You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

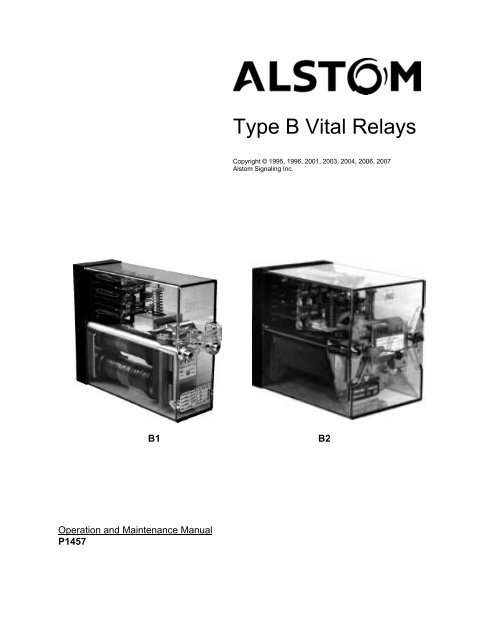

<strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong><br />

Copyright © 1995, 1996, 2001, 2003, 2004, 2006, 2007<br />

<strong>Alstom</strong> Signaling Inc.<br />

B1<br />

B2<br />

Operation and Maintenance Manual<br />

P1457

<strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong><br />

Copyright © 1995, 1996, 2001, 2003, 2004, 2006, 2007<br />

<strong>Alstom</strong> Signaling Inc.<br />

B1<br />

B2<br />

Operation and Maintenance Manual<br />

<strong>Alstom</strong> Signaling Inc.<br />

P1457, Rev. November 2007, Printed in U.S.A.

LIST OF EFFECTIVE PAGES<br />

P1457, <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong> Operation and Maintenance Manual<br />

ORIGINAL ISSUE DATE: May 1995<br />

CURRENT REVISION AND DATE: November 2007<br />

CURRENT CHANGE AND DATE: November 2007<br />

− Update Biased-Neutral Relay Test Procedure<br />

PAGE<br />

Cover<br />

Title page<br />

Preface<br />

i thru viii<br />

CHANGE OR REVISION LEVEL<br />

Nov/07<br />

Nov/07<br />

Nov/07<br />

Nov/07<br />

1–1 thru 1–16 Nov/07<br />

2–1 thru 2–50 Nov/07<br />

3–1 thru 3–16 Nov/07<br />

4–1 thru 4–22 Nov/07<br />

5–1 thru 5–10 Nov/07<br />

6–1 thru 6–28 Nov/07<br />

7–1 thru 7–68 Nov/07<br />

A–1 thru A–16 Nov/07<br />

B–1 thru B–4 Nov/07<br />

C–1 thru C–8 Nov/07<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

PREFACE<br />

NOTICE OF CONFIDENTIAL INFORMATION<br />

Information contained herein is confidential and is the property of <strong>Alstom</strong><br />

Signaling Incorporated. Where furnished with a proposal, the recipient<br />

shall use it solely to evaluate the proposal. Where furnished to customer, it<br />

shall be used solely for the purposes of inspection, installation or<br />

maintenance. Where furnished to a supplier, it shall be used solely in the<br />

performance of the contract. The information shall not be used or<br />

disclosed by the recipient for any other purposes whatsoever.<br />

FOR QUESTIONS AND INQUIRIES, CONTACT CUSTOMER SERVICE AT<br />

1–800–717–4477<br />

OR<br />

WWW.ALSTOMSIGNALINGSOLUTIONS.COM<br />

ALSTOM SIGNALING INC.<br />

1025 JOHN STREET<br />

WEST HENRIETTA, NY 14586<br />

REVISION LOG<br />

Revision Date Description By Checked Approved<br />

0 May 1995 Original Issue<br />

1 March 1996 Update illustrations JF RD NI<br />

2 October 2001 Update illustrations JF RD NI<br />

3 September 2003 Update parts TS RD NI<br />

4 April 2004 Update style MAS RD NI<br />

5 September 2006 Update Installation<br />

Procedure, Appendix<br />

A, Parts Catalog and<br />

style; add AC<br />

Microchron II Timer<br />

Relay and Appendix C<br />

MAS RD<br />

JP<br />

NI<br />

6 November 2007 Update Biased-Neutral<br />

Relay Test Procedure<br />

MAS MR NI<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

ABOUT THE MANUAL<br />

This manual is intended to provide the necessary information to maintain and ensure<br />

proper operation of <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

The information in this manual is arranged into sections. The title and a brief description<br />

of each section follow:<br />

Section 1 – GENERAL DESCRIPTION: This section gives general information on the<br />

components of <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

Section 2 – THEORY OF OPERATION: This section gives general information on the<br />

operation of <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

Section 3 – INSTALLATION: This section describes the field installation and setup of<br />

<strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

Section 4 – PREVENTIVE MAINTENANCE: This section describes the preventive<br />

maintenance procedures performed on <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

Section 5 – TROUBLESHOOTING: This section describes possible failures/symptoms<br />

along with the corrective action for <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

Section 6 – PREVENTIVE MAINTENANCE: This section describes the testing and<br />

adjustment procedures associated with corrective maintenance of <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong><br />

<strong>Relays</strong>.<br />

Section 7 – PARTS CATALOG: This section identifies and lists the spare parts<br />

associated with <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

Appendix A – RELAY ENGINEERING DATA (ED) SHEET LIST: This section identifies<br />

the engineering data sheets for <strong>Alstom</strong> <strong>Type</strong> B <strong>Vital</strong> <strong>Relays</strong>.<br />

Appendix B – GLOSSARY: This section contains a glossary of terms used in this<br />

manual.<br />

Appendix C – TOOLS AND KITS: This section summarizes the tools and tool kit used<br />

for B relay installation, maintenance, and troubleshooting.<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

MANUAL SPECIAL NOTATIONS<br />

In the <strong>Alstom</strong> manuals, there are three methods used to convey special informational<br />

notations to the reader. These notations are warnings, cautions, and notes. Both<br />

warnings and cautions are readily noticeable by boldface type two lines beneath the<br />

caption.<br />

Warning<br />

A warning is the most important notation to heed. A warning is used to tell the reader<br />

that special attention needs to be paid to the message because if the instructions or<br />

advice is not followed when working on the equipment then the result could be either<br />

serious harm or death. The sudden, unexpected operation of a switch machine, for<br />

example, or the technician contacting the third rail could lead to personal injury or death.<br />

An example of a typical warning notice follows:<br />

Caution<br />

WARNING<br />

DISCONNECT MOTOR ENERGY WHENEVER WORKING ON SWITCH<br />

LAYOUT OR SWITCH MACHINE. UNEXPECTED OPERATION OF<br />

MACHINE COULD CAUSE INJURY FROM OPEN GEARS, ELECTRICAL<br />

SHOCK, OR MOVING SWITCH POINTS.<br />

A caution statement is used when an operating or maintenance procedure, practice,<br />

condition, or statement, which if not strictly adhered to, could result in damage to or<br />

destruction of equipment. A typical caution found in a manual is as follows:<br />

Note<br />

CAUTION<br />

Turn power off before attempting to remove or insert circuit boards into a<br />

module. Boards can be damaged if power is not turned off.<br />

A note is normally used to provide minor additional information to the reader to explain<br />

the reason for a given step in a test procedure or to provide a background detail. An<br />

example of the use of a note follows:<br />

NOTE<br />

A capacitor may be mounted on the circuit board with a RTV adhesive.<br />

Use the same color RTV.<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANK.<br />

P1457, Rev. Nov/07 <strong>Alstom</strong> Signaling Inc.

Topic<br />

TABLE OF CONTENTS<br />

Page<br />

1. SECTION 1 – GENERAL DESCRIPTION ........................................................1–1<br />

1.1. INTRODUCTION TO VITAL RELAYS .........................................................1–1<br />

1.2. RELAY CHARACTERISTICS AND COMPONENTS...................................1–2<br />

1.2.1. Size .........................................................................................................1–2<br />

1.2.2. Identification ............................................................................................1–3<br />

1.2.3. Relay Prongs and Plugboard...................................................................1–5<br />

1.2.4. Mounting..................................................................................................1–7<br />

1.2.5. Registration .............................................................................................1–8<br />

1.2.6. Insulators.................................................................................................1–9<br />

1.2.7. Terminals...............................................................................................1–10<br />

1.2.8. Guide Rods............................................................................................1–14<br />

1.2.9. Wiring ....................................................................................................1–14<br />

1.2.10. Relay Contacts ......................................................................................1–15<br />

1.2.11. Coils ......................................................................................................1–15<br />

2. SECTION 2 – THEORY OF OPERATION........................................................2–1<br />

2.1. GENERAL ...................................................................................................2–1<br />

2.2. RELAY CONTACTS AND COILS................................................................2–3<br />

2.2.1. Definitions................................................................................................2–3<br />

2.2.2. Contact Groups .......................................................................................2–3<br />

2.2.3. Coils ........................................................................................................2–9<br />

2.3. BIASED-NEUTRAL TRACK RELAYS .......................................................2–13<br />

2.4. DC LINE RELAYS .....................................................................................2–15<br />

2.4.1. Neutral Line Relay .................................................................................2–15<br />

2.4.2. Biased-Neutral Line Relay.....................................................................2–16<br />

2.4.3. Magnetic-Stick Line Relay .....................................................................2–18<br />

2.4.4. Microchron II Timer <strong>Relays</strong>....................................................................2–21<br />

2.5. DC SPECIAL PURPOSE RELAYS............................................................2–29<br />

2.5.1. Highway Crossing Signal Flasher Relay................................................2–29<br />

2.5.2. Power-Transfer Relay............................................................................2–30<br />

2.5.3. Lamp-Control Relay...............................................................................2–32<br />

2.5.4. Switch-Overload Relay ..........................................................................2–33<br />

2.5.5. Code-Responsive Relay........................................................................2–34<br />

2.5.6. Code Rate Transmitter Relay ................................................................2–37<br />

2.5.7. Code-Following, VTB Relay...................................................................2–39<br />

2.6. AC TRACK RELAYS .................................................................................2–44<br />

2.6.1. Vane Relay............................................................................................2–44<br />

3. SECTION 3 – INSTALLATION.........................................................................3–1<br />

3.1. GENERAL ...................................................................................................3–1<br />

3.2. RELAY INSTALLATION TOOLS AND SUPPLIES ......................................3–1<br />

3.3. INSPECTION...............................................................................................3–1<br />

3.4. INSTALLATION ...........................................................................................3–2<br />

P1457, Rev. Nov/07 i <strong>Alstom</strong> Signaling Inc.

Topic<br />

TABLE OF CONTENTS (CONT.)<br />

Page<br />

4. SECTION 4 – PREVENTIVE MAINTENANCE .................................................4–1<br />

4.1. GENERAL ...................................................................................................4–1<br />

4.2. PREVENTIVE MAINTENANCE INTERVALS ..............................................4–2<br />

4.3. PREVENTIVE MAINTENANCE TOOLS......................................................4–3<br />

4.4. RELAY INSPECTION..................................................................................4–3<br />

4.5. ELECTRICAL TESTS..................................................................................4–9<br />

4.5.1. AC Light-Out Relay Test........................................................................4–11<br />

4.5.2. AC Vane Relay Test ..............................................................................4–12<br />

4.5.3. Biased-Neutral Relay Test.....................................................................4–13<br />

4.5.4. Code-Responsive Relay Test ................................................................4–14<br />

4.5.5. Code Rate Transmitter Relay Test ........................................................4–15<br />

4.5.6. Magnetic-Stick Relay Test.....................................................................4–16<br />

4.5.7. Microchron II Timer Relay Test..............................................................4–17<br />

4.5.8. Neutral Relay Test.................................................................................4–18<br />

4.5.9. Polarized Relay Test .............................................................................4–19<br />

4.5.10. Power-Transfer Relay Test....................................................................4–20<br />

4.5.11. Switch-Overload Relay Test ..................................................................4–21<br />

4.6. TIMING TESTS .........................................................................................4–22<br />

4.6.1. Code Rate Transmitter Relay Timing Test ............................................4–22<br />

4.6.2. Microchron II Timer Relay (DC) Timing Test .........................................4–22<br />

4.6.3. AC Microchron II Timer Relay Timing Test............................................4–22<br />

5. SECTION 5 – TROUBLESHOOTING...............................................................5–1<br />

5.1. GENERAL PHILOSOPHY ...........................................................................5–1<br />

5.2. GENERAL TROUBLESHOOTING ..............................................................5–1<br />

5.3. RELAY TROUBLESHOOTING TOOLS.......................................................5–1<br />

5.4. FIELD TROUBLESHOOTING .....................................................................5–2<br />

5.4.1. DC Relay Troubleshooting.......................................................................5–4<br />

5.4.2. AC Vane Relay Troubleshooting .............................................................5–6<br />

5.4.3. Microchron II Timer Relay Troubleshooting.............................................5–8<br />

6. SECTION 6 – CORRECTIVE MAINTENANCE ................................................6–1<br />

6.1. GENERAL PURPOSE.................................................................................6–1<br />

6.2. CORRECTIVE MAINTENANCE TOOLS.....................................................6–2<br />

6.3. REMOVAL AND REPLACEMENT PROCEDURES.....................................6–2<br />

6.3.1. B Relay Removal and Replacement........................................................6–2<br />

6.4. WIRING AND PLUGBOARD CHANGES.....................................................6–6<br />

6.4.1. Terminal Removal and Installation ..........................................................6–6<br />

6.4.2. Terminal Wiring .......................................................................................6–8<br />

6.4.3. Insulator Removal and Installation.........................................................6–10<br />

6.4.4. Current Test Terminal Wiring.................................................................6–11<br />

6.4.5. Voltage Test Terminal Wiring ................................................................6–12<br />

P1457, Rev. Nov/07 ii <strong>Alstom</strong> Signaling Inc.

Topic<br />

TABLE OF CONTENTS (CONT.)<br />

Page<br />

6.5. MECHANICAL TEST PROCEDURES.......................................................6–13<br />

6.5.1. Relay Structure Inspection ....................................................................6–14<br />

6.5.2. Mechanical Test and Adjustment Procedure .........................................6–17<br />

6.5.3. Microchron II Timer Relay Electronics Removal and Replacement .......6–23<br />

7. SECTION 7 – PARTS CATALOG ....................................................................7–1<br />

7.1. GENERAL ...................................................................................................7–1<br />

7.2. PARTS LIST................................................................................................7–1<br />

7.3. B1 NEUTRAL RELAYS ...............................................................................7–2<br />

7.4. B1 BIASED-NEUTRAL RELAYS .................................................................7–3<br />

7.5. B1 CODE-RESPONSIVE RELAY................................................................7–7<br />

7.6. B1 SLOW PICKUP, SLOW-RELEASE AND QUICK CROSSOVER<br />

RELAYS ....................................................................................................7–14<br />

7.7. B1 ELECTRONICALLY DRIVEN HIGHWAY CROSSING RELAY AND FLASHER<br />

MODULE ...................................................................................................7–15<br />

7.8. B2 NEUTRAL RELAY................................................................................7–18<br />

7.9. B2 BIASED-NEUTRAL RELAY .................................................................7–21<br />

7.10. B2 AC VANE RELAY, 2F-2B, TWO POSITION.........................................7–24<br />

7.11. B2 AC VANE RELAY, 4F-4B, TWO POSITION.........................................7–27<br />

7.12. B2 CODE RATE TRANSMITTER RELAY .................................................7–30<br />

7.13. B2 MICROCHRON II TIMER RELAY (DC)................................................7–36<br />

7.14. B2 AC MICROCHRON II TIMER RELAY ..................................................7–41<br />

7.15. TYPE VTB POLAR-BIASED RELAY .........................................................7–45<br />

7.16. B RELAY CONTACT GROUPS.................................................................7–54<br />

7.17. B RELAY PLUGBOARDS AND INSTALLATION SUPPLIES ....................7–58<br />

7.18. B RELAY REGISTRATION PLATES AND GASKETS...............................7–65<br />

A. APPENDIX A – RELAY ENGINEERING DATA (ED) SHEET LIST ................ A–1<br />

A.1. GENERAL ...................................................................................................A–1<br />

B. APPENDIX B - GLOSSARY............................................................................ B–1<br />

B.1. CONTACT DEFINITIONS............................................................................B–1<br />

B.2. GENERAL DEFINITIONS............................................................................B–2<br />

C. APPENDIX C – TOOLS AND KITS................................................................. C–1<br />

C.1. GENERAL .................................................................................................. C–1<br />

C.2. CORRECTIVE MAINTENANCE TOOLS AND TOOL KITS........................ C–1<br />

C.3. SHOP TEST RACK .................................................................................... C–5<br />

C.4. VANE RELAY TEST UNIT.......................................................................... C–6<br />

P1457, Rev. Nov/07 iii <strong>Alstom</strong> Signaling Inc.

Description<br />

LIST OF FIGURES<br />

Page<br />

Figure 1–1. <strong>Alstom</strong> <strong>Type</strong> B1 and <strong>Type</strong> B2 <strong>Type</strong> <strong>Vital</strong> <strong>Relays</strong>..................................... 1–1<br />

Figure 1–2. B1 Relay Nameplate, Nametag and Test Data Form .............................. 1–3<br />

Figure 1–3. Example B1 Relay Test Data Form......................................................... 1–4<br />

Figure 1–4. Plug Connection...................................................................................... 1–5<br />

Figure 1–5. B1 Plugboard .......................................................................................... 1–6<br />

Figure 1–6. <strong>Type</strong> B Plug Connections........................................................................ 1–7<br />

Figure 1–7. Registration Plates .................................................................................. 1–8<br />

Figure 1–8. Latching Insulator.................................................................................... 1–9<br />

Figure 1–9. Insulator Separates One Contact Terminal From the Other.................. 1–10<br />

Figure 1–10. Current Test Terminal ......................................................................... 1–11<br />

Figure 1–11. Voltage Test Terminal ......................................................................... 1–11<br />

Figure 1–12. Terminal Numbering of <strong>Type</strong> B, Size 1 (B1) DC <strong>Relays</strong>...................... 1–12<br />

Figure 1–13. Terminal Numbering of <strong>Type</strong> B, Size 2 (B2) DC <strong>Relays</strong>...................... 1–13<br />

Figure 1–14. B1 Relay showing Guide Rods and Nuts ............................................ 1–14<br />

Figure 1–15. Relay Contact Components ................................................................ 1–15<br />

Figure 1–16. Coil Terminal Numbers, B1 and B2 Relay (Rear View) ....................... 1–16<br />

Figure 2–1. Typical B1 Relay Components ................................................................ 2–2<br />

Figure 2–2. Heel Contact Engaging Pusher ............................................................... 2–4<br />

Figure 2–3. Three Different Contact Combinations .................................................... 2–4<br />

Figure 2–4. 2 Front (F) and 1 Back (B) Independent Regular Contacts ..................... 2–6<br />

Figure 2–5. 2 Front-Back (FB) Dependent Regular Contacts..................................... 2–6<br />

Figure 2–6. 2 Front-Back (FB) Dependent Heavy-Duty Contacts .............................. 2–7<br />

Figure 2–7. One Front and One Back Independent Heavy-Duty Contacts with Magnetic<br />

Blowouts................................................................................................................ 2–8<br />

Figure 2–8. Coil Construction, One Winding .............................................................. 2–9<br />

Figure 2–9. Coil Construction, Two Windings ............................................................ 2–9<br />

Figure 2–10. <strong>Type</strong> B1 Biased-Neutral Relay, Pre-1991 Cover................................. 2–13<br />

Figure 2–11. <strong>Type</strong> B1 Biased-Neutral Relay, Post-1991 Cover ............................... 2–13<br />

Figure 2–12. Typical B1 Track Relay Wiring ............................................................ 2–14<br />

Figure 2–13. B1 and B2 Neutral Line <strong>Relays</strong> Wiring ................................................ 2–15<br />

Figure 2–14. Voltage of Right Polarity Applied......................................................... 2–16<br />

Figure 2–15. No Voltage Applied.............................................................................. 2–17<br />

Figure 2–16. Voltage of Wrong Polarity Applied....................................................... 2–17<br />

Figure 2–17. Magnetic-Stick Relay, Reverse Position.............................................. 2–18<br />

Figure 2–18. Armature Picked Up with Normal Polarity ........................................... 2–19<br />

Figure 2–19. Armature Held Up By Permanent Magnet's Attraction ........................ 2–19<br />

Figure 2–20. Armature Knocked Down with Reverse Polarity.................................. 2–20<br />

Figure 2–21. B1 Magnetic-Stick Relay Wiring .......................................................... 2–20<br />

Figure 2–22. Microchron II Timer Relay Cover......................................................... 2–21<br />

Figure 2–23. Relay Contacts, Front View................................................................. 2–25<br />

Figure 2–24. AC Microchron II Timer Relay Schematic............................................ 2–25<br />

Figure 2–25. AC Motor Timer Plugboard Wiring Diagram ........................................ 2–27<br />

Figure 2–26. Electronically-Driven Flasher Relay Wiring ......................................... 2–29<br />

P1457, Rev. Nov/07 iv <strong>Alstom</strong> Signaling Inc.

Description<br />

LIST OF FIGURES (CONT.)<br />

Page<br />

Figure 2–27. <strong>Type</strong> S1/4 Half-Wave Rectifier for Power-Transfer Relay ................... 2–30<br />

Figure 2–28. Power-Transfer Relay Wiring .............................................................. 2–31<br />

Figure 2–29. Lamp-Control Relay Wiring ................................................................. 2–32<br />

Figure 2–30. Switch-Overload Relay Wiring............................................................. 2–33<br />

Figure 2–31. Code-Responsive Relay De-energized ............................................... 2–34<br />

Figure 2–32. Code-Responsive Relay Energized..................................................... 2–35<br />

Figure 2–33. Code-Responsive Relay Wiring .......................................................... 2–36<br />

Figure 2–34. Code Rate Transmitter Relay Operation ............................................. 2–37<br />

Figure 2–35. Code Rate Transmitter Relay Wiring................................................... 2–38<br />

Figure 2–36. VTB Plugboard.................................................................................... 2–39<br />

Figure 2–37. Polar-Biased Single Armature Relay................................................... 2–40<br />

Figure 2–38. VTB Relay Energized.......................................................................... 2–41<br />

Figure 2–39. VTB Relay, Two Armatures De-energized .......................................... 2–41<br />

Figure 2–40. VTB Relay, Two Armatures Energized................................................ 2–42<br />

Figure 2–41. VTB Relay Wiring................................................................................ 2–43<br />

Figure 2–42. Vane Relay Structure .......................................................................... 2–44<br />

Figure 2–43. Vane Relay Components .................................................................... 2–45<br />

Figure 2–44. Magnet Movement Drags the Metal Disc ............................................ 2–46<br />

Figure 2–45. Eddy Current Induction by Permanent Magnet ................................... 2–47<br />

Figure 2–46. Local and Track Current Cycles .......................................................... 2–48<br />

Figure 2–47. Parallel Hookup of Windings ............................................................... 2–49<br />

Figure 2–48. Series Hookup of Windings ................................................................. 2–50<br />

Figure 2–49. AC Vane Relay.................................................................................... 2–50<br />

Figure 4–1. Spanner Nut Wrench............................................................................... 4–3<br />

Figure 5–1. DC Relay Does Not Pick ......................................................................... 5–4<br />

Figure 5–2. DC Relay Does Not Release................................................................... 5–5<br />

Figure 5–3. AC Vane Relay Does Not Pick ................................................................ 5–6<br />

Figure 5–4. AC Vane Relay Does Not Release.......................................................... 5–7<br />

Figure 5–5. Microchron II Timer Relay (AC or DC) Does Not Pick............................. 5–9<br />

Figure 5–6. Microchron II Timer Relay (AC or DC) Does Not Release..................... 5–10<br />

Figure 7–1. B1 Neutral <strong>Relays</strong> ................................................................................... 7–2<br />

Figure 7–2. B1 Biased-Neutral <strong>Relays</strong> ....................................................................... 7–3<br />

Figure 7–3. B1 Code-Responsive Relay .................................................................... 7–7<br />

Figure 7–4. B1 Slow Pickup, Slow-Release and Quick Crossover........................... 7–14<br />

Figure 7–5. B1 Electronically Driven Highway Crossing Relay and Flasher Module 7–15<br />

Figure 7–6. B2 Neutral Relay ................................................................................... 7–18<br />

Figure 7–7. B2 Biased-Neutral Relay ....................................................................... 7–21<br />

Figure 7–8. B2 AC Vane Relay, 2F-2B, Two Position .............................................. 7–24<br />

Figure 7–9. B2 AC Vane Relay, 4F-4B, Two Position .............................................. 7–27<br />

Figure 7–10. B2 Code Rate Transmitter Relay ........................................................ 7–30<br />

Figure 7–11. B2 Microchron II Timer Relay (DC) ..................................................... 7–36<br />

P1457, Rev. Nov/07 v <strong>Alstom</strong> Signaling Inc.

Description<br />

LIST OF FIGURES (CONT)<br />

Page<br />

Figure 7–12. B2 AC Microchron II Timer Relay........................................................ 7–41<br />

Figure 7–13. <strong>Type</strong> VTB Polar-Biased Relay............................................................. 7–45<br />

Figure 7–14. B Relay Contact Groups...................................................................... 7–54<br />

Figure 7–15. B Relay Extra Heavy-Duty (EHD) Contact Group Magnet Detail ........ 7–55<br />

Figure 7–16. B Relay Plugboards and Installation Supplies..................................... 7–59<br />

Figure 7–17. Example Installation Supplies ............................................................. 7–60<br />

Figure 7–18. B Relay Registration Plates and Gaskets............................................ 7–66<br />

Figure C–1. <strong>Alstom</strong> B Relay Tools .............................................................................C–3<br />

Figure C–2. Shop Test Rack ......................................................................................C–5<br />

Figure C–3. Vane Relay Test Unit, Front Panel .........................................................C–6<br />

Figure C–4. Vane Relay Test Unit Circuit with Relay .................................................C–7<br />

P1457, Rev. Nov/07 vi <strong>Alstom</strong> Signaling Inc.

Description<br />

LIST OF TABLES<br />

Page<br />

Table 1–1. Relay Sizes and Weights.......................................................................... 1–2<br />

Table 1–2. Plugboard Dimensions ............................................................................. 1–5<br />

Table 2–1. Typical Relay Contact Combinations........................................................ 2–5<br />

Table 2–2. Coil Connections and Timing Characteristics ......................................... 2–11<br />

Table 2–3. AC Microchron II Timer Relay Operating Characteristics ....................... 2–26<br />

Table 2–4. Replaceable AC Motor Timers ............................................................... 2–28<br />

Table 3–1. B Relay Pre-Installation Inspection Procedure ......................................... 3–1<br />

Table 3–2. B Relay Installation Procedure ................................................................. 3–3<br />

Table 3–3. Microchron II Timer Relay (DC) Installation Procedure ............................ 3–7<br />

Table 3–4. Microchron II Timer Relay (DC) Surge Protection Installation<br />

Procedure............................................................................................................ 3–12<br />

Table 3–5. AC Microchron II Timer Relay Installation Procedure............................. 3–13<br />

Table 4–1. Preventive Maintenance Intervals ............................................................ 4–2<br />

Table 4–2. Typical B1 Relay Visual Inspection Procedure ......................................... 4–4<br />

Table 4–3. Vane Relay Visual Inspection Procedure ................................................. 4–6<br />

Table 4–3. Vane Relay Visual Inspection Procedure (Cont.) ..................................... 4–7<br />

Table 4–4. Microchron II Timer Relay Visual Inspection Procedure........................... 4–7<br />

Table 4–5. Miscellaneous Relay Visual Inspection Procedure ................................... 4–8<br />

Table 4–6. Electrical Test Procedures...................................................................... 4–10<br />

Table 4–7. AC Light-Out Relay Test Procedure ....................................................... 4–11<br />

Table 4–8. AC Vane Relay Test Procedure ............................................................. 4–12<br />

Table 4–9. Biased-Neutral Relay Test Procedure .................................................... 4–13<br />

Table 4–10. Code-Responsive Relay Test Procedure ............................................. 4–14<br />

Table 4–11. Code Rate Transmitter Relay Test Procedure...................................... 4–15<br />

Table 4–12. Magnetic-Stick Relay Test Procedure .................................................. 4–16<br />

Table 4–13. Microchron II Timer Relay Test Procedure........................................... 4–17<br />

Table 4–14. Neutral Relay Test Procedure .............................................................. 4–18<br />

Table 4–15. Polarized Relay Test Procedure........................................................... 4–19<br />

Table 4–16. Power-Transfer Relay Test Procedure ................................................. 4–20<br />

Table 4–17. Switch-Overload Relay Test Procedure................................................ 4–21<br />

Table 5–1. Troubleshooting Symbols ......................................................................... 5–3<br />

Table 6–1. Corrective Maintenance Procedures ........................................................ 6–1<br />

Table 6–2. B Relay Removal and Replacement Procedure ....................................... 6–2<br />

Table 6–3. Terminal Removal Procedure................................................................... 6–6<br />

Table 6–4. Terminal Installation Procedure................................................................ 6–7<br />

Table 6–5. Terminal Soldering Procedure.................................................................. 6–8<br />

Table 6–6. Terminal Crimping Procedure................................................................... 6–9<br />

Table 6–7. Insulator Removal and Installation Procedure ........................................ 6–10<br />

Table 6–8. Current Test Terminal Wiring Procedure................................................ 6–11<br />

P1457, Rev. Nov/07 vii <strong>Alstom</strong> Signaling Inc.

Description<br />

LIST OF TABLES (CONT.)<br />

Page<br />

Table 6–9. Voltage Test Terminal Wiring Procedure................................................ 6–12<br />

Table 6–10. Relay Structure Inspection Procedure.................................................. 6–14<br />

Table 6–11. Mechanical Test and Adjustment Procedure ........................................ 6–17<br />

Table 6–12. Microchron II Timer Electronics Removal Procedure ........................... 6–24<br />

Table 6–13. Microchron II Timer Electronics Replacement Procedure..................... 6–27<br />

Table 7–1. B Relay Drawings and Parts Lists ............................................................ 7–1<br />

Table 7–2. B1 Neutral and Biased-Neutral Relay Part Numbers................................ 7–4<br />

Table 7–3. B1 Code-Responsive Relay Part Numbers ............................................ 7–10<br />

Table 7–4. B1 Slow Pickup, Slow-Release, and Quick-Crossover and Electronically<br />

Driven Highway Crossing Relay and Flasher Part Numbers ............................... 7–16<br />

Table 7–5. B2 Neutral Relay Part Numbers ............................................................. 7–19<br />

Table 7–6. B2 Biased-Neutral Relay Part Numbers ................................................. 7–22<br />

Table 7–7. B2 Vane Relay, 2F-2B, Two Position Part Numbers .............................. 7–25<br />

Table 7–8. B2 Vane Relay, 4F-4B, Two Position Part Numbers .............................. 7–28<br />

Table 7–9. B2 Code Rate Transmitter Relay Part Numbers..................................... 7–32<br />

Table 7–10. B2 Microchron II Timer Relay Part Numbers ........................................ 7–38<br />

Table 7–11. B2 AC Microchron II Timer Relay Part Numbers .................................. 7–42<br />

Table 7–12. VTB Polar Biased Relay Part Numbers................................................ 7–46<br />

Table 7–13. B Relay Coil and Compression Spring Part Numbers .......................... 7–50<br />

Table 7–14. B Relay Contact Group Part Numbers ................................................. 7–56<br />

Table 7–15. B Relay Contact Group Pusher and Clip Part Numbers ....................... 7–57<br />

Table 7–16. B Relay Plugboard and Terminal Board Part Numbers ........................ 7–60<br />

Table 7–17. B Relay Registration Plate and Gasket Part Numbers ......................... 7–67<br />

Table A–1. ED sheets Listed By Catalog Number......................................................A–2<br />

Table A–2. ED sheets Listed By Drawing Number.....................................................A–9<br />

Table C–1. <strong>Alstom</strong> B Relay Tools...............................................................................C–1<br />

Table C–2. B Relay Tools Not Available From <strong>Alstom</strong> ...............................................C–4<br />

P1457, Rev. Nov/07 viii <strong>Alstom</strong> Signaling Inc.

General Description<br />

1. SECTION 1 – GENERAL DESCRIPTION<br />

1.1. INTRODUCTION TO VITAL RELAYS<br />

For over 70 years, <strong>Alstom</strong> Signaling, Inc. has continually perfected the <strong>Type</strong> B relays.<br />

They are the standard relay of the signaling industry. <strong>Type</strong>s B and VTB plug-in relays<br />

meet applicable manual parts of American Railway Engineering and Maintenance of<br />

Way Association (AREMA).<br />

<strong>Alstom</strong> <strong>Type</strong> B plug-in relays are used in vital circuits, and are rack-installed in<br />

equipment rooms and in wayside cases and housings. These relays are divided into two<br />

sizes, B1 and B2, as shown in Figure 1–1. Some B relays are energized by DC voltage,<br />

others by AC voltage. A vital relay is designed so that the probability of its failing to<br />

return to a prescribed state when it is de-energized is so low that for all practical<br />

purposes it is considered to be nonexistent.<br />

ALS<br />

ALS<br />

B1 RELAY<br />

B2 RELAY<br />

Figure 1–1. <strong>Alstom</strong> <strong>Type</strong> B1 and <strong>Type</strong> B2 <strong>Type</strong> <strong>Vital</strong> <strong>Relays</strong><br />

There are more than a dozen types of <strong>Type</strong> B relays, available in about 200<br />

configurations. They are designed to meet the important requirements of safety,<br />

reliability, low maintenance and long operating life. Replacement parts for relays<br />

decades old may still be available should it become necessary to extend their operating<br />

life. <strong>Alstom</strong> furnishes its customers relay application and adjustment instructions, either<br />

as part of a contract or upon request.<br />

P1457, Rev. Nov/07 1–1 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2. RELAY CHARACTERISTICS AND COMPONENTS<br />

1.2.1. Size<br />

<strong>Type</strong> B relays are made in two sizes, Size 1 and 2, and are referred to as B1 and B2<br />

relays. Two Size 1 relays occupy the same space as one Size 2 relay. Additionally,<br />

there is a special size relay, <strong>Type</strong> VTB code-responsive, which occupies the plugboard<br />

space for a B2 relay, but is not the same depth. Table 1–1 provides exact sizes and<br />

weights.<br />

Table 1–1. Relay Sizes and Weights<br />

Dimensions and Weights Size 1 Size 2 VTB<br />

Height of relay 6-5/16 in. 6-5/16 in. 7-11/16 in.<br />

Width of relay 2-7/16 in. 4-15/16 in. 4-15/16 in.<br />

Depth without plugboard 8-9/16 in. 8-9/16 in. 6-7/16 in.<br />

Depth including plugboard fully wired<br />

(approx.)<br />

15-1/2 in. 15-1/2 in. 13-3/8 in.<br />

Weight of relay with plugboard (weight of<br />

wiring not included)<br />

7 to 10 lbs. 10 to 15 lbs. 6 to 7 lbs.<br />

Weight of plugboard alone without wiring 1 lb. 2 lbs. 2 lbs.<br />

P1457, Rev. Nov/07 1–2 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.2. Identification<br />

All <strong>Type</strong> B relays carry nameplates that contain the drawing number (part number) and<br />

catalog number of the relay. Relay drawing number is also shown on the registration<br />

plates of the relay. When inquiring about a particular relay, always provide the catalog<br />

or drawing number.<br />

The drawing and catalog numbers can be used with the tables in Appendix A to look up<br />

the relay's Engineering Data (ED) Sheet number. The ED sheet contains technical<br />

specifications referenced during some maintenance procedures.<br />

Each B2 Relay has a Test Data Form on the cover and a name plate located inside the<br />

relay, visible from the front of the cover.<br />

Each B1 relay cover contains two recesses to allow attachment of two metalized<br />

polyester film or mylar tags with permanent adhesive:<br />

• a tag for relay operating and testing data<br />

• a tag for circuit nomenclature<br />

B1 <strong>Relays</strong> manufactured prior to 1991 have a different cover than those relays<br />

manufactured after 1991. The most obvious difference is the handle on the front of the<br />

relay. B1 relay nameplate, nametag and test data form locations for relays<br />

manufactured pre and post 1991 are shown in Figure 1–2.<br />

2 PIECE METAL<br />

HANDLE<br />

PLASTIC HANDLE<br />

MOLDED TO COVER<br />

NAMEPLATE<br />

NAMETAG<br />

TEST DATA<br />

FORM<br />

PRE 1991 STYLE<br />

POST 1991 STYLE<br />

Figure 1–2. B1 Relay Nameplate, Nametag and Test Data Form<br />

P1457, Rev. Nov/07 1–3 <strong>Alstom</strong> Signaling Inc.

General Description<br />

The information provided on the test data form includes the relay serial number, data<br />

from the specification sheet for the relay, the initials of the <strong>Alstom</strong> employee who tested<br />

the relay, and the date the form was completed.<br />

An example B1 relay test data form is shown in Figure 1–3. This example form includes<br />

the following:<br />

• Space 1 - The serial number as shown on relay nameplate.<br />

• Space 2 - The minimum DROP AWAY (D.A.) value from specification sheet in Amps<br />

for a DC relay or Volts for an AC relay. For example, on a 921-09 relay the space<br />

contains 0.077A for the minimum DROP AWAY. An "A" for Amps should be added<br />

or "VAC" for AC relays.<br />

• Space 3 - The maximum PICKUP (P.U.) value from specification sheet in the same<br />

style as in Space 2.<br />

• Space 4 - The maximum WORKING Current (W.C.) value from specification sheet in<br />

the same style as in Space 2.<br />

• Space 5 - The initials of the <strong>Alstom</strong> employee who tested the relay.<br />

• Space 6 - The date the form was completed in Month/Day/Year format (for example<br />

7/26/94).<br />

SERIAL NO.<br />

D.A.(MIN)<br />

P.U. (MAX)<br />

W.C. (MAX)<br />

INSP.<br />

1<br />

2<br />

3<br />

4<br />

5 6<br />

DATE<br />

Figure 1–3. Example B1 Relay Test Data Form<br />

P1457, Rev. Nov/07 1–4 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.3. Relay Prongs and Plugboard<br />

All <strong>Type</strong> B relays plug onto plugboards. Relay contacts and coil(s) are brought out<br />

through the base of the relay as prongs. The plugboard has wedge shaped plug<br />

insulators. There are two terminals per insulator, one on each side. The terminals are<br />

installed from behind the plugboard. See Figure 1–4 for a simplified mating diagram. For<br />

exact dimensions, see Table 1–2.<br />

TOP TERMINAL<br />

PLUGBOARD<br />

RELAY<br />

CONTACT<br />

BLOCK<br />

WIRES TO<br />

WIRE HARNESS<br />

RELAY<br />

SPRINGS<br />

INSULATOR<br />

SLIDING<br />

CONTACT<br />

BOTTOM<br />

PRONGS<br />

TERMINAL<br />

Figure 1–4. Plug Connection<br />

Table 1–2. Plugboard Dimensions<br />

Dimension B1 B2<br />

Overall Height 9-7/16 in. 9-7/16 in.<br />

Overall Width 2-1/2 in. 5 in.<br />

Overall Depth 10-1/2 in. 10-1/2 in.<br />

Diameter of mounting holes (clearance for 1/4 in. bolt) 9/32 in. 9/32 in.<br />

Vertical distance between centerlines of mounting holes 8-13/16 in. 8-13/16 in.<br />

There should be about a 5-inch clearance behind a plugboard to give room for wire<br />

distribution in a relay rack.<br />

P1457, Rev. Nov/07 1–5 <strong>Alstom</strong> Signaling Inc.

General Description<br />

When a relay is plugged in, two relay guide rods align the relay so that all prongs<br />

properly align with their corresponding insulators. The prongs slide onto their respective<br />

plugboard terminals, thus making contact. Figure 1–5 shows a B1 plugboard; including<br />

the location of the relay guide rods.<br />

Because plugboard terminals are connected to the wires in cables behind the<br />

plugboard, no wiring changes are necessary when replacing a <strong>Type</strong> B relay.<br />

TOP WIRE<br />

TERMINAL<br />

16<br />

15<br />

26<br />

25<br />

36<br />

35<br />

36<br />

35<br />

26<br />

25<br />

16<br />

15<br />

6<br />

5<br />

INSULATOR<br />

RELAY<br />

GUIDE<br />

RODS<br />

14<br />

13<br />

12<br />

11<br />

24<br />

23<br />

22<br />

21<br />

34<br />

33<br />

32<br />

31<br />

CONTACT<br />

TERMINALS<br />

34<br />

33<br />

32<br />

31<br />

3<br />

24<br />

23<br />

22<br />

21<br />

2<br />

14<br />

13<br />

12<br />

11<br />

1<br />

4<br />

3<br />

2<br />

1<br />

BOTTOM<br />

WIRE<br />

TERMINAL<br />

MALE<br />

REGISTRATION<br />

PLATE<br />

3A<br />

3B<br />

3C<br />

COIL<br />

TERMINALS<br />

3B<br />

3A<br />

3C<br />

3D<br />

3D<br />

1E<br />

3E<br />

TEST<br />

TERMINALS<br />

3E<br />

1E<br />

FRONT VIEW<br />

REAR VIEW<br />

Figure 1–5. B1 Plugboard<br />

P1457, Rev. Nov/07 1–6 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.4. Mounting<br />

The B relays plug on to plugboards. The contacts and the coil terminals of the relay<br />

protrude through the base of the relay as prongs. The plugboard has wedge-shaped<br />

plug insulators with flat metal terminals on the two faces of the wedge. Two rods guide a<br />

relay being plugged in, allowing the pairs of relay prongs to meet with corresponding<br />

wedges, spreading the prongs apart. The prongs slide onto the respective plugboard<br />

terminals making contact as shown in Figure 1–6.<br />

CONTACT BLOCK<br />

IN RELAY<br />

PLUGBOARD<br />

CONTACT PRONGS<br />

TERMINAL<br />

Figure 1–6. <strong>Type</strong> B Plug Connections<br />

P1457, Rev. Nov/07 1–7 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.5. Registration<br />

Registration plates prevent plugging a relay into the wrong place in a rack or module.<br />

Figure 1–7 shows two registration plates, one with holes, the other with pins. The plate<br />

with holes is attached to the base of the relay. The plate with pins is attached to the<br />

plugboard. If a relay that does not belong on the plugboard should be slipped on the<br />

guide rods, it is prevented from making contact with the terminals in the plugboard<br />

because the registration pins and holes do not correspond with one another.<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

26<br />

25<br />

24<br />

23<br />

22<br />

21<br />

36<br />

35<br />

34<br />

33<br />

32<br />

31<br />

MALE<br />

REGISTRATION<br />

PLATE<br />

3A<br />

3B<br />

3C<br />

3D<br />

FEMALE<br />

REGISTRATION<br />

FEMALE<br />

REGISTRATION PLATE<br />

PLATE<br />

RELAY<br />

1E<br />

3E<br />

PLUGBOARD<br />

Figure 1–7. Registration Plates<br />

P1457, Rev. Nov/07 1–8 <strong>Alstom</strong> Signaling Inc.

General Description<br />

The registration feature takes care of six important differences in relays:<br />

• Differences in timing<br />

• Differences in contact arrangement<br />

• Differences in contact opening<br />

• Differences between track and line relays<br />

• Differences in coil resistance<br />

• Differences in coil arrangement<br />

1.2.6. Insulators<br />

Insulators are made of molded plastic and fit into slots in the plugboard. Each insulator<br />

is held in place by a locking latch molded into a spring beam on one side of the insulator<br />

as shown in Figure 1–8. An extractor tool must be used to remove the terminals prior to<br />

removing the insulators. To release the insulator so that it can be pulled out of the<br />

plugboard, squeeze the spring beam and push the insulator towards the front of the<br />

plugboard.<br />

There are 11 insulators in a B1 plugboard and up to 20 in a B2 plugboard.<br />

PLUGBOARD<br />

SPRING BEAM<br />

SQUEEZE TOWARDS<br />

INSULATOR TO RELEASE<br />

INSULATOR<br />

INSULATORS<br />

EXTRACTOR<br />

CRIMP WIRES TO<br />

TERMINAL CONNECTIONS<br />

Figure 1–8. Latching Insulator<br />

NOTE<br />

An integral beam latch secures the insulator to the plugboard.<br />

P1457, Rev. Nov/07 1–9 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.7. Terminals<br />

B relay plugboards contain contact terminals, coil terminals and test terminals as shown<br />

in Figure 1–5. There are two types of terminals, solder terminals and crimp terminals.<br />

Refer to Section 3, Installation, for installation supplies.<br />

1.2.7.1. Contact Terminals<br />

There are two contact terminals per insulator, one on the top and one on the bottom as<br />

shown in Figure 1–9. Each terminal is completely insulated from the adjacent one, by<br />

either the insulator or the wall of plastic material that surrounds each insulator and<br />

terminal assembly.<br />

TOP TERMINAL<br />

(SOLDER TYPE)<br />

RELAY CONTACT END<br />

TOP TERMINAL<br />

(CRIMP TYPE)<br />

INSULATOR<br />

WIRE CONNECTOR END<br />

BOTTOM TERMINAL<br />

(SOLDER TYPE)<br />

BOTTOM TERMINAL<br />

(CRIMP TYPE)<br />

Figure 1–9. Insulator Separates One Contact Terminal From the Other<br />

The terminal slips into place from behind the plugboard. First, the wire is connected to<br />

the terminal; then the terminal is pushed into the proper slot in the plugboard.<br />

On B1 plugboards, there are slots for 18 contact terminals for circuits through relay<br />

contacts and 4 for circuits through the coils. On B2 plugboards, there are slots for 36<br />

contact terminals and 4 coil terminals.<br />

P1457, Rev. Nov/07 1–10 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.7.2. Test Terminals<br />

A current test terminal is provided on the plugboard directly under the relay, as shown in<br />

Figure 1–10, to allow the checking of current flow through the relay coils.<br />

NOTE<br />

Not all relay plugboards are equipped with a current and voltage test<br />

terminal.<br />

FRONT<br />

PLUGBOARD<br />

HALF<br />

NUT<br />

TO CABLE<br />

HARNESS<br />

B2<br />

PLUGBOARD<br />

1E<br />

6E<br />

INSULATING<br />

BUSHING<br />

TERMINAL<br />

POST<br />

SPANNER<br />

NUT<br />

B1<br />

PLUGBOARD<br />

1E<br />

3E<br />

CURRENT TEST<br />

TERMINALS<br />

COPPER<br />

STRAP<br />

CURRENT TEST TERMINAL<br />

TO RELAY<br />

COIL TERMINAL<br />

CIRCUIT SYMBOL<br />

Figure 1–10. Current Test Terminal<br />

A voltage test terminal is provided on the plugboard next to the current test terminal, as<br />

shown in Figure 1–11, to allow the checking of voltage across the relay coils.<br />

FRONT<br />

TO CABLE<br />

HARNESS<br />

1E<br />

6E<br />

B2 PLUGBOARD<br />

TO COIL<br />

TERMINAL<br />

B1 PLUGBOARD<br />

1E<br />

3E<br />

VOLTAGE TEST TERMINAL<br />

CIRCUIT SYMBOL<br />

VOLTAGE TEST<br />

TERMINAL<br />

Figure 1–11. Voltage Test Terminal<br />

P1457, Rev. Nov/07 1–11 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.7.3. Numbering of Contacts and Plugboard Terminals<br />

From the front of the relay, the vertical columns of contacts and their plugboard<br />

terminals are numbered 1, 2, 3, etc. from left to right. The contact springs in each row<br />

are numbered from bottom to top 1, 2, 3, etc. These numbers are molded into the<br />

plugboard adjacent to the slots. Thus, all contact terminal numbers contain two digits,<br />

as shown in Figures 1–12 and 1–13. The first digit indicates the column; the second<br />

indicates the row. For example, terminal 36 is the third column from the left, sixth row<br />

from the bottom. The terminal 23 is the second column from the left, third row from the<br />

bottom.<br />

Only the springs with contacts are numbered. The stops and pressure plate springs are<br />

not numbered.<br />

16<br />

26<br />

36<br />

36<br />

26<br />

16<br />

6<br />

15<br />

25<br />

35<br />

35<br />

25<br />

15<br />

5<br />

14<br />

24<br />

34<br />

34<br />

24<br />

14<br />

4<br />

13<br />

12<br />

23<br />

22<br />

33<br />

32<br />

33<br />

32<br />

23<br />

22<br />

13<br />

12<br />

3<br />

2<br />

11<br />

21<br />

31<br />

31<br />

3<br />

21<br />

2<br />

11<br />

1<br />

1<br />

MALE<br />

REGISTRATION<br />

PLATE<br />

3A<br />

3B<br />

3C<br />

3B<br />

3A<br />

3C<br />

3D<br />

3D<br />

1E<br />

3E<br />

3E<br />

1E<br />

FRONT VIEW<br />

REAR VIEW<br />

Figure 1–12. Terminal Numbering of <strong>Type</strong> B, Size 1 (B1) DC <strong>Relays</strong><br />

P1457, Rev. Nov/07 1–12 <strong>Alstom</strong> Signaling Inc.

General Description<br />

16<br />

26<br />

36<br />

46<br />

56<br />

66<br />

66<br />

56<br />

46<br />

36<br />

26<br />

16<br />

15<br />

14<br />

25<br />

24<br />

35<br />

34<br />

45<br />

44<br />

55<br />

54<br />

65<br />

64<br />

65<br />

64<br />

55<br />

54<br />

45<br />

44<br />

35<br />

34<br />

25<br />

24<br />

15<br />

14<br />

13<br />

23<br />

33<br />

43<br />

53<br />

63<br />

63<br />

53<br />

43<br />

33<br />

23<br />

13<br />

12<br />

22<br />

32<br />

42<br />

52<br />

62<br />

62<br />

52<br />

42<br />

32<br />

22<br />

12<br />

11<br />

21<br />

31<br />

41<br />

51<br />

61<br />

61<br />

51<br />

41<br />

31<br />

21<br />

11<br />

1C<br />

MALE<br />

REGISTRATION<br />

PLATE<br />

6C<br />

6C<br />

1C<br />

1D<br />

6D<br />

6D<br />

1D<br />

1E<br />

3E<br />

4E<br />

6E<br />

6E<br />

4E<br />

3E<br />

1E<br />

FRONT VIEW<br />

REAR VIEW<br />

Figure 1–13. Terminal Numbering of <strong>Type</strong> B, Size 2 (B2) DC <strong>Relays</strong><br />

P1457, Rev. Nov/07 1–13 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.8. Guide Rods<br />

Two guide rods, which extend from the face of the plugboard 8-1/2 inches, help guide<br />

the relay into alignment with the insulators on the plugboard.<br />

Each rod has a knurled nut and a lock nut to secure the relay on its plugboard, as<br />

shown in Figure 1–14.<br />

LOCK NUTS<br />

GUIDE RODS<br />

KNURLED<br />

NUTS<br />

Figure 1–14. B1 Relay showing Guide Rods and Nuts<br />

1.2.9. Wiring<br />

Wires strapped together in cable form are supported behind the plugboard. Each wire is<br />

identified with a tag and then connected to its terminal. The terminal is pushed into its<br />

slot in the plugboard and locked in place.<br />

The plugboard back can accommodate the mounting of a two-post terminal block as<br />

shown in Figure 1–16. This can be used to terminate coil leads where coils in a relay<br />

are circuited independent of one another.<br />

P1457, Rev. Nov/07 1–14 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.10. Relay Contacts<br />

<strong>Relays</strong> are furnished with specific contact arrangements. In all relays, the contacts are<br />

leaf springs molded in blocks. Each block is called a contact group. One end of the<br />

spring is formed into a prong, which makes contact with the plugboard terminal. The<br />

other end has a contact. Figure 1–15 shows a typical configuration of the relay contact<br />

components.<br />

FRONT<br />

CONTACT<br />

PRESSURE<br />

PLATE<br />

PLUGBOARD<br />

CONTACTS<br />

HEEL<br />

STOP<br />

PLATE<br />

Figure 1–15. Relay Contact Components<br />

1.2.11. Coils<br />

On B1 and B2 DC relays, there is space enough on each of the two cores for one fulllength<br />

coil, approximately 4 inches long. Coils shorter than this are used when the cores<br />

are partly filled with copper or aluminum washers or slugs for use in slow-acting relays.<br />

1.2.11.1. Identifying Coil Leads<br />

The two leads of a coil are designated as "in" and "out" leads. From the prong end of a<br />

coil, the IN lead is attached to the prong that is closer to the center of the coil. The OUT<br />

lead is attached to the prong furthest from the center.<br />

If a coil has two windings, the winding nearer the prongs is connected to the prongs.<br />

Leads of the second winding are tagged and have terminals applied.<br />

P1457, Rev. Nov/07 1–15 <strong>Alstom</strong> Signaling Inc.

General Description<br />

1.2.11.2. Numbering of Coil Terminals<br />

Two digit coil terminal identifiers consisting of a number and a letter are molded in the<br />

phenolic plugboard. The number is taken from the vertical row in which the terminal is<br />

located. The letter shows its position in that row. Letter A is given to the highest<br />

terminal, letter D to the lowest terminal for B relays. Letter E is use to designate test<br />

terminals. See Figure 1–16.<br />

3A<br />

1C<br />

COIL<br />

TERMINALS<br />

3B<br />

3D<br />

3C<br />

1D<br />

SPARE TERMINAL<br />

BLOCK<br />

(P/N 46048-053-01)<br />

IF SO EQUIPPED<br />

6D<br />

6C<br />

1C<br />

1D<br />

COIL<br />

TERMINALS<br />

3E<br />

1E<br />

TEST<br />

TERMINALS<br />

6E<br />

1E<br />

TEST<br />

TERMINALS<br />

B1<br />

B2<br />

Figure 1–16. Coil Terminal Numbers, B1 and B2 Relay (Rear View)<br />

P1457, Rev. Nov/07 1–16 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2. SECTION 2 – THEORY OF OPERATION<br />

2.1. GENERAL<br />

This section covers the functions of <strong>Alstom</strong> <strong>Type</strong> B relays.<br />

B relays contain various arrangements of contacts and coils. Information is presented<br />

as follows:<br />

• Relay Contacts and Coils<br />

• B1 <strong>Relays</strong><br />

• B2 <strong>Relays</strong><br />

Figure 2–1 identifies typical B1 relay components. Some type B2 relays look very<br />

similar to the typical B1 relay shown, others do not. See the B2 relay discussions for<br />

relay descriptions.<br />

P1457, Rev. Nov/07 2–1 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

COMPRESSION SPRING<br />

COVER<br />

COIL SPRING STUD<br />

ARMATURE STOP SCREW<br />

BRIDGE OR ARM. EXTENSION<br />

PUSHER<br />

BACK CONTACT<br />

HEEL CONTACT<br />

FRONT CONTACT<br />

CONTACT PRONGS<br />

BASE<br />

CONTACT GROUP<br />

PRESSURE PLATES<br />

STOP PLATES<br />

PUSHER JAW<br />

PUSHER RETAINING CLIPS<br />

ROLLER ON FINGER<br />

ARMATURE<br />

ARMATURE<br />

RETAINING<br />

PLATE<br />

ADJ. NUT<br />

LOCK NUT<br />

YOKE<br />

NUT<br />

ARMATURE<br />

BEARING<br />

PLATE<br />

NAME<br />

PLATE<br />

SAFETY<br />

PIN<br />

COIL<br />

REGISTRATION COIL<br />

PLATES PRONGS<br />

ADJUSTABLE RESIDUAL SCREW<br />

CORE<br />

NOTE: SOME PARTS MAY DIFFER IN DETAIL FROM THOSE SHOWN ABOVE BUT NAME<br />

DESIGNATION REMAINS THE SAME.<br />

Figure 2–1. Typical B1 Relay Components<br />

P1457, Rev. Nov/07 2–2 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2.2. RELAY CONTACTS AND COILS<br />

2.2.1. Definitions<br />

The following terms are used in the descriptions of how relay contacts operate:<br />

• Front -Relay contact that is open when relay is de-energized.<br />

• Heel - Contact that is driven by pusher.<br />

• Back - Relay contact that is made when relay is de-energized (normally closed).<br />

• Make - Specified dimension that will cause all front or back contacts to be just made<br />

(closed) when a gauge of the specific dimension is inserted between the armature<br />

residual screw and core face with the relay energized.<br />

• Break - All front or back contacts are just open when a gauge of a specific<br />

dimension is inserted between the armature residual screw and the core face with<br />

the relay de-energized.<br />

• Break-before-make - In a dependent front-heel-back contact, the back contact will<br />

break before the front contact makes as the relay is energized.<br />

• Makes-before-break - In a dependent front-heel-back contact, the front contact will<br />

make before the back contact breaks.<br />

A complete glossary of terms used in this manual is available in Appendix B.<br />

2.2.2. Contact Groups<br />

There are typically six springs per contact group, furnished in various combinations of<br />

contacts. The AC Vane Relay contact groups contain four springs.<br />

Springs are furnished for each group in various combinations of contacts. For example,<br />

a contact group can have two dependent front-back (FB) contacts or three independent<br />

contacts (front or back).<br />

• A dependent FB contact uses three springs, one for the stationary front (F), one for<br />

the stationary back (B), and one for the movable heel.<br />

• An independent contact uses two springs, one for the stationary contact (front or<br />

back), and one for the movable heel.<br />

P1457, Rev. Nov/07 2–3 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

The relay armature, as shown in Figure 2–2, has a bridge attached to it, which engages<br />

a pusher. The pusher engages a roller on the heel contact to move the heel contact up<br />

or down in response to the movement of the relay armature.<br />

HEEL CONTACT<br />

ROLLER<br />

ARMATURE<br />

BRIDGE<br />

PUSHER<br />

Figure 2–2. Heel Contact Engaging Pusher<br />

Typical contact groups are shown in Figure 2–3.<br />

2 Front-Back (FB) Dependent Contacts 1 Front (F) 2 Back (B) Independent Contacts<br />

3 Back (B) Independent Contacts<br />

Figure 2–3. Three Different Contact Combinations<br />

P1457, Rev. Nov/07 2–4 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2.2.2.1. Contact Combinations<br />

A B1 relay has space for three contact groups. For example, a relay with 6 front-back<br />

dependent contacts has three groups, each with 2 front-back contacts. A relay with 4<br />

front-back dependent contacts and 2 front and 1 back independent contacts also has<br />

three groups, two with 2 front-back dependent contacts, and one with 2 front and 1 back<br />

independent contacts.<br />

A typical B2 relay has space for six contact groups. For example, a relay with 12 frontback<br />

contacts has six groups, each with 2 front-back contacts. The B2 AC Vane relay<br />

has a different configuration with space for four contact groups.<br />

Table 2–1 shows the contact combinations normally furnished with B relays. For the<br />

configuration of specific arrangements, see Section 7.<br />

Table 2–1. Typical Relay Contact Combinations<br />

<strong>Type</strong><br />

B1 <strong>Relays</strong><br />

(3 Contact Groups)<br />

B2 <strong>Relays</strong><br />

(6 Contact Groups)<br />

B2 Vane <strong>Relays</strong><br />

(4 Contact Groups)<br />

Neutral 2FB, 4FB, 4F-2B, 12FB<br />

4FB-2F-1B, 6FB<br />

Biased-Neutral 4FB-2F-1B, 6FB 8FB-4F-2B, 12FB<br />

Magnetic-Stick 4 NR<br />

Power-Transfer 2FB, 6FB<br />

Light-Out 4FB, 4F-2B, 6FB<br />

AC Vane<br />

2FB, 4FB<br />

FB<br />

Front-Back Dependent Contact<br />

F<br />

Front Independent Contact<br />

B<br />

Back Independent Contact<br />

NR<br />

Normal-Reverse Dependent Contact<br />

P1457, Rev. Nov/07 2–5 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2.2.2.2. Regular Contacts<br />

Contacts for regular service are rated for a resistance load of 4 amperes continuously.<br />

Front contacts are silver-impregnated-carbon to silver; back contacts are silver to silver.<br />

See Figures 2–4 and 2–5.<br />

FRONT CONTACT SILVER<br />

IMPREGNATED CARBON<br />

HEEL SILVER<br />

BACK CONTACT SILVER<br />

Figure 2–4. 2 Front (F) and 1 Back (B) Independent Regular Contacts<br />

Figure 2–5. 2 Front-Back (FB) Dependent Regular Contacts<br />

P1457, Rev. Nov/07 2–6 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2.2.2.3. Heavy-Duty Contacts<br />

Heavy-duty contacts, shown in Figure 2–6, are commonly used in circuits of the first and<br />

second voltage ranges where the continuous resistive load current is more than four<br />

amperes. The first voltage range is 30 volts or less; the second voltage range is over 30<br />

volts to 175 volts inclusive. Front contacts are usually Silver-Impregnated-Carbon to<br />

Silver; back contacts are Silver to Silver.<br />

For the rating of contacts on relays containing heavy-duty (HD) contacts consult the<br />

specific relay's Engineering Data (ED) sheet.<br />

Figure 2–6. 2 Front-Back (FB) Dependent Heavy-Duty Contacts<br />

P1457, Rev. Nov/07 2–7 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2.2.2.4. Contacts with Magnetic Blowouts<br />

Heavy-duty contacts equipped with magnetic blowouts, shown in Figure 2–7, are<br />

generally used in d-c circuits carrying inductive loads where the continuous current is<br />

more than four amperes and where operation is in the second or third voltage ranges.<br />

The third voltage range is over 175 volts to 250 volts inclusive.<br />

For the rating of contacts on relays containing heavy-duty contacts with blowout<br />

magnets (XHD) consult the specific relay's Engineering Data (ED) sheet.<br />

MAGNETIC<br />

BLOWOUT<br />

MAGNETIC<br />

BLOWOUT<br />

Figure 2–7. One Front and One Back Independent Heavy-Duty Contacts<br />

with Magnetic Blowouts<br />

Both front and back contacts are the heavy-duty type just described. Magnets are held<br />

in clips close to the contacts. The effect is to "blow" or disperse the electric arc before it<br />

has a chance to grow and burn. The front contact opening is usually 0.125” minimum for<br />

this type of contact.<br />

Using magnetic blowout contacts sacrifices the space of one contact group in the relay.<br />

P1457, Rev. Nov/07 2–8 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2.2.3. Coils<br />

A coil may be made up of one or more separate windings, leads from these windings<br />

being fastened to prongs that engage with the plugboard terminals or to terminals that<br />

go on a binding post within the relay. See Figures 2–8 and 2–9.<br />

A typical coil is wound on a phenolic spool that slips over one core of the relay. Every<br />

coil is identified with its drawing number and nominal resistance.<br />

IN<br />

WINDING DIAGRAM<br />

OUT<br />

IN<br />

OUT<br />

CAP REMOVED<br />

CAP<br />

Figure 2–8. Coil Construction, One Winding<br />

"IN" FOR "A" WINDING<br />

"A"<br />

"B"<br />

"IN" FOR "B" WINDING<br />

"OUT" FOR "A" WINDING<br />

"OUT" FOR "B" WINDING<br />

"A"<br />

WINDING<br />

"B"<br />

WINDING<br />

WINDING DIAGRAM<br />

CAP<br />

IN<br />

OUT<br />

LEADS FOR "B" WDG.<br />

CAP REMOVED<br />

Figure 2–9. Coil Construction, Two Windings<br />

P1457, Rev. Nov/07 2–9 <strong>Alstom</strong> Signaling Inc.

Theory of Operation<br />

2.2.3.1. One-Coil <strong>Relays</strong> (Slow Acting <strong>Relays</strong>)<br />

One core of a relay can be completely filled with copper washers or a slug of aluminum<br />

or copper to make the relay slow acting. In this case, only one coil is used to operate<br />

the relay. The more washers used, or the longer the slug, the slower the relay operates.<br />

If the relay is to be slightly slow acting, short coils on the cores usually provide enough<br />

room for the required number of washers or a short slug. If the relay is to be slower<br />

acting, one coil is put on the lower core and a slug is put on the upper core.<br />

The circuit of a one-coil B1 relay is shown in Table 2–2 (3A and 3B). The IN lead of the<br />

coil is connected to the 3C terminal on the plugboard; the OUT lead is connected to the<br />

3D terminal. Positive energy is applied through the current test terminal 3E to terminal<br />

3C.<br />

The circuit for a one-coil B2 relay is shown in Table 2–2 (3A and 3B). The IN lead of the<br />

coil is in contact with the 6C terminal on the plugboard; the OUT lead contacts the 6D<br />

terminal. Positive energy is applied through the current test terminal 6E to terminal 6C.<br />

B2 neutral relays with slugs are rarely used, as there is seldom the need for B2 slowrelease<br />

relays with such large contact capacity.<br />

2.2.3.2. Two-Coil <strong>Relays</strong><br />

In two-coil B1 relays, the upper coil plugs onto terminals 3A and 3B of the plugboard,<br />

the lower coil onto terminals 3C and 3D. Connections between the coils are made on<br />

the back of the plugboard for series, parallel, or single coil operation. The circuits in<br />

Table 2–2 show these possibilities.<br />

In two-coil B2 relays, from the front of the relay, the left-hand coil plugs onto terminals<br />

1C and 1D, the right-hand coil onto terminals 6C and 6D. See Table 2–2 for a brief<br />

explanation of circuit description, timing characteristics and application notes.<br />

P1457, Rev. Nov/07 2–10 <strong>Alstom</strong> Signaling Inc.

P1457, Rev. Nov/07 2–11 <strong>Alstom</strong> Signaling Inc.<br />

1<br />

Circuit<br />

B1 Relay B2 Relay<br />

E = 2 RI<br />

I<br />

–<br />

3A<br />

R<br />

R<br />

3D<br />

2<br />

3B<br />

3C<br />

E = (1/2r)(2I)<br />

2I<br />

– r<br />

3A<br />

r<br />

3B<br />

3D 3C<br />

3A<br />

–<br />

3B<br />

4<br />

–<br />

–<br />