-2SNALD 1/2x1-S-3SNALD 1/2x1-S-4SNALD 1/2x2-S-1SNALD 1/2x2-S-2SNALD 1/2x2-S-3SNALD 1/2x2-S-4Stroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 Nm0.50 1500.50 2251.00 4501.00 6000.94 1,3501.94 2,700Adjustable Miniature ModelsModel NumberStroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 NmWE (lbs.)Effective Weightlbs, 1 lb = .45 kg2 - 2219 -190150 - 4505 - 5550 - 500400 - 2,0005 - 3520 - 13080 - 50020 - 300250 - 2,500880 - 5,00020 - 8068 - 272230 - 920780 - 3,12040 - 160136 - 544460 - 1,8401,560 - 6,240WE (lbs.)Effective Weightlbs, 1 lb = .45 kgE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulating18,000 N/A N/A35,000 N/A N/A35,000 N/A N/A200,000 N/A N/A50,000 N/A N/A250,000 N/A N/AE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulating300,000 N/A N/A400,000 N/A N/A600,000 N/A N/A600,000 N/A N/A750,000 N/A N/A870,000 N/A N/AE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulatingSA 30M 0.32 31 0.5 - 31.0 50,000 N/A N/ASA 35 0.40 35 13 - 125 53,000 N/A N/ASA 50M 0.28 50 10 - 45 120,000 N/A N/ASA 150 0.50 200 2 - 240 300,000 N/A N/ASA 1/4x1/2-S 0.50 200 2 - 240 400,000 N/A N/ASALD 3/8x1-S 1.00 600 10 - 1,200 600,000 N/A N/ASALD 1/2x1-S 1.00 1,500 10 - 3,000 750,000 N/A N/ASALD 1/2x2-S 2.00 3,000 21 - 6,000 870,000 N/A N/A23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com20General Information

Self-Compensating Mid-Size ModelsModel NumberSNALD 3325-1SNALD 3325-2SNALD 3325-3SNALD 3325-4SNALD 3350-1SNALD 3350-2SNALD 3350-3SNALD 3350-4SNALD 4525-1SNALD 4525-2SNALD 4525-3SNALD 4525-4SNALD 4550-1SNALD 4550-2SNALD 4550-3SNALD 4550-4SNALD 4575-1SNALD 4575-2SNALD 4575-3SNALD 4575-4SNALD 6450-1SNALD 6450-2SNALD 6450-3SNALD 6450-4SNALD 64100-1SNALD 64100-2SNALD 64100-3SNALD 64100-4SNALD 64150-1SNALD 64150-2SNALD 64150-3SNALD 64150-4Stroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 Nm0.91 1,3501.91 2,7000.91 3,0001.91 6,0002.91 9,0001.91 15,0003.91 30,0005.91 45,000WE (lbs.)Effective Weightlbs, 1 lb = .45 kg20 - 8068 - 272230 - 920780 - 3,12040 - 160136 - 544460 - 1,8401,560 - 6,24050 - 200170 - 680575 - 2,3001,950 - 7,800100 - 400340 - 1,3601,150 - 4,6003,900 - 15,600150 - 600510 - 2,0401,730 - 6,9205,850 - 23,400300 - 1,2001,020 - 4,0803,460 - 13,84011,700 - 46,800600 - 2,4002,040 - 8,1606,920 - 27,68023,400 - 93,600900 - 3,6003,060 - 12,24010.380 - 41,52035,100 - 140,400Adjustable Gold Line ® Primary ModelsModel NumberStroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 NmWE (lbs.)Effective Weightlbs, 1 lb = .45 kgE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulating670,000 1,100,000 1,500,00760, 000 1,200,000 1,600,000950,000 1,400,000 1,700,0001,000,000 1,700,000 2,200,0001,300,000 2,000,000 2,500,0001,300,000 2,600,000 3,400,0001,700,000 3,400,000 4,400,0002,200,000 4,400,000 5,700,000E4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulatingSALD 1/2x1-P 1.00 1,350 10 - 2,700 750,000 1,300,000SALD 1/2x2-P 2.00 2,700 21 - 5,400 870,000 1,400,000SALD 3/4x1-P 1.00 3,000 20 - 18,000 1,100,000 1,600,000SALD 3/4x2-P 2.00 6,000 35 - 32,000 1.300,000 2,000,000SALD 3/4x3-P 3.00 9,000 50 - 46,000 1,600,000 2,400,000SALD 1-1/8x2-P 2.00 16,000 120 - 50,000 1,500,000 3,000,000SALD 1-1/8x4-P 4.00 32,000 160 - 100,000 2,000,000 4,000,000SALD 1-1/8x6-P 6.00 48,000 200 - 150,000 2,500,000 5,000,000Adjustable Gold Line ® Fixed Flange Models21Model NumberStroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 NmWE (lbs.)Effective Weightlbs, 1 lb = .45 kg23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.comE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulatingSALD 3/4x1 1.00 3,000 20 - 18,000 1,100,000 1,600,000SALD 3/4x2 2.00 6,000 35 - 32,000 1,300,000 2,000,000SALD 3/4x3 3.00 9,000 50 - 46,000 1,600,000 2,400,000SALD 1-1/8x2 2.00 16,000 120 - 50,000 1,500,000 3,000,000SALD 1-1/8x4 4.00 32,000 160 - 100,000 2,000,000 4,000,000SALD 1-1/2x2 2.00 21,000 300 - 80,000 3,200,000 4,000,000SALD 1-1/2x3-1/2 3.50 36,750 350 - 120,000 5,600,000 7,000,000SALD 1-1/2x5 5.00 52,500 400 - 160,000 8,000,000 10,000,000SALD 1-1/2x6-1/2 6.50 68,250 450 - 200,000 10,400,000 13,000,000SALD 2-1/4x2 2.00 56,000 1,200 - 100,000 16,000,000 20,000,000SALD 2-1/4x4 4.00 112,000 1,500 - 200,000 20,000,000 25,000,000SALD 2-1/4x6 6.00 168,000 1,800 - 300,000 24,000,000 30,000,000SALD 2-1/4x8 8.00 224,000 2,100 - 410,000 28,000,000 35,000,000

Self-Compensating ECA ModelsModel NumberECA 2x2-1ECA 2x2-2ECA 2x2-3ECA 2x2-4ECA 2x4-1ECA 2x4-2ECA 2x4-3ECA 2x4-4ECA 2x6-1ECA 2x6-2ECA 2x6-3ECA 2x6-4ECA 2x8-1ECA 2x8-2ECA 2x8-3ECA 2x8-4ECA 2x10-1ECA 2x10-2ECA 2x10-3ECA 2x10-4ECA 3x5-1ECA 3x5-2ECA 3x5-3ECA 3x5-4ECA 3x8-1ECA 3x8-2ECA 3x8-3ECA 3x8-4ECA 3x12-1ECA 3x12-2ECA 3x12-3ECA 3x12-4Stroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 Nm2.00 32,0004.00 64,0006.00 96,0008.00 128,00010.00 160,0005.00 125,0008.00 200,00012.00 300,000WE (lbs.)Effective Weightlbs, 1 lb = .45 kg1,600 - 4,8004,000 - 12,00010,000 - 30,00025,000 - 75,0003,200 - 9,6008,000 - 24,00020,000 - 60,00050,000 - 150,0004,800 - 14,40012,000 - 36,00030,000 - 90,00075,000 - 225,0006,400 - 19,20012,000 - 36,00030,000 - 90,00075,000 - 225,0008,000 - 24,00020,000 - 60,00050,000 - 150,000125,000 - 375,0006,400 - 19,20016,000 - 48,00040,000 - 120,000100,000 - 300,00010,240 - 30,72025,600 - 76,80064,000 - 192,000160,000 - 480,00015,360 - 46,08038,400 - 115,20096,000 - 288,000240,000 - 720,000E4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulating9,600,000 12,000,000 15,600,00012,000,000 15,000,000 19,500,00014,400,000 18,000,000 23,500,0001,000,000 1,700,000 2,200,0001,300,000 2,000,000 2,500,0001,300,000 2,600,000 3,400,0001,700,000 3,400,000 4,400,0002,200,000 4,400,000 5,700,000ECA 4x6-3 6.00 420,000 8,000 - 19,000 27,000,000 45,000,000 58,000,000ECA 4x6-5 6.00 420,000 19,000 - 41,000 27,000,000 45,000,000 58,000,000ECA 4x6-7 6.00 420,000 41,000 - 94,000 27,000,000 45,000,000 58,000,000ECA 4x8-3 8.00 560,000 11,000 - 25,000 30,000,000 50,000,000 65,000,000ECA 4x8-5 8.00 560,000 25,000 - 55,000 30,000,000 50,000,000 65,000,000ECA 4x8-7 8.00 560,000 55,000 - 125,000 30,000,000 50,000,000 65,000,000ECA 4x16-3 16.00 1,120,000 22,000 - 50,000 50,000,000 80,000,000 110,000,000ECA 4x16-5 16.00 1,120,000 50,000 - 110,000 50,000,000 80,000,000 110,000,000ECA 4x16-7 16.00 1,120,000 110,000 - 250,000 50,000,000 80,000,000 110,000,000Adjustable EA ModelsModel NumberStroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 NmWE (lbs.)Effective Weightlbs, 1 lb = .45 kgE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulatingEA 2 x 2 2.00 32,000 560 - 170,000 9,600,000 12,000,000 15,600,000EA 2 x 4 4.00 80,000 510 - 160,000 12,000,000 15,000,000 19,500,000EA 2 x 6 6.00 120,000 570 - 190,000 14,400,000 18,000,000 23,500,000EA 2 x 8 8.00 170,000 580 - 200,000 16,800,000 21,000,000 27,000,000EA 2 x 10 10.00 210,000 720 - 250,000 19,200,000 24,000,000 31,000,000EA 3 x 5 5.00 140,000 1,050 - 340,000 20,000,000 25,000,000 32,500,000EA 3 x 8 8.00 250,000 1,200 - 400,000 32,000,000 40,000,000 52,000,000EA 3 x 12 12.00 390,000 1,350 - 450,000 48,000,000 60,000,000 78,000,000General InformationAdjustable SILVERLINE ® Models for Low Velocity,High Propelling Force ApplicationsModel NumberStroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 NmWE (lbs.)Effective Weightlbs, 1 lb = .45 kgE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulatingSASL 3/4x1 1.00 3,000 300 - 260,000 1,100,000 1,600,000SASL 3/4x2 2.00 6,000 350 - 500,000 1,300,000 2,000,000SASL 1-1/8x1 1.00 9,000 700 - 700,000 1,250,000 2,500,000SASL 1-1/8x2 2.00 16,000 850 - 1,300,000 1,500,000 3,000,000SASL 1-1/2x2 2.00 21,000 22,000 - 1,360,000 3,200,000 4,000,000SASL 2-1/4x2 2.00 56,000 50,000 - 3,175,000 16,000,000 20,000,00023435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com22

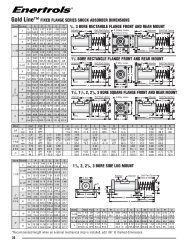

Adjustable High-Precision Metric (HPM) ModelsModel NumberStroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 NmWE (lbs.)Effective Weightlbs, 1 lb = .45 kgE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulatingHP-3000 1.00 3,000 20 - 18,000 1,100,000 1,600,000HP-6000 2.00 6,000 35 - 32,000 1,300,000 2,000,000HP-9000 3.00 9,000 50 - 46,000 1,600,000 2,400,000HP-16000 2.00 16,000 120 - 50,000 1,500,000 3,000,000HP-32000 4.00 32,000 160 - 100,000 2,000,000 4,000,000Adjustable High-Precision Metric HPSL (HPM) Series,Fixed Flange & Primary (-P)Model NumberStroke-Inches1 inch = 25.4 mmE3 Max. Energy/Cycleinch lbs1 in lb = .11 NmWE (lbs.)Effective Weightlbs, 1 lb = .45 kgE4 Max. Energy/Hour, in lbs/hour1 in lb/hour = .11 Nm/hourSelf Contained A/O Tank A/O Re-circulatingHPSL-3000 1.00 3,000 300 - 260,000 1,100,000 1,600,000HPSL-6000 2.00 6,000 350 - 500,000 1,300,000 2,000,000HPSL-8000 1.00 9,000 700 - 700,000 1,250,000 2,500,000HPSL-16000 2.00 16,000 850 - 1,300,000 1,500,000 3,000,000SNALD Mid-Size Emergency Shock Absorber RatingsWhat if your system fails, a runaway occurs or <strong>the</strong> limit switch malfunctions? SNALD Mid-Size <strong>shock</strong> absorbers can handle up to 5times <strong>the</strong> maximum energy for a single cycle or up to 3 times <strong>the</strong> maximum energy for 1,000 application cycles.SNALD 33 Series-Emergency RatingsSelf- Compensating Ratings Hydro Shock Ratings <strong>Main</strong> <strong>Catalog</strong> Maximum Energy RatingsModel Number1 CYCLE E3Energy/Cyclein lbs (Nm)1,000 CYCLES E3Energy/Cyclein lbs (Nm)1 CYCLE E3Energy/Cyclein lbs (Nm)1,000 CYCLES E3Energy/Cyclein lbs (Nm)E3 Energy/Cyclein lbs (Nm)SNALD 3325-1SNALD 3325-2SNALD 3325-3SNALD 3325-44,050 (459) 2,700 (306)6,750 (765)9,000* lbs(40,034 N)4,050 (459)5,800* lbs(25,800 N)1,350 (153)SNALD 3350-1SNALD 3350-2SNALD 3350-3SNALD 3350-48,100 (915) 5,400 (610)13,500 (1,525)10,500* lbs(46,706 N)8,100 (915)6,500* lbs(28,913 N)2,700 (305)*Maximum allowable reaction force.SNALD 45 Series-Emergency RatingsModel NumberSNALD 4525-1SNALD 4525-2SNALD 4525-3SNALD 4525-4SNALD 4550-1SNALD 4550-2SNALD 4550-3SNALD 4550-4SNALD 4575-1SNALD 4575-2SNALD 4575-3SNALD 4575-4Self- Compensating Ratings Hydro Shock Ratings <strong>Main</strong> <strong>Catalog</strong> Maximum Energy Ratings1 CYCLE E3Energy/Cyclein lbs (Nm)1,000 CYCLES E3Energy/Cyclein lbs (Nm)9,000 (1,017) 6,000 (678)*Maximum allowable reaction force.18,000 (2,034) 12,000 (1,356)27,000 (3,051) 18,000 (2,034)1 CYCLE E3Energy/Cyclein15,000 (1,695)24,000* lbs(106,757 N)24,000 (2,712)24,000* lbs(106,757 N)36,000 (4,067)24,000* lbs(106,757 N)1,000 CYCLES E3Energy/Cyclein lbs (Nm)9,000 (1,017)13,000* lbs(57,827 N)18,000 (2,034)13,000* lbs(57,827 N)27,000 (3,050)13,000* lbs(57,827 N)E3 Energy/Cyclein lbs (Nm)3,000 (339)6,000 (678)9,000 (1,017)2323435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Construction and Parts Descriptions for...Gold Line ® & SILVERLINE ® SeriesNote: This drawing appliesto all standard <strong>Enertrols</strong>1/2", 3/4", 1-1/8", 1-1/2",and 2-1/4" bore Gold Lineand SILVERLINE Series <strong>shock</strong>absorber internal parts.1. Outer Tube Assembly2. Graduated Dial3. Outer Tube4. Bearing Cartridge5. Bearing6. Rod Seal7. Seal Retainer8. Retaining Ring, Seal & Wiper9. Rod Wiper10.O-Ring11. Adjustor Assembly12. Adjustor13. Lock Screw14.Retaining Ring, Adjustor15.O-Ring16. Inner Tube Assembly17. Inner Tube18.O-Ring19.Retaining Ring, I.T./Bearing (2 Req.)20. Metering Tube21.Piston Rod Assembly22.Piston Rod23.Piston Ring24. Retaining Ring, Check Valve25. Check Valve Retainer26. Check Valve Ball27. Accumulator28. Return Spring29. Button Screw30. Button31. Port Plug32.Bleed Plug (Not Shown)General InformationOrdering Parts for <strong>Enertrols</strong>Shock Absorbers is EasyYou don't have to know part numbers to order repairor replacement parts from <strong>Enertrols</strong>. To simplify partsordering, all you have to do is:1. Identify <strong>the</strong> part name from <strong>the</strong> drawing above.2. Give us <strong>the</strong> part number, part name and modelnumber of your <strong>shock</strong> absorber. We'll ship it to you.Example:1. You need a new Button (#30 in drawing above.)2. You have a Model SALD 1-1/2x2R <strong>shock</strong> absorber.3. Tell us you need a part no. 30 (Button) for ModelSALD 1-1/2x2R.NOTE: Sub-Miniature and Miniature full threaded-bodymodels are non-repairable.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com24

Air/Oil Tank DimensionsDimensions in inches (millimeters)MODEL A B C D E F G H IAOT-3AOT-67.69(195)13.16(334)6.25(159)9.50(241)4.25(108)6.31(160)3.50(88.9)5.56(141)1.75(44.5)2.78(70.6)½-14NPT¾-14NPT¼-18NPT¾-14NPT½-14NPT¾-14NPT.41(10.3).66(16.7)External Accumulator CircuitsAir/Oil Systems provide a convenient way for additional heat dissipation and extends <strong>the</strong> cycles per hour capability of a<strong>shock</strong> absorber. Air/Oil Systems also can be used to extend <strong>the</strong> functionally of a <strong>shock</strong> absorber by delaying <strong>the</strong> pistonrod return.Units requiring an external accumulator, or fluidreservoir, are normally installed in one of threesystem configurations.Figure 1 is <strong>the</strong> simplest and is utilized purely forheat dissipation. The oil has a positive circulationpath to supply cool oil to <strong>the</strong> <strong>shock</strong> absorber.The air/oil tank may be ei<strong>the</strong>r closed, or openand vented through a filter brea<strong>the</strong>r unit. SpecifyFig. 1Fig. 2Fig. 3a spring or mechanical return <strong>shock</strong> absorbermodel with an external accumulator.Figure 2 provides a filtered, pressurized, positivecool oil circulation path. Specify an air orALDSALDALDmechanical return <strong>shock</strong> absorber model with anexternal accumulator. Operating pressure 50 to 100 PSI or 3.3 to 6.6 Bar.Figure 3 uses a solenoid valve to return <strong>the</strong> <strong>shock</strong> absorbers piston rod to <strong>the</strong> extended position on demand. The systemalso uses a filtered, pressurized, positive cool oil circulation path. Specify an air return <strong>shock</strong> absorber model with anexternal accumulator. Operating pressure 50 to 100 PSI or 3.3 to 6.6 Bar.25Installation Tips for Air/Oil Systems1. Do not install Air/Oil Systems with any <strong>shock</strong> that has an internal accumulator.2. Make certain that all air return <strong>shock</strong>s are used with an Air/Oil tank.3. Install <strong>shock</strong>s with <strong>the</strong> ports facing up and <strong>the</strong> Air/Oil Tank elevated above <strong>the</strong> <strong>shock</strong>s.4. Check for proper size tank, especially when using one (1) tank with two (2) <strong>shock</strong>s.5. Check tank for proper oil level and correct bleeding-approximately half-full.6. Do not allow a shut-off valve to be installed between <strong>the</strong> tank and <strong>the</strong> <strong>shock</strong>.7. Fittings and line size should be equal to or greater than <strong>the</strong> <strong>shock</strong> connection port.8. On recirculating installations, make sure <strong>the</strong> check valves are properly installed.9. Make sure incoming air is filtered to remove all water and contaminants.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com

Installation Recommendations and TipsMounting Structure Considerations<strong>Enertrols</strong> <strong>shock</strong> absorbers should be rigidly bolted to a non-flexing mounting structure. Refer to <strong>the</strong> "MountingStrength Required" column in <strong>the</strong> Energy Capacity table for <strong>the</strong> model you have selected.Avoid side loads of more than 5º (3º for miniature models) and align <strong>the</strong> centerline of <strong>the</strong> piston as closely aspossible to <strong>the</strong> impacting object's center of gravity. When using more than one <strong>shock</strong> absorber for a direction,be sure to balance <strong>the</strong> load as equally as possible between <strong>the</strong> <strong>shock</strong> absorbers.Rotary Installation RequirementsThe <strong>shock</strong> absorber should be mounted so that it is perpendicular to <strong>the</strong> pivot at mid stroke. This allows <strong>the</strong>maximum 5 degrees on <strong>the</strong> first 1/2 stroke and <strong>the</strong> maximum 5 degrees for <strong>the</strong> second 1/2. Miniature <strong>shock</strong>absorbers only are limited to plus or minus 3 degrees. Poly pads should not be used with rotary applications.Rs (Radius to Shock Absorber)Plus 5 degrees Maximum at ImpactPerpendicularat Mid-StrokeMinus 5 degrees Maximum at Set-DownaaStrokeFormulaS < *No. = aRsExternal Stop Recommendations+/- MaximumMounting Angle.0175 = 1/2º.0349 = 1º.0524 = 1-1/2º.0699 = 2º.0875 = 2-1/2º+/- MaximumMounting Angle.1051 = 3º.1228 = 3-1/2º.1405 = 4º.1584 = 4-1/2º.1763 = 5º*Miniature models; 3 degrees maximum, all o<strong>the</strong>rs 5 degrees maximumGeneral rule of thumb for minimum <strong>shock</strong> mount radius is a 6:1 ratio (Rs to S). For example with1 inch (25mm) of <strong>shock</strong> absorber stroke, <strong>the</strong> minimum “Rs” mount radius is 6 inches (150mm).Every type of automation equipment requires some form of external stop for two reasons; (1) to provide a firmwork positioning point and (2) to prevent <strong>the</strong> <strong>shock</strong> absorber from bottoming out. All <strong>shock</strong> absorber manufacturersrecommend to use an external stop to prevent damage to <strong>the</strong>ir product. <strong>Enertrols</strong> recommends <strong>shock</strong>absorber installations to use full stroke minus .06" or 1.6mm from <strong>the</strong> bottom of stroke.<strong>Enertrols</strong> "Positive Stop Systems" are easy to use and <strong>the</strong> most economical answer in new applications. ThePositive Stop Options provide a substantial, hardened steel work position stop (.06" or 1.6mm from bottom ofstroke) as well as <strong>shock</strong> absorber mounting arrangements. They are available for Gold Line ® , SILVERLINE ® ,Mid-Size, HPM, in Primary and Fixed Flange models.General InformationHow Short Stroking Affects a Shock Absorbers Performance<strong>Enertrols</strong> recommends choosing a <strong>shock</strong> absorber with <strong>the</strong> proper stroke and using <strong>the</strong> full stroke for deceleration.Short stroking a <strong>shock</strong> absorber produces undesirable, results, that may permanently damage <strong>the</strong> <strong>shock</strong> absorberas well as <strong>the</strong> equipment it is mounted on.Short stroking changes <strong>the</strong> intended function of a <strong>shock</strong> absorber so that it cannot be adjusted easily or properly.There will be a hard impact at <strong>the</strong> beginning of stroke. Velocity will not be dissipated sufficiently through stroke,allowing for a hard impact set down. The last problem incurred is overheating and or damage from excessiveinternal pressures produced by <strong>the</strong> energy and not using all <strong>the</strong> internal orifices as designed.23435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com26

Installation Recommendations and TipsMaking Shock Absorber Adjustments<strong>Enertrols</strong> <strong>shock</strong> absorbers are to be adjusted at installation start up. Shock absorbers are shipped with adjustment preset at90º, which is midway between "hard" and "soft". A properly adjusted <strong>shock</strong> absorber should show no noticeable impact at <strong>the</strong>beginning of <strong>the</strong> deceleration stroke and no hard set-down at <strong>the</strong> end of stroke.1. Starting with a properly sized and installed <strong>shock</strong> absorber.2. Loosen dial lock screw and set to mid range (number 9 on dial).3. Cycle <strong>the</strong> machine and observe: Hard bump end of stroke,adjust in gradual increments to a lower number. Hard bump atbeginning of stroke, adjust in gradual increments to a highernumber. Repeat procedure and adjust until no bump is noticedat ei<strong>the</strong>r end of stroke. In most installations, you will notbe able to see <strong>the</strong> actual deceleration when properly adjusted.4. Lock <strong>the</strong> dial set screw after final adjustment.5. If <strong>the</strong> final adjustment is set less than "2", a larger unit should beconsidered for <strong>the</strong> application.NOTE: Installations with 2 or more <strong>shock</strong>s; adjust simultaneously with final setting <strong>the</strong> same on each.General Installation Tips For All Applications1. Make certain you have properly sized and selected <strong>the</strong> <strong>shock</strong> absorber with appropriate mounting options for <strong>the</strong> application.2. Shock alignment must be set for <strong>the</strong> moving load to strike <strong>the</strong> button or rod squarely. The load contact should strike morethan half of <strong>the</strong> surface of <strong>the</strong> button or rod. Rotary applications refer to Tip number 15.3. The machine structure must be adequate for <strong>the</strong> application. Example: With a flange mount <strong>shock</strong> <strong>the</strong> attaching structureshould be at least as thick as <strong>the</strong> <strong>shock</strong> absorbers flange.4. For models or mounting options that do not include positive stops make certain <strong>the</strong> <strong>shock</strong> absorber piston does notbottom out at end of stroke. The <strong>shock</strong> absorber must be positioned to prevent piston travel 1/32" to 1/16" from bottom.Metric 0.75mm to 1.5mm from bottom stroke.5. Do not short stroke a <strong>shock</strong> absorber. The result will be excessive energy transmitted to <strong>the</strong> machine, overheating andpossible permanent damage <strong>the</strong> <strong>shock</strong> absorber.6. Mounting Stop Collar installations: make sure <strong>the</strong> attaching structure is <strong>the</strong> specified thickness for <strong>the</strong> <strong>shock</strong> installation.Failure may result in short stroke or bottoming out of <strong>the</strong> <strong>shock</strong> absorber.7. Check clearances of moving parts near <strong>the</strong> <strong>shock</strong> absorber to prevent damage.8. Check ambient temperature around <strong>shock</strong>s Over 125º F. or 52º C. Consult factory.9. Check for any foreign material that will affect <strong>the</strong> <strong>shock</strong>, such as chemicals, acids, steam, high degree of weld flash, abrasivedust, etc.10. Do not paint any part of a <strong>shock</strong> absorber. This may cause <strong>the</strong> piston rod to stick, oil to leak or overheating. All resulting inloss of functionality. Remove paint only with a material that will not have an effect on nitrite rubber, polyurethane or any sealingsurfaces.11. Never weld any part of a <strong>shock</strong> absorber.12. Make certain <strong>the</strong> personnel using <strong>the</strong> <strong>shock</strong> understand how <strong>the</strong> dial adjustment indicator works: LOWER NUMBER-moreresistance; HIGHER NUMBER-less resistance.13. If 2 or more <strong>shock</strong>s are used for one deceleration direction, <strong>the</strong> dial setting should be <strong>the</strong> same. Do not use different strokesor manufacturer brands toge<strong>the</strong>r.14. Air cylinders with cushions should be set fully open when used with <strong>shock</strong> absorbers.15. Rotary installations: <strong>shock</strong>s must be mounted to minimize side loads and located so <strong>the</strong>y are perpendicular to <strong>the</strong> rotatingload at mid-stroke. Maximum side load for miniature <strong>shock</strong>s are 3º all o<strong>the</strong>rs are 5º. Poly pads are not recommended to be usedin rotary applications.2723435 Industrial Park Dr., Farmington Hills, MI 48335 • p: 734-595-4500f: 734-595-6410 • customerservice@enertrols.com • www.enertrols.com