CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

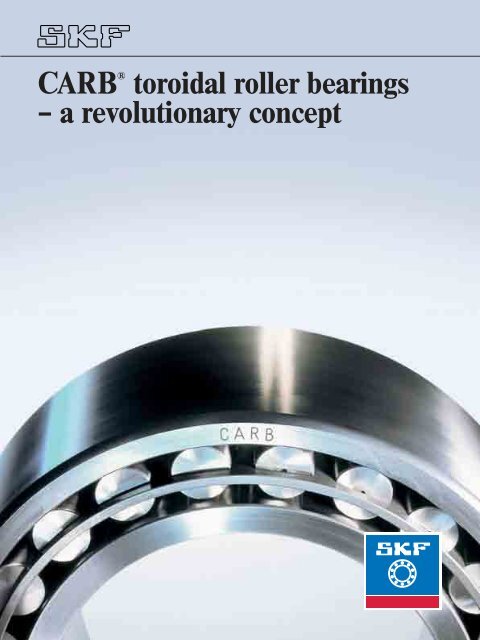

CARB ® <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

– a <strong>revolutionary</strong> concept

Contents<br />

The SKF brand now stands for more than ever before,<br />

and means more to you as a valued customer.<br />

While SKF maintains its leadership as the hallmark of<br />

quality <strong>bearings</strong> throughout the world, new dimensions<br />

in technical advances, product support and services<br />

have evolved SKF into a truly solutions-oriented supplier,<br />

creating greater value for customers.<br />

These solutions encompass ways to bring greater<br />

productivity to customers, not only with breakthrough<br />

application-specific products, but also through leadingedge<br />

design simulation tools and consultancy services,<br />

plant asset efficiency maintenance programs, and the<br />

industry’s most advanced supply management<br />

techniques.<br />

The SKF brand still stands for the very best in rolling<br />

<strong>bearings</strong>, but it now stands for much more.<br />

SKF – The knowledge engineering company<br />

1 Product information.................................................. 3<br />

The winning combination............................................. 3<br />

SKF <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> with <strong>revolutionary</strong><br />

design characteristics.................................................. 4<br />

SKF Explorer class <strong>bearings</strong> ....................................... 5<br />

The range for all requirements .................................... 6<br />

Availability.................................................................... 7<br />

Bearing features and benefits ..................................... 7<br />

The CARB <strong>toroidal</strong> <strong>roller</strong> bearing –<br />

the cornerstone of the new self-aligning system...... 8<br />

Successful in service ................................................... 10<br />

2 Recommendations....................................................12<br />

Selection of bearing size ............................................ 12<br />

Longer life or downsizing ............................................ 12<br />

Design of bearing arrangements ............................... 14<br />

Radial location ............................................................ 14<br />

Axial location .............................................................. 16<br />

Design of adjacent components ................................ 18<br />

Sealing the bearing arrangement ................................ 20<br />

Lubrication ................................................................... 22<br />

Grease lubrication ...................................................... 22<br />

Deviating conditions ................................................... 24<br />

Oil lubrication .............................................................. 25<br />

Mounting ...................................................................... 26<br />

Mounting on cylindrical seatings................................. 26<br />

Mounting on tapered seatings..................................... 27<br />

Dismounting ................................................................. 34<br />

Dismounting from a cylindrical seating ....................... 34<br />

Dismounting from a tapered seating ........................... 35<br />

SKF concept for cost saving ....................................... 36<br />

3 Product data ..............................................................37<br />

Bearing data – general ................................................ 37<br />

Product tables .............................................................. 44<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> ..................................... 44<br />

Sealed CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong>.......................... 56<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> on adapter sleeve ........ 58<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> on withdrawal sleeve ... 68<br />

Other associated SKF products ................................. 78<br />

SKF – The knowledge engineering company ............ 82<br />

2

1 Product information 2 Recommendations 3 Product data<br />

The winning combination Page ............. 12 Page ............. 37<br />

The winning combination<br />

1<br />

Self-alignment ...<br />

Self-aligning <strong>bearings</strong> are the hallmark<br />

of SKF – not surprising since SKF was<br />

founded in 1907, based on the invention<br />

of the self-aligning ball bearing by Sven<br />

Wingquist. But the development did<br />

not stop there, other SKF inventions<br />

followed: the spherical <strong>roller</strong> bearing in<br />

1919 and the spherical <strong>roller</strong> thrust<br />

bearing in 1939.<br />

Self-alignment is called for<br />

• when misalignment exists as a<br />

result of manufacturing or mounting<br />

errors<br />

• when shaft deflections occur under<br />

load<br />

and these have to be compensated for<br />

in the bearing arrangement without<br />

negative effects on performance or<br />

any reduction in bearing service life.<br />

... and axial<br />

displacement ...<br />

SKF was also heavily involved in the<br />

development of <strong>bearings</strong> having rings<br />

that can be axially displaced with<br />

respect to each other. In 1908, for<br />

example, the cylindrical <strong>roller</strong> bearing<br />

in its modern version was largely<br />

developed by Dr.-Ing. Josef Kirner of<br />

the Norma Compagnie in Stuttgart-Bad<br />

Cannstatt, which became a subsidiary<br />

of AB SKF.<br />

Cylindrical <strong>roller</strong> <strong>bearings</strong> are applied<br />

when<br />

• heavy radial loads and relatively<br />

high speeds prevail and<br />

• thermal changes in shaft length<br />

must be accommodated in the bearing<br />

with as little friction as possible –<br />

provided, of course, that there is no<br />

significant misalignment.<br />

... combined for success<br />

Previously, it was always necessary to<br />

compromise. Because misalignment or<br />

shaft bending makes the use of selfaligning<br />

<strong>bearings</strong> essential – and,<br />

depending on load and speed, the<br />

choice lay between self-aligning ball<br />

<strong>bearings</strong> and spherical <strong>roller</strong> <strong>bearings</strong>.<br />

However, in contrast to cylindrical<br />

<strong>roller</strong> <strong>bearings</strong>, those <strong>bearings</strong> cannot<br />

accommodate important axial displacements<br />

within the bearing.<br />

Therefore, it was necessary for one<br />

of the <strong>bearings</strong> to move axially on its<br />

seating in the housing. Such movement<br />

is always accompanied by considerable<br />

friction, which produces internal axial<br />

forces in the bearing arrangement.<br />

The result is a shortened bearing service<br />

life and relatively high costs for maintenance<br />

and repairs.<br />

Today, this is a thing of the past.<br />

Because Magnus Kellström, a product<br />

designer at SKF, had a brilliant idea;<br />

he invented the <strong>toroidal</strong> <strong>roller</strong> bearing.<br />

This bearing not only can compensate<br />

for misalignment without friction, but<br />

also for changes in shaft length within<br />

the bearing. Thus a completely new<br />

type of bearing for non-locating<br />

arrangements has become available<br />

to the engineering world.<br />

It is no longer necessary to compromise,<br />

and there are added benefits<br />

too – much longer service life for the<br />

complete bearing arrangement and<br />

minimized maintenance and repair<br />

costs.<br />

Self-alignment …<br />

… and axial<br />

displacement …<br />

… combined in<br />

a <strong>toroidal</strong> <strong>roller</strong><br />

bearing<br />

3

1 Product information 2 Recommendations 3 Product data<br />

Customer benefits Page ............. 12 Page ............. 37<br />

SKF <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

with <strong>revolutionary</strong> design<br />

characteristics<br />

The SKF <strong>toroidal</strong> <strong>roller</strong> bearing represents<br />

one of the most important<br />

breakthroughs in rolling bearing technology<br />

over the past sixty years. The<br />

bearing was introduced to the market<br />

the market in 1995 under the SKF<br />

trademark CARB ® .<br />

The CARB <strong>toroidal</strong> <strong>roller</strong> bearing is<br />

a completely new type of <strong>roller</strong> bearing,<br />

which offers benefits that were previously<br />

unthinkable. Irrespective of<br />

whether a new machine is to be designed<br />

or an older machine maintained<br />

there are benefits to be gained by using<br />

a <strong>toroidal</strong> <strong>roller</strong> bearing. Which of these<br />

benefits is realized depends on the<br />

machine design and its operating parameters.<br />

The CARB bearing is a single row<br />

<strong>roller</strong> bearing with relatively long, slightly<br />

crowned <strong>roller</strong>s. The inner and outer<br />

ring raceways are correspondingly<br />

concave and symmetrical (➔ fig 1 ).<br />

The outer ring raceway geometry is<br />

based on a torus (➔ fig 2 ), hence<br />

the term <strong>toroidal</strong> <strong>roller</strong> bearing.<br />

The SKF <strong>toroidal</strong> <strong>roller</strong> bearing is<br />

designed as a non-locating bearing<br />

that combines the self-aligning ability<br />

of a spherical <strong>roller</strong> bearing with the<br />

ability to accommodate axial displacement<br />

like a cylindrical or needle <strong>roller</strong><br />

bearing. Additionally, if required, the<br />

<strong>toroidal</strong> <strong>roller</strong> bearing can be made as<br />

compact as a needle <strong>roller</strong> bearing.<br />

An application incorporating an SKF<br />

<strong>toroidal</strong> <strong>roller</strong> bearing provides benefits<br />

outlined in the following.<br />

Self-aligning capability<br />

The self-aligning capability of the<br />

CARB bearing is particularly important<br />

in applications where there is misalignment<br />

as a result of manufacturing or<br />

mounting errors or shaft deflections.<br />

To compensate for these conditions,<br />

a CARB bearing can accommodate<br />

misalignment up to 0,5 degrees between<br />

the bearing rings without any<br />

detrimental effects on the bearing or<br />

bearing service life (➔ fig 3 ).<br />

Axial displacement<br />

Previously, only cylindrical and needle<br />

<strong>roller</strong> <strong>bearings</strong> could accommodate<br />

thermal expansion of the shaft within<br />

the bearing. Today, however, the CARB<br />

bearing can be added to that list (➔<br />

fig 4 ). The inner and outer rings of<br />

a CARB bearing can be displaced,<br />

with respect to each other, up to 10 %<br />

of the bearing width. By installing the<br />

bearing so that one ring is initially displaced<br />

with respect to the other one,<br />

it is possible to extend the permissible<br />

axial displacement in one direction. In<br />

contrast to cylindrical and needle <strong>roller</strong><br />

<strong>bearings</strong> that require accurate shaft<br />

alignment, this is not needed for <strong>toroidal</strong><br />

<strong>roller</strong> <strong>bearings</strong>, which can also cope<br />

with shaft deflection under load. This<br />

provides a solution to many problem<br />

cases.<br />

Long system life<br />

The ability to accommodate misalignment<br />

plus the ability to accommodate<br />

axial displacement with virtually no<br />

friction enables a CARB bearing to<br />

provide benefits to the bearing arrangement<br />

and its associated components<br />

(➔ fig 5 ).<br />

The CARB <strong>toroidal</strong><br />

<strong>roller</strong> bearing<br />

The torus<br />

Angular<br />

misalignment<br />

The most frequently<br />

occurring misalignments<br />

in operation<br />

are not a problem<br />

for a CARB <strong>toroidal</strong><br />

<strong>roller</strong> bearing<br />

Axial displacement<br />

Changes in shaft<br />

length are accommodated<br />

within the<br />

bearing virtually<br />

without friction<br />

Freedom<br />

Permissible angular<br />

misalignment + axial<br />

displacement within<br />

the bearing<br />

Fig<br />

Fig<br />

Fig<br />

Fig<br />

Fig<br />

1<br />

2<br />

3<br />

4<br />

5<br />

4

1 Product information 2 Recommendations 3 Product data<br />

Customer benefits Page ............. 12 Page ............. 37<br />

axial vibration<br />

Fig<br />

6<br />

Deviations from<br />

cylindrical form are<br />

less problematic<br />

Demands on accuracy<br />

of form of the<br />

bearing seatings<br />

are less stringent,<br />

making simpler and<br />

less costly arrangements<br />

possible<br />

Fig<br />

– conventional arrangement<br />

– with CARB as non-locating bearing<br />

time<br />

Axial vibration<br />

With a CARB bearing axial vibrations are<br />

considerably reduced, meaning longer<br />

service life and quieter operation<br />

Full dimensional interchangeability<br />

CARB advantages can be fully exploited<br />

when refurbishing non-locating bearing<br />

arrangements designed for self-aligning as<br />

well as rigid <strong>bearings</strong><br />

7<br />

• Internal axial displacement is virtually<br />

without friction; there are no internally<br />

induced axial forces, thus operating<br />

conditions are considerably improved.<br />

• The non-locating bearing as well as<br />

the locating bearing only need to<br />

support external loads.<br />

• The <strong>bearings</strong> run cooler, the lubricant<br />

lasts longer and maintenance<br />

intervals can be appreciably<br />

extended.<br />

Taken together, these benefits contribute<br />

to a longer system life.<br />

High load carrying capacity<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> can<br />

accommodate very high radial loads.<br />

This is due to the optimized design of<br />

the rings combined with the design<br />

and number of <strong>roller</strong>s. The large number<br />

of long <strong>roller</strong>s make CARB <strong>bearings</strong><br />

the strongest of all aligning <strong>roller</strong><br />

<strong>bearings</strong>. Due to their robust design,<br />

CARB <strong>bearings</strong> can cope with small<br />

deformations and machining errors of<br />

the bearing seating (➔ fig 6 ). The rings<br />

accommodate these small imperfections<br />

without the danger of edge<br />

stresses. The high load carrying<br />

capacity plus the ability to compensate<br />

for small manufacturing or installation<br />

errors provide opportunities to<br />

increase machine productivity and<br />

uptime.<br />

Increased performance<br />

or downsizing<br />

For bearing arrangements incorporating<br />

a CARB <strong>toroidal</strong> <strong>roller</strong> bearing as nonlocating<br />

bearing, internally induced axial<br />

forces are prevented. Together with high<br />

load carrying capacity this means that<br />

• for the same bearing size in the<br />

arrangement, performance can be<br />

increased or the service life extended,<br />

or<br />

• new machine designs can be made<br />

more compact to provide the same,<br />

or even higher performance.<br />

Reduced vibration<br />

Self-aligning ball or spherical <strong>roller</strong><br />

<strong>bearings</strong> in the non-locating position<br />

need to be able to slide within the<br />

housing seating. This sliding, however,<br />

causes axial vibrations which can reduce<br />

bearing service life considerably.<br />

Bearing arrangements that use<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> as the<br />

non-locating bearing are stiff because<br />

the CARB bearing can be radially and<br />

axially located in the housing and on<br />

the shaft. This is possible because<br />

thermal expansion of the shaft is<br />

accommodated within the bearing.<br />

The stiffness of the bearing arrangement,<br />

combined with the ability of the<br />

CARB bearing to accommodate axial<br />

movement, substantially reduces<br />

vibrations within the application to<br />

increase service life of the bearing<br />

arrangement and related components<br />

(➔ fig 7 ).<br />

1<br />

Fig<br />

8<br />

Full dimensional interchangeability<br />

The boundary dimensions of SKF<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> are in<br />

accordance with ISO 15:1998. This provides<br />

full dimensional interchangeability<br />

with self-aligning ball <strong>bearings</strong>, cylindrical<br />

<strong>roller</strong> and spherical <strong>roller</strong> <strong>bearings</strong><br />

in the same Dimension Series. The<br />

CARB bearing range also covers wide<br />

<strong>bearings</strong> with low cross sections normally<br />

associated with needle <strong>roller</strong><br />

<strong>bearings</strong> (➔ fig 8 ).<br />

SKF Explorer class<br />

<strong>bearings</strong><br />

All CARB <strong>bearings</strong> are manufactured to<br />

the SKF Explorer performance class.<br />

5

1 Product information 2 Recommendations 3 Product data<br />

Assortment Page ............. 12 Page ............. 37<br />

The range for all requirements<br />

Fig<br />

1<br />

C 39 C 49 C 59 C 69 C 30 C 40 C 50 C 60 C 31 C 41 C 22 C 32 C 23<br />

Overview of product range<br />

The SKF standard range of CARB <strong>toroidal</strong><br />

<strong>roller</strong> <strong>bearings</strong> comprises <strong>bearings</strong> in<br />

13 ISO Dimension Series (➔ fig 1 ). The<br />

smallest bearing has a bore diameter of<br />

25 mm and the largest one a bore diameter<br />

of 1250 mm. <strong>Bearings</strong> with a bore<br />

diameter up to 1800 mm can be produced.<br />

Whether a new bearing arrangement<br />

is to be designed or an existing<br />

arrangement upgraded most often there<br />

is an appropriate CARB <strong>toroidal</strong> <strong>roller</strong><br />

bearing available or such a bearing could<br />

be manufactured.<br />

SKF <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> are produced<br />

in<br />

• a caged version (➔ fig 2 ) as well as<br />

• a full complement version (➔ fig 3 )<br />

SKF also produces special executions<br />

to suit particular applications, e.g.<br />

• <strong>bearings</strong> with case hardened inner<br />

rings to allow a heavy interference<br />

fit on the shaft/journal of dryer or<br />

Yankee cylinders, for example;<br />

• <strong>bearings</strong> with a surface hardened<br />

cage for vibrating screens;<br />

• sealed <strong>bearings</strong>, for example, for<br />

continuous casting plants (➔ fig 4 ).<br />

The permissible misalignment and<br />

axial displacement as well as the<br />

load carrying capacity are lower<br />

than for the corresponding bearing<br />

without seals.<br />

with<br />

• a cylindrical bore, or<br />

• a tapered bore.<br />

The tapered bore has a taper of 1:12<br />

or 1:30, depending on the Dimension<br />

Series.<br />

In addition to the standard <strong>bearings</strong>,<br />

6

1 Product information 2 Recommendations 3 Product data<br />

Assortment Page ............. 12 Page ............. 37<br />

Fig<br />

2<br />

Fig 3<br />

Fig 4<br />

1<br />

Caged bearing<br />

For heavy loads and relatively high speeds<br />

Full complement bearing<br />

For very heavy loads and low speeds<br />

Sealed bearing<br />

Lubricated for life and protected against<br />

contamination<br />

Availability<br />

The product range is shown in the<br />

product tables starting on page 44.<br />

SKF recommends checking availability<br />

of those <strong>bearings</strong> marked with a triangle.<br />

To do that, contact your local SKF<br />

representative or SKF distributor. The<br />

standard range is being continuously<br />

extended and the intention is to manufacture<br />

all the products shown in the<br />

product tables in a few years time.<br />

Bearing benefits<br />

Already well proven in service, <strong>toroidal</strong><br />

<strong>roller</strong> <strong>bearings</strong> enable all types of<br />

machines and equipment to be<br />

• smaller,<br />

• lighter,<br />

• more cost-effective, and<br />

• more operationally reliable.<br />

Replacing other non-locating <strong>bearings</strong><br />

with an equivalent CARB bearing can,<br />

depending on the application, improve<br />

perform-ance and uptime while decreasing<br />

maintenance. Why not put<br />

CARB <strong>bearings</strong> to the test and reap<br />

the benefits they can provide?<br />

7

1 Product information 2 Recommendations 3 Product data<br />

Self-aligning bearing system Page ............. 12 Page ............. 37<br />

The CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

– the cornerstone of the new<br />

self-aligning bearing system<br />

The conventional solution<br />

Until recently a self-aligning bearing<br />

system consisted of two self-aligning<br />

ball <strong>bearings</strong> if there were high speeds<br />

and light loads, or two spherical <strong>roller</strong><br />

<strong>bearings</strong> when there were heavy loads<br />

and moderate speeds. These bearing<br />

systems are simple, have good load<br />

carrying capacity and can compensate<br />

for misalignment resulting from manufacturing<br />

or mounting errors as well as<br />

shaft deflections (➔ fig 1 ). So far, so<br />

good – but what happens if the shaft<br />

were to expand axially?<br />

In a traditional bearing arrangement,<br />

axial expansion of the shaft is accommodated<br />

by the non-locating bearing.<br />

The fits for this bearing are selected so<br />

that one of the bearing rings will be<br />

able to move axially on its seating as<br />

the shaft expands. Generally this<br />

movement is between the outer ring<br />

and the housing seating. This movement<br />

is always accompanied by friction,<br />

which gives rise to induced axial<br />

forces in both the <strong>bearings</strong> (➔ fig 2 ).<br />

In addition, the movement of the loose<br />

bearing on its seating can create damaging<br />

vibrations because the movement<br />

is ”stick-slip” and not smooth (➔fig 3 ).<br />

The loose fit has a negative effect<br />

on the stiffness of the bearing arrangement.<br />

The bearing ring with the loose<br />

fit can also begin to “wander”, which<br />

can wear the seating and lead to fretting<br />

corrosion and possibly “weld”<br />

the ring to its seating (➔ fig 4 ).<br />

The new solution<br />

Today, the CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

is available for the non-locating position<br />

in a self-aligning bearing system.<br />

It is no longer necessary to compromise.<br />

8<br />

Conventional<br />

solution<br />

Two spherical <strong>roller</strong><br />

<strong>bearings</strong> (or selfaligning<br />

ball <strong>bearings</strong>)<br />

compensate<br />

easily for angular<br />

misalignment of<br />

the inner ring with<br />

respect to the<br />

outer ring<br />

Axial expansion<br />

of the shaft can<br />

influence the load<br />

distribution in the<br />

<strong>bearings</strong><br />

Load conditions<br />

in a conventional<br />

solution<br />

Changes in axial<br />

force in a non-locating<br />

bearing during<br />

the machine start-up<br />

phase; internal axial<br />

forces of corresponding<br />

magnitude<br />

are produced in the<br />

locating bearing<br />

In a non-locating<br />

bearing which has<br />

been clamped in its<br />

housing bore seating,<br />

heavy axial<br />

forces prevail in the<br />

bearing arrangement<br />

after the startup<br />

phase and dramatically<br />

shorten<br />

bearing service life<br />

F a /F r<br />

0,2<br />

0,1<br />

0<br />

F a /F r<br />

1,5<br />

1<br />

0,5<br />

0<br />

Fig<br />

Fig 2<br />

F r<br />

t<br />

t<br />

Fig<br />

Fig<br />

1<br />

3<br />

4

1 Product information 2 Recommendations 3 Product data<br />

Self-aligning bearing system Page ............. 12 Page ............. 37<br />

1<br />

°C<br />

Fig<br />

Fig<br />

Fig<br />

5<br />

6<br />

7<br />

The new solution<br />

A spherical <strong>roller</strong> bearing<br />

or a self-aligning<br />

ball bearing as the<br />

locating bearing and<br />

a CARB <strong>toroidal</strong> <strong>roller</strong><br />

bearing as the nonlocating<br />

bearing compensate<br />

for angular<br />

misalignment of the<br />

rings resulting from<br />

errors of alignment or<br />

deflection under load<br />

as well as thermal<br />

changes in shaft<br />

length, virtually without<br />

friction<br />

There are no internally<br />

induced axial<br />

forces. The rings<br />

of the non-locating<br />

bearing should be<br />

axially and radially<br />

located<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> are<br />

able to compensate for misalignment<br />

and accommodate axial displacements<br />

within the bearing (➔ fig 5 ).<br />

This means that both rings of the nonlocating<br />

bearing can be axially located<br />

in the housing and on the shaft (➔ fig<br />

6 ). If it is necessary to secure the<br />

rings so that they cannot “creep”, they<br />

can be mounted with an interference<br />

fit, thus enhancing the radial stiffness<br />

of the bearing arrangement.<br />

This is an optimal solution for applications<br />

with undetermined load direction,<br />

e.g. vibrating applications, because<br />

internal preload and wear to the bearing<br />

seating in the housing are eliminated.<br />

No longer is there a compromise<br />

between a tight fit and axial freedom.<br />

A CARB <strong>toroidal</strong> <strong>roller</strong> bearing is<br />

designed to accommodate axial displacement<br />

without inducing additional<br />

axial internal forces or friction (➔ fig 6 ).<br />

This means that the loads acting on the<br />

bearing are determined exclusively<br />

by external radial and axial forces.<br />

Because of this, a bearing system<br />

incorporating a CARB bearing will<br />

have lower loads and better load distribution<br />

than a conventional bearing<br />

system. This translates into lower operating<br />

temperatures, higher operating<br />

viscosities, extended relubrication<br />

intervals, and a significantly longer<br />

service life for both the <strong>bearings</strong> and<br />

the lubricant (➔ fig 7 ).<br />

With a CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

F r<br />

9<br />

Lower operating<br />

temperatures extend<br />

relubrication intervals<br />

and bearing<br />

service life<br />

in the non-locating position, the many<br />

excellent design characteristics and<br />

properties of SKF spherical <strong>roller</strong> <strong>bearings</strong><br />

and self-aligning ball <strong>bearings</strong> can<br />

be fully exploited. This provides new<br />

opportunities to further optimize<br />

machine design.

1 Product information 2 Recommendations 3 Product data<br />

Application areas Page ............. 12 Page ............. 37<br />

Successful in service<br />

Although a recent invention, the CARB<br />

<strong>toroidal</strong> <strong>roller</strong> bearing can be found in<br />

a variety of applications spanning<br />

almost every industry. This bearing<br />

has already proven itself and in many<br />

cases has outperformed expectations<br />

by<br />

• extending service life,<br />

• increasing reliability,<br />

• reducing maintenance, and<br />

• providing more compact designs.<br />

One of the major application areas<br />

for CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> is in<br />

steelmaking and particularly in continuous<br />

casters where the multitude of<br />

guide <strong>roller</strong>s are subjected to the most<br />

difficult operating conditions. Paper<br />

machines are another important application<br />

where shaft deflections and thermal<br />

changes in roll length of up to 10 mm<br />

have to be accommodated.<br />

These are not the only fields where<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> perform<br />

successfully. They are also in service<br />

in gearboxes, large electric motors,<br />

wind power plants, water turbines, bow<br />

thrusters, crane wheels, separators,<br />

centrifuges, presses, staking machines<br />

for tanneries, rotary cultivators and<br />

mulchers.<br />

Main application areas<br />

• Steelmaking and rolling mills<br />

• Conveyors and <strong>roller</strong> beds<br />

• Paper machines<br />

• Fluid machinery<br />

• Crushers<br />

• Gearboxes of all types<br />

• Textile machines<br />

• Food and beverage<br />

processing machines<br />

• Agricultural machinery<br />

• Vibrating screens<br />

Major demands<br />

• Freedom<br />

• High load carrying capacity<br />

• High operational reliability<br />

• Long service life<br />

• Reduced maintenance<br />

• Low operational costs<br />

• Compact design<br />

• Enhanced performance<br />

• High power density<br />

Solution

1 Product information 2 Recommendations 3 Product data<br />

Application areas Page ............. 12 Page ............. 37<br />

To facilitate the incorporation of<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> in new<br />

as well as existing machines, please<br />

consult the SKF application engineering<br />

service.

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 System life Page ............. 37<br />

Selection of bearing size<br />

To calculate bearing size or the basic<br />

rating life for a <strong>toroidal</strong> <strong>roller</strong> bearing<br />

it is possible to use all the known and<br />

standardized (ISO 281) calculation<br />

methods. However, it is recommended<br />

that the SKF Life Method be applied<br />

so that the enhanced performance of<br />

SKF <strong>bearings</strong> can be fully exploited.<br />

Detailed information can be found in the<br />

SKF General Catalogue in the section<br />

“Selection of bearing size” or in the<br />

“SKF Interactive Engineering Catalogue”<br />

available on CD-ROM or online<br />

at www.skf.com.<br />

For a self-aligning bearing system<br />

that uses an SKF Explorer spherical<br />

<strong>roller</strong> bearing and a CARB bearing,<br />

system life can be calculated using the<br />

SKF rating life equation:<br />

L nm,Sys =<br />

9/8<br />

where<br />

L nm,Sys<br />

L nm,SRB<br />

L nm,CARB =<br />

1<br />

L nm,SRB<br />

9/8<br />

= SKF rating life for the bearing<br />

system (at 100 – n %<br />

reliability), millions of revolutions<br />

= SKF rating life for the locating<br />

spherical <strong>roller</strong> bearing<br />

(at 100 – n % reliability),<br />

millions of revolutions<br />

SKF rating life for the nonlocating<br />

CARB <strong>toroidal</strong><br />

<strong>roller</strong> bearing (at 100 – n %<br />

reliability), millions of revolutions<br />

1<br />

+<br />

1<br />

L nm,CARB<br />

9/8<br />

Longer life or downsizing<br />

When used in a self-aligning bearing<br />

system, the CARB bearing prevents<br />

internally induced axial forces from<br />

occuring. This is in contrast to conventional<br />

self-aligning bearing systems<br />

with two spherical <strong>roller</strong> <strong>bearings</strong> or<br />

self-aligning ball <strong>bearings</strong> where the<br />

induced internal axial forces can be<br />

20 % or more of the radial load acting<br />

on the non-locating bearing. These<br />

additional forces represent a sizeable<br />

proportion of the total load that cannot<br />

be neglected and can result in<br />

• the bearing system not achieving the<br />

requisite life, or<br />

• larger <strong>bearings</strong> being used to compensate<br />

for the additional forces.<br />

Because a CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

prevents internally induced axial<br />

forces from occuring, the load conditions<br />

in the bearing arrangement can<br />

be predicted accurately since the<br />

locating bearing is only subjected to its<br />

portion of the external radial and axial<br />

loads, while the non-locating bearing<br />

is only subjected to its portion of the<br />

radial load.<br />

Whether a spherical <strong>roller</strong> bearing<br />

(➔ diagram 1 ) or a self-aligning ball<br />

bearing (➔ diagram 2 ) is used in the<br />

locating position, the new self-aligning<br />

bearing system can substantially<br />

increase the service life of a bearing<br />

arrangement. It is also worth noting<br />

that, even if smaller <strong>bearings</strong> are used,<br />

it is often possible to achieve system<br />

lives that are longer compared to the<br />

traditional systems. This can be<br />

exploited by downsizing adjacent<br />

components and reducing costs.<br />

To take full advantage of the benefits<br />

offered by the new self-aligning<br />

system it is necessary to carefully<br />

select the bearing size – at the nonlocating<br />

as well as the locating side.<br />

For assistance, contact the SKF application<br />

engineering service.<br />

12

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 System life Page ............. 37<br />

Compare the life of a conventional selfaligning<br />

bearing system with spherical<br />

<strong>roller</strong> <strong>bearings</strong> with a bearing system<br />

containing a CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

and a spherical <strong>roller</strong> bearing<br />

Diagram<br />

1<br />

1<br />

C 3148 23148<br />

2<br />

C 3144 23144<br />

0,5<br />

Relative life of the system<br />

23148 23148<br />

0<br />

0 0,05 0,1 0,15* 0,2 0,25 0,3 0,35 0,4<br />

Coefficient of friction µ<br />

* Typical value for steel on cast iron<br />

Compare the life of a conventional selfaligning<br />

bearing system with self-aligning<br />

ball <strong>bearings</strong> with a bearing system<br />

containing a CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

and a self-aligning ball bearing<br />

6<br />

Diagram<br />

2<br />

5<br />

C 2222 2222<br />

4<br />

3<br />

Relative life of the system<br />

2<br />

C 2220 2220<br />

1<br />

2222 2222<br />

0<br />

0 0,05 0,1 0,15* 0,2 0,25 0,3 0,35 0,4<br />

Coefficient of friction µ<br />

* Typical value for steel on cast iron<br />

13

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Radial location Page ............. 37<br />

Design of bearing arrangements<br />

Two <strong>bearings</strong> are generally required to<br />

support, guide and locate a shaft in<br />

the radial and axial directions. To do<br />

this, one bearing is designated the<br />

locating bearing and the other is the<br />

non-locating bearing.<br />

In traditional self-aligning bearing<br />

systems, the locating bearing locates<br />

the shaft axially in its housing while<br />

the non-locating bearing typically<br />

moves in its housing to accommodate<br />

axial expansion of the shaft.<br />

With the new SKF self-aligning<br />

bearing system, a CARB <strong>toroidal</strong> <strong>roller</strong><br />

bearing is used in the non-locating<br />

position and either a spherical <strong>roller</strong><br />

bearing (➔ fig 1 ) or a self-aligning<br />

ball bearing (➔ fig 2 ) is used in the<br />

locating position. Because a CARB<br />

bearing can accommodate axial<br />

expansion internally like a cylindrical<br />

<strong>roller</strong> bearing, it prevents internally<br />

induced axial forces from occuring that<br />

would otherwise that would otherwise<br />

be present if the bearing had to slide<br />

on its seating in the housing. This ability<br />

to accommodate internal axial forces<br />

allows the bearing rings to be axially<br />

located on the shaft and in the housing.<br />

Radial location<br />

To take advantage of the very high load<br />

carrying capacity and full life potential of<br />

a <strong>toroidal</strong> <strong>roller</strong> bearing, the bearing<br />

rings must be fully supported around<br />

their whole circumference and across<br />

the full width of the outer ring.<br />

Selecting the proper fit<br />

To locate a shaft radially, most applications<br />

require an interference fit between<br />

the bearing rings and their seatings.<br />

However, if easy mounting and dismounting<br />

are required, the outer ring<br />

will have a looser fit.<br />

Recommendations for suitable shaft<br />

diameter and housing bore tolerances<br />

for CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> are<br />

given in tables 1 , 2 and 3 . These<br />

recommendations apply to solid steel<br />

shafts and housings made from cast<br />

iron or steel.<br />

Generally, CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

follow the fit recommendations<br />

for spherical <strong>roller</strong> <strong>bearings</strong> on shafts<br />

and in housings. However, a spherical<br />

<strong>roller</strong> bearing on the non-locating side<br />

must be axially free, which requires a<br />

loose housing fit – this is not necessary<br />

for bearing arrangements using a CARB<br />

<strong>toroidal</strong> <strong>roller</strong> bearing. CARB <strong>bearings</strong><br />

(and locating spherical <strong>roller</strong> <strong>bearings</strong>)<br />

can therefore utilise the advantages of<br />

tight outer ring fits if mounting and<br />

dismounting allow this, but for normal,<br />

stationary outer ring load it is not necessary.<br />

For example a K7 fit is applied to<br />

<strong>bearings</strong> in the split housing for a fan<br />

with an unbalanced fan rotor and a P7<br />

fit applied to a non-split housing.<br />

<strong>Bearings</strong> with a tapered bore are<br />

mounted either directly on a tapered<br />

journal or on an adapter or a withdrawal<br />

sleeve on cylindrical shaft seatings.<br />

The fit of the inner ring in these<br />

cases depends on how far the ring is<br />

driven up the tapered seating.<br />

Accuracy of associated components<br />

The accuracy of the cylindrical seatings<br />

on the shaft and in the housing bore<br />

should correspond to that of the bearing.<br />

For CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

the shaft seating should be tolerance<br />

grade 6 and the housing seating grade<br />

7. For an adapter or withdrawal sleeve,<br />

wider diameter tolerances can be<br />

SKF self-aligning bearing system with a spherical <strong>roller</strong><br />

bearing at the locating side and a CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

at the non-locating side<br />

SKF self-aligning bearing system with a self-aligning ball<br />

bearing at the locating side and a CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

at the non-locating side<br />

Fig 1<br />

Fig 2<br />

14

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Radial location Page ............. 37<br />

adopted for the cylindrical seating on<br />

the shaft, e.g. grade 9 or 10.<br />

The cylindricity as defined in<br />

ISO 1101-1996 for the bearing seating<br />

should be 1 or 2 grades better than<br />

the recommended dimensional tolerance<br />

depending on the requirements.<br />

For example, a shaft seating machined<br />

to tolerance m6 should have a cylindricity<br />

grade 5 or 4.<br />

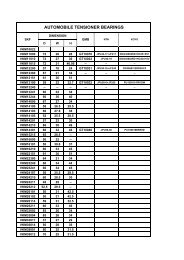

Conditions Examples Shaft diameter (mm) Tolerance<br />

over incl.<br />

<strong>Bearings</strong> with cylindrical bore<br />

Rotating inner ring load or direction of load indeterminate<br />

Normal and General 40 k5<br />

heavy loads engineering, 40 65 m5<br />

(P > 0,06 C) electric motors, 65 100 m6<br />

pumps, 100 140 n6<br />

gearboxes 140 280 p6<br />

280 500 r6 1)<br />

500 r7 1)<br />

Table<br />

1<br />

2<br />

Very heavy loads and shock loads 50 100 n6 1)<br />

with difficult working conditions 100 140 p6 1)<br />

(P > 0,12 C) 140 r6 1)<br />

<strong>Bearings</strong> with tapered bore on adapter or withdrawal sleeves<br />

Normal loads and/or normal speeds<br />

Heavy loads and/or high speeds<br />

h10/IT7/2<br />

h9/IT5/2<br />

Stationary inner ring load<br />

Easy dismounting unnecessary<br />

h6<br />

Easy dismounting desirable g6 2)<br />

Fits for solid steel<br />

shafts<br />

1)<br />

<strong>Bearings</strong> with radial internal clearance greater than Normal may be necessary<br />

2)<br />

Tolerance f6 can be selected for large <strong>bearings</strong> to provide easy displacement<br />

Table<br />

2<br />

Conditions Examples Tolerance Remarks<br />

Rotating outer ring load<br />

Heavy loads and Crushers, N6 Bearing outside diameter < 160 mm<br />

shock loads vibrating P6 Bearing outside diameter ≥ 160 mm<br />

screens, fans<br />

Stationary outer ring load<br />

Loads of all kinds General H7<br />

engineering<br />

Direction of load indeterminate<br />

Heavy shock loads<br />

M7<br />

Normal and General K7<br />

heavy loads engineering,<br />

(P > 0,06 C) electric motors, H7 Easy mounting of bearing required<br />

pumps<br />

Fits for non-split<br />

cast iron and steel<br />

housings<br />

Table<br />

3<br />

Conditions Examples Tolerance<br />

Stationary outer ring load<br />

Loads of all kinds General H7<br />

engineering<br />

Direction of load indeterminate<br />

Loads of all kinds General J7<br />

engineering,<br />

electric motors,<br />

pumps<br />

Fits for split cast<br />

iron and steel<br />

housings<br />

15

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Axial location Page ............. 37<br />

Axial location<br />

The rings of CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

should be axially located on both<br />

sides on the shaft as well as in the<br />

housing. SKF recommends arranging<br />

the bearing rings so that they abut a<br />

shoulder on the shaft or in the housing.<br />

Inner rings can be locked in position<br />

using<br />

• a shaft (lock) nut (➔ fig 3 ),<br />

• a retaining ring (➔ fig 4 ) or<br />

• an end plate screwed to the shaft<br />

end (➔ fig 5 ).<br />

Abutment and fillet dimensions<br />

The abutment and fillet dimensions,<br />

which include the diameters of shaft<br />

and housing shoulders, spacer sleeves<br />

etc. have been determined so that<br />

adequate abutment surfaces are provided<br />

for the side faces of the bearing<br />

rings without any danger of the rotating<br />

parts being fouled. The recommended<br />

abutment and fillet dimensions for each<br />

individual bearing can be found in the<br />

product tables.<br />

Outer rings are usually secured in<br />

position in the housing by the end<br />

cover (➔ fig 6 ).<br />

Instead of integral shaft and housing<br />

shoulders CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

can be mounted against<br />

• spacer sleeves (➔ fig 7 )or<br />

• retaining rings (➔ fig 8 ).<br />

<strong>Bearings</strong> with a tapered bore that are<br />

mounted<br />

• directly onto a tapered journal are<br />

usually secured to the shaft with a<br />

nut on the threaded section (➔ fig 9 ),<br />

or<br />

• on an adapter sleeve and a stepped<br />

shaft are secured against a spacer<br />

ring (➔ fig 10), or<br />

• on a withdrawal sleeve against<br />

a shaft shoulder are secured by<br />

a shaft nut (➔ fig 11 ) or an end<br />

plate (➔ fig 12).<br />

Inner ring located<br />

axially with a<br />

shaft nut<br />

Fig<br />

3<br />

Inner ring located<br />

axially with a<br />

retaining ring<br />

Fig<br />

4<br />

16

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Axial location Page ............. 37<br />

Fig<br />

5<br />

Inner ring located<br />

axially with an end<br />

plate<br />

Fig<br />

9<br />

Inner ring on a<br />

tapered shaft held<br />

in place by a shaft<br />

nut<br />

2<br />

Fig<br />

6<br />

Outer ring located<br />

axially with an end<br />

cover<br />

Fig<br />

10<br />

Inner ring on an<br />

adapter sleeve<br />

and a stepped<br />

shaft, axially<br />

located against<br />

a spacer ring<br />

Fig<br />

7<br />

Spacer sleeves<br />

used to axially<br />

locate the inner<br />

and outer rings<br />

Fig<br />

11<br />

Inner ring on a withdrawal<br />

sleeve and<br />

a stepped shaft,<br />

axially located by<br />

a shaft nut<br />

Fig<br />

8<br />

Retaining rings<br />

used to axially<br />

locate the bearing<br />

rings<br />

Fig<br />

12<br />

Inner ring on a withdrawal<br />

sleeve and<br />

a stepped shaft,<br />

axially located by<br />

an end plate<br />

17

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Associated components Page ............. 37<br />

Design of adjacent<br />

components<br />

Space on the sides of the bearing<br />

To enable axial displacement of the<br />

shaft relative to the housing, space<br />

must be provided on both sides of<br />

the bearing as indicated in fig 13 .<br />

The actual value for the width of this<br />

space can be estimated based on<br />

It is particularly important when<br />

designing large bearing arrangements<br />

to take steps so that the mounting and<br />

dismounting of the <strong>bearings</strong> are facilitated<br />

or actually made possible.<br />

C a<br />

Fig<br />

13<br />

• the value C a (from the product<br />

tables),<br />

• the axial displacement of the bearing<br />

rings from the central position<br />

expected in operation, and<br />

• the displacement of the rings caused<br />

by misalignment<br />

Free space on<br />

both sides of the<br />

bearing<br />

Fig<br />

14<br />

C areq = C a + 0,5 (s + s mis )<br />

or<br />

C areq = C a + 0,5 (s + k 1 B α)<br />

where<br />

C areq = width of space required on each<br />

side of the bearing, mm<br />

C a = minimum width of space required<br />

on each side of the bearing, mm<br />

(➔ product tables)<br />

s = thermal change in shaft length,<br />

mm<br />

s mis = axial displacement of <strong>roller</strong><br />

complement caused by misalignment,<br />

mm<br />

k 1 = misalignment factor<br />

(➔ product tables)<br />

B = bearing width, mm<br />

(➔ product tables)<br />

α = angular misalignment, degrees<br />

See also under “Axial displacement” on<br />

page 40.<br />

Normally, the bearing rings are<br />

mounted so that they are not displaced<br />

with respect to each other. However,<br />

if considerable thermal changes<br />

in shaft length can be expected, the<br />

inner ring can be mounted offset relative<br />

to the outer ring up to the permissible<br />

axial displacement s 1 or s 2 in the<br />

direction opposite to the expected<br />

thermal elongation (➔ fig 14 ). In this<br />

way, the permissible axial displacement<br />

can be appreciably extended, an<br />

advantage which is made use of in the<br />

bearing arrangement of drying cylinders<br />

in papermaking machines.<br />

By mounting the<br />

outer ring purposely<br />

displaced<br />

with regard to the<br />

inner ring the<br />

permissible axial<br />

displacement can<br />

be extended<br />

CARB <strong>toroidal</strong><br />

<strong>roller</strong> bearing on<br />

a tapered journal<br />

with oil duct and<br />

distributor groove<br />

CARB <strong>toroidal</strong><br />

<strong>roller</strong> bearing<br />

arrangement with<br />

oil ducts and distributor<br />

grooves in<br />

the shaft and<br />

housing<br />

s 1<br />

s 2<br />

Fig<br />

Fig<br />

15<br />

16<br />

18

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Associated components Page ............. 37<br />

Threaded holes for the oil injection<br />

method<br />

If the oil injection method is to be used<br />

• for mounting and dismounting<br />

<strong>bearings</strong> on tapered journals<br />

(➔ fig 15 ) or<br />

• for dismounting <strong>bearings</strong> on or in<br />

cylindrical seatings on the shaft or<br />

in the housing<br />

it is necessary to provide oil ducts and<br />

distributor grooves in the seating on<br />

the shaft or in the housing (➔ fig 16 ).<br />

The distance of the distributor groove<br />

from the side at which the bearing is to<br />

be mounted and/or dismounted should<br />

correspond to approximately a third of<br />

the bearing width. Recommended<br />

dimensions for the distributor grooves,<br />

the oil ducts and the appropriate<br />

threads for the connections are given<br />

in tables 4 and 5 .<br />

2<br />

Recommended dimensions for oil ducts<br />

and distributor grooves<br />

Threaded connection holes<br />

Table<br />

4<br />

Table<br />

5<br />

L<br />

L<br />

3<br />

Gc<br />

G a<br />

N<br />

60°<br />

Gb<br />

c<br />

h a<br />

r a<br />

b a<br />

N a<br />

N a<br />

G a<br />

G Gb<br />

Design A<br />

Design B<br />

Bearing seating Dimensions<br />

diameter b a h a r a N<br />

over incl.<br />

Thread<br />

G a<br />

Design<br />

G b<br />

Dimensions<br />

1)<br />

G c N a<br />

max<br />

mm<br />

mm<br />

– – mm<br />

100 3 0,5 2,5 2,5<br />

100 150 4 0,8 3 3<br />

150 200 4 0,8 3 3<br />

200 250 5 1 4 4<br />

250 300 5 1 4 4<br />

300 400 6 1,25 4,5 5<br />

400 500 7 1,5 5 5<br />

500 650 8 1,5 6 6<br />

650 800 10 2 7 7<br />

M 6 A 10 8 3<br />

G 1/8 A 12 10 3<br />

G 1/4 A 15 12 5<br />

G 3/8 B 15 12 8<br />

G 1/2 B 18 14 8<br />

G 3/4 B 20 16 8<br />

800 1 000 12 2,5 8 8<br />

1) Effective threaded length<br />

19

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Seals Page ............. 37<br />

Sealing the bearing<br />

arrangement<br />

When selecting the most suitable<br />

sealing arrangement for a self-aligning<br />

bearing arrangement it is necessary to<br />

pay particular attention to<br />

• the angular misalignment of the<br />

shaft and<br />

• the magnitude of the axial<br />

displacement.<br />

Otherwise the general selection criteria<br />

presented in the SKF General Catalogue<br />

(and the “SKF Interactive Engineering<br />

Catalogue”) apply and all types<br />

of seals can be used.<br />

Non-contact seals are to be preferred<br />

when the operating conditions<br />

involve<br />

Some seal types are supplied as<br />

standard with SKF bearing housings<br />

and include a double-lip contact seal,<br />

a labyrinth seal as well as a Taconite<br />

seal (➔ fig 21 ). Additional information<br />

can be found in the brochure 4403<br />

“SNL plummer block housings solve<br />

the housing problems”.<br />

Reference<br />

Additional information about radial<br />

shaft seals, V-ring seals or mechanical<br />

seals can be found in the<br />

SKF catalogue 4006 “CR seals” or<br />

in the “SKF Interactive Engineering<br />

Catalogue” on CD-ROM or online<br />

at www.skf.com.<br />

• high speeds,<br />

• large axial displacements,<br />

• high temperatures,<br />

CR seals<br />

and the sealing position is not directly<br />

exposed to contamination. The shaft<br />

should be horizontal.<br />

The simple gap-type seal (➔ fig 17 )<br />

is very suitable for sealing the nonlocating<br />

arrangement of self-aligning<br />

bearing systems. The size of the gap<br />

can be adapted to the misalignment of<br />

the shaft and is not limited in any way.<br />

Single or multi-stage labyrinth seals<br />

are obviously more efficient than the<br />

simple gap-type seal, but are more<br />

expensive. With CARB <strong>toroidal</strong> <strong>roller</strong><br />

<strong>bearings</strong>, the labyrinth passages should<br />

be arranged axially in order to provide<br />

freedom of axial movement for the<br />

shaft in operation. If considerable<br />

misalignment is expected in operation,<br />

the passages should be angled (➔ fig<br />

18 ). When split housings are used,<br />

labyrinth seals with radially arranged<br />

passages can be used, provided axial<br />

movement of the shaft relative to the<br />

housing is not limited (➔ fig 19 ).<br />

Radial shaft seals are contact seals<br />

that are suitable for sealing greased or<br />

oil lubricated CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong>,<br />

provided misalignment is slight<br />

and the seal lip counterface is sufficiently<br />

wide (➔ fig 20 ).<br />

20

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Seals Page ............. 37<br />

Labyrinth seal<br />

with radially<br />

arranged<br />

passages<br />

Fig<br />

19<br />

2<br />

Fig<br />

17<br />

Gap-type seal<br />

Radial shaft seal<br />

Fig<br />

20<br />

Fig<br />

18<br />

Labyrinth seal<br />

with angled<br />

passages<br />

Taconite seal<br />

Fig<br />

21<br />

21

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Grease lubrication Page ............. 37<br />

Lubrication<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> can be<br />

lubricated with grease as well as oil.<br />

There is no strict rule for when grease<br />

or oil should be used.<br />

Grease has the advantage over oil<br />

that it is more easily retained in the<br />

bearing than oil and grease is better if<br />

the shaft is at an angle or arranged<br />

vertically.<br />

On the other hand, oil lubrication<br />

allows higher operating speeds and<br />

temperatures and can contribute to<br />

heat removal from the bearing position,<br />

which is particularly important where<br />

external heating is involved. Very small<br />

quantities of lubricant are required to<br />

lubricate the bearing surfaces.<br />

Since CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

cannot be relubricated via the outer<br />

ring, lubricant has to be supplied from<br />

the side of the bearing. This is best<br />

done via a duct that opens immediately<br />

adjacent to the side face of the bearing<br />

outer ring. To force the lubricant to<br />

pass through the bearing, a drainage<br />

opening should be provided on the<br />

opposite side of the bearing (➔ fig 1 ).<br />

Grease lubrication<br />

For the lubrication of CARB <strong>toroidal</strong><br />

<strong>roller</strong> <strong>bearings</strong> good quality rust<br />

inhibiting greases that are resistant<br />

to ageing and have a consistency of<br />

2 or 3 are suitable. Many factors influence<br />

the choice of grease. To assist in<br />

this process, SKF greases that are<br />

suitable for CARB bearing lubrication<br />

are listed in table 1 .<br />

Lubricant supply to the bearing<br />

Operating conditions<br />

Fig<br />

1<br />

The correct quantity of grease<br />

For the majority of applications the<br />

following guidelines apply:<br />

• Caged CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

should be filled with grease to<br />

approximately 50 %. In <strong>bearings</strong><br />

that are to be greased before<br />

mounting it is recommended just to<br />

fill the space between the inner ring<br />

and the cage (➔ fig 2 ).<br />

• The free space in the bearing housing<br />

should be filled with grease to<br />

between 30 and 50 %.<br />

• Full complement CARB <strong>toroidal</strong><br />

<strong>roller</strong> <strong>bearings</strong> should be completely<br />

filled with grease.<br />

For bearing arrangements that turn<br />

slowly but where good protection<br />

against corrosion is required, all the<br />

free space in the housing can be filled<br />

with grease as there is little risk of the<br />

operating temperature increasing.<br />

SKF grease<br />

Designation Temperature Viscosity at<br />

range<br />

40/100 ˚C<br />

– – ˚C mm 2 /s<br />

Standard bearing LGMT 2 –30/+120 110/11<br />

arrangements<br />

Standard bearing arrange- LGMT 3 –30/+120 125/12<br />

ments but with relatively<br />

high ambient temperatures<br />

Operating temperatures LGHB 2 –20/+150 420/26,5<br />

always over 100 ˚C<br />

High operating temperatures, LGHP 2 –40/+150 96/10,5<br />

smooth operation<br />

Table<br />

1<br />

Shock loads, heavy loads, LGEP 2 –20/+110 200/16<br />

vibration<br />

High demands on LGGB 2 –40/+120 110/13<br />

environmental friendliness<br />

Recommended SKF greases<br />

Full details on the mentioned SKF greases as well as the complete range of SKF greases will be found in<br />

– SKF catalogue MP3000 “SKF Maintenance and Lubrication Products” or online at www.mapro.skf.com<br />

– “SKF Interactive Engineering Catalogue” on CD-ROM or online at www.skf.com<br />

22

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Grease lubrication Page ............. 37<br />

Table<br />

2<br />

Fig<br />

2<br />

Bearing design Bearing Maximum n × d m<br />

factor C/P ≥ 15 C/P ≈ 8 C/P ≈ 4<br />

CARB <strong>bearings</strong> with cage 2 350 000 200 000 100 000<br />

CARB <strong>bearings</strong> – full complement 1) 4 N.A 3) N.A 3) 20 000 2)<br />

1)<br />

The t f value obtained from diagram 1 needs to be divided by a factor 10<br />

2)<br />

For higher speeds oil lubrication is recommended<br />

3)<br />

For these C/P values a caged bearing is recommended instead<br />

2<br />

Bearing factors and recommended maximum speed limits<br />

Relubrication<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> have to<br />

be relubricated if the service life of the<br />

grease is shorter than the expected service<br />

life of the bearing. Relubrication<br />

should always be undertaken at a time<br />

when the existing lubricant is still satisfactory.<br />

The time at which relubrication should<br />

be undertaken depends on many related<br />

factors. These include bearing type and<br />

size, speed, operating temperature,<br />

grease type, space around the bearing<br />

and the bearing environment.<br />

It is only possible to base recommendations<br />

on statistical rules; the SKF<br />

relubrication intervals are defined as the<br />

time period, at the end of which 99 % of<br />

the <strong>bearings</strong> are still reliably lubricated.<br />

This represents L 1 for grease life.<br />

SKF recommends using experience<br />

data from running applications and<br />

tests, together with the estimated relubrication<br />

intervals provided in the next<br />

section.<br />

Relubrication intervals (t f )<br />

The relubrication intervals t f for normal<br />

operating conditions are provided in<br />

diagram 1 . The diagram is valid for<br />

<strong>bearings</strong> on horizontal shafts under<br />

clean conditions.<br />

The value on the horizontal axis is<br />

obtained from “n × d m ” (rotational<br />

speed × bearing mean diameter)<br />

(unit: mm/min) multiplied by the relevant<br />

CARB <strong>toroidal</strong> <strong>roller</strong> bearing factor,<br />

which depends on the applied CARB<br />

<strong>toroidal</strong> <strong>roller</strong> bearing execution and<br />

loading situation. The bearing factor<br />

and recommended maximum “n × d m ”<br />

values for CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

are given in table 2 .<br />

The t f value is then derived considering<br />

the load magnitude, given by the<br />

value of C/P. The relubrication interval<br />

(t f ) is an estimated value, valid for an<br />

operating temperature of 70 °C, using<br />

good quality lithium base greases.<br />

Different conditions are covered in<br />

detail in “Deviating conditions”.<br />

If the value of “n × d m ” approaches<br />

the limit value (> 70 %) or if ambient<br />

temperatures are high, then the use of<br />

Relubrication intervals for CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> at 70 °C<br />

tf, operating hours<br />

100 000<br />

50 000<br />

10 000<br />

5 000<br />

1 000<br />

500<br />

100<br />

0<br />

Bearing grease fill<br />

Caged CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> should<br />

not be completely filled with grease; for<br />

high speed operation fill only the space<br />

between the inner ring and the cage<br />

the calculations presented in the SKF<br />

General Catalogue, section “Speeds<br />

and vibration”, is recommended to<br />

check the operating temperature and<br />

the proper lubrication method.<br />

Diagram<br />

100 000 200 000 300 000 400 000 500 000 600 000 700 000 800 000<br />

Bearing factor n × d m<br />

C/P ≥ 15<br />

C/P ≈ 8<br />

C/P ≈ 4<br />

Example: CARB <strong>toroidal</strong> <strong>roller</strong> bearing C 2220 K<br />

The bearing has a bore diameter d = 100 mm, an outside diameter D = 180 mm and rotates at a speed<br />

n = 1 000 r/min. The load ratio C/P is 4 and the operating temperature lies between 60 and 70 °C. What is the<br />

relubrication interval?<br />

The bearing factor n × d m is obtained as follows: n × d m = 1 000 × 0,5 (d + D) = 1 000 × 0,5 (100 + 180) =<br />

140 000. Follow a vertical line from the x-axis from the point n × d m = 140 000 until it intersects the line<br />

of the load ratio C/P = 4. The relubrication interval can then be read off on the y-axis by drawing a horizontal<br />

line from the point of intersection with 3 000 operating hours.<br />

1<br />

23

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Grease lubrication Page ............. 37<br />

Deviating conditions<br />

Operating temperature<br />

To account for the accelerated ageing<br />

of grease in hot running applications,<br />

SKF recommends halving the intervals<br />

obtained from the diagram for every<br />

15 °C increase in bearing temperature<br />

above 70 °C.<br />

The relubrication interval t f may be<br />

extended at temperatures below 70 °C.<br />

In many cases the interval may also be<br />

prolonged if the load is low (C/P = 30 to<br />

50). Extending the relubrication interval<br />

t f by more than a factor of two is not<br />

recommended.<br />

For full complement <strong>bearings</strong>, t f<br />

values obtained from the diagram<br />

should not be prolonged.<br />

Moreover, it is not advisable to use<br />

relubrication intervals in excess of<br />

30 000 hours.<br />

For many applications, there are<br />

practical grease lubrication limits,<br />

when the bearing ring with the highest<br />

temperature reaches an operating temperature<br />

of 100 °C. Above this temperature<br />

special greases should be used.<br />

In addition,temperature stability of the<br />

bearing and premature seal failure<br />

should be taken into consideration.<br />

For high temperature applications,<br />

contact the SKF application engineering<br />

service.<br />

Vertical shafts<br />

For <strong>bearings</strong> on vertical shafts, the<br />

intervals obtained from the diagram<br />

should be halved.<br />

The use of a good seal or retaining<br />

shield is a prerequisite or grease will<br />

leak from the bearing arrangement.<br />

Vibrations<br />

Mild vibrations will not have a negative<br />

effect on grease life, but high vibration<br />

and shock levels, such as those in<br />

vibrating screen applications, will cause<br />

the grease to churn. In these cases the<br />

relubrication interval should be reduced.<br />

If the grease becomes too soft, a<br />

grease with a better mechanical stability<br />

(e.g. LGHB 2) and/or a stiffer grease<br />

(NLGI 3) should be used.<br />

Outer ring rotation<br />

In applications where there is outer ring<br />

rotation, the value of the bearing factor<br />

n × d m is calculated by applying the<br />

value of the bearing outside diameter D<br />

instead of d m . The use of a good sealing<br />

mechanism is a prerequisite in order<br />

to avoid grease loss.<br />

Under conditions of high outer ring<br />

speeds (i.e. > 50 % of the speed rating<br />

in the bearing tables), greases with<br />

a reduced bleeding tendency should<br />

be selected (e.g. lithium complex and<br />

polyurea).<br />

Contamination<br />

In case of ingress of contamination, a<br />

more frequent relubrication interval will<br />

reduce the negative effects of foreign<br />

particles on the bleeding characteristics<br />

of grease while reducing the damaging<br />

effects caused by overrolling of particles.<br />

Fluid contaminants (water, process<br />

fluids) also call for a reduced interval.<br />

In case of severe contamination,<br />

continuous relubrication should be<br />

considered.<br />

Requisite grease quantities<br />

for relubrication<br />

The used grease in a CARB <strong>toroidal</strong><br />

<strong>roller</strong> bearing should be replaced by<br />

fresh grease. The quantity of grease<br />

required for this depends on the bearing<br />

size; this can be determined using<br />

G p = 0,005 D B<br />

where<br />

G p = grease quantity required for<br />

periodic lubrication, g<br />

D = bearing outside diameter, mm<br />

B = bearing width, mm<br />

Grease valve<br />

Excess grease is caused to enter<br />

a circular channel in the housing cover<br />

Supplying grease to a CARB bearing<br />

When using a hand-operated grease gun, excess pressure should<br />

be avoided or the seals may be damaged<br />

Fig 3<br />

Fig 4<br />

24

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Oil lubrication Page ............. 37<br />

Grease valve<br />

If CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> are to<br />

be relubricated frequently, there is a<br />

risk that too much grease will collect in<br />

the housing. This risk can be avoided<br />

by using a grease valve that allows<br />

excess grease to leave the housing<br />

(➔ fig 3 ).<br />

The so-called grease valve consists<br />

of a washer that rotates with the shaft<br />

and forms a narrow gap to the housing<br />

cover. Excess grease is carried by the<br />

washer into this gap and leaves the<br />

housing by a grease escape hole in<br />

the base.<br />

The grease should always be<br />

supplied from the side of the bearing<br />

opposite to the grease valve so that it<br />

is forced to pass through the bearing.<br />

When the bearing is mounted on an<br />

adapter sleeve, the lock nut with locking<br />

washer acts as a grease valve,<br />

so that grease should be supplied at<br />

the side opposite to the lock nut<br />

(➔ fig 4 ).<br />

Oil lubrication<br />

Oil lubrication is recommended or<br />

must be used if<br />

• the relubrication intervals for grease<br />

are too short,<br />

• speeds and/or operating temperatures<br />

are too high for grease,<br />

• heat must be removed from the<br />

bearing position, or<br />

• adjacent components are lubricated<br />

with oil.<br />

For CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

the following methods are normally<br />

employed:<br />

• Oil bath lubrication where the oil is<br />

distributed by rotating machine<br />

components to the bearing arrangement<br />

and runs back to the sump.<br />

• Circulating oil lubrication where the<br />

circulation is achieved by a pump<br />

and where the oil is filtered and<br />

cooled before being returned to<br />

the sump. The use of this method<br />

requires efficient sealing to prevent<br />

oil leakage.<br />

The oil level should be checked regularly.<br />

The appropriate level should not<br />

be higher than the middle of the lowest<br />