Professional Documents

Culture Documents

LRXX e

Uploaded by

Sohaib KhalidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LRXX e

Uploaded by

Sohaib KhalidCopyright:

Available Formats

00:03:30

1,00660

1,0066

27,85

00:05:00

1,00661

1,0066

00:03:30

1,00660

1,0066

27,85

00:03:30

1,00668

1,0067

27,84

00:05:00

1,00666

1,0067

00:03:30

1,00668

1,0067

27,84

00:03:30

1,00666

1,0067

27,82

00:05:00

1,00667

1,0067

00:03:30

1,00666

1,0067

27,82

00:03:30

1,00667

1,0067

27,80

00:05:00

1,00665

1,0067

00:03:30

1,00667

1,0067

27,80

00:03:30

1,00667

1,0067

27,82

00:05:00

1,00665

1,0067

00:03:30

1,00667

1,0067

27,82

00:03:30

1,00669

1,0067

27,83

00:05:00

1,00668

1,0067

00:03:30

1,00669

1,0067

27,83

00:05:00

1,00671

1,0067

00:03:30

1,00671

1,0067

27,85

00:03:30

1,00671

1,0067

27,85

00:03:30

1,00674

1,0067

27,85

00:03:30

1,00675

1,0068

27,89

00:03:30

1,00677

1,0068

27,91

00:03:30

1,00679

1,0068

28,00

00:03:30

1,00676

1,0068

28,04

00:03:30

1,00673

1,0067

28,09

00:03:30

1,00673

1,0067

28,10

00:03:30

1,00670

1,0067

28,14

00:03:30

1,00670

1,0067

28,16

00:03:30

1,00671

1,0067

28,16

00:03:30

1,00675

1,0068

28,13

00:03:30

1,00681

1,0068

28,10

00:03:30

1,00684

1,0068

28,08

00:03:30

1,00690

1,0069

28,07

00:03:30

1,00690

1,0069

28,09

00:03:30

1,00691

1,0069

28,04

00:03:30

1,00686

1,0069

27,94

00:03:30

1,00685

1,0069

27,90

00:03:30

1,00682

1,0068

27,90

00:03:30

1,00676

1,0068

27,95

00:03:30

1,00674

1,0067

27,97

00:05:00

1,00671

1,0067

00:03:30

1,00674

1,0067

27,97

00:03:30

1,00676

1,0068

27,97

00:05:00

1,00674

1,0067

00:03:30

1,00676

1,0068

27,97

00:03:30

1,00675

1,0068

27,97

00:05:00

1,00673

1,0067

00:03:30

1,00675

1,0068

27,97

00:03:30

1,00679

1,0068

27,96

00:05:00

1,00675

1,0068

00:03:30

1,00679

1,0068

27,96

00:03:30

1,00679

1,0068

27,96

00:05:00

1,00676

1,0068

00:03:30

1,00681

1,0068

27,94

00:03:30

1,00680

1,0068

27,91

00:05:00

1,00678

1,0068

00:03:30

1,00680

1,0068

27,91

00:03:30

1,00680

1,0068

27,95

00:05:00

1,00678

1,0068

00:03:30

1,00680

1,0068

27,95

00:03:30

1,00684

1,0068

27,97

00:05:00

1,00681

1,0068

00:03:30

1,00684

1,0068

27,97

00:03:30

1,00686

1,0069

27,98

00:05:00

1,00684

1,0068

00:03:30

1,00686

1,0069

27,98

00:03:30

1,00686

1,0069

27,98

00:05:00

1,00681

00:03:30

1,00686

1,0069

27,98

00:03:30

1,00679

1,0068

27,97

00:05:00

1,00676

00:03:30

1,00679

1,0068

27,97

00:03:30

1,00679

1,0068

00:05:00

1,00674

00:03:30

1,00679

1,0068

27,95

00:03:30

1,00675

1,0068

00:05:00

1,00671

00:03:30

1,00675

1,0068

27,92

00:03:30

1,00671

1,0067

00:05:00

1,00670

00:03:30

1,0067

27,91

00:03:30

1,00675

1,0068

00:05:00

00:03:30

1,0068

27,90

00:03:30

1,0067

00:05:00

00:03:30

1,0067

27,88

00:03:30

1,0067

00:05:00

00:03:30

00:03:30

LR.10/LR.11

Instruction bulletin

Calibration and Service

User: ..................................................................................................................

Plant: ...............................................................................................................

00:05:00

00:03:30

27,85

27,84

27,80

ACM Ingenieurgemeinschaft fr MSSRT GmbH

A-3002 Purkersdorf, Wiener Strae 43, Tel. +43-2231-678 46, Fax +43-2231-678 46-20

E-mail office@acm.co.at, Internet www.acm.co.at

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Table of contents

INSTRUCTION BULLETIN

1)

2)

3)

4)

5)

6)

Declaration of conformity ..................................................................................................... 7

Survey LR.10 ........................................................................................................................................................... 8

Installation and mechanical connections ................................... 10

Electric connections ....................................................................................................................... 13

Technical data .................................................................................................................................................... 15

General view of opened LR.10 unit .............................................................. 16

CALIBRATION AND SERVICE

1)

Operation principle of LR.10 ...................................................................................... 21

1.1

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

1.1.6

1.1.7

1.1.8

The optical screen ................................................................................................................................................

Ideal absorption ................................................................................................................................................................

Actual absorption ...........................................................................................................................................................

Device under air ..............................................................................................................................................................

Device under water .....................................................................................................................................................

Device at about 7 BRIX ......................................................................................................................................

Device at about 14 BRIX ..................................................................................................................................

Device at about 25 BRIX ..................................................................................................................................

Characteristics of the screenshot ............................................................................................................

2)

Systemparameters ................................................................................................................................. 26

2.1

2.2

2.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.5

2.6

Hardware and software requirements ............................................................................

The mainboard ...........................................................................................................................................................

Connecting the software ..........................................................................................................................

Software windows and tools ..............................................................................................................

Parameter window ........................................................................................................................................................

Organisation window ................................................................................................................................................

Activate working lines ..............................................................................................................................................

Activate optical control .........................................................................................................................................

The window working lines .....................................................................................................................

The window optical control ...............................................................................................................

3)

Calibration of LR.10 ......................................................................................................................... 33

3.1

3.1.1

3.1.2

3.2

How to calibrate a standard cell 0...15 BRIX .................................................

Zero point calibration ..............................................................................................................................................

Reference calibration .................................................................................................................................................

One point calibration of syrup cells ..................................................................................

4)

Setup the dataport .............................................................................................................................. 35

4.1

4.2

4.3

Display interpretation .................................................................................................................................... 37

Using the slave-mode ACM.bus ................................................................................................... 37

Using PCs oder DIS.20 modules ................................................................................................ 37

5)

Causes of malefunction and removal .................................................... 38

5.1

5.2

5.3

Pollution of the camera .............................................................................................................................. 38

Pollution of the optical system within the cabinet ................................. 38

Pollution / calcification of the prism ................................................................................. 39

6)

Appendix ........................................................................................................................................................................... 40

21

21

22

22

23

23

24

24

25

27

27

27

29

29

30

30

30

31

32

33

33

33

33

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

00:03:30

1,00660

1,0066

27,85

00:05:00

1,00661

1,0066

00:03:30

1,00660

1,0066

27,85

00:03:30

1,00668

1,0067

27,84

00:05:00

1,00666

1,0067

00:03:30

1,00668

1,0067

27,84

00:03:30

1,00666

1,0067

27,82

00:05:00

1,00667

1,0067

00:03:30

1,00666

1,0067

27,82

00:03:30

1,00667

1,0067

27,80

00:05:00

1,00665

1,0067

00:03:30

1,00667

1,0067

27,80

00:03:30

1,00667

1,0067

27,82

00:05:00

1,00665

1,0067

00:03:30

1,00667

1,0067

27,82

00:03:30

1,00669

1,0067

27,83

00:05:00

1,00668

1,0067

00:03:30

1,00669

1,0067

27,83

00:05:00

1,00671

1,0067

00:03:30

1,00671

1,0067

27,85

00:03:30

1,00671

1,0067

27,85

00:03:30

1,00674

1,0067

27,85

00:03:30

1,00675

1,0068

27,89

00:03:30

1,00677

1,0068

27,91

00:03:30

1,00679

1,0068

28,00

00:03:30

1,00676

1,0068

28,04

00:03:30

1,00673

1,0067

28,09

00:03:30

1,00673

1,0067

28,10

00:03:30

1,00670

1,0067

28,14

00:03:30

1,00670

1,0067

28,16

00:03:30

1,00671

1,0067

28,16

00:03:30

1,00675

1,0068

28,13

00:03:30

1,00681

1,0068

28,10

00:03:30

1,00684

1,0068

28,08

00:03:30

1,00690

1,0069

28,07

00:03:30

1,00690

1,0069

28,09

00:03:30

1,00691

1,0069

28,04

00:03:30

1,00686

1,0069

27,94

00:03:30

1,00685

1,0069

27,90

00:03:30

1,00682

1,0068

27,90

00:03:30

1,00676

1,0068

27,95

00:03:30

1,00674

1,0067

27,97

00:05:00

1,00671

1,0067

00:03:30

1,00674

1,0067

27,97

00:03:30

1,00676

1,0068

27,97

00:05:00

1,00674

1,0067

00:03:30

1,00676

1,0068

27,97

00:03:30

1,00675

1,0068

27,97

00:05:00

1,00673

1,0067

00:03:30

1,00675

1,0068

27,97

00:03:30

1,00679

1,0068

27,96

00:05:00

1,00675

1,0068

00:03:30

1,00679

1,0068

27,96

00:03:30

1,00679

1,0068

27,96

00:05:00

1,00676

1,0068

00:03:30

1,00681

1,0068

27,94

00:03:30

1,00680

1,0068

27,91

00:05:00

1,00678

1,0068

00:03:30

1,00680

1,0068

27,91

00:03:30

1,00680

1,0068

27,95

00:05:00

1,00678

1,0068

00:03:30

1,00680

1,0068

27,95

00:03:30

1,00684

1,0068

27,97

00:05:00

1,00681

1,0068

00:03:30

1,00684

1,0068

27,97

00:03:30

1,00686

1,0069

27,98

00:05:00

1,00684

1,0068

00:03:30

1,00686

1,0069

27,98

00:03:30

1,00686

1,0069

27,98

00:05:00

1,00681

00:03:30

1,00686

1,0069

27,98

00:03:30

1,00679

1,0068

27,97

00:05:00

1,00676

00:03:30

1,00679

1,0068

27,97

00:03:30

1,00679

1,0068

00:05:00

1,00674

00:03:30

1,00679

1,0068

27,95

00:03:30

1,00675

1,0068

00:05:00

1,00671

00:03:30

1,00675

1,0068

27,92

00:03:30

1,00671

1,0067

00:05:00

1,00670

00:03:30

1,0067

27,91

00:03:30

1,00675

1,0068

00:05:00

00:03:30

1,0068

27,90

00:03:30

1,0067

00:05:00

00:03:30

1,0067

27,88

00:03:30

1,0067

00:05:00

00:03:30

00:03:30

00:03:30

Instruction bulletin

00:05:00

27,85

27,84

27,80

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Declaration of conformity

Manufacturer:

ACM Ingenieurgemeinschaft GmbH

A-3002 Purkersdorf bei Wien

Wiener Strae 43

Tel. +43/2231/678 46

Austria

declares in its sole responsibility that the product BMS.50-concept, consisting of

the Laserrefractometer series LR.10 with 24 VDC power supply

corresponds to the standards of the guidelines and the quota

legal basis:

low voltage guideline

EMV guideline

certification

73/23/EWG according to EN 61010-T1

EN50081-1: 1992; EN50082-2: 1995;

EN61000-3-2: 1995

TV Austria (Vienna)

Purkersdorf, 15th of September 1998

place and date of making out

name and signature of the authorized person

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Survey LR.10

Stainless steel housing

Output

Input

Flow adapter

In- and output have a 3/8-adapter. The extension lines are installed in hoseedition, both adapters have an outside thread. We recommend the laying of fix

pipes.The last part (approx. 25 cm) has to be provided with a flexible pipe to avoid

passing on of impacts and heavy mechanical vibrations to the measuring unit.

The flow adapter is provided with screws and can be dismantled for cleaning

purpose.

If the prism surface is cleaned, it is only allowed to clean the glass surface with fine

cotton wool (cotton swab, clean paper handkerchief,...) by circling movements.

Take pure alcohol as a cleansing agent (available in drugstores). Do not use any

corrosive liquid because the surface could get dull. Apart from this no chaving

cleansing agents or tools should be used.

Afterwards the flow adapter is fastened again. It is very important to reassamble

all parts very carefully to avoid leaking!

Take care of the built-in Pt 100 sensor!!!

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

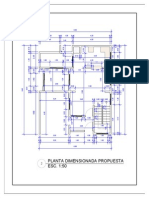

Installation, mechanical connections

The installation of the Laserrefractometer in the product pipe is according to the

following drawing. On principle the following points have to be taken into account:

All connections have to be made proof to avoid degassing.

If the measuring unit is installed directly into the product pipe, there has to

be permanent flow around the measuring window. Deposit formation has to

be avoided (medium build-up)!

The flow must be upwards so that the flow chamber stays filled with the

medium, even if there is a production stop.

If the measuring unit is installed in a horizontal pipe, the unit must be set

sideways. The electronics must not be directed up- or downwards.

The measuring unit must be fixed separatly via assembly frame because of

its weight.

For the installation in the product main pipe a special double bow is delivered.This

has a milk pipe fitting on both sides. Therefore cone seats and coupling nut must

be provided on the plant side. We recommend to make also a straight tube as

spare for a dismounted unit.

If the measuring unit is integrated in a bypass, the installation of the bypass is made

in accordance to the 3/8 pipe system.According to the drawing the flow chamber

has a 3/8 outside thread. The bypass is established as written in the following

description. Please take into consideration that both pipes can be closed by ball

valve.

For getting representative measuring data the minimal flow should not fall below

100 l/h. Depending on the construction of the bypass an appropriate flow must be

guaranteed. If a pressure increase pump is used, the pressure increase should be

at least 1 bar, the flow should be between 300 and 500 l/h.

10

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

11

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

12

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Electric connections

The Laserrefractometer is supplied by 24 VDC power (direct current).The supply

comes from the switching cabinet of the machine supplier.The power consumption

should not exceed 800 mA. Before switching on the power supply it is imperative

to control the polarity. Faulty connection can lead to defects in the electronics of

the measuring unit.

As for the LR.10 runs with direct current lower than 48V, there is power safe as

a precautionary measure. That is why the machine supplier is responsible for the

appropriate realization of all required electronic precautionary measures as

necessary on site. ACM takes on no guarantee concerning this item.

The measuring electronics supply one valid measuring value per second as a serial

data transfer to a reception module. The data format is digital and is liable to the

RS 485 port.The communication parameters are 9600 baud, 8 data bits, 1 stop bit,

no parity. You find the transfer report as an attachment.

13

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

14

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Technical data

Dimensions

Weight

Power supply

Power consumption

Signal output

Data format

Analog output

Measuring range

width 220 x hight 360 x depth 162 mm

depending on flow chamber, approx. 5 kg net

24 VDC

approx. 800 mA

RS 485 serial data bus

9600 baud, 8 data bits, 1 stop bit, no parity

4...20 mA (optional)

0 to 30 Brix standard

40 to 80 Brix Syrup (LR.11)

0 to 100 mBrix for dietary drinks

70 to 120 % for dietary drinks if specially calibrated

(CC)

Measuring cycle

1 valid measuring value per second

Accuracy

+/- 0,01 Brix standard und Syrup (LR.11)

+/- 0,005 Brix for mBrix (dietary drinks)

+/- 0,15 % if specially calibrated for diet (CC)

Temp. compensation 20 C via Pt 100

Temperature range 4-30 C for measuring cycle LR.10

4-85 C for measuring cycle LR.11

up to 150 for cleaning purpose (CIP)

Data display

LCD with background light

Cooling

Papst ventilator 24 VDC

Prism type

K5-standard

CPU-unit

version 2 with SMD-CPU

CCD-unit

version 2 round

Analog unit

version 2 PT 100

Housing

stainless steel with 4x PG11

Prism piece

stainless steel round - standard

Camera holder

syrup version aluminium

Required spare parts

There is no need of spare parts for operating the laserrefractometer. ACM

guarantees 24 hour spare part delivery via UPS within Europe and also service on

demand. If there is still a demand of delivery of recommended spare parts, we

propose as follows:

1 piece LCD data display with background light 10 x 2 Sharp or Batron

1 piece cooling vantilator Papst 24 VDC type MMF-08C24DS

15

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

General view of opened LR.10-unit,

compact-edition

Internal LC-data

display 2x16 signs

Analogue signals

4...20 mA input (optional)

Optical system with

the laser, only for

authorized people!

2x relay output

for alarms

Power supply

24 VDC / 0,8 A

RS 485 data bus

RS 232 service

and modem interface

The picture shows the opened LR.10 (or 11) measuring unit. The electronics and

the data display are shown on the left side. On the other side you can find the

optical system including the laser and the CCD-camera covered by a black piece

of metal. Not authorized staff must not manipulate anything in this part of the

device because of the possibility of a malefunction afterwards. Apart from this a

laser of class 1 ( 1 mW) is used, so that appropriate protection glasses are

absolutely imperative!

For the connection of the power supply and of the signal line it is necessary to use

the attached connecting diagramm. Optionally 4x4...20 mA signals can be connected

and data can be transferred by the RS 485 port. There are also 2 optional relays,

wich can be controlled externally by RS 485 data communication. Please use again

the attached connecting diagramm.

16

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

17

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

18

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

00:03:30

1,00660

1,0066

27,85

00:05:00

1,00661

1,0066

00:03:30

1,00660

1,0066

27,85

00:03:30

1,00668

1,0067

27,84

00:05:00

1,00666

1,0067

00:03:30

1,00668

1,0067

27,84

00:03:30

1,00666

1,0067

27,82

00:05:00

1,00667

1,0067

00:03:30

1,00666

1,0067

27,82

00:03:30

1,00667

1,0067

27,80

00:05:00

1,00665

1,0067

00:03:30

1,00667

1,0067

27,80

00:03:30

1,00667

1,0067

27,82

00:05:00

1,00665

1,0067

00:03:30

1,00667

1,0067

27,82

00:03:30

1,00669

1,0067

27,83

00:05:00

1,00668

1,0067

00:03:30

1,00669

1,0067

27,83

00:03:30

1,00671

1,0067

27,85

00:05:00

1,00671

1,0067

00:03:30

1,00671

1,0067

27,85

00:03:30

1,00674

1,0067

27,85

00:03:30

1,00675

1,0068

27,89

00:03:30

1,00677

1,0068

27,91

00:03:30

1,00679

1,0068

28,00

00:03:30

1,00676

1,0068

28,04

00:03:30

1,00673

1,0067

28,09

00:03:30

1,00673

1,0067

28,10

00:03:30

1,00670

1,0067

28,14

00:03:30

1,00670

1,0067

28,16

00:03:30

1,00671

1,0067

28,16

00:03:30

1,00675

1,0068

28,13

00:03:30

1,00681

1,0068

28,10

00:03:30

1,00684

1,0068

28,08

00:03:30

1,00690

1,0069

28,07

00:03:30

1,00690

1,0069

28,09

00:03:30

1,00691

1,0069

28,04

00:03:30

1,00686

1,0069

27,94

00:03:30

1,00685

1,0069

27,90

00:03:30

1,00682

1,0068

27,90

00:03:30

1,00676

1,0068

27,95

00:03:30

1,00674

1,0067

27,97

00:05:00

1,00671

1,0067

00:03:30

1,00674

1,0067

27,97

00:03:30

1,00676

1,0068

27,97

00:05:00

1,00674

1,0067

00:03:30

1,00676

1,0068

27,97

00:03:30

1,00675

1,0068

27,97

00:05:00

1,00673

1,0067

00:03:30

1,00675

1,0068

27,97

00:03:30

1,00679

1,0068

27,96

00:05:00

1,00675

1,0068

00:03:30

1,00679

1,0068

27,96

00:03:30

1,00679

1,0068

27,96

00:05:00

1,00676

1,0068

00:03:30

1,00681

1,0068

27,94

00:03:30

1,00680

1,0068

27,91

00:05:00

1,00678

1,0068

00:03:30

1,00680

1,0068

27,91

00:03:30

1,00680

1,0068

27,95

00:05:00

1,00678

1,0068

00:03:30

1,00680

1,0068

27,95

00:03:30

1,00684

1,0068

27,97

00:05:00

1,00681

1,0068

00:03:30

1,00684

1,0068

27,97

00:03:30

1,00686

1,0069

27,98

00:05:00

1,00684

1,0068

00:03:30

1,00686

1,0069

27,98

00:03:30

1,00686

1,0069

27,98

00:05:00

1,00681

00:03:30

1,00686

1,0069

27,98

00:03:30

1,00679

1,0068

27,97

00:05:00

1,00676

00:03:30

1,00679

1,0068

27,97

00:03:30

1,00679

1,0068

00:05:00

1,00674

00:03:30

1,00679

1,0068

27,95

00:03:30

1,00675

1,0068

00:05:00

1,00671

00:03:30

1,00675

1,0068

27,92

1,00670

Calibration and Service

00:03:30

1,00671

1,0067

00:05:00

00:03:30

1,0067

27,91

00:03:30

1,00675

1,0068

00:05:00

00:03:30

1,0068

27,90

00:03:30

1,0067

00:05:00

00:03:30

1,0067

27,88

00:03:30

1,0067

00:05:00

00:03:30

00:03:30

00:03:30

00:05:00

27,85

27,84

27,80

19

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

20

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Operation principle of LR.10

Our Laserrefraktometer LR.10/55 performs by refraction of backlight a picture

of the liquid behind the prism. The position of this shape depends on the liquids

refraction index and the temperature. The refraction index itself depends on the

concetration and type of dissolved materials.Temperature is acquired permanently.

So the concentration can be calculated continuously.

1.1 The optical screen

1.1

The optical screen

Like an ordinary refractometer our LR.10 has an optical screen. It is divided into

a bright and a dark area. Acquisition of the Brix value means comparison with the

shown scale.

The Laserrefractometer uses a scale, that depends on the temperature. This scale

is handled in the LR.10 as cell profile.

1.1.1 Ideal absorption

1.1.1

Ideal absorption

Optical theory says, that the transition bright to dark has this shape.

21

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

1.1.2

Actual absorption

1.1.2 Actual absorption

Reality shows different results.

1.1.3

Device under air

22

1.1.3 Device under air

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

1.1.4 Device under water

1.1.4

Actual absorption

1.1.5 Device at about 7 BRIX

1.1.5

Device at about 7 Brix

23

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

1.1.6

Device at about 14 Brix

1.1.6 Device at about 14 BRIX

1.1.7

Device at about 25 Brix

1.1.7 Device at about 25 Brix

24

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

1.1.8 Characteristics of the screenshot

1.1.8

Characteristics

of the screenshot

For a closer classification of the pictures quality there are some parameters:

Measurement window: This area indicates, where the line has its biggest

change / ascent. Software searches for this area automatically. The user has

no access to this area in this software.

Bright value: value of the brightest pixel within the measurement window.

Dark value: value of the darkest pixel within the measurement window.

Laser current is regulated, in order to keep this pixel always beyond opt.

hystereses

Start value: left margin

Stop value: right margin

25

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

System parameters

The parameters of the LR.10 devide in two fields:

Parameters

System

parameter

responsible for:

calibration of the Pt-100

electr. adjustment of the optic

system

organisation

26

Cell profile

various

responsible for:

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

medium, range and used optic

2.1 Hardware and software requirements

SETUP works with WIN95 / WIN98 / WIN NT

2.1

Hardware

and software

requirements

The PC is connected by an usual cable (zeromodem 2x SUB-D 9 plugs) via the

Service-port to the LR.10.

COM parameters: 19200BD,N,8,1 (Setup by default)

2.2

The mainboard

2.2 The mainboard

2.3 Connecting the software

To open the refractometer in order to operate to

its system data and actual values, use the button

open COM.

The com port is open and connection is

granted.You can use the device with / without

modem. Before transferring its systemdata the refractometer requests a password.

2.3

Connecting

the software

27

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

The preset password is 3002.

When connected, the software shows an image of the parameters and gives you

the tools to operate the specified cell. (LR, CO, BA)

The last line shows the device code and the version of the firmware.

28

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

2.4 Windows and Tools

2.4

Windows

and tools

For working to the LR the software gives you four tools.

Parameter window

Organisation window

Working lines

Optical control

2.4.1 Parameter window

2.4.1

Parameter windows

In parameter window all system and actual parameters can be watched at one time.

Change one parameter by clicking with the mouse on the value and change it.

This Parameters are relevant:

T1Offset, T1Scale

Calibration of the Pt 100

Reference

Zero-point of the optic system.

X Multiplicator, X-Divisor

Gain of the optic. Typ. 990 .. 1020, each.

Max. laser current

This parmeter defines the overload-value. Medium of too high refraction

index or shadow by pollution causes the laser current to go up until

blooming of the camera may occur. To avoid this the parameter Max.current

limits the output of the controller. While limiting, the software shows overstatus. All mA-outputs are set to 20 mA, digital output goes up to MAXINT

(32678). Set this parameter about 20-30 dots above the maximal appearing

current during production.

Integrator

Integration time 0 (7 secs) - 3 (27 secs)

Fan-in

Eliminates jumps from inconsisting medium before calculation

29

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

0 (180 pixels) - 3 (320 pixels)

The button Set will store the given configuration into the cell.

The button Load causes the cell to transmit all parameters in one.

To display actual parameters continuously the measurement cell can be requested

for a specified number of loops to link the calculating task to the comport. Use

the UpDown-selector to change the count of loops.To start this procedure, press

Request Data. All system parameters can be changed during the loop, so you can

watch them changing. (for example during calibration). You can stop the cycle by

pressing Cancel at any time or wait until the counter has run out.

The firmware is realtime multitasking, so all the actions by the service port will

have absolutely no effect on the flow of data on the bus port and other reactions

even in use with a modem.

2.4.2

Organisation window

2.4.2 Organisation window

The organisation window gives you 10 strings for free use. You may enter serial

number, customer informations and informations of commissioning or last revision.

2.4.3

Activate working lines

2.4.3 Activate working lines

Working lines determine the kind of used optic. To operate to this item

press the button. You will get the according window.

2.4.4

Activate optical control

2.4.4 Activate optical control

Our optic cannot be checked by eye, due to their small details. It is necessary

to use the tool optical control. This button opens the according window.

30

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

2.5 The window working lines

2.5

The window

working lines

The window displays all available working lines in the refractometer.

Load all working lines from the LR and verify all checksums.

Store all working lines from the PC to the device.

All actions are secured by checksums.

Store to disc.

Use files with extension *.klf.

31

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

2.6

The window

optical control

Analog to Store.

2.6 The window Optical Control

To check the screenshot of the camera just press this button with the little

camera.

The window gives you the chance to check an actual low level snapshot from the

CCD.

Every time pressed a screenshot is transmitted. Due to the resolution and

the transfer speet this action takes about 2 seconds. The X-axis shows the pixel.

Our CCD has 3000 pixel.Y-axis displays the brightness. Horizontal zoom can be

altered in order to have a more detailed view.

32

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Calibration of LR.10

The shown value is calculated by the incoming X-value.

To calibrate the cell it is necessary to transform the X-value by this formula:

X-value: = (X-value - reference) * multiplicator / divisor

3.1 How to calibrate a standard cell 0...15

BRIX

First of all your cell has to be open and test loops ON. Calibration will be a two

point calibration.

3.1.1 Zero point calibration

3.1

How to calibrate

a standard cell

0...15 BRIX

3.1.1

Zero point calibration

Be sure that water with constant flow passes your cell. The best temperature will

be at about 12-16 C, normal operating temperature.

Multiplicator and Divisor are set both to 1000. Now the shown Brix value can be

adjusted to zero.

Remember: only distilled water has exactly 0.000 BRIX. We are using usual water.

Water from the ion exchanger: 10-40 mBrix

Water from fountain: 50-100 mBrix

Industrial water: 100-150 mBrix

Set the reference and watch the Brix value:

High Brix -> decrease reference

Low Brix -> increase reference.

-> change of the reference by 320 causes the brix to change 1 BRIX.

Note: due to the internal operation of the LR.10 changes can appear on delay

some seconds.

If zerocal is finished,you can set up a known concentration by adding syrup to the

water. We usually use a solution of 10.20 BRIX (=Coke).

3.1.2 Reference calibration

3.1.2

Reference calibration

Calibration is performed by changing the multiplicator / divisor.

3.2 One point calibration of syrup cells

Syrup cells with optic 67.3 and 60.0 only have a virtual zero point. Therefore they

are one point calibrated. Be sure that syrup with a constant flow passes the

refractometer. Temperature should be as constant as possible.

3.2

One point

calibration

of syrup cells

Calibrate the cell in normal operation at nominal Brix value.

33

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

To be sure you can call the menu optical control.

Be sure, that multiplicator and divisor are set to 1000.

Perform if:

High Brix -> decrease reference

Low Brix -> increase reference.

short Optic 60 mm:

change reference value at 1000 dots causes the Brix to change 5 BRIX.

34

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Setup the Dataport valid from version 1.009

The operating mode of the data port is set by the 8-terminal DIP-switch on the

main-PCB.

Table 1:

Note 1: the operating mode and adress/range is displayed in the second line of

the front-display, first two digits.

Note 2: Using the PCS-module you can configurate them absolutely free.

35

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Table 3:

mA-output for Adam/ICP set by Jumper 3-7

36

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

4.1 Display Interpretation

Diagnosis values in HEX.

Typical values:

bright value

dark value

contrast value

laser current

4.1

Display

interpretation

>$7F (127)

<$0F (15)

>$0A (10)

<$44 (70) depending on kind of appliance

4.2 Using the slave-mode ACM.bus.

See documentation ACM-bus protocoll.

4.3 Using PCS or DIS.20 modules

ACM-DIS.20 protocoll is supported.

4.2

Using the slave

mode ACM.bus

4.3

Using PCs or

DIS.20 modules

The following values are available:

#00

Brix value for standard beverages 0.00 - 32.00 Brix

#01

Brix value for syrup 0.00 - 78.00 Brix

#02

reserve

#03

reserve

#04

process temperature

Delay time between data strings: 30 msec

37

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Causes of malefunction and removal

5.1

Pollution of

the camera

5.1 Pollution of the camera

By working within the cabinet, for example connecting, inserting a bag of SilicaGel

etc. it might happen that a hair or fiber enters the fan and from there the optic. It

becomes a problem if the particle deposits on the cameras surface. The shadow

might cause faulty measurement. You can detect this malefunction only in optic

parameter.

Removal of this fault: use a cotton wool swab to clean the camera.

Check the result by optic control ok.

5.2

Pollution of the

optical system

within the cabinet

5.2 Pollution of the optical system within the

cabinet

pollution of the lens

pollution of the prism (might be condensation)

Removal of this fault: cleaning the optic; check the result by optic control ok.

38

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

5.3 Pollution / calcification of the prism

If CIP process works only caustic, calcification can occur.

5.3

Pollution /

calcification

of the prism

These parameters change by increasing pollution:

contrast decreases (30:2 - 25:2 etc.)

d/dx too (6 - 5 - 4 etc.)

Measurement becomes unreliable and stopps working after a while:

Removal of this fault: dismount the flow chamber on the back side, dissolve

citric acid and clean the glass opening using a cotton wool swab, check the

result by optic control.

39

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

Appendix

40

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

41

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

42

ACM Ingenieurgemeinschaft GmbH - Doku-Version 2.0-10/01

43

You might also like

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionFrom EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNo ratings yet

- Wago Perspecto 762: ManualDocument50 pagesWago Perspecto 762: ManualQuadroNo ratings yet

- KISTLER Torque Sensor Type 4503ADocument6 pagesKISTLER Torque Sensor Type 4503ASantiago MolinaNo ratings yet

- Ecostruxure Control Advisor: Continuous Improvement GuideDocument20 pagesEcostruxure Control Advisor: Continuous Improvement Guideabdel taibNo ratings yet

- Reg48 User GuideDocument108 pagesReg48 User GuideDiegoNo ratings yet

- Pmi BGDocument1 pagePmi BGendah9887No ratings yet

- TraneDocument33 pagesTranejake1000100% (1)

- Operators Manual: For In-Vitro Diagnostic Use Only!Document57 pagesOperators Manual: For In-Vitro Diagnostic Use Only!Mina TariqNo ratings yet

- WinCC V4 Manual Part 3 - 3Document422 pagesWinCC V4 Manual Part 3 - 3www.otomasyonegitimi.comNo ratings yet

- Flowmeter Endress+HauserDocument70 pagesFlowmeter Endress+Hausersanach100% (1)

- Active Robot Training ManualDocument114 pagesActive Robot Training ManualGuillermo Alejandro MontielNo ratings yet

- S4-M96 - 2400 Electrical DiagramsDocument62 pagesS4-M96 - 2400 Electrical DiagramsmartinimartiiniNo ratings yet

- Service Manual: Color Video CameraDocument63 pagesService Manual: Color Video Cameraaurumstar2000100% (1)

- An-MPU-9250A-03 MPU-9250 Accel Gyro and Compass Self-Test Implementation v1 0 - 062813Document14 pagesAn-MPU-9250A-03 MPU-9250 Accel Gyro and Compass Self-Test Implementation v1 0 - 062813Herry WijayaNo ratings yet

- Open Modbus TCP For NCM - CP Redundant EnglishDocument71 pagesOpen Modbus TCP For NCM - CP Redundant EnglishJose LunaNo ratings yet

- Harmony XAC Pendant Control Stations: CatalogDocument62 pagesHarmony XAC Pendant Control Stations: CatalogMarcosNo ratings yet

- PDF Manual Tecnico Hgu Modelo rtf8115vw - CompressDocument9 pagesPDF Manual Tecnico Hgu Modelo rtf8115vw - CompressNatalia VásquezNo ratings yet

- STM32F30xx-31xx Standard Peripheral Library UM1581Document584 pagesSTM32F30xx-31xx Standard Peripheral Library UM1581John LeungNo ratings yet

- MRAC - Pendulum SimulationDocument6 pagesMRAC - Pendulum SimulationTecKnus BarbosaNo ratings yet

- MKS ROBIN Nano Motherboard ManualDocument42 pagesMKS ROBIN Nano Motherboard ManualdowncartiNo ratings yet

- Motor Condition MonitorDocument25 pagesMotor Condition MonitorVirgilioNo ratings yet

- Vspe Api 32 KeyDocument1 pageVspe Api 32 Keysergio1102No ratings yet

- Omron CJ2 Auxiliar Area MemoryDocument38 pagesOmron CJ2 Auxiliar Area MemoryAline Oliveira FotografaNo ratings yet

- Portable Fundus Camera FC160Document37 pagesPortable Fundus Camera FC160AbiNo ratings yet

- EEE598 Project 2 Group2-1Document12 pagesEEE598 Project 2 Group2-1Giser AliNo ratings yet

- 2014-Instruction of MAGYN Electromagnetic FlowemterDocument66 pages2014-Instruction of MAGYN Electromagnetic Flowemterinfo -ADDMASNo ratings yet

- DASBAENFTP62UDocument540 pagesDASBAENFTP62UAlexandre MarchioteNo ratings yet

- Advant Controller 31Document132 pagesAdvant Controller 31max_ing100% (1)

- 3ADR020077C0204 REV D PLC Automation Version 05.05.2021Document292 pages3ADR020077C0204 REV D PLC Automation Version 05.05.2021Panelo AlvarezNo ratings yet

- Ford North America Standard Fault MonitoringDocument8 pagesFord North America Standard Fault MonitoringJeevanath VeluNo ratings yet

- System 800xa 5.0: Product CatalogDocument104 pagesSystem 800xa 5.0: Product CatalogDuy Anh BuiNo ratings yet

- Service News 10 Liasys New ENGLDocument41 pagesService News 10 Liasys New ENGLNGUYEN MEDICALNo ratings yet

- 01 HERMOS CTLS Peribox TrackingConveyor PresentationDocument8 pages01 HERMOS CTLS Peribox TrackingConveyor PresentationcristiNo ratings yet

- Epson SCARA Robot BrochureDocument16 pagesEpson SCARA Robot BrochureProduccion TAM100% (1)

- 1756-HSC Various ConfigurationsDocument6 pages1756-HSC Various ConfigurationsPaul Ramos CarcaustoNo ratings yet

- Vertical Load Best PracticesDocument4 pagesVertical Load Best PracticesNelsonNo ratings yet

- Technical Information: Model ZR22G, ZR402G Direct In-Situ Separate Type Zirconia Oxygen Analyzers (Hardware Edition)Document35 pagesTechnical Information: Model ZR22G, ZR402G Direct In-Situ Separate Type Zirconia Oxygen Analyzers (Hardware Edition)Atreyo SahaNo ratings yet

- Tm210tre 25-Eng PDFDocument54 pagesTm210tre 25-Eng PDFVladan MilojevićNo ratings yet

- Kistler 5018 ManualDocument82 pagesKistler 5018 ManualgabrielkempeneersNo ratings yet

- Unit 3 PLC (Programmable Logic Controller)Document66 pagesUnit 3 PLC (Programmable Logic Controller)hicinobNo ratings yet

- Automation Studio One-Line Electrotechnical GuideDocument69 pagesAutomation Studio One-Line Electrotechnical GuideAlexandre Marchiote100% (1)

- User's Manual For TL-30x Laser Engraving and Cutting Control SystemDocument103 pagesUser's Manual For TL-30x Laser Engraving and Cutting Control SystemGPrado100% (1)

- YAG DN A Operator Manual PDFDocument152 pagesYAG DN A Operator Manual PDFMiloš ProdanovićNo ratings yet

- Utils C Ultra PDFDocument693 pagesUtils C Ultra PDFPredescu DarieNo ratings yet

- Direct AccessDocument362 pagesDirect AccessAlfredo Francisco Romero PlasenciaNo ratings yet

- Debugger Hc12Document52 pagesDebugger Hc12carver_uaNo ratings yet

- Changzhou RATTM MOTOR Co.,Ltd: RTM100-30-24Z/3.0 220V User InstructionsDocument10 pagesChangzhou RATTM MOTOR Co.,Ltd: RTM100-30-24Z/3.0 220V User InstructionsrusbogdanclaudiuNo ratings yet

- SafetyNet Logic Workbench Getting Started GuideDocument103 pagesSafetyNet Logic Workbench Getting Started GuideRekik MHNo ratings yet

- Orbisphere 3610Document80 pagesOrbisphere 3610Leon Alberto RivasNo ratings yet

- Bluetooth HC 05Document13 pagesBluetooth HC 05Jaime Leonardo CruzNo ratings yet

- TRMK 54 - Rekap SaldoDocument2 pagesTRMK 54 - Rekap SaldoyohraslitbangNo ratings yet

- الشمسDocument185 pagesالشمسgggfhNo ratings yet

- الزهرةDocument185 pagesالزهرةgggfhNo ratings yet

- TRMK 54 - Rekap SaldoDocument2 pagesTRMK 54 - Rekap SaldoyohraslitbangNo ratings yet

- Nilai Rapor SD k13Document8 pagesNilai Rapor SD k13Emank JanitraNo ratings yet

- عطاردDocument185 pagesعطاردgggfhNo ratings yet

- زحلDocument185 pagesزحلgggfhNo ratings yet

- Practica I-Inf Apli.Document2 pagesPractica I-Inf Apli.reyleon85No ratings yet

- S942008004 - Cahyo Agung Saputra - Uts Dinamika Tanah 12 Okt 2021Document6 pagesS942008004 - Cahyo Agung Saputra - Uts Dinamika Tanah 12 Okt 2021Cahyo Agung SaputraNo ratings yet

- 10266Document102 pages10266Sohaib KhalidNo ratings yet

- Heinbockel - Tensor Calculus - PartDocument5 pagesHeinbockel - Tensor Calculus - Partapi-3835172No ratings yet

- Boiler Energy Audit ManualDocument29 pagesBoiler Energy Audit ManualAnubhav100% (11)

- IELTS Listening TestDocument10 pagesIELTS Listening TestBasmanMarkus100% (1)

- SteamDocument36 pagesSteamsalilm31100% (2)

- Iec60364 PDFDocument105 pagesIec60364 PDFMircea Murar60% (5)

- AB SMC Flex 150 ManualDocument162 pagesAB SMC Flex 150 Manualjpollard2No ratings yet

- Energy Efficient MotorsDocument8 pagesEnergy Efficient MotorsformechNo ratings yet

- 3 PhmotorDocument4 pages3 PhmotorMissboy AjengkelinNo ratings yet

- Flow Switch HoneywellDocument1 pageFlow Switch HoneywellSohaib Khalid100% (1)

- VLT Micro FC 51 Parameter SettingDocument83 pagesVLT Micro FC 51 Parameter SettingSohaib Khalid0% (1)

- 5 Ways To Decrease CO EmissionsDocument1 page5 Ways To Decrease CO EmissionsSohaib KhalidNo ratings yet

- Resolução Levenspiel Impares Cap 7 PDFDocument7 pagesResolução Levenspiel Impares Cap 7 PDFChrislei RizzattiNo ratings yet

- 2088 DatasheetDocument14 pages2088 DatasheetSohaib KhalidNo ratings yet

- DC PNP Electrical Design: WiringDocument1 pageDC PNP Electrical Design: WiringSohaib KhalidNo ratings yet

- CE Conformity PDFDocument1 pageCE Conformity PDFSohaib KhalidNo ratings yet

- The Industrial Internet@Work: Marco Annunziata & Peter C. EvansDocument37 pagesThe Industrial Internet@Work: Marco Annunziata & Peter C. EvansSohaib KhalidNo ratings yet

- Bimetall Thermometer Typ21 enDocument2 pagesBimetall Thermometer Typ21 enSohaib KhalidNo ratings yet

- Instruction Manual: Butterfly Valve With HandleDocument0 pagesInstruction Manual: Butterfly Valve With HandleSohaib KhalidNo ratings yet

- Ba SV en Pnem PDFDocument0 pagesBa SV en Pnem PDFSohaib KhalidNo ratings yet

- Operating Instructions Type 6213: 2-Way Solenoid Valve, Internally Piloted, Normally Closed (Circuit Function A)Document2 pagesOperating Instructions Type 6213: 2-Way Solenoid Valve, Internally Piloted, Normally Closed (Circuit Function A)Sohaib KhalidNo ratings yet

- Basic Soft Starter PrinciplesDocument9 pagesBasic Soft Starter PrinciplesmitelectricalNo ratings yet

- Direttiva 99 92 CEDocument8 pagesDirettiva 99 92 CEslan79bisNo ratings yet

- Butterfly Valve GS - SS - ZFA PDFDocument6 pagesButterfly Valve GS - SS - ZFA PDFSohaib KhalidNo ratings yet

- Bimetall Thermometer Typ21 enDocument2 pagesBimetall Thermometer Typ21 enSohaib KhalidNo ratings yet

- FES0069C Div2Document2 pagesFES0069C Div2Sohaib KhalidNo ratings yet

- Machine Safety GuideDocument64 pagesMachine Safety GuideSohaib KhalidNo ratings yet

- DEPA-Druckluft-Membranpumpen, Serie L DEPA Air Operated Diaphragm Pumps, Series LDocument1 pageDEPA-Druckluft-Membranpumpen, Serie L DEPA Air Operated Diaphragm Pumps, Series LSohaib KhalidNo ratings yet

- Earth CalcualtionDocument7 pagesEarth CalcualtionAndrew1221568No ratings yet

- Bimetall Thermometer Typ21 enDocument2 pagesBimetall Thermometer Typ21 enSohaib KhalidNo ratings yet

- 123Document3 pages123Phoebe AradoNo ratings yet

- Class 12 Physics Derivations Shobhit NirwanDocument6 pagesClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniNo ratings yet

- Code of Ethics For Civil Engineers PiceDocument3 pagesCode of Ethics For Civil Engineers PiceEdwin Ramos Policarpio100% (3)

- Service Quality Dimensions of A Philippine State UDocument10 pagesService Quality Dimensions of A Philippine State UVilma SottoNo ratings yet

- Regulasi KampenDocument81 pagesRegulasi KampenIrWaN Dompu100% (2)

- 23 Ray Optics Formula Sheets Getmarks AppDocument10 pages23 Ray Optics Formula Sheets Getmarks AppSiddhant KaushikNo ratings yet

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocument13 pagesStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorNo ratings yet

- I. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)Document5 pagesI. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)thmeiz.17sNo ratings yet

- ISO Position ToleranceDocument15 pagesISO Position ToleranceНиколай КалугинNo ratings yet

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- IPA Smith Osborne21632Document28 pagesIPA Smith Osborne21632johnrobertbilo.bertilloNo ratings yet

- Gas Compressor SizingDocument1 pageGas Compressor SizingNohemigdeliaLucenaNo ratings yet

- The Pneumatics of Hero of AlexandriaDocument5 pagesThe Pneumatics of Hero of Alexandriaapi-302781094No ratings yet

- Work Energy Power SlidesDocument36 pagesWork Energy Power Slidessweehian844100% (1)

- Technical Sheet Racloflex NTDocument2 pagesTechnical Sheet Racloflex NTAnthony AngNo ratings yet

- Ficha Técnica Panel Solar 590W LuxenDocument2 pagesFicha Técnica Panel Solar 590W LuxenyolmarcfNo ratings yet

- Approvals Management Responsibilities and Setups in AME.B PDFDocument20 pagesApprovals Management Responsibilities and Setups in AME.B PDFAli LoganNo ratings yet

- 2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - LibroDocument82 pages2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - Librovallejo13No ratings yet

- Applications of Wireless Sensor Networks: An Up-to-Date SurveyDocument24 pagesApplications of Wireless Sensor Networks: An Up-to-Date SurveyFranco Di NataleNo ratings yet

- "Tell Me and I Forget, Teach Me and I May Remember, Involve MeDocument1 page"Tell Me and I Forget, Teach Me and I May Remember, Involve MeBesufkad Yalew YihunNo ratings yet

- RH-A Catalog PDFDocument1 pageRH-A Catalog PDFAchmad KNo ratings yet

- Chapter 2 Short-Term SchedulingDocument49 pagesChapter 2 Short-Term SchedulingBOUAZIZ LINANo ratings yet

- Puma PypDocument20 pagesPuma PypPrashanshaBahetiNo ratings yet

- G.Devendiran: Career ObjectiveDocument2 pagesG.Devendiran: Career ObjectiveSadha SivamNo ratings yet

- Analisis Kebutuhan Bahan Ajar Berbasis EDocument9 pagesAnalisis Kebutuhan Bahan Ajar Berbasis ENur Hanisah AiniNo ratings yet

- Pearson R CorrelationDocument2 pagesPearson R CorrelationAira VillarinNo ratings yet

- 28 TerminalsDocument42 pages28 TerminalsAlin FazacasNo ratings yet

- Uniform Motion WorksheetDocument8 pagesUniform Motion Worksheetnikhil patro100% (1)

- Leveriza Heights SubdivisionDocument4 pagesLeveriza Heights SubdivisionTabordan AlmaeNo ratings yet

- Ilovepdf MergedDocument503 pagesIlovepdf MergedHemantNo ratings yet