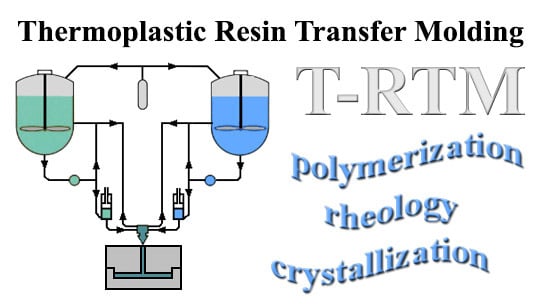

A Review of Thermoplastic Resin Transfer Molding: Process Modeling and Simulation

Abstract

:1. Introduction

2. T-RTM Equipment and Process Parameters

3. The Kinetic Modeling of Polymerization and Crystallization

3.1. Reaction Chemistry

3.2. Polymerization Kinetic Models

3.2.1. The Malkin Model (1979–1984)

3.2.2. The Camargo Model (1983)

3.2.3. The Lin Model (1985)

3.2.4. The Kamal-Sourour Model (1973–1976) adopted by Teuwen (2011–2013)

3.3. AROP Crystallization Kinetic Models

3.3.1. The Avrami Model Adapted by Bolgov (1979–1981)

3.3.2. The Malkin Model (1984)

3.3.3. The Lee and Kim Model (1988)

3.3.4. The Kim Model (1997)

3.3.5. The Tonoyan Model (2007)

3.3.6. The Johnson-Mehl-Avrami-Kolmogorov (JMAC) Equation Adapted by Vicard (2017)

3.4. Experimental Methods of the Investigation of the Kinetics of the AROP of CL

3.4.1. Adiabatic Reactor Tests

3.4.2. DSC Tests

3.4.3. The Extrapolation Technique

3.4.4. The Curve-Resolving Technique

4. Rheokinetic Modeling

4.1. The Malkin Model (1981)

4.2. The Sibal Model (1983)

4.3. The Castro-Macosko Model (1982) Adopted by Taki (2017)

4.4. Rheokinetic Models for Thermosets

4.5. Experimental Methods for the Rheokinetic Investigation of the AROP of CL

5. The Influence of Pressure on Reaction Rate and Pressure-Volume-Temperature Modeling

5.1. The Behavior of Thermosets under Pressure

5.2. Thermoplastic Behavior under Pressure

5.3. Thermoplastic Behavior under Pressure

5.4. Experimental Methods for Measuring pvT Behavior

6. Simulation of the T-RTM Process

7. Conclusions and Future Prospects

Funding

Conflicts of Interest

Abbreviations

| ABC | adipol-bis-caprolactam; |

| AROP | anionic ring opening polymerization; |

| C8H13NO2 | N-acetylcaprolactam; |

| CFD | computational fluid dynamic; |

| CL | caprolactam; |

| DEA | Dielectric Analysis; |

| DSC | Differential Scanning Calorimetry; |

| EtMgBr | ethyl magnesium bromide; |

| HCC | hexamethylene-1,6-bis(carbamidecaprolactam); |

| HMDI | hexamethylenediisocyanate; |

| KL | potassium salt of lactam; |

| LCM | liquid composite molding; |

| LiL | lithium salt of lactam; |

| NaH | sodium hydrate; |

| NMR | Nuclear Magnetic Resonance; |

| PA | polyamide; |

| T-RTM | thermoplastic resin transfer molding; |

| XRD | X-Ray Diffraction; |

| compressibility factor; | |

| the degree of crystallinity at the termination of the crystallization process; | |

| [A] | activator concentration; |

| [I] | initiator concentration; |

| [M0] | initial monomer concentration; |

| crystallization enthalpy; | |

| polymerization enthalpy; | |

| activation volume for the reaction; | |

| a | thermal diffusivity; |

| C | heat capacity; |

| E | activation energy of the process; |

| ms | sample mass; |

| Mw | molecular weight of the polymer; |

| P | pressure; |

| P0 | reference pressure; |

| Q | thermal effect of the reaction; |

| R | universal gas constant; |

| T | processing temperature; |

| t0 | characteristic crystallization time; |

| Tc | crystallization temperature; |

| Tm | melting temperature of the polymer; |

| Tp | polymerization temperature; |

| Tref | reference temperature; |

| α | degree of crystallinity; |

| αeq | equilibrium degree of crystallinity; |

| β | conversion degree; |

| γg, γ | reaction ratio of the monomer at gelation and at any time up to gelation; |

| η | viscosity; |

| η0 | viscosity of the monomer; |

| θ | crystallization induction period. |

References

- Ageyeva, T.; Sibikin, I.; Karger-Kocsis, J. Polymers and Related Composites via Anionic Ring-Opening Polymerization of Lactams: Recent Developments and Future Trends. Polymers 2018, 10, 357. [Google Scholar] [CrossRef] [PubMed]

- Sibikin, I.; Karger-Kocsis, J. Toward Industrial Use of Anionically Activated Lactam Polymers: Past, Present and Future. Adv. Ind. Eng. Polym. Res. 2018, 1, 48–60. [Google Scholar] [CrossRef]

- van Rijswijk, K.; Bersee, H.E.N. Reactive Processing of Textile Fiber-Reinforced Thermoplastic Composites–an Overview. Compos. Part A Appl. Sci. Manuf. 2007, 38, 666–681. [Google Scholar] [CrossRef]

- Meixian, L. Modeling of CFRTP Composites Manufacturing Process with In-Situ Polymerization. Ph.D. Thesis, Graduate School of Engineering Seoul National University, Seoul, Korea, 2017. [Google Scholar]

- Wesołowski, J.; Płachta, K. The Polyamide Market. Fibres Text. East. Europe 2016, 24, 12–18. [Google Scholar] [CrossRef]

- Roda, J. Polyamides. In Handbook of Ring-Opening Polymerization; Dubois, F., Coulembier, O., Raques, J.-M., Eds.; Wiley-VCH Verlag: Weinheim, Germany, 2009; pp. 165–195. [Google Scholar]

- Joyce, R.M.; Ritter, D.M. Process for Making Polymeric Materials. U.S. Patent US 2,251,519, 5 August 1941. [Google Scholar]

- Šebenda, J. Lactam Polymerization. J. Macromol. Sci.-Chem. 1972, 6, 1145–1199. [Google Scholar]

- Reimschuessel, H.K. Nylon 6. Chemistry and Mechanisms. J. Polym. Sci. Macromol. Rev. 1977, 12, 65–139. [Google Scholar] [CrossRef]

- Russo, S.; Casazza, E. Ring-Opening Polymerization of Cyclic Amides (Lactams). In Polymer Science: A Comprehensive Reference; Penczek, S., Grubbs, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; Volume 4, pp. 331–396. [Google Scholar]

- Luisier, A.; Bourban, P.-E.; Manson, J.-A.E. Time–Temperature–Transformation Diagram for Reactive Processing of Polyamide 12. J. Appl. Polym. Sci. 2001, 8, 963–972. [Google Scholar] [CrossRef]

- Luisier, A.; Bourban, P.-E.; Manson, J.-A.E. Initiation Mechanisms of an Anionic Ring-Opening Polymerization of Lactam-12. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 3406–3415. [Google Scholar] [CrossRef]

- Luisier, A.; Bourban, P.E.; Månson, J.A.E. Reaction Injection Pultrusion of PA12 Composites: Process and Modelling. Compos. Part A. 2003, 34, 583–595. [Google Scholar] [CrossRef]

- Chen, K.; Jia, M.; Sun, H.; Xue, P. Thermoplastic Reaction Injection Pultrusion for Continuous Glass Fiber-Reinforced Polyamide-6 Composites. Materials 2019, 12, 463. [Google Scholar] [CrossRef]

- Chen, K.; Jia, M.; Hua, S.; Xue, P. Optimization of Initiator and Activator for Reactive Thermoplastic Pultrusion. J. Polym. Res. 2019, 26, 40. [Google Scholar] [CrossRef]

- Holmes, M. Expanding the Market for Long Fiber Technology. Reinf. Plast. 2018, 62, 154–158. [Google Scholar] [CrossRef]

- Ringenbach, S.; Richeton, J.; Coulton, J. Hyundai’s Breakthrough Front Bumper Crash Beam. JEC Compos. Mag. 2015, 98, 39–41. [Google Scholar]

- van Rijswijk, K.; Teuwen, J.J.E.; Bersee, H.E.N.; Beukers, A. Textile Fiber-Reinforced Anionic Polyamide-6 Composites. Part I: The Vacuum Infusion Process. Compos. Part A 2009, 40, 1–10. [Google Scholar] [CrossRef]

- van Rijswijk, K.; van Geenen, A.A.; Bersee, H.E.N. Textile Fiber-Reinforced Anionic Polyamide-6 Composites. Part II: Investigation on Interfacial Bond Formation by Short Beam Shear Test. Compos. Part A 2009, 40, 1033–1043. [Google Scholar] [CrossRef]

- van Rijswijk, K.; Bersee, H.E.N.; Jager, W.F.; Picken, S.J. Optimisation of Anionic Polyamide-6 for Vacuum Infusion of Thermoplastic composites: Choice of Activator and Initiator. Compos. Part A 2006, 37, 949–956. [Google Scholar] [CrossRef]

- van Rijswijk, K.; Bersee, H.E.N.; Beukers, A.; Picken, S.J.; van Geenen, A.A. Optimisation of Anionic Polyamide-6 for Vacuum Infusion of Thermoplastic Composites: Influence of Polymerisation Temperature on Matrix Properties. Polym. Test. 2006, 25, 392–404. [Google Scholar] [CrossRef]

- van Rijswijk, K.; Lindstedt, S.; Bersee, H.E.N.; Gleich, K.F.; Titzschkau, K.; Dade, E.J.M. Reactively Processed Polyamide-6 Structural Composites for Automotive Applications. In Proceedings of the 6th Annual SPE Automotive Composites Conference, Troy, MI, USA, 12–14 September 2006; pp. 435–442. [Google Scholar]

- van Rijswijk, K.; Lindstedt, S.; Vlasveld, D.P.N.; Bersee, H.E.N.; Beukers, A. Reactive Processing of Anionic Polyamide-6 for Application in Fiber Composites: A Comparitive Study with Melt Processed Polyamides and Nanocomposites. Polym. Test. 2006, 25, 873–887. [Google Scholar] [CrossRef]

- Teuwen, J.J.E.; van Geenen, A.A.; Bersee, H.E.N. Novel Reaction Kinetic Model for Anionic Polyamide-6. Macromol. Mater. Eng. 2013, 298, 163–173. [Google Scholar] [CrossRef]

- Teuwen, J. Thermoplastic Composite Wind Turbine Blades. Kinetics and Processability. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2011. [Google Scholar]

- Teuwen, J.T.E.; van Rijswijk, K.; Bersee, H.E.N.; Beukers, A. Effect of Fibre Textile Reinforcement on Anionic Polyamide-6 Composite Properties. In Proceedings of the 16th International Conference on Composite Materials, Kyoto, Japan, 8–13 July 2007; Kageyama, K., Ishikawa, T., Eds.; Japan Society for Composite Materials: Kyoto, Japan, 2007. [Google Scholar]

- van Rijswijk, K.; Teuwen, J.J.E.; Bersee, H.E.N.; Beukers, A. The Interface of Reactive- and Melt Processed Polyamide-6 Composites. In Proceedings of the 16th International Conference on Composite Materials, Kyoto, Japan, 8–13 July 2007; Kageyama, K., Ishikawa, T., Eds.; Japan Society for Composite Materials: Kyoto, Japan, 2007. [Google Scholar]

- Joncas, S.; van Rijswijk, K.; Bersee, H.E.N. Mechanical Properties of Vacuum Infused Anionic Polyamide-6 (APA-6) Glass Fiber Composites: A Benckmark Study. In Proceedings of the 27th International SAMPE Europe Conference, Paris, France, 27–29 March 2006; SAMPE: Paris, France; pp. 1–6. [Google Scholar]

- van Rijswijk, K. Thermoplastic Composite Wind Turbine Blades. Vacuum Infusion Technology for Anionic Polyamide-6 Composites. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2007. [Google Scholar]

- Bitterlich, M.; Ehleben, M.; Wollny, A.; Desbois, P.; Renkl, J.; Schmidhuber, S. Tailored to Reactive Polyamide 6. Kunstoffe Int. 2014, 3, 47–51. [Google Scholar]

- Schmidhuber, S.; Fries, E.; Zimmermann, P. It couldn’t be More Hybrid. Thermoplastic-Matrix RTM on the Roof Frame of the Roading Roadster. Kunstst. Int. 2017, 1–2, 36–38. [Google Scholar]

- Sealy, C. Molding the Future: Engel Takes Composite Approach to Composites. Reinf. Plast. 2016, 60, 138–141. [Google Scholar] [CrossRef]

- Humphry, J.; Wolter, N.; Yang, N.; Vandi, L.-J.; Truss, R.; Martin, D.J.; Heitzmann, M.T. Process Modelling in Anionically Polymerised Polyamide-6 (APA6) for the in situ Polymerisation of Composite Matrices. Compos. Commun. 2018, 8, 111–114. [Google Scholar] [CrossRef]

- Davé, R.S.; Kruse, R.L.; Stebbins, L.R.; Udipi, K. Polyamides from Lactams via Anionic Ring-Opening Polymerization: 2. Kinetics. Polymer 1997, 38, 939–947. [Google Scholar] [CrossRef]

- van Rijswijk, K.; Joncas, S.; Malek, O.; Bersee, H.E.N.; Beukers, A. Vacuum Infused Thermoplastic Composites for Turbine Blades. In Polymer Composite Materials for Wind Power Turbines; Lilholt, H., Madsen, B., Andersen, T.L., Mikkelsen, L.P., Thygesn, A., Eds.; Riso National Laboratory: Roskilde, Denmark, 2006; pp. 307–315. [Google Scholar]

- Wilfong, D.L.; Pommerening, C.A.; Gardlund, Z.G. Separation of Polymerization and Crystallization Processes for Nylon-6. Polymer 1992, 33, 3884–3888. [Google Scholar] [CrossRef]

- Khodabakhshi, K.; Gilbert, M.; Dickens, P. Monitoring of Small-Scale Anionic Polymerization of Caprolactam; a Method to be Used in an Additive Manufacturing Process. Polym. Adv. Technol. 2013, 24, 503–510. [Google Scholar] [CrossRef]

- Sebenda, J. Polymerization. In Lactam-Based Polyamides; Puffr, R., Kubanek, V., Eds.; CRC Press: Boca Raton, FL, USA, 1991; Volume 1, p. 328. [Google Scholar]

- Sebenda, J. Structural heterogeneity of lactam polymers. In Structural Order in Polymers, Proceedings of the the International Symposium on Macromolecules, Florence, Italy, 7–12 September 1980; Ciardelli, F., Giusti, P., Eds.; Pergamon Press: Florence, Italy, 1980; pp. 95–110. [Google Scholar]

- Šittler, E.; Šebenda, J. Alkaline Polymerization of 6-Caprolactam. XXXIV. The Kinetics of Polymerization of Caprolactam Initiated by Sodium Caprolactam. Collect. Czech. Chem. Commun. 1968, 33, 3182–3190. [Google Scholar] [CrossRef]

- Greenley, R.Z.; Stauffer, J.C.; Kurz, J.E. The Kinetic Equation for the Initiated, Anionic Polymerization of η-Caprolactam. Macromolecules 1969, 2, 561–567. [Google Scholar] [CrossRef]

- Rigo, A.; Fabbri, G.; Talamini, G. Kinetic Study of Anionic Polymerization of 6-Caprolactam by Differential Calorimetry. J. Polym. Sci. Polym. Lett. Ed. 1975, 13, 469–477. [Google Scholar] [CrossRef]

- Alfonso, G.C.; Chiappori, C.; Razore, S.; Russo, S. Activated anionic polymerization of epsilon-caprolactam for rim process. In ACS Symposium Series; Oxford University Press: Oxford, UK, 1985; pp. 163–179, Reaction Injection Molding Chapter. [Google Scholar]

- Lin, D.J.; Ottino, J.M.; Thomas, E.L. A Kinetic Study of the Activated Anionic Polymerization of ε-Caprolactam. Polym. Eng. Sci. 1985, 25, 1155–1163. [Google Scholar] [CrossRef]

- Cimini, R.A.; Sundberg, D.C. A Mechanistic Kinetic Model for the Initiated Anionic Polymerization of ε-Caprolactam. Polym. Eng. Sci. 1986, 26, 560–568. [Google Scholar] [CrossRef]

- Ueda, K.; Yamada, K.; Nakai, M.; Matsuda, T.; Hosoda, M.; Tai, K. Synthesis of High Molecular Weight Nylon 6 by Anionic Polymerization of ε-Caprolactam. Polym. J. 1996, 28, 446. [Google Scholar] [CrossRef]

- Mateva, R.; Petrov, P. On the Activating Anionic Polymerization of ε-Caprolactam in Bulk Caused by bis Carbamyl Derivatives. Eur. Polym. J. 1999, 35, 325–333. [Google Scholar] [CrossRef]

- Russo, S.; Maniscalco, S.; Moretti, P.; Ricco, L. Fast-Activated Anionic Polymerization of ε-Caprolactam in the Bulk under Quasi-Adiabatic Conditions: Comparison of Different Kinetic Models. J. Polym. Sci. Part A Polym. Chem. 2013, 51, 4474–4480. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Frolov, V.G.; Ivanova, A.N.; Andrianova, Z.S. The Nonisothermal Anionic Polymerization of Caprolactam. Polym. Sci. USSR 1979, 21, 691–700. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Frolov, V.G.; Ivanova, A.N.; Andrianova, Z.S.; Alekseichenko, L.A. The Kinetics of Anionic Polymerization of Caprolactam in the Presence of Carbamylcaprolactams. Polym. Sci. USSR 1980, 22, 1097–1103. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Kulochikhin, S.G.; Frolov, V.G.; Demina, M.I. Rheokinetics of Anionic Polymerization of Caprolactam. Polym. Sci. USSR 1981, 23, 1471–1479. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Ivanova, S.L.; Frolov, V.G.; Ivanova, A.N.; Andrianova, Z.S. Kinetics of Anionic Polymerization of Lactams. (Solution of Non-Isothermal Kinetic Problems by the Inverse Method). Polymer 1982, 23, 1791–1800. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Beghishev, V.P.; Bolgov, S.A. The Exothermal Effects of Superimposed Processes of Activated Anionic Polymerization of ε-Caprolactam and Crystallization of the Polymer Formed. Polymer 1982, 23, 385–390. [Google Scholar] [CrossRef]

- Camargo, R.E.; Gonzalez, V.M.; Macosko, C.W.; Tirrell, M. Bulk Polymerization Kinetics by the Adiabatic Reactor Method. Rubber Chem. Technol. 1983, 56, 774–783. [Google Scholar] [CrossRef]

- Kamal, M.R.; Sourour, S. Kinetics and Thermal Characterization of Thermoset Cure. Polym. Eng. Sci. 1973, 13, 59–64. [Google Scholar] [CrossRef]

- Kamal, M.R. Thermoset Characterization for Moldability Analysis. Polym. Eng. Sci. 1974, 14, 231–239. [Google Scholar] [CrossRef]

- Sourour, S.; Kamal, M.R. Differential Scanning Calorimetry of Epoxy Cure: Isothermal Cure Kinetics. Thermochim. Acta 1976, 14, 41–59. [Google Scholar] [CrossRef]

- Vicard, C.; De Almeida, O.; Cantarel, A.; Bernhart, G. Experimental Study of Polymerization and Crystallization Kinetics of Polyamide 6 Obtained by Anionic Ring Opening Polymerization of ε-Caprolactam. Polymer 2017, 132, 88–97. [Google Scholar] [CrossRef]

- Begishev, V.P.; Bolgov, S.A.; Malkin, A.Y.; Subbotina, N.I.; Frolov, V.G. Thermal Effects of Polymerization Accompanied by Crystallization. Vysolomol. Soyed. 1979, 21, 714–718. (In Russian) [Google Scholar]

- Begishev, V.P.; Bolgov, S.A.; Malkin, A.Y.; Subbotina, N.I.; Frolov, V.G. Calorimetric Investigation of Anionically Activated Polymerization of e-Caprolactam Accompanied by Crystallization of the Formed Polymer. Vysolomol. Soyed. 1980, 22, 124–128. (In Russian) [Google Scholar]

- Bolgov, S.A.; Begishev, V.P.; Malkin, A.Y.; Frolov, V.G. Role of the Functionality of Activators During Isothermal Crystallization Accompanying the Activated Anionic Polymerization of ε-Caprolactam. Polym. Sci. USSR 1981, 23, 1485–1492. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Beghishev, V.P.; Keapin, I.A.; Andrianova, Z.S. General Treatment of Polymer Crystallization Kinetics—Part 2. The Kinetics of Nonisothermal Crystallization. Polym. Eng. Sci. 1984, 24, 1402–1408. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Beghishev, V.P.; Keapin, I.A.; Bolgov, S.A. General Treatment of Polymer Crystallization Kinetics — Part 1. A New Macrokinetic Equation and Its Experimental Verification. Polym. Eng. Sci. 1984, 24, 1396–1401. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, S.C. Reaction-Induced Crystallization Kinetics during the Anionic Polymerization of ε-Caprolactam. Polym. Eng. Sci. 1988, 28, 13–19. [Google Scholar] [CrossRef]

- Kim, K.J.; Hong, D.S.; Tripathy, A.R. Kinetics of Adiabatic Anionic Copolymerization of ε-Caprolactam in the Presence of Various Activators. J. Appl. Polym. Sci. 1997, 66, 1195–1207. [Google Scholar] [CrossRef]

- Tonoyan, A.H.; Sargsyan, A.G.; Schick, C.; Davtyan, S.P. Crystallization Kinetics under Nonisothermal Polymerization Conditions; Nova Science Publishing: New York, NY, USA, 2007; p. 73. [Google Scholar]

- Vicard, C.; De Almeida, O.; Cantarel, A.; Bernhart, G. TTT Diagram of the Anionic Polymerization PA6 from e-Caprolactam. In Proceedings of the 21st International Conference on Composite Materials (ICCM21), Xian, China, 20–25 August 2017. [Google Scholar]

- Humphry, J.; Vandi, L.-J. Time-Temperature Transformation Modelling for the in situ Processing of Thermoplastics as a Composite Matrix. In Proceedings of the International Conference on Processing and Fabrication of Advanced Materials (PFAM-XXV), Auckland, New Zealand, 20–25 January 2017; p. 11. [Google Scholar]

- Korshak, V.V.; Frunze, T.M.; Davtyan, S.P.; Kurashev, V.V.; Volkova, T.V.; Kot’elnikova, V.A.; Shleifman, R.B. Kinetics of Activated Anionic Polymerization of e-Caprolactam under Non-Isothermal Conditions. Polym. Sci. USSR 1979, 21, 2161–2169. [Google Scholar] [CrossRef]

- Frunze, T.M.; Shleifman, R.B.; Belavtseva, E.M.; Genin, Y.V.; Volkova, T.V.; Kotel’nikov, V.A.; Radchenko, L.G.; Davtyan, S.P.; Kuraschev, V.V.; Tsvankin, D.Y. Kinetic Studies of Structure Formation during Anionic Adiabatic Polymerization of ε-Caprolactam. J. Polym. Sci. Polym. Phys. 1980, 18, 1523–1532. [Google Scholar] [CrossRef]

- Russo, S.; Imperato, A.; Mariani, A.; Parodi, F. The Fast Activation of ε-Caprolactam Polymerization in Quasi-Adiabatic Conditions. Macromol. Chem. Y Phys. 1995, 196, 3297–3303. [Google Scholar] [CrossRef]

- Nováková, V.; Šáchová, M.; Brožek, J.; Bernat, P.; Roda, J. Polymerization of Lactams, 89 Magnesium Caprolactamates as Initiators of ε-Caprolactam Polymerization. Macromol. Symp. 1996, 102, 115–122. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, Y.Y.; Yoon, B.S.; Yoon, K.J. Mechanism and Kinetics of Adiabatic Anionic Polymerization of ε-Caprolactam in the Presence of Various Activators. J. Appl. Polym. Sci. 1995, 57, 1347–1358. [Google Scholar] [CrossRef]

- Dencheva, N.; Denchev, Z.; Pouzada, A.S.; Sampaio, A.S.; Rocha, A.M. Structure–Properties Relationship in Single Polymer Composites Based on Polyamide 6 Prepared by in-Mold Anionic Polymerization. J. Mater. Sci. 2013, 48, 7260–7273. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Kiss, L. Attempts of Separation of the Polymerization and Crystallization Processes by Means of DSC Thermograms of Activated Anionic Polymerization of e-Caprolactam. Macromol. Chem. 1979, 180, 1593–1597. [Google Scholar] [CrossRef]

- Kiss, L.; Karger-Kocsis, J. DSC Investigations on the Alkaline Polymerization of ε-Caprolactam. J. Therm. Anal. 1980, 19, 139–141. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Kiss, L. DSC Studies on the Activated Anionic Polymerization of ε-Caprolactam in the Presence of Crown Compounds. J. Polym. Sci. Polym. Symp. 1981, 69, 67–71. [Google Scholar] [CrossRef]

- Khodabakhshi, K.; Gilbert, M.; Fathi, S.; Dickens, P. Anionic Polymerisation of Caprolactam at the Small-Scale via DSC Investigations. J. Therm. Anal. Calorim. 2014, 115, 383–391. [Google Scholar] [CrossRef]

- Barhoumi, N.; Maazouz, A.; Jaziri, M.; Abdelhedi, R. Polyamide from Lactams by Reactive Rotational Molding via Anionic Ring-Opening Polymerization: Optimization of Processing Parameters. Express Polym. Lett. 2013, 7, 76–87. [Google Scholar] [CrossRef]

- Taki, K.; Shoji, N.; Kobayashi, M.; Ito, H. A Kinetic Model of Viscosity Development for in situ Ring-Opening Anionic Polymerization of ε-Caprolactam. Microsyst. Technol. 2017, 23, 1161–1169. [Google Scholar] [CrossRef]

- Thomassey, M.; Revol, B.P.; Ruch, F.; Schell, J.; Bouquey, M. Interest of a Rheokinetic Study for the Development of Thermoplastic Composites by T-RTM. Univ. J. Mater. Sci. 2017, 5, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Sibal, P.W.; Camargo, R.E.; Macosko, C.W. Designing Nylon-6 Polymerization Systems for RIM. Polym. Proc. Eng. 1983, 1, 147–169. [Google Scholar]

- Davé, R.S.; Kruse, R.L.; Udipi, K.; Williams, D.E. Polyamides from Lactams via Anionic Ring-Opening Polymerization: 3. Rheology. Polymer 1997, 38, 949–954. [Google Scholar] [CrossRef]

- Dave, R.S.; Udipi, K.; Kruse, R.L. Chemistry, Kinetics, and Rheology of Thermoplastic Resins Made by Ring Opening Polymerization. In Processing of Composites; Dave, R.S., Loos, A.C., Eds.; Hanser: Munich, Germany, 2000; p. 500. [Google Scholar] [CrossRef]

- Castro, J.M.; Macosko, C.W. Studies of Mold Filling and Curing in the Reaction Injection Molding Process. AlChE J. 1982, 28, 250–260. [Google Scholar] [CrossRef]

- Stolin, A.M.; Merzhanov, A.G.; Malkin, A.Y. Non-Isothermal Phenomena in Polymer Engineering and Science: A Review. Part II: Non-Isothermal Phenomena in Polymer Deformation. Polym. Eng. Sci. 1979, 19, 1074–1080. [Google Scholar] [CrossRef]

- Dusi, M.R.; Lee, W.I.; Ciriscioli, P.R.; Springer, G.S. Cure Kinetics and Viscosity of Fiberite 976 Resin. J. Compos. Mater. 1987, 21, 243–261. [Google Scholar] [CrossRef]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-Forming Liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Dkiera, M.; Lamnawara, K.; Maazouz, A. Rheokinetic Studies for In-Situ Monitoring of T-RTM Process: Rheology Coupled to Dielectric Analysis and FTIR Spectroscopy. In Proceedings of the PPS-32: 32nd International Conference of the Polymer Processing Society-Conference Papers, Lyon, France, 25–29 July 2017; AIP Conference Proceeding: Lyon, France, 2017. [Google Scholar] [CrossRef]

- Maazouz, A.; Lamnawar, K.; Dkier, M. Chemorheological Study and in-situ Monitoring of PA6 Anionic-Ring Polymerization for RTM Processing Control. Compos. Part A 2018, 107, 235–247. [Google Scholar] [CrossRef]

- Ramos, J.A.; Pagani, N.; Riccardi, C.C.; Borrajo, J.; Goyanes, S.N.; Mondragon, I. Cure Kinetics and Shrinkage Model for Epoxy-Amine Systems. Polymer 2005, 46, 3323–3328. [Google Scholar] [CrossRef]

- Goyanes, S.; Salgueiro, W.; Somoza, A.; Ramos, J.A.; Mondragon, I. Direct Relationships between Volume Variations at Macro and Nanoscale in Epoxy Systems. Pals/pvT Measurements. Polymer 2004, 45, 6691–6697. [Google Scholar] [CrossRef]

- Delaunay, D.; Boyard, N.; Sobotka, V. Pressure-Volume-Temperature (pvT) Analysis. In Micro- and Nanostructures Epoxy/Rubber Blends; Thomas, S., Sinturel, C., THomas, R., Eds.; Wiley-VCH Verlag: Weinheim, Germany, 2014; pp. 179–191. [Google Scholar]

- Johari, G.P.; Mc Ananama, J.; Wasylyshyn, D.A. The Effects of Pressure and Temperature on Molecular Dynamics during Linear-Chain Polymerization by Dielectric Measurements. J. Chem. Phys. 1996, 105, 10621–10631. [Google Scholar] [CrossRef]

- Boyard, N.; Vayer, M.; Sinturel, C.; Erre, R.; Delaunay, D. Analysis and Modeling of pvTx Diagram of an Unsaturated Polyester Resin, Thermoplastic Additive, and Mineral Fillers Blend. J. Appl. Polym. Sci. 2003, 88, 1258–1267. [Google Scholar] [CrossRef]

- Rodgers, P.A. Pressure-Volume-Temperature Relationships for Polymeric Liquids: A Review of Equations of State and Their Characteristic Parameters for 56 Polymers. J. Appl. Polym. Sci. 1993, 48, 1061–1080. [Google Scholar] [CrossRef]

- Szabó, F.; Kovács, J.G. Development of a Pressure–Volume–Temperature Measurement Method for Thermoplastic Materials Based on Compression Injection Molding. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Szabo, F.; Kovach, J.G. Development of a Novel pvT Measuring Technique. Mater. Sci. Forum 2013, 729, 126–131. [Google Scholar] [CrossRef]

- García-Manrique, J.; Hoto, R.; Gascón, L.; Andrés, J. A Numerical Simulation of Woven/Anionic Polyamide 6 Composite Part Manufacturing Using Structural Reactive Injection Moulding Process. J. Thermoplast. Compos. Mater. 2016, 29, 219–233. [Google Scholar] [CrossRef]

- Deléglise, M.; Le Grognec, P.; Binetruy, C.; Krawczak, P.; Claude, B. Modeling of High Speed RTM Injection with Highly Reactive Resin with on-Line Mixing. Compos. Part A 2011, 42, 1390–1397. [Google Scholar] [CrossRef]

- Abisset-Chavanne, E.; Chinesta, F. Toward an Optimisation of the Reactive Resin Transfer Molding Process: Thermo-Chemico-Mechanical Coupled Simulations. Int. J. Mater. Form. 2013, 7, 249–258. [Google Scholar] [CrossRef]

- Imbert, M.; Abisset-Chavanne, E.; Comas-Cardona, S.; Prono, D. Efficient Dual-Scale Flow and Thermochemo-Rheological Coupling Simulation During On-Line Mixing Resin Transfer Molding Process. J. Compos. Mater. 2017, 52, 313–330. [Google Scholar] [CrossRef]

- Imbert, M. High Speed Reactive Resin Transfer Moulding (RTM) Process Simulation for Mass Production of Automotive Structural Parts. SAE Int. J. Mater. Manuf. 2015, 8, 503–515. [Google Scholar] [CrossRef]

- Imbert, M.; Comas-Cardona, S.; Abisset-Chavanne, E.; Prono, D. Introduction of Intra-Tow Release/Storage Mechanisms in Reactive Dual-Scale Flow Numerical Simulations. J. Compos. Mater. 2018, 53, 125–140. [Google Scholar] [CrossRef]

- Nagy, J.; Reith, L.; Fischlschweiger, M.; Steinbichler, G. Modeling the Influence of Flow Phenomena on the Polymerization of ε-Caprolactam. Chem. Eng. Sci. 2014, 111, 85–93. [Google Scholar] [CrossRef]

- Nagy, J.; Reith, L.; Fischlschweiger, M.; Steinbichler, G. Influence of Fiber Orientation and Geometry Variation on Flow Phenomena and Reactive Polymerization of ε-Caprolactam. Chem. Eng. Sci. 2015, 128, 1–10. [Google Scholar] [CrossRef]

| Year | The Goal of the Experiments | Monomer/Initiator/Activator (amount) | Thermal Mode | Results/Comments | Reference |

|---|---|---|---|---|---|

| 1975 | A kinetic study on the AROP of CL by DSC in isothermal conditions and in a conversion range of 20–90%. | CL/NaCL/HMDI* | Tp = 180–201 °C | The authors proved that DSC could be effectively used for the investigation of the kinetics of the AROP of CL, and to obtain data in agreement with those for adiabatic measurements. | [42] |

| 1979 | The study describes an attempt to separate the polymerization and crystallization in the AROP of CL and the evaluation of the individual enthalpies of each phenomena by means of the curve-resolving technique. | CL/LiL/N-acetylcaprolactam (1 mol /%/1 mol %) CL/NaCL/N-acetylcaprolactam (1 mol /%/1 mol %) CL/KL/N-acetylcaprolactam (1 mol %/1 mol %) | °C/min | = −144 ± 6 J/g = −222 ± 5 J/g (100% crystallinity) The curve-resolving technique is proposed. | [75] |

| 1982 | An approach to separate crystallization and polymerization enthalpies was proposed. The method is based on the assumption that only the polymerized portion of the reaction mass can be crystallized. | CL/NaCL/AcCL | Tp = 160 °C–200 °C | The autocatalytic nature of the AROP of CL was confirmed. The values of the polymerization and crystallization kinetics constants were determined. | [53] |

| 1992 | The study delineates the separation of polymerization and crystallization and the effects of heating rate, catalyst and activator concentration on the kinetics of both processes. | CL/NaH/ABC (1:1; 2:1; 3:1; 5:1) | ms = 25–40 mg and 25 °C/min Cooling rate: and 25 °C/min Tp = 150 °C–200 °C | The authors examined the effect of initiator and activator concentration on polymerization and crystallization. They observed polymerization followed by crystallization when polymerization temperature was lower than crystallization temperatures. Crystallization was not observed for polymerization at temperatures higher than the melt crystallization temperature. The driving force for immediate crystallization following polymerization was attributed to the high degree of supercooling. | [36] |

| 2012 | The authors discussed the effect of processing parameters, such as polymerization temperature and different initiator/activator concentrations, on the kinetics of polymerization. | CL/C1/C20 | - | A temperature of 150 °C and formulation CL/C1/C20 (100/4/4) were demonstrated to be optimal. At 150 °C, AROP led to a similar degree of conversion as in the case of melt-processed PA-6. | [79] |

| 2013 | To study the influence of heating strategy on the AROP of CL. | CL/EtMgBr/C8H13NO2 (2.5 mol %/2.5 mol %) CL/C10/C20 (2.5 mol %/1.25 mol %) | °C/min (5 °C/min interval) Tp = 110–150 °C (5 °C interval) ms = 4–24 mg | The authors proved that the mechanism of polymerization does not differ significantly for small-scale and bulk samples. The relationship between heating rate and polymerization-crystallization was found. The peak temperature of polymerization increases with increasing heating rate. At fast cooling rates, PA-6 quenched before the crystallization process is completed. Increasing the heating and cooling rates result in production irregularities and poorer crystalline structure. Monomer conversion increases when the maximum temperature is increased from 140 °C to 180 °C, and decreases afterwards. | [78] |

| 2017 | To determine a heat flow curve, which involved the kinetics of polymerization and crystallization from 50 °C to 250 °C at various heating rates | CL/GAP-1DA/GAP-1R | °C/min = 30–260 °C | The DSC heat flow curve was separated into polymerization and crystallization curves with the use of the Kamal model and the generalized Avrami model, respectively. | [80] |

| 2017 | To characterize the AROP of CL under isothermal and non-isothermal conditions via DSC. | CL/C1/C20P (1.4 mol/kg/2.0 mol/kg) | Polymerization and crystallization have opposite temperature dependencies. The reduction of the temperature of synthesis or heating rate slows down the kinetics of polymerization, while increasing crystallization. Crystallization kinetics strongly depend on the kinetics of chain extension and polymerization controls the overall time of synthesis. | [58] |

| Year | Experimental Setup Description | Monomer/Initiator/Activator (Amount) | Thermal Modes | Results/Comments | Reference |

|---|---|---|---|---|---|

| 1997 | Equipment: Rheometrics Dynamic Mechanical Analyzer, RMS-800. Rheometer platens: disposable aluminum parallel plates (D50 mm, 0.5 mm gap). The reactive mixture is delivered into the rheometer platen gap by simultaneous injection of two streams (one containing CL with the initiator, and the other containing CL with the activator) through a static mixture. Shear mode: sinusoidal oscillatory shear rate rad s−1. Sample surface to volume ratio: 40 cm−1 | CL/CLMgBr/acyllactam (133 mmol L−1/90 mmol L−1) | Isothermal Tp = 120 °C − 160 °C (step 10 °C) | 1. The reaction time (required for the complex viscosity level of 103 Pa∙s) for the examined reactive mixture was extremely short: 90 s at 120 °C 45 s at 160 °C. 2. Below 50% conversion, complex viscosity can be described by the Sibal model: | [83,84] |

| 2013 | Equipment: strain-controlled rheometer ARES. Rheometer platens: cone and plate (D40 mm, 0.06 mm gap). The reactive mixture is premixed and quickly introduced with a syringe into the gap between the preheated cone and plate. | CL/C1/C20 (100/3/3) CL/C1/C20 (100/4/4) | Isothermal Tp = 150 °C − 220 °C (step 10 °C) | The isoviscosity curves vs. time and temperature were obtained for the AROP of CL. | [79] |

| 2017 | Equipment: parallel plate rheometer MCR-301 Rheometer platens: upper plate – disposable aluminum plate D50 mm and D25 mm; lower plate – aluminum cup D75 mm; 0.5 mm gap. The reactive mixture is premixed and quickly poured into the rheometer cup. | CL/ GAP-1DA/ GAP-1R | Isothermal Tp = 80 °C − 170 °C (step 10 °C) | The obtained viscosity data was used to determine constants of the modified Castro-Macosko model. | [80] |

| 2017 | Equipment: rheometer (ARES). Rheometer platens: disposable aluminum cone-plate (D25 mm), specially designed to prevent the evaporation of the reaction mixture. A special oil bath was used as isolator. The reactive mixture is introduced in powder form. Shear rates: 0.1/1/10/100 s−1 | CL/C10/C20 (4.5 wt%/ 3.0 wt%) | Isothermal Tp = 140 °C − 170 °C (step 10 °C) | It was found that the shear rate strongly influenced the kinetics of polymerization. The higher the polymerization temperature and shear rate are, the shorter polymerization time becomes. The time to reach the viscosity of 100 Pa∙s is between 75 s and 250 s. | [81] |

| 2018 | Equipment: Thermo Scientific™ HAAKE™ MARS™ Rheometer coupled with FTIR | CL/C1/C20P (100/3/3) (100/4/4) | Isothermal Tp = 190 °C, 230 °C | A correlation between the dielectric parameters and viscosity change was proposed: , Is ionic conductivity, m is the power factor. -Temperature-Transformation diagrams were plotted. | [89,90] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ageyeva, T.; Sibikin, I.; Kovács, J.G. A Review of Thermoplastic Resin Transfer Molding: Process Modeling and Simulation. Polymers 2019, 11, 1555. https://doi.org/10.3390/polym11101555

Ageyeva T, Sibikin I, Kovács JG. A Review of Thermoplastic Resin Transfer Molding: Process Modeling and Simulation. Polymers. 2019; 11(10):1555. https://doi.org/10.3390/polym11101555

Chicago/Turabian StyleAgeyeva, Tatyana, Ilya Sibikin, and József Gábor Kovács. 2019. "A Review of Thermoplastic Resin Transfer Molding: Process Modeling and Simulation" Polymers 11, no. 10: 1555. https://doi.org/10.3390/polym11101555