Professional Documents

Culture Documents

System Design Manual - Part 1 - Load Estimation

Uploaded by

ChowKC030 ratings0% found this document useful (0 votes)

542 views156 pagesCarrier System Design Manual - Part 1 Load Estimation

Original Title

System Design Manual - Part 1_Load Estimation

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCarrier System Design Manual - Part 1 Load Estimation

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

542 views156 pagesSystem Design Manual - Part 1 - Load Estimation

Uploaded by

ChowKC03Carrier System Design Manual - Part 1 Load Estimation

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 156

(Aeved(-tg SHA

design manual

LOAD ESTIMATIN¢

SYSTEM DESIGN MANUAL,

SUMMARY OF PART ONE

This part of the System Design Manual

presents data and examples to guide the

engineer when preparing practical cooling

and heating load estimotes.

After the load has been determined, the

“Applied Psychrometries” chapter will bridge

the gap between the load estimate and

‘equipment sel

The text of this manual is offered os o

‘general guide for the use of industry and of

consulting engineers in designing systems.

Judgment is required for application to spe-

cific installations, and Carrier is not respon

sible for any of the uses made of this text.

© carrie Corporation 1960

Eighth Printing 1968

Ninth Printing 1972 (510304)

PART LOAD ESTIMATING

oy

CONTENTS

survey and load estima!

design conditions

storage

solar heat gain-glass

heat and moisture flow

Infiltration and ventilation

internal and system heat gain

applied psychrometrics

‘The primary function of air conditioning is to

maintain conditions that are (1) conducive to

human comfort, of (2) required by a product, or

process within # space. To perform this function,

equipment of the proper capacity must be installed

and controlled throughout the year. The equipment

wacity is determined by the actual instantaneous

peak load requirements; type of control is deter

mined by the conditions to be maintained during

peak and partial load, Generally, it is impossible to

measure either the actual peak or che partial load

in any given space; these loads must be estimated.

It is for this purpose that the data contained in Part

Thas been compiled,

Before the load can be estimated, it is impera:

survey be made to assure

tive that @ comprehens

ecurate evaluation of the load components. I the

ntancous load,

building facilities and che actual ins

within 2 given mass of the building are carefully

studied, an economical equipment selection and sys

tem design can result, and smooth, trouble free per

formance is then possible.

‘The heat gain or loss is the amount of heat in-

stantaneously coming into or going out of the space.

The actual load is defined as that amount of heat

which is instantaneously added or removed by the

iment. The instantaneous heat gain and the

actual load on the equipment will rarely be equal,

because of the thermal inertia or storage effect of

the building structures surrounding a conditioned

space

Chapters 2, 4, 5, 6, and 7 contain the data from

which the instantaneous heat gain or loss is esti:

mated. Chapter 3 provides the data and procedure

lor applying storage actors to the appropriate heat

gains to result in the actual load, Chapter 8 provides

the bridge between the load estimate and the equip:

ment selection, It furnishes the procedure for estab-

ishing the eriteria to fulfill the conditions required

by a given project.

The basis of the data and its use, with examples,

are included in each chapter with the tables and

charts; also an explanation of how each of the heat

gains and the loads manifest themselves.

CHAPTER 1. BUILDING SURVEY AND LOAD ESTIMATE

BUILDING SURVEY

SPACE CHARACTERISTICS AND HEAT LOAD

SOURCES

An accurate survey of the load components of the

space to be air conditioned! is a basic requirement

lor a realistic estimate of cuoling and heating loads.

‘of Ug survey is the

The completeness an acrwva'

ery foundation of the e:tinate, aud its importance

can not be overemphasized. Mechanical and archi:

tectural drawings, complete field sketches and, in

some cases, photographs ol important aspects are

part ol a good survey, The following physical aspects

must be considered

Location of the

ct 0:

1. Orientation of building

space to be air conditioned with 1

a) Compass points sun and wind effects,

bb) Nearby permanent structures ~ shading

clfects

©) Reflective surfaces — water, sand, parking

lots, ete

2. Use of space(s) — Ollie, hospital, department

store, specialty shop, machine shop, factory,

assembly plant, ete.

8. Physical dimensions of space(s) — Length,

width, and height

4. Ceiling heigit — Floor to floor height, floor to

ceiling, clearance between suspended ceiling

and beams,

Columns and beams — Size, depth, also knee

braces

6. Construction materials ~ Materials and thick:

ness of walls, roo’, ceiling, floors and parti

sive position in the struc

tions, and their

7. Susvounding conditions — Exterior color of

root, shaded by adjacent building

or sunlit, Attic spaces — unvented or vented,

ty or forced ventilation. Surrounding

spaces conditioned 01 unconditioned — tem.

perature of non-conditioned adjacent spaces,

such as furnace or boiler room, and kitchens.

ace, basement.

walls and 104

Floor on ground, crawl

8. Windows — Size and location, wood or metal

sash, single or double hung. Type of glass —

single or multipane. Type of shading device.

Dimensions of reveals and overhangs.

|. Doors — Location, type, size, and frequency of

Stairways, elevators, and escalators — Location,

temperature of space if open to uncondi-

tioned area. Horsepower of machinery, ven-

tilated or not.

People — Number, duration of occupancy,

nature of activity, any special concentration.

[At times, it is requived to estimate the number

of people on the basis of square feet per per

son, or on average traffic

Lighting — Wattage at peak. Type ~ incan-

descent, fluorescent, recessed, exposed. If the

lights are recessed, the type of air flow over

the lights, exhaust, return or supply, should

bbe anticipated. Ar times, itis required to esti:

mate the wattage on a basis of watts per sq fe

due to Jack of exact information,

|. Motors — Location, nameplate and brake

horsepower, and usage, ‘The latter is of great

significance and should be carefully evalu

ated.

The power input to electric motors is not

necessarily equal to the rated! horsepower di

vided by the motor efficiency. Frequently these

motors may be operating under a continuous

overload, ar may be operating at less than

rated capacity. It is always advisable to meas

ure the power input wherever possible. This

is especially important in estimates for indus-

tia] installations where the motor machine

load is normally a major portion of the cool

ing load,

Appliances, business machines, electronic

equipment — Location, rated wattage, steam

or gas consumption, hooded or unhooded, ex

haust air quantity installed or required, and

usage.

Greater accuracy may be obtained by measur-

ing the power or gas input during times of

peak loading. The regular service meters may

often be used for this purpose, provided power

or gas consumption not contributing to the

room heat gain can be segregated.

Avoid pyramiding the heat gains from various

appliances and business machines. For exam.

ple, a toaster or a watfle iron may not be used

uring the evening, or the fry kettle may not

be used during morning, or not alt business

ET CET

PART 1. LOAD ESTIMATING

machines in a given space may be used at the

same time.

Electronic equipment often requires individ.

ual air conditioning. The manufacturer's

recommendation for temperature and humid-

ity variation must be followed, and these re-

quirements are often quite stringent,

15, Ventilation — Clim per person, cfm per sq ft,

scheduled ventilation (agreement with pur

chaser), see Chapter 6. Excessive smoking or

odors, code requirements. Exhaust fans—type,

size, speed, chin delivery.

16. Thermal storage — Includes system operating

schedule (12, 16 or 24 hours per day) speci

cally during peak outdoor conditions, permis

sible temperature swing in space during a

design day, rugs on floor, nature of surface

materials enclosing the space (see Chapter 3).

17, Continuous or intermittent operation —

Whether system be required to operate every

business day during cooling season, or only

‘occasionally, such as churches and ballrooms.

IE intermictent operation, decermine duration

of time available for precooling or pulldown.

LOCATION OF EQUIPMENT AND SERVICES

‘The building survey should also include informa-

tion which enables the engineer to select equipment

location, and plan the air and water distribution

systems. The following is a guide to obtaining this

information|

1, Available spaces ~ Location of all stairwells,

elevator shafts, abandoned smokestacks, pipe

shafts, dumbwaiter shafts, etc., ancl spaces for

air handling apparatus, refrigeration ma.

chines, cooling towe's, pumps, and services

{also see Item 5),

Possible obstructions — Locations of all elec:

tical conduits, piping lines, and other ob-

structions or interferences that may be in the

way of the duct system,

3. Location of all fire walls and partitions ~

Requiring fire dampers (also see Item 16).

4. Location of outdoay air intakes —In reference

to strect, other buildings, wind direction, dire,

and shorceircuiting of unwanted contami:

nants.

5. Power service — Location, capacity, current

limitations, voltage, phases and cycle, 3 or 4

wire; how additional power (if required) may

be brought in and where.

6. Water service — Location, size of lines, ca

CHAPTER 1. BUILDING SURVEY AND LOAD ESTIMATE

pacity, presure, maximum temperature

Steam service — Location, size, capacity, tem-

perature, pressure, type of return system.

8. Refrigeration, brine or chilled water (if fur-

nished by customer)—Type of system, capacity,

temperature, gpm, pressure

9, Architectural characteristics of space ~ For

Selection of outlets that will blend into the

space design

10, Existing air conveying equipment and ducts —

For possible reuse

11. Drains — Location and capacity, sewage dis

posal

12, Control facilities ~ Compressed ait source and

pressure, electrical.

18, Foundation and support — Requirements and

facilities, strength of building.

14, Sound and vibration control requirements —

Relation of refrigeration and air handling

apparatus location to critical areas

15, Accessibility for mouing equipment to the

final location — Elevators, stairways, doors,

accessibility from street.

16. Codes, local and national — Governing wi

drainage, water supply, venting of refrigera-

tion, construction of refrigeration and air

handling apparatus rooms, ductwork, fire

dampers, and ventilation of buildings in gen-

val and apparatus rooms in particular.

AIR CONDITIONING LOAD ESTIMATE

‘The air conditioning load is estimated to provide

the basis for selecting the conditioning equipment.

It must take into account the heat coming into the

space from outdoors on a design day, as well as the

heat being generated within the space. A design day

is defined as:

1. Aday on which the dry- and wetbulb tempera

tures are peaking simultaneously (Chapter 2,

‘Design Conditions”.

2, A day when there is little or no haze in the air

to reduce the solar heat (Chapter 4, "Solar Heat

Gain Thru Glass").

8. All of the internal loads are normal (Chapter

7, “Internal and System Heat Gain”)

‘The time of peak load can usually be established

hy inspection, although, in some cases, estimates

must be made for several different times of the day.

‘Actually, the situation of having all of the loads

peaking at the same time will very rarely occur. To

be realistic, various diversity factors must be applied

ED 11 conattioniog Company

to some of the load components: refer to Chapter 3,

“Heat Storage, Diversity, and Stratification.”

‘The infiltration and ventilation air quantities are

estimated as described in Chapter 6.

Fig. 1 illustrates an air conditioning load estimate

form and is designed to permit systematic load eval

uation. This form contains the referenecs identified

to the particular chaptersof data and tables required

to estimate the various lozd components.

‘OUTDOOR LOADS

‘The loads from outdoo's consist of:

1. The sun rays entering windows — Table 15,

pages 44-49, and Table 16, page 52, provide

data from which the solar heat gain through

glass is estinnated.

The solar heat gain is usually reduced by

means of shading devices on the inside or out-

side of the windows; factors are contained in

Table 16. In addition to this reduction, all or

part of the window may be shaded by reveals,

overhangs, and by adjacent buildings. Chart 1,

page 57, and Table 18, page 58, provide an

easy means of determining how much the

window is shaded at a given time,

A large portion of the solar heat gain is radiant

and will be partially stored as described in

Chapter 3. Tables 7 thru 11, pages 30-34, pro-

vide the storage factors to be applied to solar

heat gains in order to arrive at the actual

cooling load imposed on the air conditioning

equipment. These s:orage factors are applied to

peak solar heat gains obtained from Table 6,

page 29, with overall factors from Table 16,

page 52.

2 The sun rays striking the walls and roof —

These, in conjunction with the high outdoor

air temperature, cause heat to flow into the

space. Tables 19 and 20, pages 62 and 63, pro-

vide equivalent temperature differences for

sunlit and shaded walls and roofs, Tables 21,

, 23, 24, 25, 27, and 28, pages 66-72, provide

the transmission coefficients or rates of heat

flow for avariety of roof and wall constructions.

3. The aiv temperature outside the conditioned

space — A higher ambient temperature causes

hheat to flow thru tae windows, partitions, and.

floors. Tables 25 and 26, pages 69 and 70, and

Tables 29 and 30, pages 73 and 74, provide

the transmission coefficients, The temperature

differences used to estimate the heat flow thru

these structures are contained in the notes after

each table.

a PART 1. LOAD ESTIMATING.

mel REFERENCES i i

au TABLE REFEREN: TABLE FEFEREN

SaUanTeais=auesr | iss Secure

3 | couse” won Saree pagent x Tas 1007 | coworrions | ea

a | Dosa sromer “sorrx HESS SS nessa | 2

4 veneer nm Tai 1 com puree tnx tee exe

Og SOLAR © TRANS. GAli Yen] —— wo aon

s | mens ea Ata omer

TRANS GAIN-—EXCEFT WALLS © ROOF 4 .

WEINAE WEA —

ESAS x ae neg tt (Table 26, page 70) = 152109 f floor area Foe 28 og (Fatie29, page 3 = 29.5 Ih'sq ft floor area pace) soxa0 Celing + 22 cosa (Table 29, page 73) 296 Ih sqft oor area pes NOTE: One-half of the paxtition, floor and ceiling thick hess is used. ssuming that the spaces above and below are consitioned snd are utilizing the other { balves for stone of heat, ‘Total sceight per sq f¢ 0 for area 52+ 1524205 429.5 = 97-4 Taig fe TThe overall factor for the window with the white venetian bind i 0.56 (Tabfe 16, pge 52) and the correction for sel ssh =1).85 A, Storage fart, 4 pam = 046 (Table 7) ‘The peak solar heat gain for a west exposure in July at 40" North latitude = 164 Beu he}sq fe), (Table 6) Actual cooling toad - i Acasa cooling load = (tno fy) a0 0 Bh Table 12 is used wo determine the actual cooling Toad from the heat gain from lights, These data may also be used to deterriine the actual cooling load from: 1. People — except in densely populated arcas such as auditoriums, theaters, ex. The radiane hheat exchange from the body is reduced in situations like this Because there is relatively less surface available forthe body to radiate to. Some appliances and machines that operate peviodially, with hot exterior surfaces sich ‘ 5 ovens, dryers hot tanks, et NOTE: For Items 1 and 2 above, use values listed for fhuorescent exposed lights. CHAPTER 8, HEAT STORAGE, DIVERSITY, AND SI Example 2 — Actual Cooling Load, Lights and People Tine same roo as in Bsampte J with a light heat Swati per a ft of floor area not including ballast, exposed in of RATIFICATION 1.28 Solution “The time elapsed after the lights are (am. to pm) orned on is 8 hours Storage load factor = 87 (Teble 12), fiuoreacent fights and 4 people, The room temperature to he faineained at 18 F aly with 26-hour operation ducing the peak load periods Find The actual cooling load at 4 pam. jive at 8 a.m}, Sensiile heat gain from peosle =215 Bahr (Table 48, page 100) Actual cooling toad (8X4 18520 20) + (A HC215) ] 87 = 5190 Bru hr with the lights eomed on asthe peopl TABLE 6—PEAK SOLAR HEAT GAIN THRU ORDINARY GLASS* Bru/(hrifsq ft) EXPOSURE NORTH LATITUDE ; eae reine SBE : im : tar | Monti wepNe]® | | s [sw Nw [Were Monta tar ' °° Btaten | to | te | ter | rte | te Mie | Ho | sgefebtorn ee Reale a) 3 | ls rales eee Ly % ne arn a pee 163, dune ¥ ie 3 | i 3 seit | 20) | ‘ete 90 | 39 | 250 Dee = June | 162 Dee | 40° | aunties” Wi tiie] seater | 40 28 SET ee aT | + Saboroved trom Table 15, page 48 se lin Sous latitudes cons prety of alts rein whith eer {Soler hast gan on North expovre (it Nort tudes ron South expor rarege forthe 12h period (8 am to 6 pin). The erage ay fete toughest te day The stor heot goin values for tht expanse ore the 0 PART 1. LOAD ESTIMATING 13 TABLE 7—STORAGE LOAD FACTORS, SOLAR HEAT GAIN THRU GLASS Wii WeTERWAL SHADE 24 Hour Operation, Constant Space Temperaturet wocwm | att oa ara Ti] prose mom tay | stteoove! FT Tel olelnpalapalelels[ellepsperefeiayapeye] Sones nwareor | vee |%al0 ae 90,230 onlay] ac as cool an cfs] somauw pea aa (2m alam al ale ee 6 | 39/36 a ann Fianna saxon “ fal 30/909 at), i ae(ea[orloor ol ololece le] To acm fea] a0 aa las 14a aoa aon a5 seuthon ee 00/28 aan a7 as ar 3/5) 1244 an |08 97406 0s oe c/93] —Nonbaee we __|o sols7/ 95) 0¢ 0 [av 26 [05/4 a3/sa|ar/e [ole joe [a Taam [ow a an 1 ola aaa ar ast ato es PB faeS oe tl Seale Se Seon an anon aan ae | 08/08 | 0% .10).3 [83 63 66] 60 47) 29/9/18 16) 14 13) 08 |07] seumwe a on oan 35 6| 30) uso] 26|30|.ar 199k a6 08 | $a eles or fo ln a ole 1 a] or 0 va [3643838281976] afm [a a wa | oiniale maclaasaisil iene eaely, | ooloelae a 30 [a2] 35a |as|n aap aoa an as ah .08 |.09 10) 10 10 .16).33 |49 61 |.60/.a9|.17/.15/.19 12/10/08 |.08 08 07 06) sce Paraeded te uae aaa a alg al oy ae aPae ae ee sooo ic3 a3 or ce 10 [390,028 1012 on Ls 8 [an ot ioe lag fo asa a|oe at aalaglageig aes aa faae ag] Sh mn joane os 96 ou 98990 a6 a2 08 [08 04 [os 02 on oh ats Eauotion Costing Load, Bt = [Paok sla heot pain, Bu/tl lag Hi, (Toble 6) he Weight per 4g of fo x [Window ares, v0 8) % [Shade factor, Maze factor, te, (Choplr % [Storage Fodor, (above Table at dese time!) ld on the imide of the glass nal shading deve is ony type of shod le factors opply when meintining @ CONSTANT TEMPERATURE in the spose during the eperotng period, Where the temperature it sllowed to swing, edditonalstorege will result during peak lood parieds Reler to Table 13 for aoslcate wocces hoon 1 Wolls,1b) + 4 (Weight of Partitions lor ond ior Area in Room, 49 Room on Bid Exterior {One or more oui wal) = 2H Weigh of Fortion, Floor ond Celing, fb) (Weight of Ounide Walls, 1b) + (Weight of Fler, Floo: Area in Boom, sq #1 Room in Bldg Interior No tide wall) = semen Reon (flor on grovnd) = \ = (slab of Oude Wall Potions, Flos Favre Beltdng or Tone = ‘Air Conditioned Foo Ares, s@ #1 ‘With cg on floor—Wight of loo ould be mulipied by 0.50 10 compensate for inating effet of rs Wigs per 1g fof common types of construction ae contained in Taler 2) thr 33, page 66 tre Yo ing) A (Wig of Parton: ond Ceing, Ib) 131 CHAPTER §, HEAT STORAGE, DIVERSITY, AND STRATIFICATION TABLE 8—STORAGE LOAD FACTORS, SOLAR HEAT GAIN THRU GLASS WITH BARE GLASS OR WITH EXTERNAL SHADE? 24 Hour Operation, Constant Space Temperaturet ret oe aes = mt soot 22] 20 [10 i aiehe = 19 | a7 33 37.15} .04].13].12) ~ Taso 8 ever [11.10 10.20 |. a9 |.36 [143 |47 | 46 |40 34 Jae |e) .14).r3[.02 woven | ae Th Rialelals als See eT] sommes ae |e ou fi ae as [a [70 an | 25 aetna Tie waver fon nn ar fie too 0)9 ae Lay |ae| a ee 3 | [aaa oe ee ee we : Se [08 5 850s [or ar ae na |p [a ar | 70 59 2slde [tal ae as [a0 a ever [10 [10 a0 10/10 \10 j20/ 10.12 [17 [25].94/.9 [34] 26 26 |as|.a0|ae 16|.24 13.12/10. onmowest ios" Yon ayn Lan ov lan on| an La [19 |30|40 a a0 2 jae ante ta a0] 10)68] Sean ‘er (at [oe er (an [oe (001013 27 | | 459 10] or os | 09/02/01 Neat aoe over fie jas oy ar a [se 7 fan fon jon 727 sp Lat [as a [a7 Lae ay [a7 2829.21 | “ see Lar Lap cat star (an au [70 [70 [vu [rm a0 aot Lat [ara ajar [202 ne ts auoton: Cooling Load, Btu/hr = [Pak solar heat gon Bu/br (9 fl, Teble 6 x [Window area, sq) 2 [Shade festor, Haxe factor, et (Chapter 4] % [Storage fastor, above Toble st dented tne] cor shaded by externa projections ore store gle — Any window wit ne inside shading device. Windows with shading devices onthe ou tenidered bare gloss thew factor apply when msintaining © CONSTANT TEMPERATURE ia the spoce during the operating period Where the tempercture i Thawed te near additonal storage will rvlt during peak load pends. Refer to Teble 13 for epaiable factors {Weight per eat eho ide Wels a oon, ea en tg eno nee Foe arms wa = he af Yo sta 7 1 (Wein of Por oom in Bldg Interior (Na outide wal) = a ee Weight f Ove Wat (Wag of borane Ron fer on rena ~ (SANS Ould Mat Wei (Weight of Outside Wel, Parton, Foot, Celings, tol crate ng or ee ihr Candioneg Floor Aree, 5a ft With rg on floor Weight of flor sculd be multiplied by 0.50 fo compenssie for imutng effet ofr Weighs periq ff eommon typeof contrcion ore contained in Tables 21 tw 93, pages 66 thre 76 { i 132 PART 1. LOAD ESTIMATING TABLE 9—STORAGE LOAD FACTORS, SOLAR HEAT GAIN THRU GLASS WITH INTERNAL SHADING DEVICE 16 Hour Operation, Constant Space Temperature cxrosum | anieertele am oe pear Pe Sanat exrosune ‘Merm tery | ettiecreres) TST Ta [el] w][ujwiilala[*l#l|+[7jeje| Semin ceed reese cle ae a ala | 26/20 [0 lar as |] ao | ov oe ww | Ma) sls ARE S| we ula |as ss || j2 2 tals aonb. z i i | Wa | a9 | ae ot fe oa — [ie Al fe S| tonne 7 ae i ae nse 75 Te a ( Equation: Coating Loos Btv/ir = [Pek solar heat gain, x [Window area, qf] % |Shoue fect Haze factor, ete, (Chapter 4) % [Storage foe, (above Toble ot deaed tne!) “tieral shading device i any 1yB# of shade looted onthe inde ofthe glor ‘Thee foctorsopely hon molntining © CONSTANT TEMPERATURE in the space during the operating pered. Where the temperature is ‘during peak lood perinde. Reler to Toble 13 for splices soroge focor. lowed to suing, odaitonal storage mill Weight per zg ft of 1 (Weight of Ounide Well, el Ls (Ws Fleer Aree in Room, 3c f (Weight of Portions, Hoar ond Cen, Ib Room in Bly ntvor (No outside wale) = Fas ana see ons Flor ond Ceting, ib] foam on Bg Exterior (One or more ouside wal (Weight of Oude Wath, 1) (Wag of Fr bl = Ye (Wai of Pr Bosenem Room [Hooton ground) = 0M st Cute. Is) (ign For ” Weight of Ouside Wall Portions, Floors, Clings, Stuctral Members and Sippets Ib ee eral ‘ir Condhioned Foor Ares, qf Wins ug on floor—Weight of floor sould be mulied by 0.80 to compensate fr inloing eff of \Weigits per sg fof common types of contution are contained in Toler 2) Th 28, pager 6 try 76 a CHAPTER 3, HEAT STORAGE, DIVERSITY, AND STRATIFICATION 1.33 ) TABLE 10—STORAGE LOAD FACTORS, SOLAR HEAT GAIN THRU GLASS WITH BARE GLASS OR WITH EXTEINAL SHADE 16 Hour Operation, Content Space Temperoturet inert te ether area) TS Te Te lw[ nial: [2[>[e[s[e[r7[elo (Goeth tes) ao ) = lala or = [Pook olor boot gain Sth) (og fl Tobe 6 2% [Window oreo, sq) % [Shade factor, Haze fete, et (Chapter 4] % [Storage fosor, (above Table ot desied tne) Fauotion, Cooling Load, tore glo — Any window with no inde shading device. Windows with shading devices on the outside or shaded by exterel proietons ore ‘comideres bore gst. ‘Thome factors epply when meintaning © CONSTANT TEMPERATURE in the spoce during the operating period. Wh the temperatre i Cnt ee eee Soh dong pet ood peads eere Toh 13 er apple veces fo veg per se tor sigh of Oude Waly 1] +3 (Wegh eect, Fer ond Clin, roam on dg Enter (One mor nie wot) ~ sitll Ou n+ fg Pron, Foro ag BY | Ineror (No ouside wats) = 2S ght ef Paritions, lose ond Celng Ib) Floor Ares in Room, og ft fe Wott, tb) + (Wight of Foor, b) + % (Weight of Paritions ond Ceing Ib) Foor Area In Boom, sf 1s ond Suppers bl sig ot Joment Room [Fearon ground) = (Welatt of Oude W. Fetiion, Hoo, Cains, Sracarl Me ae “hi Condiioned Fsor Aree, 23 ft ‘Wit rg on floor Weight of floor sould be mulipied by 0.40 to compensate fr ilting ater! of rs. Weighs per sa fof common of consrution ere conined ia Tables 21 thre 83, poges 66 hry 76 nai Lot PART 1, LOAD ESTIMATING TABLE TI=STORAGE LOAD FACTORS, SOLAR HEAT GAIN THRU GLASS ( 12 Hour Operation, Constant Spoce Temperaturet rE HABE [aan oat Om BevmAT BHATT weonTh SUN TIME exrowure | thpersae exrorune (eon ah | ot ere ra - mm (eon te ray ; wimp [2] 2[* nfeli] a] ay eys oe $y e/a ea a a Sf aaa te $3 ay 7a [a [aoa] aoa] at 33)e{39| (| a8[2¢] cow $374 42 |a0 [5 |49 | 25) at 54.99/28] 23) 18) 18/12 i at 907422 aa s [areal a] 130] aa Scone 9 35, 67096 2 69 a7 a South 26 22 3831 |e4 73 51 ].31 44) 37 |.3 43 North y 2 ana a0 3e 36 30/28 38 ane ‘fap ar ae ts [lara n “ere ha a8 39 [07 a 8 2 (a0 a7 as 29a a0 aa 8 echt ah ar ae [a at a 8 3s ah| [as 38] seamen le (ant ao fe 1a 8 ae aul a7 oa, 17/ 30 a0 ae ve 8 |e nee [98 oe 8690 96. se|.06 [25 175/79 9 ae asap a1 2 9990] down ( 98 36 98/98 [38] sa] 96 90 9681/4, 86 a9 91 93 9304 94) 95, 9898 = a es oe 7 shee [Peck olor heot goin, Bt /lh) (eq, (Tale) 2 [Window area, 1a % [Shade fstor, Hose fotr, et (Chapter 4] % [Storage fosor, (obave Teble ot desired tine) Equation: Cooling Loc ‘inert shading device i ony type of shade le {boce glass Any window with no inde sheding davie, Windows with shoding devices on the ouide or sheded by external projections ore ‘camidered bore glass ‘Thats fetes epely when maintining o CONSTANT TEMPERATURE In the seco during the operating period. Whare the temperature Is ‘lowed fo sing, Sddltionel soroge wil result during peck lood periede. Reler fo Table 13 for epplicoble storage Focor Salah per sgt of tof Oude Wal 8 + 1 (aight of Prion Het ord Cetin, ) {oom on Bde Exterior (One or mee eid wa) = ht 2 il of 14 Ig of Pantin, Fe and Csig fom in dg ror Oe cuide wo] = SS ee Weight of Oude Wolk, B= (Weight f For, i + % Wei of Partin: nd Cia, Sorement Room (Fear on eran = © ca ae eo (Weight of Outde Wall Partition, Foot, Catngs, Stctral Membart and Support, ‘ir Conditioned Poot Area, 9 ‘With rg on floor—Weight of Foor shold be mulinied by 0.50 Ye compensate for insulting effet of ra Weighs por sq fof common types of eoncucton are contsined in Taber 21 thw 33, poger 86 the 76 EnireSuiling or Zone — CHAPTER 3, HEAT STORAGE, DIVERSITY, AND STRATIFICATION 1.35 TABLE 12—STORAGE LOAD FACTORS, HEAT GAIN—LIGHTS* Lights On 10 Hourst with Equipment Operating 12, 16 and 24 Hours, Constant Space Temperature raul Sree: | | wetours NUMBER OF HOURS AFTER LOHTS ARE TURNED ON Anion | pera | ANON | Wesson [o]a 2] 24 [2] e] 7] ]» [eo] nv [ra| [sve [or [ia] vo [20 [ay [na [a | al Teo @ over [ar] ar|zv] | 70) 79| 80] 03] aa 96] 7]29] 26 [20] 20].19|07|.05] 24) 02] 1 [10 [08 oe i | 24 too [31 a7 |72| 74] 791-81 [89] 95 97) 80) 90 30 | 26 (2219 16].15 13] 12) 10) 09/08 07 [06 i 20__[25|7403|08| 91 94) 96] 96] 90] 989087 12060) 06) 09] 92 01 or] ar] 0 [eo : Toa over |.s0|02] 40] ae| ae] 2a] as] 05.2.0] v0 |22).2e [a5].20 | rr] 2 | 6 100. |-46| 79 44/86] 87/96) s6| e9| 29] 30] 90) 20| 26 |22].19\6) || | | : 30.29] 77 [as ae 9295) 9] 56 90| 90) 99| 2617 12) 08 [os | i 130 a over |.43|90) 911 93|90| 96] 95] 98] 99) 96) 0637 ] : | 12 too 1 92) 94|94| 95) 95| 96] 36] 97/36, | Vy ryt yd 30___[az_6|91,93| 95] 97_98].96) 99.99] 97/26] | ee sete ae Toa eww fat zal 63] 70170) 77] 79] ans an] ae lave |as|ae| aol vel va|as va foa $,,| 24 100 | 24/56 63 68) 72/75 78) 20|-62].84) 86 | 40].24 29/25) 20).18|.17).18].14)12).10 j09) 08 ate 30 17/65 | 77, 84] 88| 92) 94) 98|.97| 98| 96 .35]23 .06|.11 .07].05|.04) 03) 02] 01 01 |0 | 0 piigh : | Be Tse & ever |. 78 [791 0) 00|a1| #2] c0| eu] -e| 07 |a9|a5 21/20 as | gilt) 16 oo |'45) 73 \7e|-82|82 2| 89) 04/25, 07/20/40] 36 29/28 20 | ie8 30 22-49 80 88 89 92.94] 95|.97| 96) 96).38].28 06 .11 07 | ai too nover [or|te an) a0|n | 92] 93] 9s|95]s0) | i 12 too | se) sae |a8! 90) 92/90] 24|94| 94 98].a8) || | at ‘0 _[al.e1 26) 91/.93 98 97) 97/ 98] 99] 99) 38 Lit | soe 150.8 over 29) 33/.41|7/.52/ 37" 45) 69] 7a] zal se| 32] ae| 02] 37] 24|.a1| 27/25] 29|.21 [18] 04 Beh | a [seo [ran ae sore al 2 27 eo} at 792} 27/9} 2] voc] 2 Hy fe [0 ae ae, 70,8227) a0) 99] 45] 97| 9) 52|24| 24! 26,01] 07|05| 04] 02] 02] 01 [0 | 0 $325) | 150 & over |s7).e4/0 72) 73) 78|.74| 74] 75| 76) 70.09] 52 4s) a2 37 252) 16 too” [irl so ar 7274 77 76) 70 80) a1) 02/ 40] 3444 7 22 die ‘3>__[-07| 33 0| 70 aa) e6|:1| 93 95|97| 90] se] a4] 24 te] i2ty ar t 44 ie Twos ww |75)79 2524s] ae] 9/01| 9) 11] 25 j 323 12 100, 166) 77.81! 24) 86) 88| 99) .99| 92] .93] 93) 72) zs 30 34) 72.02) 8) 95) 95| 97| 98] 98) $2 L | L Trae Toson Spy wien Babating © CONSTANT TEMPERATURE In tha apace cing the operating period, Where the Temperature is allowed 12 Wit gs operating {highs On crags wil out suring pook load periods. Refer fo Teble 13 fr me nomber ot hous athe tine of equipment oper Occsinoly edusinens may be raged to take otcoun of Kits The flowing the procedure toad he lod fectors [ALWITH UGHTS IN OPERATION FOR SHORTER PERIOD THAN 10 OURS ond the equipment operating 12, 16 of 24 hous ot he Hine ing fr 24 hour 2 Uwe the storage load fairs ov ted up to he fine the lghs fore onal of bs. St me foad factor beyond the 10 how fon the right of eary ine] to the ff tothe haut the fights ore fred of This Teoves fst few hovrs of equlpment operation without osignoted load fetore . Enropolte the los few hour at the some rte of raguction Shine and hours inthe tle 2. Eavipment aneroting fr 18 hows crfollow ine procedsre in Step 1 ng the erage led fotor ‘oles in 24hour equipment opertin robe, bs. Now tonsa © new ssh of lo0g forors by adding the new Toives for the ish hour fo th denoted 0, 1718 hor Ho he Tar hour, te TABLE 15—SOLAR HEAT GAIN THRU ORDINARY GLASS (Contd)

30° Btu /tn (fsa oe) 30°

3oNOR TATTUDE [AM con Time tae SOUTH caTTUDE

a a A CD

ert aaheresl sta] lal als Tout

Nera Fae | ey Psy yey a] Shaan

tor Tepe (et el eet ied il tad te

Be ee eta te

sine n | Soe alr el er ay a al el els vec 22

seit | ELL ET LL Al Lal ol ae i

Seat Se te

Ww sf] ef ala] alas) | | eaten

peas [ST AL EF [aed ts | to asso 29 [a ie

North Wy io) 4] 3 Tay 14 | raf ie] os ‘South ~

[Rete (ee het al a] ols] if ele Sete

vor ns (Bote Lee Led ee at sd ned aed ot at het | av ar

Se SS ee ea

Pee Srey ey Sl ela wl] el al a] seme :

[ss | EL SELL SLL AL SL Sli Lael ood | Neto

vaya Pee SS eee phe nor a

Nocthwost 4] efi] 3 (4) ta | te] 48, 31 | 93 | Southwest

eto Lady hed [fate tt ate [att 21 | fete

iat See ea ae aT a

Neha | sfeotlual of ay al tel ay E elgilaesee

ave | Est sacs med sshd asd i eto td oh a aes reo

sta Se ees oT ey Secor

a | Sen reer al el otal ale a ala) wn a

sy AT SLATE RTT SLB Lido || of Lat | Neto

anno [at Sh a a ee eer aera | we cers

Worms [oa] sll abcd ial tah isl a] se Pee] oe] 22 | sectent

eos [BLS] dh asta | tS and [a | S| ieee

ar SSpep epee ay + fea

Ne | sal Stal el al eles S| Se

seman LB Se eke al Le 3 ee Man 2

fe — Eee ey ae ancl

« [Eun 8) eyes] sal se] a] oe | ss 3) ear 1

seat SL SL ial eel aL als Lat oN at

van me PSE SR a tet

Www | of sl el al ali sie BT ew |

Horizont of} 25] ai | 135] 179 | 202] 202 | 202 0 | Horizontal

ar ape ay ae

Pete |S] ata! el a] a oY Seta

corn | Br Sel alas ele of es wen 70

St SSH eC op aad

| sea A oY Nene 2

1 ceeee re |Bleral ay Ao

ram [wet gape oe nue

Wee | of 3 ay ul al a OT et

Newry [BL afb Laso| aal S| seems

aa ope ap iy =] Seah

Rete | 8) etal 3] ula | 9] et

wovar | pat of tat lusl gl el etal Ts S| es way 2

See eee ree $A

. [ee SY tap ae] ef ee] ee] oe [ise] | ST Noa :

ery | OL SL EL OL Lee] me iS a Lier Le Lae | 6 | Netto

aan Pee CE Ea eye suey 2

[resort | ool t[e] af] 2] 2] 2] fs] te] “3] 0 | Southwest

[etiam [8] sf 8] tfbe Lt] ad fst | of L$] 3] 8 | Bo

The SET aT aT ar eT ee

rereae (3) tt st la] al al ul | a) 3] 8] sete

re 31 et hiatal SL ett ul sts] S| ol em

SE See aT Faye] oT Rea

vec 2 | soon oy eres ceeds] e[uste| eo] o] meme | sunens

sean ST SL ap ae eS Ta [is Led 1 gL ete

aaa SL epee ey ape] ed

Weve 13) ot at st al ol el al al] elo] s| sete |

Neteret 1 8) 8] tf ol ssl at [al se ol] 3] e| secon _|

eat Se Deep aaa

soir enn | SSR Hee Aitiode | ogo ah o | ann Seam a

» onection | yes eri? | —1S% [Mant | 40.7% per tooors | “Fis peri0F | = 7% per tor

ED + consenng compar

40°

PART 1, LOAD ESTIMATING

TABLE 15—SOLAR HEAT GAIN THRU ORDINARY GLASS (Contd)

Bru/(hr) (ea ft sash area)

40°

er NRTA ATU _[ A TON TIME aa] SOUTH LATTUDE

Se ee

Tors spapal bal wpa «| el 2] 2] 2

went FRR BY ss] ey ie] a) a) By ef tafe

fos pa ee

get ep ep ey ep ee) ee

une at | Sook tT ers Mel se] ual aa] ue] os] to] te] wo] osc 22

te | LLB LBL il tal Se] i] elit bioe| ae | st

st Sh aie aay ef re Poe

Wee | ot 8) al ol] toe) cs] oo a3] te fed ie

Notas [EL 12] 22 [ao [aid attrat dana aia |p | Se PRED aT | orzo

SE eet ey ey rey] ay ed 22] seh

elisa) acl sel el is] te] te] B] te] io] 7s | Seetteaw

wu 2 vos |r gee ae] SL edad el | | io § | ae Jan

ast eh ss ae ep ap ay toy | Neate

* ser ol a) el al el al e| | 5] to] 3 | Nem ‘

spit Lael se] 42) Bt sl tol el ue] sel st | Netheen

wae a1 [Wat Spock af at eh ei breed rer re] West Nov ai

Sat el el tal aa] tel ts| | sole] ar ioe | Sethnase

2a AS] fabt La | an8| att Jae [zs | St ae] 3 [!9¢ | ero

capa ep ep ey ey ye] 2] Seth

feet eR) Py cll ef Bln] a] a | utes

nue soley ele al uel tel el aL) alt eee ea 0

Sete ee ST TT eT None

‘ TPOSTETP TST aoe | a a] at] | 8) 3 | Nok ‘

af 3) eS a Su 2 Lito] se] cd al oe | ae | Nemes

aon ze vie 3h BE ae iors ieey rer ee] et ocr 2

Wns Lot bl til tal isl tal te] is] te] se] e2| l02| 2 | Seuthoast

Neathwast | 2] $1 sto | 28) wz ata |b) ves | 50 100] 47 | “9 | Heras

Tort a aL aay ayy 2] aye) ] seat

rot | OL tas) a] ol a] celal 3] | 3] ] 3] geuteaw

serra | fa gy zl otal isl oll at st $18 | eae MAR 22

ee Tey eT eT eT ae

a | sean 8) fe) ac PH tela] oso] vel ei] a4] 2 fo] Now &

cee LO Z| a Gal el “al “ae [a] tp Luer ise] 35 | 8 | Nertteet

wana Wat Sh ea RR aerate Tie} | We serra

Were) ot al shal alc) ela] cal ae] a8] at) & | exthea

Nomis |S at | ob [ize] oss one] os [vo] os [eee | 21 | 0] Horace

fer ae a aL ayy ys] fe) seat

noth Po) ag) a] | ul ol 2] a] ij to] | 2 8 | Seitheen

ocr | fat BL eta] al ol lal ul el ol 2 ot be arn 0

Lp EE PP any toy et 0 Nene

a | Sou OP Pisa | es tee [see] oe] oe] 21) 0 | Now 2

seat | 3) 2] Sa] '95) bol "Sl tor [Nesp ton] et st] | 0 | Netheen

ream [Wet ghee seater asp] wer wus;

Were To) al al ol ul il | a) ul ve] 33| 35] 2 | Souhved

Neonat 2] 21 of | eS] orf sais [aor] | | “e] 0 | Hest

enh eT ay ay 3] ey 8] sor

Noe | ot hazy a] cl al ulin) a] [3] 8] 8 | Seutouw

wov 21 | gat ol ole laoel os] sol | tol a] of 3] of of Bee way 21

tear gh eae eer ey aT 8] OY err

a | eu 378) fice] fee] estat] ie] we] os so] 9] 0 | Non *

cag |S] 9) 22 [| | Saeed tel eel tee oe] Of 0 | Netvae

van ar Par + Sap eye et 0] | wet aur 2

Warne | ol ot a) a] st ml uf ie) a] | 2] 8] 8 | Seutheen

Neate | 81 Sh 2] al oa sol ce | or) [| ie] 6] 0 | Heracot

Non gee ey aye) ap 2 | Seah

nowt eT ] gy 3] | al tol tol io o| 8) 2] 9) 8] Sethean

i Sloot th atl ol tt vel wok at gl a} ol 0 faa

Shecar Satta Te aT aay STP] Rena

ore 22 | South Sy Sf Se (ze] tal ice ws fice] ve] se] st] 0] 9 | Nea JUNE 21

th | OL SL) SSL Sn) 5 tee [ter] tae ie] el OL OL Nets

at ap eee oo a

Were To) os) at cl a) io) iol el | | 2] | 2 | Seuttees

newt 1 1 2) 2] 8] ob] rel oslo] so] oe] 6] 0] 0 Hovawnta

Steel Suh a Devnet Dewpoint South

sel Guin | SNCS Mow Aiade oraon are | neat Bom 67 | Stee, en.

fon | ac astrin | iss tment | +07% per 000 rotor” [MEW porloe | OSH

sold Fac Values — Monty Masnums Bowed Vous — Yeu mosimare

CHAPTER 4, SOLAR HEAT GAIN THRU GLASS

) TABLE 15—SOLAR HEAT GAIN THRU ORDINARY GLASS (Conta)

50° Bru/{thr} (eq ft sosh orea) 50°

SNORT LATTE [A SUN TINE maw Foe oaiTOve

Northe TH1125] 94 | 50] 16] ia} 14] is] is] 3] 12] 10] 8 | Southeast

SEPT 22 |_East of ior {ize |i | 93] 43} iz} ia | 2 a] 4} o MAR 22,

) erection | xc NSH 7 | —1s%y (Man) | -+0.2% ner 1o00Ft |e Teper tOF | Te per tO sia

Valuos — Youty maximums

Bold Face Values — Monthly Mi We

EBD 1 crettenngcompeny

ee hee

wo

em

See Heat Gain to Space

econoeo £521) $ABR

138 Ror 61K

Ly

big, 15 — Ruactioy os Stan Heat (R), 528% Heat

Apsonnine Gtass, 30° ANGLE OF INCIDENCE

ALL GLASS TYPES — WITH AND WITHOUT

SHADING DEVICES

Glass, other than ordinay glass, absorbs more

solar heat because it

1, May be thicker, or

2. May be spec

dheat absorbit

ly treated to absorb solar heat

glass).

‘hese special glass types reduce the wansmitted

solar heat but increase the amount of absorbed

solar heat flowing into the space. Normally they

rellect slightly less than ordinary glass because part

of the rellection takes place on the inside surface

\ portion of heat reflected from the inside surface

js absorbed in passing back through the glass. The

vera effcet, however, is to reduce the solar heat

feain to the conditioned space as shown in Fig. 15,

(Reler to Hem 8, page 51. for absorptivity, reflec

tivity and transmissibility of common types of glass

at 40° angle of incidence.)

The solar heat gain frctor through 52%, heat

absorbing glass as compared to ordinary glass is

GAR/.88R = .728 or .73. This multiplier (78) is

tised with Table 15 to decermine the solar heat gain

thru 52%, heat absorbing gless. Multipliers for vari

‘ous types of glass are listed in Table 16.

The effectiveness of a shading device depends

on its ability to keep solar heat from the condi:

tioned space. AMI shading devices vefleet and absorb

4 major portion of the solar gain, leaving a small

portion to be transmitted, The outdoor shading

devices are much mare cifective than the inside de:

ices because all of the rellected solar heat is kept

‘out and the absorbed heat is dissipated to the out

door air, Inside devices necessarily dissipate cheir

absorbed heat within the conditioned space and

ial,

PART 1, LOAD ESTIMATING

Heat Gain to Space

Sedo x19 Ry + (7 FT RY + (IZ TT RY

(08.51 TTR) + (40.15 X 1 TTR)

= 42 Ror 49 R

Fic. 16 — Reactios ox SoLak Hat (R) Yi-aNcte

PLATE GLASs, WHITE VENETIAN BLIND, 30° ANGLE

or INCIDENCE

ust also reflect the solar heat back through the

glass (Fig, 16) wheveir some of it is absorbed. (Refer

to Item 8, puge 51. for absorptivity, rellectivity and

transmissibility of common shading deviees ar 30°

angle of incidence.)

The solar heat gain thru glass with an inside

shading device may be expressed as follows:

= [bie + tens ta ates + Aaat]

where

(= solar het gain rospace. Brahe #)

{Gar lone mena Ba Gin), Grom Fable 15)

Ssh asorpaie

car sefectity

ai

shating device

5 = camerson factor 0m Fig 2

R

8

Pa

rc

For drapes the above formula changes as follows,

caused hy the hot air space between glass and drapes:

R

ates + aero]

Q

ae

Dhag te (RFAna + ta

The transmission factor U_for glass with 100%

drape is 0.80 Beu/ (bri (sq fe) (F.

The solar heat gain factor Uhr the combination

Fig. 16 as compared to ordinary glass is 49R /.88R

=.557 or 56. (Refer to Table 16 for Jj-inch regular

plate glass with a white venetian blind.)

eae:

CHAPTER 4, SOLAR HEAT GAIN THRU GLASS

NOTE: Actually the reaction on the solar heat reflected back

Inrough the glass from the blind isnot always identi

fal to the Rist pass ae assumed in this example, The

first pase hraugh the glass filers out most of solar

1s to be absorbed! in the glass, and the

the

radiation t

Second pass alors somewhat les. For simp!

reaction is assumed identical, since the quantities are

hhormally small on the second pass

Basis of Table 16

‘Over-all Factors for Solar Heat Gain thru Glass,

With and Without Shading Devices

The factors in Table 16 are based on:

1. An outdoor film coefficient of 2.8 Bru/(lw)

(sq ft) (deg F) at 5 mph wind velocity

An inside film coefficient of 1.8 Bau /(hr)(oq £)

(deg F), 100-200 fpm. This is not 1.47 as nor-

mally used, since the present practice in well

designed systems is to sweep the window with

a stream of air

4. A 80° angle of incidence which is the angle

au which most exposures peak. The 30° angle

of incidence is approximately the balance

point of solar heat

though the atmosphere and the decreased

transmissibility of glass. Above the 30:

the transmissibility. of glass decreases,

below the 30° angle the atmosphere absorbs

fon reduction coming

angle

or reflects more.

All shading devices fully drawn, except roller

shades. Experience indicates that roller shacles

are seldom fully drawn, so the factors have

been slightly increased.

45°

5. Venetian blind slats horizontal at 45° and

shading sercen slats horizontal at 17°

Outdoor canvas awnings ventilated at sides and

top. (See Table 16 Zootnote.)

7. Since Table 15 is based on the net solar heat

gain thr ordinary glass, all calculated solar

heat factors are divided by .88 (Fig. 12).

The average absorptivity, reflectivity and trans

missability for common glass and shading de

vices at a 30° angle of incidence along with

shading factors appear in the table below

Use of Table 16

—Over-all Factors for Solar Heat Gain thru Glass,

With and Without Shading Devices

The factors in Table 16 are niultiplied by the

values in Table 15 to determine the solar eat gain

thra different combinations of glass and shading.

devices, The correction factors listed under Table 15

are to be used i applicable. Transmission due to

temperature difference between the inside and out

rust be added to the solar heat gain to

door air

determine total gain thru glass

Exomple 3 — Partially Drawn Shades

fe it necessary £0 estimate the cooling loud in

i are nat 10 be fully The

Occasionally

a building where the Dli

procedure is ilestrated in the Following example

Given

West expose, 40° Nov

Theemopane window wh white ven

drain.

a

ve

latitude

Jan blind om inside

sola beat goin,

Solstion:

hy inspection of Table 15, the boxed boldface values for

peak solar heat gain, occurring at 4:00 pam. on July 2

= 164 eu/ihayg 6)

TS OF GAS OR aay] ences | Ta

Toke pees | | a Solar Factont

Oana cin +e ts

sare : 8

eg Late | te

Neti Goor ss ed

Ban Corer zn | a

ra Co =

Eine Cloth Big 618-9179) =

sp Coun igo Gay |

Firglan Gahan (38 [4 |

sce, he ol ow |

Fiberglass Cloth, Dark G _ oO 20 |

DisrarCioh White G8 SA) 8

Pato Gh: Dah Chen, Ving Conte |

tue ral sae) s |

eet a a a

Factors for various draperies are given for guidance only since

the sciual drapery material may be different jn. color and

enue; fgues in parentheses are ounces per sq yd, and yarn

“arp Ailing, Consult manvfactarers for actal vales

ED 1 cttenercomrny

#Compared to ordinary glass.

ding device in combination with ordinary glass

Fora!

PART 1, LOAD ESTIMATING

“Thermopane windows have no sash; therefore, sash area

correction = 1/85 (hottom Table 15)

se ihis example, 4 of the window i covered with the Soliton:

Jn this example HG, not therefore, the soar heat gain My Inpction of Table 15 the hoxed boldface value for

factor equals 3% of the overall factor + 14 of the glass peak solar leat gain, occaring at 4:00 p.m. on July 29

factor 4 bh) 96)

Factor for yg dean = 4 X52) + (4 80) (Table 16) sic ssh window correction = 1/85 (bottom Table 15)

=a Solex “R" glass absorbs 50.9%, of the solar heat (footnotes

erhen gn st x2 roe 1) ehh ace ie ae ee

=H Buu de) 4 1) Thum Table 16, the factor = 33.

xomple 4 Peok Solar Heot Gin thr Solex"R” Gloss syarheoguin= 1%". = at mar 608)

‘West exposite, 40° North latitude

Ye Soten "Re glass in steel sas, double hung window

TABLE 16—OVER-ALL FACTORS FOR SOLAR HEAT GAIN THRU GLASS

WITH! AND WITHOUT SHADING DEVICES*

Apply Factors to Table 15

Outdoor wind velocity, 5 mph — Angle of incidence, 30° — Shading devices fuly covering window

TRIBE oursie

~ )oursibe oursiog

cuss | VENEUN DUNGY fvenStaN'Btno] SRRING | AGUNG

years (ete) caret etre ace Fae a ea

Stabe

iam | Medium | ook | ake Masive Dor | abt

eas | Neder | @25.] ea eee) Sat | eS,

SRDNARY GAS AT

Ae mer Lee os ete Pe a oe [

HEAT ABSORAING GLASSTT

tse wo |) 2 | ml 2] a} uw |} ae |

abr eee Bl] fe foie] an | as | om

Sito 70% Aboring BS] 2 | ste |e | oe | to | ie |e

DOUBLE PANE i

Ordinary Clas wo fa | | ol om | af ao | wf ae | oe

Result ee TS [el | a] le | | ue |

Soo st%e nbsthing subi else arse terra :

di Glass inside. a 3 ° Zz ' 0 10 7

490509, Absting sue a | wa :

Regular Plate inside, so ” o e ! ‘0 io 7

THPLE PANE

Sein hiss pn lal fw] a | | ae | oa | ae |

Regul Pate ey") & | oitof te | is | | iw |e

TAINTED GLASS

Tigh Calor 28

Nation Color *

Dat Cale 20

STAINED GLASSEE

Anbar ee 10

Oat tea Hy

Den Bee rd

Dat race 2

Groped Goes “

tight Opolscst °

Oat Oplscet 2

iii |

VA 20298

S| lent

TP] rrezerre

aces

eenecne

Fic, 17 — Reaction on Sonar Heat (R), INCH

PLATE GLASS, WHITE VENETIAN BLIND, 14 INCH

PLATE GLass, 80° ANGLE OF INCIDENCE,

APPROXIMATION OF FACTORS FOR COMBINATIONS:

NOT FOUND IN TABLE 16

Occasionally combinations of shading devices and

types of glass may be encountered that are not cov:

ered in Table 16, These factors can be approximated

(1) by using the solar heat gain flow diagrams in

Fig. 15 and 16, (2) by applying the absorptivity, re

flectivity and transmissibility of glass and shades

listed in the table on fage 5/, or determined from

manufacturer, and (3) by distributing heat absorbed

within the dead air space and glass panes (Fig. 17).

Example 5 — Approximation of Over-oll Factor

Given

A combination as in Fig. 16 backed on the inside with an:

fother pane of if-inch regular plate glass,

Finds

‘The over-all factor.

Solution

Figure 17 shows the disti)ution of solar heat. The heat a

sorbed hetoreen the glass panes (dead air space) is divided

459% and 550%, respectively heeween the in and out Row. ‘The

heat absorbed within the glase panes is divided 20% in and

80%, out for the outer pane, and 73% in and 25% owt for

the inner pane. These divisions are based on reasoning par

tially stated in the notes onder Fig. 13. which assume the

‘outdoor fm coeficient of 28 Buu (he) (qf) (deg F). the

\loor fm coffcient of 18 Btu/ (hr) (sq fe) eg F), and the

‘overall thermal condvetince of the air space of 1.87 Buu

fe) 64 1) (ex)

Heat gain wo space Fig. 17)

(F515 12 TTR) + (77 X12 TTR)

445 ((37 TOR) + (08 % 51 % TTR)

(08 12 x 77R)]

$20 (15R) + (15> 81 x TTR)

= 2688 oF 27K

Solar heat gain factor as compared to or

TRV ABR = 31

rs: Solar Gain Without Shoder

Solor Gain Wh shode

(Soler Data fom

5} % (Glan Feet from tobe)

{Soler Dote from Table 18) x (Overall Factor from table]

Soler Gain With Shoder Pertialy Drown ~ (Solar Doto from Table 1S}

[iPrasion Brown % Overall Fedor) + (1 ~ Fron Drown) x (Gloss Forel

for Table 16:

“Shoding devices fully drown except eller shades. For fully drown

foller shades, mutiny bgt colors By 73, med colors by 98, ond

(ork colors by 108

*ocors for solar elfivde ongles of 40° or a

‘elow 40, some did lar Foye pass th

minis

At solar stitodes

(MULTIPLIERS FOR SOLAR ALTITUDES BELOW 40°

“commercial shade, slsminum Metal slots 057 Inches wide, 17.5

per inc

‘Yat heat absorbing gloss wie in comer! sir condoning I in the

OW te 55% range; induntel apotcains normaly use 56% to

704, Tho folowing tomle presente te cbsorpon auaien ofthe

fret common iat ypeu—

SOLAR RADIATION ARSORIED BY MEAT ABSORBING GLASS

[are | oe =" |

T T slots Corp. | Ya

Stem fsoem|saoem. | | P| tHe ee Gionce, a, Uawses |

Faden |7avam |7200m | 4g | op | 167 bey Swensford | Ye | Pole BleGreen,

4:30 pm_| 430 pm. | 4:30 pm tnburgh Plote Glow

oder by 1.

1 agoinst balding on sides end 0p,

VA PoleGreen 509

ses, ui he predominant cle.

{

i

|

156

nisi

PART |. LOAD ESTIMATING

GLASS BLOCK

Glass block differs from sheet glass in that there

is an apprecinble absorption of solar heat and a

fairly long time lag before the heat reaches the in.

side {about 3 hours). This is primarily caused by

the thermal storage capacity of the glass block it

sell. “Che high absorption of heat increases the

inside surface temperature of the sunlit glass block

which pray require room temperatures (©

maintain comlort conditions as explained in Ghap-

ter

Shadling devices on the outdoor side of glass block

almost as effective as with any other kind of

iulass since they keep the heat away from the glass.

Shading devices on the inside are not effective in

reducing the heat gain because most of the heat

rellected is absorbed in the glass block.

Bosis of Table 17

— Solar Heat Gain Factors for Gloss Block,

With and Without Shading Devices

‘The factors in Table 17 are the average of tests

conducted by the ASHAE on several types of glass

block,

nce glass block windows have no sish, the [ae

tors in Table 17 have been increased to include the

1/.85 multiplier in Table 15.

Use of Table 17

— Solar Heat Gain Factors for Glass Block,

With and Without Shading Devices

‘The factors in Table 17 are used to determi

solar heat gain thru all cypes of glass block,

‘The transmission of heat caused by a difference

between the inside and outdoor temperatures must

Iso be figured, using the appropriate “U" value,

hapter 5

e the

Example 6 ~ Peak Solar Heat Gain, Gloss Block

Given

‘West exposure, 40° North Tatvade

Glass black window

Find:

Peak solar heat gain

Solution:

iy inspection of Table 15, te peak sol

‘on July 3.

Solae heat gain

O00 pan, = (39 15) # (21K 48) £78

AtH00 pam, = (80% 161) = (21% 8) = BH

AeG:00 pam, = (39x 118) + (21 x 14) = 76

Peak solar heat gain occurs 3:00 p.m on July 28.

heat gain overs

TABLE 17—SOLAR HEAT GAIN FACTORS FOR GLASS BLOCK

WITH AND WITHOUT SHADING DEVICES*

Apply Factors to Toble 15

THULTIPLVING FACTORS FOR GIASS BLOCK

Exposure exrosure

IN NORTH n'soura

Tariruoes taniTupes

30 Southeast

| 30 Eee

30 Northeast

Summer ; 2 Summer}

‘Winter 30 Winer

a5 2 35 Nonhwert a

39 | ey 30 West

Ea 24 [iteees 2) Southwest

Favors indde cercecon for no sash with last Block windows.

Solar heat gain witht shading devices

= (8 xl) + (Bo x ll

1 heat goin wth outdoor shading devices

= (Bex + Bo % Ue) X25

Solar best gan with nad shading devices

= BX h + Bo X te) x 90

cE

{Use the summer Focors for ll lives, Nenh or South. Use the

winter fier for infermediote season, 30° te $0° North er South

Tonnage

8) = Istntonsoustaramisin factor from Table 17.

By = Absorpon araninion factor fom Tobe 17.

A = Sclorheot goin vole rom Toble 15 for the dested tine ond

in value from Table 15 for 3 hours sollor than

ond some wal focng

CHAPTER 4, SOLAR HEAT GAIN THRU GLASS

1.55

SHADING FROM REVEALS, OVERHANGS,

FINS AND ADJACENT BUILDINGS

All windows are shaded to a greater or lesser

degree by the projections close to it and by build.

ings around it, This shading reduces the solar

heat gain through these windows by keeping the

direct rays of the sun off part or all of the window.

The shaded portion has only the diffuse com:

ponent striking it, Shading of windows is signiti-

cant in monumental type buildings where the

reveal may be large, even at the time of peak solar

heat gain. Chart 7, this chapter, is presented to

simplify the determination of the shading of win-

dows by these projections.

Besis of Chart 1

= Shading from Reveals, Overhangs, Fins ond

Adjacent Buildings

‘The location of che sun is defined by the solar

arimuth angle and the solar altitude angle as shown

in Fig, 18, The solar azimuth angle is the angle in a

horizontal plane between North and the vertical

plane passing through the sun and the point on

earth, The solar altiwude angle is the angle in a

vertical plane between che sun and a horirontal

plane through a point on earth. The location of the

sun swith respect to the particular wall facing is de-

fined by the wall solar azimuth angle and the solar

altitude angle, The wall solar azimuth angle is the

angle in the horizontal plane between the perpen-

dicular to the wall and the vertical plane passing,

through the sun and the point on earth.

‘The shading of a window by a vertical projection

alongside the window (see Fig. 19) is the tangent of

the wall solar azimuth angle (B), times depth of

the projection, The shading of a window by a hori-

rontal projection above the window 1s the tangent

fof angle (X), a resultant of the combined effects of

the altitude angle (A) and the wall solar azimuth

angle (B), times the depth of the projection,

Tan A, sola altivude angle

“Gos ¥, wallsolar wana angle

TanX =

‘The upper part of Chart 1 determines the tan

gent of the wall solar azimuth angle and the bottom

pare determines tan X,

Use of Chart 1

~ Shading from Reveals, Overhangs, Fins and

Adjecent Buildings

‘The procedure to determine the top and side

shading from Chart 1 is,

1. Determine the solar azimuth and altitude an-

gles from Table 18,

ED cosine comer

Fic, 18 — Sonar ANGLES:

Fic, 19 — Suapinc ny WALL PROJECTIONS

2 Locate the solar azimuth angle on the scale in

upper part of Chari F

8. Proceed horizontally to the exposure desired,

4, Drop vertically to "Shading from Side” scale.

5. Multiply the depth of the projection (plan

view) by the "Shading from Side.”

6. Locate the solar alsitude angle on the scale in

lower part of Chart 1

Move horizontally until the "Shading trom

Side" value (45 deg. lines) determined in Step

4 is intersected,

8, Drop vertically 10 “Shading trom Top" from.

intersection.

9. Multiply the depth of the projection (elev

tion view) by the "Shading from Top.”

1-56

Qk

fe SN

400" pp fe

Fic, 20 — SHADING OF BUILDING BY ADJACENT

Bum DING

Example 7 — Shoding of Building by Adjacent Building

Given

uliings locate as shown in Fig. 20.

Find:

Shading at 4 pat, July 28, of building to he airconditioned

Solution:

TL ig recommenda! that the building plans and elevations

he sketched t0 scale with approximate location of the sun

to enable the engineer to visualize the shading conditions

From Tole 18, solarazimuth angle

sola alttade angle = 35

From @hart J, shading from side= fet

sacling from tops = 786

PART 1, LOAD ESTIMATING

Dd eevanon

Fic, 21 — SHADING OF REVEAL AND OVERHANG

eget of building in shade,

515 = IT

ja

‘eight of building in shade, H= 100 — (75 x 3) = 475 f

‘The oir conditioned building is shaded to a height of 47.5

fe and 625 fe along the face at 4:00 pan. on fuly 23

Example 8 — Shading cf Window by Reveals

Giver:

A steel easement window on the west side with an Sine

reveal

Find

‘Shading by the reveal at 2 pam. on July 23, 40" Novth

Latitude,

Solution:

From Table 18, solar asimuth angle =

solar altitude angle

From Chart 1, shading from side reveal

Shading from top reveal

raxe.

48%,

Main

Example 9 — Shading of Window by Overhang

and Reveal

Given:

“The same window as in Example $ with a 2 f¢ overhang

G inches shove the window.

Find!

Shading by reveal and overhang at 2 pam. on July 23, 40°

North Latitude

Solution:

Refer to Fig, 2

Shading from side reveal (ame as Evannple 8) = 4.8 in

Shading from overhang 18 x (24 +8)

Since the overhang is 6 inches above the window, the portion

of window shaded = 576 6.0 = 51.6 in

ey

ii sis

CHAPTER 4, SOLAR HEAT GAIN THRU GLASS

SOLAR AZIMUTH ANGLE

Ls7

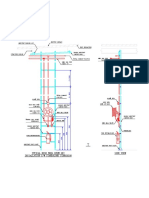

CHART 1—SHADING FROM REVEALS, OVERHANGS, FINS AND ADJACENT BUILDINGS

T

1 Ge [rw Given:

's20 “ 7 ‘West facing, stel casement window with an Bineh

reveal and 821 overhang 6 Inches above window

i Find.

© 300 Y ¥ | ‘Shading by reveat and overhang at 2 pm, July 28,

| 40" North Latin

am Bs

BE Solution

280 — From Table 18,

{ ‘nat ang

Te al ‘ue ang

woo, re From Char?

ae i 1. Enter at solar azimuth angle (242*) to west

f (i) exponrechading tom skle = 04 inch

inch

12

240 2. Enter at solar altitude angle (57*) to shad

ing from side (06 inch ine) Shading torn

top = 18 inch int

'4r00 ser 4. Shaaling hy reveal = 05 x 8 = 48 in

vl i 4 Shading by overharg=18(24-+8)—6=51.6

160. 6 4 ee lf

200 ‘ :

Ls ue CRS

SSR TROT GF re RT wy? be

wis ¢ |

seoe RANE x 2h T as]

x beer

8 x Ca ae

5 wan

j X

\ ELEVATION

N

s

x

\ |

4 20 i

g S .

Zoos

8 eel NI

z A

5 a0 : d

= as

& 50 1

Boss

co

6s t i

\

70

1

7

] 1

so :

Lo eee IS 0

SHADING FROM TOP (INCH/INCH)

138 PART 1. LOAD ESTIMATING

TABLE 18—SOLAR ALTITUDE AND AZIMUTH ANGLES

Nome | a 7 WS pee 20 | wey | Jone 1] ah 3 [avg Sop] a3] Wo 21 [Dee | aap

ube | Hagan AE AA ana a ae ata Aa Da ar an Ar ANT Aran ar] le

va ans 15 a} 5 | vo} ss | 26] 14 | cafe | os | ue] oe] es vs fice |e ars fie [ine | 3

28/1] 30 [tes a0 | ef 32 | 9] de] Gf |B] ds] BY 36 33 Ji a ta fat |i |

Saal Sette] Go] ae] Se] aa] Se] SA) | a] Se] SESS Sofiia |S fine | [at Jao

ES] ta] 3 ta] 95) 3] 9 Sa] os | Sef ae | 2] és | dele 5 | tapas fies |e |e tt

war se aol 70 [ite] va | ‘o| 79] ol] ‘ols | 3 | 70] “ol me 49 [tao [70 [iso [or [103 [aw

o es faa 7 Yaar] vs [are 7 [res [sae | [ane Pes [| TT Tyas es as far [zee | UPN

£1 el Ee [eal So 71] Zu ta] ot |206|s2 [21 | Se [5 | se ba [ee | [230 |S [os | 2

a2 / Ba) ae [2ee| 5 [dn | ae [| a te [35010 [20] foe |

26) 7} 30 | 29] 30] 271] 30| 3] 26 so [der |e [30 [22 [ie |

ia dee] 12 | 2ee| 8 200] 13 [2ne| 14 1B fase [16 Lae 1s Be |

TTS] 2] ye oa

vo fun} 12 fam} as] 93) ae] tf a ra fica |io fia] sus | 9

eft} 23 |e] ab] $e) ar fa 27 Jie [017 [28 lian |

BY aad M1] tig] aa] Sel ae ae as Er its] ize [3s [ize |

ae fe] Se fae] SS fice] or] a So a ize] aa | 180 [48 [38 |e

i fe] Se | Va) o2 | 183] Su] | 2 eres) iss |S fae [at

} wr |i] $6 | 10) 66 [a6] a6 | “3 co et fies | [ies [59 [Nao [ta

o 7 foal s¢ [ate] 72 fase] 7S |] D fee [aie Per foos [= aoe PCP

46 [ae] Se |e) Se [ose] 6 ela [ia [eet | [at | a

3 ase] a es] ae 3ei| a fi [oe [39 [ite (4s fie | 2

: 24] 33] 2 [3] 30 [245] 5 or isa | [oes | |oae | 4

uy] 12 | 353] 18 2a] te 4 [dsr | fa [ae |"s foes | &

if 2o| "2 é

+ Gane

ce} sng 10 ta 14} as] a8 so fioe| ofa] sfur | 4

ve | tat] 3 | 18/28 at ae 22] } 8 fiat [ar fae |

40a] 4a tei] a2| toe ae 3a at | 0] 0 fan [53 |

fe | ea] 29 29] $6] tao] 3 ie ia |e fe fa

33 & tee] &| | 9 fs [ica] ise fae fica

war | ao] & | 188] 30 aa] a 5 | 1 | 0 [sno [49 [100

e 47 [02] & [2oH] a8] 217] 22 SE [roe] e722 fee [97

23] a) «3 [2er| | ho] oo 2 [3 | a [2 [ie fats

5 50 0] 46] a9| a2 [2821 5 | | 30 [200 [28 [ar

13 [2a] 23 | a] 2s | 20] 92 23 | 208 | [dae | foe

2} Ra] fa |e] Te [208] Te fa fase |S ae |'S [ash

a}ins} 7 fror| a2] so] we] er] as afior] 2 fuss

vied 0b [11e) a8 [ee 31 | 2] 8 va [ite fa figs [ar faze

24/54) 30 [| Se [Hie] ae [oe] ae sa iy | 24 [58 | |e

32) 4d] 20 er] |] $e | at fo [ia | 32 [ite |e Jute

36 ta] 42/155) $F] isn] or | zo] S656 | 38 [10s [38 fae

usr #5 [i] |i) fo | ea] 9 | a0] oo [| eo [3s [180

ae BET Teal we for] 67 [aoe] oF [20] 79 “ae faor [ae [ie 5 fs

a2 [aie| So [219] a6 [230] Se] 20] ch io [ata | [ate [2 [ote

24 [ou] 30 | 3] Se | ee] a aoe] fn fe [as | [za [21 ane

1239] 19 || ae 25¢| 31 fas | $s to [eee | [ase [i fae

22) "7 285] 13 Jed] te [95 | 2a 3a |'3 [ies ‘

20 |

ra 99] 9 | 9) s fu

alias # [to | fuse [38 |e | fas | s fr

1) al B]iz] a [|e Bathe nca tea rea ie

2 fie] 2 | aa] st [aa] gr 3 as fas fete [21 fiat

i fied Sefer] Se fier | 3 3 Yes [aa |e [Bs fas

ur 55 [a So [iao| at [140] 99 [iso [30 [ins (3s [tee

o [ie “42 [2] 58 [200 37 [iow f2e Jive fas [ios

Babi Sle 8 |ai| 9 2 fave [ae fort | [aoe

3 1B B [200] 0 [ea] 35 fear |'a [ae |'S [ah

[ie] 1 fda | [32 [iso

eT ale

to fior {a8 | Sa fas

3 fas] ua fizu| i fila) 6 fogs |e vo fiat | a fies

10 [te] 12 134] a7 Jae | [rao | 48 1 fide a 88 |e Joe

18 ian] 23 fiat Be [as [aa [ose | 2 zi [ae [13 [ist [ia |iae

49 fies] a fide) 39 {180 [is | Se fr [ide [te Jigs [is ies

tar 2 [ino] 3 [sa] 40 | ho | 1 [180 | 28 fs [hea [2a [iso i> [iso

a Te TTse] 7 fase] | 200] | [Se Fr five Jie [ives [i9e

15 [aoe] [ota] de |i | ex | | 2 [28 | ss fone 2a [av | ioe ta ose

i [22a] tr | ae] 29 [ta | [daa | ate | 4 fo Jeet [10 fo |'2 [ar

3 88] 10 [25] ts foe fas ose | 36 fae | fk ro feds |S fas

Leso|ie [30 | ose

Sahube July 23 fhug. 24 fept. 22 [Ost 23 |Nov. 21 |Dee. 22 [Ape 20. [Mey 21 jane 21

“Ure manta iaialed top fo Navth Lalfuder: and ve monty bottom for South Latte

Pires pes

139

CHAPTER 5. HEAT AND WATER VAPOR FLOW

THRU STRUCTURES

This chapter presents the methods and data for

determining the sensible and latent heat gain or loss

thru the outdoor structures of a building or thru a

structure strounding a space within the building.

Ivalso presents data for determining and preventing

‘water Vapor condensation on che enclosure surfaces

or within the structure materials.

Heat flows from one point to another whenever a

temperature difference exists between the two points;

the direction of flow is always towards the loner tem-

perature, Water vapor also flows from one point to

another whenever a difference in vapor pressure

exists between the two points; the direction of flow is

towards the point of low vapor pressure. The rate at

which the heat or water vapor will flow varies with

the resistance to flow between the two points in the

material, I the cemperature and vapor pressure of

the water vapor correspond to saturation conditions

at any point, condensation occurs,

HEAT FLOW THRU BUILDING STRUCTURES,

Heat gain thyu the exterior construction (walls

and sof) is normally calculated at the time of

greatest heat flow. Tt is caused by solar heat being

absorbed at the exterior surface and by the tem

perature difference between the outdoor and indoor

air. Both heat sources are highly variable thruout

any one day and, therefore, result in unsteady state

hheat flow thru the exterior construction, This un

steady state flow is difficult to evaluate for each in-

dividual situation; however, it can be handled best

by means of an equivalent temperature difference

across the structure,

The equivalent temperature difference is that tem:

perature difference which results in the total heat

flow thru the structure as caused by the variable

solar radiation and outdoor temperature. The equiv

alent temperature difference across the structure

must take into account the different types of con:

struction and exposures, time of day, location of the

Duilding (latitude), and design conditions. The heat

flow thru the structure may then be calculated, using.

the steady state heat flow equation with the equiv-

alent temperature difference,

q=UASt,

where = heat flow, Bu/hr

U = transmission coefficient,

Beu/ (hr)(sq 2) deg F temp diff)

A =area of surlace, sq ft

A, = equiv temp diff F

Heat loss thru the exterior construction (walls and

roof) is normally calculated at the time of greatest

heat flow. This occurs early in the morning after 2

few hours of very low outdoor cemperatures. This

approaches steady state heat flow conditions, and for

all practical purposes may be assumed as such.

Heat flow thru the interior construction (floors,

ceilings and partitions) is caused by a difference in

temperature of the air on both sides of the structure

‘This temperature difference is essentially constant

thruout the day and, therefore, the heat flow can be

determined from the steacy state heat flow equation,

using the actual temperatures on either side.

EQUIVALENT TEMPERATURE DIFFERENCE —

SUNLIT AND SHADED WALLS AND ROOFS

“The process of transferring heat thru a wall under

indicated unsteady state conditions may be visu-

alized by picturing a T2-inch brick wall sliced into

12 one:inch sections, Assume that temperatures in

each slice ave all equal at the beginning, and that the

indoor and outdoor temperatures remain constant

When the sun shines on this wall, most of thesolar

heat is absorbed in the first slice, Fig. 22. This raises

the temperature of the frst slice above that of the

outdoor air and the secend slice, causing heat to

flow to the outdoor air ard also to the second slice,

Fig. 23. The amount of heat flowing in either direc

tion depends on the resistance to heat flow within

the wall and thru the outdoor air film. The heat flow

into the second slice, in turn, raises its temperature,

causing heat to flow into the third slice, Fig. 24.

‘This process of absorbing heat and passing some on

to the next slice continues thru the wall to the last

or 12th slice where the reraining heat is transferred

to the inside by convection and radiation. For this

particular wall, it takes approximately 7 hours for

i

RRR

ip

r

hte

Fic, 25 — BrHavior oF Ansoxnep SOLAR HEAT

DURING SECOND TIME INTERVAL

eee

Fig. 24 — Benavio oF Ansoxnen SoLar HEAT

purine Tiny inte INTERVAL

solar heat to pass thru the wall into the room.

Because each slice must absorb some heat before

passing it on, the magnitude of heat released to

Inside space would be reduced to about 10% of that

absorbed in the slice exposed to the sun.

These diagrams do not account for possible

changes in solar intensity oF outdoor temperature,

LOAD ESTIMATING

S|]

aaa SseHaSE mr

Fic, 25 — Benavior oF Ansonnep SOLAR HEAT DURING

SECOND Tint INTERVAL PLUS ADDITIONAL SOLAR

Herat Agsorven puRiNG THis INTERVAL

A

BR

ERO

ES

Fig. 26 —Benavion oF Ansonnep Sola HEAT DURING

‘Truno Tine INTervat PLUS ADDITIONAL SOLAR Hat

[AgsORRED DURING THIS INTERVAL

‘The solar heat absorbed at each time interval by

the outdoor surface of the wall throughout the day

goes thru this same process, Figs, 25 and 26 show the

total solar heat flow during the second and third

time intervals.

A rise in outdoor temperature reduces the amount

of absorbed heat going to the outdoors and more

flows thru the wall.

‘This same process occurs with any type of wall

construction to a greater or lesser degree, depending

on the resistance to heat flow thru the wall and the

thermal capacity of the wall.

oy

Bi

CHAPTER 5. HEAT AND WATER VAPOR FLOW THRU STRUCTURES 161

NOTE: The thermal capacity of a wall or roof is

the density of the material in the wall or

roof, times the specific heat of the material,

times the volume,

This progression of heat gain to the interior may

occur over the full 24hour period, and may result

in a heat gain to the space during the night, If the

equipment is operated less than 24 hours, Le. either

skipping the peak load requirement or as a routine

procedure, the nighttime radiation to the sky and

the lowering of the outdoor temperature may de-

crease the transmission gain and often may reverse

it, Therefore, the heat gain estimate (sun and trans-

mission thru the roof and outdoor walls), even with

equipment operating less than 24 hows, may be

evaluated by the use of the equivalent temperature

data presented in Tables 19 and 20.

Basis of Tables 19 and 20

= Equivalent Temperature Difference for Sunlit and

Shaded Walle and Roofs

Tables 19 and 20 are analogue computer calcula:

tions using Schmidr’s method based on the following

conditions:

1. Solar heat in July at 40° North latitude,

2. Outdoor daily range of dry-bulb temperatures,

20 deg F

3, Maximum outdoor temperature of 95 F db and,

8 design indoor temperature of 80 F db, ie. a

design difference of 15 deg F.

4. Dark color walls and roofs with absorptivity

, of 0.90, For light color, absorptivity is 0.50;

for medium color, 0.70.

5, Sun time.

The specific heat of most construction materials

is approximately 0.20 Beu/(Ib)(deg F); the thermal

capacity of typical walls or roofs is proportional to

the weight per sq ft; this permits easy interpolation,

Use of Tables 19 and 20

—Equivelent Temperature Difference for Sunlit and

Shaded Walls and Roofs

‘The equivalent temperature differences in Tables

19 and 20 are multiplied by the transmission coeff

cients listed in Tables 21 thru 33 to determine the

heat gain thru walls and roofs per sq ft of area dur

ing the summer. The total weight per sq ft of walls

and roofs is obtained by adding the weights per sq

ft of cach component of a given structure, These

weights are shown in italics and parentheses in

Tables 21 thru 33.

ED 0 conten compeny

Example 1 — Equivalent Temperature Difference, Root

Given

A flat voot exposed 10 the sun, sith built-up roofing, 14

Involation, $ in, wood deck and sumpended acoustical

le ceiling

Room desige temperature =80 F dls

Outdoor design temperature = 05 F dls

Daily range = 20 deg

Find:

Equivalent temperature ah

snce at 4 pum, July

Solution:

Wijsq ft 8424

12 Ihjsq fe (Table 27, page 71)

Equivalent temperature difference

44 leg F (Table 20 interpolated)

Example 2 — Daily Range and Design Temperature

Difference Correction

AL times the daily range may be more oF less han 20 seg Fr

the difference between outdone and room design temperatures

‘may be more or less than 18 deg F. The corrections to be

applied tothe equivalent temperature difference for combina

tions of these ewo variables ate listed in the notes following

Tables 19 and 20.

Given:

“The same toot as in Esempl> 1

Room design temperature

Outeloor design temperature

Daily range = 26 deg F

Find

Equivalent temperature diffeence winder changed conditions

Solution:

Design temperatore difference

Daily range = 26 deg F

Correction 0 6

I deg F (Table 204, intespolated)

Equivalent temperatuse difference = 43 ~ 1 = 42 deg F

7 deg F

alent temperature difference

Exomple 3— Other Months ond Latitudes

‘Occasionally the heat gin thew wall oF roof must be known

for months and Intituces other than those listed in Note 3

following Table 20. This equieslent temperature difference is

Aetermisied from the equation in Note J. This equation ad.

josts the equivalent temperate diference for solar radiation

‘only. Additional correction may have to be made for differ

fences between outdoor and indoor design temperatures other

than 15 deg F, Refer o Tables 19 and 20, pages @2 and 63,

and! to the correction Table 204. Corrections for these differ:

fences must be made first; then the corrected equivalent

applied in cortections for latitade

Given

12 in, common trick wall acing west, with no interior

New Orleans, 30° North latiuude

Finis, Joeated

Find

Equivalent temperanine difference in November at 12 noon,

Solution:

"The correction for design temperatu

follow

temperature differences for both sun and shade must be |

1-62

PART 1, LOAD ESTIMATING

Exomple 3, contd

Summer design dry-bulb for New Orleans

SF dbs Table 1, poge 11)

Wincer design dry-bulb for New Orleans

a0 F ay (Table F, page 11)

Yearly vange = 75 deg F

Corcction in outdoor design temperature for November

amis yearly range of 75 deg F

158 (Table 3. page 19)

Oundowe design dry-ull cemperature in November at 8 pa.

ves OF

With an 80 F dy room design, the autdaor to indoor die

‘ence ie $0-— 80 = O deg F

Average daily range in New Orleans

Sideg F (Table J, pre 11)

‘The design difference of} deg F and a 19 deg F daily range

results in a “113 deg F aldition to the equivalent tempers

tive difference, by interpolation in Table 204

Equivalent temperature sifferencen for 12 in. brick wall in

New Orleas at IZ noon in November

Mog for west wall in suk

25 (Table 19)~ 115 =~ 4.5 deg F