The future is now

Hall 03 Stand 3F91 04 - 10 Maggio 2023 Düsseldorf Let’s meet at +39 0173 61.05.64 • www.tecno-3.it Headquarter: Tecno 3 S.r.l. - Corneliano d’Alba - ITALY Tecno 3 Switzerland Tecno 3 USA INC TECNO3 INAUGURATES THE NEW ERA OF CONTINUOUS MELTING

world of the food industry asks, TECNO3 responds.

The

today it

possible to melt continuously and in little space Fat loaves, cocoa and chocolate mass, anhydrous butter and hydrated, in one plant. Technological innovation, production optimization, power and security. 10064 PINEROLO - ITALIA Tel. +39 0121393127 info@chiriottieditori.it www.foodexecutive.com Supplemento al n. 04, aprile 2023 di Industrie AlimentariSped. in A.P.D.L. 353/2003 (Conv. in L. 27/02/2004 n° 46) art. 1 comma 1 DCB TOn. 103 anno 2023IP n. 103 - April 2023 ISSN 1590-6515

TECHNOLOGY ITALIAN

From

is

FOOD & PACKAGING

departments

3

18

24

PRODUCT TRENDS - Global opportunity for Hard-Boiled confectionery

- Industry faces an opportunity challenge for ‘real food’ - Global forecast on cocoa and chocolate market - High competition in the confectionery market - The plant-based protein market

CONSUMER TRENDS - Consumers seek out brands that respond to their core values - More consumers seek nutrient-dense foods while meat-reducing slows

FOOD PROCESSING - Food Automation Market worth 12.26 billion USD

- The world of continuous melting inaugurates a new era - Meet Sarp at Interpack - No compromise in Food Safety - Combination of plasma processing and pulsed electric field on the characteristics of yoghurt drink - Simplified model of airflow and heat transfer in a pallet of food product generating heat - New technology to produce meat analogues with soy, pea and gluten - Whole peanut milk productionA novel technology for high-moisture textured soy protein

36

PACKAGING TRENDS - Food: packaging against waste - Electron beam irradiation of vacuum-packaged pork - The role of packaging on the flavor of fluid milk - Packaging for beverages is growing more sustainable - Dairy packaging market: global opportunity and industry forecast - Research on the structure of the PET bottle bottom - Effects of irradiation on the shelf-life and quality of vacuumpackaged beef steaks

50 PACKAGING EQUIPMENT - Industrial packaging: for safe travels around the globe - Simple, flexible automation: beyond the machineThe labelling solution preferred by Wine & Spirits - Reduce, reuse, and recycle: SMI solutions for a compact, eco-sustainable end of line

60 NUTRITION - New rice grains with dazzling color and flavorImproving flavour and texture of B12-fortified bread - Potential of raw and fermented maize gluten feed in bread making - Increasing the content of lactose-free milk macronutrients - Cassava starch as a novel gluten-free for baking product - Rosemary extract as drink ingredients - Extruded snacks from pulses and pseudocereal proteins - Effects of soybean oil body as a milk fat substitute on ice creamChickpea extract as leavening and anti-staling agent for gluten-free breads - Study on optimization of preparation process of coconut plant-based yoghurt

68 RESEARCH - Bringing your food full circle - Potential of lactic acid bacteria to produce functional fermented whey beverage - Aloe vera and carrageenan based edible film improves storage stability of ice cream - A comparative study between freeze-dried and spray-dried goat milk - Evaluation of quality changes of cloudy mixed juices after high pressure processing - Effects of ultra high pressure-magnetic field treatment on stored shrimp - Improving fresh cheese shelf-life through hyperbaric storage - Techno-functional properties of black soldier fly larvae - Novel lactic acid bacteria starter from insect microbiome to plant-based fermentations - Effect of roasting degree on major coffee compounds - Extruded mozzarella cheese properties influenced by renneted casein gels

76 NEWS - Fresh fruits and nuts processing - First USDA winter peas for food - Cellular agriculture key technology for food securityInternational events in Italy

80 COMPANY INDEX APRIL - issue 103

Four-monthly - ISSN 1590-6515

April

issue 103

OUR WEBSITES

www.chiriottieditori.it shop.chiriottieditori.it www.foodexecutive.it www.pasticceriainternazionale.it www.tuttogelato.it www.alimentifunzionali.it

Chiriotti Editori s.r.l. Viale Rimembranza 60

10064 Pinerolo - To - Italia Tel. 0121 393127 info@chiriottieditori.it www.chiriottieditori.it

for free subscriptions call to +39 0121 378147 or send an e-mail to: abbonamenti@chiriottieditori.it La riproduzione, anche parziale, di articoli ed illustrazioni pubblicati sulla rivista è riservata e non può avvenire senza espressa autorizzazione scritta dell’Editore. L’Editore non assume alcuna responsabilità per quanto riguarda eventuali errori contenuti negli articoli e per quanto espresso dagli Autori.

Publisher

Alberto CHIRIOTTI Direttore Responsabile alberto@chiriottieditori.it

Contributing Editors

Laura SBARATO, Simonetta MUSSO, Rossella CONTATO, Matteo BARBONI

Assistant Editor

Chiara MANCUSI mancusi@chiriottieditori.it

Graphics

Anna BOSCOLO

Marketing Manager

Monica PAGLIARDI pagliardi@chiriottieditori.it

Advertising Manager

Luca RUSSO russo@chiriottieditori.it

General Manager

Giuseppe CHIRIOTTI

All Rights reserved. Reproduction, even partial, of articles and illustrations published in the journal is forbidden and can not take place without written permission of the Publisher. The Publisher assumes no responsibility for any errors contained in the articles and for what is expressed by the Authors and/or by the companies.

PRINTED by Graf Art

Officine Grafiche Artistiche Venaria (To)

COPYRIGHT:

© 2023 Chiriotti Editori srl Supplemento del mensile

“Industrie Alimentari”

AUTORIZZAZIONE: n. 262 (19-11-1962)

del Tribunale di Pinerolo

PERIODICITÀ:

mensile - sped. in A.P. comma

20/B, art. 2, legge 662/96Torino

INTERNET:

www.chiriottieditori.it

Unione Stampa Periodica Italiana Copyright Clearance Center

PRODUCT TRENDS

Global opportunity for Hard-Boiled confectionery

According to the latest report by Allied Market Research, the global hard-boiled confectionery market size was valued at $15.6 billion in 2021, and is projected to reach $21.3 billion by 2031, growing at a CAGR of 3.2% from 2022 to 2031.

Hard-boiled confectionery refers to the sweet or candy made by boiling or heating sugar-based syrups at a temperature of around 160°C. Hard-boiled confectionery is also known as hard candy, boiled sweet, and sugar candy.

Economic growth, rise in disposable income, and rise in affordability are several important factors that are driving the hard-boiled confectionery market growth globally. In the past few years, trend of nuclear families has surged significantly and growth in the number of working couples is contributing actively in the increasing income of the families. This is further fueling the affordability of various confectionery items and premium products, which is exponentially propelling the growth of the global hard-boiled confectionery market.

Moreover, the growing trend of gifting confectionery items is a major factor that has a significant contribution in the overall growth of the hard-boiled confectionery industry. The rise in the consumers’ preference toward gifting confectionery products during celebratory and festive occasions such as Halloween, Diwali, Eid, birthdays, and school functions, is significantly boosting the demand for the hardboiled confectionery across the globe. The trend of gifting confectionery items is gaining a rapid traction

in the developing economies, which is expected to offer a significant impetus to the growth of the market during the forecast period.

Furthermore, rising young population is anticipated to propel the demand for the hard-boiled confectioneries in the forthcoming years. The demographic shifts and changing consumer tastes & preferences is encouraging new product development and introduction of innovative flavors in the herd-boiled candies. The manufacturers are boosting their investments toward development of new flavors along with the adoption of innovative fillings to enhance the taste of the hard-boiled confectioneries is expected to boost the growth of the global hard-boiled confectionery market during the forecast period.

A notable increase in the prevalence of diabetes among the global population along with rise in health-consciousness among the consumers is expected to drive the demand for the low-calorie or sugar-free hard-boiled confectionery items in the future. According to the International Diabetes Federation (IDF), in 2021, around 537 million people aged 20 years to 79 years were suffering from diabetes, globally. This number is expected to reach 643 million by 2030 and to 783 million by 2045. Therefore, a significant rise in the prevalence of diabetes among the

italian food & packaging technology - ciii (2023) - april 3

global population is expected to drive the low-calorie hard-boiled confectionery market demand during the forecast period. Moreover, rising health-consciousness among adults, growing consumer expenditure on wellness products, and rising awareness regarding the availability of sugar-free hard-boiled confectioneries are anticipated to provide impetus to the market.

Further, rising initiatives by the manufacturers to invest in sustainable development is expected to boost the sales of the confectionery products at premium prices. The majority of the eco-conscious consumers associate their physical well-being with environmental issues that significantly influences their purchases. The eco-conscious consumers tend to spend more and buy confectioneries at premium prices for sustainably produced products. In 2017, Mars, a confectionery giant, announced to invest $1 billion to help cut emission of greenhouse gases from its value chain by 67% by the year 2050. This type of sustainability-oriented investments by the confectionery manufacturers is expected to attract the eco-conscious consumers, especially in the developed regions such as North America and Europe.

However, fluctuations in the prices of raw materials and rise in prevalence of type 1 diabetes among children are the major factors that may hamper the market growth during the forecast period. Fluctuations in prices of sugar are the result of various factors such as low yields, political tensions, climate change, and draughts. The global sugar prices increased rapidly from around $12.0 per Lbs. (pound) in January 2019 to $18.9 per Lbs. in January 2022. Therefore, sugar prices increased due to less production and more demand, may reduce the profitability of the manufacturers to a great extent. Furthermore, according to the IDF, over 1.2 million children and adolescents (0 to 19 years of age) were living with type 1 diabetes across the globe, in 2021. Surging prevalence of diabetes among the young population may negatively impact the demand for the hard-boiled confectionery market in the future.

According to the hard-boiled confectionery market analysis, the hard-boiled confectionery market is segmented on the basis of type, flavor, age group, distribution channel, and region. On the basis of type, the market is categorized into suckers and lollipops, jawbreakers, candy canes, rock candy, drops and disks, and others. By flavor, it is segmented into

cherry, watermelon, lemon, strawberry, orange, butterscotch, and others. Depending on the age group, the market is categorized into children, adult, and geriatric. By distribution channel, the market is divided into supermarkets and hypermarkets, convenience stores, specialty stores, e-commerce, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA (Latin America, the Middle East, and Africa).

Suckers and lollipops segment dominated the market in 2021 due to its huge popularity and demand among children

According to the hard-boiled confectionery market forecast, by type, the suckers and lollipops was the largest segment accounting for 40.6% of the hard-boiled confectionery market share in 2021 and is expected to sustain its significance during the forecast period. This massive growth of this segment is attributed to the huge demand and consumption of suckers and lollipops among children. The intro-

4 italian food & packaging technology - ciii (2023) - april product trends

duction of multiple flavors in lollipops and easy availability coupled with captivating marketing strategies adopted by the manufacturers to attract children has significantly boosted the growth of this segment. For instance, Foltin and Foltin (F&F) Ltd., a Hungary-based lollipop manufacturer has partnered with The Walt Disney Company to supply their lollipops to Disneyland Paris. The lollipops were packed with foil of different popular Disney characters to attract the children.

Strawberry was the largest segment in 2021

As per the hard-boiled confectionery market trends, by flavor, the strawberry was the dominant segment in 2021. This growth is attributed to the enhanced taste and nutritional benefits associated with the strawberries. The nutritional benefits of strawberry help in maintaining good cholesterol, lower blood pressure, and decrease the risks of cancer. Moreover, the fruity and acidic

taste of strawberry enhances the experience of the hard-boiled confectionery consumers. Further, the manufacturers are experimenting to combine various flavors with strawberry to create a new combination that goes well with strawberry. The huge popularity of the strawberry flavored hard candies among the consumers is expected to sustain the dominance of the strawberry segment during the forecast period.

Children was the largest segment in 2021, as children are the largest consumers of hard-boiled confectioneries across the globe

By age group, the children segment dominated the market in 2021. Children are the leading consumers of the hard-boiled confectioneries. According to the World Bank, in 2021, around 25% of the global population consisted of 14 years or below age group. With the improvement in the technologies and adoption of advanced tools in fertility clinics, the fertility rate of women is improving globally. Moreover, rising global population is expected to boost the demand for the hard-boiled confectionery in the future. The presence of huge number of young populations in developing and underdeveloped economies has led to the increased demand for the hard-boiled confectionery in the nations such as India, China, and Brazil.

E-commerce is expected to be the fastest-growing segment during the forecast period

Depending on the distribution channel, e-commerce is anticipated to witness the highest CAGR during the forecast period. The e-commerce platform serves as a popular medium for the purchase of packaged food like hard-boiled confectionery. This is attributed to easy availability and the benefits such as information about the attributes of the products, time-saving features, and the facility of home delivery provided by the e-commerce platform. In addition, consumers prefer to buy products online since it is convenient and offers a large selection of brands that are not available in retail. Moreover, the e-commerce sales channel has increased the consumer reach owing to which it has evolved as a key source of revenue for many hard-boiled confectionery companies. Consumers are becoming

italian food & packaging technology - ciii (2023) - april 5 product trends

more aware about the many purchase patterns that exist in society as technology advances and internet services become more widely available. The technology attracts the millennials and generation Z and is expected to influence the buying pattern of products. According to the United Nations Conference on Trade and Development (UNCTAD), the e-commerce sector’s proportion of total retail sales increased from 16% to 19% in 2020. Furthermore, online sales are expected to grow notably shortly, due to the rapid increase in mobile users. An increase in e-commerce sales, improvements in logistics services, and ease in payment options further boost the growth of the global hard-boiled confectionery market.

Asia-Pacific was the largest market in 2021 and is expected to be the fastestgrowing region during the forecast period

Region-wise, Asia-Pacific was the leading market in 2021 and is expected to be the fastest-growing market from 2022 to 2031. Asia-Pacific is home to over 60% of the global population with a majority of the population being young. The presence of a huge youth population, rise in employment, rise in disposable income, change in food habits of the consumers, and rise in number of product launches are the major factors that are expected to drive the growth of the Asia-Pacific hard-boiled confectionery market during the forecast period. Moreover, rising prevalence of

diabetes coupled with growing geriatric population in the region are expected to boost the demand for the low-calorie hard-boiled confectionery products. According to the IDF, 3 in 4 individuals in low and middle-income nations were living with diabetes in 2021. Further, according to the United Nations, around 80% of the geriatric population is expected to live in low and middle-income countries by 2050. Therefore, the demand for sugar-free hard candies is expected to rise significantly in Asia-pacific during the forecast period.

Ferrero International S.A., Lotte Corporation, Mars, Incorporated, Mondelez International, Inc., Nestle S.A., Parle Products Pvt. Ltd., Perfetti Van Melle, The Hershey Company, Tootsie Roll Industries, and Valeo Foods Group are the major companies profiled in the hard-boiled confectionery market report. These manufacturers are constantly engaged in various developmental strategies such as partnerships, mergers, acquisitions, and new product launches to gain competitive edge and exploit the prevailing hard-boiled confectionery market opportunities.

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the hard-boiled confectionery market analysis from 2021 to 2031 to identify the prevailing hard-boiled confectionery market opportunities.

www.alliedmarketresearch.com

6 italian food & packaging technology - ciii (2023) - april product trends

Industry faces an opportunity challenge for ‘real food’

Consumers’ expectations that convenient, packaged foods should be simpler and less processed are set to become more important over the rest of this decade, predicts food industry expert Julian Mellentin of New Nutrition Business. He says there’s growing evidence that consumers are increasingly shunning ultra-processed foods (UPFs) and looking for more ‘real foods’.

In a recent survey of consumers, 20% of Americans and 40% of Spanish consumers said they were trying to avoid UPFs, the highest numbers since the consultancy began asking this question. “The growing consumer interest in ‘less processed’ has grown out of the clean label trend of identifying something undesirable in our food and avoiding it,” says Mellentin. “What’s different is that we are entering a new phase. Brands will have to do more to reinvent “ultra- processed foods” and to deliver products that get closer to consumers’ expectations of ‘real food’.”

Avoiding UPFs means, to a growing number of consumers, choosing fresh and natural foods. When the International Food Information Council (IFIC) asked Americans about the most common attributes of a healthy food, the top answer, given by 37% of people, was ‘fresh’, while 20% of consumers said ‘minimal or no processing’.

8 italian food & packaging technology - ciii (2023) - april product trends

“The opportunity over the next 3-5 years is for packaged food companies – gradually, step-by-step – to renovate products,” says Mellentin. “That will require a focus on ingredients and processing technology which deliver the safety, convenience and palatability people seek while doing so with as little processing as possible – or at least with a type of processing that people accept.”

“Ingredient suppliers have an important role to play in enabling this change, just as they have through the last 20 years of changing consumer preferences about clean label and free-from,” he adds.

Companies do not need to renovate their entire product line, says Mellentin: “A significant percentage of mainstream consumers want to continue enjoying their favourite foods just as they are. The result may be that companies will have some products within their portfolio that meet consumer expectations for less processed and real food – just as today they have free-from or gluten-free lines in their portfolio.”

In his recent report, 10 Key Trends in Food, Nutrition & Health 20234, Mellentin notes that there are many companies for whom ‘simply processed’ and ‘real’ are already part of strategy:

- Yoplait’s French-inspired Oui by Yoplait yoghurt, marketed in the US, communicates simple ingredients and artisanal-style packaging and production. It was the first product of its kind from General Mills, the world’s 10th-biggest food company. The simplicity of the production process is explained to consumers. Oui achieved over $100 million in Year 1 retail sales with 3 SKUs and has since been expanded to 26 SKUs.

- Danone is responding to the trend in Spain, where it may be the most advanced. An amazing 40% of Spanish people claim to be avoiding UPFs – the highest number in Europe. The desire to avoid UPFs is partly cultural, but it also owes something to Carlos Rios, a Spanish blogger and nutrition guru with 1.5 million followers on Instagram. He is the creator of Realfooding, a movement which encourages people to avoid UPFs. Danone has become the first major food company to engage with the Realfooding project. One of Danone’s natural drinking yoghurts, with just 4 ingredients, now carries the Realfooding endorsement.

- Technology has an important role to perform in enabling packaged products to deliver on consumer expectations. US-based plant milk marketer Elmhurst has developed a technology called HydroRelease, which enables it to create a two-ingredient, nutritionally-dense plant milk which delivers on consumer expectations of simple processing and few ingredients, in marked contrast to most plant milks on the market. www.new-nutrition.com

italian food & packaging technology - ciii (2023) - april 9 product trends

Global forecast on cocoa and chocolate market

The cocoa market is projected to reach USD 26.3 billion by 2027 growing at a CAGR of 4.5% from 2022 to 2027, while the chocolate market is projected to reach USD 160.9 billion by 2027 growing at a CAGR of 4.7% from 2022 to 2027 according the latest MarketsandMarkets report.

Increasing sales of chocolate confectionery products to be consumed as comfort food is responsible for making it a regular grocery items in households. Chocolate is considered a traditional gift on special occasions and festivals such as Christmas, Easter, Halloween, and Valentine’s Day in American and European countries, a trend which is now adopted in some Asian countries such as India, China, and Japan. The seasonal and festive sales of chocolate products highly impact the market as a large portion of chocolate products are consumed in this segment.

The Cocoa and chocolate market has been growing in accordance with the rising demand for health benefits of cocoa in chocolate products are the key drivers for the chocolate market. In addition to this, chocolates are being consumed as a premium and comfort food which is a rising trend among consumers, further proliferating the market growth.

MARKET DYNAMICS

Health benefits of chocolates

Chocolates have a long history of being used as a health food. In the 18th century, a chocolaty drink was used in England to prevent and cure stomach

aches. Today, ORAC (Oxygen Radical Absorbance Capacity) is used to compare the antioxidant capacity of different foods. Chocolates, along with apples and blueberries, are considered to be one of the best ORAC rating foods. Consuming chocolate also pre-

10 italian food & packaging technology - ciii (2023) - april

vents the stress hormone, cortisol, from being released. Instead of relying on medication, consumers prefer to incorporate ingredients that improve their health into their normal diet.

Dark chocolate is becoming more popular among consumers due to its high cocoa content and flavonoids, especially a subtype known as flavanols that is linked to a lower risk of heart disease. Additionally, those who consume dark chocolate or high cocoa content have a lower chance of developing insulin resistance and high blood pressure. Thus, the health benefits associated with cocoa and its products are the biggest driver for the cocoa and chocolate market.

High raw material prices

The major restraint impacting the market is the high price of raw material, i.e., cocoa and sugar. Chocolate prices are highly dependent on raw materials. Cocoa and sugar are the most important raw

materials in chocolate manufacturing and constitute over 80% of the raw material cost for chocolate production. Hence, the rising cost of raw material will impact the market for chocolate.

According to the International Cocoa Organization, the world largest supplier of cocoa is Africa, which accounts for 72% of the global production of cocoa. Ivory Coast and Ghana are the major countries producing cocoa, but these countries are also facing certain issues such as fairtrade discrepancies, environmental issues, spells of government unrest, and reducing labor force as more population is leaving farming as an occupation and opting other professions.

Low penetration rate in Developing Countries

Developing Countries such as India and China offer a great opportunity for growth to major chocolate companies due to low penetration rates in these markets. In these countries, chocolate is mostly used for confectionery. The market for premium chocolates is almost undeveloped in such countries. However, the scenario is about to change, with major companies such as Kraft Foods, Ferrero, and Mars launching their premium products in Asian countries.

A major cause for the rising demand for chocolates is the rising disposable income of customers in Asia Pacific’s developing nations. Over the past several years, the availability of local brands has boosted chocolate sales in South Korea, Japan, India, and China. Due to evolving taste preferences and rising brand loyalty, international brands such as Ghirardelli, Mars, Ferrero, and Hershey’s have also seen growth in these countries.

Changing consumer preferences

A major threat to the chocolate industry is the changing consumer preferences of chocolates. Chocolates were consumed as a confectionery item, but now there is a growing demand for the healthy chocolate option, with an inclination toward dark chocolate, a rich source of polyphenols.

As per a recent survey conducted by Barry Callebaut, 36% of Europeans want chocolates with health benefits, while 38% would like chocolates with reduced sugar content. Consumers are even

italian food & packaging technology - ciii (2023) - april 11 product trends

willing to pay up to 10% more for chocolate with health benefits. Such consumer trends have forced companies such as Hero Nutritional and Barry Callebaut to launch chocolates with health benefits.

Companies will have to make sure that their new product launches are in accordance with consumer tastes and preferences. Since chocolate is a perishable product, any decrease in the demand for a particular product could result in large inventories with very limited time for disposal.

Seasonal and festive-related sales

Chocolate is considered a traditional gift on special occasions and festivals such as Christmas, Easter, Halloween, and Valentine’s Day in American and European countries, a trend which is now adopted in some Asian countries such as India, China, and Japan. Chocolate sales shoot up during festive seasons. Keeping this seasonal effect of sales in mind, companies trying to venture into developing economies, such as India and China, are focusing on specialty products for traditional festivals such as the Chinese New Year, Raksha Bandhan, and Diwali in India.

Currently, the seasonal and festive sales of chocolate products highly impact the market as a large portion of chocolate products are consumed in this segment. Depending on the situation, they are produced in a variety of shapes, sizes, colors, and product materials. Thus, this high demand for chocolates and its products during festivals would enhance the market for cocoa and chocolate.

Large number of applications

Chocolate is used in several applications, including confectionery, beverages, and baking. Chocolate is setting its foot rapidly in the baking industry, with lots of chocolates being looked upon as a flavor for biscuits, cakes, and pastries. In the global flavor industry, several new product types are being developed, such as energy drinks, yogurt, and dairy beverages.

Additionally, chocolate liquor is generally used for applications in the production of bittersweet chocolate and baking applications.

Cocoa is used in the pharmaceutical industry for providing the chocolate essence or flavour to the

drugs to improve the palatability or compliance of the dosage forms for consumers.

In addition to that, natural cocoa butter is frequently used in cosmetics as a humectant, a lubricant to maintain the moisture, and to enhance the aroma of products. These applications of cocoa and chocolate can drive its market in the coming years.

North America dominated the cocoa and chocolate market

The key players in the North American Cocoa and chocolate market include Mondelez international (US), Blommer chocolate (US), Hershey (US) and Mars Inc. (US). The rising demand for chocolate in North America enhances the growth of cocoa simultaneously in the region as it is the key raw material used in the production of chocolate. Moreover, the increasing demand for chocolate among consumers triggers the demand for cocoa butter as it provides the chocolate with its melt-in-the-mouth texture. The U.S. accounted for the highest chocolate consumption and production in the North American region.

In Canada, chocolate is becoming more expensive due to the rising cost of raw materials, particularly sugar but the rising popularity of giving chocolates as gifts, Canada is likely to see a significant increase in the acceptability of pricey chocolates in the upcoming years.

The Mexican chocolate market is expanding as a result of rising disposable income, booming foreign investment, and an increase in annual chocolate events like the Mexico Chocolate Expo.

Key market players

The key players in cocoa and chocolate market include Mars, Inc. (US), Mondelez International (US), Nestle S.A. (Switzerland), Meiji Holding Co. Ltd. (Japan), Ferrero International (Italy), Olam Group (Singapore), Barry Callebaut (Switzerland), Cargill Incorporated (US), Cocoa Processing Company (Ghana), Archer Daniel Midland (ADM) Company (U.S.), Chocoladefabriken Lindt & Sprüngli AG (Switzerland) and Pladis Global(UK).

12 italian food & packaging technology - ciii (2023) - april product trends

www.marketsandmarkets.com

DI BARTOLO SRL Via Garibaldi, 165 95011 Calatabiano (CT) Tel. +39 095 645103 info@dibartolosrl.it www.dibartolosrl.it Since 1951, we are your tailor made ingredients partner.

High competition in the confectionery market

Most people enjoy a sweet tooth, but with the trend towards more sustainability, there is also an increase in demand for sweets with more eco-friendly packaging. This puts severe pressure on the confectionery industry to adopt packaging processes and materials which are gentle to natural resources. Many producers of packaging already are able to offer sustainable solutions for chocolate, biscuits, etc.

The European confectionery industry is one of the most dynamic and largest sectors in terms of production and export.

More than 12,000 companies produce 14.7 million tons of confectioneries each year, says the European association Caobisco. Worldwide, however, the USA are the biggest producers of confectionery with a predicted turnover of 264 billion Euro in 2023 and the largest absolute growth, according to Euromonitor International, over the next five years.

Chocolate especially is what consumers prefer above all. In the European ranking by Chocosuisse in 2020, Switzerland led the per-capita consumption of chocolate with more than eleven kilograms per year, followed by Germany (9.2 kg), Estonia (8.3 kg) and Denmark (8.2 kg). Estonia even had the highest per-capita consumption of confectionery in 2022, according to Euromonitor – every inhabitant statistically ate a total of 13.6 kg. Prognostics say that this trend in the Baltic country will experience a large growth over the next five years.

A current survey by the German online platform Statista shows: Women eat more sweets. In the year 2022, about 34% of women said they

consume sweets or savoury snacks every day. The number for men was 23%. In a different study, one quarter of the participants told the market investigators of POSpulse, that since the pandemic they have been consuming more sweets and snacks.

14 italian food & packaging technology - ciii (2023) - april product trends

Manufacturers source the main raw ingredients for confectionery and snack foods mostly from Germany or the EU, according to the German Federal association BDSI. This makes the confectionery industry not only an important partner for the German and European agriculture, short transport distances also mean that it contributes to saving resources. International trade is of course important for the confectionery industry, too. Using roughly 400,000 tons of cocoa, the most important raw ingredient for chocolate, German manufacturers of confectionery process 10% of the global annual crop. All in all, European manufacturers use about half of the world’s available cocoa, according to Caobisco.

Currently, the industry like many others faces an existential crisis: Exploding costs for energy and raw materials, but also disruptions to delivery chains and the availability of raw materials disproportionately affect small and mid-size family businesses. For example, in autumn 2022, the cost increase for sugar was 100%, butter was 57% more expensive, and wheat 60%. “For our companies, the enormous

pressure from rising costs leads to them questioning production sites or even their very existence. This is not only caused by the soaring cost of energy and raw materials in 2022, but also by negative pressure dependent on location, which in Germany has been higher than average for a long time. This includes expenditures on wages, taxes and the growing lack of qualified personnel”, says Dr. Carsten Bernoth, CEO of the German Federal association of German producers of confectionery (BDSI). ‘”For our producers, it is impossible to compensate for these considerably rising costs by saving or by proportionately raising sales prices.”

In spite of the crises, confectionery is one of the segments of the food industry with the highest turnover; this segment achieves the fourth highest. It is therefore no surprise that the confectionery market is one of the most competitive within the German retail market. And the industry is facing new requirements. Especially the growing awareness of consumers regarding health and the environment is creating a new demand for sugar-free varieties and packages that are more environmentally friendly. For manufacturers of confectionery this also means they have to create their packaging processes to be more flexible and more efficient. There is a growing trend towards automated production and packaging processes, and their sweet delicacies more often come in a sustainable wrap.

For example, we have the first chocolate bars that are not wrapped in an inner aluminium foil and are just packaged in cardboard – however, as this is in direct contact with food, it needs a coating. Confectionery producer Fazer now uses a light, dispersion coated cardboard from Metsä Board for its advent calendars. Switching to the new material has reduced the use of plastics by 1,200 kg each year compared to the previous PE coated cardboard, says the company. The advent calendar is now also fully able to be recycled, the light weight and the new material’s efficient use of resources also cut its carbon footprint by one quarter. “Virgin fibre cardboard offers the necessary safety for advent calenders, especially where chocolate and cardboard come into direct contact. Our dispersion coated cardboard also has neutral sensory properties, which means the taste of the chocolate is preserved for a long time”, says Olli Haaranoja, Sales Director at Metsä Board.

italian food & packaging technology - ciii (2023) - april 15 product trends

www.interpack.com

The plant-based protein market

According to the latest research carried out by MarketsandMarkets, the plant-based protein market size is projected to grow from USD 10.3 billion in 2020 to USD 15.6 billion by 2026, in terms of value, recording a compound annual growth rate (CAGR) of 7.2% during the forecast period. The rise in population with lactose intolerance is one of the major factors driving the market growth for plant-based protein. North America region accounted for the largest market share in the global plant-based protein market.

The plant-based protein market is segmented, based on type, into isolates, concentrates, and textured protein. The isolates segment is projected to grow at the highest CAGR during the forecast period since it has a high concentration of protein with the advantage of color, flavor, and functional properties. This makes it an ideal raw ingredient to be used in applications such as beverages, infant foods, children food, textured protein products, and other types of specialty foods.

The market is also segmented, based on application, into food, and feed. The food segment is pro-

jected to be a leading segment in the plant-based protein market, since, plant-based foods represent the growing consumer segment of the market with an increasing number of manufacturers utilizing the characteristics of plant-based proteins to develop new product types and alternatives to conventional products. Plant-based foods are now occupying mainstream presence driven by large-scale manufacturers such as Beyond Meat (US), Impossible Foods (US), Danone (France), and Tyson Foods (US).

Based on source, the market is segmented into soy, pea, wheat, and others, that include potato, canola, and rice. The pea-based protein segment is projected to grow at a higher CAGR during the forecast period, owing to its nutritional benefits and easy integration into final products. Furthermore, the demand for pea protein continues to grow from application industries. Moreover, rising consumer preference for pea-based protein due to increasing health consciousness and awareness regarding the benefits of pea-based protein, particularly in the European and the North American regions, is expected to drive their market growth.

The Asia Pacific region is projected to grow at the highest CAGR in the plant-based protein market during the forecast period due to the growing application of plant-based protein in the food segment. The Asia Pacific region continues to be a strong prospect for manufacturers based in North America. The young demographic and growing interest in plant-based products have resulted in organizations expanding their scope for improved geographic coverage in the region. Countries such as China and India with a strong agricultural background have emerged as key entry points into the region with a well-established infrastructure suited for the processing of plantbased proteins.

16 italian food & packaging technology - ciii (2023) - april product trends

www.marketsandmarkets.com

CONSUMER TRENDS

Consumers seek out brands that respond to their core values

“Redefining Value” heads Innova Market Insights’ Top Ten Trends for 2023, as consumers adapt to a global cost-of-living crisis in the face of economic and political volatility. With budgets stretched and supplies under strain, brands need to be flexible in action and open in spirit to connect with consumers, while also taking full advantage of rapidly emerging technological opportunities.

The eagerly awaited annual trends from food innovation and insight specialist Innova are based on wide-ranging global consumer surveys. Coupled with comprehensive market and new product data, they reveal not only what is driving consumer decisions now, but also ways in which brands and innovators can successfully adapt to future realities.

Over the last year, cost and value for money have become more important to more than half of food and beverage consumers worldwide. Today’s shoppers are increasingly exploring money-saving strategies, such as choosing lower cost items and cooking from scratch. But they remain determined to sample new experiences, ensure personal wellbeing and support planetary health. There is more pressure on brands and manufacturers to deliver value while still meeting these wider public expectations.

“Redefining value throughout the food and beverage industry will lead in 2023 as consumers seek brands that listen, understand and respond to their core values. They want brands that provide quality,

18 italian food & packaging technology - ciii (2023) - april

trust and confidence via their product formulations, communications and wider sustainability actions,” highlights Lu Ann Williams, Global Insights Director at Innova Market Insights.

In addition to a heightened demand for competitive pricing, consumers have told Innova they still seek nutritional value and expect a continued shared responsibility for environmental security. Meanwhile, younger generations who have grown up in an inclusive digital age are gaining greater influence, changing markets and creating new opportunities. Against that complex backdrop, here’s a taste of what Innova’s Top Ten Trends show is in store for the food and beverage industry in 2023:

1. Redefining Value

Brands, innovators, producers and consumers are wrestling with rising costs and greater instability. Combating this requires a deep understanding of where consumers draw the line on compromise. Strategies such as simple price increases, or flexible ingredient lists to cope with supply chain fluctuations, can work in the short term. However, brands need to be open in their communication and clearly show the benefits they are bringing.

Despite political and economic volatility becoming the second biggest concern for consumers in 2022, the health of the planet remains the top global issue and financial pressures are leading to an increase in eco-friendly behaviors. Consumers tell Innova they have reduced food waste and upcycled or recycled more as part of their belt-tightening. As the cost-of-living crisis continues, brands can achieve success through actions that combine economic benefits with clear health and sustainability goals.

2. Affordable Nutrition

Over the past 12 months, 62% of consumers have reported a noticeable rise in the cost of their food and beverages. As a result, they are turning their attention to simple but nutritious goods that are affordable. Key behaviors include buying in bulk, opting for private labels, cooking from scratch, reducing spending on luxury items and purchasing fewer items. Consumers are actively looking for affordable ways to maintain a healthy diet, offering brands many opportunities to test their capabilities to new limits. To meet the nutritional, environmental and economic demands of consumers, manufacturers must innovate to extract maximum value from raw materials and the production process.

3. Generational Push

Younger consumers, raised in an interactive digital world, are creating trends and defining what markets should be providing. For Gen Z and Millennials, food and brand choices are important signifiers of lifestyle, beliefs and values. These demographics have a strong voice and are used to sharing their views openly and widely. While health is an increasingly important purchase driver – as it also is across old-

consumer trends italian food & packaging technology - ciii (2023) - april 19

Innova Market Insights is a global knowledge leader in the food and beverage industry. Founded in 1994, for over 25 years, it has built its reputation on its extensive tracking system for new food and beverage product launches in 90 countries. With its advanced data analytics Innova Market Insights converts industry-leading market research into meaningful guidance on present and future trends in FMCG.

er generations – novel and international flavors are winning the hearts of a young and experimental audience. These consumers embrace the new and different, while being extremely responsive to positive engagement from brands.

4. Plant-Based: Unlocking a New Narrative

The rapid rise of the plant-based sector has, almost inevitably, hit some roadblocks, necessitating a refocusing on consumer demands for high quality, flavorsome products. No longer merely a mimic, green gastronomy will blossom as a standalone sector in 2023, giving brands significant opportunities to diversify and expand. Consumers still want to see improvements in taste and texture, but there is a huge appetite for culinary creativity and worldwide flavor profiles. Two-thirds of respondents to Innova’s global survey expressed a desire to try plant-based versions of traditional, local cuisines. The industry is responding with a large increase in ready-meal offerings, while there is great scope for expansion into

meal kits and inventive recipe combinations. Interest in underused ingredients is also growing, creating opportunities to introduce variation in flavor and nutrition while simultaneously addressing supply concerns.

5. Farming the Future

Public curiosity for innovative technologies such as vertical and regenerative farming is increasing. As well as helping to maximize flavor, nutrition and yield, these advances can win consumer support where they are shown to improve the quality and sustainability of global food production. Today’s consumer is increasingly invested in the source of food as it ties in with major global concerns of health, sustainability and waste. The welfare of agricultural workers is equally important, with 65% of respondents to Innova’s surveys agreeing they would rather buy fruit and vegetables from farmer’s markets than large stores. Brands need to demonstrate how novel production techniques are benefiting farmers, people and the planet.

Commenting on the food and beverage industry’s future direction of travel, Lu Ann Williams reveals: “At Innova, we have seen a considerable consumer demand for value redefined throughout the supply chain, with creative and flexible approaches to the use of technology and reducing waste proving pivotal. With financial concerns a dominating factor, 2023 is a significant year for new developments that answer these growing demands. Based on our consumer and market research, our Top Trends deliver insights to support brands as they innovate and grow.”

www.innovamarketinsights.com

consumer trends 20 italian food & packaging technology - ciii (2023) - april

+ NEWS + INFORMATION www.foodexecutive.com FOODEXECUTIVE 1-4.indd 4 31/03/21 16:32

“RAPID” PUMPS

Sanitary - Self priming. Both for liquid and for thick products (Creams and Sauces).

“FARMINOX” FILTERS

Packingless plate filters. Working through paperboard filter-sheets.

made of stainless steel machined from bars, NO CAST PARTS, NO WELDINGS.

NEW BEGINNING! info@wolhfarth.it - www.wolhfarth.it V. Cavour, 31 - 26858 Sordio (LO) - Italy - Tel. +39 02 9810153 - Fax +39 02 98260169

DESIGN

THE MOMENT FOR A

HYGIENIC

for an easy cleaning SAFETY

FDA certified materials, suitable for the use in contact with foods. ENDURANCE

More consumers seek nutrient-dense foods while meat-reducing slows

Consumer interest in eating more nutrient-dense foods continues to climb, with 18% of people saying they look for more nutrient-dense foods – foods that pack in a lot of beneficial nutrients relative to their energy content.

“Compared to 2021, this was the eating behaviour that had the biggest increase in consumer interest,” says food industry expert Julian Mellentin. In a recent survey of consumers in five countries by consultancy New Nutrition Business, of which Mellentin is director, nutrient density was mentioned by 18% of consumers, compared to 12% in 2021.

Of the five countries surveyed (USA, UK, Australia, Brazil and Spain), Brazil had the highest level of interest in nutrient density, at 37%. Spain ranked second with 23%, and the UK scored lowest with only 7% of people interested in eating more nutrient-dense foods. Consumers aged under 34 are more likely to be looking for nutrient density than older consumers.

“In contrast, the trend of consuming fewer carbohydrates appears to be levelling off,” Mellentin adds. Across the five countries, 26% of respondents said they were trying to eat fewer carbs in 2022 – the same as in 2021.”

“Consumer beliefs about food and health have become increasingly diverse over the last 10

consumer trends 22 italian food & packaging technology - ciii (2023) - april

years,” Mellentin explains. “People do their own research online and try out new eating patterns to find out what works for them. And interestingly, most eating patterns reach a natural ceiling with about 25%-30% of consumers. With the exception of sugar reduction, very few become a truly mass behaviour.”

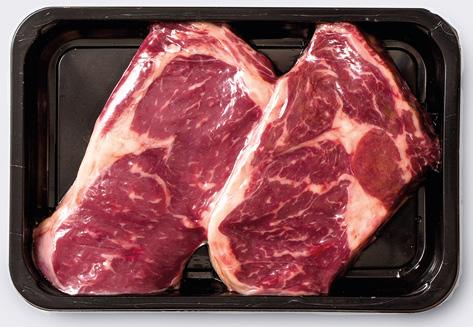

The trend to consume less meat, which grew very strongly from 2014 onwards, is also levelling off. In 2022, 24% of people said they were reducing their meat consumption, unchanged from 2020.

Brazil and Spain had the most meat reducers (31% and 30% respectively). The US scored lowest on meat reduction (18% of consumers). It’s a behaviour which is more common among consumers aged 55 and above than among younger consumers. “It seems counter-intuitive, but it’s what we have been finding for several years, as have many of our customers,” says Mellentin. “The idea that it’s the young driving meat reducing largely comes from lazy journalism.”

As a sign of the growing diversity of consumers’ health beliefs, there are more emergent new health interests showing up – concerns that are still niche, but which have been growing steadily over the past five years. Two examples are:

1. Eating to improve hormonal health – followed by 8% of consumers in the US, Australia and Spain, slightly more in Brazil, and 4% in the UK. “It’s an issue that matters more to women than men and affects wellbeing over the whole of their adult lives. It’s an issue that women often say the medical mainstream pays little attention to. An increasing number are managing their hormonal health through food and supplements.”

2. Also emergent is the avoidance of seed-oils – such as canola or sunflower – which is a concern for 6% of people, up from almost zero back in 2019. This growing interest relates to concerns about inflammation.

“These emergent behaviours are much more important for corporate strategy than veganism,” Mellentin adds. “A vegan diet is the choice followed by the lowest percentage of consumers in all countries – just 3%. Veganism has shown no increase since 2019. It’s notable that a topic which is often described by the media as growing is in reality a topic of least interest in the real world.”

consumer trends italian food & packaging technology - ciii (2023) - april 23

www.new-nutrition.com

FOOD PROCESSING

Food automation market worth 12.26 billion USD

According the market analysis agency MarketsandMarkets, the complex pattern of globalization and the changing dynamics of consumer consumption are revolutionizing the food processing sector.

While the consumer is shifting towards more advanced value-added food categories, there is also a growing demand for processing basic products such as fruits, vegetables and grains which require technologically

advanced equipment. Besides, the food processing and handling equipment demand is exhibiting strong growth, with the rising demand for prepared food products globally, changes in consumer lifestyles, along with a transformative leap forward in technological capabilities and increasing investment opportunities in the food processing industry.

AI and robotics are transforming the food industry automation process. According to the Robotic Industries Association and Association for Advancing Automation, orders of robotic systems by food and consumer goods manufacturers grew by 56% in 2020. The development of the hospitality industry, tourism industry, and the increase in the use of temperature-controlled storage equipment for perishable and processed food items drive the demand for foodservice equip-

24 italian food & packaging technology - ciii (2023) - april

ment in commercial kitchens. Increased adoption of robotics is shaping the global foodservice sector.

Food automation refers to the various automatic equipment used by manufacturers in the food & beverage industry and is a technology- and process-driven market. The growth of the food automation market is primarily driven by the following factors:

• Consumer shift toward processed food & beverage products

• Growth in investment in R&D activities for innovative products to attract consumers

• Strict regulations on foodbased products from various governing bodies

Automation Across the Supply Chain

Automation leverages technological solutions within the supply chain, boosts the output, and ensures continuity. Since the supply chain is an integral part of the production and distribution process, automation optimizes the farm to fork operation. As farmers and retailers become more aware of the benefits of automation, their eagerness to adopt these disruptive methods is on the rise. Various governments have also introduced tech-enabled systems like the Agricultural Market Information System (AMIS, a centralized platform that can be accessed by all authorized agencies to boost the transparency and continuity of the food market. The information stored on this platform is also used to make policy decisions and find effective resolutions for the existing challenges plaguing the food sector.

Robotics in Agriculture

Image processing is largely used in AI-driven software and hardware applications. For instance, in drones, AI is used to process multispectral images to monitor crop health or detect the spread of pests. Blue River Technology (a subsidiary of John Deere) uses machine learning to apply herbicides autonomously and accurately. Various agricultural robots (fruit picking, seeding, weed removal, pesticide spraying, and surveying) developed at present are being integrated with image processing technology. AI is being programmed to differentiate between fruits, weeds, and other plants using machine learning technology. Real-time data management and monitoring software used in agriculture also utilize AI. AI can process weather, soil, moisture, and temperature data together to help farmers in decision-making. In indoor farming applications, AI is also utilized in robots for maximum space optimization when moving pots and plants. It can also help create

seasonal forecasting models to improve crop productivity. For livestock, AI systems can deliver the exact quantity of feed required depending on the growth stage of farm animals.

Robotics in Food Manufacturing

Automation in food & beverage plants plays an important role in food safety, equipment safety and personnel safety. Automated equipment can monitor tanks and systems to help ensure cleaning, set off sophisticated alarms to alert if a product is out of the temperature safety zone and ensure systems aren’t over pressurized or at risk of rupture. For example, new/recent generations of automated dairy processing equipment can even lock out the wrong ingredients. Beverage processors are looking for new machinery that can be easily integrated into the production line and can be continuously integrated from one piece of equipment to another. For instance, GEA’s HOPSTAR Dry is a

food processing italian food & packaging technology - ciii (2023) - april 25

system for cold extraction of hop oils, and Germany’s Stortebeker Craft Brewery entered into an agreement in 2019, for homogenous beer production using fully automated, stabilized processes. The system besides ensuring quality, optimizes process time as well. HOPSTAR Dry, GEA has developed a process that significantly improves extraction efficiency – by 30 to 50% compared to a static process.

AI is being used in the food business to enhance supply chain operations by:

• Food standards surveillance

• Product testing at each level

• Managing inventories with accurate estimates

• Tracking of products from harvest to distribution

• Ensuring that staff adheres to basic hygiene standards

Robotics in Food Packaging

Automation is a key operational strategy within the packaging industry, wherein it is predominantly used in the palletizing and movement of materials. Automated packaging systems help

the company provide customers with improvements in efficiency and product consistency. Specifically, the consistent gauge or thickness of the film helps customers improve their production efficiency, product quality and reduce waste, resulting in enhanced sustainability.

Robotics in Food Service

Autonomous food delivery attempts to address the growing industry. The restaurant industry has been undergoing unprecedented changes recently, especially since Covid-19 paralyzed the industry. As the cost of technology is dropping, even small businesses are incorporating robotics and AI. A robot named Flippy was used by the US-based burger eatery CaliBurger to flip hamburgers. The Flippy robot resembles a miniature, motorized cart with a 6-axis mechanical arm attached to it. Pizza Hut Canada partnered with Serve Robotics, a leading autonomous sidewalk delivery company, and launched a pilot program in September 2022. The partnership to provide Vancouver customers with the

convenience and reliability of zero-emissions robotic delivery, shaping the future of sustainable, self-driving delivery.

Process Automation: Key to Modern Brewing

Modern brewing industry necessitates hygiene and quality standards, thus implying the significance of process automation. AI, the Internet of Things (IoT), automated systems, robotics, and sensors are thereby becoming essential for the modern brewing industry. Process sensors enable increased automation in the beer production process, improving the efficiency of the process, quality control, and the quality of the final product. For instance, temperature sensors are used to monitor the temperature of the mash during the brewing process alongside monitoring the temperature of cleaning agents, thus regulating the process. Baumer provides smart sensor solutions to reduce complexity and optimize the process in brewing industry, catering to the hot brew house environment, the hygienic and cold requirements in cellars, and the silos.

Digital Transformation in the Food Industry Is Imperative

COVID-19 pandemic held the existing supply chains to the test, and disruption occurred across the industry. Innovative technologies like artificial intelligence (AI), Internet of Things (IoT) devices and the blockchain have emerged and been adopted by food and beverage businesses. One classic example is pandemic induced pressure for

food processing 26 italian food & packaging technology - ciii (2023) - april

meat processors to implement robotics. Tyson Foods invested USD 500 million in technology and automation in the past three years, including the opening of Tyson’s Manufacturing Automation Center in August 2019. There is a certain push for more robots in factories to debone and filet meat. The future of meat manufacturing probably includes 3D scanners and automated cutting, with Tyson, Smithfield, Cargill and JBS looking at ways to incorporate more automation.

Automation has streamlined the process of food packaging for various uses, including palletizing and depalletizing, packaging and repacking, pick and put, grading and sorting, processing, logistics, etc. Automation results in improved product quality, reduced labor cost and higher safety, process efficiency, predictive maintenance, and enhanced food

safety, and therefore is the key for smart food processing and handling. Besides, waste reduction has long been a key focus area. Automation can help food businesses improve their supply and demand management. An

end-to-end solution, such as a food-specific ERP system, can provide accurate data on the amount of stock needed based on real-time demand.

www.marketsandmarkets.com

food processing

Agenda AITA Analysis and Control Applied Research Automation and Electronics Beer Beverages Books Cereals Companies Conferences Energy and Sustainability Feed Food Food Safety Health and Wellness Hygiene Ingredients Laws Machines and Equipment Marketing Milling News Nutrition Packaging Pasta Soft Drinks Spirits Wine www.foodexecutive.com the latest news on the food&beverage world PUBB FOODEXECUTIVE NEW ITA 1-2.indd 2 16/05/18 11:32

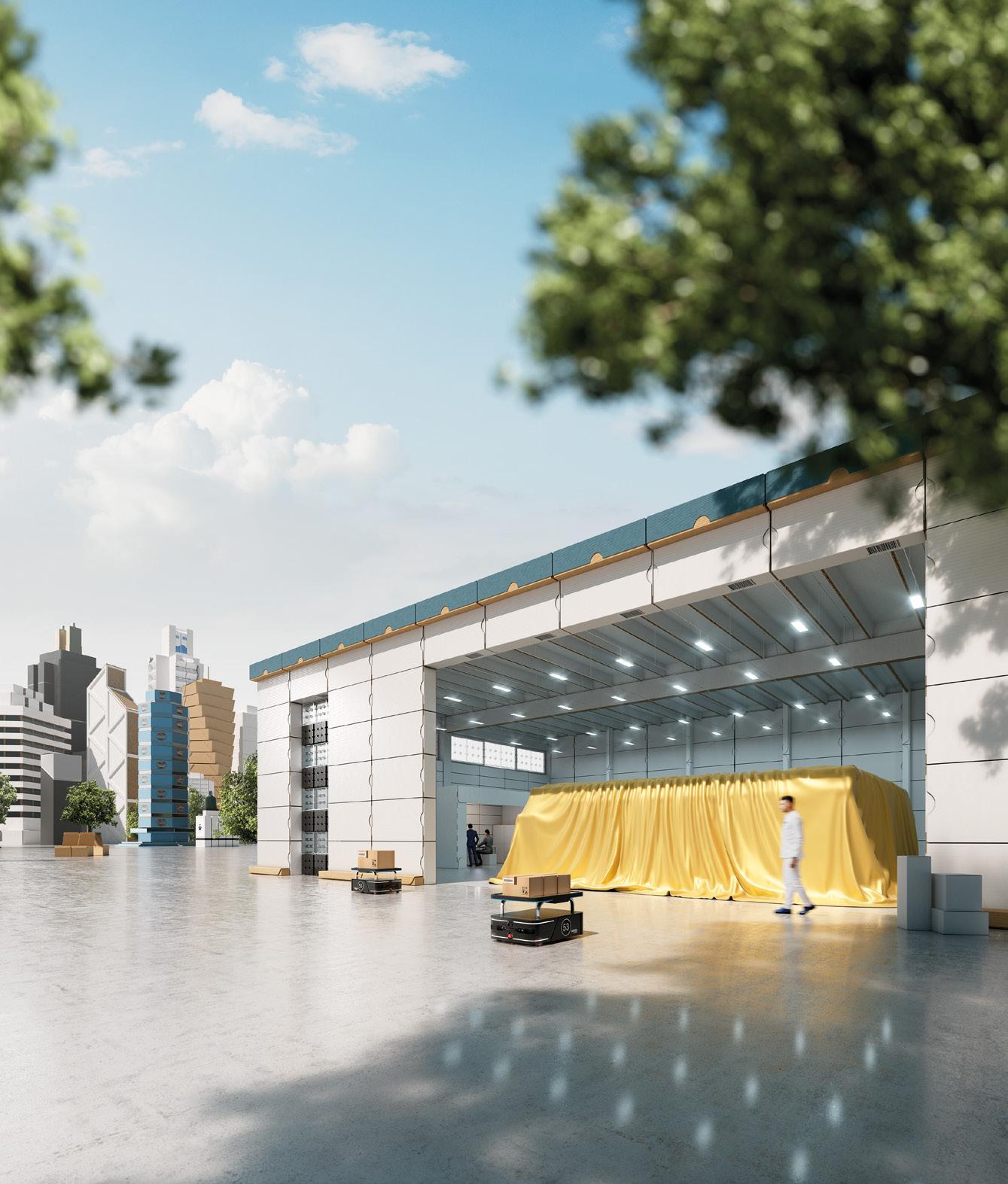

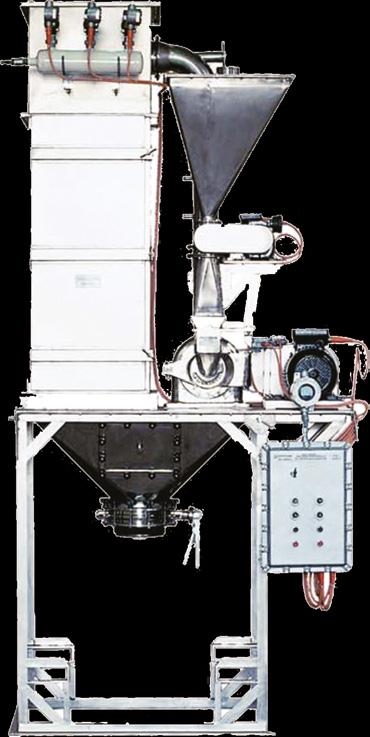

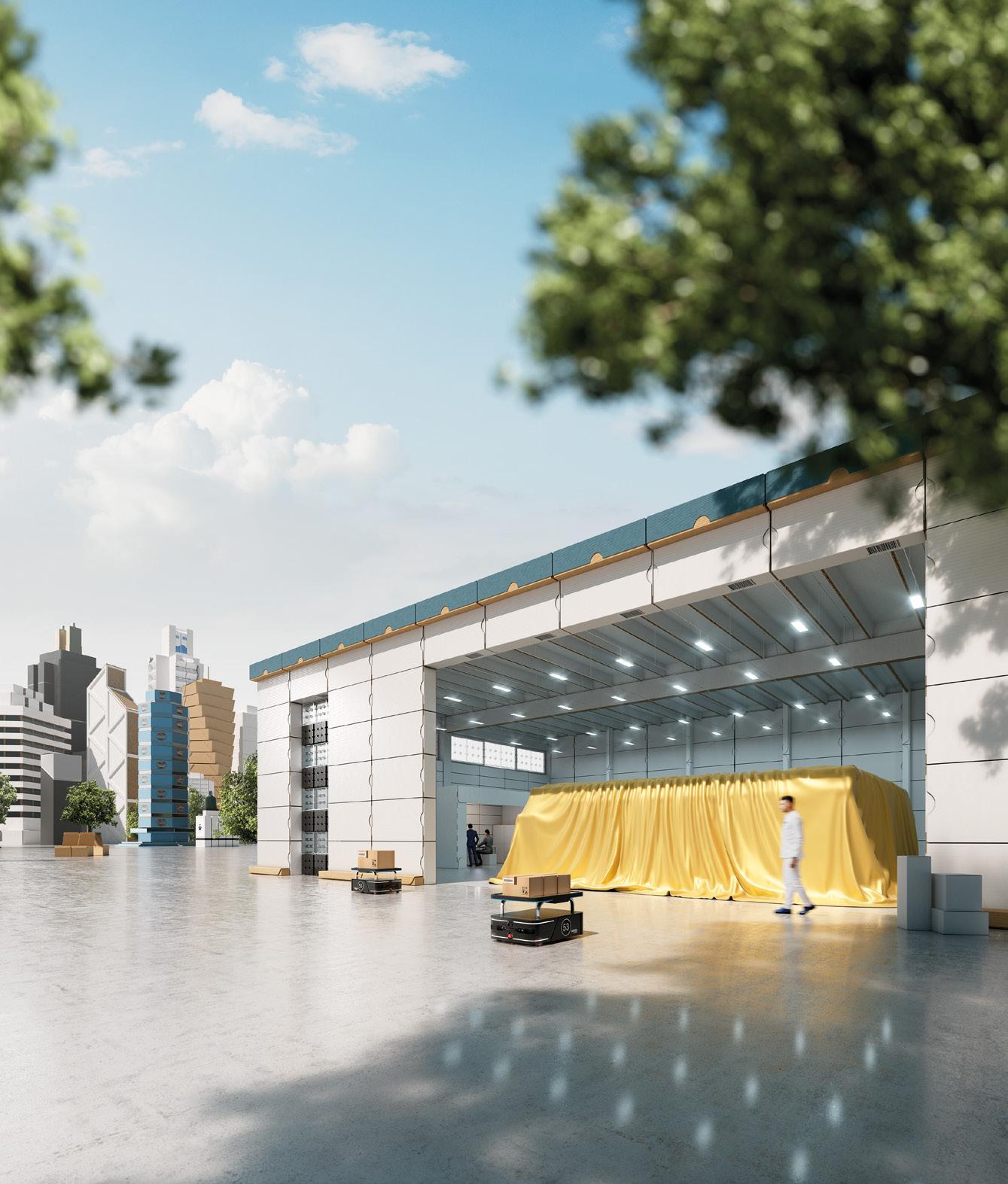

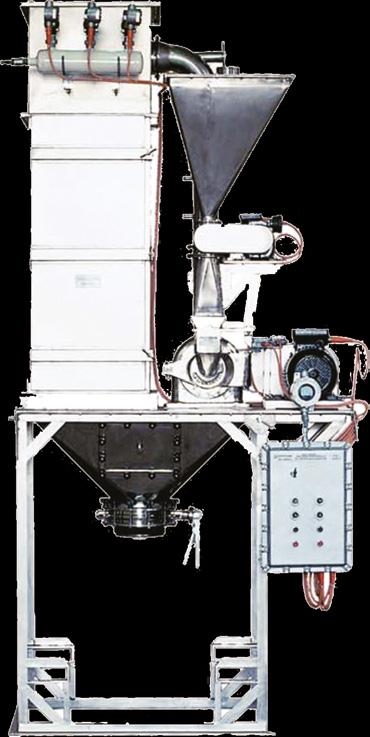

The world of continuous melting inaugurates a new era

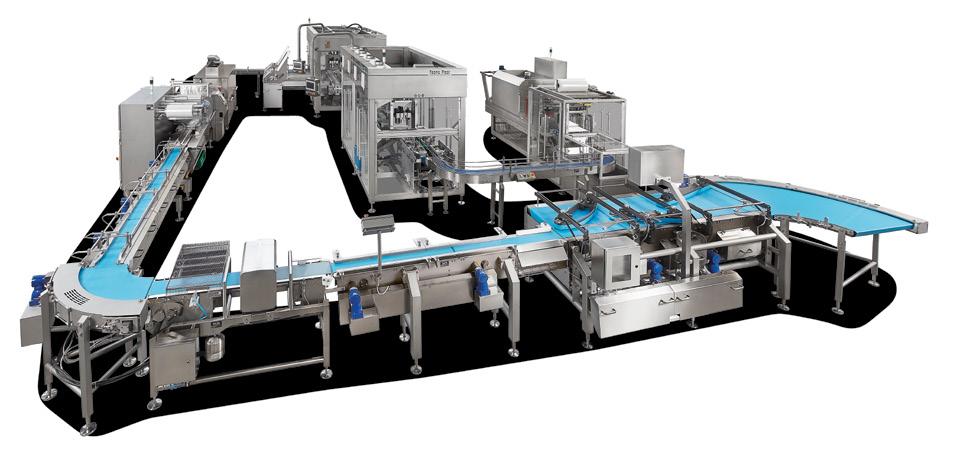

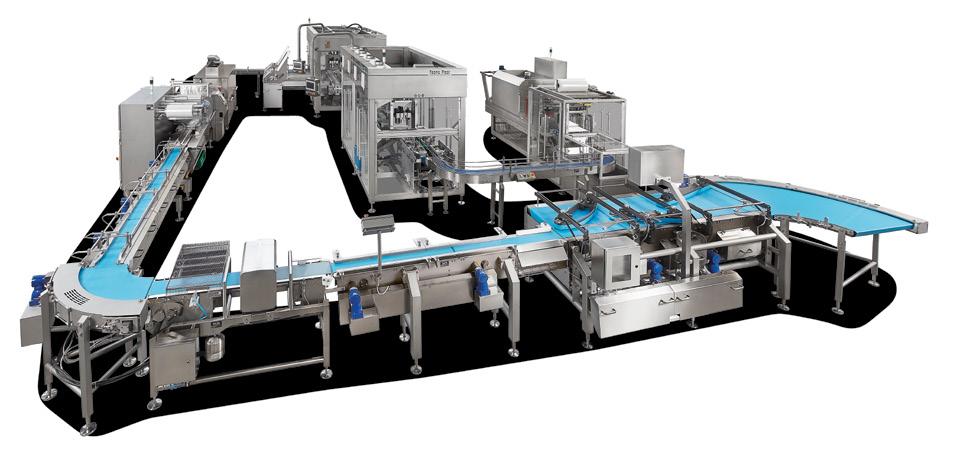

Tecno3 brings the sector of continuous melting into an increasingly technological future.

A team of professionals, researchers and engineers have been designing the new continuous melter for two years.

The innovative scope of this study immediately catches the eye: a single plant for processing raw materials of different types: within the family of fats, cocoa, butter and dairy products.

Tecno3 has always distinguished itself by the disruptive technological drive, strengthened by the awareness that innovation always starts from listening to the needs of its customer. The world of the food industry will therefore not only be pleased to see its demands met, but also surprised to admire all the new potential.

If the primary need was therefore to enjoy more compact and smooth solutions, the pro-

duction capacity of the continuous melter is certainly moving in this direction.

The new melter is capable of melting up to 1,000 kg of product, through a mechanism of crushing and melting the blocks.

Adding 3 phases it is also possible to go further, reaching 3,000 kg of product.

The phases that compete in sequence are as follows:

1. Insertion of an additional crushing unit;

2. Crushing and grinding of the last fragments;

3. Featuring of the final melting unit for chips.

Optimization does not only pass through productivity, but also through the reduction of the footprint. Thanks to the integration of the thermoregulation system within the system it is pos-

sible to gain up to 50% of space. But not only that.

The time to install the machine within the production layout also halves.

A sign that the future of melting is ahead in the name of progress.

Another important novelty concerns the cleaning system.

In fact, the innovative washing device, allows a time saving in the face of a higher yield, thanks to the alternation of two types of fluids, depending on the needs.

• Washing with preheated water followed by a perfect drying system that also provides for sanitation for the dairy world.

• Wash with fats and oils that can be used when the ingredients in the plant are compatible with the next recipe. In this way, raw materials are optimized while minimizing waste.

Finally, the great theme of safety finds adequate and concrete answers in a new type of approach, smarter. Control barriers leave room for radars signaling the risk area. No needing to remove the protective grids anymore reduces cleaning and maintenance time. All this always respecting the rules relating to safety parameters.

The new continuous melter is also able to receive input from the operator in a much more intuitive way. It is talking about usability, which, in the age of the Internet of Things, cannot ignore the values of simplicity and speed.

food processing 28 italian food & packaging technology - ciii (2023) - april

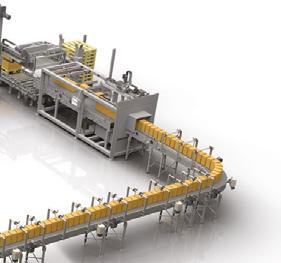

The new continuous melter designed by Tecno3.

In the human-machine dialogue function, the operator plays an important role. Depending on the information available to the people, they must perform actions that condition the smooth operation of machines and systems without compromising safety and availability. It is therefore essential that the design quality of the interfaces and the dialogue

function be such that the operator can be assured of safe operation under all circumstances.

And this is what the new continuous melter signed Tecno3 promises.

(Tecno3 - Via Mastri Cestai 2 - 12040 Corneliano d’Alba - CN - Italy - Tel. +39 0173 610564 - e-mail: a.mattis@tecno-3.itwww.tecno-3.it)

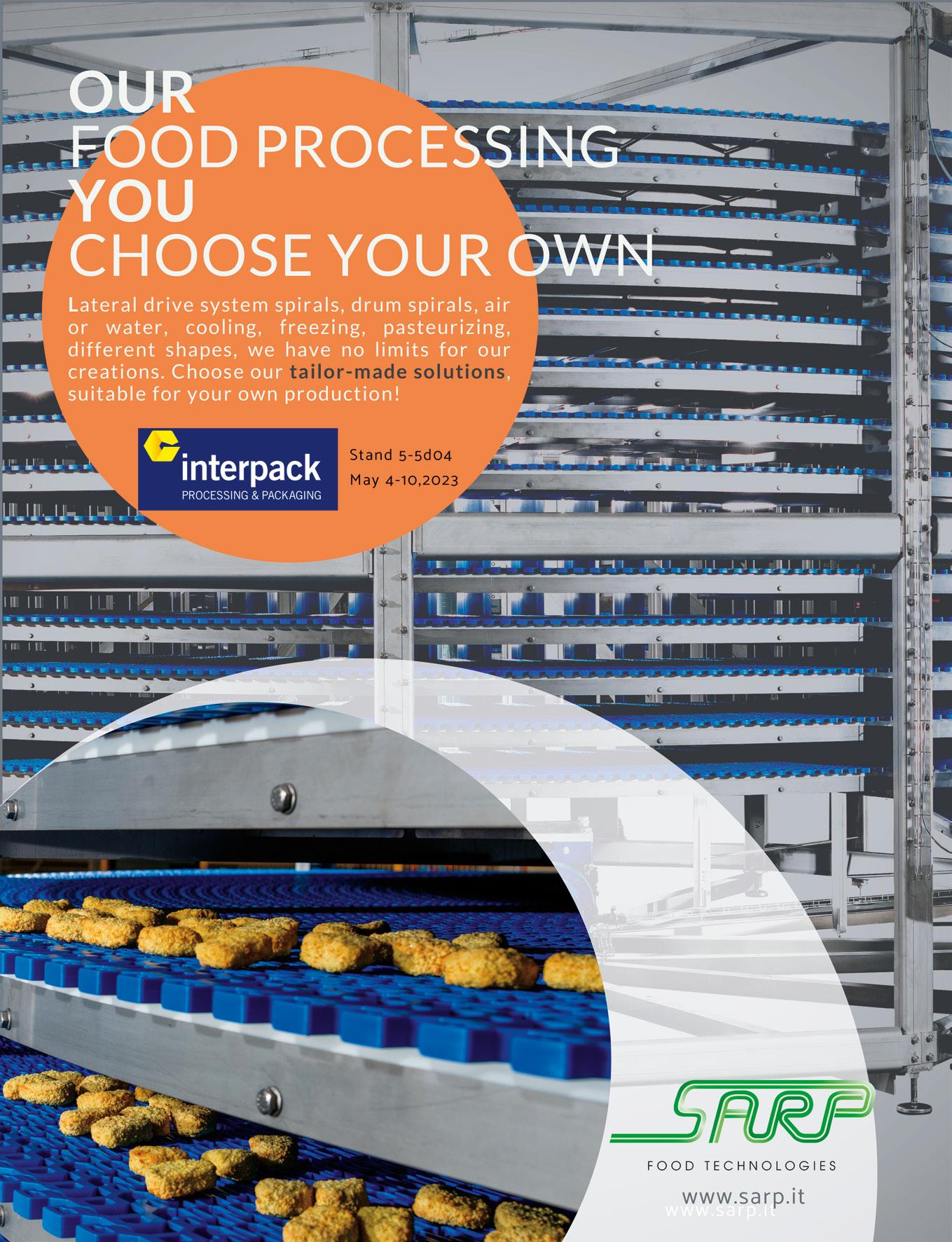

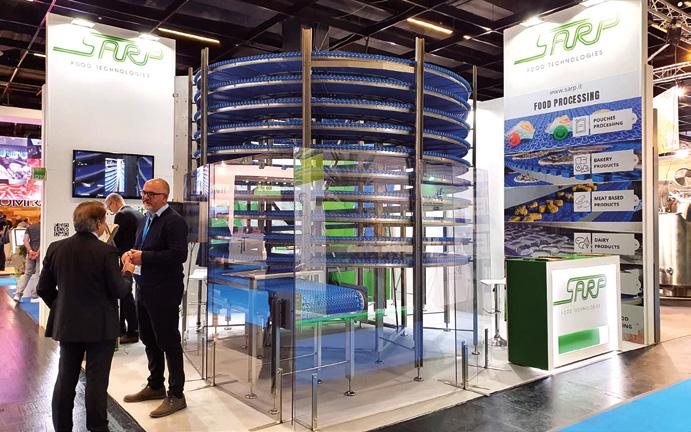

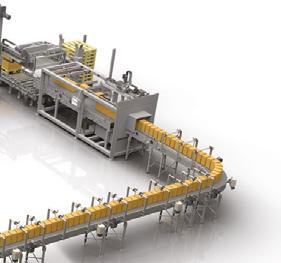

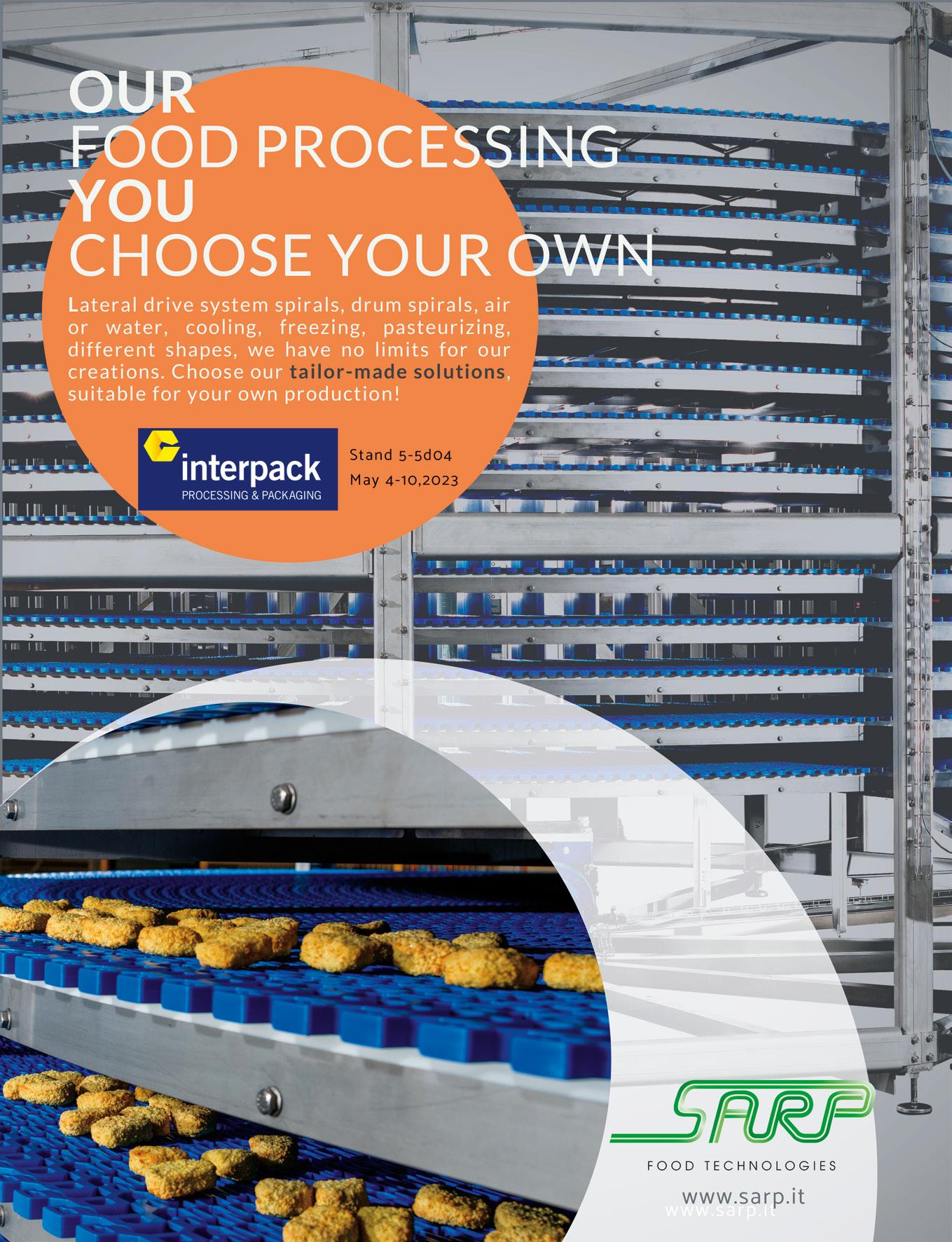

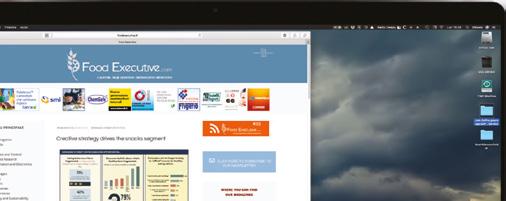

Meet Sarp at Interpack

Interpack show, which will be held in Dusseldorf, Germany, from 4th to 10th of May 2023, is one of the most important international appointments for the food and beverage industry and Sarp could not miss it! The occasion is perfect to discover which Sarp solutions are perfect for your business.

Since 1986, the company has been designing and manufacturing spiral belt conveyors for food processing that mainly, but not only, involve freezing, cooling, and pasteurization.

The main goal is to provide a customized solution that can guarantee excellent performance in terms of:

• Organization of space: the development in the height of the machine which benefits from an adaptable space between the layers, guarantees compact solutions with high performance. The main footprint of the equipment can be customized and used to find convenient room for treatment systems that can be integrated into the main structure.

• Easy cleaning and reduced maintenance: each section of

the machinery is easily accessible, to ensure thorough sanitization. Furthermore, high-temperature cleaning systems designed to answer to customers’ specifics requirement are integrated into the spiral or the insulating room, to guarantee maximum hygiene, with minimum effort.

• Best performance: the study of air flows is essential to make treatments homogeneous and suitable for the different types of products, whether packaged or loose, small or large.

What will be presenting at Interpack? Sarp is going to show

its cooling spiral for food products, which can be fitting for bakery products, dairy, meat, or fruits and vegetables.

The cooling treatment is performed at room temperature or at a controlled temperature with the use of an insulating room. The studies on the airflow not only allow the temperature to remain uniform in the surrounding environment but also allow the surface of the product to be correctly pervaded by the airflow, to make the heat treatment faster and more efficient by preventing moisture development.

Sarp focuses on energy saving, giving you the possibility of combining the advantages of an insulated chamber with an evaporation system that uses and filters the external air, saving production power and optimizing the air exchange.

Come and visit Sarp booth: Hall 5 Stand 5D04.

(Sarp - Via Montebelluna di S. Andrea 43 - 31033 Castelfranco Veneto - TV - Italy - Tel. +39 0423 482633 - email: sarp@sarp.itwww.sarp.it)

food processing italian food & packaging technology - ciii (2023) - april 29

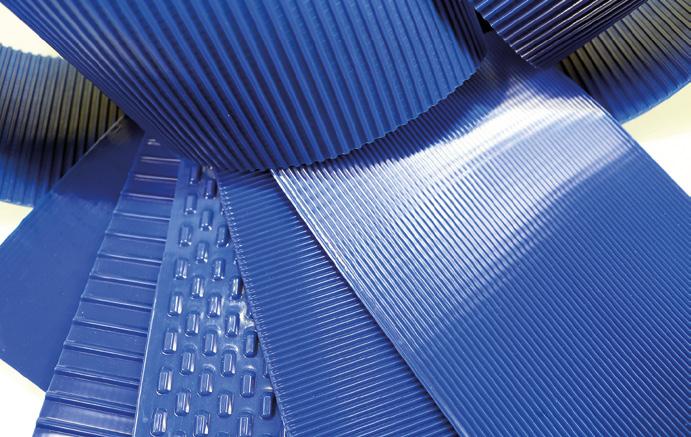

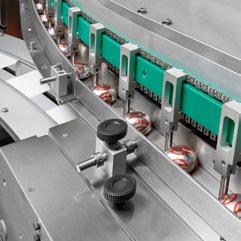

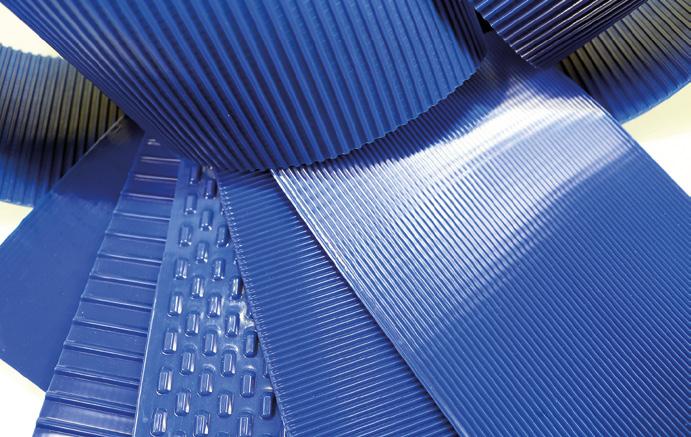

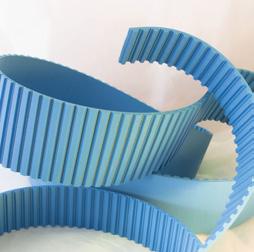

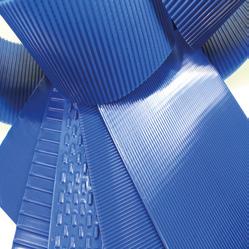

No compromise in Food Safety

At Ammega, Food Safety is of utmost importance for the sake of consumers’ and their health. As a parenting company, it is steadfastly committed to this idea and take steps to continually develop solutions that raise the bar for hygienic conditions and safety, thus making this House of Brands the ultimate Food Grade systems provider.

Ammega Group has developed a strong brand image of a responsible leader who genuinely cares about the welfare of their clients. Top tier industry experts, engineers, and designers are its the true pride. Those exceptional talents are equipped with the highest technological equipment to regularly raise the level of hygienic practices on your production line.

The Ammega Group meets the Food Safety standards at the highest levels by combining the assets of all family brands. As a result, Ammega solutions abide

by international guidelines for the safe handling of food, including those set by the American FDA, the European USDA, and the EHEDG.

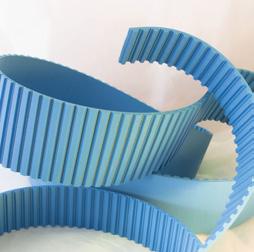

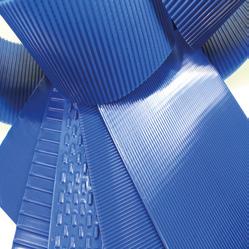

Megadyne – member of Ammega Group - understands the critical importance of Food Safety standards in power transmission products. Commitment to this concept is unwavering, and widely noticeable through Megadyne ground-breaking belts supplied with contamination prevention attributes.

The offer consists of:

XMD Timing Belts – Belt and cleat fragments from all Megalinear XMD and Megaflex XMD belts can be spotted by metal and x-ray detectors. A special hygienic design features sealed edges and the use of blue as a contrast colour.

Megalinear FC – matches the power and precision for synchronous conveying (balanced tracking, low running tension and low vibration) meeting the criteria where food contact is required: MAXIMUM RELIABILITY, TOTAL HYGIENE.

Megapower FC –Designed for use in both dry and wet applications Megapower FC urethane made with industry desirable blue color offers good chemical resistance and can be used in applications where belt cleaning is required

Visit us at Interpack

The entire Ammega group encourages to join the company at Interpack Exhibition to discover the Ammega Food Safety Solutions.

(Ammega Italia - Via S. Lucia 114 - 10075 Mathi - TO - Italy - Tel +39 011 9268052 - Fax +39 011 9241746 - email: info@megadynegroup.com - www. ammega.com)

food processing 30 italian food & packaging technology - ciii (2023) - april

Megadyne

Megadyne Blue-FC (Ammega).

Megadyne XMD timing belts (Ammega).

SAFETY!

Food safety is of paramount importance to protect consumers and their health. As Megadyne, we take up measures to continuously develop solutions improving the level of hygiene and safety in compliance with ISO 22000, EC 1935/2004, EU 10/2011 and FDA standards: Metal & X-Ray Timing Belts, Mega ex FCM, Megalinear and Megapower FC (Food Contact). Contact us to make your food production safer.

www.megadynegroup | info@megadynegroup.com

HALL 4 STAND E44 04-10|05|2023

DÜSSELDORF

WE MAKE YOU BUSINESS MOVE

Scan to watch the video

NO COMPROMISE IN FOOD

Member of Ammega group SUBSCRIBE

Combination of plasma processing and pulsed electric field on the characteristics of yoghurt drink

In a study published in the Journal of Food Processing and Preservation, the properties of the milk treated with combination of solution plasma (SP) processing and pulsed electric field (PEF) for different periods (5 and 10min) was investigated by Turkish Researchers.

biotic viability, texture and sensory quality in terms of consumer preference were investigated. It was determined that the viscosity and dry matter values of the solution plasma-treated samples were lower compared to the samples produced by heat treatment, and these values decreased further with the increase in plasma application time. It was also found that the maximum increase in L* and b* values of all samples during storage was in the samples treated with plasma for 10min. The viability of the probiotic bacteria in probiotic Ayran samples were determined to be within the

therapeutic level (>6.27 log10 cfu ml-1) with higher scores for sensorial qualifications.

Consumers’ expectations of more nutritious and microbiologically safe food have enabled the development of new processing technologies. Probiotic fermented milk products are products that provide health benefits in the prevention of gastrointestinal diseases, regulation of metabolism, and stimulation of the immune system. The processing of these dairy products with non-thermal technologies provides advantages in preserving their functional properties.

Simplified model of airflow and heat transfer in a pallet of food product generating heat

The microbiological, physicochemical, and sensory properties of the probiotic yoghurt drink (Ayran) produced from these milks were determined during storage. PEF was performed at voltage 3500V, repetition 17,000Hz, and pulse width 2.58mus on the raw milk. Lactobacillus acidophilus and Bifidobacterium animalis subsp. lactis probiotic cultures were used in production with conventional yoghurt bacteria

Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. In addition to the pro-

During storage, pallets of food product generating heat (e.g., cheese, fruit, and vegetable) are exposed to low velocity ventilation. In addition, the boxes have often little perforation. Therefore airflow is weak inside the boxes located downstream of the pallet; and if the product generates heat, its temperature can rise above the recommended one.

Computational fluid dynamics modeling can predict these phenomena but needs an expertise of numerical fluid flow, a detailed description of product and packaging and leads to expensive computational costs. A simplified model was developed by French

Researchers based on a hydraulic network analogy and the results were published in the Journal of Food Process Engineering.

Given the vent holes areas of the boxes and the heat generation, it predicts the global air flow

food processing 32 italian food & packaging technology - ciii (2023) - april

(flow through the box faces) and the product temperature. The predictions are in good agreement with experimental data. The software (Matlab executable) is easy to use and needs only some seconds to compute. It can be used to predict temperature evolution along a cold chain and

to improve packaging and logistic operating conditions. Practical applications. Based on a on a hydraulic network analogy, a simplified zonal model of airflow and heat transfer in a pallet of food generating heat is built with the Matlab software. It takes into account the vent holes areas of the

boxes and the heat generation, and allows predicting the distribution of air fluxes through the box faces and the product temperature. The major advantage of this model is that it is easy to use and needs only some seconds to compute. Therefore, it can be easily used in industrial field.

New technology to produce meat analogues with soy, pea and gluten

Modern plant-based meat analogues should have a pronounced fibrous structure as an important characteristic. In a study published in Innovative Food Science and Emerging Technologies journal, Swiss Researchers demonstrate that the combination of high moisture extrusion cooking (HMEC) with well-defined shear during cooling is a new process to make fibrous products using common meat analogue ingredients.

The shear was applied via a cooling die attached to the extruder that was specially designed for that purpose. The in-house developed cooling die consists of two sequential rotating inner cylinders with a separate drive-unit in an outer cylinder that can be thermo-regulated.

Three rotational speeds of the inner cylinder, 45, 75 and 105 min-1, were tested for pea protein isolate, soy protein concentrate, vital wheat gluten and blends of pea or soy with gluten. A large effect on macro-and micro-texture and anisotropy index was found when the concentra-

tion of gluten was increased. The different ingredients and blends had different optimal conditions and reacted differently to the applied shear. Interestingly, the angle of the fibers observed in the samples differed at the different rotational speeds. This was attributed to the shear thinning behavior of the plant proteins and the velocity gradient

in the rotating die, arising from the temperature and viscosity gradient. The ability to change the shear rate as an independent parameter in the rotating cooling die is unique and allows texture adjustments during processing. This is an important improvement for industrial HMEC and opens new product design possibilities.

food processing italian food & packaging technology - ciii (2023) - april 33

Whole peanut milk production

A novel whole peanut milk (WPM) was prepared by an innovatively invented industry-scale microfluidization system (ISMS) at different pressures (0-120 MPa) developed by Chinese Researchers.

The effects of pressures on the physical properties, microstructure, and flavor properties of WPM were investigated. With the increase of ISMS pressure, the physical stability of WPM was effectively improved. The WPM processed at 120 MPa possessed relatively good physical stability without delamination for 67 h at 4°C. The particle size of WPM decreased (to ~25 μm at 120 MPa),

and the distribution of particle size changed from polydisperse to monodisperse. Meanwhile, ISMS exhibited an upward trend on apparent viscosity with the increased pressure. The confocal laser scanning microscopy indicated the globular protein was broken and deformed gradually, then, bound to the oil droplet with increased pressure. The protein of WPM120 even formed a three-dimensional network to wrap oil droplets under the observation of cryo-scanning electron microscopy. Furthermore, the WPM120 exhibited the highest content of flavor substances based on GC-MS analysis.

This Chinese study published in LWT - Food Science and Technology journal aims to provide a feasible method for preparing whole peanut milk by using a green physical treatment.

A novel technology for high-moisture textured soy protein