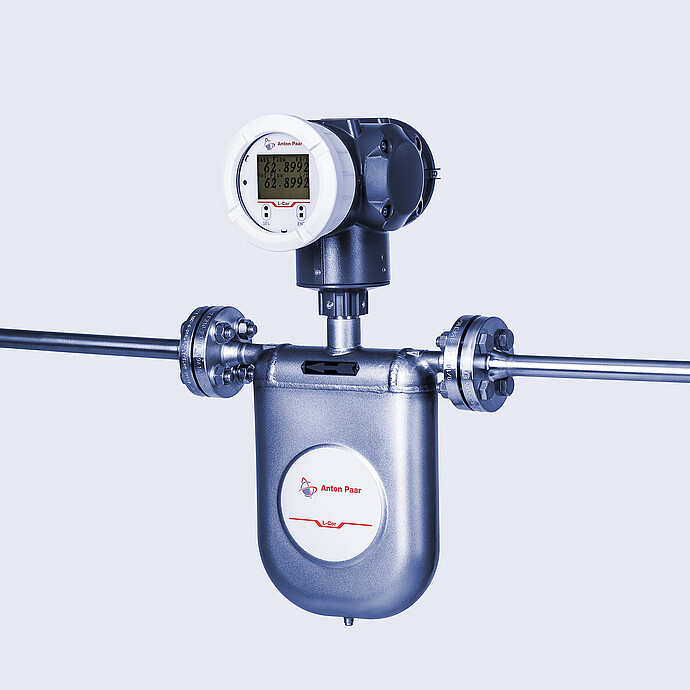

Coriolis Flow Meter:

L-Cor

- Large flow range: 0.4 g/min to 1,400 t/h

- Broad temperature range: -200 °C to +200 °C

- Stainless steel and alloy c wetted parts available

Need high accuracy in demanding environments? Look no further than our Type U L-Cor 8000 Coriolis mass flow meters. These provide you the highly accurate measurements for mass flow and density.

Flow – with Anton Paar.

Key features

A Coriolis flow meter that’s perfect for batching processes

Discover the ideal solution for your batching processes with our Coriolis flow meter. This cutting-edge meter not only provides highly accurate measurements at 0.1% accuracy but also boasts fast response times. With its precision and efficiency, you can streamline your batching operation to ensure optimal performance and productivity. Trust in our Coriolis flow meter to elevate the accuracy and speed of your process control.

One portfolio to cover all of your needs

Easily conduct precise measurements of mass flow across a range spanning from 0.4 grams per minute to 1,400 metric tons per hour. From micro dosing applications for handling fragrances to large volume custody transfer measurements, our sensor covers the entire spectrum. Whether you're dealing with minute quantities or colossal volumes, our solution ensures the utmost precision and reliability, meeting the diverse needs of your applications.

Broad temperature range for various measurement types

Cover all of your process temperature needs with our 550 °C temperature span. Our versatile U sensors are available in various configurations, including cryogenic and explosion-proof versions capable of measuring temperatures as low as -200°C for hazardous areas. Additionally, we offer high-temperature variants that enable measurements of up to 350°C. This range ensures that you have the right sensor for any temperature application, empowering you to achieve precise and reliable temperature measurements across the spectrum of your operations.

Various wetted parts for tough environments

Choose from a variety of wetted parts options for your Coriolis flow meter, including stainless steel and alloy C, to ensure compatibility with even the most aggressive fluid environments. This versatility guarantees that you can confidently employ our meters in challenging settings where chemical exposure is a concern. With our range of wetted parts materials, you not only optimize performance but also enhance durability and corrosion resistance, making our Coriolis flow meters the trusted choice for your fluid measurement needs.

A partner with broad knowledge in concentration measurement

When you choose to collaborate with us, you're partnering with a dedicated ally possessing extensive expertise in concentration measurement across a wide range of applications. Our in-depth knowledge lets us offer you tailored solutions and invaluable insights, ensuring your specific needs are met with precision and efficiency. You can trust us to be the reliable partner by your side, helping you excel in concentration measurement, no matter the complexity or scope of your projects.

Technical specifications

| L-Cor 8000 | L-Cor 8100 | L-Cor 8200 | L-Cor 8300 | ||||

| Flowrate | 0.024 kg/h to 9 kg/h | 0.72 kg/h to 72 kg/h | 3.6 kg/h to 120,000 kg/h | 3420 kg/h to 700,000 kg/h | 108 kg/h to 342,000 kg/h | 108 kg/h to 700,000 kg/h | 24 kg/h to 2,550 kg/h |

| Flow accuracy | ± 0.2% | ± 0.1% | ± 0.1% ± ZS | ± 0.1%* | ± 0.2% ± ZS | ||

| Flow repeatability | ± 0.05% | ± 0.05% ± ZS | ± 0.05% | ± 0.1% ± ½" ZS | |||

| Density range | 30 kg/m3 to 2,000 kg/m3 | 300 kg/m3 to 2,000 kg/m3 | |||||

| Density accuracy | ± 3 kg/m3 | ± 0.5 kg/m3 | ± 3 kg/m3 | ± 0.5 kg/m3 | ± 4 kg/m3 | ||

| Nominal diameter | 1/4" | 3/8" | 3/8" to 3" | 4" to 6" | 1" to 6" | 1/2" | |

| Ambient temperature | - 40 °C to +55 °C | ||||||

| Process temperature | - 200 °C to +200 °C | -40 °C to +350 °C | -200 °C to +50 °C | -200 °C to +200 °C | |||

| Process pressure absolute | 150 bar (at 20 °C) | According to flange specification | Max. 430 bar (at 20°C) | ||||

| Process connection | Thread R 1/4 | ASME B16.5 Class 150, 300, 600 EN 1092-1 PN40 Tri-clamp ISO 2852 Thread R/Rc | ASME B16.5 Class 150, 300, 600 EN 1092-1 PN40 | ASME B16.5 Class 150, 300, 600 EN 1092-1 PN40 | ASME B16.5 Class 150, 300, 600 EN 1092-1 PN40 | Rc 3/8 Rc 3/4 | |

| Wetted parts | 1.4404 (SUS316L) | 1.4404 (SUS316L) Alloy C-22 | 1.4404 (SUS316L) | 1.4404 (SUS316L) | Alloy C-22 | ||

| Ex-version | ATEX/IECEx CSA NEPSI | ||||||

| Communication | Bell 202/Analog Modbus/Analog Profibus PA Fieldbus | ||||||

| Transmitter mounting | Integral/ separate | ||||||

* ± ZS is applied for flow rates below 5 % of the maximum measuring range. Accuracy valid at reference conditions. ZS = Zero stability error = (Zero stability)/(Flowrate at the moment) x100%

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage | Beer | Mass Flow Measurement in the Beer Brewing Process Application Reports

-

Dosing | Dosing Under Control: Optimized Dosing via Coriolis Flowmeter Application Reports

-

Petroleum | Custody Transfer Metering System using Coriolis Technology Application Reports

-

Petroleum | Drilling Fluid in the Upstream Segment Application Reports

-

Petroleum | Evaluating water presence in the midstream segment Application Reports

-

Petroleum | Product determination in the downstream segment Application Reports

-

Petroleum | Volume to mass conversion in the downstream segment Application Reports