Z855 – Z875 Z895 – Z8125 SERIES

Z855 – Z875 Z895 – Z8125 SERIES

Z855 – Z875 Z895 – Z8125 SERIES

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8” SUBMERSIBLE<br />

ELECTRIC PUMPS<br />

50 Hz<br />

<strong>Z855</strong> <strong>–</strong> <strong>Z875</strong><br />

<strong>Z895</strong> <strong>–</strong> <strong>Z8125</strong> <strong>SERIES</strong><br />

EDITION 03-2006

INDEX<br />

Z8 Series Specifications............................................................................ 3<br />

Table of Materials .................................................................................... 4<br />

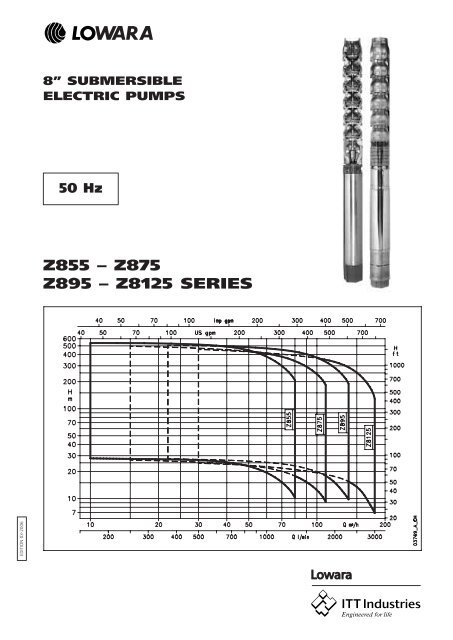

Hydraulic Performance Range, Z8 Series 50 Hz ....................................... 5<br />

Pump Cross-Section and List of Main Components .................................. 26<br />

L6C Series Motors ................................................................................... 27<br />

MC8 Series Motors.................................................................................. 31<br />

MC10 Series Motors................................................................................ 33<br />

AISI 316 F6 Series Motors ....................................................................... 35<br />

FW8 Series Motors .................................................................................. 37<br />

FW10 Series Motors ................................................................................ 39<br />

Accessories.............................................................................................. 41<br />

Technical Appendix.................................................................................. 61

8”<br />

Submersible<br />

Electric<br />

Pumps<br />

<strong>Z855</strong><br />

<strong>Z875</strong><br />

<strong>Z895</strong><br />

<strong>Z8125</strong><br />

Series<br />

MARKET SECTORS<br />

AGRICULTURAL, INDUSTRIAL<br />

APPLICATIONS<br />

• Water supply from deep wells.<br />

• Pressure boosting and water distribution in civil and<br />

industrial systems.<br />

• Supply of surge tanks and reservoirs.<br />

• Firefighting and washing systems.<br />

• Water level control.<br />

• Irrigation.<br />

• Mining.<br />

SPECIFICATIONS<br />

PUMP<br />

Delivery: up to 180 m3 /h.<br />

Head: up to 550 m.<br />

• Maximum pump overall diameter<br />

(2 cable covers included): 198 mm<br />

for all versions.<br />

• Maximum electric pump immersion<br />

depth:<br />

250 m with L6C motors,<br />

40 m with MC8 and MC10 motors,<br />

standard configuration (with lip<br />

seal); version with mechanical seal<br />

available on request (max.<br />

immersion depth 350 m).<br />

• Maximum permissible quantity of<br />

suspended sand: 100 g/m 3 .<br />

• Standard delivery outlet:<br />

Rp 5” for all versions.<br />

• Motor power: from 5.5 to 150 kW<br />

MOTOR<br />

• L6C motor: three-phase water-filled<br />

asynchronous motors with<br />

hermetically sealed stator<br />

• MC8 and MC10 rewindable threephase<br />

asynchronous motors with<br />

water-filled winding.<br />

• Three-phase version:<br />

L6C: from 3 to 37 kW 380-415V, 50Hz<br />

MC8: from 30 to 92 kW 380-415V,<br />

50Hz<br />

MC10: from 92 to 150 kW 380-415V,<br />

50Hz<br />

• Maximum supply voltage variations:<br />

L6C 400V ±10%,<br />

MC8, MC10 400V +6% -10%.<br />

• PVC windings for MC8 and MC10<br />

motors.<br />

• Horizontal operation:<br />

L6C up to 37 kW provided that the<br />

associated pump can apply an axial<br />

thrust of at least 250 N on the<br />

entire operating field.<br />

MC8 and MC10 available on request<br />

for all versions<br />

• Maximum number of starts per<br />

hour: 25 (L6C), 15 (MC8) and 10<br />

(MC10).<br />

• Maximum temperature of water in<br />

contact with motor: 35°C (L6C),<br />

25°C (MC8 and MC10).<br />

CONSTRUCTION<br />

FEATURES<br />

PUMP<br />

• Robust and lightweight, easy to<br />

maintain and corrosion resistant in<br />

non-aggressive environments.<br />

<strong>–</strong> Impellers and diffusers<br />

made of stainless steel.<br />

<strong>–</strong> Delivery casing made of<br />

stainless steel.<br />

<strong>–</strong> Non-return valve made of<br />

stainless steel, with<br />

integrated spring.<br />

<strong>–</strong> Suction support made of<br />

stainless steel.<br />

<strong>–</strong> Shaft made of stainless<br />

steel.<br />

• The guide bearings and wear rings<br />

ensure high resistance to wear and<br />

guarantee the constant and<br />

long-lasting performance of<br />

the hydraulic characteristics.<br />

• Coupling and flange mounting<br />

dimensions meet NEMA standards.<br />

• ZR8 version in DUPLEX<br />

stainless steel is also available.<br />

OPTIONAL FEATURES<br />

MOTOR<br />

Different voltages and frequencies.<br />

High temperature versions.<br />

• MC8 and MC10 for horizontal<br />

installation.<br />

ACCESSORIES<br />

Coupling flange.<br />

• Panels.<br />

Cables.<br />

3

TABLE OF MATERIALS Z8<br />

COMPONENT<br />

Delivery head / Valve Casing<br />

Valve<br />

Valve seat<br />

Valve spring<br />

Diffuser / Bowl<br />

Diffuser O-Ring<br />

Impeller<br />

Taperlock<br />

Wear ring<br />

Lower support / Suction Casing<br />

Suction strainer<br />

Pump shaft<br />

Coupling<br />

Bearing bush<br />

Thrust Bearing<br />

Screw, stud, nut<br />

Cable protection<br />

MATERIAL<br />

TABLE OF MATERIALS ZR8<br />

COMPONENT<br />

Delivery head / Valve Casing<br />

Valve<br />

Valve seat<br />

Valve spring<br />

Diffuser / Bowl<br />

Diffuser O-Ring<br />

Impeller<br />

Taperlock<br />

Wear ring<br />

Lower support / Suction Casing<br />

Suction strainer<br />

Pump shaft<br />

Coupling<br />

Bearing bush<br />

Thrust Bearing<br />

Screw, stud, nut<br />

Cable protection<br />

IDENTIFICATION CODES<br />

Z R 8 9 5 1 0 / 3 A <strong>–</strong> MC8<br />

Motor code<br />

EUROPE<br />

DESIGNATION<br />

Stainless steel EN 10213-4-GX5CrNi19-10 (1.4308) A744-CF 8<br />

Stainless steel EN 10213-4-GX5CrNi19-10 (1.4308) A744-CF 8<br />

NBR 90<br />

Stainless steel EN 10088-1-X5CrNiMo17-12-2 (1.4401) AISI 316<br />

Stainless steel EN 10213-4-GX5CrNi19-10 (1.4308) A744-CF 8<br />

NBR 70<br />

Stainless steel EN 10213-4-GX5CrNi19-10 (1.4308) A744-CF 8<br />

Duplex stainless steel EN 10088-1-X2CrNiMoN22-5-3 (1.4462) A276/A790-S31803<br />

POM (DELRIN ® )<br />

Stainless steel EN 10213-4-GX5CrNi19-10 (1.4308) A744-CF 8<br />

Stainless steel DIN 17440-X6CrNiMoTi17-12-2 (1.4571) AISI 316Ti<br />

Stainless steel EN 10088-1-X17CrNi16-2 (1.4057) AISI 431<br />

Stainless steel EN 10088-1-X17CrNi16-2 (1.4057) AISI 431<br />

EPDM + LOXAMID ®<br />

PTFE + 25% carbon<br />

Stainless steel ISO 3506-1/2 A4-70 AISI 316<br />

Stainless steel EN 10088-1-X5CrNi18-10 (1.4301) AISI 304<br />

MATERIAL<br />

DESIGNATION<br />

EUROPE<br />

USA<br />

USA<br />

z8-2p50_c_tm<br />

Duplex stainless steel EN 10213-4-GX2CrNiMoCuN25-6-3-3 (1.4517)<br />

Duplex stainless steel EN 10213-4-GX2CrNiMoCuN25-6-3-3 (1.4517)<br />

NBR 90<br />

Hastelloy C4 DIN17744-NiMo16Cr16Ti (2.4610) N06455<br />

Duplex stainless steel EN 10213-4-GX2CrNiMoCuN25-6-3-3 (1.4517)<br />

NBR 70<br />

Duplex stainless steel EN 10213-4-GX2CrNiMoCuN25-6-3-3 (1.4517)<br />

Duplex stainless steel EN 10088-1-X2CrNiMoN22-5-3 (1.4462) A276/A790-S31803<br />

POM (DELRIN ® )<br />

Duplex stainless steel EN 10213-4-GX2CrNiMoCuN25-6-3-3 (1.4517)<br />

Stainless steel EN 10088-1X1NiCrMoCu25-20-5 (1.4539) AISI 904L<br />

Duplex stainless steel EN 10088-1-X2CrNiMoN22-5-3 (1.4462) A276/A790-S31803<br />

Duplex stainless steel EN 10088-1-X2CrNiMoN22-5-3 (1.4462) A276/A790-S31803<br />

EPDM + LOXAMID ®<br />

PTFE + 25% carbon<br />

Duplex stainless steel EN 10088-1-X2CrNiMoN22-5-3 (1.4462) A276/A790-S31803<br />

Stainless steel EN 10088-1X1NiCrMoCu25-20-5 (1.4539) AISI 904L<br />

zr8-2p50_a_tm<br />

Reduction type<br />

Number of reduced stages<br />

Number of stages<br />

Flow rate in m 3 /h<br />

Type of pump (R = DUPLEX version)<br />

Blank = 50 Hz<br />

EXAMPLE: ZR8 9510/3A - MC8<br />

6 = 60 Hz<br />

8” electric pump, 50 Hz, made of DUPLEX, flow rate 95 m 3 /h, 10 stages including 3 reduced ones, coupled to an 8” MC8 motor.<br />

4

Z8 <strong>SERIES</strong><br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

5

<strong>Z855</strong> <strong>SERIES</strong>, 1 TO 7 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 167 500 833 1217 1333<br />

TYPE POWER m 3 /h 0 10 30 50 73 80<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z855</strong> 01 5,5 28,7 28 27 23 14 10,2<br />

<strong>Z855</strong> 02/2A 7,5 45,7 44,4 43 35 14,9<br />

<strong>Z855</strong> 02/1A 7,5 51,3 49,9 48 40 20,5<br />

<strong>Z855</strong> 02 9,3 57 55,6 53 45 27 19,7<br />

<strong>Z855</strong> 03/2A 11 74,2 72,1 69 57 27,7<br />

<strong>Z855</strong> 03 15 86,1 83,9 80 69 41 30,7<br />

<strong>Z855</strong> 04/2A 15 102,7 99,9 96 79 41<br />

<strong>Z855</strong> 04 18,5 114,6 111,7 107 91 55 40,7<br />

<strong>Z855</strong> 05/3A 18,5 125,6 122,2 117 97 49<br />

<strong>Z855</strong> 05/2A 22 132,3 128,8 124 104 56,7<br />

<strong>Z855</strong> 05 22 143,5 139,8 134 114 68 50,5<br />

<strong>Z855</strong> 06/2A 30 160,7 156,6 150 127 70,9<br />

<strong>Z855</strong> 06 30 172 167,6 160 137 83 61,3<br />

<strong>Z855</strong> 07/2A 30 188,6 183,6 176 148 82,3<br />

<strong>Z855</strong> 07 30 199,7 194,5 186 158 93 68,8<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z855-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z855</strong> 01-L6C 1191 200 140 1631 70<br />

<strong>Z855</strong> 02/2A-L6C 1355 200 140 1660 81<br />

<strong>Z855</strong> 02/1A-L6C 1355 200 140 1660 81<br />

<strong>Z855</strong> 02-L6C 1380 200 140 1685 84<br />

<strong>Z855</strong> 03/2A-L6C 1560 200 140 1730 97<br />

<strong>Z855</strong> 03-L6C 1615 200 140 1785 103<br />

<strong>Z855</strong> 04/2A-L6C 1750 200 140 1785 112<br />

<strong>Z855</strong> 04-L6C 1825 200 140 1860 119<br />

<strong>Z855</strong> 05/3A-L6C 1960 200 140 1860 128<br />

<strong>Z855</strong> 05/2A-L6C 2020 200 140 1920 134<br />

<strong>Z855</strong> 05-L6C 2020 200 140 1920 134<br />

<strong>Z855</strong> 06/2A-L6C 2285 200 140 2050 155<br />

<strong>Z855</strong> 06-L6C 2285 200 140 2050 155<br />

<strong>Z855</strong> 07/2A-L6C 2420 200 140 2050 164<br />

<strong>Z855</strong> 07-L6C 2420 200 140 2050 164<br />

z855-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 198 mm with L6C motor.<br />

2) T min valid only for max flow speed of 4,2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

6

<strong>Z855</strong> <strong>SERIES</strong>, 1 TO 7 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the non-return valve has been considered.<br />

These performances are valid for liquids with density ρ = 1,0 kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

7

<strong>Z855</strong> <strong>SERIES</strong>, 8 TO 19 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 167 500 833 1217 1333<br />

TYPE POWER m 3 /h 0 10 30 50 73 80<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z855</strong> 08/2A 37 217 211,5 202,8 171 96,1<br />

<strong>Z855</strong> 08 37 228,3 222,5 212,7 181 107,3 79,4<br />

<strong>Z855</strong> 09/2A 37 244,8 238,3 227,8 191,2 106,8<br />

<strong>Z855</strong> 09 44 260,6 254,2 244,3 210,6 128,5 96,9<br />

<strong>Z855</strong> 10/2A 44 277,5 270,5 260,1 221,5 128,4<br />

<strong>Z855</strong> 10 44 288,8 281,7 270,3 231,9 140,2 105,2<br />

<strong>Z855</strong> 11/2A 52 305,6 298 286,6 244,8 143,2<br />

<strong>Z855</strong> 11 52 316,9 309,2 296,8 255,4 155,4 116,9<br />

<strong>Z855</strong> 12 55 346,6 338,3 324,8 279,8 170,5 128,5<br />

<strong>Z855</strong> 13 59 375,3 366,1 351,3 302,3 183,7 138,2<br />

<strong>Z855</strong> 14 66 404,5 394,7 379,1 326,6 198,9 149,9<br />

<strong>Z855</strong> 15 66 432,8 422,2 404,9 348 210,9 158,4<br />

<strong>Z855</strong> 16 75 461,6 450,3 432,1 372,2 226,5 170,5<br />

<strong>Z855</strong> 17 92 491,8 479,8 461,2 398,8 244,6 185<br />

<strong>Z855</strong> 18 92 520 507,3 487,4 420,8 257 194<br />

<strong>Z855</strong> 19 92 551,2 538 517 446,3 273,5 206,9<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z855a-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z855</strong> 08/2A-L6C 2685 200 140 2180 186<br />

<strong>Z855</strong> 08-L6C 2685 200 140 2180 186<br />

<strong>Z855</strong> 09/2A-L6C 2820 200 140 2180 194<br />

<strong>Z855</strong> 09-MC8 2835 203,3 192 2195 276<br />

<strong>Z855</strong> 10/2A-MC8 2970 203,3 192 2195 284<br />

<strong>Z855</strong> 10-MC8 2970 203,3 192 2195 284<br />

<strong>Z855</strong> 11/2A-MC8 3195 203,3 192 2285 313<br />

<strong>Z855</strong> 11-MC8 3195 203,3 192 2285 313<br />

<strong>Z855</strong> 12-MC8 3370 203,3 192 2325 328<br />

<strong>Z855</strong> 13-MC8 3555 203,3 192 2375 347<br />

<strong>Z855</strong> 14-MC8 3780 203,3 192 2465 374<br />

<strong>Z855</strong> 15-MC8 3915 203,3 192 2465 382<br />

<strong>Z855</strong> 16-MC8 4140 203,3 192 2555 408<br />

<strong>Z855</strong> 17-MC8 4475 203,3 192 2755 455<br />

<strong>Z855</strong> 18-MC8 4610 203,3 192 2755 463<br />

<strong>Z855</strong> 19-MC8 4745 203,3 192 2755 472<br />

z855a-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 198 mm with L6C motor.<br />

C = 201,5 mm with MC8 motor.<br />

2) T min valid only for max flow speed of 4,2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

8

<strong>Z855</strong> <strong>SERIES</strong>, 8 TO 19 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the non-return valve has been considered.<br />

These performances are valid for liquids with density ρ = 1,0 kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

9

<strong>Z875</strong> <strong>SERIES</strong>, 1 TO 6 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 250 700 1167 1700 1833<br />

TYPE POWER m 3 /h 0 15 42 70 102 110<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z875</strong> 01 5,5 28,9 26,9 24,2 20,1 11,8 9,2<br />

<strong>Z875</strong> 02/2A 7,5 44,1 42,1 38,2 29,3 11,3<br />

<strong>Z875</strong> 02/1A 9,3 50,8 48 43,3 34,7 17,6<br />

<strong>Z875</strong> 02 11 57,9 54,1 48,7 40,5 23,9 18,6<br />

<strong>Z875</strong> 03/3A 11 66,1 63,1 57,2 43,7 16,9<br />

<strong>Z875</strong> 03/2A 15 73,5 69,7 63,3 50,4 24<br />

<strong>Z875</strong> 03/1A 15 80,1 75,3 68 55,3 29,8<br />

<strong>Z875</strong> 03 18,5 87,5 81,7 73,9 61,8 37 29,1<br />

<strong>Z875</strong> 04/2A 18,5 102,3 96,5 87,4 70,3 35,6<br />

<strong>Z875</strong> 04 22 116,5 108,8 98,1 81,8 48,8 38,1<br />

<strong>Z875</strong> 05/3A 22 124,7 117,9 106,7 85,2 41,4<br />

<strong>Z875</strong> 05/2A 30 132,1 124,4 112,9 92,1 49,3<br />

<strong>Z875</strong> 05 30 145,3 135,8 122,5 102,3 61 47,7<br />

<strong>Z875</strong> 06/2A 30 160 150,4 135,9 110,6 59,7<br />

<strong>Z875</strong> 06/1A 30 166,5 156 140,6 115,5 65,8<br />

<strong>Z875</strong> 06 37 174,2 162,8 147,1 122,7 73,1 57,2<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z875-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z875</strong> 01-L6C 1208 200 140 1631 71<br />

<strong>Z875</strong> 02/2A-L6C 1389 200 140 1660 82<br />

<strong>Z875</strong> 02/1A-L6C 1414 200 140 1685 85<br />

<strong>Z875</strong> 02-L6C 1459 200 140 1730 89<br />

<strong>Z875</strong> 03/3A-L6C 1611 200 140 1730 99<br />

<strong>Z875</strong> 03/2A-L6C 1666 200 140 1785 105<br />

<strong>Z875</strong> 03/1A-L6C 1666 200 140 1785 105<br />

<strong>Z875</strong> 03-L6C 1741 200 140 1860 112<br />

<strong>Z875</strong> 04/2A-L6C 1893 200 140 1860 121<br />

<strong>Z875</strong> 04-L6C 1953 200 140 1920 127<br />

<strong>Z875</strong> 05/3A-L6C 2105 200 140 1920 137<br />

<strong>Z875</strong> 05/2A-L6C 2235 200 140 2050 149<br />

<strong>Z875</strong> 05-L6C 2235 200 140 2050 149<br />

<strong>Z875</strong> 06/2A-L6C 2387 200 140 2050 159<br />

<strong>Z875</strong> 06/1A-L6C 2387 200 140 2050 159<br />

<strong>Z875</strong> 06-L6C 2517 200 140 2180 172<br />

z875-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 198 mm with L6C motor.<br />

2) T min valid only for max flow speed of 4.2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

10

<strong>Z875</strong> <strong>SERIES</strong>, 1 TO 6 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the non-return valve has been considered.<br />

These performances are valid for liquids with density ρ = 1,0 Kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

11

<strong>Z875</strong> <strong>SERIES</strong>, 7 TO 18 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 250 700 1167 1700 1833<br />

TYPE POWER m 3 /h 0 15 42 70 102 110<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z875</strong> 07/2A 37 189 177,5 160,4 131 71,8<br />

<strong>Z875</strong> 07 37 202 188,7 169,8 140,8 82,7 64,2<br />

<strong>Z875</strong> 08/3A 37 210,1 197,7 178,3 143,9 76,7<br />

<strong>Z875</strong> 08/2A 44 221,5 208 188,9 156,2 88,7<br />

<strong>Z875</strong> 08 44 234,9 219,6 198,8 166,5 100,6 79,3<br />

<strong>Z875</strong> 09/2A 44 249,9 234,6 212,4 175,1 99,1<br />

<strong>Z875</strong> 09 52 263,6 246,4 223 187,2 113,3 89,3<br />

<strong>Z875</strong> 10/2A 52 278,5 261,3 236,7 196 112,1<br />

<strong>Z875</strong> 10 52 291,8 272,7 246,5 206,5 124,1 97,5<br />

<strong>Z875</strong> 11/2A 55 308,6 298,4 262,1 217,4 125,1<br />

<strong>Z875</strong> 11 59 322,3 301,3 272,5 228,5 138 108,7<br />

<strong>Z875</strong> 12 66 352,1 329,1 297,9 249,9 151,1 119,2<br />

<strong>Z875</strong> 13 75 381,2 356,4 322,6 271 164,3 129,7<br />

<strong>Z875</strong> 14 75 409,5 382,8 346,2 290,3 175,1 137,9<br />

<strong>Z875</strong> 15 92 440,2 411,5 373 313,8 190,6 150,7<br />

<strong>Z875</strong> 16 92 471,8 441,2 399,6 336 204,6 162,1<br />

<strong>Z875</strong> 17 92 500,3 467,8 423,3 355,4 215,7 170,4<br />

<strong>Z875</strong> 18 92 530,1 495,7 449,6 378,8 231,2 183,3<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z875a-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z875</strong> 07/2A-L6C 2669 200 140 2180 181<br />

<strong>Z875</strong> 07-L6C 2669 200 140 2180 181<br />

<strong>Z875</strong> 08/3A-L6C 2821 200 140 2180 190<br />

<strong>Z875</strong> 08/2A-MC8 2836 203,3 192 2195 271<br />

<strong>Z875</strong> 08-MC8 2836 203,3 192 2195 271<br />

<strong>Z875</strong> 09/2A-MC8 2988 203,3 192 2195 281<br />

<strong>Z875</strong> 09-MC8 3078 203,3 192 2285 301<br />

<strong>Z875</strong> 10/2A-MC8 3230 203,3 192 2285 310<br />

<strong>Z875</strong> 10-MC8 3230 203,3 192 2285 310<br />

<strong>Z875</strong> 11/2A-MC8 3422 203,3 192 2325 325<br />

<strong>Z875</strong> 11-MC8 3472 203,3 192 2375 336<br />

<strong>Z875</strong> 12-MC8 3714 203,3 192 2465 363<br />

<strong>Z875</strong> 13-MC8 3956 203,3 192 2555 389<br />

<strong>Z875</strong> 14-MC8 4108 203,3 192 2555 399<br />

<strong>Z875</strong> 15-MC8 4460 203,3 192 2755 446<br />

<strong>Z875</strong> 16-MC8 4612 203,3 192 2755 455<br />

<strong>Z875</strong> 17-MC8 4764 203,3 192 2755 464<br />

<strong>Z875</strong> 18-MC8 4916 203,3 192 2755 474<br />

z875a-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 198 mm with L6C motor.<br />

C = 201,5 mm with MC8 motor.<br />

2) T min valid only for max flow speed of 4.2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

12

<strong>Z875</strong> <strong>SERIES</strong>, 7 TO 18 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the non-return valve has been considered.<br />

These performances are valid for liquids with density ρ = 1,0 Kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

13

<strong>Z895</strong> <strong>SERIES</strong>, 1 TO 6 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 367 1000 1500 2150 2300<br />

TYPE POWER m 3 /h 0 22 60 90 129 138<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z895</strong> 01 7,5 28,5 27,7 25,3 21,6 12,3 9,8<br />

<strong>Z895</strong> 02/2B 11 38,7 38,3 35,2 27,5<br />

<strong>Z895</strong> 02/2A 15 47,7 46,6 44 36,4 17,8<br />

<strong>Z895</strong> 02 15 57 55,4 50,7 43,2 24,6 19,5<br />

<strong>Z895</strong> 03/2B 18,5 67,2 66,1 60,8 49,4<br />

<strong>Z895</strong> 03/1A 22 81,1 79 73 61,8 34<br />

<strong>Z895</strong> 03 30 86 83,8 77,3 66,4 39 30,4<br />

<strong>Z895</strong> 04/2B 30 96 94,1 86,7 71,8<br />

<strong>Z895</strong> 04/2A 30 104,5 102 94,7 79,7 42,5<br />

<strong>Z895</strong> 04 30 113,8 110,7 101,4 86,5 49,3 39,2<br />

<strong>Z895</strong> 05/3A 37 128 125 116,4 97,5 50,8<br />

<strong>Z895</strong> 05 37 141,9 138 126,4 107,5 60,9 48,7<br />

<strong>Z895</strong> 06/3A 44 158,4 154,8 144,6 122,4 67,1<br />

<strong>Z895</strong> 06 44 172,6 168,1 154,9 132,8 77,7 60,5<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z895-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z895</strong> 01-L6C 1237 200 140 1660 73<br />

<strong>Z895</strong> 02/2B-L6C 1459 200 140 1730 89<br />

<strong>Z895</strong> 02/2A-L6C 1514 200 140 1785 96<br />

<strong>Z895</strong> 02-L6C 1514 200 140 1785 96<br />

<strong>Z895</strong> 03/2B-L6C 1741 200 140 1860 112<br />

<strong>Z895</strong> 03/1A-L6C 1801 200 140 1920 118<br />

<strong>Z895</strong> 03-L6C 1931 200 140 2050 131<br />

<strong>Z895</strong> 04/2B-L6C 2083 200 140 2050 140<br />

<strong>Z895</strong> 04/2A-L6C 2083 200 140 2050 140<br />

<strong>Z895</strong> 04-L6C 2083 200 140 2050 140<br />

<strong>Z895</strong> 05/3A-L6C 2365 200 140 2180 162<br />

<strong>Z895</strong> 05-L6C 2365 200 140 2180 162<br />

<strong>Z895</strong> 06/3A-MC8 2532 203,3 192 2195 254<br />

<strong>Z895</strong> 06-MC8 2532 203,3 192 2195 254<br />

z895-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 198 mm with L6C motor.<br />

C = 201,5 mm with MC8 motor.<br />

2) T min valid only for max flow speed of 4,2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

14

<strong>Z895</strong> <strong>SERIES</strong>, 1 TO 6 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the ∆Hv non-return valve has not been considered.<br />

∆Hv = 0,0000533*Q 2 Flow resistance = 0,2 / 0,45 / 0,75 m at 60 / 90 / 120 m 3 /h<br />

These performances are valid for liquids with density ρ = 1,0 Kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

15

<strong>Z895</strong> <strong>SERIES</strong>, 7 TO 18 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 367 1000 1500 2150 2300<br />

TYPE POWER m 3 /h 0 22 60 90 129 138<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z895</strong> 07/3A 52 186,5 182,1 169,6 144 79,8<br />

<strong>Z895</strong> 07 55 201,5 196,4 181,3 156,2 92,4 72,4<br />

<strong>Z895</strong> 08/3A 59 215,7 210,6 196 166,7 93,3<br />

<strong>Z895</strong> 08 59 229,9 223,9 206,3 177,2 104 81,1<br />

<strong>Z895</strong> 09/3A 66 244,4 238,6 221,9 188,9 106,2<br />

<strong>Z895</strong> 09 75 258,9 252,4 233 200,8 119 93,2<br />

<strong>Z895</strong> 10/3A 75 272,9 266,3 247,3 210,9 119,3<br />

<strong>Z895</strong> 10 75 287 279,6 257,6 221,5 130 101,4<br />

<strong>Z895</strong> 11 92 316,3 308,2 284,6 245,2 145 113,4<br />

<strong>Z895</strong> 12 92 346,3 337,6 311,5 268,1 158,8 124,4<br />

<strong>Z895</strong> 13 110 374,9 365,6 338,1 291,9 174 137,5<br />

<strong>Z895</strong> 14 110 403,1 393 363 312,8 185,4 145,2<br />

<strong>Z895</strong> 15 129 434,2 423,5 391,4 337,7 201,8 159<br />

<strong>Z895</strong> 16 129 462,6 451 416,2 358,6 213,2 169<br />

<strong>Z895</strong> 17 129 490,9 478,4 440,9 379,4 224,2 175,5<br />

<strong>Z895</strong> 18 150 520,2 507,1 468,5 404,2 241 189,3<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z895a-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z895</strong> 07/3A-MC8 2774 203,3 192 2285 282<br />

<strong>Z895</strong> 07-MC8 2814 203,3 192 2325 288<br />

<strong>Z895</strong> 08/3A-MC8 3016 203,3 192 2375 308<br />

<strong>Z895</strong> 08-MC8 3016 203,3 192 2375 308<br />

<strong>Z895</strong> 09/3A-MC8 3258 203,3 192 2465 336<br />

<strong>Z895</strong> 09-MC8 3348 203,3 192 2555 353<br />

<strong>Z895</strong> 10/3A-MC8 3500 203,3 192 2555 362<br />

<strong>Z895</strong> 10-MC8 3500 203,3 192 2555 362<br />

<strong>Z895</strong> 11-MC8 3852 203,3 192 2755 409<br />

<strong>Z895</strong> 12-MC8 4004 203,3 192 2755 418<br />

<strong>Z895</strong> 13-MC10 4124 236 236 2702 538<br />

<strong>Z895</strong> 14-MC10 4276 236 236 2702 548<br />

<strong>Z895</strong> 15-MC10 4578 236 236 2852 604<br />

<strong>Z895</strong> 16-MC10 4730 236 236 2852 613<br />

<strong>Z895</strong> 17-MC10 4882 236 236 2852 622<br />

<strong>Z895</strong> 18-MC10 5164 236 236 2982 671<br />

z895a-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 201,5 mm with MC8 motor.<br />

C = 236 mm with MC10 motor.<br />

2) T min valid only for max flow speed of 4,2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

16

<strong>Z895</strong> <strong>SERIES</strong>, 7 TO 18 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the ∆Hv non-return valve has not been considered.<br />

∆Hv = 0,0000533*Q 2 Flow resistance = 0,2 / 0,45 / 0,75 m at 60 / 90 / 120 m 3 /h<br />

These performances are valid for liquids with density ρ = 1,0 Kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

17

<strong>Z8125</strong> <strong>SERIES</strong>, 1 TO 6 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 500 1333 2083 2800 3000<br />

TYPE POWER m 3 /h 0 30 80 125 168 180<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z8125</strong> 01 7,5 27,1 24,7 21 17,1 9,4 6,9<br />

<strong>Z8125</strong> 02/2B 11 41,9 38,8 31,8 22,3<br />

<strong>Z8125</strong> 02/2A 15 48,3 44,6 37,5 28,9 13<br />

<strong>Z8125</strong> 02 15 54,3 49,5 42 34,1 18,8 13,7<br />

<strong>Z8125</strong> 03/3A 18,5 71,9 66,2 55,5 42,6 19,3<br />

<strong>Z8125</strong> 03 22 81,7 74,6 63,4 51,5 28,7 20,7<br />

<strong>Z8125</strong> 04/2B 30 97 89,2 74,8 57,5<br />

<strong>Z8125</strong> 04/2A 30 102,6 94,1 79,5 63,1 32,9<br />

<strong>Z8125</strong> 04 30 108,5 99 84,1 68,3 37,8 27,5<br />

<strong>Z8125</strong> 05/3A 37 126,4 116 97,9 77,1 39,3<br />

<strong>Z8125</strong> 05 37 135,2 123,4 104,7 84,8 46,6 34,2<br />

<strong>Z8125</strong> 06/3A 44 156,4 143,5 121,7 97,1 50,2<br />

<strong>Z8125</strong> 06 44 165,5 151,1 128,8 105 60 41,9<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z8125-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z8125</strong> 01-L6C 1237 200 140 1660 73<br />

<strong>Z8125</strong> 02/2B-L6C 1459 200 140 1730 89<br />

<strong>Z8125</strong> 02/2A-L6C 1514 200 140 1785 96<br />

<strong>Z8125</strong> 02-L6C 1514 200 140 1785 96<br />

<strong>Z8125</strong> 03/3A-L6C 1741 200 140 1860 112<br />

<strong>Z8125</strong> 03-L6C 1801 200 140 1920 118<br />

<strong>Z8125</strong> 04/2B-L6C 2083 200 140 2050 140<br />

<strong>Z8125</strong> 04/2A-L6C 2083 200 140 2050 140<br />

<strong>Z8125</strong> 04-L6C 2083 200 140 2050 140<br />

<strong>Z8125</strong> 05/3A-L6C 2365 200 140 2180 162<br />

<strong>Z8125</strong> 05-L6C 2365 200 140 2180 162<br />

<strong>Z8125</strong> 06/3A-MC8 2532 203,3 192 2195 254<br />

<strong>Z8125</strong> 06-MC8 2532 203,3 192 2195 254<br />

z8125-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 198 mm with L6C motor.<br />

C = 201,5 mm with MC8 motor.<br />

2) T min valid only for max flow speed of 4,2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

18

<strong>Z8125</strong> <strong>SERIES</strong>, 1 TO 6 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the ∆Hv non-return valve has not been considered.<br />

∆Hv = 0,0000533*Q 2 Flow resistance = 0,35 / 0,75 / 1,35 m at 80 / 120 / 160 m 3 /h<br />

These performances are valid for liquids with density ρ = 1,0 Kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

19

<strong>Z8125</strong> <strong>SERIES</strong>, 7 TO 18 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

Q = DELIVERY<br />

PUMP RATED l/min 0 500 1333 2083 2800 3000<br />

TYPE POWER m 3 /h 0 30 80 125 168 180<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

kW<br />

<strong>Z8125</strong> 07/3A 52 183,3 168 142,6 114,3 60,2<br />

<strong>Z8125</strong> 07 52 192,3 175,6 149,8 122,5 69,8 48,8<br />

<strong>Z8125</strong> 08/3A 55 210,9 193,2 164,1 131,8 70,3<br />

<strong>Z8125</strong> 08 59 220,5 201,3 171,8 140,4 80,3 55,9<br />

<strong>Z8125</strong> 09/3A 66 239 218,9 186 149,8 80,6<br />

<strong>Z8125</strong> 09 66 248,1 226,5 193,2 157,8 90,3 62,9<br />

<strong>Z8125</strong> 10/3A 75 266,2 243,7 207,3 167,4 90,7<br />

<strong>Z8125</strong> 10 75 275,3 251,4 214,6 175,4 100,3 69,9<br />

<strong>Z8125</strong> 11 92 304,2 277,8 237,4 194,4 112,2 76,8<br />

<strong>Z8125</strong> 12 92 332,7 303,9 259,6 212,5 123 84,5<br />

<strong>Z8125</strong> 13 110 361,2 329,9 282,3 231,6 134,9 93,1<br />

<strong>Z8125</strong> 14 110 387,9 354,2 302,8 248 143,5 98,5<br />

<strong>Z8125</strong> 15 110 414,3 378,3 323 264,2 151,9 104<br />

<strong>Z8125</strong> 16 129 444,5 406 347 284,4 165,3 113,9<br />

<strong>Z8125</strong> 17 129 470,9 430,1 367,3 300,6 173,7 119,5<br />

<strong>Z8125</strong> 18 150 500,4 457,1 391 320,8 186,8 128,9<br />

DIMENSIONS AND WEIGHTS<br />

ELECTRO-<br />

PUMP<br />

TYPE<br />

DIMENSIONS (mm)<br />

z8125a-2p50_a_th<br />

ELECTRO-<br />

PUMP<br />

WEIGHT<br />

A (4) C (1) M Tmin (2) kg (3)<br />

<strong>Z8125</strong> 07/3A-MC8 2774 203,3 192 2285 282<br />

<strong>Z8125</strong> 07-MC8 2774 203,3 192 2285 282<br />

<strong>Z8125</strong> 08/3A-MC8 2966 203,3 192 2325 297<br />

<strong>Z8125</strong> 08-MC8 3016 203,3 192 2375 308<br />

<strong>Z8125</strong> 09/3A-MC8 3250 203,3 192 2465 336<br />

<strong>Z8125</strong> 09-MC8 3250 203,3 192 2465 336<br />

<strong>Z8125</strong> 10/3A-MC8 3500 203,3 192 2555 362<br />

<strong>Z8125</strong> 10-MC8 3500 203,3 192 2555 362<br />

<strong>Z8125</strong> 11-MC8 3852 203,3 192 2755 409<br />

<strong>Z8125</strong> 12-MC8 4004 203,3 192 2755 418<br />

<strong>Z8125</strong> 13-MC10 4124 236 236 2702 538<br />

<strong>Z8125</strong> 14-MC10 4276 236 236 2702 548<br />

<strong>Z8125</strong> 15-MC10 4428 236 236 2702 557<br />

<strong>Z8125</strong> 16-MC10 4730 236 236 2852 613<br />

<strong>Z8125</strong> 17-MC10 4882 236 236 2852 622<br />

<strong>Z8125</strong> 18-MC10 5164 236 236 2982 671<br />

z8125a-2p50_a_td<br />

1) Max electric-pump diameter with 2 motor cables included.<br />

In case of 1 motor cable C = 201,5 mm with MC8 motor.<br />

C = 236 mm with MC10 motor.<br />

2) T min valid only for max flow speed of 4.2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) Without cables.<br />

4) For pumps without non-return valve, reduce dimension A by 110 mm, and reduce weight by 4 kg.<br />

20

<strong>Z8125</strong> <strong>SERIES</strong>, 7 TO 18 STAGES<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

The flow resistance of the ∆Hv non-return valve has not been considered.<br />

∆Hv = 0,0000533*Q 2 Flow resistance = 0,35 / 0,75 / 1,35 m at 80 / 120 / 160 m 3 /h<br />

These performances are valid for liquids with density ρ = 1,0 Kg/dm 3 and kinematic viscosity υ = 1 mm 2 /sec.<br />

21

<strong>Z855</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP<br />

TYPE<br />

MAX POWER<br />

ABSORBED BY PUMP<br />

at 2900 rpm<br />

DIMENSIONS (mm)<br />

WEIGHT<br />

kW L (3) I Umin (2) kg (3)<br />

<strong>Z855</strong> 01 4,6 325 235 1000 26,6<br />

<strong>Z855</strong> 02/2A 6,4 460 235 1000 35,2<br />

<strong>Z855</strong> 02/1A 7,7 460 235 1000 35,2<br />

<strong>Z855</strong> 02 9,0 460 235 1000 35,2<br />

<strong>Z855</strong> 03/2A 10,8 595 235 1000 43,9<br />

<strong>Z855</strong> 03 13,3 595 235 1000 43,9<br />

<strong>Z855</strong> 04/2A 15,1 730 235 1000 52,5<br />

<strong>Z855</strong> 04 17,6 730 235 1000 52,5<br />

<strong>Z855</strong> 05/3A 18,3 865 235 1000 61,2<br />

<strong>Z855</strong> 05/2A 20,8 865 235 1000 61,2<br />

<strong>Z855</strong> 05 22,0 865 235 1000 61,2<br />

<strong>Z855</strong> 06/2A 23,9 1000 235 1000 69,8<br />

<strong>Z855</strong> 06 26,4 1000 235 1000 69,8<br />

<strong>Z855</strong> 07/2A 28,3 1135 235 1000 78,5<br />

<strong>Z855</strong> 07 30,8 1135 235 1000 78,5<br />

<strong>Z855</strong> 08/2A 32,7 1270 235 1000 87,1<br />

<strong>Z855</strong> 08 35,2 1270 235 1000 87,1<br />

<strong>Z855</strong> 09/2A 37,1 1405 235 1000 95,8<br />

<strong>Z855</strong> 09 39,6 1405 235 1000 95,1<br />

<strong>Z855</strong> 10/2A 41,5 1540 235 1000 103,8<br />

<strong>Z855</strong> 10 44,0 1540 235 1000 103,8<br />

<strong>Z855</strong> 11/2A 45,9 1675 235 1000 112,4<br />

<strong>Z855</strong> 11 48,4 1675 235 1000 112,4<br />

<strong>Z855</strong> 12 52,8 1810 235 1000 121,1<br />

<strong>Z855</strong> 13 57,2 1945 235 1000 129,7<br />

<strong>Z855</strong> 14 61,6 2080 235 1000 138,4<br />

<strong>Z855</strong> 15 66,0 2215 235 1000 147<br />

<strong>Z855</strong> 16 70,4 2350 235 1000 155,7<br />

<strong>Z855</strong> 17 74,8 2485 235 1000 164,3<br />

<strong>Z855</strong> 18 79,2 2620 235 1000 173<br />

<strong>Z855</strong> 19 83,6 2755 235 1000 181,6<br />

z855p-2p50_a_td<br />

MOTOR COUPLING<br />

MOTOR<br />

DIMENSIONS (mm)<br />

N k d z b E H7 R X<br />

6" (NEMA) 182 111 13,5 4 17 76,16 73 24<br />

8" (NEMA) 182 152,4 18 4 17 127 101,3 40<br />

6" and 8" coupling according to NEMA standards<br />

z8-mtcn-2p50_a_td<br />

1) Max pump diameter with 1 motor cable included.<br />

2) U min valid only for max flow speed of 4.2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) For pumps without non-return valve, reduce dimension L by 110 mm, and reduce weight by 4 kg.<br />

22

<strong>Z875</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP<br />

TYPE<br />

MAX POWER<br />

ABSORBED BY PUMP<br />

at 2900 rpm<br />

kW L (3) I Umin (2) kg (3)<br />

<strong>Z875</strong> 01 5,3 342 235 1000 26,9<br />

<strong>Z875</strong> 02/2A 7,6 494 235 1000 36,2<br />

<strong>Z875</strong> 02/1A 9,0 494 235 1000 36,2<br />

<strong>Z875</strong> 02 10,5 494 235 1000 36,2<br />

<strong>Z875</strong> 03/3A 11,3 646 235 1000 45,4<br />

<strong>Z875</strong> 03/2A 12,7 646 235 1000 45,4<br />

<strong>Z875</strong> 03/1A 14,2 646 235 1000 45,4<br />

<strong>Z875</strong> 03 15,6 646 235 1000 45,4<br />

<strong>Z875</strong> 04/2A 17,7 798 235 1000 54,6<br />

<strong>Z875</strong> 04 20,6 798 235 1000 54,6<br />

<strong>Z875</strong> 05/3A 21,5 950 235 1000 63,9<br />

<strong>Z875</strong> 05/2A 22,9 950 235 1000 63,9<br />

<strong>Z875</strong> 05 25,8 950 235 1000 63,9<br />

<strong>Z875</strong> 06/2A 28,0 1102 235 1000 73,1<br />

<strong>Z875</strong> 06/1A 29,5 1102 235 1000 73,1<br />

<strong>Z875</strong> 06 30,9 1102 235 1000 73,1<br />

<strong>Z875</strong> 07/2A 33,2 1254 235 1000 82,3<br />

<strong>Z875</strong> 07 36,1 1254 235 1000 82,3<br />

<strong>Z875</strong> 08/3A 36,9 1406 235 1000 91,5<br />

<strong>Z875</strong> 08/2A 38,3 1406 235 1000 90,9<br />

<strong>Z875</strong> 08 41,2 1406 235 1000 90,9<br />

<strong>Z875</strong> 09/2A 43,5 1558 235 1000 100,1<br />

<strong>Z875</strong> 9 46,4 1558 235 1000 100,1<br />

<strong>Z875</strong> 10/2A 48,6 1710 235 1000 109,4<br />

<strong>Z875</strong> 10 51,5 1710 235 1000 109,4<br />

<strong>Z875</strong> 11/2A 53,8 1862 235 1000 118,6<br />

<strong>Z875</strong> 11 56,7 1862 235 1000 118,6<br />

<strong>Z875</strong> 12 61,8 2014 235 1000 127,8<br />

<strong>Z875</strong> 13 67,0 2166 235 1000 137<br />

<strong>Z875</strong> 14 72,1 2318 235 1000 146,3<br />

<strong>Z875</strong> 15 77,3 2470 235 1000 155,5<br />

<strong>Z875</strong> 16 82,4 2622 235 1000 164,7<br />

<strong>Z875</strong> 17 87,6 2774 235 1000 174<br />

<strong>Z875</strong> 18 92,7 2926 256 1000 183,2<br />

MOTOR COUPLING<br />

DIMENSIONS (mm)<br />

WEIGHT<br />

z875p-2p50_a_td<br />

MOTOR<br />

DIMENSIONS (mm)<br />

N k d z b E H7 R X<br />

6" (NEMA) 182 111 13,5 4 17 76,16 73 24<br />

8" (NEMA) 182 152,4 18 4 17 127 101,3 40<br />

10" 232 190,5 M16 4 21 127 101,3 84<br />

6" and 8" coupling according to NEMA standards<br />

z8a-mtcn-2p50_a_td<br />

1) Max pump diameter with 1 motor cable included.<br />

2) U min valid only for max flow speed of 4.2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) For pumps without non-return valve, reduce dimension L by 110 mm, and reduce weight by 4 kg.<br />

23

<strong>Z895</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP<br />

TYPE<br />

MAX POWER<br />

ABSORBED BY PUMP<br />

at 2900 rpm<br />

DIMENSIONS (mm)<br />

WEIGHT<br />

kW L (3) I Umin (2) kg (3)<br />

<strong>Z895</strong> 01 7,7 342 235 1000 26,9<br />

<strong>Z895</strong> 02/2B 10,0 494 235 1000 36,2<br />

<strong>Z895</strong> 02/2A 12,8 494 235 1000 36,2<br />

<strong>Z895</strong> 02 15,2 494 235 1000 36,2<br />

<strong>Z895</strong> 03/2B 17,4 646 235 1000 45,4<br />

<strong>Z895</strong> 03/1A 21,4 646 235 1000 45,4<br />

<strong>Z895</strong> 03 22,5 646 235 1000 45,4<br />

<strong>Z895</strong> 04/2B 24,6 798 235 1000 54,6<br />

<strong>Z895</strong> 04/2A 27,4 798 235 1000 54,6<br />

<strong>Z895</strong> 04 29,8 798 235 1000 54,6<br />

<strong>Z895</strong> 05/3A 33,7 950 235 1000 63,9<br />

<strong>Z895</strong> 05 37,2 950 235 1000 63,9<br />

<strong>Z895</strong> 06/3A 41,1 1102 235 1000 73,1<br />

<strong>Z895</strong> 06 44,6 1102 235 1000 73,1<br />

<strong>Z895</strong> 07/3A 48,6 1254 235 1000 81,7<br />

<strong>Z895</strong> 07 52,1 1254 235 1000 81,7<br />

<strong>Z895</strong> 08/3A 56,0 1406 235 1000 90,9<br />

<strong>Z895</strong> 08 59,5 1406 235 1000 90,9<br />

<strong>Z895</strong> 09/3A 63,5 1558 235 1000 100,1<br />

<strong>Z895</strong> 09 67,0 1558 235 1000 100,1<br />

<strong>Z895</strong> 10/3A 70,9 1710 235 1000 109,4<br />

<strong>Z895</strong> 10 74,4 1710 235 1000 109,4<br />

<strong>Z895</strong> 11 81,8 1862 235 1000 118,6<br />

<strong>Z895</strong> 12 89,3 2014 235 1000 127,8<br />

<strong>Z895</strong> 13 96,7 2166 256 1000 137<br />

<strong>Z895</strong> 14 104,2 2318 256 1000 146,3<br />

<strong>Z895</strong> 15 111,6 2470 256 1000 155,5<br />

<strong>Z895</strong> 16 119,0 2622 256 1000 164,7<br />

<strong>Z895</strong> 17 126,5 2774 256 1000 174<br />

<strong>Z895</strong> 18 133,9 2926 256 1000 183,2<br />

MOTOR COUPLING<br />

z895p-2p50_a_td<br />

MOTOR<br />

DIMENSIONS (mm)<br />

N k d z b E H7 R X<br />

6" (NEMA) 182 111 13,5 4 17 76,16 73 24<br />

8" (NEMA) 182 152,4 18 4 17 127 101,3 40<br />

10" 232 190,5 M16 4 21 127 101,3 84<br />

6" and 8" coupling according to NEMA standards<br />

z8a-mtcn-2p50_a_td<br />

1) Max pump diameter with 1 motor cable included.<br />

2) U min valid only for max flow speed of 4.2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) For pumps without non-return valve, reduce dimension L by 110 mm, and reduce weight by 4 kg.<br />

24

<strong>Z8125</strong> <strong>SERIES</strong><br />

DIMENSIONS AND WEIGHTS<br />

PUMP<br />

TYPE<br />

MAX POWER<br />

ABSORBED BY PUMP<br />

at 2900 rpm<br />

DIMENSIONS (mm)<br />

WEIGHT<br />

kW L (3) I Umin (2) kg (3)<br />

<strong>Z8125</strong> 01 7,5 342 235 1000 26,9<br />

<strong>Z8125</strong> 02/2B 10,0 494 235 1000 36,2<br />

<strong>Z8125</strong> 02/2A 12,2 494 235 1000 36,2<br />

<strong>Z8125</strong> 02 14,8 494 235 1000 36,2<br />

<strong>Z8125</strong> 03/3A 18,1 646 235 1000 45,4<br />

<strong>Z8125</strong> 03 22,0 646 235 1000 45,4<br />

<strong>Z8125</strong> 04/2B 24,3 798 235 1000 54,6<br />

<strong>Z8125</strong> 04/2A 26,5 798 235 1000 54,6<br />

<strong>Z8125</strong> 04 29,0 798 235 1000 54,6<br />

<strong>Z8125</strong> 05/3A 32,5 950 235 1000 63,9<br />

<strong>Z8125</strong> 05 36,3 950 235 1000 63,9<br />

<strong>Z8125</strong> 06/3A 39,7 1102 235 1000 73,1<br />

<strong>Z8125</strong> 06 43,5 1102 235 1000 73,1<br />

<strong>Z8125</strong> 07/3A 47,0 1254 235 1000 81,7<br />

<strong>Z8125</strong> 07 50,8 1254 235 1000 81,7<br />

<strong>Z8125</strong> 08/3A 54,2 1406 235 1000 90,9<br />

<strong>Z8125</strong> 08 58,0 1406 235 1000 90,9<br />

<strong>Z8125</strong> 09/3A 61,5 1558 235 1000 100,1<br />

<strong>Z8125</strong> 09 65,3 1558 235 1000 100,1<br />

<strong>Z8125</strong> 10/3A 68,7 1710 235 1000 109,4<br />

<strong>Z8125</strong> 10 72,5 1710 235 1000 109,4<br />

<strong>Z8125</strong> 11 79,8 1862 235 1000 118,6<br />

<strong>Z8125</strong> 12 87,0 2014 235 1000 127,8<br />

<strong>Z8125</strong> 13 94,3 2166 256 1000 137<br />

<strong>Z8125</strong> 14 101,5 2318 256 1000 146,3<br />

<strong>Z8125</strong> 15 108,8 2470 256 1000 155,5<br />

<strong>Z8125</strong> 16 116,0 2622 256 1000 164,7<br />

<strong>Z8125</strong> 17 123,3 2774 256 1000 174<br />

<strong>Z8125</strong> 18 130,5 2926 256 1000 183,2<br />

z8125p-2p50_a_td<br />

MOTOR COUPLING<br />

MOTOR<br />

DIMENSIONS (mm)<br />

N k d z b E H7 R X<br />

6" (NEMA) 182 111 13,5 4 17 76,16 73 24<br />

8" (NEMA) 182 152,4 18 4 17 127 101,3 40<br />

10" 232 190,5 M16 4 21 127 101,3 84<br />

6" and 8" coupling according to NEMA standards<br />

z8a-mtcn-2p50_a_td<br />

1) Max pump diameter with 1 motor cable included.<br />

2) U min valid only for max flow speed of 4.2 m/s.<br />

For higher speeds please contact our sales network.<br />

3) For pumps without non-return valve, reduce dimension L by 110 mm, and reduce weight by 4 kg.<br />

25

Z8 <strong>SERIES</strong> PUMPS<br />

PUMP CROSS SECTION AND LIST OF COMPONENTS<br />

REF. N.<br />

1 Stage casing<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

DESCRIPTION<br />

Suction casing<br />

Delivery casing<br />

Valve body<br />

Bearing bush<br />

Impeller<br />

Wear ring<br />

Shaft<br />

Coupling<br />

Locking sleeve<br />

Thrust bearing<br />

Wing valve<br />

Valve seat<br />

Valve spring<br />

Suction strainer<br />

Motor cable<br />

Cable guard<br />

O-ring<br />

10" Motor adapter<br />

Clamping plate<br />

z8-2p50_a_tp<br />

26

Submersible<br />

motors<br />

L6C<br />

Series<br />

Submersible liquid-cooled motors.<br />

The choice of component materials ensures optimum<br />

operating performances, superior quality, reliability and<br />

ease of installation.<br />

SPECIFICATIONS<br />

● Stainless steel outer sleeve.<br />

● Shaft extension and coupling<br />

dimensions to NEMA standards.<br />

● Class F insulation.<br />

● Protection class: IP68<br />

● Compensating bellows for internal<br />

liquid expansion.<br />

● Axial load supported by Kingsburytype<br />

thrust bearing.<br />

● Mechanical seal protected by<br />

sand guard.<br />

● Maximum immersion depth: 250m<br />

● Maximum number of starts per<br />

hour, at regular intervals:<br />

25 for direct start.<br />

● Maximum supply voltage variations<br />

allowed : ±10%<br />

● Maximum water temperature: 35°C.<br />

Max. temperature applies to motors<br />

working in an installation capable of<br />

delivering a flow of water around the<br />

motor jacket of at least 0.2 m/s.<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

Axial thrust:<br />

16000 N from 4 to 22 kW motors<br />

27000 N from 30 to 37 kW motors<br />

Extractable supply cable<br />

fitted with watertight connector.<br />

Versions:<br />

<strong>–</strong> Three-phase:<br />

4 to 37 kW 380-415 V, 50 Hz<br />

Motors with double cable outlet for<br />

star/delta start can be supplied upon<br />

request.<br />

Can also operate in horizontal<br />

position, provided that the associated<br />

pump can apply an axial thrust of at<br />

least 250 N on the entire operating<br />

field.<br />

Screws included.<br />

OPTIONAL FEATURES<br />

● Silicon Carbide mechanical seal.<br />

● Special voltages.<br />

● Inverter applications.<br />

● PT 100 temperature sensor.<br />

IDENTIFICATION CODE<br />

L6C 110 T 40 5<br />

❏ HIGH STATIC<br />

TORQUE<br />

❏ POWER SUPPLY<br />

CABLE WITH<br />

EXTRACTABLE<br />

CONNECTOR<br />

EXAMPLE: L6C110T405<br />

L6C MOTOR:<br />

RATED POWER 11 kW; THREE-PHASE;<br />

RATED VOLTAGE 400 V; 50Hz<br />

5 = 50 Hz<br />

6 = 60 Hz<br />

RATED VOLTAGE<br />

T = THREE-PHASE<br />

RATED POWER IN kW x 10<br />

L6C <strong>SERIES</strong> NAME<br />

27

L6C <strong>SERIES</strong> MOTORS<br />

MOTOR CROSS SECTION AND TABLE OF MATERIALS<br />

REF. NAME MATERIAL<br />

REFERENCE STANDARDS<br />

N° EUROPE USA<br />

1 Flange, inner and outer sleeve Stainless steel EN 10088-1-X5CrNi18-10 (1.4301) AISI304<br />

2<br />

Shaft extension (up to 18.5 kW) Stainless steel EN 10088-3-X5CrNiMo17-12-2 (1.4401) AISI316<br />

Shaft extension (from 22 kW) Stainless steel (Duplex) EN 10095 X3CrNiMoN27-5-2 (1.4460) AISI329<br />

3 Upper support Cast iron EN-GJL-200 Class 25 B<br />

4 Intermediate support Cast iron EN-GJL-200 Class 25 B<br />

5 Mechanical seal<br />

Allumina - graphite<br />

6 Elastomers<br />

NBR<br />

7 Lower support Cast iron EN-GJL-200 Class 25 B<br />

8 Compensating bellows<br />

NBR<br />

9 Bearings<br />

Carbon-graphite<br />

10 Cable<br />

11 Fixed sand guard<br />

EPDM<br />

Stainless steel EN 10088-1-X5CrNi18-10 (1.4301) AISI304<br />

12 Removable sand guard<br />

13 Bolts and screws<br />

NBR<br />

Stainless steel EN 10088-1-X5CrNi18-10 (1.4301) AISI304<br />

14 Lower cover Stainless steel EN 10088-1-X5CrNi18-10 (1.4301) AISI304<br />

15 Mechanical seal spacer<br />

16 Sand guard gasket<br />

nickel plated A105<br />

CR neoprene<br />

Cooling liquid<br />

Demineralized water + antifreeze<br />

l6c-2p50_c_tm<br />

28

L6C <strong>SERIES</strong> MOTORS<br />

DIMENSIONS AND WEIGHTS AT 50 Hz<br />

MOTOR RATED POWER DIMENSIONS mm WEIGHT<br />

TYPE kW HP A kg<br />

L6C40T 4 5,5 600 39,4<br />

L6C55T 5,5 7,5 631 43,2<br />

L6C75T 7,5 10 660 45,2<br />

L6C93T 9,3 12,5 685 48,8<br />

L6C110T 11 15 730 52,8<br />

L6C150T 15 20 785 59<br />

L6C185T 18,5 25 860 66,4<br />

L6C220T 22 30 920 72,4<br />

L6C300T 30 40 1050 85<br />

L6C370T 37 50 1180 98<br />

l6c-2p50_b_td<br />

29

L6C <strong>SERIES</strong> MOTORS<br />

THREE-PHASE OPERATING CHARACTERISTICS AT 50 Hz<br />

MOTOR RATED RATED OPERATING CHARACTERISTICS<br />

DIRECT MAX WATER CABLE TYPE<br />

TYPE POWER VOLTAGE AT RATED POWER<br />

START TEMPERATURE<br />

RATED<br />

THREE-PHASE<br />

CURRENT<br />

kW HP V A rpm η % cosϕ Ca/Cn Ia °C Ncxsec.(mm 2 ) L (m)<br />

380 10,3 2825 75 0,8 1,7 40<br />

L6C40T405 4 5,5 400 10,6 2845 74 0,75 1,7 41<br />

415 11 2860 74 0,7 1,7 42<br />

380 13,9 2820 77 0,8 1,8 53<br />

L6C55T405 5,5 7,5 400 14 2845 76 0,75 1,8 53<br />

415 14,6 2860 76 0,71 1,8 53<br />

380 17,6 2820 78 0,82 2 69<br />

L6C75T405 7,5 10 400 18 2840 77 0,78 2 70<br />

415 18,3 2850 77 0,73 2 73<br />

380 21,7 2820 78 0,82 2,1 83<br />

L6C93T405 9,3 12,5 400 22 2840 79 0,8 2,1 85<br />

415 22,8 2850 78 0,79 2,15 88<br />

380 25 2815 77 0,87 2,1 113<br />

L6C110T405 11 15 400 25,5 2840 78 0,82 2,1 115<br />

415 26 2845 77 0,79 2,15 118<br />

380 33,5 2810 80 0,84 2,2 137<br />

L6C150T405 15 20 400 33,4 2840 81 0,8 2,2 137<br />

415 34,2 2850 81 0,76 2,25 140<br />

380 40,5 2820 81 0,83 2,3 176<br />

L6C185T405 18,5 25 400 41 2845 82 0,8 2,3 177<br />

415 42 2855 82 0,73 2,35 180<br />

380 47,5 2810 81 0,88 2,3 191<br />

L6C220T405 22 30 400 47 2825 82 0,84 2,3 195<br />

415 47,5 2835 82 0,8 2,35 198<br />

380 63 2810 82 0,89 2,4 250<br />

L6C300T405 30 40 400 61,5 2830 82 0,85 2,4 250<br />

415 63,5 2840 81 0,8 2,45 250<br />

380 79,5 2820 82 0,87 2 296<br />

L6C370T405 37 50 400 79,3 2830 81 0,84 2,2 310<br />

415 80 2840 81 0,8 2,3 320<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

4x4<br />

4x4<br />

4x4<br />

4x8<br />

4<br />

4<br />

4<br />

4x6 4<br />

4x8<br />

4<br />

4x4 4<br />

4x4<br />

4x4 4<br />

4x4<br />

4<br />

4<br />

4<br />

l6c-2p50_c_te<br />

30

Submersible<br />

motors<br />

MC8<br />

Series<br />

APPLICATION<br />

Three-phase asynchronous submersible water filled<br />

motor, with short-circuit rotor and special water-resistant<br />

windings.<br />

The choice of component materials ensures optimum<br />

operating performances, high reliability and ease of<br />

installation.<br />

SPECIFICATIONS<br />

• Shaft extension and coupling<br />

dimensions to NEMA standards<br />

Rewindable stator PVC<br />

insulation<br />

Protection class: IP58<br />

Fill liquid<br />

The motors are filled with water<br />

containing non-toxic antifreeze<br />

(15%). This liquid, besides<br />

protecting the motor from low<br />

temperatures, helps to inhibit<br />

oxidation and improve lubrication.<br />

• Large compensating<br />

diaphragm for internal liquid<br />

expansion. The motor is also<br />

equipped with a relief valve<br />

enabling the escape of liquid in the<br />

event of abnormal temperature<br />

increases.<br />

• Axial load supported by oscillating<br />

bearing.<br />

• To prevent fluid exchange between<br />

the external and internal<br />

environments, all the standard<br />

motors are equipped with two lip<br />

seals.<br />

Motors with mechanical seal are<br />

available on request.<br />

• Maximum immersion depth:<br />

<strong>–</strong> 40 m for standard motors<br />

(lip seal)<br />

<strong>–</strong> 350 m for motors with<br />

mechanical seal (on request).<br />

• Maximum number of evenly<br />

distributed starts per hour: 10<br />

• Maximum supply voltage (400 V)<br />

variations:<br />

+6%-10%.<br />

Maximum axial thrust: 50,000 N.<br />

•<br />

Available versions<br />

MC8 three-phase 30 kW to 92 kW<br />

400V<br />

Different voltages available on request<br />

PVC winding<br />

•<br />

The motors are supplied with three 5-<br />

metre lengths of H07BBF-type circular<br />

single-core cable.<br />

•<br />

Ambient temperature: 25°C; the<br />

motors must operate in installations<br />

ensuring a minimum water velocity<br />

around the motor sleeve of 0.20 m/s.<br />

OPTIONAL<br />

FEATURES<br />

4-pole motors.<br />

Special voltages of up to 1000 V.<br />

Horizontal installation.<br />

Inverter applications.<br />

High temperature windings.<br />

• Different materials.<br />

ACCESSORIES<br />

• Panels.<br />

Drop cables.<br />

31

MC8 <strong>SERIES</strong> MOTORS<br />

DIMENSIONS AND WEIGHTS AT 50 Hz<br />

MOTOR INPUT<br />

DIMENSIONS (mm) WEIGHT<br />

TYPE<br />

POWER<br />

kW HP L kg<br />

MC 8 - 40 30 40 1015 145<br />

MC 8 - 50 37 50 1105 162<br />

MC 8 - 60 44 60 1195 180<br />

MC 8 - 70 52 70 1285 200<br />

MC 8 - 75 55 75 1325 206<br />

MC 8 - 80 59 80 1375 217<br />

MC 8 - 90 66 90 1465 235<br />

MC 8 - 100 75 100 1555 252<br />

MC 8 - 125 92 125 1755 290<br />

mc 8-2p50_a_td<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

MOTOR RATED RATED OPERATING CHARACTERISTICS<br />

DIRECT<br />

MAX<br />

CABLE TYPE<br />

TYPE OUTPUT VOLTAGE AT RATED OUTPUT<br />

START<br />

WATER<br />

RATED<br />

TEMPERATURE<br />

THREE-PHASE<br />

CURRENT<br />

kW HP V A rpm η % cosϕ Ca/Cn Ia/In °C Ncxsez.(mm 2 ) L (m)<br />

MC8-40<br />

MC8 -50<br />

MC8-60<br />

MC8-70<br />

MC8-75<br />

MC8-80<br />

MC8-90<br />

MC8-100<br />

MC8-125<br />

30<br />

37<br />

44<br />

52<br />

55<br />

59<br />

66<br />

75<br />

92<br />

40<br />

50<br />

60<br />

70<br />

75<br />

80<br />

90<br />

100<br />

125<br />

380 65 2905 83 0.85 1.2 4.67 3x10 5<br />

25<br />

415 59 2900 83 0.84 1.09 4.7 3x10 5<br />

380 82.5 2860 82 0.85 1.16 4.62 3x10 5<br />

25<br />

415 76 2860 82 0.85 1.17 4.64 3x10 5<br />

380 94 2870 84 0.86 0.95 4.10 3x16 5<br />

25<br />

415 85 2870 85 0.86 0.99 4.23 3x16 5<br />

380 112 2865 82 0.85 1.14 5.83 3x16 5<br />

25<br />

415 104 2865 82.5 0.85 1.16 5.8 3x16 5<br />

380 118 2850 82 0.86 1.26 4.90 3x16 5<br />

25<br />

415 110 2850 82.5 0.86 1.27 4.84 3x16 5<br />

380 125 2875 84 0.86 1.21 4.55 3x16 5<br />

25<br />

415 115 2870 83.5 0.85 1.20 4.51 3x16 5<br />

380 141 2870 84 0.86 1.08 4.60 3x16 5<br />

25<br />

415 130 2870 84 0.85 1.16 4.74 3x16 5<br />

380 156 2875 83 0.86 1.03 4.61 3x25 5<br />

25<br />

415 144 2880 83 0.85 1.10 4.71 3x25 5<br />

380 192 2885 85 0.86 0.93 4.24 3x35 5<br />

25<br />

415 176 2885 84.5 0.85 0.97 4.32 3x35 5<br />

mc8-2p50_a_te<br />

32

Submersible<br />

motors<br />

MC10<br />

Series<br />

APPLICATIONS<br />

Three-phase asynchronous submersible water filled<br />

motor, with short-circuit rotor and special water-resistant<br />

windings.<br />

The choice of component materials ensures optimum<br />

operating performances, high reliability and ease of<br />

installation.<br />

SPECIFICATIONS<br />

• Rewindable stator PVC<br />

insulations<br />

Protection class: IP58<br />

Fill liquid<br />

The motors are filled with water<br />

containing non-toxic antifreeze<br />

(15%). This liquid, besides<br />

protecting the motor from low<br />

temperatures, helps to inhibit<br />

oxidation and improve lubrication.<br />

• Large compensating<br />

diaphragm for internal liquid<br />

expansion. The motor is also<br />

equipped with a relief valve<br />

enabling the escape of liquid in the<br />

event of abnormal temperature<br />

increases.<br />

• Axial load supported by oscillating<br />

bearing.<br />

• To prevent fluid exchange between<br />

the external and internal<br />

environments, all the standard<br />

motors are equipped with two lip<br />

seals.<br />

Motors with mechanical seal are<br />

available on request.<br />

• Maximum immersion depth:<br />

<strong>–</strong> 40 m for standard motors (lip<br />

seal)<br />

<strong>–</strong> 350 m for motors with<br />

mechanical seal (on request).<br />

• Maximum number of evenly<br />

distributed starts per hour: 8<br />

• Maximum supply voltage (400 V)<br />

variations:<br />

+6%-10%.<br />

Maximum axial thrust: 65,000 N.<br />

•<br />

Available versions<br />

MC10 three-phase 92 kW to 150 kW<br />

400V<br />

Different voltages available on request<br />

PVC winding<br />

•<br />

The motors are supplied with three 5-<br />

metre lengths of H07BBF-type circular<br />

single-core cable.<br />

•<br />

Ambient temperature: 25°C; the<br />

motors must operate in installations<br />

ensuring a minimum water velocity<br />

around the motor sleeve of 0.20 m/s.<br />

OPTIONAL<br />

FEATURES<br />

4-pole motors.<br />

Special voltages of up to 1000 V.<br />

Horizontal installation.<br />

Inverter applications.<br />

High temperature windings.<br />

• Different materials.<br />

ACCESSORIES<br />

• Panels.<br />

Drop cables.<br />

33

MC10 <strong>SERIES</strong> MOTORS<br />

DIMENSIONS AND WEIGHTS AT 50 Hz<br />

MOTOR INPUT<br />

DIMENSIONS (mm) WEIGHT<br />

TYPE<br />

POWER<br />

kW HP L kg<br />

MC 10-125 92 125 1562 360<br />

MC 10-150 110 150 1702 401<br />

MC 10-175 129 175 1852 448<br />

MC 10-200 150 200 1982 487<br />

mc 10-2p50_a_td<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

MOTOR RATED RATED OPERATING CHARACTERISTICS<br />

DIRECT<br />

MAX<br />

CABLE TYPE<br />

TYPE OUTPUT VOLTAGE AT RATED OUTPUT<br />

START<br />

WATER<br />

RATED<br />

TEMPERATURE<br />

THREE-PHASE<br />

CURRENT<br />

kW HP V A rpm η % cosϕ Ca/Cn Ia/In °C Ncxsez.(mm 2 ) L (m)<br />

MC10-125<br />

MC10-150<br />

MC10-175<br />

MC10-200<br />

92<br />

110<br />

129<br />

150<br />

125<br />

150<br />

175<br />

200<br />

380 190 2910 85 0.85 1.02 5.30 3x35 5<br />

25<br />

415 177 2910 85 0.85 1.06 5.31 3x35 5<br />

380 237 2905 86.5 0.84 1.41 5.63 3x50 5<br />

25<br />

415 216 2905 85.5 0.84 1.44 5.7 3x50 5<br />

380 274 2915 86 0.83 1.57 5.80 3x70 5<br />

25<br />

415 250 2915 86.5 0.83 1.54 5.78 3x50 5<br />

380 312 2930 85 0.84 1.64 5.82 3x70 5<br />

25<br />

415 292 2925 84.5 0.85 1.59 5.6 3x70 5<br />

mc10-2p50_a_te<br />

34

Submersible<br />

motors<br />

AISI 316<br />

F6 Series<br />

Water-filled submersible motors.<br />

The choice of component materials ensures optimum<br />

operating performances, superior quality, reliability and<br />

ease of installation.<br />

SPECIFICATIONS<br />

Stainless steel outer casing<br />

• Shaft extension and coupling<br />

dimensions to NEMA standards.<br />

Watertight stator<br />

Insulation class: F.<br />

• Shaft supported by bearings<br />

lubricated by fill liquid.<br />

Mechanical seal.<br />

• Maximum immersion<br />

depth:<br />

350 metres.<br />

• Maximum number of evenly<br />

distributed starts per hour:<br />

20 for direct start.<br />

• Versions:<br />

<strong>–</strong> F6 three-phase from 4 to 45 kW,<br />

380-415 V, 50 Hz.<br />

• Removable power supply<br />

cable fitted with watertight<br />

connector.<br />

• F6 motors with dual cable outlet for<br />

star-delta starting are available on<br />

request; three-phase 220 V and 500<br />

V motors are also available.<br />

• The maximum temperature at<br />

which the motors operate in a 6”<br />

well or in any other installation<br />

should ensure a minimum water<br />

velocity over the motor of at least<br />

0.16 m/s.<br />

● Operating position: vertical and<br />

horizontal.<br />

F6 MOTOR<br />

MATERIALS<br />

PART NAME<br />

MATERIAL<br />

Outer sleeve<br />

Stainless steel<br />

1.4571<br />

Shaft extension Stainless steel<br />

1.4542<br />

Upper and lower support 1.4408<br />

Mechanical seal SiC/SiC<br />

Elastomers<br />

Nitrile rubber<br />

and buna N<br />

Lower protection Stainless steel<br />

1.4401<br />

Compensating EPDM<br />

bellows<br />

Cooling liquid Distilled water +<br />

antifreeze<br />

35

F6../316 <strong>SERIES</strong> MOTORS<br />

DIMENSIONS AND WEIGHTS AT 50 Hz<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

MOTORS NOMINAL DIMENSIONS (mm) WEIGHT<br />

TYPE<br />

POWER<br />

kW HP A kg<br />

F605T534/316 4 5,5 571 37,5<br />

F607T534/316 5,5 7,5 604 41,1<br />

F610T534/316 7,5 10 636 45,2<br />

F612T534/316 9,3 12,5 669 47,5<br />

F615T534/316 11 15 701 50,9<br />

F620T534/316 15 20 766 56,7<br />

F625T534/316 18,5 25 831 63,3<br />

F630T534/316 22 30 896 69,3<br />

F640T534/316 30 40 1026 83,9<br />

F650T534/316 37 50 1395 135<br />

f6-316-2p50_a_td<br />

MOTOR RATED RATED OPERATING CHARACTERISTICS<br />

DIRECT<br />

MAX.<br />

CABLE TYPE<br />

TYPE POWER VOLTAGE AT RATED POWER<br />

START<br />

WATER<br />

RATED<br />

TEMPERATURE<br />

THREE-PHASE<br />

CURRENT<br />

kW HP V A rpm η % cosϕ Ca/Cn Ia °C Ncxsec.(mm 2 ) L (m)<br />

380 9,5 2840 77 0,85 1,43 42 4G4 4<br />

F605T534/316 4 5,5 400 9,3 2860 78 0,82 1,64 43 30 4G4 4<br />

415 9,3 2880 78,5 0,78 1,69 46 4G4 4<br />

380 12,8 2850 78 0,85 1,62 60 4G4 4<br />

F607T534/316 5,5 7,5 400 12,5 2870 79 0,82 1,88 64 30 4G4 4<br />

415 12,8 2880 78 0,78 1,93 66 4G4 4<br />

380 16,3 2850 79 0,87 1,72 83 4G4 4<br />

F610T534/316 7,5 10 400 16 2860 79 0,86 1,9 83 30 4G4 4<br />

415 16,2 2880 79 0,81 2,07 91 4G4 4<br />

380 21 2870 81 0,86 1,98 106 4G4 4<br />

F612T534/316 9,3 12,5 400 20,7 2870 81 0,8 2,19 112 30 4G4 4<br />

415 21 2890 80 0,78 2,40 116 4G4 4<br />

380 24 2860 81 0,87 1,94 126 4G4 4<br />

F615T534/316 11 15 400 23,3 2860 81 0,85 2,09 129 30 4G4 4<br />

415 24,1 2870 79,5 0,81 2,27 136 4G4 4<br />

380 32 2850 82 0,86 2,08 164 4G4 4<br />

F620T534/316 15 20 400 31,3 2860 81 0,85 2,15 169 30 4G4 4<br />

415 31 2870 81 0,83 2,35 179 4G4 4<br />

380 40 2850 82 0,87 2,23 220 4G4 4<br />

F625T534/316 18,5 25 400 38,5 2850 82 0,85 2,47 231 30 4G4 4<br />

415 38,5 2850 82 0,83 2,68 240 4G4 4<br />

380 47 2840 82 0,88 2,12 255 4G4 4<br />

F630T534/316 22 30 400 45,3 2860 83 0,86 2,37 268 30 4G4 4<br />

415 45 2870 82,5 0,84 2,54 278 4G4 4<br />

380 64,1 2860 82,5 0,85 2,38 373 3x8.4+1G8.4 4<br />

F640T534/316 30 40 400 63,5 2860 83 0,84 2,64 393 30 3x8.4+1G8.4 4<br />

415 64,5 2880 82,5 0,81 2,86 407 3x8.4+1G8.4 4<br />

380 80 2840 83,5 0,86 2,02 390 3x8.4+1G8.4 4<br />

F650T534/316 37 50 400 73 2880 84,5 0,87 2,27 410 30 3x8.4+1G8.4 4<br />

415 73,5 2890 84,7 0,85 2,45 426 3x8.4+1G8.4 4<br />

F6-316-2p50_a_te<br />

36

Submersible<br />

motors<br />

FW8<br />

Series<br />

APPLICATIONS<br />

Three-phase asynchronous submersible water-filled<br />

motor, with short-circuit rotor and special water resistant<br />

windings.<br />

The choice of component materials ensures optimum<br />

operating performances, superior quality, reliability and<br />

ease of installation.<br />

SPECIFICATIONS<br />

• Shaft extension and coupling<br />

dimensions to NEMA standards.<br />

Rewindable stator<br />

PVC insulation<br />

Protection class: IP68<br />

Fill liquid<br />

The motors are filled with water<br />

containing non-toxic antifreeze. This<br />

liquid, besides protecting the motor<br />

from low temperatures, helps to<br />

inhibit oxidation and improve<br />

lubrication.<br />

• Large compensating<br />

diaphragm for internal liquid<br />

expansion. The motor is also<br />

equipped with a relief valve<br />

enabling the escape of liquid in the<br />

event of abnormal temperature<br />

increases.<br />

• Axial load supported by oscillating<br />

bearing.<br />

• To prevent fluid exchange between<br />

the external and internal<br />

environments, all the standard<br />

motors are equipped with a silicon<br />

carbide mechanical seal.<br />

• Maximum immersion depth:<br />

350 metres.<br />

• Maximum number of evenly<br />

distributed starts per hour: 10<br />

• Maximum supply voltage variation<br />

(415 V +6%, 380 V <strong>–</strong>10%).<br />

Maximum axial thrust: 45,000 N.<br />

• Available versions:<br />

FW8 three-phase: 45 kW to 93 kW<br />

380-415 V; different voltages<br />

available on request.<br />

PVC winding<br />

•<br />

cable.<br />

•<br />

The motors are supplied with 6 m<br />

Ambient temperature: 30°C. The<br />

motors must operate in installations<br />

ensuring a minimum water velocity<br />

around the motor sleeve of 0.20<br />

m/s for 30-52 kW, 0.5 m/s for 55-<br />

93 kW.<br />

OPTIONAL<br />

FEATURES<br />

Special voltages.<br />

• Horizontal installation: all models<br />

except for the 93 kW one.<br />

Inverter applications.<br />

High temperature windings.<br />

• Different materials.<br />

ACCESSORIES<br />

• Panels.<br />

Drop cables.<br />

37

FW8 <strong>SERIES</strong> MOTORS<br />

DIMENSIONS AND WEIGHTS AT 50 Hz<br />

MOTOR RATED<br />

DIMENSIONS (mm) WEIGHT<br />

TYPE<br />

POWER<br />

kW HP L kg<br />

FW845T405 45 60 1230 156<br />

FW852T405 52 70 1340 179<br />

FW855T405 55 75 1340 179<br />

FW860T405 60 80 1470 198<br />

FW867T405 67 90 1470 198<br />

FW875T405 75 100 1560 215<br />

FW883T405 83 112 1560 247<br />

FW893T405 93 125 1740 247<br />

fw8-2p50_b_td<br />

OPERATING CHARACTERISTICS AT 50 Hz<br />

MOTOR<br />

TYPE<br />

THREE-PHASE<br />

FW845T405 45 60<br />

FW852T405<br />

FW855T405<br />

FW860T405<br />

FW867T405<br />

FW875T405<br />

FW883T405<br />

FW893T405<br />

RATED<br />

POWER<br />

RATED<br />

VOLTAGE<br />

OPERATING CHARACTERISTICS<br />

AT RATED POWER<br />

RATED<br />

DIRECT<br />

START<br />

MAX WATER<br />

TEMPERATURE<br />

CABLE TYPE<br />

CURRENT<br />

Ncxsez. L<br />

kW HP V A rpm η % cosϕ Ca/Cn Ia °C mm 2 m<br />

52<br />

55<br />

75<br />

70<br />

75<br />

60 80<br />

67 90<br />

100<br />

83 112<br />

93 125<br />

380 93 2900 85,2 0,88 1,46 491 4G10 6<br />

400 90 2910 85,9 0,86 1,62 520 30 4G10 6<br />

415 89 2910 85,8 0,84 1,77 541 4G10 6<br />

380 107 2900 85,3 0,89 1,62 575 4G16 6<br />

400 103 2910 86,2 0,87 1,81 608 30 4G16 6<br />

415 101 2920 86,7 0,85 1,98 633 4G16 6<br />

380 114 2900 85,7 0,88 1,65 624 4G16 6<br />

400 110 2915 86,4 0,86 1,87 660 30 4G16 6<br />

415 109 2920 86,2 0,84 2,02 688 4G16 6<br />

380 122 2900 86,5 0,89 1,61 698 4G16 6<br />

400 116 2910 87,0 0,88 1,81 725 30 4G16 6<br />

415 115 2920 87,1 0,86 1,96 768 4G16 6<br />

380 137 2900 86,4 0,89 1,60 759 3x25 6<br />

400 133 2910 86,9 0,86 1,79 797 30 3x25 6<br />

415 131 2920 86,6 0,84 1,94 828 3x25 6<br />

380 154 2900 85,9 0,89 1,69 892 3x25 6<br />

400 148 2910 86,7 0,87 1,91 942 30 3x25 6<br />

415 147 2920 86,6 0,84 2,08 982 3x25 6<br />

380 166 2910 87,2 0,89 1,75 1019 3x25 6<br />

400 160 2920 87,6 0,88 1,99 1077 30 3x25 6<br />

415 156 2925 88,0 0,86 2,14 1120 3x25 6<br />

380 188 2910 87,5 0,88 1,82 1186 3x25 6<br />

400 183 2920 87,8 0,86 2,05 1276 30 3x25 6<br />

415 184 2930 87,7 0,83 2,21 1308 3x25 6<br />

fw8-2p50_b_te<br />

38

Submersible<br />

motors<br />

FW10<br />

Series<br />

APPLICATIONS<br />

Three-phase asynchronous submersible water-filled<br />

motor, with short-circuit rotor and special water resistant<br />

windings.<br />

The choice of component materials ensures optimum<br />

operating performances, superior quality, reliability and<br />

ease of installation.<br />

SPECIFICATIONS<br />

• Shaft extension and coupling<br />

dimensions to NEMA standards.<br />

Rewindable stator<br />

PVC insulation<br />

Protection class: IP68<br />

Fill liquid<br />

The motors are filled with water<br />

containing non-toxic antifreeze<br />

(15%). This liquid, besides<br />

protecting the motor from low<br />

temperatures, helps to inhibit<br />

oxidation and improve lubrication.<br />

• Large compensating<br />

diaphragm for internal liquid<br />

expansion. The motor is also<br />

equipped with a relief valve<br />

enabling the escape of liquid in the<br />

event of abnormal temperature<br />

increases.<br />

• Axial load supported by oscillating<br />

bearing.<br />

• To prevent fluid exchange between<br />

the external and internal<br />

environments, all the standard<br />

motors are equipped with a silicon<br />

carbide mechanical seal.<br />

• Maximum immersion depth:<br />

350 meters.<br />

• Maximum number of evenly<br />

distributed starts per hour: 8<br />

• Maximum supply voltage variation<br />

(415 V +6%, 380 V <strong>–</strong>10%).<br />

Maximum axial thrust: 60,000 N.<br />

• Available versions:<br />

FW10 three-phase: 110 kW to<br />

185 kW<br />

380-415 V; different voltages<br />

available on request.<br />

PVC winding<br />

• The motors are supplied with 6 m<br />

cable.<br />

• Ambient temperature: 25°C. The<br />

motors must operate in installations<br />

ensuring a minimum water velocity<br />

around the motor sleeve of<br />