MAWS HydroMet™ Systems for Meteorological and Hydrological ...

MAWS HydroMet™ Systems for Meteorological and Hydrological ...

MAWS HydroMet™ Systems for Meteorological and Hydrological ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

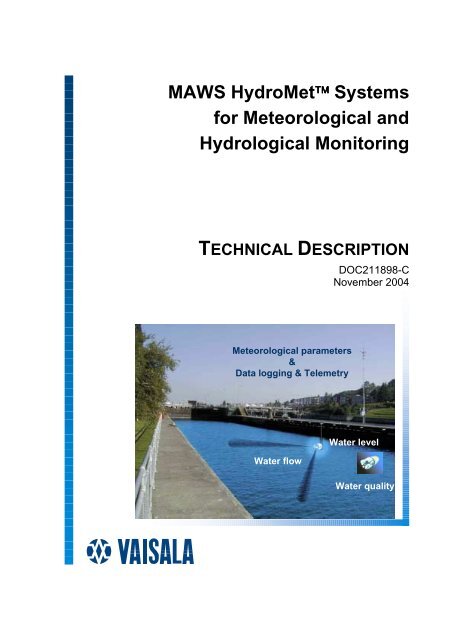

<strong>MAWS</strong> HydroMet <strong>Systems</strong><br />

<strong>for</strong> <strong>Meteorological</strong> <strong>and</strong><br />

<strong>Hydrological</strong> Monitoring<br />

TECHNICAL DESCRIPTION<br />

DOC211898-C<br />

November 2004<br />

<strong>Meteorological</strong> parameters<br />

&<br />

Data logging & Telemetry<br />

Water flow<br />

Water level<br />

Water quality

PUBLISHED BY<br />

Vaisala Oyj Phone (int.): +358 9 8949 1<br />

P.O. Box 26 Fax: +358 9 8949 2227<br />

FIN-00421 Helsinki<br />

Finl<strong>and</strong><br />

Visit our Internet pages at http://www.vaisala.com/<br />

© Vaisala 2004<br />

The contents are subject to change without prior notice.

_________________________________________________________________________________<br />

Table of Contents<br />

GENERAL INFORMATION ............................................................................3<br />

Technology................................................................................3<br />

St<strong>and</strong>ardization – Economies of Scale <strong>and</strong> Scope ...............5<br />

Life Cycle Cost..........................................................................6<br />

Reliability <strong>and</strong> Flexibility..........................................................7<br />

Exp<strong>and</strong>ability ............................................................................8<br />

Quality Assurance ....................................................................9<br />

MAIN COMPONENTS ..................................................................................11<br />

QML201 Logger.......................................................................12<br />

Compact Flash Memory Card Option ...................................13<br />

QMI108 Digital I/O Module .....................................................14<br />

Display <strong>and</strong> Keyboard Units..................................................15<br />

QMD201 ..............................................................................16<br />

QMD202 ..............................................................................16<br />

QMD170 ..............................................................................17<br />

<strong>MAWS</strong> Enclosure ....................................................................17<br />

ENC542PLM........................................................................17<br />

QBR101B Battery Regulator..................................................20<br />

Transient Protection Devices ................................................20<br />

Options ....................................................................................21<br />

SOFTWARE..................................................................................................23<br />

General Characteristics .........................................................23<br />

Sensor Library ........................................................................24<br />

Generic Sensor Interfaces .....................................................25<br />

Digital Input/Output..............................................................26<br />

Data Quality Control...............................................................28<br />

Auto-calibration....................................................................28<br />

Climatological/Measurement Limits Check .........................28<br />

Sensor Status In<strong>for</strong>mation...................................................29<br />

Checking Statistical Calculations ........................................30<br />

Calculations ............................................................................31<br />

Data Messages <strong>and</strong> Reports..................................................34<br />

Alarms..................................................................................35<br />

Data Acquisition...................................................................36<br />

Remote Maintenance ..........................................................37<br />

Logged Data in Reports.......................................................37<br />

Data Compression...............................................................38<br />

Communication.......................................................................39<br />

Power Management................................................................40<br />

Power monitoring of telemetry devices ...............................41<br />

Dynamically Controlled Timer Function...............................41<br />

DATA LOGGING ..........................................................................................43<br />

VAISALA _________________________________________________________________________ 1

Technical Description ________________________________________________________________<br />

Internal Flash Memory........................................................... 43<br />

External Compact Flash Card............................................... 44<br />

TELEMETRY AND COMMUNICATION ...................................................... 47<br />

Serial I/O Lines ....................................................................... 47<br />

Hardwire Telemetry................................................................ 49<br />

Wireless Telemetry ................................................................ 51<br />

POWERING.................................................................................................. 55<br />

Solar Power ............................................................................ 55<br />

SOLAR12-75....................................................................... 56<br />

SOLAR24............................................................................ 57<br />

Backup Batteries.................................................................... 58<br />

Optional Mains (AC) Power Supply MGP15V-M3................ 58<br />

OPERATING ENVIRONMENT .................................................................... 61<br />

Operating temperature .......................................................... 61<br />

ESD/EMI .................................................................................. 62<br />

MASTS ......................................................................................................... 63<br />

DKP206W & DKP210W - Pole Masts .................................... 63<br />

DKP102 - 2 m Pole Mast ........................................................ 65<br />

AFTER SALES SERVICE............................................................................ 67<br />

Commitment to Long Term Service ..................................... 67<br />

TECHNICAL DATA...................................................................................... 69<br />

QML201 Logger...................................................................... 69<br />

ENC542PLM Enclosure ......................................................... 70<br />

Mains Power Supply Unit MGP15V (Optional) .................... 71<br />

Battery Regulator QBR101B ................................................. 72<br />

Solar Panels............................................................................ 73<br />

Backup Batteries.................................................................... 74<br />

2 ________________________________________________________________________________

Chapter 1 _________________________________________________________ General In<strong>for</strong>mation<br />

CHAPTER 1<br />

GENERAL INFORMATION<br />

This document give you detailed in<strong>for</strong>mation on the <strong>MAWS</strong><br />

HydroMet systems, which offer advanced environmental monitoring<br />

features integrated into a compact <strong>and</strong> economical system package.<br />

For more details on available sensors <strong>and</strong> telemetry solutions, please<br />

refer to the following technical description documents:<br />

• <strong>MAWS</strong> <strong>Systems</strong>- <strong>Meteorological</strong> Sensors (DOC211899)<br />

• <strong>MAWS</strong> <strong>Systems</strong> - <strong>Hydrological</strong> Sensor (DOC211895)<br />

• <strong>MAWS</strong> <strong>Systems</strong> - Sensors <strong>for</strong> Soil Measurements (DOC211896)<br />

• <strong>MAWS</strong> System - Telemetry (DOC211897)<br />

Technology<br />

The <strong>MAWS</strong> HydroMet systems integrated around the QML201<br />

Logger are new generation, fully integrated systems especially<br />

designed <strong>for</strong> applications where no commercial power or<br />

communication networks are present or are too expensive to be<br />

installed. Due to their flexibility <strong>and</strong> economical design, the <strong>MAWS</strong><br />

systems are the ideal choice <strong>for</strong> both meteorological <strong>and</strong> hydrological<br />

applications. The possibility of using the same <strong>and</strong> st<strong>and</strong>ard<br />

equipment <strong>for</strong> various applications lowers the cost of training, spare<br />

parts <strong>and</strong> logistics support – the Total Life Cycle Cost of the network<br />

investment. QML201 based systems offer the most economical<br />

solution when the total life cycle cost of operating the entire network<br />

is fully considered.<br />

VAISALA _________________________________________________________________________ 3

Technical Description ________________________________________________________________<br />

The <strong>MAWS</strong> HydroMet <strong>Systems</strong> are integrated in a compact, readyto-install<br />

package:<br />

• <strong>MAWS</strong>301 <strong>for</strong> applications requiring larger back-up batteries<br />

<strong>and</strong>/or multiple telemetry solutions.<br />

The <strong>MAWS</strong> systems are compact, environmentally robust <strong>and</strong> low<br />

power systems to provide reliable <strong>and</strong> continuous data on a multitude<br />

of meteorological <strong>and</strong> hydrological parameters. Based on the latest<br />

technology both in measurements <strong>and</strong> communication, <strong>MAWS</strong>301<br />

can be interfaced with a large choice of telecommunication equipment<br />

such as st<strong>and</strong>ard PSTN <strong>and</strong> GSM modems (incl. GPRS packetswitched),<br />

CDMA (incl. 1xRTT packet-switched), radio modems <strong>and</strong><br />

satellite transmitters. The direct connection to the LAN network (via<br />

tcp/ip) can easily be made using an economical COM Server module.<br />

The <strong>MAWS</strong> systems have been designed <strong>for</strong> applications where only a<br />

few sensors are required. However, these systems can easily be<br />

upgraded, even in the field, to include a larger set of sensors,<br />

including smart sensors such ceilometer, visibility <strong>and</strong> present weather<br />

sensors <strong>and</strong> multi-parameter water quality sondes <strong>and</strong> ADCP flow<br />

sensors. The same basic system with its options <strong>and</strong> accessories can<br />

cater <strong>for</strong> all the needs of meteorological <strong>and</strong> hydrological networks.<br />

<strong>MAWS</strong>301 Automatic Weather Station Installation<br />

4 ________________________________________________________________________________

Chapter 1 _________________________________________________________ General In<strong>for</strong>mation<br />

The new Digital I/O module option exp<strong>and</strong>s the use of the<br />

<strong>MAWS</strong> system into supervisory <strong>and</strong> control systems. This<br />

allows users to add controlling features such as<br />

burglary/v<strong>and</strong>alism alarms, flood gate controls <strong>and</strong><br />

optimization of telemetry device power, to name but a few.<br />

St<strong>and</strong>ardization – Economies of Scale <strong>and</strong><br />

Scope<br />

In<strong>for</strong>mation technology, sensor technology, electronics <strong>and</strong> data<br />

communication have developed rapidly in recent years. This has made<br />

the automation of meteorological <strong>and</strong> hydrological networks very<br />

economical <strong>and</strong> attractive to meteorological <strong>and</strong> hydrological<br />

institutes, power corporations <strong>and</strong> other authorities that need to<br />

monitor weather <strong>and</strong>/or manage water systems such as rivers, lakes,<br />

reservoirs <strong>and</strong> ground water. Hydrometeorological networks, which<br />

typically consist of hundreds of automatic monitoring stations,<br />

telecommunication systems, databases <strong>and</strong> application software <strong>for</strong><br />

users, are installed over wide geographical areas that often include<br />

remote areas. The equipment must be able to survive harsh weather<br />

conditions while providing in<strong>for</strong>mation on the prevailing weather,<br />

precipitation, water quality <strong>and</strong> existing water reserves that the<br />

authority needs to manage - whether scarce or overabundant - or give<br />

timely <strong>and</strong> accurate <strong>for</strong>ecasts, whether short or long-term.<br />

Meanwhile, dem<strong>and</strong> <strong>for</strong> meteorological <strong>and</strong> hydrological data is<br />

growing constantly due to new requirements arising from legislation,<br />

environmental awareness <strong>and</strong> the push <strong>for</strong> efficiency in many of the<br />

industries that drive our modern society. Nowcasting, including the<br />

<strong>for</strong>ecasting of floods <strong>and</strong> severe weather events, is creating new<br />

requirements <strong>for</strong> real-time monitoring.<br />

A hydrometeorological network is rarely used on its own <strong>and</strong> in many<br />

cases the same infrastructure is used <strong>for</strong> other applications as well.<br />

Complementary meteorological <strong>and</strong> climatological observations, or<br />

vise versa, are frequently required in order to be able to produce<br />

timely <strong>and</strong> accurate <strong>for</strong>ecasts, warnings, reports <strong>and</strong> other end<br />

products. New <strong>for</strong>ecasting models require more data <strong>and</strong> more<br />

parameters to be monitored - both in meteorology <strong>and</strong> in hydrology.<br />

If the network is located in a populated area, the hydrometeorological<br />

stations can provide accurate real-time weather in<strong>for</strong>mation to the<br />

local community, environmentally hazardous industry, fire brigades,<br />

holiday resorts etc, who would not otherwise have accurate<br />

meteorological in<strong>for</strong>mation available. By using the same sensor, data<br />

VAISALA _________________________________________________________________________ 5

Technical Description ________________________________________________________________<br />

logger <strong>and</strong> telecommunication technology the network operator can<br />

enjoy the benefits of economies of scale <strong>and</strong> scope by reducing the<br />

cost of network design <strong>and</strong> maintenance servicing, including spare<br />

parts <strong>and</strong> training. The archived savings in network operation can then<br />

be used to further automate the conventional network or otherwise<br />

improve hydrometeorological services.<br />

Life Cycle Cost<br />

Although some administrative procedures still favor a “lowest bidder<br />

is the winner” policy, the Total Life Cycle Cost (TLCC) is becoming a<br />

subject of greater importance. The TLCC is the total cost during the<br />

expected lifetime of the meteorological <strong>and</strong> hydrological equipment.<br />

A basic concept of the TLCC contains the following four elements;<br />

T = P + R + O + C<br />

Product Cost<br />

Resource Cost<br />

Operating Cost<br />

Contingency Cost<br />

P<br />

R<br />

O<br />

C<br />

An optimum selection would be a combination of a low T <strong>and</strong> a good<br />

overall per<strong>for</strong>mance of the equipment to be purchased. We have aimed<br />

at a low Life Cycle Cost when designing the <strong>MAWS</strong> system <strong>and</strong> when<br />

selecting its system components <strong>and</strong> accessories.<br />

The Product Cost contains, in addition to the basic price quoted,<br />

installation, testing <strong>and</strong> documentation, packaging <strong>and</strong> transportation,<br />

taxis <strong>and</strong> duties etc.<br />

The Resource Cost includes site preparation works such as site<br />

purchasing, access to the site, possible building(s), electricity etc. The<br />

<strong>MAWS</strong> systems are compact, lightweight <strong>and</strong> easy to install.<br />

Frequently they are powered by solar panel <strong>and</strong> communicate via<br />

wireless telemetry, thus minimizing site preparation costs.<br />

When talking about unmanned, automated equipment the major part<br />

of the Operating Cost comes from the telecommunication <strong>and</strong><br />

maintenance costs. In addition, modification <strong>and</strong> upgrade costs will<br />

play a more significant role in future systems. The <strong>MAWS</strong> systems<br />

already have field proven extended Mean Time Between Failure<br />

(MTBF) rates. In addition, maintenance is made easy with modular,<br />

easy to replace modules <strong>and</strong> sensors with connectors. A wide range of<br />

telemetry options always offer the most economical <strong>and</strong> reliable<br />

alternative <strong>for</strong> data transmission.<br />

6 ________________________________________________________________________________

Chapter 1 _________________________________________________________ General In<strong>for</strong>mation<br />

The Contingency Cost primarily contains possible risks in the planned<br />

purchase such as a defective product, late delivery, inability to deliver<br />

at all, or inability to support the investment with spare parts <strong>and</strong><br />

upgrades during the life time of the equipment, frequently calculated<br />

as 10- 15 years. Vaisala, as the largest manufacturer of meteorological<br />

systems, can guarantee timely delivery. In addition, it is Vaisala’s<br />

policy to support its equipment <strong>for</strong> its whole lifetime with spare parts,<br />

training, upgrades <strong>and</strong> technical support, incl. HelpDesk functions.<br />

Reliability <strong>and</strong> Flexibility<br />

Vaisala's HydroMet Station <strong>MAWS</strong>301 combines Vaisala's <strong>and</strong><br />

H<strong>and</strong>ar's long term expertise with a new, compact data logger design.<br />

The design has been derived from field experience with the<br />

MILOS200, MILOS500, QLC50, QLI50 <strong>and</strong> H<strong>and</strong>ar's 555 systems in<br />

synoptic, climatological, hydrological <strong>and</strong> research applications <strong>and</strong> in<br />

the most dem<strong>and</strong>ing industrial use. There are over 25,000 of these<br />

pieces of equipment installed in over 70 countries.<br />

<strong>MAWS</strong> HydroMet systems are an excellent choice <strong>for</strong> applications<br />

requiring ease of installation, low power consumption, automatic<br />

operation <strong>and</strong> interfacing with modern telecommunication options<br />

such as satellite transmitters <strong>and</strong> packed-switched data networks.<br />

The <strong>MAWS</strong> systems are easy to install <strong>and</strong> maintain. All connections<br />

are pre-wired. The sensors are equipped with ready-made cables <strong>and</strong><br />

connectors/gl<strong>and</strong>s <strong>for</strong> quick installation. All optional modules such as<br />

modems, mains power supplies <strong>and</strong> surge arrestors are easily mounted<br />

on DIN-rails without any special tools.<br />

VAISALA _________________________________________________________________________ 7

Technical Description ________________________________________________________________<br />

The <strong>MAWS</strong> is the most modern HydroMet system including all<br />

necessary functions designed on a single printed board logger. Using<br />

the latest Surface Mounted Technology the board is very compact <strong>and</strong><br />

uses little current. It has a very high Mean-Time-Between-Failure<br />

(MTBF) value (over 20,000 hours strictly according to MIL-HNDB-<br />

217F).<br />

The <strong>MAWS</strong> HydroMet systems are field proven in various<br />

installations around the world. The <strong>MAWS</strong> stations are already in use<br />

in over 65 countries around the world.<br />

For example, the <strong>MAWS</strong>301 stations are used in the Surface Weather<br />

<strong>and</strong> Airport systems in the SIVAM (Sistema de Vigilancia da<br />

Amazonia) in Brazil. Climatological networks in Pol<strong>and</strong>, Romania<br />

<strong>and</strong> Brazil are equipped with the <strong>MAWS</strong> systems. The Swedish<br />

<strong>Hydrological</strong> <strong>and</strong> <strong>Meteorological</strong> Institute (SMHI) automated their<br />

whole hydrological network using the <strong>MAWS</strong>301. In addition, the US<br />

Air <strong>for</strong>ce’s new generation Tactical <strong>Meteorological</strong> (TACMET)<br />

Observation System is based on the same <strong>MAWS</strong> technology with<br />

300 systems already in field operations. For further details of <strong>MAWS</strong><br />

references, please see the <strong>MAWS</strong> Reference List.<br />

Based on Vaisala’s continuous product development, the <strong>MAWS</strong><br />

HydroMet system offers a versatile system concept with a planned<br />

upgrade path to meet future customer requirements.<br />

Exp<strong>and</strong>ability<br />

<strong>MAWS</strong> HydroMet systems are already economical in applications,<br />

requiring only few sensors. However, they are easily <strong>and</strong><br />

economically exp<strong>and</strong>able to incorporate a large number of sensors,<br />

including intelligent sensors with different types of serial interface.<br />

The total number of inputs in the basic data logger is 20 analog inputs<br />

(single ended) with the possibility to use them as digital inputs (state),<br />

2 counters <strong>and</strong> a dedicated input <strong>for</strong> a Vaisala atmospheric pressure<br />

sensor (frequency). Intelligent sensors can be interfaced using the RS-<br />

232, RS-485 <strong>and</strong> SDI-12 serial interfaces, up to 7 ports.<br />

The new optional expansion modules include:<br />

• QMI108 Digital I/O Module with 8 digital inputs <strong>and</strong> 8 digital<br />

outputs <strong>for</strong> digital measurements <strong>and</strong> control purposes.<br />

• QMU101 Sensor Multiplexer with additional 20 single ended (10<br />

diff.) analog inputs<br />

8 ________________________________________________________________________________

Chapter 1 _________________________________________________________ General In<strong>for</strong>mation<br />

Quality Assurance<br />

Vaisala's quality management system meets the requirements of the<br />

ISO 9001 quality system st<strong>and</strong>ard. Vaisala's quality management<br />

system has been granted the ISO 9001 Quality System Certificate No.<br />

1413-02 (First issue 1993-03-18) by the Finnish St<strong>and</strong>ardization<br />

Organization <strong>and</strong> the IQNet -The International Certification Network.<br />

The Finnish Defense Forces have granted Vaisala a Certificate No.8<br />

<strong>for</strong> meeting the requirements of AQAP 110 <strong>and</strong> ISO 9001 since<br />

1.12.1990. More in<strong>for</strong>mation on Vaisala's Quality Assurance system is<br />

available in a separate document.<br />

WAA151 Anemometer <strong>and</strong><br />

WAV151 Wind vane with<br />

WT521 transmitter, cross<br />

arm <strong>and</strong> 10 m cable<br />

QMW110<br />

Combined Wind Sensor<br />

with 10 m cable <strong>and</strong> mast<br />

mounting accessories<br />

Pyranometer<br />

SOLAR24<br />

Solar panel, 24 W<br />

with cable <strong>and</strong> mast<br />

mounting accessories<br />

QMH102<br />

Temperature <strong>and</strong><br />

Relative Humidity<br />

Probe inside<br />

DTR502<br />

Radiation Shield<br />

Satellite antenna<br />

Mast<br />

Sensor support arm<br />

QMR102 Rain<br />

gauge <strong>and</strong> st<strong>and</strong><br />

<strong>MAWS</strong>301<br />

Automatic Weather<br />

Station with PMT16A<br />

Pressure sensor,<br />

incl. rad. shield <strong>and</strong><br />

mast mounting<br />

accessories<br />

Soil temperature sensor(s)<br />

An Example of a Typical Met. Station Layout<br />

VAISALA _________________________________________________________________________ 9

Technical Description ________________________________________________________________<br />

GSM antenna<br />

QMW110<br />

Combined Wind<br />

Sensor with 10 m<br />

cable <strong>and</strong> mast<br />

mounting<br />

accessories<br />

FD12P<br />

PW & Visibility Sensor<br />

Pyranometer<br />

QMH102<br />

Temperature <strong>and</strong><br />

Relative Humidity Probe<br />

in DTR502 Radiation Shield<br />

QMR102<br />

Rain Gauge<br />

<strong>and</strong> st<strong>and</strong><br />

DKP12SUP1<br />

DKP12<br />

10 m pole mast<br />

<strong>MAWS</strong>301<br />

Automatic Weather<br />

Station with PMT16A<br />

Pressure sensor ,<br />

BWT15SX Mains power<br />

sypply, comms modules,<br />

incl.. rad. shield <strong>and</strong> mast<br />

mounting accessories<br />

2-wire RS-485<br />

cable not included<br />

CT25K<br />

Ceilometer with cloud<br />

coverage algorithm<br />

Mains (AC) power<br />

2-wire RS-485 Mains (AC) power<br />

cable not included<br />

+5 cm<br />

+-0<br />

-5 cm<br />

-10 QMT107<br />

-20 Multi -level Soil<br />

-50 Temperature probe<br />

Mains (AC) power<br />

-100<br />

An Example of a Met. Station with an Extended Set of Sensors<br />

QMR102<br />

Rain gauge<br />

GSM antenna<br />

Solar panel<br />

<strong>MAWS</strong>110<br />

incl. back-up battery,<br />

GSM data terminal<br />

<strong>and</strong> accessories<br />

Pole mast<br />

Water level<br />

sensor<br />

An Example of a Typical Pluviometric / Water Level Station<br />

10 _______________________________________________________________________________

Chapter 2 __________________________________________________________ Main Components<br />

CHAPTER 2<br />

MAIN COMPONENTS<br />

<strong>MAWS</strong> HydroMet systems are integrated into the versatile<br />

<strong>MAWS</strong>301. The basic <strong>MAWS</strong> HydroMet system comprises the<br />

following main components.<br />

Back-up batteries of<br />

7, 12, 24 or 48 Ah<br />

Telemetry options, incl:<br />

PSTN & cellular modems,<br />

UHF modems, LAN<br />

satellites: readiness <strong>for</strong><br />

multiple telemetry<br />

solutions<br />

QML201 Logger with<br />

options (Digital I/O,<br />

Sensor Mux. etc)<br />

Power supply options,<br />

battery regulator, surge<br />

arrestors etc<br />

Main Components (photo of <strong>MAWS</strong>301 system)<br />

VAISALA ________________________________________________________________________ 11

Technical Description ________________________________________________________________<br />

QML201 Logger<br />

The QML201 is a complete data logger with a highly specialized<br />

single board computer (CPU) which makes the measurements <strong>and</strong><br />

calculations, controls all system functions <strong>and</strong> telemetry devices <strong>and</strong><br />

logs data. The simplicity of the single board approach reduces the<br />

need <strong>for</strong> excess interconnecting wires <strong>and</strong> cables. It also greatly<br />

enhances reliability <strong>and</strong> reduces the cost of maintaining a spare part<br />

stock. This board contains the 32-bit Motorola CPU <strong>for</strong> data<br />

processing <strong>and</strong> 10 differential (20 single ended) analog sensor inputs.<br />

There are also three (3) frequency sensor interfaces, the 16 bit A/D<br />

converter, 1.7 Mbytes of secure Flash memory <strong>for</strong> data logging, RS-<br />

232 <strong>and</strong> RS-485 serial ports, a real-time-clock <strong>and</strong> a power supply<br />

also providing sensor excitations.<br />

The QML201 has an internal Real-Time-Clock with a resolution of 1<br />

second (internally in milliseconds) <strong>and</strong> stability better than 20<br />

seconds/month. The RTC is backed up with a lithium battery. There is<br />

also the possibility of reading <strong>and</strong> adjusting the RTC using comm<strong>and</strong>s<br />

issued via serial ports, both locally <strong>and</strong> remotely, e.g. from the central<br />

data collection software. In addition, the RTC can be synchronized by<br />

GPS clock, as an independent device or built-in, e.g. in satellite<br />

transmitters.<br />

Optional modules include, <strong>for</strong> example, a Compact Flash (CF)<br />

memory card, various communication modules <strong>and</strong> a built-in pressure<br />

transducer.<br />

QML201 Logger<br />

12 _______________________________________________________________________________

Chapter 2 __________________________________________________________ Main Components<br />

The printed board uses the latest SMT <strong>and</strong> CPLD (Complex<br />

Programmable Logic Device) technologies <strong>and</strong> is uni<strong>for</strong>mly coated <strong>for</strong><br />

better protection <strong>and</strong> reliability in high humidity environments.<br />

Each sensor input has a varistor (VDR) protection against induced<br />

transients. The maintenance terminal connection (RS-232, COM0)<br />

also has transzorb diodes in its inputs.<br />

When long signal cables are needed, these will be equipped with<br />

optional devices <strong>for</strong> surge voltage protection. These surge arrestors<br />

consist of a combination of VDR, gas-filled discharge tube, transzorb<br />

diodes <strong>and</strong> coils, thus providing excellent protection. These DIN-rail<br />

mountable devices are easy to change without any special tools.<br />

Compact Flash Memory Card Option<br />

The QML201 Logger has a place <strong>for</strong> a st<strong>and</strong>ard Compact Flash<br />

memory card, the same as is used <strong>for</strong> example in a digital camera, <strong>for</strong><br />

logging a large amount of data. CF cards offer logging capacity from<br />

32 Mbytes to hundreds of Mbytes at a very economical cost. CF cards<br />

do not need any back-up battery <strong>for</strong> preserving contents practically<br />

indefinitely.<br />

The data is logged into the daily files making it easy to locate any<br />

particular data set e.g. <strong>for</strong> further analysis.<br />

Compact Flash Memory Card Option<br />

These cards can be read directly to the PC. Several different types of<br />

readers are commercially available at any PC or camera store; internal<br />

PCMCIA (PC-card) readers <strong>and</strong> external readers connected to the<br />

USB or parallel port of a PC.<br />

VAISALA ________________________________________________________________________ 13

Technical Description ________________________________________________________________<br />

Compact Flash Memory Card Readers<br />

QMI108 Digital I/O Module<br />

The new QML201 Logger provides the possibility to extend the<br />

digital I/O capacity of <strong>MAWS</strong> with the optional Digital I/O Module<br />

QMI108 equipped with eight digital inputs <strong>and</strong> eight digital outputs.<br />

Digital I/O Module QMI108<br />

0312-025<br />

14 _______________________________________________________________________________

Chapter 2 __________________________________________________________ Main Components<br />

The main characteristics of the QMI108 module are:<br />

• The module interfaces to the logger via the SPI connector, there<strong>for</strong>e<br />

it does not use any RS- channels.<br />

• The module has eight (8) open collector outputs with 30 VDC / 1 A<br />

continuous drive capability <strong>and</strong> LED indicators.<br />

• The eight (8) inputs of the module tolerate voltages from 0 to 25<br />

VDC (the absolute maximum 30 VDC), <strong>and</strong> they have 40 ms<br />

(typical) contact debouncing circuitry.<br />

• The module con<strong>for</strong>ms to the same environmental immunity <strong>and</strong><br />

emission st<strong>and</strong>ards than the logger.<br />

• The module also allows connection of slow pulse inputs, e.g. tipping<br />

bucket rain gauges.<br />

• The module is located inside the enclosure beside the logger.<br />

Display <strong>and</strong> Keyboard Units<br />

The <strong>MAWS</strong>301 HydroMet systems can be equipped with optional<br />

display <strong>and</strong> keyboard units at installation sites where an operator<br />

needs to see data locally <strong>and</strong>/or insert some own observations or<br />

reference data into the system. There are three different models of<br />

QMD - display <strong>and</strong> keyboard units utilizing the same hardware <strong>and</strong><br />

software technology.<br />

The QMD displays are programmable LCD displays with back light..<br />

They can show several lines of alphanumeric data. The full display<br />

size expressed in characters is 20*6 (width * height). The QMD<br />

displays include keypad with user-friendly menu, whose content is<br />

also configurable by the user. The displayed data is sent as reports to<br />

the display. The contents, <strong>for</strong>mat <strong>and</strong> updating intervals of these<br />

reports are user configurable. The update interval can be anything<br />

between 1 second <strong>and</strong> 24 hours. The QMD displays are <strong>for</strong>:<br />

• Viewing data messages whose contents are freely configurable by<br />

the user using the <strong>MAWS</strong> Lizard Setup software.<br />

• Setting up of an extended set of system parameters<br />

• Per<strong>for</strong>ming one-point calibration in the field (gain & offset)<br />

• Entering data <strong>and</strong>/or text messages via the keyboard.<br />

VAISALA ________________________________________________________________________ 15

Technical Description ________________________________________________________________<br />

QMD201<br />

The QMD201 unit is mounted on the door of the enclosure. The units<br />

can be accessed without opening the enclosure. This unit is mainly <strong>for</strong><br />

sites, where the enclosure will be installed indoors, e.g. in a "hut" built<br />

<strong>for</strong> a stilling well.<br />

QMD202<br />

The QMD202 unit is mounded on a DIN-rail inside the enclosure.<br />

Access is only by opening the enclosure door, which can be firmly<br />

locked.<br />

16 _______________________________________________________________________________

Chapter 2 __________________________________________________________ Main Components<br />

QMD170<br />

The QMD170 h<strong>and</strong>held unit is attached to the RS-232 port connector<br />

at the bottom flange of the enclosure. There is no need to open the<br />

door of the enclosure. The QMD170 unit is powered by its own<br />

rechargeable battery. Due to its light weight <strong>and</strong> small size, the<br />

QMD170 is easily carried to the installation site in the pocket. The<br />

length of the cable is 3 meters.<br />

<strong>MAWS</strong> Enclosure<br />

ENC542PLM<br />

The ENC542PLM is a polyester enclosure rein<strong>for</strong>ced with fiberglass<br />

<strong>for</strong> the <strong>MAWS</strong>301 HydroMet system. This robust enclosure has space<br />

<strong>for</strong> the QML201 Logger, multiple communication equipment, battery<br />

charger <strong>and</strong> maintenance free Lead-acid batteries of different sizes<br />

with a capacity of up to 48 Ah. Optional devices such as a mains<br />

power supply <strong>and</strong> protective devices <strong>for</strong> communication lines can also<br />

be installed inside the enclosure. All of these devices are installed on<br />

easy-to-remove DIN-rails except the back up battery which is installed<br />

by means of a screw fixed mounting clamp.<br />

VAISALA ________________________________________________________________________ 17

Technical Description ________________________________________________________________<br />

The modular design allows optional devices to be installed on two<br />

levels. These installation modules can easily be removed <strong>for</strong><br />

maintenance or replacement. The installation frame <strong>for</strong> equipment is<br />

made of stainless steel, which also provides excellent protective<br />

grounding.<br />

The enclosure material is highly resistant to corrosion, ultra-violet<br />

radiation, principal chemicals <strong>and</strong> atmospheric agents. The door<br />

sealing is ensured by using an extruded polyurethane foam gasket.<br />

The door has two keyed locks.<br />

The protection rating is min. IP 65 (equiv. NEMA 4X) i.e. dust tight<br />

<strong>and</strong> sealed against water jets. The enclosure material is selfextinguishing.<br />

The ENC542PLM enclosure can be equipped with an optional metal<br />

radiation shield, which is painted white. This shield gives additional<br />

protection against excessive sun radiation or falling material such as<br />

ice, tree branches etc. In addition, as st<strong>and</strong>ard there is a white back<br />

plate, this gives additional protection against excessive sun radiation.<br />

The enclosure has an optional pressure compensation element<br />

installed on the bottom plate. This element compensates <strong>for</strong> varying<br />

degrees of pressure caused by the temperature differences. The<br />

element has a GoreTex membrane filter, which prevents moisture<br />

sucking in while the enclosure is cooling off, because the element can<br />

"breathe". This membrane filter element together with plastic material<br />

of high quality <strong>and</strong> white painted shields significantly reduces water<br />

condensation inside the enclosure. There<strong>for</strong>e no drying agent, such as<br />

silicacel bags, is required inside the enclosure.<br />

18 _______________________________________________________________________________

Chapter 2 __________________________________________________________ Main Components<br />

In hydrological application where the equipment is frequently<br />

installed in small huts built e.g. over the stilling well, the radiation<br />

shield is not necessary.<br />

For future needs, the ENC542PLM enclosure has spare space reserved<br />

<strong>for</strong> optional devices.<br />

Bottom View of the ENC542PLM enclosure with extended<br />

meteorological configuration, all connectors are labeled<br />

All sensors, power supplies <strong>and</strong> communication devices are connected<br />

to the equipment inside the enclosure via environmentally sealed<br />

connectors.<br />

The protection class of all connectors is IP66 as a minimum. Each<br />

connector is identified individually with a label. The enclosure used in<br />

hydrological systems is normally economized <strong>for</strong> these applications.<br />

The atmospheric pressure sensor is located on the CPU board of the<br />

QML201 Logger. There is a static pressure head <strong>for</strong> venting out the<br />

pressure sensor, thus minimizing the wind effect on the pressure<br />

measurement.<br />

There is space <strong>for</strong> future expansion by installing new sensors <strong>and</strong>/or<br />

communication devices both in the CPU’s sensor inputs <strong>and</strong> in the<br />

enclosure.<br />

VAISALA ________________________________________________________________________ 19

Technical Description ________________________________________________________________<br />

QBR101B Battery Regulator<br />

The QBR101B Battery Regulator maintains the charging of the<br />

integral 12 V battery. The charge/recharge control includes a<br />

temperature compensation function as well as deep discharge<br />

protection of the battery. QBR101B also allows simultaneous inputs<br />

from both a solar panel <strong>and</strong> mains (AC) power.<br />

QBR101B Battery Regulator<br />

Also included are LED lamps <strong>for</strong> indicating Battery OK/Low <strong>and</strong><br />

Charge/Recharge conditions. In order to maximize autonomy time, the<br />

lamps are activated only while pressing the ON button.<br />

QBR101B is a rail-mountable unit allowing easy maintenance.<br />

Transient Protection Devices<br />

Each sensor input in the QML201 has varistor (VDR) protection<br />

against induced transients. The maintenance terminal I/O port has<br />

transzorb diodes in their inputs. A coaxial surge arrestor is used <strong>for</strong><br />

the RF signal input when radio or satellite equipment is being used.<br />

In case of long signal cables, additional transient protectors can be<br />

installed on the DIN-rail. These surge arrestors consist of a<br />

combination of VDR, gas discharge, transzorb diodes <strong>and</strong> coils, thus<br />

providing excellent protection.<br />

These are easy to change in the field without tools. In addition, these<br />

devices are industry st<strong>and</strong>ard <strong>and</strong> readily available locally, too.<br />

20 _______________________________________________________________________________

Chapter 2 __________________________________________________________ Main Components<br />

Surge Arrestor <strong>for</strong> the 230 <strong>and</strong> 115 VAC Mains Power<br />

Surge Arrestors <strong>for</strong> RS - serial lines <strong>and</strong> PT100 sensor<br />

Optional coaxial surge arrestors will be used <strong>for</strong> UHF / VHF antennas.<br />

Options<br />

In the <strong>MAWS</strong> enclosures there is space <strong>for</strong> various types of optional<br />

devices, such as:<br />

- Communication equipment (modems, satellite terminals, radio<br />

modem).<br />

- Mains power supplies, e.g. <strong>for</strong> the heating of a rain gauge or wind<br />

sensor<br />

- Additional protective devices against over-voltage <strong>and</strong> electric<br />

discharge, e.g. <strong>for</strong> communication lines or long signal cables.<br />

VAISALA ________________________________________________________________________ 21

Technical Description ________________________________________________________________<br />

This page intentionally left blank<br />

22 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

CHAPTER 3<br />

SOFTWARE<br />

General Characteristics<br />

The <strong>MAWS</strong> HydroMet systems utilize Vaisala’s field-proven <strong>and</strong><br />

accurate sensors, which are in extensive use in over 100 countries all<br />

over the world from Antarctica to tropical isl<strong>and</strong>s. The offered suite of<br />

meteorological sensors measures wind direction <strong>and</strong> speed, pressure,<br />

air <strong>and</strong> surface temperature, relative humidity, precipitation <strong>and</strong> global<br />

solar radiation. There is space <strong>for</strong> exp<strong>and</strong>ing the station with optional<br />

sensors such as soil temperature, net radiation, leaf wetness, water<br />

level etc. when necessary.<br />

The library of sensors also includes intelligent sensors such as a cloud<br />

height ceilometer with cloud cover algorithm, visibility <strong>and</strong> present<br />

weather.<br />

The suite of hydrological sensors includes various types of sensor <strong>for</strong><br />

measuring water level, water temperature, precipitation <strong>and</strong><br />

intelligent, multi-parameter water quality sondes <strong>and</strong> acoustic Doppler<br />

profilers <strong>for</strong> flow <strong>and</strong> discharge measurements.<br />

The operation of the <strong>MAWS</strong> systems can be easily set-up <strong>and</strong><br />

modified with the help of the user-friendly <strong>MAWS</strong> Lizard Setup<br />

program. Using the ready-made templates, this setup software guides<br />

the user through the simple set-up routines. Modifications to the<br />

system configuration <strong>and</strong> operation can easily be carried out by the<br />

user.<br />

All the configuration settings can be stored in the <strong>MAWS</strong> Lizard’s<br />

configuration library where they are easily available <strong>for</strong> modifications<br />

or <strong>for</strong> creating a new setup based on the old one. In addition, there is<br />

an Import/Export function <strong>for</strong> adding new setup files, or, <strong>for</strong> example,<br />

VAISALA ________________________________________________________________________ 23

Technical Description ________________________________________________________________<br />

<strong>for</strong> sending an old file to the Vaisala Helpdesk in case troubleshooting<br />

or other assistance is needed.<br />

Lizard Configuration Software<br />

Sensor Library<br />

The <strong>MAWS</strong> HydroMet systems have a large <strong>and</strong> continuously<br />

updated sensor library. The sensor library includes the default setting<br />

<strong>for</strong> the most common meteorological <strong>and</strong> hydrological sensors,<br />

including Vaisala’s optical sensors <strong>for</strong> cloud height, visibility <strong>and</strong><br />

present weather.<br />

Example of Sensor Setup Template<br />

24 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

Generic Sensor Interfaces<br />

In addition to the sensors with default settings, the <strong>MAWS</strong> Lizard<br />

software has options <strong>for</strong> configuring generic voltage, PT100, counter,<br />

frequency, mA <strong>and</strong> potentiometric inputs as well as numeric string<br />

received via serial interface(s).<br />

Each sensor can have user specified validation <strong>and</strong> conversion/<br />

linearization parameters (up to the 3rd degree factor). This feature<br />

enables the interfacing <strong>and</strong> conditioning of customer’s own sensors.<br />

Generic Sensor Interface Setup Template<br />

In the generic numeric receiver, the user can define receiving<br />

parameters <strong>for</strong> a data string via serial port(s). In addition, the SDI-12<br />

interface can be used <strong>for</strong> interfacing sensors supporting this st<strong>and</strong>ard<br />

protocol, which is frequently used especially with hydrological<br />

sensors.<br />

VAISALA ________________________________________________________________________ 25

Technical Description ________________________________________________________________<br />

Digital Input/Output<br />

Basic QML201 Logger<br />

In addition to digital frequency/counter inputs (2 + 1 pcs), analog<br />

inputs can be used <strong>for</strong> monitoring digital state. Furthermore, the state<br />

status in<strong>for</strong>mation can be used <strong>for</strong> controlling one of the excitation<br />

voltages, e.g. as a contact enclosure that can be activated by an event.<br />

Optional QMI108 Digital I/O Module<br />

The digital inputs <strong>and</strong> outputs of QMD108 are freely <strong>and</strong> individually<br />

configurable by the user.<br />

Hardware Setup View: Digital I/O Configuration<br />

The Hardware Setup view also provides the possibility to select<br />

which outputs are controlled by Timers. The on/off cycle <strong>for</strong> the<br />

selected outputs can then be configured in the Timers view. The other<br />

possibility to control the outputs is to use alarms, <strong>for</strong> example, to<br />

activate the output signal when the alarm condition is met. The alarm<br />

condition is configured in the Alarms view.<br />

The following template shows an example of the Timers view. In the<br />

example the configuration is as follows:<br />

- Output 0 toggles between on <strong>and</strong> off in a one minute cycle.<br />

- Output 5 is on <strong>for</strong> one minute be<strong>for</strong>e each full hour.<br />

26 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

Timers View: Timer Configuration <strong>for</strong> Digital Outputs<br />

The following example shows the Alarms view. In the example, the<br />

configuration activates output 3 when the air temperature measured by<br />

the QMH101 sensor rises above +15 °C.<br />

Alarms View: Controlling Digital Output Using Alarm<br />

The inputs of the QMI108 module can be used as any other<br />

application variables, that is <strong>for</strong> reporting, logging <strong>and</strong> as alarm<br />

inputs.<br />

In the Reports view, the input statuses are available as individual<br />

variables IN0 through IN7 <strong>and</strong> combined as bits into a single status<br />

word ALL. The input module status is also available as <strong>for</strong> the<br />

sensors.<br />

VAISALA ________________________________________________________________________ 27

Technical Description ________________________________________________________________<br />

Reports View: Digital Inputs in the Report<br />

Data Quality Control<br />

The QML201 Logger has a 32-bit CPU, a 16-bit A/D conversion, <strong>and</strong><br />

advanced software with data quality control features in order to ensure<br />

the continuous accuracy of the measured <strong>and</strong> calculated data.<br />

Auto-calibration<br />

The <strong>MAWS</strong> software automatically per<strong>for</strong>ms the offset recalibration<br />

of the A/D converter <strong>and</strong> electronics every 15 minutes. In addition, the<br />

self-calibration will be initiated automatically whenever there is a<br />

temperature change of more than 1° C measured onboard the CPU.<br />

The full ADC calibration will be made every 10th calibration time, i.e.<br />

at least every 150-min.<br />

Climatological/Measurement Limits<br />

Check<br />

The built-in quality control software checks the measured sensor data<br />

against the user-set minimum <strong>and</strong> maximum limit values <strong>and</strong> step<br />

changes between two successive measurements. The user can set these<br />

data validation parameters independently <strong>for</strong> each measured parameter<br />

<strong>and</strong> each site. There is also built-in test software to ensure the<br />

reliability of the sensors’ measurements.<br />

28 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

Data Validation<br />

Sensor Status In<strong>for</strong>mation<br />

The <strong>MAWS</strong> logger provides status values indicating detailed<br />

in<strong>for</strong>mation about the state of the connected sensors. Depending on<br />

the sensor, this indication may vary, <strong>for</strong> example between ok <strong>and</strong> out<br />

of range, or may provide more accurate diagnostic in<strong>for</strong>mation. For<br />

all sensors, the value is contained in the variable status, which can be<br />

included in the report(s) <strong>and</strong>/or monitored in order to produce an<br />

alarm, e.g. <strong>for</strong> maintenance purposes. The following table provides the<br />

list of currently available status indications:<br />

VAISALA ________________________________________________________________________ 29

Technical Description ________________________________________________________________<br />

Possible Values <strong>for</strong> the Status Variable<br />

Value Meaning Note<br />

0 The sensor is working properly (OK).<br />

1 Not measured yet<br />

2 Interface is not initialized. 1)<br />

3 Communication timeout has occurred. 1)<br />

4 Unknown data is received. 1)<br />

5 Communication is functioning, but sensor reports errors. 1)<br />

Use sensor's own service interface to determine cause.<br />

6 Sensor communication is paused because service 1)<br />

connection is opened through <strong>MAWS</strong>.<br />

7 Message sequence numbers are overlapping in the 1)<br />

Autotrac satellite transceiver interface.<br />

8..19 Not available<br />

20 Excitation failure is caused by an overload in the 2)<br />

excitation output.<br />

21 The input voltage is out of range or A/D conversion has 2)<br />

failed due to an internal error.<br />

22 Sensor is disconnected or connection cables are 2)<br />

broken.<br />

23 Sensor output exceeds the min/max limits defined in the 2)<br />

Measurement configuration view.<br />

24 Change in sensor output has exceeded the maximum 2)<br />

step defined in the Measurement configuration view.<br />

25 An internal configuration error has occurred. 2)<br />

26 Error in reference measurement, usually caused by 2)<br />

damaged sensor/logger or electrical interference.<br />

27 Internal voltage error occurred or the logger is<br />

2)<br />

damaged.<br />

28 PMT16 calibration data error. 2)<br />

29 Data invalidated <strong>for</strong> unspecified reason. 2)<br />

99 Sensor status is not supported. 2)<br />

1) Value is available only <strong>for</strong> sensors with serial interface.<br />

2) Value is available only <strong>for</strong> sensors with a conventional, that is analogue or counter/frequency, interface.<br />

Checking Statistical Calculations<br />

The statistical calculations are made only when the minimum number<br />

of valid measurements are available. This number (%) is also a user<br />

configurable parameter which can be set individually <strong>for</strong> each<br />

calculation.<br />

Data Quality Control in Statistical Calculations<br />

30 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

Calculations<br />

Statistical calculations such as minimum, maximum, averages,<br />

st<strong>and</strong>ard deviation, <strong>and</strong> cumulative values, are calculated over user set<br />

periods at user set intervals independently <strong>for</strong> each measured <strong>and</strong><br />

calculated parameter.<br />

An Example of the Calculations Setup Window<br />

The extreme values can have time stamps accurate to seconds<br />

(selectable <strong>for</strong>mat hh:mm:ss).<br />

A library of ready made calculations is available in the <strong>MAWS</strong><br />

software, including, <strong>for</strong> example, unit conversions, dew point, QNH,<br />

QFF, QFE, evapotranspiration, wind chill, heat stress <strong>and</strong> frost point,<br />

MacArthur fire index, rain duration (requires DRD11A sensor) etc. In<br />

addition, the sunshine duration can be calculated using the data from<br />

the global solar radiation sensor. The CM6B or CM11 global solar<br />

radiation sensor is recommended <strong>for</strong> this purpose.<br />

VAISALA ________________________________________________________________________ 31

Technical Description ________________________________________________________________<br />

The List of Unit Conversions<br />

The calculation module also offers the possibility to make various<br />

arithmetic operation one or two oper<strong>and</strong>s, which can be any measured,<br />

calculated or manually entered parameters. The operations include:<br />

• Add<br />

• Subtract<br />

• Multiply<br />

• Divide<br />

• Square root<br />

• Power<br />

• Logarithm, lg(A)<br />

• Logarithm10, log(A)<br />

• Exponent<br />

• Absolute<br />

• Sine<br />

• Cosine<br />

• Tangent<br />

32 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

An Example of Arithmetic Operation<br />

The special Wind Task is <strong>for</strong> calculating statistical values <strong>for</strong> wind<br />

speed <strong>and</strong> <strong>for</strong> wind direction in the vector <strong>for</strong>mat. The list of<br />

calculations also includes the Sigma-Theta calculation <strong>for</strong> wind<br />

turbulence.<br />

An Example of the Wind Calculation Setup Options (Partial List)<br />

VAISALA ________________________________________________________________________ 33

Technical Description ________________________________________________________________<br />

Data Messages <strong>and</strong> Reports<br />

The <strong>for</strong>mats <strong>and</strong> contents of the output message are freely<br />

configurable by the user(s). <strong>MAWS</strong> HydroMet systems can be<br />

configured to produce several different kinds of fully automated<br />

messages to serve various users of the data. The data messages can<br />

include measured <strong>and</strong> calculated data items, complete reports, user<br />

inserted data <strong>and</strong>/or ASCII text. In addition, the data messages can<br />

include diagnostics data such as battery voltage, internal temperature,<br />

status of the mains power, enclosure door open/close etc.<br />

The <strong>for</strong>matting of the messages is done using the <strong>MAWS</strong> Lizard<br />

Setup software. The software is fully configurable <strong>and</strong> there<strong>for</strong>e there<br />

is no need to write new software code <strong>and</strong> no prior knowledge of<br />

programming is needed.<br />

Several Data Messages Can Be Configured to Be Sent to Different<br />

Output Ports<br />

In addition, the reports can be easily configured to simulate already<br />

existing data <strong>for</strong>mats.<br />

34 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

An Example of a Configuration Template <strong>for</strong> a Tabular Message<br />

Alarms<br />

The alarms function is also a completely user configurable feature.<br />

Any measured or calculated parameter can be used <strong>for</strong> testing the user<br />

set alarm criteria.<br />

Example: It is possible to combine several alarm criteria (AND or OR<br />

- type functions) e.g. to create an alarm when the wind direction is<br />

more than 275 degrees <strong>and</strong> wind speed exceeds 20 m/s.<br />

Whenever an alarm condition has been detected, a user configured<br />

alarm message will be automatically sent to the specified<br />

communication port(s). Alternatively, triggering an alarm can cause<br />

logging of a user defined data group or set an excitation voltage e.g.<br />

<strong>for</strong> controlling a relay. The system supports multiple alarm functions.<br />

There are several alternative triggering functions <strong>for</strong> alarms such as<br />

below minimum, above maximum or a combination of these limits.<br />

In addition, the Alarm module can be used to dynamically adjust the<br />

timer functions, such as the report transmission interval or measuring<br />

intervals. For a more detailed description, see the Dynamically<br />

Controlled Timer Functions section.<br />

VAISALA ________________________________________________________________________ 35

Technical Description ________________________________________________________________<br />

An Example of the Alarms Setup Window<br />

Data Acquisition<br />

The transmission of the reports can be:<br />

• Self-timed: <strong>MAWS</strong> sends data at user set interval(s). The<br />

interval(s) can be changed remotely on comm<strong>and</strong>. The interval is<br />

freely configurable between 1 second <strong>and</strong> 24 hours at 1 second<br />

intervals. In addition, these intervals can be changed automatically<br />

when a user set parameter exceeds its threshold values. In this way<br />

the data can be transmitted more frequently, e.g. when the water<br />

level is rising <strong>and</strong> the development of a potential flood situation<br />

requires more real-time data. This feature also allows<br />

telecommunication costs to be optimized.<br />

• Polled: data acquisition system polls <strong>MAWS</strong> stations whenever<br />

data is needed. Polling can retrieve data message(s) or data logged<br />

into the station's memory (see Logged Data in Reports below)<br />

• ALARM: based on a measured or calculated parameter exceeding<br />

preset threshold value(s).<br />

• FTP: data transfer via FTP (File Transfer Protocol) in GSM,<br />

GPRS <strong>and</strong> PSTN networks. AWS acts as an FTP client placing a<br />

file on the FTP Server's hard disk using the central data collection<br />

software at a user configurable interval <strong>and</strong>/or at an ALARM.<br />

36 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

Data transmission can include any combination of the above<br />

mentioned methods.<br />

Remote Maintenance<br />

Reporting functions can also be efficiently used <strong>for</strong> remote<br />

maintenance by:<br />

- the system monitoring itself with real-time self-diagnostics tasks<br />

<strong>and</strong> providing system alarms in case of system failure,<br />

- providing system maintenance in<strong>for</strong>mation to the system operators<br />

remotely, so that the system status can be analyzed <strong>and</strong> required<br />

maintenance procedures planned in advance prior to maintenance<br />

on site, <strong>and</strong><br />

- providing a maintenance interface to maintenance technicians on<br />

remote sites.<br />

A system status message can include in<strong>for</strong>mation on internal<br />

temperature, available battery capacity <strong>and</strong> the status of charging,<br />

amongst other things. In addition, hardware <strong>and</strong> software version<br />

numbers can be included in these messages. This message can be<br />

transmitted e.g. once a day at a set time, typically at midnight.<br />

Logged Data in Reports<br />

In the <strong>MAWS</strong> systems, it is possible to <strong>for</strong>mat output reports using the<br />

data items in logged data files. The user can select the number of<br />

records from the logged file to be included in the report. There are two<br />

automatically made report <strong>for</strong>mats. When using the SCAN <strong>for</strong>mat, the<br />

logged data items are organized in columns, in such a way that one<br />

column consists of the measurements of one item over a user-set<br />

period of records. In the CHANNEL ordered report <strong>for</strong>mat, the logged<br />

data are organized in rows, with one row consisting of the<br />

measurements of one item over a period of records. The data items are<br />

by default separated by a space, but the user can also change this<br />

parameter.<br />

This option is most convenient when the data is not needed in nearreal-time<br />

but will be sent e.g. every 3 or 6 hours only.<br />

VAISALA ________________________________________________________________________ 37

Technical Description ________________________________________________________________<br />

Data Compression<br />

The cost of telecommunications is often the most significant annual<br />

cost in operating the network. In order to lower this cost the <strong>MAWS</strong><br />

system offers two automatic data compression methods which are user<br />

configurable. This function is particularly useful when the data is<br />

transferred using methods which are costly or otherwise limit the<br />

amount of data to be transferred. Such methods include, <strong>for</strong> example,<br />

satellite systems <strong>and</strong> SMS (Short Message Service) messages in<br />

cellular data transfer.<br />

There are two methods <strong>for</strong> automatic report <strong>for</strong>matting: BASE32 <strong>and</strong><br />

BCD. Depending on the parameters <strong>and</strong> the length of the message, the<br />

data reduction can even be over 50 %.<br />

An Example of the Compression Setup Window<br />

Base32 Compression<br />

The BASE32 report <strong>for</strong>matting method produces ASCII data <strong>and</strong> thus<br />

printable characters. With this method every measured value is scaled<br />

<strong>and</strong> converted using a radix of 32 instead of 1. The compression ratio<br />

is approximately from 30 to 60 %.<br />

38 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

Example: temperature value, string presentation:<br />

Original: -18.7<br />

(5bytes)<br />

Offset: -18.7+50=31.3 (if -50 is minimum of measured value)<br />

Scale: 31.3*10=313 (if 0.1 is resolution of measurement)<br />

313 -> BASE32 -> 9P (2bytes)<br />

BCD Compression<br />

The BCD (Binary Coded Decimal) method is a Positional Number<br />

System, with a radix of 10 <strong>and</strong> coefficients expressed in 4-bit binary<br />

words. The BCD <strong>for</strong>matting method produces non-printable binary<br />

reports.<br />

Example2:<br />

3 | 1 | 3<br />

8421|8421|8421<br />

0011|0001|0011<br />

313 -> BCD -> 001100010011 (1,5bytes)<br />

Communication<br />

The available telemetry devices are selectable from the list. All<br />

equipment has its own default setting which can be modified by the<br />

user whenever necessary.<br />

List of Communication Equipment<br />

VAISALA ________________________________________________________________________ 39

Technical Description ________________________________________________________________<br />

The <strong>MAWS</strong> system can have up to 7 serial ports <strong>for</strong> connecting to<br />

telemetry equipment as well as to sensors with serial interface. The<br />

communication ports are easily managed using their own setup<br />

template:<br />

Communication Ports Setup Template<br />

Multiple telemetry devices can be connected at the same time thus<br />

increasing reliability at critical monitoring site(s).<br />

Power Management<br />

The <strong>MAWS</strong> HydroMet system includes several advanced power<br />

management features, which guarantee long term operation during<br />

main power failures. In addition to the very low power consumption<br />

of the QML201 Logger itself, the following features are included:<br />

• Monitoring of presence of the main power voltage<br />

• Monitoring the voltage level of the back-up battery<br />

• Monitoring the presence of charging <strong>for</strong> back-up batteries.<br />

• Switching off heater circuits whenever the main power is OFF.<br />

• Controlling powering of the telemetry devices according to the user<br />

configured schedule whenever the mains power is OFF<br />

40 _______________________________________________________________________________

Chapter 3 __________________________________________________________________ Software<br />

• Controlling powering of the telemetry devices according to the user<br />

configured schedule whenever the charging of the back-up batteries<br />

from the solar panel is OFF.<br />

• Reducing the telecommunication rate whenever the system works<br />

on back-up batteries.<br />

• Reducing the sampling rate whenever the system works on back-up<br />

batteries.<br />

The low power monitoring is an intelligent algorithm taking into<br />

account the charging state of the back-up batteries <strong>and</strong> repeated mains<br />

power failures.<br />

Power monitoring of telemetry<br />

devices<br />

The <strong>MAWS</strong> station offers intelligent power monitoring features <strong>for</strong><br />

guaranteeing extended operation. When there is a failure in supplying<br />

primary power to a remote station, the <strong>MAWS</strong> system can be<br />

configured to switch off the power from the telemetry device <strong>for</strong> most<br />

of that time. In order to conserve the back-up battery capacity, the<br />

power can be switched on at user-defined times <strong>for</strong> a short period to<br />

transmit an alarm or other critical data. Whenever the primary power<br />

is recovered, the telemetry device will again be powered normally.<br />

Dynamically Controlled Timer Function<br />

<strong>MAWS</strong> application execution is mostly controlled by timers, which<br />

are configured to fixed intervals using the <strong>MAWS</strong> Lizard Setup<br />

Software.<br />

Timer intervals controlled by thresholds provide the means to change<br />

these intervals dynamically according to limit values (thresholds)<br />

while the system is running. Each measured <strong>and</strong>/or calculated data<br />

item can be configured to be monitored by thresholds.<br />

For example, the following topics can be h<strong>and</strong>led using this control<br />

method:<br />

- Power consumption control when operating on backup batteries.<br />

<strong>MAWS</strong> can keep the communication equipment permanently on<br />

when external AC-power/solar charging is available, <strong>and</strong> switch to<br />

VAISALA ________________________________________________________________________ 41

Technical Description ________________________________________________________________<br />

cyclic powered mode (low power mode) when the system is<br />

running on back-up batteries.<br />

- Communication cost reduction. When the measured conditions are<br />

normal, data messages can be transmitted less frequently, but<br />

when preset limits are exceeded by user set parameter(s), the faster<br />

transmission cycle can automatically be taken into use.<br />

Interval threshold configuration view<br />

The Interval thresholds are configured in the <strong>MAWS</strong> Lizard's alarm<br />

configuration view. The above picture shows a typical setup <strong>for</strong><br />

managing transmission intervals <strong>for</strong> reports. For each timer there can<br />

be up to five (5) thresholds configured.<br />

Example of thresholds definition<br />

42 _______________________________________________________________________________

Chapter 4 ______________________________________________________________ Data Logging<br />

CHAPTER 4<br />

DATA LOGGING<br />

Internal Flash Memory<br />

The QML201 Logger has 1.7 Megabytes of secure flash memory<br />

available <strong>for</strong> the logging of measured <strong>and</strong> calculated data. The flash<br />

memory does not need any external or internal back-up batteries, <strong>and</strong><br />

preserves its contents <strong>for</strong> many years.<br />

There can be several logging schedules where the parameters <strong>and</strong><br />

logging intervals are user definable. The intervals are configurable<br />

from 1 second to 24 hours at 1-second intervals. Data are logged into<br />

the daily files, which can be retrieved through the communication<br />

channel(s) locally using a laptop PC, or remotely via a modem.<br />

The user can also specify how many days of back-up data is held in<br />

the memory. When the memory is full the system will automatically<br />

free space by deleting old files, but will always preserve the user<br />

specified amount of most recent files in the memory.<br />

The logged files can easily be retrieved e.g. onto a PC’s hard disk<br />

using the <strong>MAWS</strong> Terminal software, which is included in the <strong>MAWS</strong><br />

delivery. The <strong>MAWS</strong> Terminal automatically converts the binary files<br />

into Comma Separated Value (CSV) <strong>for</strong>mat used e.g. by Microsoft’s<br />

Excel software.<br />

In addition, the logged data can be used in data reports that are sent<br />

via communication port(s).<br />

VAISALA ________________________________________________________________________ 43