Highlights

-

As an emerging preparation strategy for MXenes, Lewis acidic etching has attracted increasing attention in the past few years benefiting from a series of merits.

-

Lewis acidic etching method is mainly presented from etching mechanism, terminations regulation, in-situ formed metals and delamination of multi-layered MXenes.

-

The applications of MXenes and MXene-based composites obtained by Lewis acidic etching route in energy storage and conversion, sensors and microwave absorption are carefully summarized.

Abstract

Since the discovery in 2011, MXenes have become the rising star in the field of two-dimensional materials. Benefiting from the metallic-level conductivity, large and adjustable gallery spacing, low ion diffusion barrier, rich surface chemistry, superior mechanical strength, MXenes exhibit great application prospects in energy storage and conversion, sensors, optoelectronics, electromagnetic interference shielding and biomedicine. Nevertheless, two issues seriously deteriorate the further development of MXenes. One is the high experimental risk of common preparation methods such as HF etching, and the other is the difficulty in obtaining MXenes with controllable surface groups. Recently, Lewis acidic etching, as a brand-new preparation strategy for MXenes, has attracted intensive attention due to its high safety and the ability to endow MXenes with uniform terminations. However, a comprehensive review of Lewis acidic etching method has not been reported yet. Herein, we first introduce the Lewis acidic etching from the following four aspects: etching mechanism, terminations regulation, in-situ formed metals and delamination of multi-layered MXenes. Further, the applications of MXenes and MXene-based hybrids obtained by Lewis acidic etching route in energy storage and conversion, sensors and microwave absorption are carefully summarized. Finally, some challenges and opportunities of Lewis acidic etching strategy are also presented.

Similar content being viewed by others

1 Introduction

The great success of graphene triggers enormous exploration in other two-dimensional (2D) materials, such as transition metal dichalcogenides, hexagonal boron nitride, layered double hydroxides (LDHs), graphitic carbon nitride, germanene, and black phosphorus [1,2,3,4,5,6,7,8,9,10]. In 2011, multi-layered Ti3C2Tx was first reported by Gogotsi and Barsoum’s group, which announces the birth of a brand-new and large family of 2D materials, namely transition metal carbides, nitrides and carbonitrides termed as MXenes [11,12,13]. They are generally derived from MAX precursors which possess a formula of Mn+1AXn (n = 1–4), where M stands for early transition metals (e.g., Ti, Ta, V, Mo, Nb, and Cr), A is mainly group 13 or 14 elements, such as Al, Si and Ga, and X refers to carbon or nitrogen (Fig. 1a) [14,15,16]. So far, 155 MAX phases have been successfully synthesized [17]. It is worth mentioning that some non-MAX ternary layered compounds such as Mo2Ga2C, Zr3Al3C5 and Hf3Al3C5 can also be used as precursors to prepare MXenes [18,19,20,21]. Structurally, MAX precursors possess typical hexagonal closely packed crystal structure with a P63/mmc space group, and they are established by stacking of Mn+1Xn building blocks that are interleaved with A-site atom layer along the c direction, leading to strong M-X covalent/metallic/ionic mixed bond and weak M-A metallic bond [21,22,23]. The difference in bond strength allows the A-site atoms to be selectively removed from MAX phase by a top-down method, and the remaining loosely stacked Mn+1Xn architectures terminated with mixed surface groups T (e.g., –O, –OH, and –F) are named as MXenes, leading to a general chemical formula of Mn+1XnTx (n = 1–4, x ≤ 2) (Fig. 1b) [24,25,26].

a Element composition of MAX phase. Reproduced with permission from [16] Copyright 2022, Elsevier. b Schematic illustration of the preparation of various MXenes from corresponding MAX phases. Reproduced with permission from [26] Copyright 2021, Wiley–VCH. c The annual published article numbers of MXenes. d Schematic of s-MXenes, i-MXenes and o-MXenes

The publications of MXenes have increased significantly in the past eight years and reach around 2600 in 2021 (Fig. 1c). It is noteworthy that the majority of reported articles are focused on Ti3C2Tx MXene owing to its superior electronic conductivity (24,000 S cm−1) and large interlayer spacing [27,28,29,30]. Correspondingly, great progress has been achieved in the development of MXenes, especially in compositional and structural diversity. First, there are four kinds of MXenes with different stoichiometries including M2XTx, M3X2Tx, M4X3Tx and M5X4Tx [27, 31,32,33]. Then, when the number of elements at the M-site exceeds two, MXenes can be categorized into three types according to the distribution of M-site atoms, namely s-MXenes with disordered arrangement, i-MXenes with in-plane ordering and o-MXenes with out-of-plane ordering (Fig. 1d) [15, 34,35,36]. Additionally, X-site atoms can be occupied by carbon, nitrogen or both [37,38,39]. Furthermore, the surface groups of MXenes mainly comprise of –O, –OH, –F, –Cl, –Br, –I, –S, –Se, –Te, –NH, etc., and can also be adjusted by etchants, termination substitution reaction and storage environment [40,41,42,43]. To date, nearly 50 various MXenes have been experimentally fabricated [44]. Considering the great tunability of M-site atoms, X-site atoms and surface terminations as well as the structural diversity of MXenes (Fig. 2), the number of MXenes will increase dramatically in the near future, eventually developing into a huge family [45].

MXenes generally exhibit a series of unique properties, including superior electronic conductivity, large and tunable gallery spacing, low ion diffusion barrier, rich surface chemistry, outstanding redox activity, hydrophilicity and wonderful mechanical strength (Fig. 2), making MXenes promising candidates for various fields [34, 45,46,47,48]. Specifically, large gallery spacing and rapid ion migration kinetics allow their use in high-performance metal-ion batteries and supercapacitors (SCs) [28, 39, 49, 50]. Flexibility, rich surface chemistry, adjustable interlayer spacing and high mechanical strength of MXenes enable them to be utilized as advanced separation membranes [51]. Excellent electronic conductivity and light weight of MXenes permit their apply in electromagnetic interference shielding, and ample redox centers endow them with superior catalysis capability [52,53,54]. Additionally, MXenes colloidal solution can be readily processed into freestanding papers and additive-free inks owing to the superior hydrophilicity [55, 56]. More importantly, the large compositional space, structural diversity and rich interlayer environment of MXenes offer great possibilities for unique combination and adjustability of properties (Fig. 2). For example, nitride MXenes display stronger polarity, higher electronic conductivity and more active sites compared with carbide counterparts, which renders them promising materials for secondary batteries [57]. Besides, high entropy MXenes such as (Ti1/5V1/5Zr1/5Nb1/5Ta1/5)2CTx offers high mechanical strain owing to the distinct lattice distortions, which can effectively induce the uniform nucleation and deposition of Li metal [58]. Last but not least, the terminations play a key role in tuning the physicochemical characteristics of MXenes, especially in electronic properties. For example, MXenes without surface group possess high electron density near the Fermi level, while surface groups can generally alter the density of states and shift the Fermi level, finally resulting in semiconductor-like characteristics [59,60,61]. Furthermore, Nb2C MXene with –Cl, –S or –Se surface groups demonstrated superconductivity, whereas the O or F-terminated Nb2C fail to enter the superconducting state in the low-temperature region [42, 62]. In summary, MXenes have been widely explored in various fields up to now and the great tunability of electronic, optical, magnetic, mechanical and thermal properties would gradually expand their applications in the future [45, 63].

The effective synthesis strategy is able to adjust the properties of MXenes and make large-scale manufacturing possible [43, 64]. Until now, various preparation approaches for MXenes have been proposed. HF aqueous solution was first exploited to etch MAX precursors in 2011, which endows MXenes with distinct accordion-like morphology and mixed terminations of –OH, –O and –F [11]. However, the strong corrosiveness of HF prevents some researchers from participating in the research of MXenes. In 2014, Ghidiu et al. reported the in-situ formation of HF etchant by simply mixing LiF and HCl, which is able to achieve the etching of MAX precursor and improve the safety of experimental operation simultaneously [65]. Nevertheless, it is extremely challenging to prepare MXenes with uniform surface terminations by HF or LiF/HCl etching. Very recently, ZnCl2 Lewis acidic salt was employed to etch Ti3AlC2 MAX, which was based on the replacement reaction between Zn2+ cations and zero-valence Al of Ti3AlC2 MAX, finally leading to Zn metal-decorated multi-layered Ti3C2Cl2 MXene [66]. This strategy was further developed into a general route by using various Lewis acidic molten salts etchants to synthesize MXenes [67]. Compared with HF or LiF/HCl etching, Lewis acidic molten salts etching strategy demonstrates a series of advantages, such as greatly enhanced safety because of avoiding the direct or indirect use of hazardous HF, great universality to etch non-Al MAX precursors, the ability to endow MXenes with controllable surface terminations, easy accessibility to in-situ formed metals-modified MXenes and the potential for large-scale application.

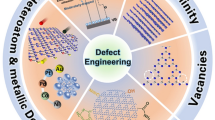

The Lewis acidic molten salts etching approach has received considerable attention since 2019 [66, 67], which can be proved by the increasing article numbers (Fig. 3a). In summary, the MXenes and MXene-based composites prepared by Lewis acidic etching route have been applied by researchers from different fields, and significant progress has been achieved in the development of Lewis acidic etching (Fig. 3b–c), showing great utilization potential. Therefore, it is highly required to summarize these advances timely. Nevertheless, to the best of our knowledge, there has been no review discussing the research progress of Lewis acidic molten salts etching approach. Herein, we systematically summarize the recent advances of Lewis acidic etching strategy. First, we briefly introduce the traditional synthesis techniques of MXenes based on non-Lewis acidic etching route, mainly including HF etching, in-situ HF etching, bifluoride salts etching, electrochemical etching, alkali etching, common molten salts etching, etc. Then, Lewis acidic etching strategy are mainly presented from the following four aspects: etching mechanism, terminations regulation, in-situ formed metals and delamination of multi-layered MXenes (Fig. 4). Subsequently, the applications of MXenes and MXene-based composites produced by Lewis acidic molten salts etching route in energy storage and conversion, sensors and microwave absorption have been comprehensively discussed. Finally, we also propose some perspectives for the challenges and opportunities of Lewis acidic etching. This review aims to provide some help in the future development of Lewis acidic molten salts etching strategy and enable more researchers to fully understand this emerging method, thereby promoting its widespread utilization.

a Annual publications of Lewis acidic etching method. b Application ratio of MXenes and MXene-based composites prepared by Lewis acidic etching route in different fields. c A timeline showing the development progress of Lewis acidic etching route. Image published in 2019.03: Reproduced with permission from [66] Copyright 2019, American Chemical Society. Image published in 2020.04: Reproduced with permission from [67] Copyright 2020, The Authors, published by Springer Nature. Image published in 2020.06: Reproduced with permission from [157] Copyright 2020, Wiley–VCH. Image published in 2020.07: Reproduced with permission from [42] Copyright 2020, The American Association for the Advancement of Science. Image published in 2021.08: Reproduced with permission from [112] Copyright 2021, The Authors, published by Springer Nature. Image published in 2021.09: Reproduced with permission from [122] Copyright 2021, Wiley–VCH. Image published in 2022.08: Reproduced with permission from [147] Copyright 2022, Wiley–VCH. Image published in 2022.11: Reproduced with permission from [126] Copyright 2022, The Authors, published by Wiley–VCH

2 MXene Synthesis: Non-Lewis Acidic Etching Methods

2.1 HF Etching

It is well known that graphene can be obtained by mechanical exfoliation of graphite because there is only weak van der Waals interaction between the layers [68, 69]. However, the metallic bond between M and A atoms in MAX precursors is stronger than van der Waals force, which makes it impossible to obtain MXenes via mechanical stripping of MAX precursors [21, 26]. Therefore, researchers have to explore other methods to prepare MXenes. In 2011, Gogotsi and Naguib et al. immersed Ti3AlC2 MAX precursor in HF aqueous solution at room temperature and the Al layers can be selectively removed owing to the large difference between Ti-C and Ti–Al bond strength, thus leading to the successful preparation of multi-layered Ti3C2Tx MXene with obvious accordion-like morphology (Fig. 5a–b) [11, 70,71,72]. For the HF etchant, H+ cations serve as oxidant and F− anions act as ligand to combine with by-product of the reaction. The etching process is presented as follows:

a Schematic showing the preparation of multi-layered Ti3C2Tx MXene by HF etching. Reproduced with permission from [70] Copyright 2022, American Chemical Society. b SEM image of multi-layered Ti3C2Tx MXene. Reproduced with permission from [72] Copyright 2020, Springer Nature. c SEM image of single-layered Ti3C2Tx MXene. Reproduced with permission from [82] Copyright 2021, American Chemical Society. d Schematic exhibiting the reaction mechanism between Ti3AlC2 and bifluorides. Reproduced with permission from [93] Copyright 2016, Elsevier. e Schematic of the electrochemical etching of Ti3AlC2 MAX in a binary aqueous electrolyte. Reproduced with permission from [98] Copyright 2018, Wiley–VCH. f Schematic of synthesis of Ti3C2Tx MXene by NaOH-assisted hydrothermal method. Reproduced with permission from [101] Copyright 2018, Wiley–VCH. g Synthesis of Mo2N and V2N MXene via ammoniation strategy. Reproduced with permission from [105] Copyright 2017, Royal Society of Chemistry. h Schematic diagram showing the preparation of Ti3C2Tx MXene via iodine-assisted etching. Reproduced with permission from [108] Copyright 2021, The Authors, published by Wiley–VCH

Specifically, the almost zero-valence Al atoms in Ti3AlC2 precursor lose electrons to become Al3+ cations and then combine with F− anions ligand to form soluble AlF3 [70, 71]. Simultaneously, the multi-layered Ti3C2 MXene is generally modified with –O, –OH and –F groups based on Eqs. (2–4). The introduction of surface functional groups results in the shift of (002) peak to lower angle, which can effectively confirm the successful preparation of MXenes [70, 73]. Since then, a series of MXenes such as Ti2CTx, Nb2CTx, V2CTx, Ti3CNTx and Nb4C3Tx have been successfully prepared by HF etching [13, 74,75,76,77]. Additionally, the obtained multi-layered MXenes can be intercalated by large organic molecules such as dimethyl sulfoxide (DMSO), urea, tetramethylammonium hydroxide (TMAOH), isopropanol (IPA), isopropyl amine (i-PrA), tetrabutylammonium hydroxide (TBAOH), which further expands the gallery spacing and weakens the interlayer interaction [78,79,80,81], finally enabling the multi-layered MXenes to be delaminated into few-layered or single-layered MXenes (Fig. 5c) [82].

MAX precursors with different M-site atoms, A-site atoms, X-site atoms and n values usually require different HF concentration, etching time and reaction temperature. Generally, Mo-based and Nb-based MAX require higher HF concentration than Ti-based MAX to prepare corresponding MXenes [83, 84]. In addition, the etching of Si-based MAX including Ti3SiC2 requires HF and other strong oxidants (H2O2, KMnO4, etc.) to complete together [85]. Besides, compared with carbide MXenes, nitride MXenes require more precise adjustment of etching parameters during the preparation process, because the M–N bond may be broken under the attack of HF etchant [57]. However, harsh reaction environment could result in the formation of defects, such as Ti vacancy, which can adversely affect the electronic conductivity of MXenes [86]. Furthermore, some non-MAX precursors such as Zr3Al3C5, Hf3Al4C6 and Mo2Ga2C can also be etched by HF to obtain Zr3C2Tx, Hf3C2Tx and Mo2CTx MXene, respectively, which greatly expands the scope of precursors and is of great significance to the development of MXenes [18,19,20]. In general, HF etching method with excellent universality plays a crucial role in the rapid development of MXenes and some researchers still adopt this approach to prepare MXenes until now. Nevertheless, the strong corrosiveness of HF greatly increases the experimental risk and deteriorates its industrialization prospect. The development of a greener, safer and milder etchant is still the focus in the field of MXenes.

2.2 In-Situ HF Etching

In 2014, a relatively safe etching route by mixing HCl and LiF was proposed by Ghidiu et al. to prepare Ti3C2Tx MXene [65]. In this approach, HF can be in-situ generated to initiate the etching process based on Eq. (5) and Li+ cations spontaneously intercalate into the interlayer of Ti3C2Tx MXene.

The c-lattice parameter of MXenes obtained by LiF/HCl etching is greatly larger than that of MXenes prepared by HF etching, which is mainly owing to the intercalation of Li+ cations and water molecules. Benefiting from the hydrophilic nature, the prepared Ti3C2Tx MXene demonstrates clay-like behavior and can be processed into different desired shapes such as rolled film. Additionally, clay-like Ti3C2Tx MXene can be shaped into the letter “M” and exhibit a high electrical conductivity of 1500 S cm−1. More importantly, thanks to the insertion of Li+ ions and water, the van der Waals forces between the layers are weakened and multi-layered MXenes can be directly centrifuged after sonication to obtain few-layered MXenes. It is worth mentioning that the molar ratio of LiF and Ti3AlC2 MAX has a great influence on the lateral size of the final Ti3C2Tx MXene, and higher LiF concentration favors the complete etching of Ti3AlC2 MAX and intercalation of more Li+ ions into the MXene interlayers.

Therefore, in-situ HF etching is further upgraded to the “minimally intensive layer delamination” (MILD) method in 2017 by increasing the molar ratio of LiF and Ti3AlC2 MAX to 7.5:1.0, which can achieve the delamination of multi-layered MXenes via simple hand-shaking process rather than ultrasonication [87]. The obtained Ti3C2Tx MXene nanosheets demonstrate large lateral size and high quality, resulting in a high electronic conductivity of 4600 ± 1100 S cm−1. So far, other fluoride salts including NaF, KF, FeF3, etc., and acids such as H2SO4 have also been used by researchers [88,89,90,91]. For example, Soundiraraju et al. reported the successful preparation of Ti2NTx MXene by immersing Ti2AlN MAX in a mixture of KF and HCl [89]. Generally, the in-situ HF etching method based on LiF/HCl etchant has appeared the most in the recently published articles on MXenes. The biggest advantage of in-situ HF etching route is the improvement of experimental safety and the ability to prepare MXenes nanosheets with larger lateral sizes and fewer defects. However, cations (Li+, Na+, K+, etc.) will intercalate into MXenes interlayers during the preparation process and it is difficult to eliminate them from MXenes, which may have an adverse impact on the further application of MXenes in some fields. The relationship between structure and properties should be further investigated.

2.3 Bifluoride Salts Etching

In 2014, bifluoride NH4HF2 was used to etch the Ti3AlC2 MAX precursor to obtain Ti3C2Tx MXene [92]. The reaction mechanism is summarized as follows:

In this method, the selective etching of Al layers from Ti3AlC2 MAX and the intercalation of NH3 and NH4+ into the interlayer of Ti3C2Tx MXene occur simultaneously. The intercalation of ammonium species effectively increases the interlayer spacing. Further, NaHF2 and KHF2 were also utilized as etchants to prepare Ti3C2Tx MXene by Feng et al. in 2017 and the etching mechanisms are similar to that of NH4HF2 [93] (Fig. 5d). In 2020, Natu et al. used NH4HF2 to etch Ti3AlC2 MAX with polar organic solvents as the reaction medium instead of water, successfully realizing the water-free synthesis of Ti3C2Tx MXene [94]. The NH4HF2 can be decomposed into HF and NH4F, and HF plays the role of etching the Al atomic layers. It is noteworthy that the as-prepared Ti3C2Tx MXene is highly fluorinated and the ammonium cations surrounded by organic solvent molecules can intercalate into the layers, which endows MXene with the largest interlayer spacing of 5.07 nm up to now. Overall, the bifluoride salts etching is safer relative to HF etching. However, bifluoride salts are currently only used to etch Ti3AlC2 MAX and the universality of the method requires to be further improved.

2.4 Electrochemical Etching

During the etching process of MAX precursors by using the three methods mentioned above, the researchers may be directly or indirectly exposed to hazardous HF, which reduces the safety of the experimental process. Moreover, high content of -F surface group may reduce the electronic conductivity of obtained MXenes and block ion transport, which is not conducive to their application in metal-ion batteries [59]. Therefore, it is urgent to explore fluorine-free etching method. In 2014, Gogotsi et al. removed M-atom and A-atom layers from Ti3AlC2, Ti2AlC and Ti3SiC2 MAX precursors to prepare carbide-derived carbons via electrochemical etching approach [95]. In 2015, Zhao et al. selectively extracted Ti atom layers from Ti2SC MAX to obtain carbon/sulfur nanolaminates through electrochemical etching [96]. It can be observed that the above two works failed to obtain MXenes by electrochemical etching method. In 2017, Sun et al. firstly synthesized Ti2CTx MXene without -F termination in diluted HCl aqueous electrolyte at 0.6 V for 5 days via electrochemical etching [97], and the mechanism can be exhibited as follows:

At first, only the surface of Ti2AlC MAX that is in contact with the electrolyte can be etched and the generated Ti2CTx MXene is coated on the surface of MAX, which prevents electrolyte from entering the interior and makes it difficult for the inner MAX to be further etched. Subsequently, the Ti2CTx MXene on the surface will be transformed into a carbon layer. Finally, a three-layered structure including carbide-derived carbon, Ti2CTx MXene and unetched Ti2AlC MAX are obtained, thus leading to a low yield of MXenes. Some key parameters such as electrolyte concentration, etching potential and time have been proven to have a direct impact on the final etching products.

In 2018, Feng et al. prepared Ti3C2Tx MXene with a large lateral size of 18.6 μm in a binary aqueous electrolyte containing NH4Cl and TMAOH (Fig. 5e) [98]. In this method, the weak Ti–Al bond is broken and then Al3+ cations combine with Cl− anions to form AlCl3. The obtained Ti3C2 can be terminated by –OH group and the etching process is illustrated as follows:

It is noteworthy that the intercalation of ammonium species and TMAOH can expand the interlayer spacing of Ti3C2Tx MXene and expose more active sites, greatly promoting the etching of inner MAX phase and thus resulting in a relatively high etching yield of at least 60%. Later, a general strategy based on thermal-assisted electrochemical etching route was proposed by Hao’s group to synthesize various MXene (Ti2CTx, Cr2CTx and V2CTx) [99]. In this approach, 1 M HCl solution is chosen as electrolyte and the heating facilitates the etching of MAX precursor. Specifically, when the etching time and temperature is increased to 9 h and 50 °C, respectively, the obvious accordion-like morphology can be observed for Ti2CTx MXene. In general, the electrochemical etching enables the preparation of fluorine-free MXenes for the first time and is safer and milder than conventional HF etching method. However, over-etching and low etching yield are unavoidable issues, which greatly hinders the large-scale utilization of electrochemical etching method.

2.5 Alkali Etching

In addition to acids, alkalis can also be utilized to selectively etch MAX precursors. The earliest attempt to prepare MXenes via alkali etching was to immerse Ti3AlC2 MAX in dilute aqueous NaOH solution at 80 °C by Xie et al. in 2014 [100]. However, only the outermost MAX can be etched owing to the low NaOH concentration. Further, Zhang et al. proposed a NaOH-assisted hydrothermal process in 2018 to prepare Ti3C2Tx MXene with a high yield of 92% (Fig. 5f) [101]. In this method, the OH− anions attack Al-atom layers in Ti3AlC2 MAX to form Al (oxide) hydroxides, which can further dissolve in alkali solution as soluble Al(OH)4− anions. It is noteworthy that high reaction temperature (270 °C) and NaOH concentration (27.5 M) can greatly speed up the whole process and promote complete etching of Ti3AlC2 MAX. The etching process can be described as follows:

It is worth mentioning that special attention should be paid to controlling reaction condition when MXene is prepared by alkali etching method. A recent work by our group found that Ti3C2Tx MXene can be completely converted to K2Ti8O17 nanowires after immersed in 5 M KOH solution at 50 °C for 10 days [102]. The reaction mechanism can be described as follows: The Ti-C bond in Ti3C2Tx MXene is easily destroyed in the concentrated alkali environment and MXene is oxidized into titanium oxide nanoparticles, and the titanium oxide nanoparticles can then react with KOH to generate the final K2Ti8O17 nanowires. Accordingly, the stability of various MXenes in concentrated alkali solution deserves further investigation. In general, although MXenes with abundant –O and –OH functional groups can be prepared via alkali etching route, harsh reaction condition greatly increases the experimental risk, which makes alkali etching unsuitable for large-scale preparation of MXenes.

2.6 Common Molten Salts Etching

The above-mentioned methods for preparing MXenes are all based on the wet chemical etching route. However, Gogotsi et al. reported molten salts etching method to prepare Ti4N3Tx MXene in 2016, which opens the door to the preparation of MXenes via dry chemical etching techniques [103]. In this method, a mixture of LiF, NaF and KF is used to selectively etch Al-atom layers from Ti4AlN3 MAX precursor at 550 °C under Ar atmosphere to synthesize Ti4N3Tx MXene, and the few-layered nanoflakes can be obtained by TBAOH intercalation and subsequent ultrasonication. It is worth mentioning that since the discovery of MXenes, Ti4N3Tx is the first nitride MXene that has been experimentally synthesized. In 2021, Zong et al. reported the synthesis of Ti2NTx MXene by etching Ti2AlN MAX precursor with the mixture of fluoride salt (KF, LiF, and NaF) in a molar ratio of 1:3 at 550 °C [104]. Up to now, the family of nitride MXenes only contains Ti2N, Mo2N, V2N and Ti4N3 [89, 103, 105], which is mainly due to the difficulty in preparation. Firstly, the number of nitride MAX precursor is relatively limited due to the high formation energy. Then, M-A bond in nitride MAX exhibits high strength compared with that of carbide MAX, indicating that larger exfoliation energy is needed for nitride MAX. Finally, nitride MXene is prone to dissolve in HF solution and exhibits poor structural stability owing to the low cohesive energy [38, 71]. Therefore, great efforts should be made to explore the suitable etching route for nitride MAX. In general, molten salts etching, as the first method to prepare nitride MXenes, is of great significance. However, this method is only applicable to the preparation of Ti4N3Tx and Ti2NTx MXene at present, and the obtained MXene exhibits high content of -F surface group. The above two key points greatly limit the development of common molten salts etching method.

2.7 Other Etching Methods

In addition to the etching methods described above, there are other methods that can also be used to prepare MXenes. In 2017, Gogotsi’s group presented an ammoniation strategy to transform Mo2C and V2C MXene to corresponding Mo2N and V2N at 600 °C by using NH3 as nitrogen source (Fig. 5g) [105], which further enriches the family of nitride MXenes. It is worth mentioning that the obtained Mo2N and V2N MXene demonstrate higher room temperature electronic conductivity than their carbide counterparts. In 2020, Sun et al. successfully prepared mesoporous Mo2C MXene via ultraviolet-driven etching of Mo2Ga2C precursor, which avoids the utilization of hazardous HF and greatly improves the experimental safety [106]. They also presented thermal reduction strategy to synthesize Ti2C MXene from Ti2SC MAX. In this method, reductive gas such as H2 can react with weakly-bonded S atoms, continuously accelerating the etching process [107]. In 2021, iodine-assisted etching route was developed by Feng et al. to synthesize Ti3C2Tx MXene rich in -O terminations in anhydrous acetonitrile at 100 °C (Fig. 5h) [108]. Owing to the water-free etching process, Ti3C2Tx MXene with an average lateral size of 1.8 µm exhibits superior structural integrity and can be stored stably in water for more than 2 weeks. Further, Jawaid et al. successfully prepared halogenated Ti3C2Tx MXene under anhydrous environment by using halogens (Br2, I2, ICl, IBr) as etchants, and the halogen terminations may endow MXenes with some new properties [109]. Besides, ionic liquids such as 1-butyl-3-methylimidazolium hexafluoro-phosphate (BMIMPF6) was utilized as etchant to prepare Ti2CTx MXene at 80 °C for 20 h [110]. The ionic liquids can intercalate into interlayers, leading to expanded interlayer spacing and the separation of layers.

Compared with above-mentioned top-down methods, the bottom-up approaches are usually able to synthesize defect-free 2D materials, which can also be utilized to obtain high-quality MXenes. In 2015, Ren et al. developed chemical vapor deposition method to fabricate large-area high-quality ultrathin α-Mo2C nanosheets, which possess a thickness of few nanometers and a lateral size of around 100 µm [111]. Moreover, the prepared α-Mo2C MXene exhibits superior stability under various environments including water, HCl or annealing at 200 °C in air. More importantly, this method reveals excellent generality and can also be used to construct WC and TaC crystals. In conclusion, many various methods have been proposed to prepare MXenes until now. However, each etching route has its own shortcomings and is unlikely for large-scale utilization in the future. As we all know, exploring a safe, green, non-hazardous, low-cost and easily scalable preparation method is the biggest challenge for the researchers in the fields of MXenes, which plays a crucial role in the development of MXenes in the next decades.

3 MXene Synthesis: Lewis Acidic Etching Method

In 2019, Huang’s group proposed a brand-new, safe and green method, namely Lewis acidic molten salts etching, to prepare Cl-terminated MXene [66]. Owing to a series of advantages, Lewis acidic etching has attracted intensive attention since it was presented, greatly promoting the development of MXenes in the past three years. The introduction of Lewis acidic molten salts etching approach is mainly classified into following four aspects: etching mechanism, terminations regulation, in-situ formed metals and delamination of multi-layered MXenes.

3.1 Etching Mechanism

The mechanism of Lewis acidic molten salts etching method is based on the replacement reaction between Lewis acidic molten salts and A-site atoms in MAX precursor. Taking the etching of Ti3AlC2 MAX precursor by the firstly used Lewis acidic salt ZnCl2 as an example, Huang et al. thoroughly mixed the Ti3AlC2 and ZnCl2 with a molar ratio of 1:1.5 in a glovebox and the mixture was placed in alumina crucible, which is then heated at 550 °C for 5 h in a tube furnace under Ar atmosphere (Fig. 6a) [66]. It can be observed that main peaks of final product shift to lower angles relative to those of Ti3AlC2 MAX in the X-ray diffraction (XRD) patterns (Fig. 6b), revealing an enlarged lattice parameter. Additionally, the densely-packed structure can still be kept, and high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image in Fig. 6c suggests that interlayer element is brighter compared with other elements, thus proving that Ti3ZnC2 MAX has been successfully prepared. The specific formation mechanism can be described by Eqs. (15–16):

a Schematic showing the preparation of Ti3C2Cl2 MXene by ZnCl2 Lewis acidic salt etching. b XRD patterns of Ti3AlC2 and Ti3ZnC2 MAX. c HAADF-STEM image of Ti3ZnC2 MAX and corresponding energy-dispersive spectroscopy (EDS) mapping. d SEM image of multi-layered Ti3C2Cl2 MXene. e XRD patterns of Ti3C2Cl2 MXene and Ti3C2Cl2/Zn hybrids. f Cl 2p XPS spectra of Ti3C2Cl2 MXene. g EDS mapping analysis showing the Lewis acidic etching of Ti3AlC2 MAX. Reproduced with permission from [66] Copyright 2019, American Chemical Society. h Schematic demonstrating the preparation of Ti3C2Tx MXene by CuCl2 etching. i Schematic showing the relationship between redox potential of A-site elements, redox potential of Lewis acidic salts and Gibbs free energy. Reproduced with permission from [67] Copyright 2020, The Authors, published by Springer Nature. j Schematic illustration of the one-pot synthesis of Ti3C2Tx MXene under air atmosphere. Reproduced with permission from [112] Copyright 2021, The Authors, published by Springer Nature. k Phase diagram of NaCl/ZnCl2 mixture. Reproduced with permission from [113] Copyright 2021, Wiley–VCH

It is well-known that ZnCl2 will exist in the form of molten state at 550 °C and is ionized into Zn2+ cations. Then, the Zn2+ with strong electron obtaining ability will react with Al atoms in Ti3AlC2 to generate Al3+ cations and Zn atoms. Al3+ cations are prone to combine with Cl− anions to form AlCl3, which will evaporate at 178 °C. At the same time, Zn atoms can diffuse into the interlayer of Ti3C2 and occupy the position originally belonging to Al atoms, thereby leading to the generation of new MAX phase Ti3ZnC2. It is worth mentioning that the removal of AlCl3 from the system considerably accelerates the element replacement reaction.

When the molar ratio of Ti3AlC2 and ZnCl2 further increases to 1:6, Ti3C2 MXene with -Cl termination instead of Ti3ZnC2 MAX can be successfully obtained. Firstly, the classical multi-layered structure is observed for Ti3C2Cl2 MXene (Fig. 6d). Then, the XRD pattern of as reacted product indicates that the strongest (104) peak at around 39° of Ti3AlC2 MAX almost vanishes and the (002) peak moves to a lower angle of 7.94° (Fig. 6e), suggesting an expanded interlayer spacing. Additionally, the characteristic XRD peaks of Zn metal can also be observed. Further, Ti-Cl chemical bond in Ti3C2Cl2 MXene can be confirmed by Cl 2p X-ray photoelectron spectroscopy (XPS) spectra (Fig. 6f) [66]. Above discussions effectively confirm the formation of Ti3C2Cl2 MXene and the reaction process can be described by following equations:

As exhibited in Fig. 6a, the formation of Ti3C2Cl2 MXene can be divided into two stages including the initial formation of Ti3ZnC2 MAX shown in Eqs. (15–16) and the subsequent reaction of Ti3ZnC2 MAX with excessive ZnCl2 to obtain Ti3C2Cl2 exhibited in Eqs. (17–19). Specifically, the Zn atoms in Ti3ZnC2 MAX can be separated from interlayer and react with excessive Zn2+ to generate Zn22+ cations, and the Cl− anions can easily intercalate into the interlayer of Ti3C2, forming Ti–Cl chemical bond (Fig. 6g). Meanwhile, the Zn22+ cations gain electron to form Zn metal. In general, Zn2+ cations and Cl− anions in ZnCl2 act as H+ and F− in HF etchant, respectively.

Later in 2020, Prof. Huang and coworkers generalized the previously proposed Lewis acidic etching method, which greatly expands the family of Lewis acidic molten salts (FeCl2, CoCl2, NiCl2, CuCl2, CdCl2, CuI, CuBr2, etc.) and can prepare various MXenes from Al, Si and Ga-based MAX precursors [67]. They immersed Ti3SiC2 MAX in CuCl2/NaCl/KCl mixed molten salts at 750 °C (Fig. 6h), and NaCl and KCl play a role in providing molten salts environment. The etching process is illustrated as follows:

Specifically, the zero-valence Si atoms in the interlayer lose electrons to become Si4+ cations and then combine with Cl− anions to form SiCl4, which can readily escape as gas at around 57 °C. Subsequently, the Cu2+ cations can obtain electrons to transform into Cu metal. Finally, excessive Cl− anions can be grafted onto exposed Ti atoms, resulting in the formation of Ti3C2Cl2 MXene. It is worth mentioning that individual HF is difficult to etch Ti3SiC2 [85], while Lewis acidic salts can readily complete the above etching process, which reflects the superiority of Lewis acidic etching. After the etching process, NaCl, KCl and excessive CuCl2 can be eliminated by washing the etching products with deionized water.

Further, Huang et al. proposed an effective criterion to determine whether the A-site atoms in MAX can react with metal ions in the Lewis acidic salts. They found that the metal ions in the Lewis acidic salts with high electrochemical redox potential can etch the MAX precursor with low redox potential A-site atoms. The relationship between redox potential of A-site elements, redox potential of Lewis acidic salts and Gibbs free energy is illustrated in Fig. 6i. For example, CuCl2 molten salt can easily remove the Si atoms from Ti3SiC2 MAX as mentioned above, which is ascribed to the higher redox potential of Cu2+/Cu pair (−0.43 V versus Cl2/Cl−) compared with that of Si4+/Si pair (−1.38 V versus Cl2/Cl−). The general etching reaction between A-site elements in MAX phase and Lewis acidic molten salts MQy (Q = Cl, Br or I) can be described as follows:

It can be inferred that the difficulty degree of etching Mn+1AXn precursors by Lewis acidic molten salts is independent of M, X and n values, and only depends on the redox potential of A-site element. Therefore, based on Lewis acidic etching criterion, a large number of MAX phases (Ti3AlC2, Ti3ZnC2, Ti3SiC2, Ti3AlCN, Ti2GaC, Ti2AlC, Ta2AlC, Nb2AlC, etc.) can be etched by using different Lewis acidic salts (FeCl2, CoCl2, NiCl2, CuCl2, CdCl2, AgCl, CuI, CuBr2, etc.).

The reaction mechanism of Lewis acidic etching method is basically clear now, but the understanding of Lewis acidic etching method can still be further deepened by optimizing etching parameters such as reaction atmosphere and etchant compositions. For example, in order to prevent the oxidation of the prepared MXenes, the inert gas such as Ar is generally used for protection in the process of Lewis acidic etching. However, Lin et al. proposed a simple one-pot synthesis method, containing molten salts shielded strategy for MAX preparation and subsequent in-situ Lewis acidic etching, to achieve the preparation of MXenes under air atmosphere (Fig. 6j) [112]. Specifically, they thoroughly mixed Ti, Al and C powders with NaCl and KCl salts, and the mixture was then pressed into a pellet. Subsequently, the pellet was further placed in a salt bed composed of NaCl and KCl which can melt at around 650 °C to insulate the air, and the Ti3AlC2 MAX can be obtained by heating at 1300 °C for 1 h in muffle furnace without Ar protection. Finally, CuCl2 was introduced to the reaction system at 700 °C to achieve the in-situ etching of Ti3AlC2 MAX for 10 min, thus leading to the quick formation of Cl-terminated Ti3C2Tx MXene. Therefore, with the assistance of the molten salts shielding strategy, Lewis acidic molten salts can directly etch MAX precursor in air atmosphere, which greatly promotes the development of Lewis acidic etching method. In addition, Zhang et al. demonstrated one-step eutectic etching strategy for the synthesis of in-plane porous Ti3C2Cl2 MXene by regulating the etchant composition from ZnCl2 to NaCl/ZnCl2 mixture [113]. When ZnCl2 is used to etch the MAX phase, the volatilization of generated AlCl3 at high temperature will cause structural/crystal defects in the precursor, which will then evolve into void space. However, the generated pores will gradually collapse owing to the absence of temporary physical support during cooling process. Further, they found that when the etchant is changed into a mixture of ZnCl2 and NaCl in a molar ratio of 4:6, the NaCl mole percent will gradually increase to 72% with the progress of etching process, which makes the salt melt shift across the phase boundary and leads to the precipitation of NaCl particles at 550 °C based on the phase diagram (Fig. 6k). The formation of NaCl particles can occupy void space to prevent the shrinkage and collapse of pores, finally resulting in a large increase in mesoporous volume and specific surface area. Therefore, the pore structure of the prepared MXenes can be greatly adjusted by the manipulation of etchant composition. The above-mentioned two works indicate that the Lewis acidic etching method still possesses broad development space and can be further improved from different aspects in the future.

3.2 Terminations Regulation

A large number of theoretical calculations and experiments have proved that the composition of surface groups can considerably influence the physical and chemical properties of MXenes, such as electronic property, mechanical property, magnetic property, optical property, chemical stability, dispersibility and redox activity [15, 26, 55, 61, 63, 114,115,116]. Therefore, in order to accurately explore that how surface functional groups affect the properties of MXenes, it is pretty important to synthesize MXenes with controllable surface chemistry. However, preparing MXenes with single and uniform surface groups has been a huge challenge for researchers. Taking HF etching as an example, MXenes exhibits mixed surface terminations including –O, –OH and –F [31, 43]. Firstly, the complex and uncontrollable surface termination greatly affect the properties of MXenes, which is not conducive to the management of experimental variables and the large-scale preparation of MXenes. Additionally, functional groups like –F can irreversibly react with Li+ or Na+ cations and block their transport, which negatively affects the electrochemical performance of MXenes electrodes [117, 118]. Therefore, preparing MXenes with fluorine-free surface groups should be the best choice for researchers in the fields of lithium-ion batteries (LIBs) or sodium-ion batteries (SIBs). However, it is difficult to obtain MXenes with homogeneous and fluorine-free terminations before 2019. Fortunately, the fabrication of MXenes with totally controllable surface chemistry is realized by the propose of Lewis acidic molten salts etching strategy. The functional groups of MXenes prepared by Lewis acidic etching mainly depends on the Lewis acidic salts anions. For example, Ti3C2 MXene terminated by –Cl functional group can be synthesized by Cl− anions-containing Lewis acidic salts etching. However, a small part of -Cl terminations may be replaced by –O groups during the washing process, and the content of –O surface group mainly depends on the competition between –O and –Cl terminations [67, 119]. Lin et al. proved that -O surface group in Nb2C MXene prepared by CuCl2 etching demonstrates stronger competitiveness compared with –Cl surface groups, thus leading to Nb2CTx MXene rich in –O termination, while the competition between –O and –Cl for Ti3C2 MXene is relatively weak [119]. Since the –O functional groups are conducive to the electrochemical process of metal-ion batteries and SCs [120, 121], it is necessary to further increase the content of –O termination in Ti3C2Tx MXene. Pang et al. etched Ti3AlC2 by CuCl2·2H2O or CoCl2·6H2O Lewis acidic salts [122], the additional introduction of six water molecules can effectively raise the number of –O functional groups and the etching process can be described as follows:

Due to the wide variety of halogen elements in the Lewis acidic molten salts, MXene can also be terminated by other halogen anions. For example, Ti3C2 MXene with –Br or –I functional groups can be obtained via CuBr2 or CuI etching, respectively (Fig. 7a-b). Further, Ti3C2 MXene can be endowed with –BrI, –ClI and –ClBr binary terminals as well as –ClBrI ternary halogen terminations. It is gratifying to note that Ti3C2 MXene with –Cl, –Br or –I functional groups all exhibit metallic-level conductivity (Fig. 7c), while F or OH-terminated Ti3C2 MXene often demonstrates semiconductor behavior [11, 66, 123, 124]. More importantly, due to the strong electrochemical reactivity, Br or I-terminated Ti3C2 MXene demonstrates excellent zinc storage performance. However, Ti3C2 MXene with –O, –F, –OH and –Cl functional groups exhibit low discharge specific capacity and oblique charge discharge curve when used as cathode for zinc-ion batteries (ZIBs) [123]. The above discussion reveals that the electrochemical performance of MXene electrodes can be greatly enhanced by adjusting the type of functional groups. Additionally, the halogen terminations of MXenes can be used as halogen sources and nucleation sites to prepare MXene/halide heterostructures. For example, Cui et al. synthesized intimate contact Bi12O17Cl2/Ti3C2 MXene 2D/2D heterojunctions by the in-situ growth of Bi12O17Cl2 nanosheets on the surface of Cl-terminated Ti3C2 MXene that was obtained via CuCl2 etching [125].

a–b HAADF-STEM images and corresponding EDS mapping of Ti3C2Br2 and Ti3C2I2 MXene, respectively. c Electronic structure of Ti3C2Br2 MXene. Reproduced with permission from [123] Copyright 2021, American Chemical Society. d Schematic showing the preparation of Ti3C2Tx MXene via Lewis acidic etching and subsequent termination substitution in molten inorganic salts as well as corresponding HAADF-STEM images and EDS analysis. e Biaxial straining of Ti3C2Tx MXene lattice induced by the terminations. f Temperature-dependent resistivity of Nb2CTx MXenes. Reproduced with permission from [42] Copyright 2020, The American Association for the Advancement of Science. g Schematic of the preparation of N-containing Ti3C2Tx MXene via FeCl2 Lewis acidic salt etching. h EELS analysis of pristine Ti3C2Tx and N-containing Ti3C2Tx MXene. Reproduced with permission from [126] Copyright 2022, The Authors, published by Wiley–VCH

Since the bond dissociation energies of Ti–Br and Ti–Cl bond are smaller than that of Ti–O, Ti–OH and Ti–F bonds [126], it is possible to chemically modify the surface of MXenes originally terminated with –Br or –Cl functional groups at a relatively low temperature. Based on this point, Kamysbayev et al. proposed a universal strategy to successfully prepare O, S, Se, Te and NH-terminated Ti3C2 MXene and non-terminated Ti3C2 via Lewis acidic etching and subsequent termination substitution/elimination reactions in molten inorganic salts (Fig. 7d) [42]. Firstly, Ti3C2Br2 MXene was prepared by mixing Ti3AlC2 MAX with CdBr2 Lewis acidic salt. As followed, Ti3C2Br2 MXene was dispersed in CsBr/KBr/LiBr eutectic salt at 300 °C and then reacted with NaNH2, Li2O, Li2S, Li2Se or Li2Te at around 500–600 °C in an Ar-filled glove box to synthesize Ti3C2(NH), Ti3C2O, Ti3C2S, Ti3C2Se, Ti3C2Te MXene, respectively. Moreover, when treated with LiH at 300 °C, the surface groups of Ti3C2Br2 MXene can be completely eliminated, thus leading to the formation of bare Ti3C2 MXene. This strategy realizes the controllable chemical transformation of functional groups for the first time. The surface groups can significantly regulate the interatomic spacings of MXenes lattice and their electronic properties. For example, the Ti3C2Te lattice exhibits a greater in-plane lattice expansion (18%) (Fig. 7e). More importantly, Cl, S and Se-terminated Nb2C MXene prepared by the above-mentioned strategy exhibits unprecedented superconductivity behavior (Fig. 7f), while Nb2C MXene with –F and –O terminations synthesized by HF etching fails to demonstrate superconducting state, which is also proved by theoretical calculations [62]. The discovery of superconductivity phenomenon is mainly attributed to the influence of functional groups including –Cl, –S and -Se on MXenes structure, such as lattice strain, carrier localization, phonon frequency, and electron–phonon coupling [127], which greatly promotes the research of MXenes in the field of physics.

Very recently, Zhang et al. reported the synthesis of Ti3C2Brx MXene through CuCl2 etching of Ti3AlC2 precursor and subsequent termination substitution in AlBr3/NaBr/KBr eutectic molten salts [128]. When the molar ratio of AlBr3 is lower than 50%, the AlBr3/NaBr/KBr molten system with plenty of naked Na+, K+ and Br− demonstrates strong Lewis basicity. The Na+ and K+ cations can intercalate into the interlayer of MXene and the previous –Cl termination can be replaced by the Br− anions via nucleophilic reaction, which simultaneously achieves the increase of interlayer spacing and the substitution of surface groups. The enlarged interlayer spacing leads to an expanded multi-layered morphology of Ti3C2Brx MXene, which may be conducive to the following delamination process to obtain few-layered nanosheets. In addition, Liu et al. synthesized N-containing Ti3C2Tx MXene via FeCl2 Lewis acidic etching, subsequent magnet cleaning and final thermal treatment in Li3N/LiCl/KCl molten salts (Fig. 7g) [126]. The magnet cleaning process can not only effectively remove Fe nanoparticles, but also prevent the –Cl surface group from being largely replaced by –O, which is beneficial for following termination substitution reaction. The dramatic decrease in Cl L2,3-edge intensity and appearance of N–K edge in electron energy-loss spectroscopy (EELS) confirm that the -Cl functional groups can be transformed to –N terminations in Li3N/LiCl/KCl Lewis basic molten salts (Fig. 7h), thus leading to the N-containing Ti3C2Tx MXene.

In short, combined with Lewis acidic etching, termination exchange reactions in Lewis basic molten salts medium can endow MXenes with unconventional terminations, which have never appeared before and are hard to be directly obtained by individual Lewis acidic etching. By selecting various Lewis bases with different anions such as S2−, Se2−, Te2−, N3− and NH2−, researchers can obtain the desired surface groups-terminated MXenes. The above discussions fully reveal the great potential of the halogenated MXenes synthesized by Lewis acidic etching method in various fields. Taking consideration of the rich selection of M and X elements as well as various surface groups mentioned above, there are a large number of new MXenes that can be explored, which may show some excellent properties. Up to now, the regulation of MXene surface groups through chemical transformation is still in its infancy and plenty of theoretical calculations and experiments are required to further explore the effect of these new functional groups on the properties of different MXenes, such as electrical conductivity, ion diffusion kinetics, thermal conductivity, work function, optical conductivity, mechanical property, hydrophilicity, chemical and thermal stability.

3.3 In-Situ Formed Metals

According to the etching mechanism shown in Eq. (22), metal ions in the Lewis acidic molten salts can be in-situ reduced to various metals during the etching process of MAX precursors, thus leading to the formation of MXenes/metals composites. Taking CuCl2 etching of Ti3SiC2 MAX as an example, Cu nanoparticles can be uniformly anchored among the multi-layered Ti3C2Tx MXene matrix and the Ti3C2Tx/Cu hybrids can be successfully obtained [67]. It is worth mentioning that Cu nanoparticles are able to be loaded in the Ti3C2Tx MXene matrix through one-step in-situ growth process, so the interaction between them is stronger than that of Ti3C2Tx/Cu composites prepared by mechanical mixing, which is another key advantage of Lewis acidic etching method relative to traditional etching route. Recently, it has been reported that when the Ti3AlC2 MAX precursor is etched by CuCl2·2H2O or CoCl2·6H2O, the obtained Ti3C2Tx MXene can be decorated with Cu or Co nanoparticles (Fig. 8a), respectively [122]. The strong interaction between Cu nanoparticles and –O surface group of Ti3C2Tx MXene can be proved by X-ray absorption (XAS) spectrum (Fig. 8b), effectively preventing the detachment of Cu from the Ti3C2Tx MXene matrix. Furthermore, owing to the diversity of MXene compositions and the large family of Lewis acidic molten salts, various metal nanoparticles (Fe, Co, Ni, Zn, Ag, Cd, Sn, etc.) can be distributed among the different MXenes (Ti3C2, Ti3CN, Ti2C, Ta2C, Nb2C, etc.), which greatly enriches the choice of researchers.

a Schematic illustration of the synthesis of Ti3C2-Cu/Co composites. b XAS spectra of Ti3C2-Cu hybrids. Reproduced with permission from [122] Copyright 2021, Wiley–VCH. c Schematic showing the preparation of Ti3C2Tx/Sn composites by SnCl2 Lewis acidic salt etching. d SEM image of Ti3C2Tx/Sn hybrids. Reproduced with permission from [145] Copyright 2022, Elsevier. e Schematic diagram of the preparation of Ti3C2Tx/CuS composites. f High-resolution transmission electron microscope (HRTEM) image of Ti3C2Tx/CuS. Reproduced with permission from [148] Copyright 2022, Royal Society of Chemistry

In the early development stage of the Lewis acidic etching strategy, researchers generally remove the in-situ generated metal nanoparticles from MXenes/metals composites in order to obtain pure MXenes, which almost becomes a custom. However, metal or metal compounds have been intensively investigated in energy storage and conversion, electromagnetic interference shielding and other fields in the past few decades [129,130,131,132,133]. Consequently, rational and effective application of various metals in MXenes/metals composites obtained by Lewis acidic etching is worth investigating. Additionally, MXenes have been widely utilized to support metal or metal compounds. Based on the excellent synergistic effect between MXenes and metals or metal compounds, MXenes/metals hybrids and MXenes/metal compounds composites exhibit better performance than their individual components and have been widely investigated in various fields [54, 73, 134,135,136,137,138]. Nevertheless, the traditional fabrication process of MXenes/metals hybrids or MXenes/metal compounds composites usually requires the synthesis of MXenes and the subsequent introduction of additional metal sources, which makes the preparation process complicated [117, 139,140,141,142,143,144]. As mentioned above, Lewis acidic salts can achieve the etching of MAX precursor and the introduction of metal sources simultaneously. Therefore, if Lewis acidic molten salts are used to etch MAX phases, the obtained MXenes/metals composites can be applied directly, and then the MXenes/metal compounds composites can be prepared by one-step sulfurization, phosphorization, tellurization or selenization treatment of MXenes/metals composites, which opens a new window for the universal construction of MXene-based hybrids through Lewis acidic etching route, showing great research potential.

In general, MXenes/metals or MXenes/metal compounds composites can be obtained quickly and easily by taking full advantage of Lewis acidic etching products. As expected, the MXenes/metals and MXenes/metal compounds composites prepared by Lewis acidic etching route have been rationally applied in some fields due to the superior structural stability. For example, the reported Ti3C2–Cu composites via CuCl2·2H2O molten salts etching exhibit superior electrochemical performance in SCs when used as electrode material [122]. Additionally, Sn-nanoconfined Ti3C2Tx MXene was synthesized by one-step SnCl2 molten salt etching (Fig. 8c–d), and demonstrated excellent cyclic stability as anode for LIBs [145]. Further, CoCl2 etching and in-situ sulfidation process were used to prepare strongly coupled N-doped MXene-CoS2 composites, which can effectively alleviate the shuttle effect of lithium polysulfides (LiPSs) in lithium-sulfur (Li–S) batteries [146]. Recently, our group presented a general method to fabricate a series of Ti3C2Tx MXene/transition metal sulfides (MSy, M = Fe, Co, Ni or Cu) composites via Lewis acidic etching and subsequent sulfurization treatment (Fig. 8e-f) [147, 148]. When served as anodes for SIBs, the readily produced hybrids can show greatly boosted sodium storage performance owing to the interfacial electronic coupling. Until now, the applications of Lewis acidic molten salts etching products, especially the in-situ formed metals, have been relatively rare and concentrated in the field of energy storage. More rational utilization of etching products in other fields, such as electromagnetic interference shielding, demonstrates great potential and deserves further exploration.

3.4 Delamination of Multi-Layered MXenes

The MXenes prepared by Lewis acidic etching strategy exhibit obvious multi-layered accordion morphology. In order to demonstrate true 2D morphology, it is necessary to implement intercalation and delamination process to obtain single-layered or few-layered MXene nanosheets, which can expose more active sites and possess higher surface area [71]. In general, MXenes prepared by HF etching are terminated with –O and –OH functional groups and therefore show excellent hydrophilicity [81], which makes it easy to disperse MXenes in water. The well-dispersed MXenes can then be intercalated by organic molecules (urea, amine, DMSO, TMAOH, TBAOH, IPA, etc.) and inorganic substances (LiCl, NaCl, KCl), which increases the gallery spacing and weakens the van der Waals force and hydrogen bond between MXene layers [43, 78,79,80, 149, 150]. Finally, the few-layered MXenes nanosheets can be obtained by ultrasonic and centrifugation processing [151, 152]. Nevertheless, MXenes prepared by Lewis acidic etching method fail to be terminated by –OH functional group, which greatly decreases their hydrophilicity [153,154,155]. Therefore, it is difficult to uniformly disperse the obtained MXenes in water to form stable colloidal solution, which greatly reduces the delamination efficiency, thus exhibiting a low yield of few-layered and single-layered nanosheets. In order to enhance the delamination efficiency, researchers often considerably extend the sonication time, which tends to endow MXenes with small lateral size and poor quality. In general, most of the MXenes synthesized by Lewis acidic etching is at the multi-layered state according to the published articles, and only a few of them are at the few-layered state.

For example, Ti3C2Clx nanosheets with lateral dimensions of 0.4–2.0 μm were prepared by 10 h ultrasonication treatment of multi-layered MXene obtained by ZnCl2 etching [156]. Yang et al. synthesized Ti3C2Tx nanosheets through ZnCl2 etching and IPA intercalation assisted by ultrasonication treatment for 20 h [157]. Additionally, Zhao et al. successfully produced Ti3C2Clx nanosheets via ZnCl2 etching and subsequent ultrasonication process lasting 20 h [158]. Further, Zhou et al. prepared Cl-terminated Ti3C2 MXene by CdCl2 molten salt etching, and the multi-layered MXene was intercalated by IPA molecule followed by 25 h ultrasonication process to obtain few-layered nanosheets with lateral size of hundreds of nanometers [159]. Furthermore, Liu et al. used large organic base molecule TBAOH to intercalate into Ti3C2Tx MXene produced by CuCl2 etching, followed by ultrasonication bath for 6 h at low temperature to separate the layers, leading to the few-layered nanosheets with a lateral size of around 600 nm [153]. It is worth mentioning that TMAOH intercalated Lewis acidic salts etched-Ti3C2Tx MXene suspension can be stably stored for 2 weeks without obvious precipitation. Finally, DMSO molecule intercalation and ultrasonication process can also be used to delaminate the Cl-terminated Ti3C2 MXene prepared by CuCl2 etching to obtain few-layered samples [125]. To sum up, due to the poor hydrophilicity of MXenes prepared by Lewis acidic etching, the delamination usually requires large organic molecules and long-time sonication, which leads to low yields of few-layered MXenes and small lateral sizes of nanosheets.

In order to solve the above-mentioned issues, two viable and effective methods have been proposed. The first method is to enhance the hydrophilicity of MXenes, and the other method is to disperse MXenes in organic solvents instead of water for intercalation and delamination. For example, Arole et al. presented a method to produce water-dispersible Ti3C2Tx nanosheets via SnF2 molten salt etching, KOH washing, DMSO intercalation and bath sonication for 1 h (Fig. 9a) [154]. The KOH washing facilitates the introduction of –OH terminal groups on Ti3C2Tx MXene and thus greatly boosts the formation of stable Ti3C2Tx suspension with a zeta potential of −31.7 mV. The few-layered or single-layered Ti3C2Tx nanosheets can be prepared by DMSO intercalation and sonication for only 1 h (Fig. 9b), which is conducive to reduce the required energy during the sonication process. Finally, the Ti3C2Tx film produced by vacuum filtration exhibits an electronic conductivity of 706 S cm−1, In addition, Kamysbayev et al. immersed multi-layered Ti3C2Tx (T = –Cl, –S or –NH) MXene obtained by Lewis acidic etching and surface functionalization in n-butyllithium (n-BuLi) hexanes solution to complete the Li+ intercalation process (Fig. 9c). Then, the lithium-intercalated Ti3C2Tx MXene was added to the polar organic solvent N-methyl formamide (NMF) rather than water, leading to the stable colloidal solution with a zeta potential of −29.3 mV after bath sonication for 1 h (Fig. 9d) [42]. The as-prepared Ti3C2Tx suspension of single-layered nanosheets exhibit obvious Tyndall effect and superior crystallinity (Fig. 9e–g), showing the advantage and potential of delamination in polar organic solvents. However, n-BuLi is difficult to be widely used as intercalator due to its high risk. In conclusion, although some progress has been made in the delamination of multi-layered MXenes obtained by Lewis acidic etching, there is still no simple, safe and effective method to prepare MXene nanosheets with high yield and large lateral size.

a Schematic of the synthesis of KOH-treated few-layered Ti3C2Tx MXene nanosheets. b Transmission electron microscope (TEM) image of Ti3C2Tx nanosheets. Reproduced with permission from [154] Copyright 2021, The Authors. c Schematic of the intercalation and delamination process. d Zeta potential of Ti3C2Cl2 MXene in NMF and inset representing the high concentrated MXene inks in NMF and N2H4. e Digital photographs of stable colloidal solutions of Ti3C2Tx MXenes (T = –Cl, –NH and –S) in NMF showing Tyndall effect. f TEM image of Ti3C2Cl2 MXene nanosheets and inset showing its selected area electron diffraction (SAED) pattern. g XRD patterns of multi-layered and delaminated Ti3C2Cl2 MXene. Reproduced with permission from [42] Copyright 2020, The American Association for the Advancement of Science

Table 1 compares non-Lewis acidic etching strategies with Lewis acidic etching in terms of some key indicators such as universality, scalability, safety and terminations.

It can be concluded that Lewis acidic etching exhibits good universality, scalability and safety relative to other methods. Table 2 comprehensively summarizes the parameters for the preparation of various MXenes by Lewis acidic etching, which includes the molar ratio of MAX precursor and Lewis acidic salts, reaction temperature, time and atmosphere. Additionally, delamination parameters such as the type of intercalators and sonication time are also presented.

4 Applications

Benefiting from the unique layered structure, superior electronic conductivity, low ion diffusion barrier, uniform and tunable surface functional groups and large interlayer spacing, the obtained MXenes and MXene-based composites via Lewis acidic molten salts etching route have been intensively investigated in various fields, such as energy storage, energy conversion, sensors and microwave absorption.

4.1 Energy Storage

Due to the rapid consumption of fossil fuels and gradually serious environmental pollution, the development of clean renewable energy has become more and more important [160, 161]. However, the intermittency and instability of renewable energy makes it necessary to store the generated electricity [162]. In recent years, electrochemical energy storage devices have received increasing research interests because of their fast response speed, versatility and application flexibility [163]. Among the various electrochemical energy storage devices, LIBs currently occupy an absolute dominant position. Other technologies such as SIBs, ZIBs, Li–S batteries and SCs are in a rapid development period [164]. In particular, SIBs are promising for large-scale energy storage in the following few years owing to the low price and abundant sodium resources [165].

4.1.1 Lithium-Ion Batteries

In the past three decades, significant progress has been made in the development of LIBs technology. Derived from the high power and energy density, long cycle life, high energy conversion efficiency and low discharge rate, LIBs system has now been widely used in consumer devices, electric vehicles and large-scale energy storage [166, 167]. Layered materials have been intensively studied as electrode materials for LIBs due to their unique structural stability. As early as 2012, Tang et al. confirmed that Ti3C2 MXene possesses low Li+ diffusion barrier, superior electronic conductivity, low discharge voltage and high lithium storage capacity via theoretical computation, making it a promising LIBs anode [59]. Since then, a large number of works have experimentally proved that MXene-based anodes can deliver relatively high discharge capacity, stable long-term cyclic performance and outstanding rate performance [72, 168,169,170,171]. The theoretical capacities of MXene electrodes depends on formula weight, interlayer spacing as well as the type of transition metals and surface groups. MXenes with low formula weights such as V2C and Ti2C can afford large gravimetric capacities [88, 172, 173]. In addition, large interlayer spacing can allow more Li+ ions to intercalate into the MXenes, accordingly leading to higher specific capacities [30, 174]. Surface functional groups such as –F and –OH has been proved to impede Li+ transportation via theoretical calculations, which is unfavorable for realization of theoretical specific capacity [59, 172]. However, O-terminated Ti3C2 MXene can absorb two Li layers, confirming the lithium affinity of –O functional groups and thus contributing to the enhanced lithium storage capacity (Fig. 10a) [120].

a Valence electron localization function of Ti3C2O2Li2 with or without an extra Li layer. Reproduced with permission from [120] Copyright 2014, American Chemical Society. b Rate performance of Nb2CTx MXene. c Long-term cyclic performance of Nb2CTx MXene. Reproduced with permission from [119] Copyright 2021, Wiley–VCH. d CV curves of Ti2CTx and Ti3C2Tx MXene. Reproduced with permission from [112] Copyright 2021, The Authors, published by Springer Nature. e SEM image of Ti3C2Tx MXene prepared from 60 batch of Ti3AlC2 MAX. f Specific capacities of Ti3C2Tx, Ti2CTx and Ti3CNTx MXene at various C-rates. Reproduced with permission from [175] Copyright 2022, Zhengzhou University. g Elemental composition comparison of Ti3C2Fx, Ti3C2Clx and Ti3C2Brx MXenes. h Long-term cyclic performance of Ti3C2Fx, Ti3C2Clx and Ti3C2Brx MXenes at 1 A g−1. Reproduced with permission from [178] Copyright 2022, Elsevier. i TEM image of Ti3C2Tx/Sn anode after 2200 cycles. Reproduced with permission from [145] Copyright 2022, Elsevier

It is worth mentioning MXenes obtained by Lewis acidic etching method may exhibit better electrochemical performance due to the absence of –F and –OH surface groups and the introduction of –O termination. In 2020, Li et al. prepared multi-layered Ti3C2Tx MXene (T = –O and –Cl) via CuCl2 etching of Ti3SiC2 precursor [67]. When used as anode for LIBs, the obtained Ti3C2Tx MXene exhibit a distinct pseudocapacitive-shaped cyclic voltammetry (CV) curves without redox peaks in organic electrolyte. In comparison, MXene anodes synthesized by HF etching generally show obvious redox peaks in CV profiles [168, 171]. In addition, Ti3C2Tx MXene delivers a discharge capacity of 205 mAh g−1 at 0.6C rate, corresponding to the fact that per Ti atom can transfer around 0.4 electrons. Further, superior long-term cyclic stability up to 2400 cycles can be obtained for multi-layered Ti3C2Tx MXene electrode. The superior lithium storage performance can be attributed to the strong adsorption ability of -O surface group on Li+ cations [120]. Moreover, the Li+ insertion/deinsertion storage mechanism can be confirmed by the enlarged/decreased interlayer spacing through in-situ XRD measurement. In 2021, the Nb2CTx MXene (T = –O and –Cl) with obvious accordion-like morphology was prepared by CuCl2 molten salt etching of Nb2AlC precursor [119]. The theoretical calculations indicate that –O surface groups can obtain more electrons from Nb atoms than –Cl termination for Nb2CTx MXene, thus resulting in the substitution of –O for –Cl functional groups during ammonium persulfate solution washing process, which is conducive to its lithium storage performance. Nb2CTx MXene anode delivers a high discharge capacity of 330 mAh g−1 at 50 mA g−1 (Fig. 10b), which is larger than the theoretical specific capacities of Nb2C (305 mAh g−1) and Nb2CO2 (292 mAh g−1). Additionally, capacity rising phenomenon can be clearly observed for Nb2CTx MXene at 1000 mA g−1 (Fig. 10c), which can be attributed to the electrochemical activation and common pillaring effect.

In 2022, Lin et al. prepared Ti2CTx and Ti3C2Tx MXene by one-pot method in an air atmosphere with Ti, C, and Al powders as precursor, simultaneously achieving the synthesis of MAX and in-situ CuCl2 etching in molten salts system [112]. When served as anodes for LIBs, Ti2CTx and Ti3C2Tx electrode both exhibit rectangular and symmetric CV curves in a voltage range of 0.1–2 V (Fig. 10d), which is similar to those of previously reported MXene electrodes prepared by Lewis acidic etching [67]. Furthermore, Ti2CTx anode shows discharge capacities of 256 and 164 mAh g−1 at 0.5 and 10 mV s−1, respectively. In comparison, specific capacities of 164 and 113 mAh g−1 can be obtained for Ti3C2Tx electrode at the same scan rate. The superior rate performance of these two MXene electrodes is mainly due to the pseudocapacitive-controlled charge storage mechanism. Later, Chen et al. reported the synthesis of Ti3C2Tx, Ti2CTx, Ti3CNTx and Ti4N3Tx MXene via molten salts-shielded synthesis strategy in air atmosphere with MAX phases as precursor and CuCl2 molten salt as etchant [175]. The low-melting eutectic salt reaction medium can effectively restrain the oxidation of MXenes at high temperature. More importantly, the proposed method can be used to prepare Ti3C2Tx MXene on a relatively large scale. The distinct accordion-like structure can still be obtained for Ti3C2Tx MXene prepared from 60 g batch of Ti3AlC2 MAX (Fig. 10e), demonstrating superior scalability. Among the Ti3C2Tx, Ti2CTx and Ti3CNTx MXene electrodes, Ti2CTx anode delivers the largest discharge capacity, and the three electrodes all exhibit excellent rate performance (Fig. 10f).

Recently, Cao et al. demonstrated the successful preparation of multi-layered Ti2NTx MXene (T = –O and vCl) via CuCl2 etching at 450 °C for 1 h [176]. The existence of Ti-Cl and Ti–O bonds can be confirmed by XPS and XAS measurement. Theoretical calculations indicate that the Gibbs energy change of –O substituting –Cl termination is −2.3 eV, while the value of –O replacing –F surface group is 0.07 eV, demonstrating that –Cl can be readily substituted by –O. The obtained Ti2NTx MXene can deliver high discharge capacities of 303.4 and 158.4 mAh g−1 at 0.1 and 5 A g−1, respectively. More importantly, a large capacity of 350 mAh g−1 after 1,200 cycles at 1 A g−1 can be obtained for Ti2NTx electrode, revealing outstanding cycling stability. A hybrid capacitor by pairing Ti2NTx anode and super activated carbon cathode can demonstrate an energy density of 45.36 Wh kg−1 at 123.32 W kg−1. It is noteworthy that the MXene electrodes mentioned above are all at multi-layered state, and few-layered MXene electrodes may show better electrochemical performance. Liu et al. reported the synthesis of exfoliated Ti3C2Tx MXene (termed as e-MS-Ti3C2Tx) via CuCl2 molten salts etching and subsequent TBAOH intercalation [153]. The e-MS-Ti3C2Tx electrode delivers discharge capacities of 225 and 95 mAh g−1 at 0.2 and 16 A g−1, respectively, which is higher than that of unexfoliated Ti3C2Tx anode. The boosted rate performance of e-MS-Ti3C2Tx electrode is mainly assigned to the enhanced contact area between electrode and electrolyte after exfoliation. Additionally, the increased content of -O termination after TBAOH treatment will also benefit the lithium storage performance [177].

The type of halogen terminations may have an influence on the electrochemical performance of MXene. Liu et al. synthesized Ti3C2Tx MXene with –F, –Cl or –Br functional groups via HF, NiCl2 or NiBr2 etching, respectively [178]. The typical accordion morphology can be afforded for three halogenated MXenes. The element composition analysis shows that Ti3C2Brx MXene possesses the highest content of –O surface group among the Ti3C2Fx, Ti3C2Clx and Ti3C2Brx MXene (Fig. 10g). This phenomenon is mainly assigned to the fact that the formation energy of Ti–Br bond is the lowest compared with that of Ti–Cl and Ti–F bonds according to theoretical calculations. Consequently, –O can easily replace the -Br surface group when the prepared Ti3C2Brx MXene is exposed to air, and the highest content of -O functional group contributes to the largest discharge capacity of 189 mAh g−1 for Ti3C2Brx anode. Finally, the Ti3C2Brx electrode exhibits the best rate performance and cyclic performance relative to Ti3C2Fx and Ti3C2Clx anode (Fig. 10h). The electrode materials mentioned above are all individual MXenes, while the MXene/active metal composites can also be utilized as anodes for LIBs. Wu et al. reported the preparation of Sn-nanoconfined Ti3C2Tx MXene hybrids via SnCl2 molten salt etching of Ti3AlC2 [145]. The Sn nanoparticles are in-situ grown and confined between the Ti3C2Tx MXene during the etching process. It is noteworthy that the confined effect of MXene can effectively prevent the aggregation of Sn nanoparticles at high temperature and accommodate its large volume variation upon cycling. As a result, Ti3C2Tx/Sn anode remains a reversible capacity of 226.2 mAh g−1 after 1000 cycles at 0.2 A g−1, which is higher than that of pure Ti3C2Tx and Sn electrode. The volume expansion of Sn nanoparticles can gradually enlarge the interlayer spacing of MXene from 1.17 to 1.34 nm after 2200 cycles (Fig. 10i), which greatly exposes more active sites upon cycling and contributes to the obvious capacity rising phenomenon.

4.1.2 Sodium-Ion Batteries

SIBs possess a similar working mechanism to LIBs. It is well known that the working voltage of SIBs is lower than that of LIBs, thus resulting in a relatively low energy density of SIBs [179, 180]. However, due to the abundance of sodium resources and attractive cost-effectiveness [181], SIBs are promising to be utilized in some fields that do not require high energy density, such as large-scale energy storage [182, 183]. As a type of negative electrode for SIBs, transition metal sulfides exhibit high theoretical specific capacities and safe discharge voltage [184]. Nevertheless, large volume expansion and inferior charge transfer kinetics of transition metal sulfides greatly deteriorate their sodium storage performance [185]. Our group has been working on improving the electrochemical performance of transition metal compounds in the past few years [73, 117]. Recently, we proposed a general strategy for constructing Ti3C2Tx MXene/transition metal sulfides (Ti3C2Tx/MSy, T = –O and –Cl, M = Fe, Co and Ni) heterostructures as SIBs anodes through directly sulfurizing Lewis acidic etching products (MXenes/metal composites) (Fig. 11a–b) [147]. Different from the traditional construction process of preparing MXene first, then adsorbing transition metal ions and finally vulcanizing, this strategy simplifies the preparation procedure of MXene/transition metal sulfides hybrids via rationally utilizing Lewis acidic etching products. Additionally, this fabrication process avoids the use of HF as etchant and water as reaction medium, which effectively improves the experimental safety and alleviates the oxidation of MXene, respectively. For the fabricated Ti3C2Tx/FeS2 heterostructures, FeS2 nanoparticles are in-situ grown and tightly fixed on the Ti3C2Tx MXene substrate (Fig. 11c–d), demonstrating a stable framework for continuous Na+ insertion/extraction. Furthermore, O 1 s XPS spectrum and theoretical calculations confirm that Ti3C2Tx MXene and FeS2 nanoparticles demonstrate interfacial electronic coupling effect via Ti–O–Fe bonds (Fig. 11e–f), facilitating the rapid interfacial electron transfer from MXene to FeS2. Additionally, Ti3C2Tx/FeS2 hybrids also exhibit rapid Na+ diffusion kinetics and mechanical strain release channels. Consequently, derived from the above advantages, the Ti3C2Tx/FeS2 anode delivers a reversible capacity of 474.9 mAh g−1 after 600 cycles at 5 A g−1 (Fig. 11g), and reveals a high capacity of 456.6 mAh g−1 at 10 A g−1, suggesting outstanding long-term cyclic performance and rate capability. In addition, the full-cell device assembled with Ti3C2Tx/FeS2 anode and Na3V2(PO4)3 cathode can demonstrate a discharge capacity of 431.6 mAh g−1 after 1000 cycles at 3 A g−1 and an energy density of around 130 Wh kg−1 at a power density of 415 W kg−1, indicating superior application prospect of Ti3C2Tx/FeS2 heterostructures.

a Schematic of the fabrication process of Ti3C2Tx/MSy hybrids. b XRD pattern of Ti3C2Tx/FeS2 composites. c SEM image of Ti3C2Tx/FeS2 hybrids. d HRTEM image of Ti3C2Tx/FeS2. e O 1 s XPS spectra of Ti3C2Tx/FeS2. f Charge density difference of Ti3C2Tx/FeS2 composites. g Cyclic performance of Ti3C2Tx MXene and Ti3C2Tx/FeS2 hybrids at various current densities. Reproduced with permission from [147] Copyright 2022, Wiley–VCH